The Assessment of Energy Efficiency versus Planning of Rail Freight Traffic: A Case Study on the Example of Poland

Abstract

:1. Introduction

2. Literature Review

- review of various methods of effectiveness assessment, incl. the WTW technology [18],

3. Methodology

3.1. Mathematical Model of the Problem

- allocation of railway vehicles dedicated to freight traffic: locomotives and railcars to perform a defined transport task, taking into account the fact that the size of rolling stock inventory is limited; the solution is assessed in terms of the energy efficiency of the allocation,

- routing of a train launched in connection with the implementation of a defined transport task within the railway network,

- determination of transport conditions for a defined transport task taking into account the allocated rolling stock (locomotives and railcars) and the route.

- In order to select the rolling stock to perform specific tasks, it is necessary to:

- identify the location of the shipping points and unloading points as well as intermediate operating points for the implementation of transport—GSK,

- determination of technical characteristics of point elements (forwarding points) and linear railway network, e.g., unloading and loading times or travel times along a given route section—FSK,

- determination of locomotives and railcars being at the disposal of the railway operator—ST, i.e., determination of the technical characteristics of a given locomotive or railcars, e.g., max. speed, number of axles, capacities etc.—FST,

- defining the size of tasks to be performed (the size of the transported freight in a given service)—ZPD,

- defining transport tariffs—TTP,

- determining the energy efficiency of a specific transport task performance—EE.

- the performance of the transport task consists of transporting a specific volume of cargo from senders to recipients,

- cargo is transported with the use of locomotives and railcars suitable for the cargo being transported according to the NHM catalogue [60],

- the performance of transport tasks takes place within the established rail transport network,

- in the case of launching a train with a loading gauge exceeded, lines adapted to this will be used,

- the route of the shipment (transport task), constituting a transport need, should consist of successive sections of the railway line,

- the performance of a given transport task is carried out according to the appropriate transport tariff (basic charge appropriate for a given transport task changed with the use of an appropriate combination of multipliers),

- optimization takes place at the level of a specific transport task, and not at the network level,

- we assume that the capacity is available for the implementation of the reported transport task; the possible lack of capacity on individual open line may result in the extension of the obtained transport time,

- we assume that the current state of the rolling stock at the disposal is the input data; we determine the best solution for this state; we do not assume its update and implementation delay (one of the criteria is minimizing the duration of the transport),

- we assume that the task is performed with the use of the block train system; in the future, we will extend the method to the implementation of transport in the single wagon system.

3.2. Mathematical Formulation of the Problem

3.2.1. Model Parameters

- binary variables x(nol,zpd) about the interpretation of the use of a given section of the railway network for the implementation of a specific transport task, stored in the matrix D(zpd),

- binary variables dtr(zpd,lok,wag) about the interpretation of allocating an appropriate number of locomotives of specific series and a specified number of railcars of specific series for the implementation of a given transport task, stored in the matrix DTR(zpd),

- variables about the interpretation of the conditions of transporting the shipment being declared for transport for a specified route and selected locomotive and railcars, notated in the form of a vector WP(zpd):

- dl(zpd)—length of the transport task route,

- O(zpd)—a vector containing a list of railway line sections along which the transport needs will be fulfilled,

- VMAX(zpd)—a vector containing a list of permissible speeds for sections of railway lines along which the transport needs will be fulfilled,

- NMAX(zpd)—a vector containing a list of permissible axle loads for sections of railway lines along which the transport needs will be fulfilled,

- WMAX(zpd)—a vector containing a list of the permissible number of railcars for sections of railway lines along which the transport needs will be fulfilled,

- OMAX(zpd)—a vector containing a list of the permissible number of axles for sections of railway lines along which the transport needs will be fulfilled,

- DMAX(zpd)—a vector containing a list of the permissible length of trains for sections of railway lines along which the transport needs will be fulfilled,

- rzmh(DTR(zpd))—total braked weight of the train: of the dispatched locomotive and dispatched railcars,

- TNOL(zpd)—a vector containing theoretical travel times for sections of railway lines along which the transport needs will be fulfilled,

- t(zpd)—theoretical travel time for the fulfilment of the transport need,

- k(zpd)—transport cost for the fulfilment of the transport need.

- tow(zpd,nhm)—the subject of carriage in the transport task is the commodity with the number NHM,

- sp(zpd,pe)—the transport task with the zpd number begins at the operating point pe called the point of dispatch,

- sk(zpd,pe)—the transport task ends at the operating point pe called the collection point,

- zp(zpd)—the size of the transport need,

- ps(zpd)—the fact that the transport need is a shipment with the loading gauge exceeded.

3.2.2. Quality Assessment Indices for Solving the Problem of Selecting the Rolling Stock for the Implementation of Tasks Based on the Assessment of the Energy Efficiency of the Solution

- F1(k(zpd))—minimizing the cost of shipment transport within the railway network:

- F2(D(zpd), DTR(zpd))—minimizing energy consumption necessary to carry out the shipment transport within the railway network (determination of the energy efficiency of the proposed solution):

3.2.3. Constraints Used in the Problem of Selecting the Rolling Stock for the Performance of Tasks Based on the Assessment of the Energy Efficiency of the Solution

- train parameters concerning:

- maximum train speed,

- maximum axle loads of vehicles (locomotives and railcars),

- actual braked weight of the train composition,

- necessity to meet a transport need with the loading gauge exceeded,

- shipment parameters concerning:

- a specific load should be transported in a railcar of a specific series in agreement with its allocation,

- the place of transport commencement,

- the place of transport completion,

- allocating an appropriate number of railcars,

- allocating a locomotive whose towing capacity will allow the train to move,

- infrastructure parameters concerning:

- transport route,

- a given section of the railway line,

- the number of railcars allocated for task performance,

- number of railcar axles allocated for task performance,

- the sum of the length of the locomotive and railcars allocated for task performance,

- the sum of the number of locomotive and railcar axles allocated for task performance,

- allocation of a locomotive whose type of traction corresponds to the type of traction located on individual sections of railway lines,

- bearing a basic charge and possibly an additional fee,

- imposing correction factors.

3.3. The Procedure of the Method

- STEP 1: Defining the input parameters. It is necessary to define the initial and terminal stations for commodity transport, define their type and the amount of weight to be transported.

- STEP 2: Using the input parameters and the “Stations” dictionary (STEP 2a) it is possible to describe the transport task (STEP 2b). When describing the task, the “NHM” dictionary containing standardized types of cargo should be used, so that the type of commodity is written in the form of commodity groups to be transported (STEP 2c).

- STEP 3: Identifying the data being searched for: incl. locomotives, railcars, train length, number of axles, weight, speed, percentage of braked weight.

- STEP 4: Answering the question whether the first search for a solution is taking place. If not, go to the “Restrictions and conditions of train passage” section. If yes, go to the next step.

- STEP 5: On the basis of the dictionary “Locomotives” and “Railcars”, the allocation of vehicles for the performance of the defined transport task takes place.

- STEP 6: Define the train composition necessary for the transport by determining its weight, length, number of railcars, number of axles, maximum axle load on the rail and maximum speed.

- STEP 7: Basing on the specified parameters of the train composition, as well as on the basis of the data contained in the dictionaries “Stations”, “Railway lines” and “Railway sections”, the optimal route for the transport is determined by specifying: maximum speed, maximum axle load on the rail, type of traction and loading gauge parameters.

- STEP 8: As a result of the work, we obtain a set of restrictions and conditions for train passage. The limitations arise by comparing the values found with the parameters of the train route (STEP 8a). In the scope of transport conditions, the tariff cost, is determined, i.e., pursuant to the “Freight Tariff” dictionary.

- STEP 9: A report on results is generated, in the form of determining the train composition, restrictions and running costs.

- STEP 10: Verifying the correctness of the obtained results. If the results are correct, the operation of the method ends. If the obtained results are not satisfactory, the assumptions are changed (STEP 10a). Corrections may be introduced by changing the locomotive, changing the train composition or changing the route (STEPS 10b, 10c and 10d). After a correction is made, go to step 8 “Train passage restrictions and conditions”.

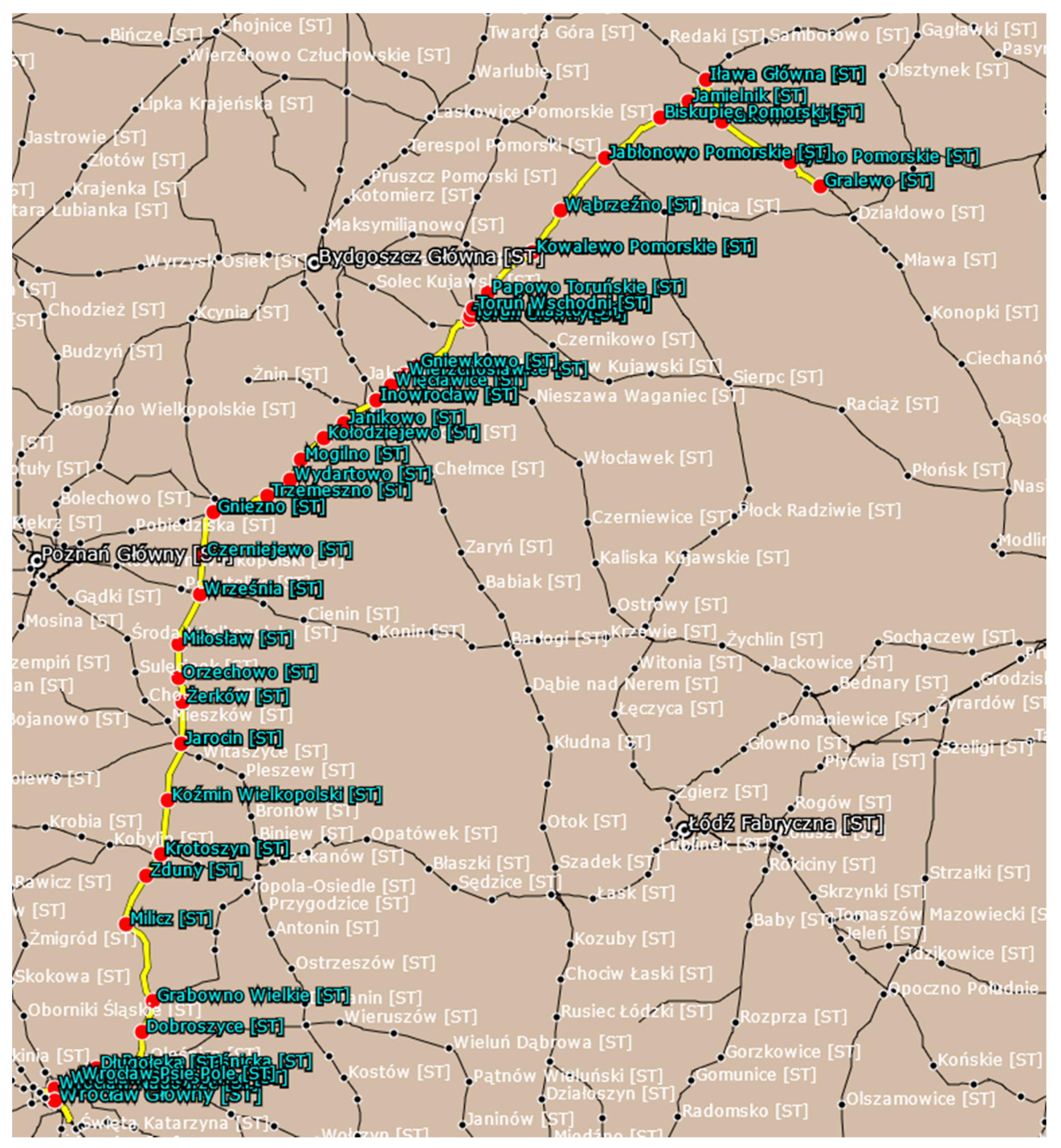

4. Case Study—Selection of Rolling Stock for Task Performance on the Basis of the Assessment of Energy Efficiency of the Solution on the Example of Poland

4.1. Identification of Input Parameters

- the object of transport: stones for the construction of a railway line,

- the initial station of transport: Gralewo,

- the terminal station of transport: Wrocław Brochów,

- the weight of the object of transport: 2000 tons,

- information that the shipment is not a shipment exceeding the loading gauge.

4.2. Results of the Selection of Rolling Stock for the Implementation of Tasks Based on the Assessment of Energy Efficiency of the Solution

- carrying out an allocation of railway vehicles dedicated to freight traffic: an appropriate number of the correct series of locomotives and an appropriate number of the correct series of freight cars to perform the defined transport task,

- routing a train launched in connection with the implementation of a defined transport task within the railway network (taking into account the effects of the selecting rolling stock for task performance,

- identifying transport conditions for a specified transport task.

4.2.1. Selecting a Locomotive and Railcars to Perform the Transport Task

4.2.2. Determining the Route of Freight Transport

4.2.3. Determining the Conditions of Transport for Individual Tasks

5. Summary and Conclusions

- planning train traffic on the railway network in a variant other than the shortest,

- planning train traffic on the railway network in the form of graphic timetable,

- planning the work of traction crews in terms of assigning a traction crew to service trains,

- planning of maneuvering work and the operation of the support facilities in setting maneuvering crews to individual stations with shunting locomotives and drawing up a plan for the maintenance of traction vehicles and wagons by technical facilities (inspections).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hilmola, O. European railway freight transportation and adaptation to demand decline: Efficiency and partial productivity analysis from period of 1980–2003. Int. J. Product. Perform. Manag. 2007, 56, 205–225. [Google Scholar] [CrossRef]

- Gołębiowski, P.; Żak, J.; Jacyna-Gołda, I. Approach to the Proecological Distribution of the Traffic Flow on the Transport Network from the Point of View of Carbon Dioxide. Sustainability 2020, 12, 6936. [Google Scholar] [CrossRef]

- Jacyna, M.; Gołębiowski, P.; Pyza, D. Railway Traffic Organization Model Considering Allocation of Platform Edges for Passenger Trains. Arch. Transp. Syst. Telemat. 2018, 11, 27–33. [Google Scholar]

- Taheri, J.; Zomaya, A.Y. A simulation tool for mobility management experiments. Int. J. Pervasive Comput. Commun. 2009, 5, 360–379. [Google Scholar] [CrossRef]

- Jacyna, M.; Żak, J.; Gołębiowski, P. Models of Traffic Flow Distribution for Various Scenarios of the Development of Proecological Transport System. Arch. Transp. 2014, 32, 17–28. [Google Scholar] [CrossRef]

- Gołębiowski, P.; Gołda, I.J.; Izdebski, M.; Kłodawski, M.; Jachimowski, R.; Szczepański, E. The evaluation of the sustainable transport system development with the scenario analyses procedure. J. Vibroeng. 2017, 19, 5627–5638. [Google Scholar] [CrossRef]

- Ojha, D.; Gokhale, R.A. Logistical business continuity planning-scale development and validation. Int. J. Logist. Manag. 2009, 20, 342–359. [Google Scholar] [CrossRef]

- Voss, C.; Clutterbuck, D. Just in Time: A Global Status Report; Springer: Berlin, Germany, 1989. [Google Scholar]

- Jacyna, M.; Semenov, I. Models of vehicle service system supply under information uncertainty. Eksploat. I Niezawodn. 2020, 22, 694–704. [Google Scholar] [CrossRef]

- Stawowy, M.; Rosiński, A.; Siergiejczyk, M.; Perlicki, K. Quality and Reliability-Exploitation Modeling of Power Supply Systems. Energies 2021, 14, 2727. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Lewczuk, K.; Karoń, G. Noise and environmental pollution from transport: Decisive problems in developing ecologically efficient transport systems. J. Vibroeng. 2017, 19, 5639–5655. [Google Scholar] [CrossRef]

- Ruzzenenti, F.; Basosi, R. Evaluation of the energy efficiency evolution in the European road freight transport sec-tor. Energy Policy 2009, 37, 4079–4085. [Google Scholar] [CrossRef]

- Meng, F.; Liu, G.; Yang, Z.; Casazza, M.; Cui, S.; Ulgiati, S. Energy efficiency of urban transportation system in Xiamen, China. An integrated approach. Appl. Energy 2017, 186, 234–248. [Google Scholar] [CrossRef]

- Zhou, G.; Chung, W.; Zhang, Y. Measuring energy efficiency performance of China’s transport sector: A data envelopment analysis approach. Expert Syst. Appl. 2014, 41, 709–722. [Google Scholar] [CrossRef]

- Cui, Q.; Li, Y. The evaluation of transportation energy efficiency: An application of three-stage virtual frontier DEA. Transp. Res. Part D Transp. Environ. 2014, 29, 1–11. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, Q.; Chu, J.; Liu, H.; Liang, L. Measuring energy and environmental efficiency of transportation systems in China based on a parallel DEA approach. Transp. Res. Part D Transp. Environ. 2016, 48, 460–472. [Google Scholar] [CrossRef]

- Djordjević, B.; Krmac, E. Evaluation of Energy-Environment Efficiency of European Transport Sectors: Non-Radial DEA and TOPSIS Approach. Energies 2019, 12, 2907. [Google Scholar] [CrossRef] [Green Version]

- Kosai, S.; Nakanishi, M.; Yamasue, E. Vehicle energy efficiency evaluation from well-to-wheel lifecycle perspective. Transp. Res. Part D Transp. Environ. 2018, 65, 355–367. [Google Scholar] [CrossRef]

- Zhang, C.; Ho, S.H.; Chen, W.H.; Fu, Y.; Chang, J.S.; Bi, X. Oxidative torrefaction of biomass nutshells: Evaluations of energy efficiency as well as biochar transportation and storage. Appl. Energy 2019, 235, 428–441. [Google Scholar] [CrossRef]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Varga, B.O.; Iclodean, C.; Mariasiu, F. Electric and Hybrid Buses for Urban Transport: Energy Efficiency Strategies; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Wang, N.; Shen, R.; Wen, Z.; De Clercq, D. Life cycle energy efficiency evaluation for coal development and utili-zation. Energy 2019, 179, 1–11. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, A.; Fernández-Cardador, A.; Cucala, A.P.; Falvo, M.C. Energy Efficiency and Integration of Urban Electrical Transport Systems: EVs and Metro-Trains of Two Real European Lines. Energies 2019, 12, 366. [Google Scholar] [CrossRef] [Green Version]

- Ciccarelli, F.; DEL Pizzo, A.; Iannuzzi, D. Improvement of Energy Efficiency in Light Railway Vehicles Based on Power Management Control of Wayside Lithium-Ion Capacitor Storage. IEEE Trans. Power Electron. 2014, 29, 275–286. [Google Scholar] [CrossRef]

- De Martinis, V.; Corman, F. Data-driven perspectives for energy efficient operations in railway systems: Current practices and future opportunities. Transp. Res. Part C Emerg. Technol. 2018, 95, 679–697. [Google Scholar] [CrossRef]

- Jacyna, M.; Gołębiowski, P.; Urbaniak, M. Multi-option Model of Railway Traffic Organization Including the Energy Recuperation. In Programmieren für Ingenieure und Naturwissenschaftler; Springer: Berlin/Heidelberg, Germany, 2016; pp. 199–210. [Google Scholar]

- Urbaniak, M.; Kardas-Cinal, E.; Jacyna, M.; Cinal, K. Optimization of Energetic Train Cooperation. Symmetry 2019, 11, 1175. [Google Scholar] [CrossRef] [Green Version]

- Frilli, A.; Meli, E.; Nocciolini, D.; Pugi, L.; Rindi, A. Energetic optimization of regenerative braking for high speed railway systems. Energy Convers. Manag. 2016, 129, 200–215. [Google Scholar] [CrossRef]

- Kuznetsov, V.G.; Sablin, O.I.; Chornaya, A.V. Improvement of the regenerating energy accounting system on the direct current railways. Arch. Transp. 2015, 36, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Mayet, C.; Bouscayrol, A.; Delarue, P.; Chattot, E.; Verhille, J.N. Electrokinematical Simulation for Flexible Energetic Studies of Railway Systems. IEEE Trans. Ind. Electron. 2017, 65, 3592–3600. [Google Scholar] [CrossRef]

- Matusevych, O.; Kuznetsov, V.; Sychenko, V. The method for increasing the efficiency of equipment’s maintenance in railway traction power supply systems. Arch. Transp. 2018, 47, 39–47. [Google Scholar] [CrossRef]

- Destraz, B.; Barrade, P.; Rufer, A.; Klohr, M. Study and simulation of the energy balance of an urban transportation network. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Institute of Electrical and Electronics Engineers (IEEE), Aalborg, Denmark, 2–5 September 2007; pp. 1–10. [Google Scholar]

- Szkoda, M.; Satora, M.; Konieczek, Z. Effectiveness assessment of diesel locomotives operation with the use of mobile maintenance points. Arch. Transp. 2020, 54, 7–19. [Google Scholar] [CrossRef]

- Agenjos, E.; Gabaldon, A.; Franco, F.G.; Molina, R.; Valero, S.; Ortiz, M.; Gabaldon, R.J. Energy efficiency in rail-ways: Energy storage and electric generation in diesel electric locomotives. In Proceedings of the 20th International Conference and Exhibition on Electricity Distribution, Prague, Czech Republic, 8–11 June 2009; pp. 1–7. [Google Scholar]

- Popescu, M.; Bitoleanu, A. A Review of the Energy Efficiency Improvement in DC Railway Systems. Energies 2019, 12, 1092. [Google Scholar] [CrossRef] [Green Version]

- Gunselmann, W. Technologies for increased energy efficiency in railway systems. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005; p. 10. [Google Scholar]

- Caris, A.; Macharis, C.; Janssens, G.K. Planning Problems in Intermodal Freight Transport: Accomplishments and Prospects. Transp. Plan. Technol. 2008, 31, 277–302. [Google Scholar] [CrossRef] [Green Version]

- Crainic, T.G.; Ferland, J.-A.; Rousseau, J.-M. A Tactical Planning Model for Rail Freight Transportation. Transp. Sci. 1984, 18, 165–184. [Google Scholar] [CrossRef]

- Crainic, T.G.; Florian, M.; Léal, J.-E. A Model for the Strategic Planning of National Freight Transportation by Rail. Transp. Sci. 1990, 24, 1–24. [Google Scholar] [CrossRef]

- Lindholm, M.; Behrends, S. Challenges in urban freight transport planning—A review in the Baltic Sea Region. J. Transp. Geogr. 2012, 22, 129–136. [Google Scholar] [CrossRef]

- Kukulski, J.; Gołębiowski, P.; Makowski, J.; Jacyna-Gołda, I.; Żak, J. Effective Method for Diagnosing Continuous Welded Track Condition Based on Experimental Research. Energies 2021, 14, 2889. [Google Scholar] [CrossRef]

- Kwon, O.K.; Martland, C.D.; Sussman, J.M. Routing and scheduling temporal and heterogeneous freight car traffic on rail networks. Transp. Res. Part E Logist. Transp. Rev. 1998, 34, 101–115. [Google Scholar] [CrossRef]

- Lusby, R.M.; Larsen, J.; Bull, S. A survey on robustness in railway planning. Eur. J. Oper. Res. 2018, 266, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; D’Ariano, A.; Yin, J.; Meng, L.; Tang, T.; Ning, B. Passenger demand oriented train scheduling and rolling stock circulation planning for an urban rail transit line. Transp. Res. Part B Methodol. 2018, 118, 193–227. [Google Scholar] [CrossRef]

- Narayanaswami, S.; Rangaraj, N. Scheduling and rescheduling of railway operations: A review and expository analysis. Technol. Oper. Manag. 2011, 2, 102–122. [Google Scholar] [CrossRef]

- Billionnet, A.; Costa, M.C.; Sutter, A. An efficient algorithm for a task allocation problem. J. ACM 1992, 39, 502–518. [Google Scholar] [CrossRef]

- Chu, W.W.; Holloway, L.J.; Lan, M.T.; Efe, K. Task Allocation in Distributed Data Processing. IEEE Comput. 1980, 13, 57–69. [Google Scholar] [CrossRef]

- Shatz, S.; Wang, J.-P.; Goto, M. Task allocation for maximizing reliability of distributed computer systems. IEEE Trans. Comput. 1992, 41, 1156–1168. [Google Scholar] [CrossRef]

- Khamis, A.; Hussein, A.; Elmogy, A. Multi-robot Task Allocation: A Review of the State-of-the-Art. Coop. Robot. Sens. Netw. 2015, 31–51. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, C.-S. A hybrid heuristic to solve a task allocation problem. Comput. Oper. Res. 2000, 27, 287–303. [Google Scholar] [CrossRef]

- Giordani, S.; Lujak, M.; Martinelli, F. A Distributed Algorithm for the Multi-Robot Task Allocation Problem. In Trends in Applied Intelligent Systems; Springer: Berlin/Heidelberg, Germany, 2010; Volume 6096, pp. 721–730. [Google Scholar]

- Assad, A.A. Models for rail transportation. Transp. Res. Part A Gen. 1980, 14, 205–220. [Google Scholar] [CrossRef]

- Gainanov, D.N.; Konygin, A.V.; Rasskazova, V.A. Modelling railway freight traffic using the methods of graph theory and combinatorial optimization. Autom. Remote Control. 2016, 77, 1928–1943. [Google Scholar] [CrossRef]

- Crainic, T.G.; Roy, J. OR tools for tactical freight transportation planning. Eur. J. Oper. Res. 1988, 33, 290–297. [Google Scholar] [CrossRef]

- Crainic, T.G.; Laporte, G. Planning models for freight transportation. Eur. J. Oper. Res. 1997, 97, 409–438. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Zhang, J. An optimal service model for rail freight transportation: Pricing, planning, and emission reducing. J. Clean. Prod. 2019, 218, 565–574. [Google Scholar] [CrossRef]

- Szaciłło, L.; Jacyna, M.; Szczepański, E.; Izdebski, M. Risk assessment for rail freight transport operations. Eksploat. I Niezawodn.–Maint. Reliab. 2021, 23, 476–488. [Google Scholar] [CrossRef]

- Abbink, E. Solving Large Scale Crew Scheduling Problems by Using Iterative Paartitioning (No. EI 2008-03); Report/Econometric Institute, Erasmus University Rotterdam: Rotterdam, The Netherlands, 2008; pp. 1–15. [Google Scholar]

- Abbink, E.J.; Albino, L.; Dollevoet, T.; Huisman, D.; Roussado, J.; Saldanha, R.L. Solving large scale crew scheduling problems in practice. Public Transp. 2011, 3, 149–164. [Google Scholar] [CrossRef]

- PKP Cargo S.A. Zharmonizowany Spis Towarów (NHM); PKP Cargo S.A.: Warszawa, Poland, 2019. [Google Scholar]

- Terczyński, P. Atlas Lokomotyw Elektrycznych; Kolpress: Poznań, Poland, 2017. [Google Scholar]

- Terczyński, P. Atlas Lokomotyw Spalinowych; Kolpress: Poznań, Poland, 2017. [Google Scholar]

- Terczyński, P. Atlas Wagonów Towarowych; Kolpress: Poznań, Poland, 2011. [Google Scholar]

- PKP Cargo S.A. Taryfa Towarowa PKP Cargo S.A.; PKP Cargo S.A.: Warszawa, Poland, 2021. [Google Scholar]

| Vehicle | Parameter | Parameter Value |

|---|---|---|

| LOCOMOTIVES | series | ET21 (electric) |

| number | 1 | |

| axles in total | 6 | |

| total length | 17.5 m | |

| max. speed | 100 km/h | |

| empty weight | 78 tons | |

| braked weight | 50 tons | |

| percentage of braked weight | 64.1% | |

| max. axle load of the locomotive on the rail | 13 tons | |

| RAILCARS | series | Eans |

| number | 19 | |

| number of railcars | 19 | |

| axles in total | 76 | |

| total length | 342 m | |

| max. speed | 100 km/h | |

| empty weight | 427.5 tons | |

| braked weight | 950 tons | |

| percentage of braked weight | 62.5% | |

| load limit | 1520 tons | |

| max. axle load of the railcar on the rail | 20 tons |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gołębiowski, P.; Jacyna, M.; Stańczak, A. The Assessment of Energy Efficiency versus Planning of Rail Freight Traffic: A Case Study on the Example of Poland. Energies 2021, 14, 5629. https://doi.org/10.3390/en14185629

Gołębiowski P, Jacyna M, Stańczak A. The Assessment of Energy Efficiency versus Planning of Rail Freight Traffic: A Case Study on the Example of Poland. Energies. 2021; 14(18):5629. https://doi.org/10.3390/en14185629

Chicago/Turabian StyleGołębiowski, Piotr, Marianna Jacyna, and Andrzej Stańczak. 2021. "The Assessment of Energy Efficiency versus Planning of Rail Freight Traffic: A Case Study on the Example of Poland" Energies 14, no. 18: 5629. https://doi.org/10.3390/en14185629

APA StyleGołębiowski, P., Jacyna, M., & Stańczak, A. (2021). The Assessment of Energy Efficiency versus Planning of Rail Freight Traffic: A Case Study on the Example of Poland. Energies, 14(18), 5629. https://doi.org/10.3390/en14185629