Improved DTC-SVM Based on Input-Output Feedback Linearization Technique Applied on DOEWIM Powered by Two Dual Indirect Matrix Converters

Abstract

:1. Introduction

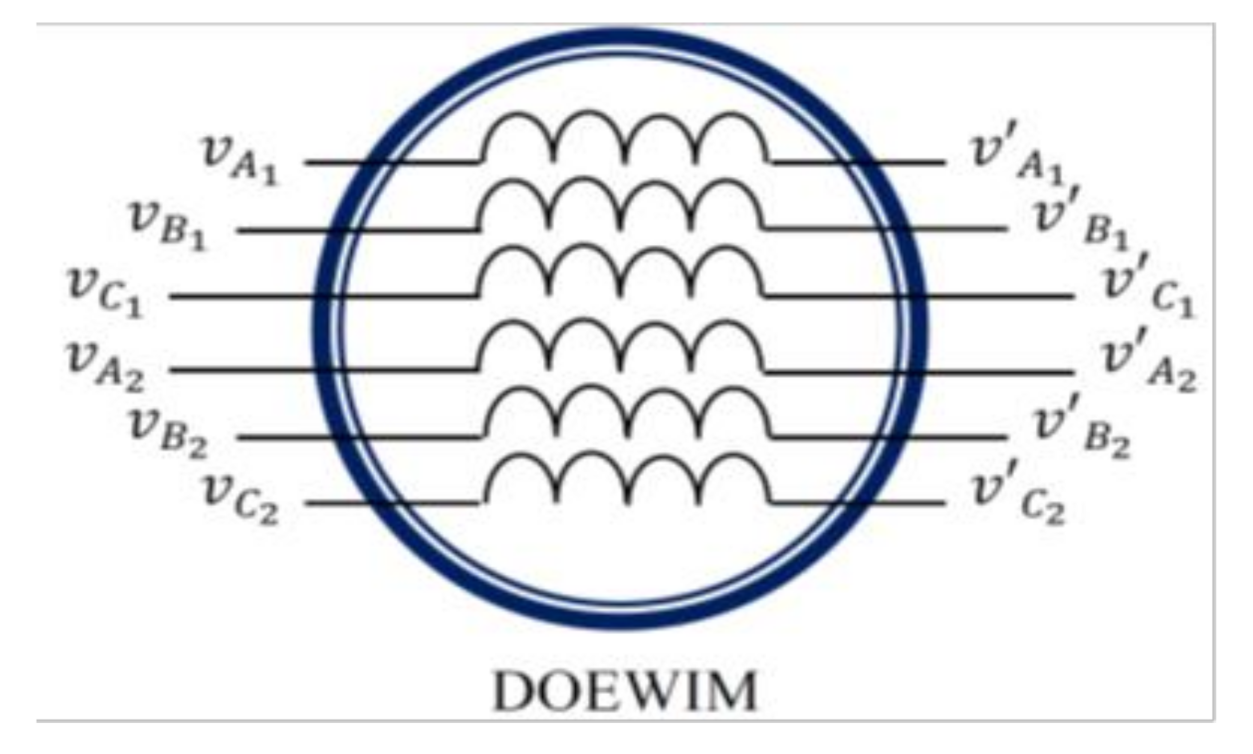

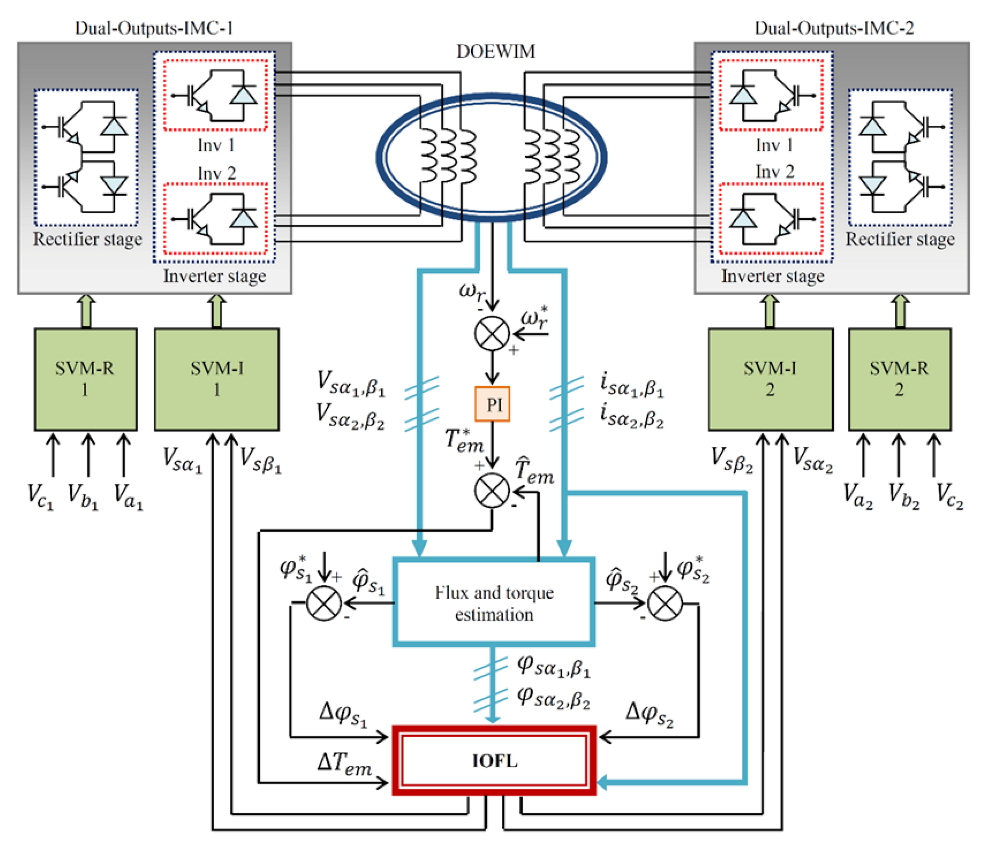

2. Description and Modeling of the Dual Open-End Winding Induction Motor

2.1. Dual Open-End Winding Induction Motor Description

2.2. Dual Open-End Winding Induction Motor Modeling

- The saturation and hysteresis effects of the magnetic circuit are neglected.

- The effect of the temperature variation on the resistances and inductances of the windings is also neglected.

- The air gap thickness is uniform and the notching effect is negligible.

- The magnetomotive force has a sinusoidal spatial distribution.

- The machine has a symmetrical construction.

- The two stator windings are balanced and identical.

- The mutual leakage inductance common to the two windings is negligible.

- The stator and rotor voltages equations:

- The stator and rotor flux equations:

- The mechanical equation:

3. Indirect Matrix Converter

3.1. Dual-Outputs Indirect Matrix Converter Topology

- First, we discuss the modelling of the first IMC.

- Second, we discuss the modelling of the second IMC.

3.2. Space Vector Modulation for Dual-Outputs Indirect Matrix Converter

3.2.1. Rectifier Stage Control

3.2.2. Inverter Stage Control

3.3. Common Mode Voltage

- is the common-mode voltage at the first end of the first stator;

- is the common-mode voltage at the second end of the first stator;

- is the common-mode voltage at the first end of the second stator; and

- is the common-mode voltage at the second end of the second stator.

4. Direct Torque Control Technique

Stator Flux and Electromagnetic Torque Estimation

5. Input–Output Feedback Linearization

- Dynamic equations:

- The electromagnetic torque expression is the same as was given in Equation (36).

5.1. IOFL Technique

- First stator:

- Second stator:

- First stator:

- Second stator:

5.2. Non-Linear Control Law

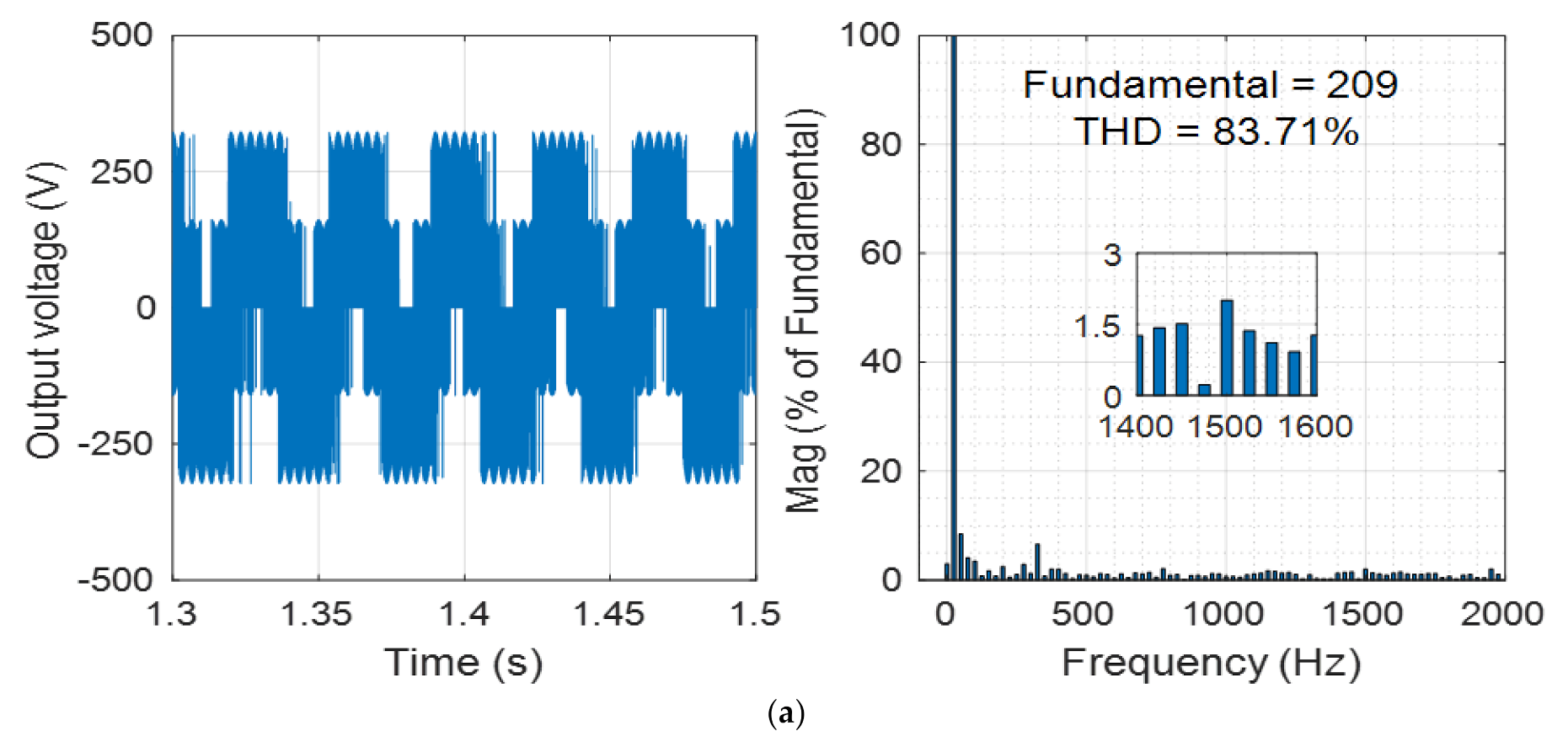

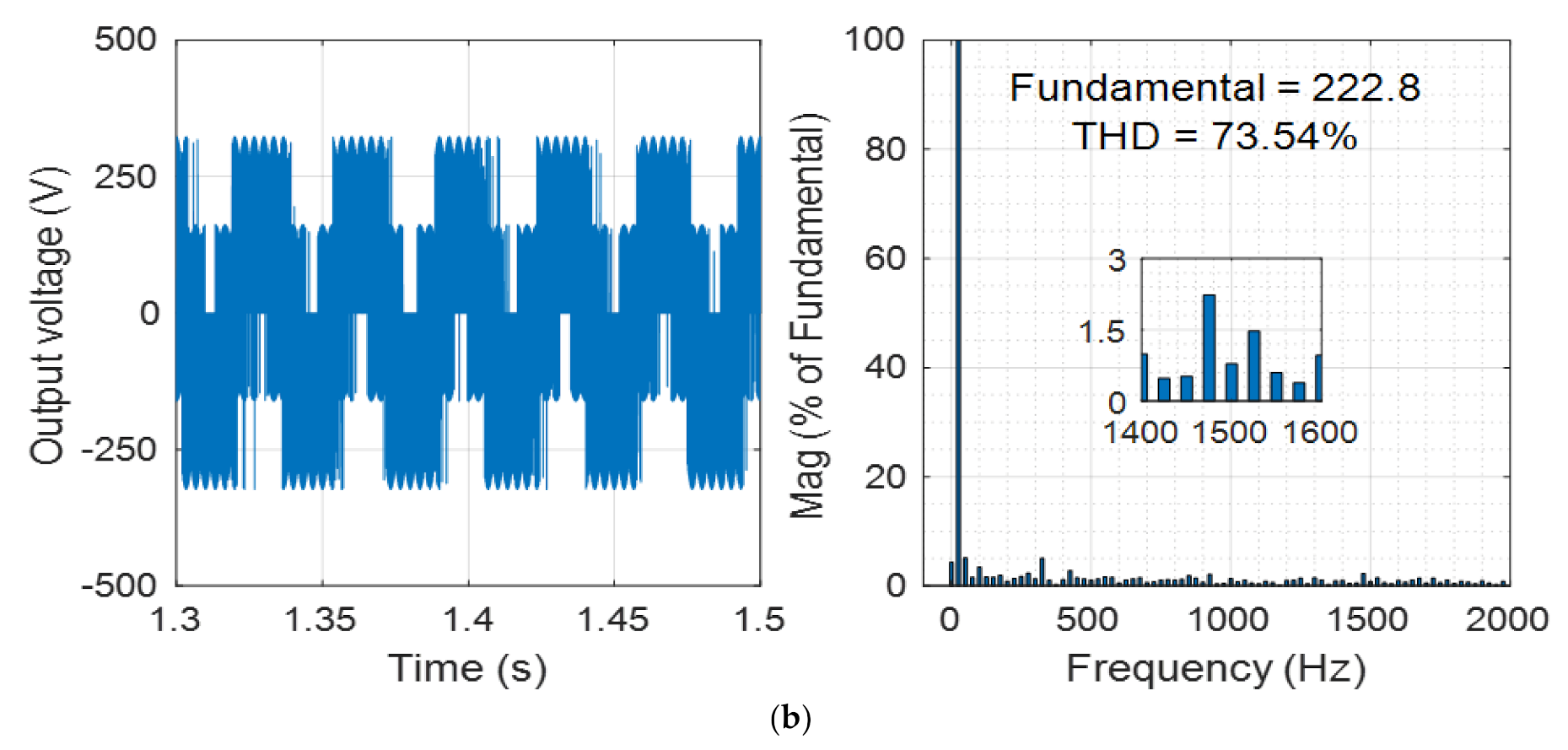

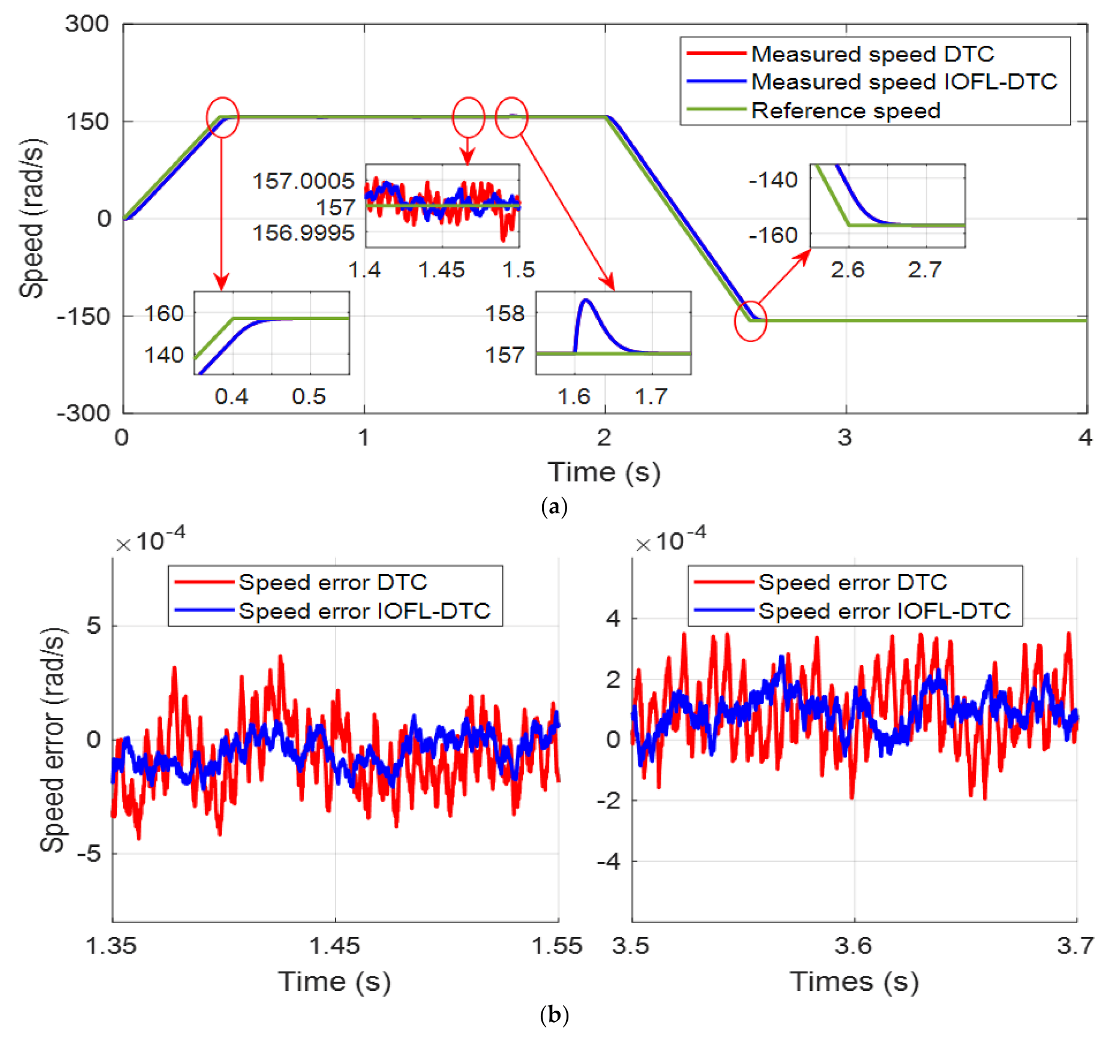

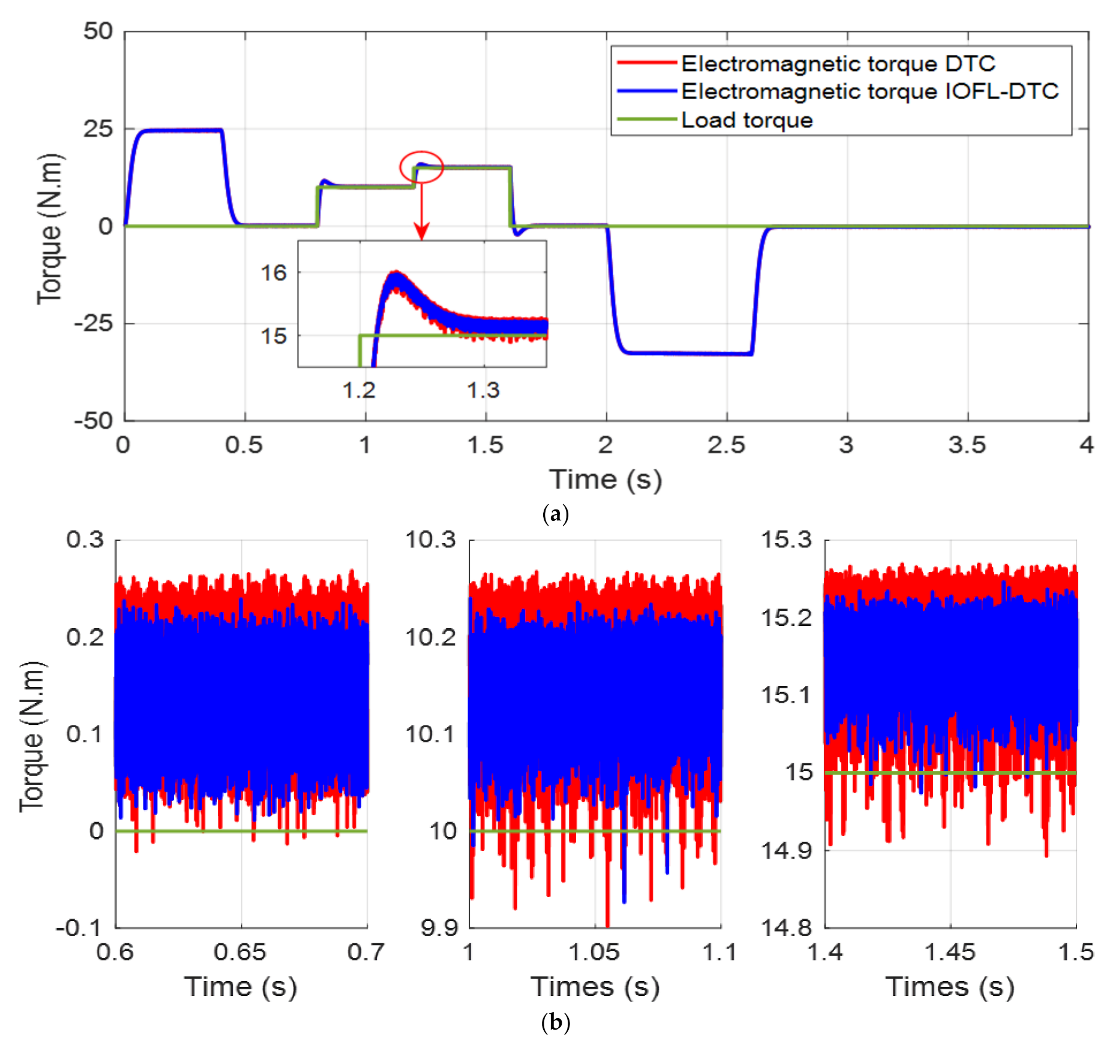

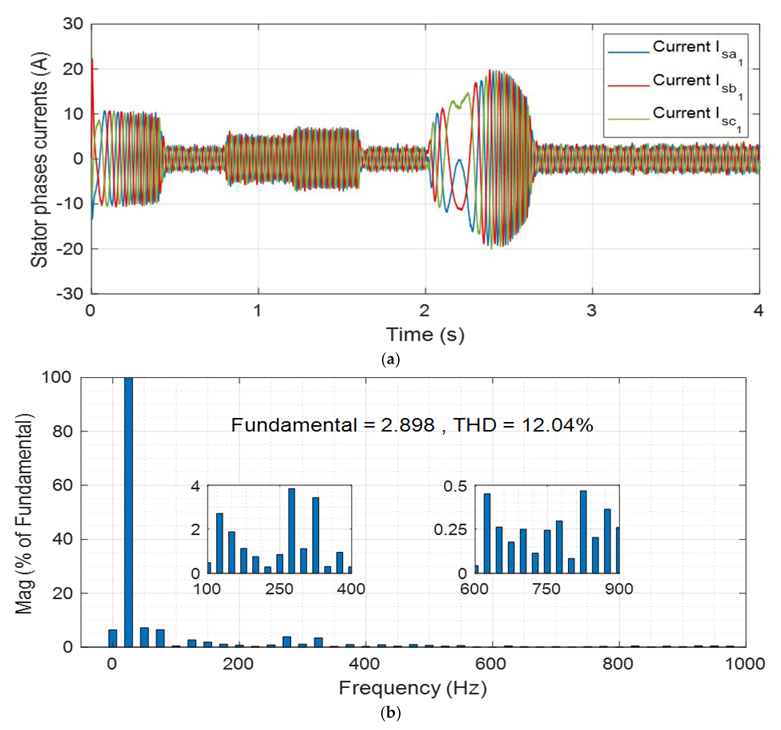

6. Simulation Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOEWIM | dual open-end windings induction motor |

| DSIM | dual-stator induction motor |

| DTC | direct torque control |

| SVM | space vector modulation |

| IOFL | input–output feedback linearization |

| CMV | common-mode voltage |

| FOC | field-oriented control |

| MC | matrix converter |

| IMC | indirect matrix converter |

| DC | direct current |

| AC | alternating current |

| THD | total harmonic distortion |

Appendix A

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| : mutual inductance | : friction coefficient | ||

| : rotor inductance | : number of pole pairs | ||

| : stator inductances | : moment of inertia | ||

| : stator resistances | : nominal voltage | ||

| : rotor resistance | : nominal power |

References

- Kali, Y.; Saad, M.; Doval-Gandoy, J.; Rodas, J. Discrete Terminal Super-Twisting Current Control of a Six-Phase Induction Motor. Energies 2021, 14, 1339. [Google Scholar] [CrossRef]

- Kali, Y.; Ayala, M.; Rodas, J.; Saad, M.; Doval-Gandoy, J.; Gregor, R.; Benjelloun, K. Current Control of a Six-Phase Induction Machine Drive Based on Discrete-Time Sliding Mode with Time Delay Estimation. Energies 2019, 12, 170. [Google Scholar] [CrossRef] [Green Version]

- Marouani, K.; Baghli, L.; Hadiouche, D.; Kheloui, A.; Rezzoug, A. A New PWM Strategy Based on a 24-Sector Vector Space Decomposition for a Six-Phase VSI-Fed Dual Stator Induction Motor. IEEE Trans. Ind. Electron. 2008, 55, 1910–1920. [Google Scholar] [CrossRef]

- Moati, Y.; Kouzi, K. Investigating the Performances of Direct Torque and Flux Control for Dual Stator Induction Motor with Direct and Indirect Matrix Converter. Period. Polytech. Electr. Eng. Comput. Sci. 2019, 64, 97–105. [Google Scholar] [CrossRef]

- Khadar, S.; Kouzou, A.; Rezzaoui, M.M.; Hafaifa, A. Sensorless Control Technique of Open-End Winding Five Phase Induction Motor under Partial Stator Winding Short-Circuit. Period. Polytech. Electr. Eng. Comput. Sci. 2019, 64, 2–19. [Google Scholar] [CrossRef] [Green Version]

- Rahali, H.; Zeghlache, S.; Benyettou, L.; Benalia, L. Backstepping Sliding Mode Controller Improved with Interval Type-2 Fuzzy Logic Applied to the Dual Star Induction Motor. Int. J. Comput. Intell. Appl. 2019, 18, 1950012. [Google Scholar] [CrossRef]

- Nirsha, K.I.; Rajeevan, P.P. A direct torque control scheme for dual inverter fed induction motor drive with a common DC voltage source. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar] [CrossRef]

- Ranjit, M.; Gowtami, S.; Babu, B.G. Reduction of zero sequence voltage using multilevel inverter fed open-end winding induction motor drive. Acta Electrotech. Inform. 2016, 16, 52–60. [Google Scholar] [CrossRef]

- Foti, S.; Testa, A.; De Caro, S.; Scimone, T.; Scelba, G.; Scarcella, G. Multi-level open end windings multi-motor drives. Energies 2019, 12, 861. [Google Scholar] [CrossRef] [Green Version]

- Reddy, B.V.; Somasekhar, V.T. A Dual Inverter Fed Four-Level Open-End Winding Induction Motor Drive With a Nested Rectifier-Inverter. IEEE Trans. Ind. Inform. 2012, 9, 938–946. [Google Scholar] [CrossRef]

- Nirsha, K.I.; Rajeevan, P.P. Parameter sensitivity analysis of DTC scheme for dual inverter fed open-end winding IM drive with single DC source. In Proceedings of the 2017 IEEE International WIE Conference on Electrical and Computer Engineering (WIECON-ECE), Dehradun, India, 18–19 December 2017. [Google Scholar] [CrossRef]

- Prasad, S.V.S.; Singh, R.R.; Somasekhar, V.T.; Lakhimsetty, S. Performance evaluation of an induction motor drive with direct torque control for open-end winding and cascaded three-level topologies. In Proceedings of the 2017 6th International Conference on Computer Applications in Electrical Engineering-Recent Advances (CERA), Roorkee, India, 5–7 October 2017. [Google Scholar] [CrossRef]

- Kumar, K.V.P.; Kumar, T.V. Improvised direct torque control strategies of open end winding PMSM fed with multi-level inversion. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018. [Google Scholar] [CrossRef]

- Ranjit, M.; Reddy, T.B.; Suryakalavathi, M. Performance Improvements in Open End Winding Induction Motor Drive Using Decoupled PWM Techniques. Energy Procedia 2017, 117, 810–817. [Google Scholar] [CrossRef]

- Saad, K.; Abdellah, K.; Ahmed, H.; Iqbal, A. Investigation on SVM-Backstepping sensorless control of five-phase open-end winding induction motor based on model reference adaptive system and parameter estimation. Eng. Sci. Technol. Int. J. 2019, 22, 1013–1026. [Google Scholar] [CrossRef]

- Ansari, S.; Chandel, A. Simulation based comprehensive analysis of direct and indirect matrix converter fed asynchronous motor drive. In Proceedings of the 2017 4th IEEE Uttar Pradesh Section International Conference on Electrical, Computer and Electronics (UPCON), Mathura, India, 26–28 October 2017. [Google Scholar] [CrossRef]

- Nguyen, T.; Lee, H.-H. A New SVM Method for an Indirect Matrix Converter With Common-Mode Voltage Reduction. IEEE Trans. Ind. Inform. 2013, 10, 61–72. [Google Scholar] [CrossRef]

- Benachour, A.; Berkouk, E.M.; Mahmoudi, M.O. Study and comparison between two DTC strategies of induction machine fed by direct matrix converter. J. Renew. Sustain. Energy 2017, 9, 55501. [Google Scholar] [CrossRef]

- Riedemann, J.; Clare, J.C.; Wheeler, P.; Blasco-Gimenez, R.; Rivera, M.; Pena, R. Open-end winding induction machine fed by a dual-output indirect matrix converter. IEEE Trans. Ind. Electron. 2016, 63, 4118–4128. [Google Scholar] [CrossRef]

- Tuyen, N.D.; Dzung, P.Q. Space Vector Modulation for an Indirect Matrix Converter with Improved Input Power Factor. Energies 2017, 10, 588. [Google Scholar] [CrossRef] [Green Version]

- Bak, Y.; Lee, E.; Lee, K.-B. Indirect Matrix Converter for Hybrid Electric Vehicle Application with Three-Phase and Single-Phase Outputs. Energies 2015, 8, 3849–3866. [Google Scholar] [CrossRef]

- Lavanya, N.; Rao, M.V.G. Control of indirect matrix converter by using improved SVM method. Int. J. Power Electron. Drive Syst. 2015, 6, 370–375. [Google Scholar] [CrossRef]

- Van Huynh, V.; Nguyen, T.D.; Dao, V.-T.; Tran, Q.-H. An Efficient Carrier-Based Modulation Strategy for Five-Leg Indirect Matrix Converters to Drive Open-End Loads with Zero Common-Mode Voltage. Electr. Power Compon. Syst. 2019, 47, 1303–1315. [Google Scholar] [CrossRef]

- Tran, Q.-H.; Lee, H.-H. A new SVM method to reduce common-mode voltage of five-leg indirect matrix converter fed open-end load drives. J. Power Electron. 2017, 17, 641–652. [Google Scholar] [CrossRef]

- Lazreg, M.-H.; Bentaallah, A. Sensor-less speed control of double star induction machine with five level DTC exploiting neural network and extended Kalman filter. Iran. J. Electr. Electron. Eng. 2019, 15, 142–150. [Google Scholar] [CrossRef]

- Lallouani, H.; Saad, B.; Letfi, B. DTC-SVM Based on Interval Type-2 Fuzzy Logic Controller of Double Stator Induction Machine Fed by Six-Phase Inverter. Int. J. Image Graph. Signal Process. 2019, 11, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Ouledali, O.; Meroufel, A.; Wira, P.; Bentouba, S. Direct Torque Fuzzy Control of PMSM Based on SVM. Energy Procedia 2015, 74, 1314–1322. [Google Scholar] [CrossRef] [Green Version]

- Bouzeria, H.; Fetha, C.; Bahi, T.; Abadlia, I.; Layate, Z.; Lekhchine, S. Fuzzy Logic Space Vector Direct Torque Control of PMSM for Photovoltaic Water Pumping System. Energy Procedia 2015, 74, 760–771. [Google Scholar] [CrossRef] [Green Version]

- Babu, M.V.; Rajeevan, P.P. Current error space vector based PWM scheme for dual inverter fed open-end winding induction motor with single DC-source. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar] [CrossRef]

- Lakhimsetty, S.; Prasad, V.K.J.D. Comparative performance analysis of decoupled SVPWM techniques for a four—Level open end winding induction motor drive. In Proceedings of the 2016 IEEE 7th Power India International Conference (PIICON), Bikaner, India, 25–27 November 2016. [Google Scholar] [CrossRef]

- Karampuri, R.; Jain, S.; Somasekhar, V.T. Phase displaced SVPWM technique for five-phase open-end winding induction motor drive. In Proceedings of the 2016 IEEE Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 5–6 March 2016. [Google Scholar] [CrossRef]

- Ammar, A.; Bourek, A.; Benakcha, A. Nonlinear SVM-DTC for induction motor drive using input-output feedback linearization and high order sliding mode control. ISA Trans. 2017, 67, 428–442. [Google Scholar] [CrossRef]

- Lascu, C.; Jafarzadeh, S.; Fadali, S.M.; Blaabjerg, F. Direct Torque Control With Feedback Linearization for Induction Motor Drives. IEEE Trans. Power Electron. 2017, 32, 2072–2080. [Google Scholar] [CrossRef]

- Belkacem, S.; Naceri, F.; Abdessemed, R. Reduction of torque ripple in DTC for induction motor using input-output feedback linearization. Serbian J. Electr. Eng. 2011, 8, 97–110. [Google Scholar] [CrossRef]

- Ammar, A. Performance improvement of direct torque control for induction motor drive via fuzzy logic-feedback linearization: Simulation and experimental assessment. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 672–692. [Google Scholar] [CrossRef]

- Costa, B.L.G.; Graciola, C.L.; Angélico, B.A.; Goedtel, A.; Castoldi, M. Metaheuristics optimization applied to PI controllers tuning of a DTC-SVM drive for three-phase induction motors. Appl. Soft Comput. 2018, 62, 776–788. [Google Scholar] [CrossRef]

- Rahali, H.; Zeghlache, S.; Benalia, L.; Layadi, N. Sliding mode control based on backstepping approach for a double star induction motor (DSIM). Adv. Model. Anal. C 2018, 73, 150–157. [Google Scholar] [CrossRef]

- Munoz-Garcia, A. Analysis and Control of a Dual Stator Winding Squirrel Cage Induction Machine Drive. Doctoral Thesis, University of Wisconsin-Madison, Madison, WI, USA, 1999. [Google Scholar]

- Hadiouche, D. Contribution to the Study of Dual Stator Induction Machine: Modeling, Suppling and Structure. Doctoral Thesis, University of Henri Poincaré Nancy-I, Nancy, France, 2001. [Google Scholar]

- Ogunjuyigbe, A.; Ayodele, T.; Adetokun, B. Modelling and analysis of dual stator-winding induction machine using complex vector approach. Eng. Sci. Technol. Int. J. 2018, 21, 351–363. [Google Scholar] [CrossRef]

- Tran, Q.-H.; Lee, H.-H. A three-vector modulation strategy for indirect matrix converter fed open-end load to reduce common-mode voltage with improved output performance. IEEE Trans. Power Electron. 2016, 32, 7904–7915. [Google Scholar] [CrossRef]

- Benachour, A.; Berkouk, E.; Mahmoudi, M.O. Study and implementation of indirect space vector modulation (ISVM) for direct matrix converter. In Proceedings of the 2015 3rd International Conference on Control, Engineering & Information Technology (CEIT), Tlemcen, Algeria, 25–27 May 2015. [Google Scholar] [CrossRef]

- Tewari, S.; Gupta, R.K.; Somani, A.; Mohan, N. Indirect matrix converter based open-end winding AC drives with zero common-mode voltage. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016. [Google Scholar] [CrossRef]

- Rahman, K.; Iqbal, A.; Al-Hitmi, M.A.; Dordevic, O.; Ahmad, S. Performance Analysis of a Three-to-Five Phase Dual Matrix Converter Based on Space Vector Pulse Width Modulation. IEEE Access 2019, 7, 12307–12318. [Google Scholar] [CrossRef]

- Depenbrock, M. Direct self-control (DSC) of inverter-fed induction machine. IEEE Trans. Power Electron. 1988, 3, 420–429. [Google Scholar] [CrossRef]

- Casadei, D.; Serra, G.; Tani, A. The use of matrix converters in direct torque control of induction machines. IEEE Trans. Ind. Electron. 2001, 48, 1057–1064. [Google Scholar] [CrossRef]

- Talaeizadeh, V.; Kianinezhad, R.; Seyfossadat, S.; Shayanfar, H. Direct torque control of six-phase induction motors using three-phase matrix converter. Energy Convers. Manag. 2010, 51, 2482–2491. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sellah, M.; Kouzou, A.; Mohamed-Seghir, M.; Rezaoui, M.M.; Kennel, R.; Abdelrahem, M. Improved DTC-SVM Based on Input-Output Feedback Linearization Technique Applied on DOEWIM Powered by Two Dual Indirect Matrix Converters. Energies 2021, 14, 5625. https://doi.org/10.3390/en14185625

Sellah M, Kouzou A, Mohamed-Seghir M, Rezaoui MM, Kennel R, Abdelrahem M. Improved DTC-SVM Based on Input-Output Feedback Linearization Technique Applied on DOEWIM Powered by Two Dual Indirect Matrix Converters. Energies. 2021; 14(18):5625. https://doi.org/10.3390/en14185625

Chicago/Turabian StyleSellah, Mourad, Abdellah Kouzou, Mostefa Mohamed-Seghir, Mohamed Mounir Rezaoui, Ralph Kennel, and Mohamed Abdelrahem. 2021. "Improved DTC-SVM Based on Input-Output Feedback Linearization Technique Applied on DOEWIM Powered by Two Dual Indirect Matrix Converters" Energies 14, no. 18: 5625. https://doi.org/10.3390/en14185625

APA StyleSellah, M., Kouzou, A., Mohamed-Seghir, M., Rezaoui, M. M., Kennel, R., & Abdelrahem, M. (2021). Improved DTC-SVM Based on Input-Output Feedback Linearization Technique Applied on DOEWIM Powered by Two Dual Indirect Matrix Converters. Energies, 14(18), 5625. https://doi.org/10.3390/en14185625