Overview on Lead-Cooled Fast Reactor Design and Related Technologies Development in ENEA

Abstract

1. Introduction

- PASCAL: under the coordination of ENEA, the PASCAL “Proof of Augmented Safety Conditions in Advanced Liquid–Metal-Cooled Systems” project aims at addressing several topics that have been requested in order to substantiate the pre-licensing processes that are ongoing in Romania for ALFRED and in Belgium for MYRRHA. The general approach is to perform experimental work, in such a way to provide both data that can be directly used to support the safety claims for the two systems, and data that can be used for the validation of the simulation codes and methods that are used in the evaluation or verification of the safety performances.

- PIACE: under the coordination of ENEA, the PIACE “Passive Isolation Condenser” project aims at supporting the technology transfer from the research to industry in the area of the safety of nuclear installations. An innovative decay heat removal system for nuclear reactors, presently under technology validation in the relevant environment (such as the SIRIO facility), will be scaled-up to achieve a system prototype demonstration in an operational environment, relevant for LFRs/accelerator driven systems (ADSs) and light water reactors (LWRs).

- PATRICIA: under the coordination of SCKCEN, the “Partitioning and Transmuter Research Initiative in a Collaborative Innovation Action” project will investigate advanced partitioning to efficiently separate the radioactive chemical Americium from spent fuel, and it will study the development of transmutation systems. It will also explore the behaviour of Americium-bearing fuel under irradiation and conduct safety-related research.

- GEMMA: under the coordination of ENEA, the “Generation IV Materials Maturity” project aims at qualifying and codifying the selected structural materials for the construction of Generation IV reactors, as envisaged within the European Sustainable Nuclear Industrial Initiative (ESNII), mainly ALFRED, ASTRID, and MYRRHA.

- PUMMA: under the coordination of CEA, the “Plutonium Management for More Agility” project aims to outline various options for Plutonium management in Generation IV systems. It also aims to assess their impact on the full fuel cycle, taking into account safety and performance. In contrast with previous studies involving 15–30% plutonium concentrations in MOX fuel, this project will provide results relating to 45% plutonium fuels.

2. Integral Experiments

2.1. Thermal-Hydraulic Experiments

2.2. Steam Generator Tube Rupture Experiments

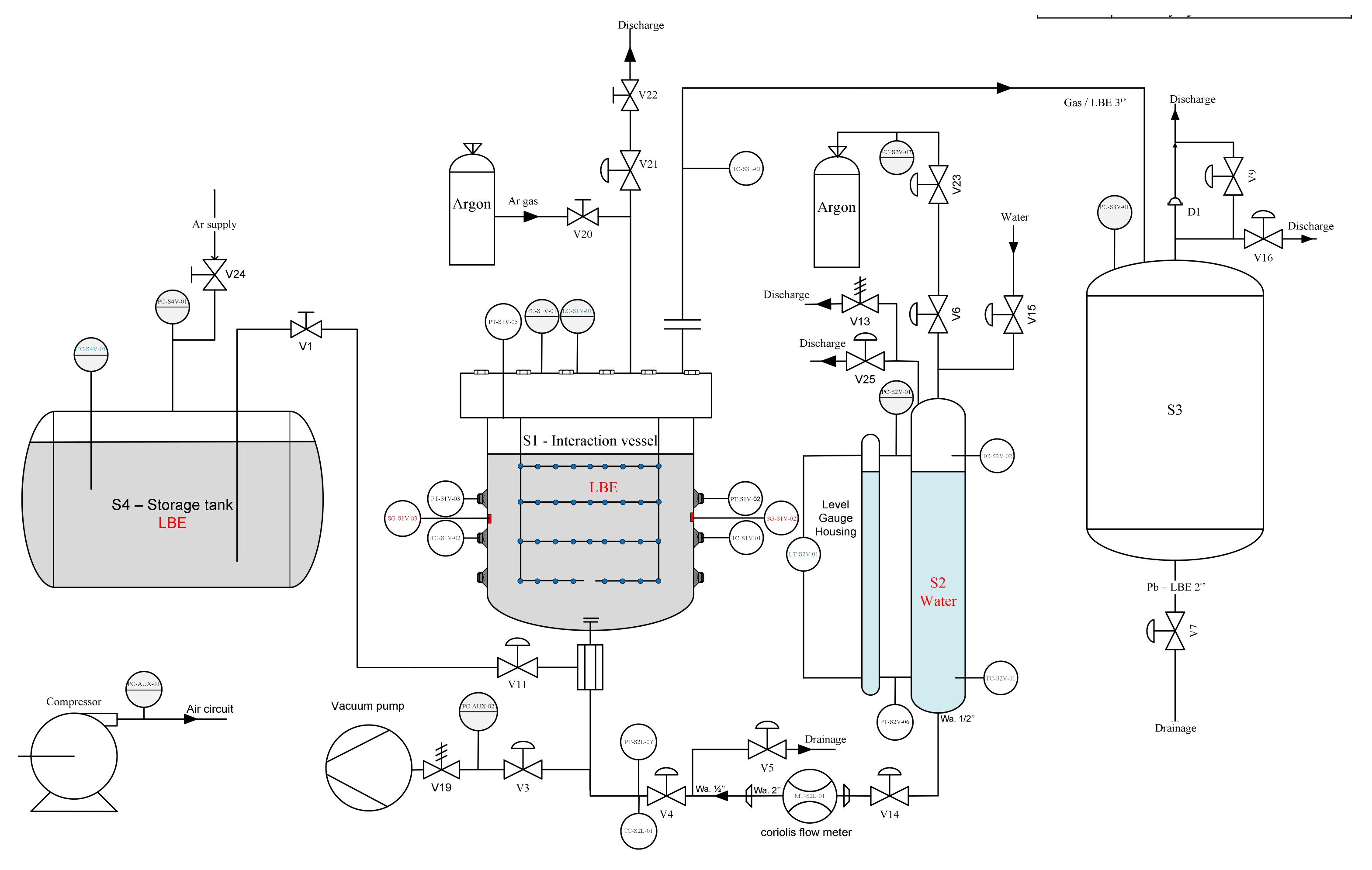

3. Separate Effect Tests on HLM/Water Interaction

4. Core Design and Safety Assessment

4.1. Core Design Activities

- the so called “42-0 approach” and the support tool “A-BAQUS” for the design of a uranium-free, plutonium isogenerator and minor actinides (MAs) burner core for an ADS [33];

- the approach for the so called “adiabatic reactor concept”, to design a critical core that targets the isogeneration of plutonium and of MAs, which therefore operates in a closed fuel cycle as a net burner of uranium only [34].

4.2. NACIE Experiments, CFD Applications, and Flow-Induced Vibration Experiments

4.3. Flow Blockage Experiments, ALFRED Analysis, ALFRED Design FA

4.4. CFD Assessment of Flow Blockage in ALFRED FA

5. Numerical Tools for LFR

6. Conceptual Design of Auxiliary Systems for ALFRED

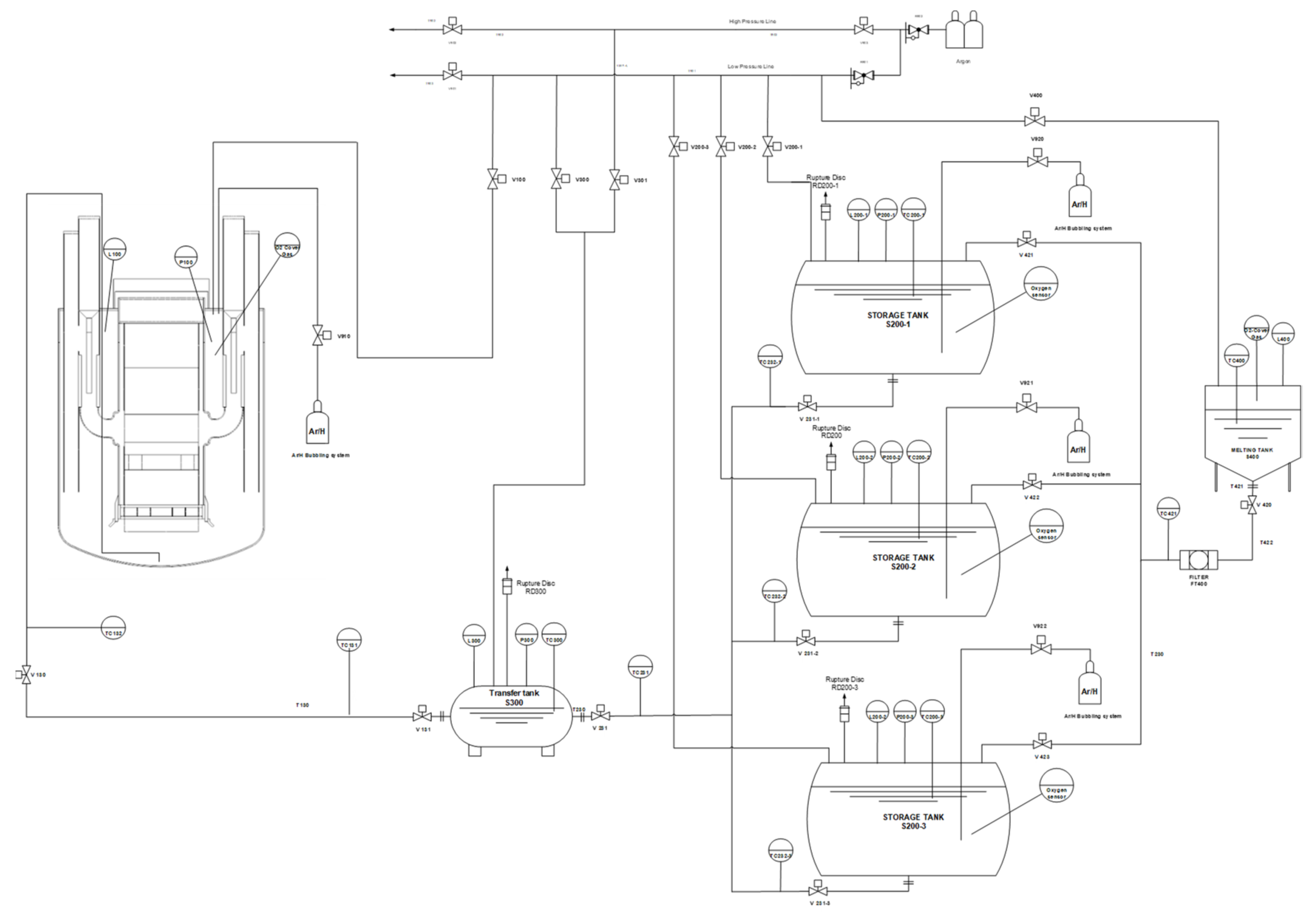

6.1. Fill and Drain System

6.2. Cover Gas Purification System

7. Structural Materials, Coatings and Coolant Chemistry

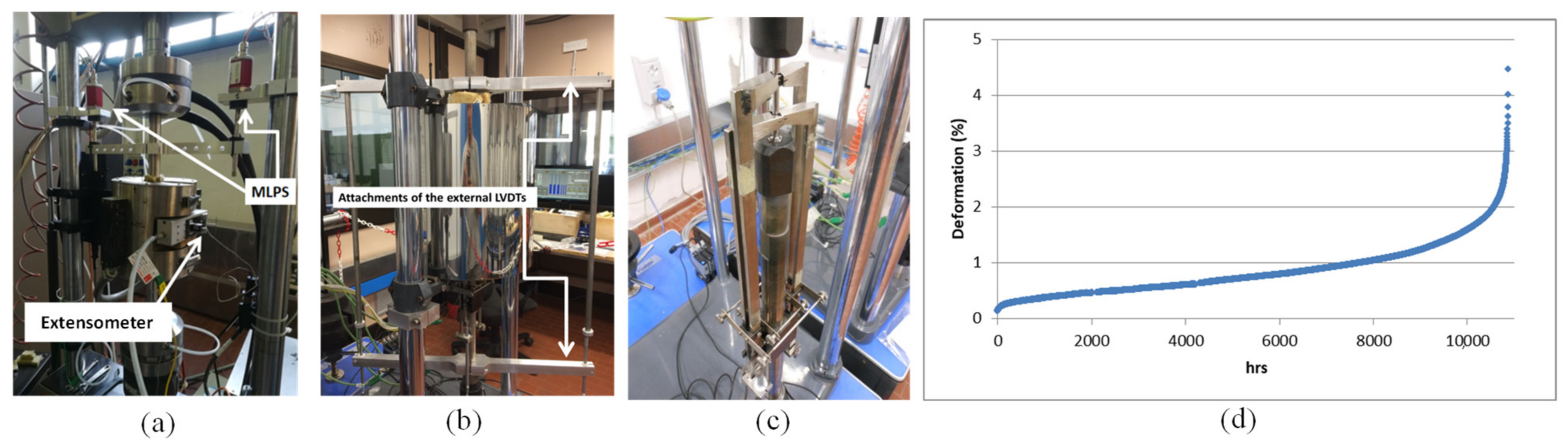

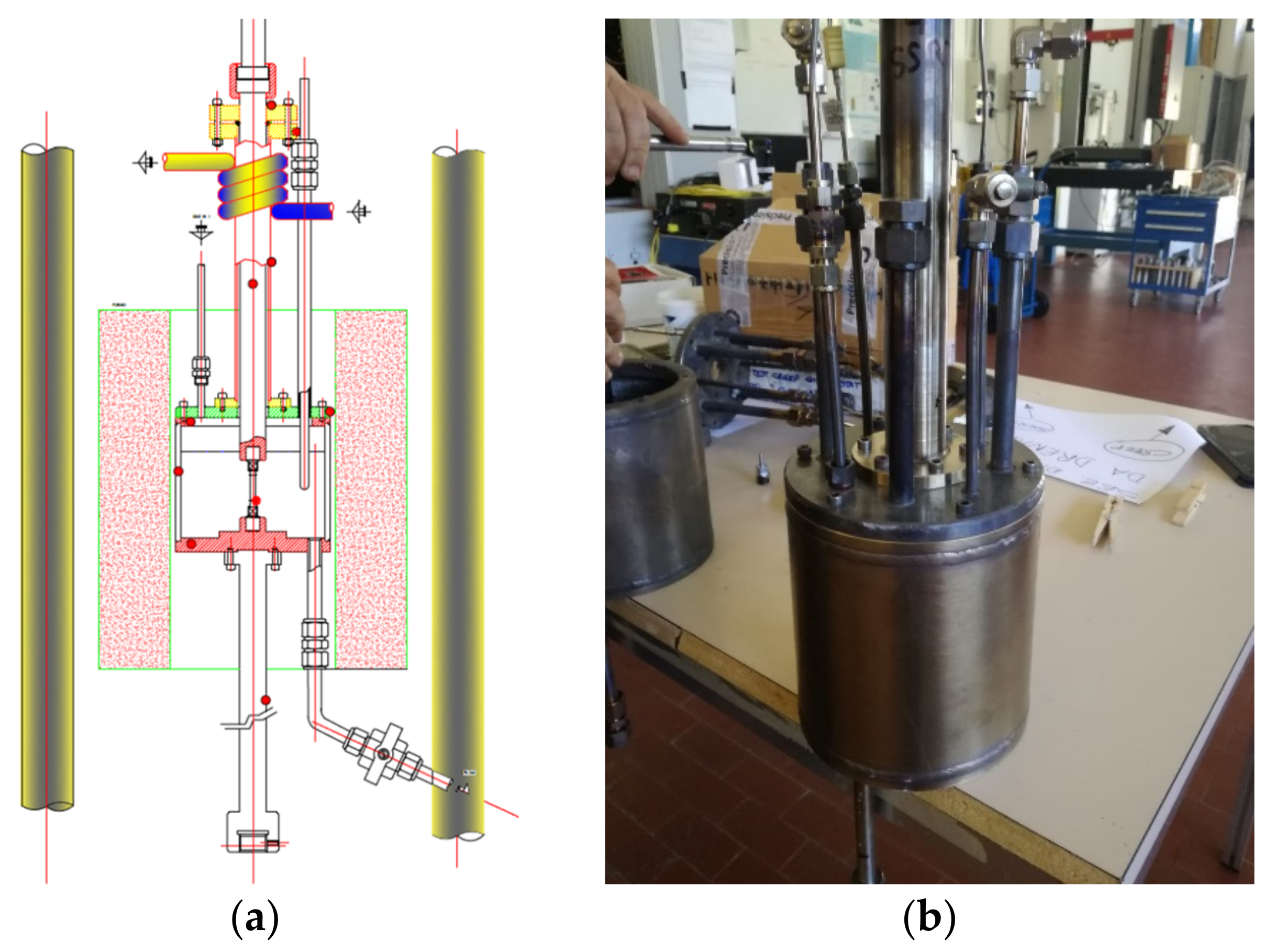

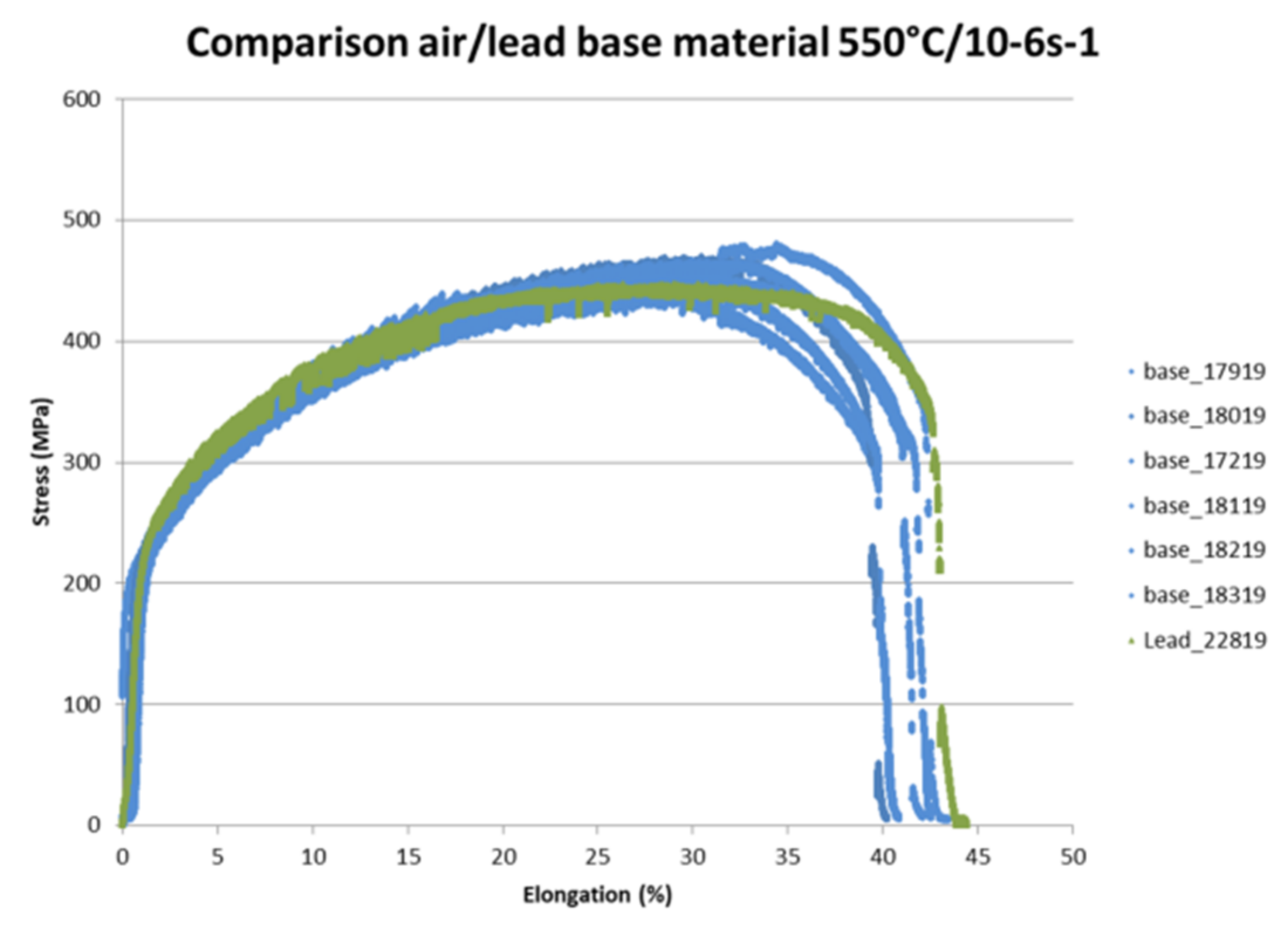

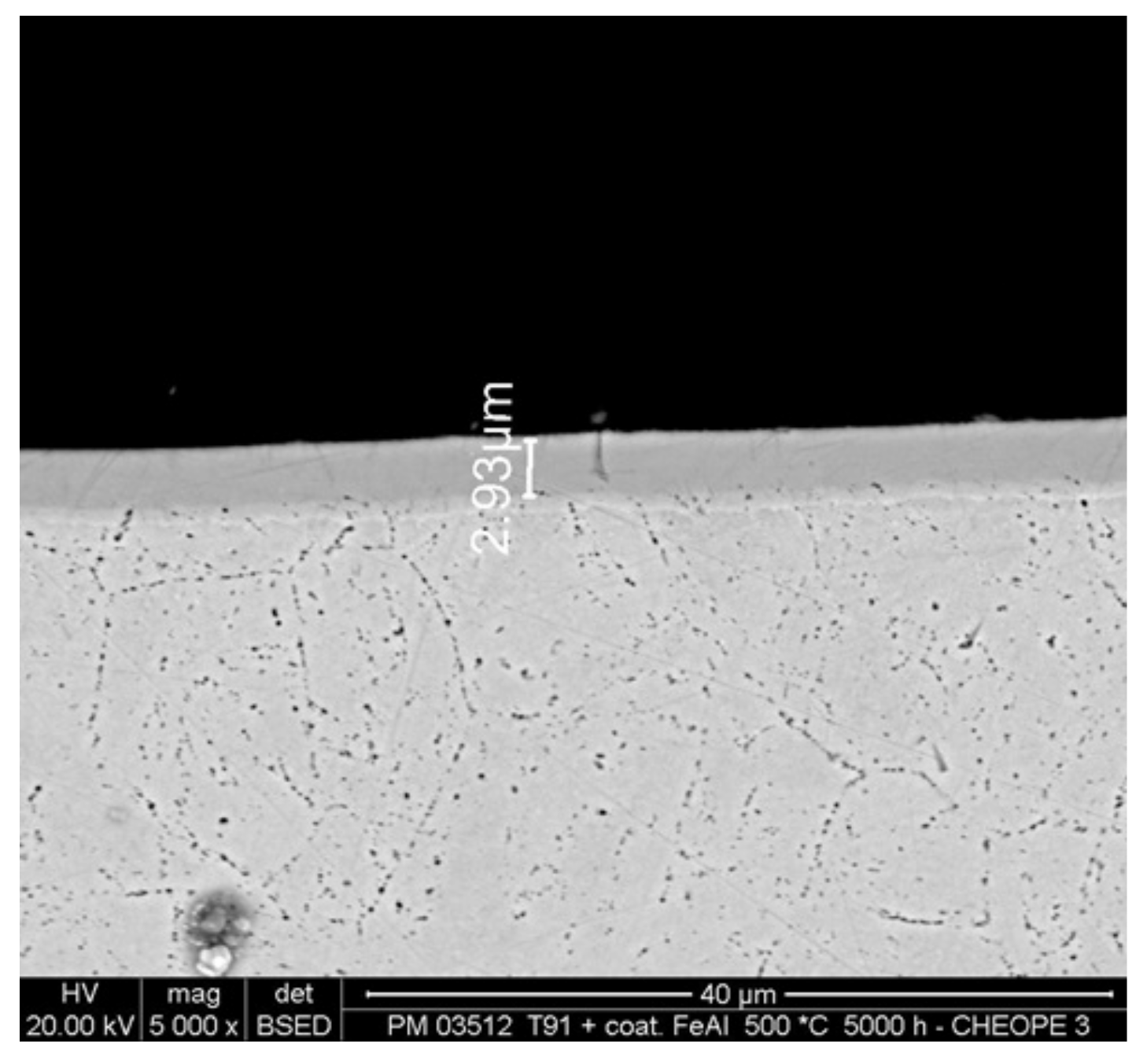

7.1. Structural Materials and Mechanical Tests in Lead

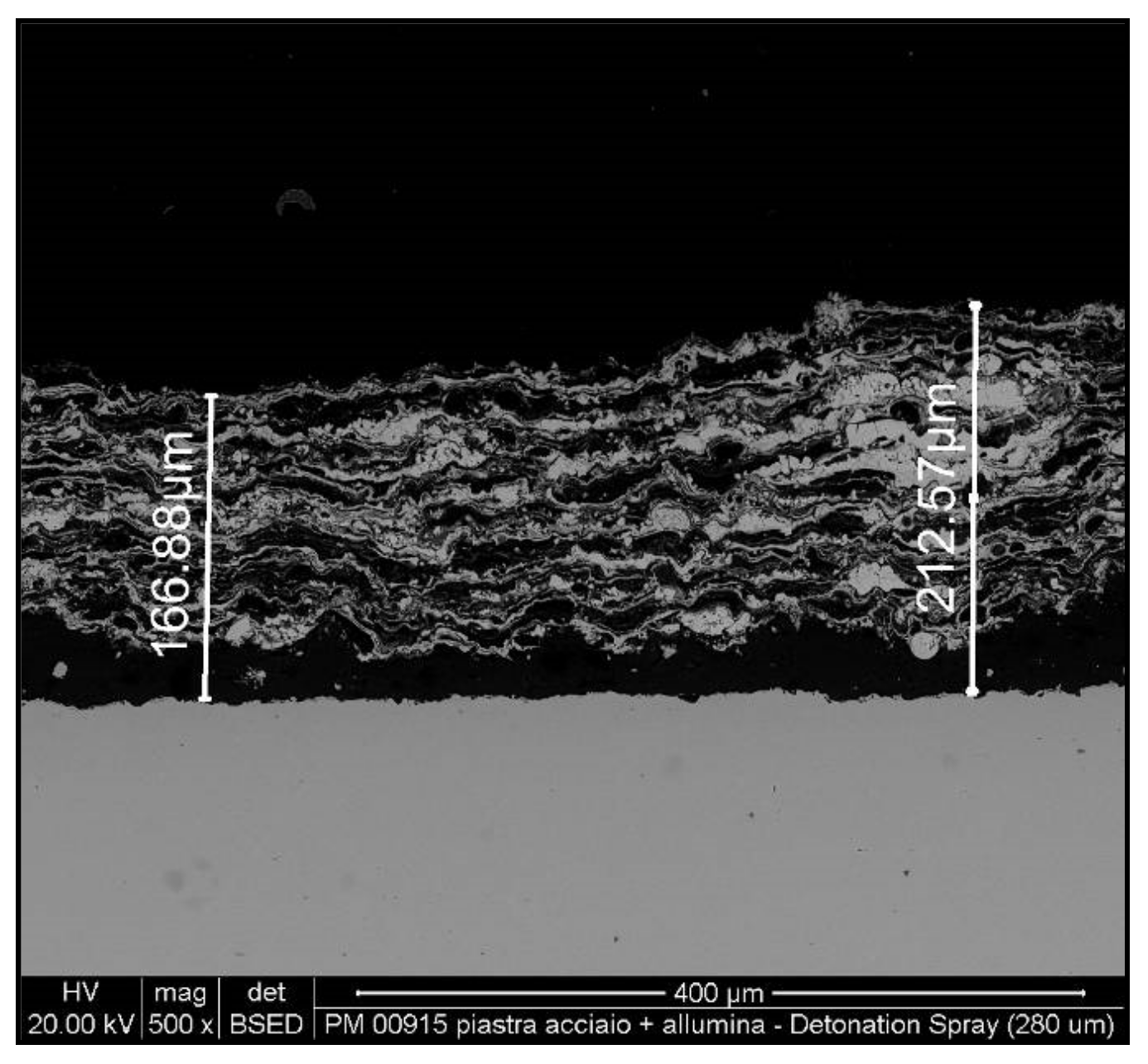

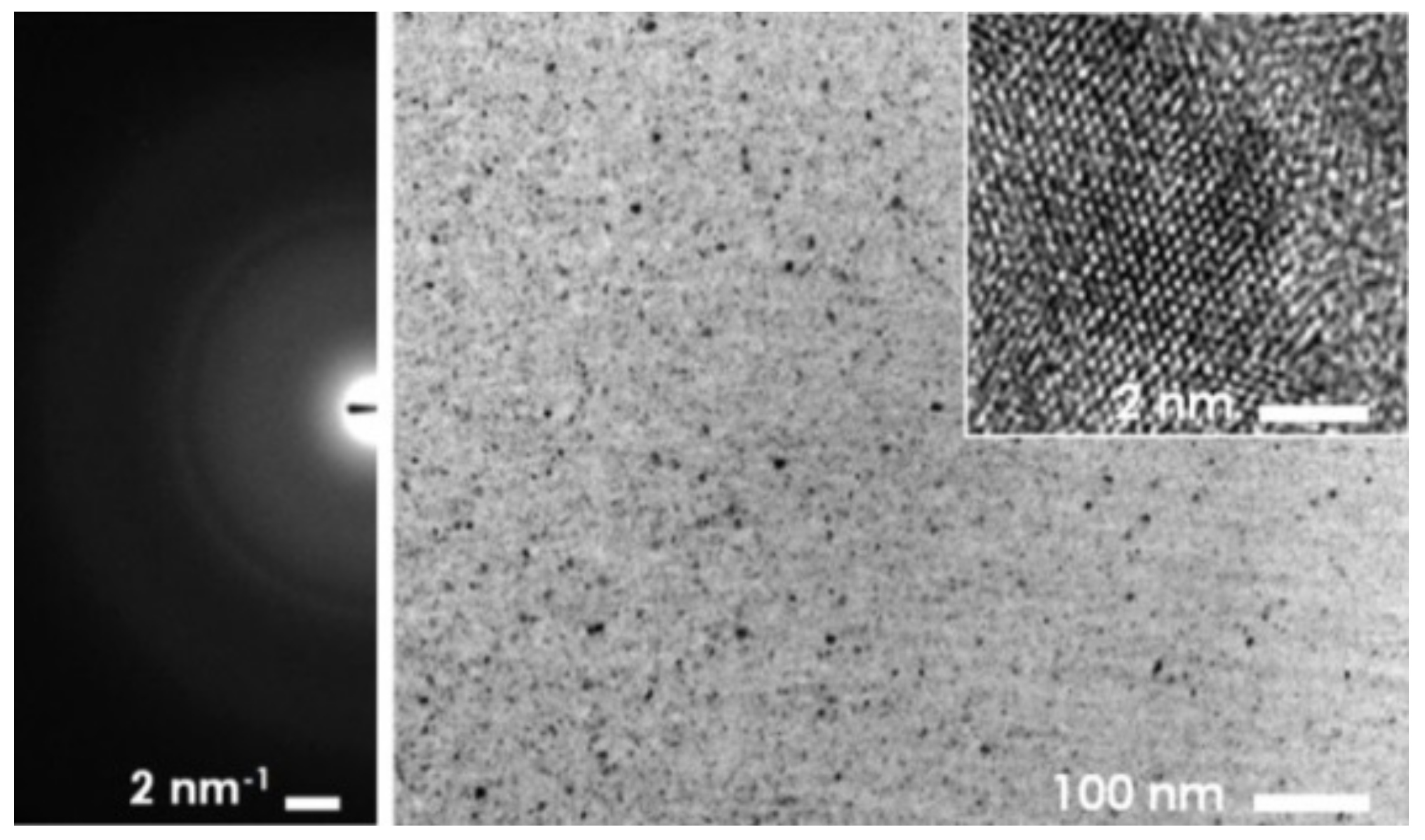

7.2. Advancements in Corrosion Studies and Coatings Technologies

7.3. Lead Coolant Chemistry Control for ALFRED Design: Overview on the R&D Activity

8. Conclusions

- ✓

- the development and characterization of oxygen control systems suitable for large pools and experiments on lead conditioning in large pool systems;

- ✓

- corrosion assessment in lead and experiments to address mechanical properties’ degradation in lead;

- ✓

- fuel assembly thermal-hydraulics characterization and, subsequently, tests on deformed bundles for safety assessment;

- ✓

- tests on flow-induced vibration (FIV) and flow blockage;

- ✓

- steam generator (SG), deep coolers (DCs), reactor circulation pump (RCP), isolation condenser, and other components’ performance and reliability assessments in large pools;

- ✓

- steady state and transient tests in large lead-cooled pools, aiming at investigating the thermal-hydraulics behavior of LFR primary systems; an experimental database will be made available for code verification and validation (V&V);

- ✓

- steam generator tube rupture (SGTR) experiments in relevant conditions for LFRs;

- ✓

- experiments on fuel–coolant interaction, fuel dispersion and relocation, fission products (FPs) retention and polonium retention are considered to have high priority because of the lack of data in these fields;

- ✓

- tests of the fuel handling system and manipulator, which are mandatory to complete and sustain the licensing process of the LFRs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ADS | Accelerator Driven Systems |

| ALD | Atomic Layer Deposition |

| ALFRED | Advanced Lead-cooled Fast Reactor European Demonstrator |

| APRIL | Alumina-coating for tritium Permeation Reduction for Innovative LFR |

| BFPS | Blockage Fuel Pin Simulator |

| CFD | computational fluid dynamics |

| CIRCE | CIRColazione Eutettico |

| DC | Deep Coolers |

| DHR | Decay Heat Removal |

| ESNII | European Sustainable Nuclear Industrial Initiative |

| FALCON | Fostering ALfred CONstruction |

| FIV | Flow-Induced Vibration |

| FP | Fission Product |

| FPS | Fuel Pin Simulator |

| HLM | Heavy Liquid Metal |

| HX | Heat eXchanger |

| LBE | Lead-Bismuth Eutectic |

| LFR | Lead-cooled Fast Reactor |

| LSM-GDC | Lantanum-Strontium-Manganite—Godolinia-Doped Ceria |

| LSCF-GDC | Lantanum-Strontium-Cobalt-Ferrite—Godolinia-Doped Ceria |

| LME | Liquid Metal Embrittlement |

| LVDT | Linear Variable Displacement Transformer |

| LWR | Light Water Reactors |

| MLPS | Magnetostrictive Linear Position Sensor |

| MYRRHA | Multi-purpose hYbrid Research Reactor for High-tech Applications |

| MYRTE | MYRRHA Research and Transmutation Endeavour |

| NACIE | NAtural CIrculation Experiment |

| PATRICIA | Partitioning and Transmuter Research Initiative in a Collaborative Innovation Action |

| PFD | Process Flow Diagram |

| PHX | Primary Heat eXchanger |

| PLD | Pulsed Laser Deposition |

| PLOFA | Protected Loss Of Flow Accident |

| PUMMA | Plutonium Management for More Agility |

| RCP | Reactor Circulation Pump |

| SESAME | Simulations and Experiments for the Safety Assessment of MEtal cooled reactors |

| SFR | Sodium cooled Fast Reactor |

| SG | Steam Generator |

| SGBT | Steam Generator Bayonet Tube |

| SGTR | Steam Generator Tube Rupture |

| SMR | Small Modular Reactor |

| SSRT | Slow Strain-Rate Tensile |

| STH | System Thermal-Hydraulic |

| TRANSAT | TRANSversal Actions for Tritium |

| TS | Test Section |

| YPSZ | Yttria Partially Stabilized Zirconia |

| V&V | Verification and Validation |

References

- Lorusso, P.; Bassini, S.; Del Nevo, A.; Di Piazza, I.; Giannetti, F.; Tarantino, M.; Utili, M. GEN-IV LFR development: Status & perspectives. Prog. Nucl. Energy 2018, 105, 318–331. [Google Scholar] [CrossRef]

- Tarantino, M.; Agostini, P.; Benamati, G.; Coccoluto, G.; Gaggini, P.; Labanti, V.; Venturi, G.; Class, A.; Liftin, K.; Forgione, N.; et al. Integral Circulation Experiment: Thermal-hydraulic simulator of a heavy liquid metal reactor. J. Nucl. Mater. 2011, 415, 433–448. [Google Scholar] [CrossRef]

- SESAME Project, EURATOM H2020, Grant Agreement N. 654935. 2015. Available online: https://cordis.europa.eu/project/id/654935/it (accessed on 31 March 2019).

- MYRTE Project, EURATOM H2020, Grant Agreement N. 662186. 2015. Available online: https://cordis.europa.eu/project/id/662186/it (accessed on 30 September 2019).

- Martelli, D.; Forgione, N.; Di Piazza, I.; Tarantino, M. HLM fuel pin bundle experiments in the CIRCE pool facility. Nucl. Eng. Des. 2015, 292, 76–86. [Google Scholar] [CrossRef]

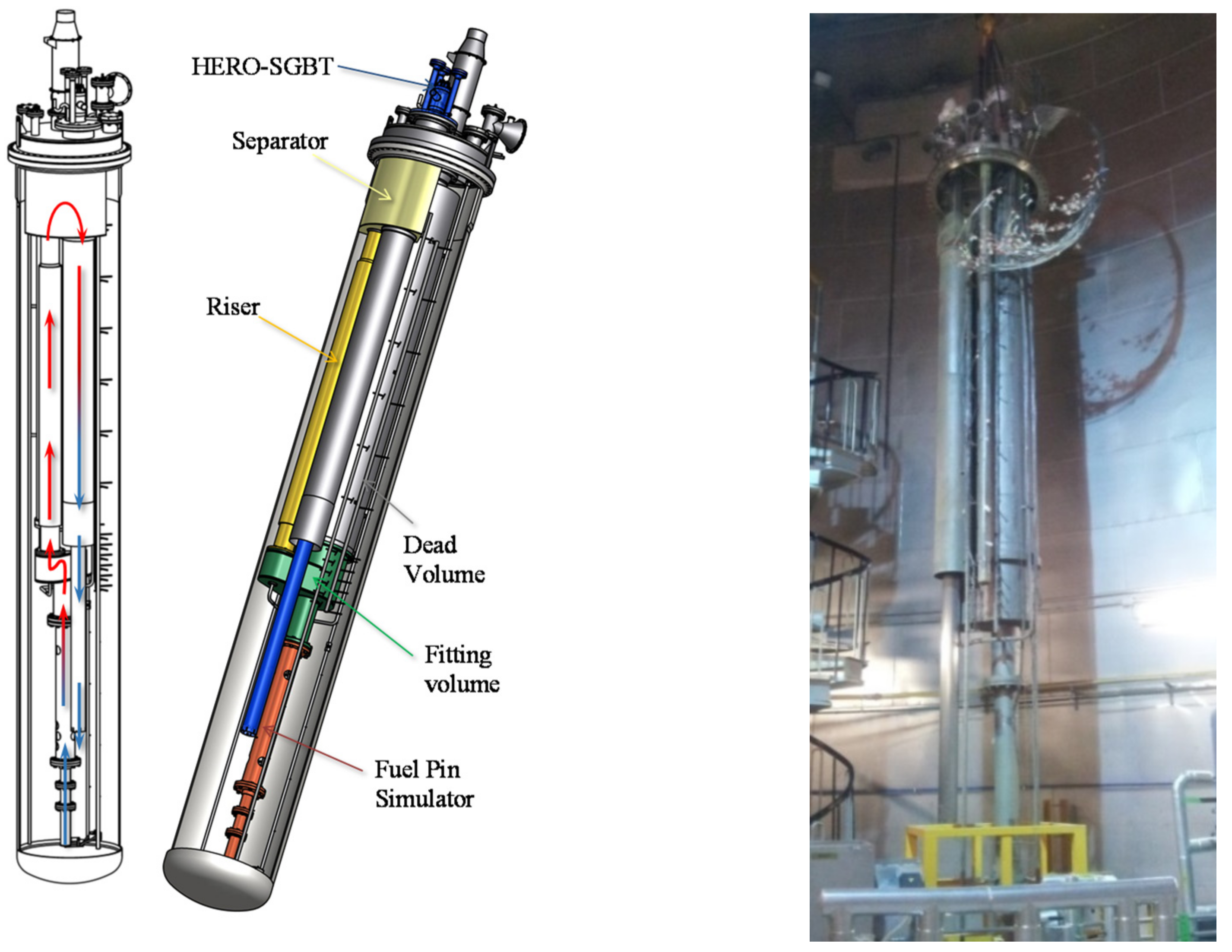

- Lorusso, P.; Pesetti, A.; Tarantino, M. ALFRED steam generator assessment: Design and pre-test analysis of HERO experiment. In Proceedings of the 2018 26th International Conference on Nuclear Engineering. Volume 6B: Thermal-Hydraulics and Safety Analyses (ICONE 2018), London, UK, 22–26 July 2018. [Google Scholar]

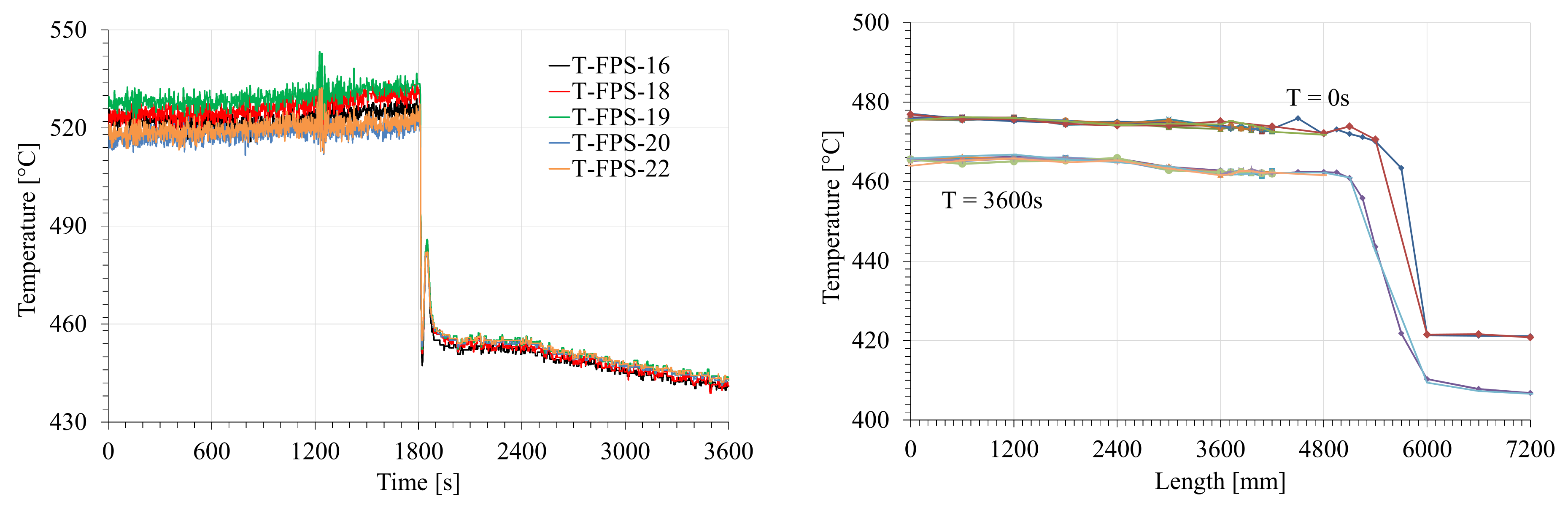

- Lorusso, P.; Pesetti, A.; Tarantino, M.; Narcisi, V.; Giannetti, F.; Forgione, N.; Del Nevo, A. Experimental Analysis of Stationary And Transient Scenarios of ALFRED Steam Generator Bayonet Tube In CIRCE-HERO Facility. Nucl. Eng. Des. 2019, 352, 110169. [Google Scholar] [CrossRef]

- Lorusso, P.; Pesetti, A.; Tarantino, M.; Narcisi, V. Protected Loss of Flow Accident Simulation In Circe-Hero Facility: Experimental Test And System Code Assessment. In Proceedings of the 2019 27th International Conference on Nuclear Engineering, Tsukuba, Japan, 19–24 May 2019. ICONE27-2269. [Google Scholar]

- Lorusso, P.; Pesetti, A.; Barone, G.; Castelliti, D.; Caruso, G.; Forgione, N.; Giannetti, F.; Martelli, D.; Rozzia, D.; Van Tichelen, K.; et al. MYRRHA primary heat exchanger experimental simulations on CIRCE-HERO. Nucl. Eng. Des. 2019, 353, 110270. [Google Scholar] [CrossRef]

- Castelliti, D.; Hamidouche, T.; Lorusso, P.; Tarantino, M. H2020 MYRTE CIRCE-HERO experimental campaign post-test activity and code validation. In Proceedings of the 18th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-18), Portland, OR, USA, 18–23 August 2019. [Google Scholar]

- Narcisi, V.; Giannetti, F.; Del Nevo, A.; Tarantino, M.; Caruso, G. Post-test simulation of a PLOFA transient test in the CIRCE-HERO facility. Nucl. Eng. Des. 2019, 355, 110321. [Google Scholar] [CrossRef]

- Galleni, F.; Barone, G.; Martelli, D.; Pucciarelli, A.; Lorusso, P.; Tarantino, M.; Forgione, N. Simulation of operational conditions of HX-HERO in the CIRCE facility with CFD/STH coupled codes. Nucl. Eng. Des. 2020, 361, 110552. [Google Scholar] [CrossRef]

- Lorusso, P.; Del Nevo, A.; Narcisi, V.; Giannetti, F.; Caruso, G.; Zwijsen, K.; Breijder, P.A.; Hamidouche, T.; Castelliti, D.; Rozzia, D.; et al. Total Loss of Flow Benchmark in CIRCE-HERO integral test facility. Nucl. Eng. Des. 2021, 376, 111086. [Google Scholar] [CrossRef]

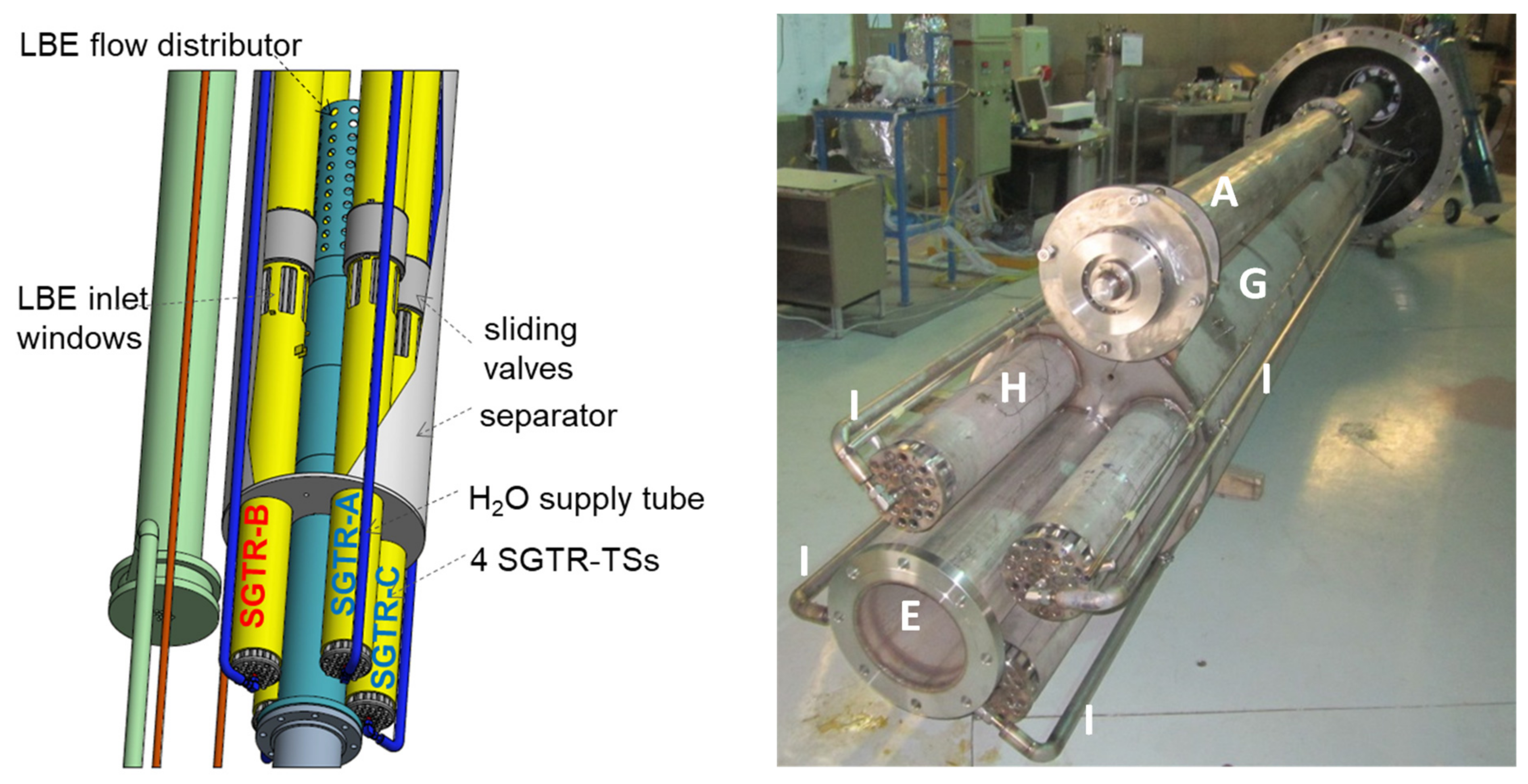

- MAXSIMA Project, FP7-EURATOM-FISSION, Grant Agreement N. 323312. 2012. Available online: https://cordis.europa.eu/project/id/323312/it (accessed on 21 October 2018).

- Castelliti, D. MYRRHA Primary Heat Exchanger Technical Description; Report SCK-CEN-I-400; European Nuclear Society: Brussels, Belgium, 20 September 2013. [Google Scholar]

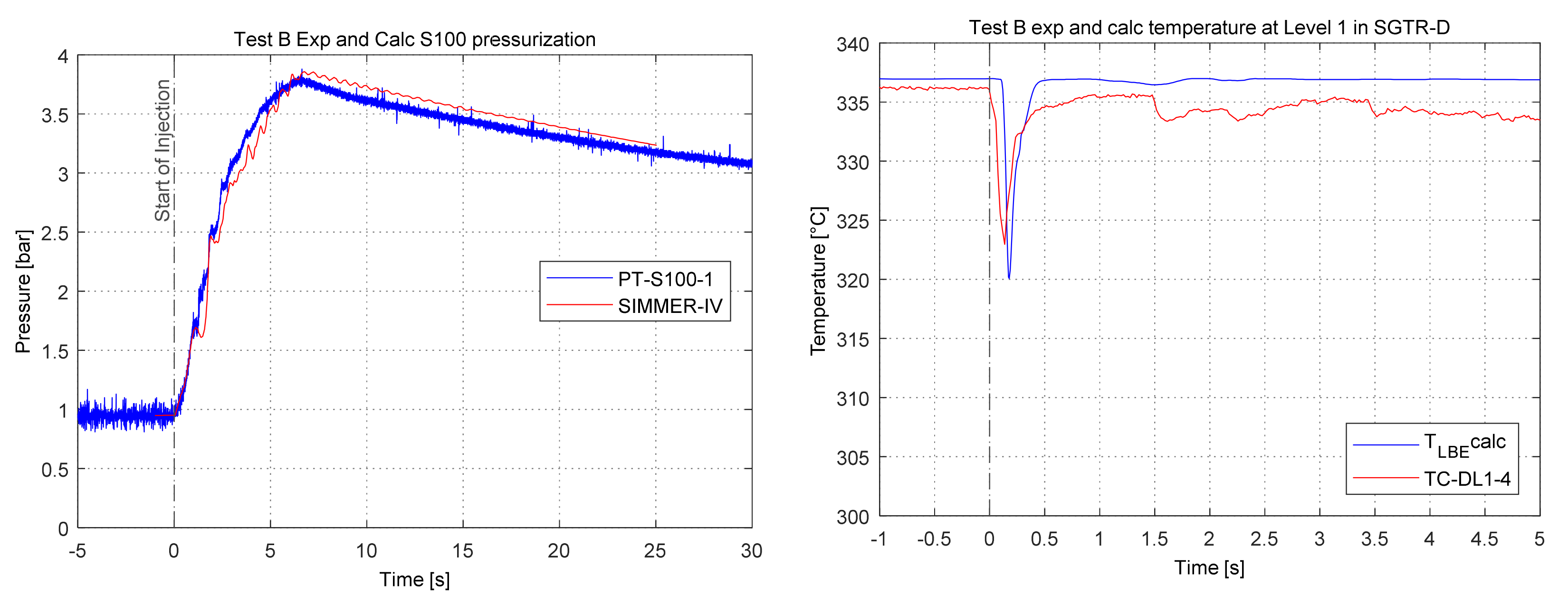

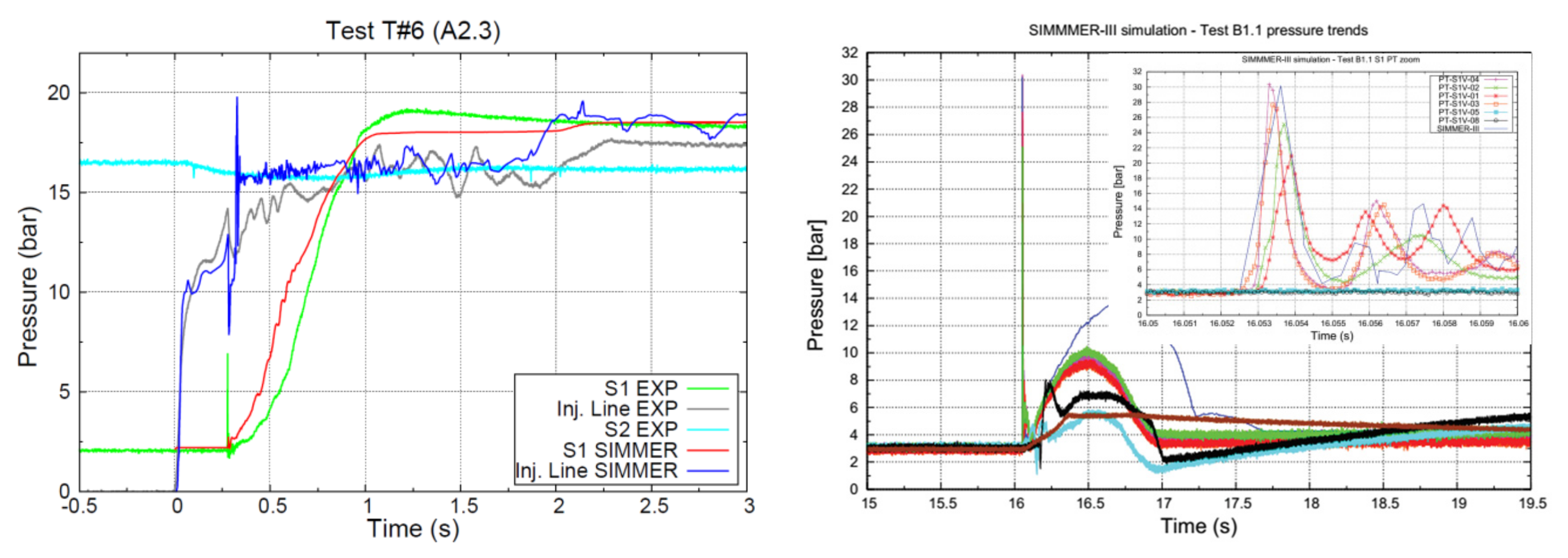

- Pesetti, A.; Tarantino, M.; Polazzi, G.; Sermenghi, V. Final Report on the SGTR Event in HLM pool and Post Test Analysis, MAXSIMA Deliverable D4.3; SCK CEN: Brussels, Belgium, 2017. [Google Scholar]

- Pesetti, A.; Tarantino, M.; Gaggini, P.; Polazzi, G.; Forgione, N. Commissioning of CIRCE facility for SGTR experimental investigation for HLMRS and pre-test analysis by SIMMER IV code. In Proceedings of the 25th International Conference on Nuclear Engineering (ICONE25-67419), Shanghai, China, 14–18 May 2017. [Google Scholar]

- Pesetti, A.; Tarantino, M.; Forgione, N. Experimental and numerical analysis of Steam Generator Tube Rupture event for MYRRHA reactor in CIRCE facility with SIMMER-IV code. In Proceedings of the 26th International Conference on Nuclear Engineering (ICONE26-82503), London, UK, 22–26 July 2018. [Google Scholar]

- Kondo, S.; Brear, D.J.; Tobita, Y.; Morita, K.; Maschek, W.; Coste, P.; Wilhelm, D. Status and achievement of assessment programme for SIMMER III a multiphase multicomponent code for LMFBR safety analysis. In Proceedings of the 8th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-8), Kyoto, Japan, 30 September–4 October 1997. [Google Scholar]

- THINS Project, 7th FP of Euratom for Nuclear Research and Training Activities (2007–2011), Grant Agreement No.: 249337. Available online: https://cordis.europa.eu/project/id/249337/reporting (accessed on 30 September 2019).

- LEADER Project, 7th FP of Euratom on Advanced Nuclear Systems for Increased Sustainability/Fission 2009 2.2.1: Conceptual Design of Lead and Gas Cooled Fast Reactor Systems, Grant Agreement No.: FP7-249668. Available online: https://cordis.europa.eu/project/id/249668 (accessed on 30 September 2019).

- Del Nevo, A.; Giannini, N.; Pesetti, A.; Forgione, N. Final Report on the Experimental Investigation of the HLM/Water Interaction in A HLM Pool Facility, THINS Deliverable D4.1.04; ENEA: Rome, Italy, 2015. [Google Scholar]

- Pesetti, A.; Del Nevo, A.; Forgione, N. Assessment of SIMMER-III code based on Steam Generator Tube Rupture experiments in LIFUS5/Mod2 facility. In Proceedings of the 24th International Conference on Nuclear Engineering (ICONE24-60711), Charlotte, NC, USA, 26–30 June 2016. [Google Scholar]

- Pesetti, A.; Del Nevo, A.; Forgione, N. Experimental investigation and SIMMER-III code modelling of LBE–water interaction in LIFUS5/Mod2 facility. Nucl. Eng. Des. 2015, 290, 119–126. [Google Scholar] [CrossRef]

- Del Nevo, A.; Ciampichetti, A.; Forgione, N. Investigating HLM-Water Interaction Experiments in LIFUS5/Mod2 Facility. In Proceedings of the 15th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-15), Pisa, Italy, 12–17 May 2013. [Google Scholar]

- Del Nevo, A.; Ciampichetti, A.; Forgione, N.; Mannori, S. LIFUS5/Mod2: The Experimental Facility for HLM/Water Interaction Investigation. In Proceedings of the 20th International Conference on Nuclear Engineering, (ICONE20-POWER2012-54733), Anaheim, CA, USA, 30 July–3 August 2012. [Google Scholar]

- Pesetti, A.; Forgione, N.; Del Nevo, A. Water/Pb-Bi Interaction Experiments in LIFUS5/Mod2 Facility Modelled by SIMMER code. In Proceedings of the 22th International Conference on Nuclear Engineering, (ICONE22), Prague, Czech Republic, 7–11 July 2014. [Google Scholar]

- Del Nevo, A.; Giannini, N.; Pesetti, A.; Forgione, N. Experimental and numerical investigations of interaction between heavy liquid metal and water for supporting the safety of LFR GEN. IV reactor design. In Proceedings of the 16th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-16), Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- Pesetti, A.; Del Nevo, A.; Forgione, N. Experimental investigation of Spiral Tubes Steam Generator Rupture Scenarios in LIFUS5/Mod2 facility for ELFR. In Proceedings of the 24th International Conference on Nuclear Engineering (ICONE24-60715), Charlotte, NC, USA, 26–30 June 2016. [Google Scholar]

- Pesetti, A.; Del Nevo, A.; Forgione, N. Experimental investigation in LIFUS5/MOD2 facility of Spiral-Tube Steam Generator Rupture scenarios for ELFR. In Proceedings of the 25th International Conference on Nuclear Engineering (ICONE25-67420), Shanghai, China, 14–18 May 2017. [Google Scholar]

- Eboli, M.; Del Nevo, A.; Pesetti, A.; Forgione, N. Experimental campaign in support of the safety studies of the SGTR in LFR. In Proceedings of the 18th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-18), Portland, OR, USA, 18–23 August 2019. [Google Scholar]

- Eboli, M.; Del Nevo, A.; Forgione, N.; Giannetti, F.; Mazzi, D.; Ramacciotti, M. Experimental Characterization of Leak Detection Systems in HLM Pool using LIFUS5/Mod3 Facility. Nucl. Technol. 2020, 206, 1409–1420. [Google Scholar] [CrossRef]

- Artioli, C. A-BAQUS, a multi-entry graph assisting the neutronic design of an ADS. Case study: EFIT. In Proceedings of the Fifth International Workshop on the Utilisation and Reliability of High Power Proton Accelerator HPPA5, Mol, Belgium, 6–9 May 2007. [Google Scholar]

- Artioli, C.; Grasso, G.; Petrovich, C. A new paradigm for core design aimed at the sustainability of nuclear energy: The solution of the extended equilibrium state. Ann. Nucl. Energy 2010, 37, 915–922. [Google Scholar] [CrossRef]

- Lodi, F.; Grasso, G. Extension of the sub-channel code ANTEO+ to the mixed convection regime. Nucl. Eng. Des. 2017, 322, 368–378. [Google Scholar] [CrossRef]

- Castelluccio, D. Assessment of the Impact of Nuclear Data Uncertainties on the Core Design of ALFRED. Ph.D. Thesis, Tor Vergata University of Rome, Rome, Italy, 2021. [Google Scholar]

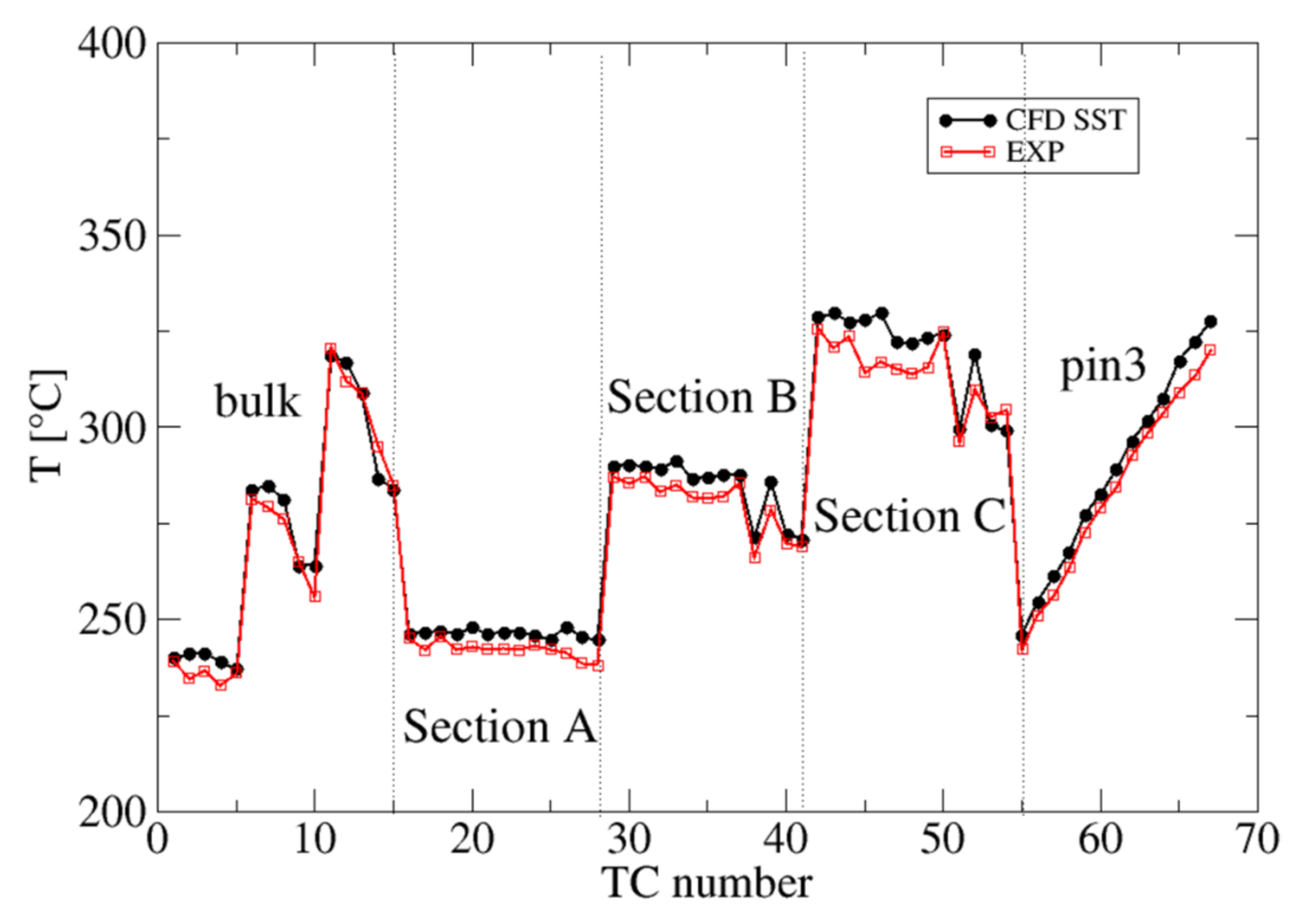

- Di Piazza, I.; Angelucci, M.; Marinari, R.; Tarantino, M.; Forgione, N. Heat Transfer On HLM Cooled Wire-Spaced Fuel Pin Bundle Simulator In The Nacie-Up Facility. Nucl. Eng. Des. 2016, 300, 256–267. [Google Scholar] [CrossRef]

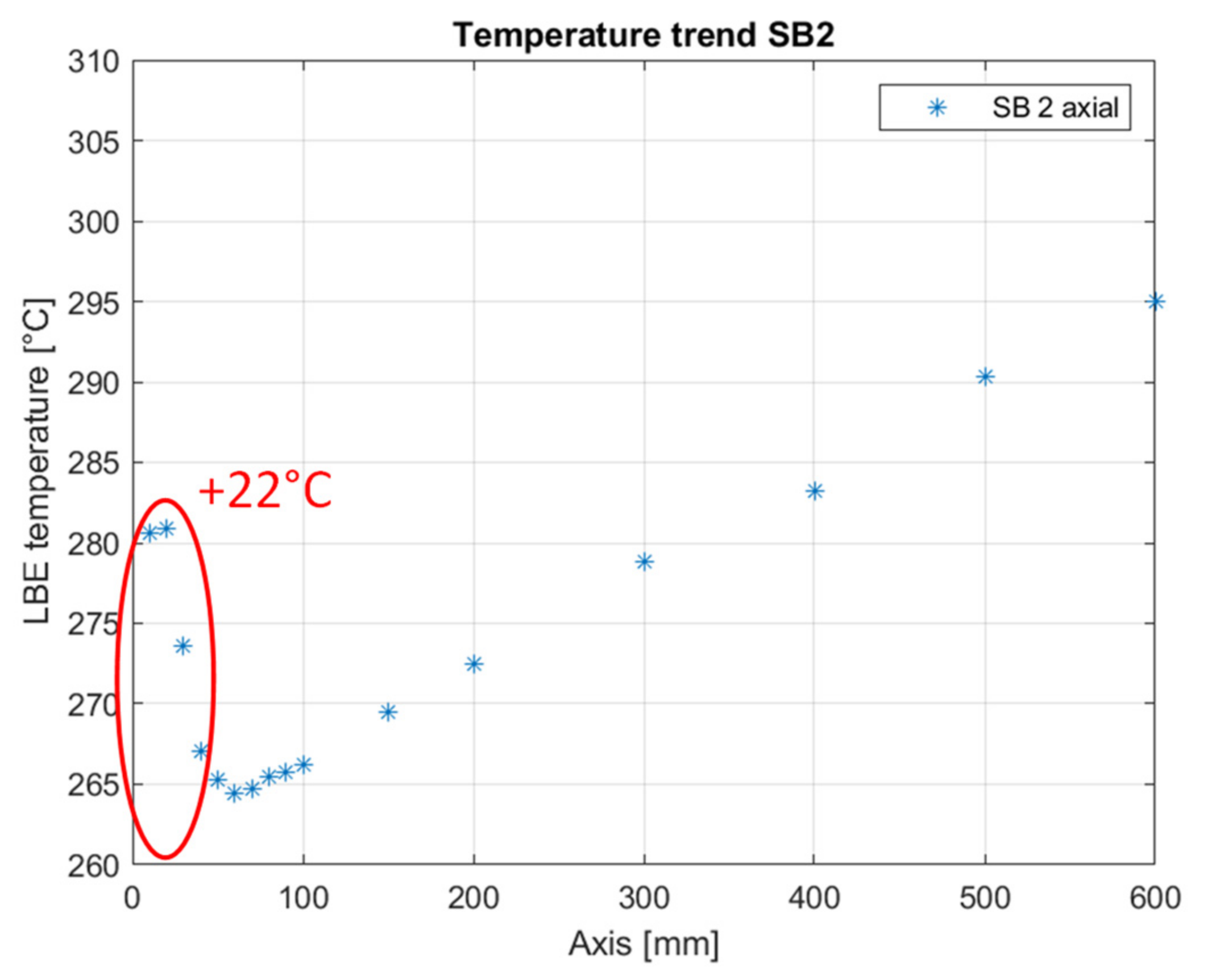

- Marinari, R.; Di Piazza, I.; Forgione, N.; Magugliani, F. Pre-test CFD simulations of the NACIE-UP BFPS test section, A. Nucl. Energy 2017, 110, 1060–1072. [Google Scholar] [CrossRef]

- Angelucci, M.; Di Piazza, I.; Martelli, D. Experimental campaign on the HLM loop NACIE-UP with instrumented wire-spaced fuel pin simulator. Nucl. Eng. Des. 2018, 332, 137–146. [Google Scholar] [CrossRef]

- Di Piazza, I.; Angelucci, M.; Marinari, R.; Taranitno, M.; Martelli, D. Thermo-fluid dynamic transients in the NACIE-UP facility. Nucl. Eng. Des. 2019, 352, 110182. [Google Scholar] [CrossRef]

- Marinari, R.; Di Piazza, I.; Tarantino, M.; Angelucci, M.; Martelli, D. Experimental tests and post-test analysis of non-uniformly heated 19-pins fuel bundle cooled by Heavy Liquid Metal. Nucl. Eng. Des. 2019, 343, 166–177. [Google Scholar] [CrossRef]

- Martelli, D.; Marinari, R.; Barone, G.; Di Piazza, I.; Tarantino, M. CFD thermo-hydraulic analysis of the CIRCE fuel bundle, A. Nuc. Energy 2017, 103, 294–305. [Google Scholar] [CrossRef]

- Di Piazza, I.; Magugliani, F.; Tarantino, M.; Alemberti, A. A CFD analysis of flow blockage phenomena in ALFRED LFR demo fuel assembly. Nucl. Eng. Des. 2014, 276, 202–215. [Google Scholar] [CrossRef]

- Marinari, R.; Di Piazza, I.; Tarantino, M.; Forgione, N. Blockage fuel pin simulator experiments and simulation. Nucl. Eng. Des. 2019, 353, 110215. [Google Scholar] [CrossRef]

- Marinari, R.; Martelli, D.; Di Piazza, I.; Tarantino, M. ICONE27-2031, CFD analysis of flow blockage in the ALFRED FA. In Proceedings of the 2019 27th International Conference on Nuclear Engineering (ICONE 27), Tsukuba, Japan, 19–24 May 2019. [Google Scholar]

- D’Auria, F.; Salah, A.B.; Petruzzi, A.; Del Nevo, A. State of the Art in Using Best Estimate Calculation Tools in Nuclear Technology. Nucl. Eng. Tech. 2006, 38, 11–32. [Google Scholar]

- Umminger, K.; Del Nevo, A. Integral Test Facilities and Thermal-Hydraulic System Codes in Nuclear Safety Analysis. Sci. Technol. Nucl. Install. 2012, 2012, 826732. [Google Scholar] [CrossRef]

- Aksan, S.N.; D’Auria, F.; Städtke, H. User effects on the thermal-hydraulic transient system code calculations. Nucl. Eng. Des. 1993, 145, 159–174. [Google Scholar] [CrossRef]

- Glaeser, H. 13-Verification and validation of system thermal-hydraulic computer codes, scaling and uncertainty evaluation of calculated code results, in F. D’Auria. In Thermal-Hydraulics of Water Cooled Nuclear Reactors; Woodhead Publishing: Cambridge, UK, 2017; pp. 831–903. [Google Scholar] [CrossRef]

- The RELAP5 Development Team. Code Structure, System Models and Solution Methods. In RELAP5/MOD3 Code Manual; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 1995. [Google Scholar]

- RELAP5-3D© Code Manual Volume IV: Models and Correlations, INL/MIS-15-36723, Revision 4.3; INL, The RELAP5-3D© Code Development Team, Idaho, October 2015. Available online: https://publications.sckcen.be/portal/en/publications/myrrha-primary-heat-exchanger-design(f11d3f96-338d-4fd5-8433-82f1a500d14b).html (accessed on 30 September 2019).

- Balestra, P.; Giannetti, F.; Caruso, G.; Alfonsi, A. New RELAP5-3D lead and LBE thermophysical properties implementation for safety analysis of Gen IV reactors. Sci. Technol. Nucl. Install. 2016, 2016, 1687946. [Google Scholar] [CrossRef]

- Oriolo, F. Modifiche del Codice RELAP5 Versione MOD3.2 per la Simulazione di Sistemi Refrigerati con Leghe di Pb o Pb-Bi; RL 031/00; Università di Pisa: Pisa, Italy, 20 November 2000. [Google Scholar]

- Martelli, E.; Giannetti, F.; Caruso, G.; Tarallo, A.; Polidori, M.; Barucca, L.; Del Nevo, A. Study of EU DEMO WCLL breeding blanket and primary heat transfer system integration. Fusion Eng. Des. 2018, 136, 828–833. [Google Scholar] [CrossRef]

- Barone, G.; Martelli, D.; Forgione, N. Implementation of Lead-Lithium as working fluid in RELAP5/Mod3.3. In Proceedings of the 30th Symposium on Fusion Technology, Giardini Naxos, Italy, 16–21 September 2018. [Google Scholar] [CrossRef]

- Coccoluto, G.; Gaggini, P.; Labanti, V.; Tarantino, M.; Ambrosini, W.; Forgione, N.; Napoli, A.; Oriolo, F. Heavy liquid metal natural circulation in a one-dimensional loop. Nucl. Eng. Des. 2011, 241, 1301–1309. [Google Scholar] [CrossRef]

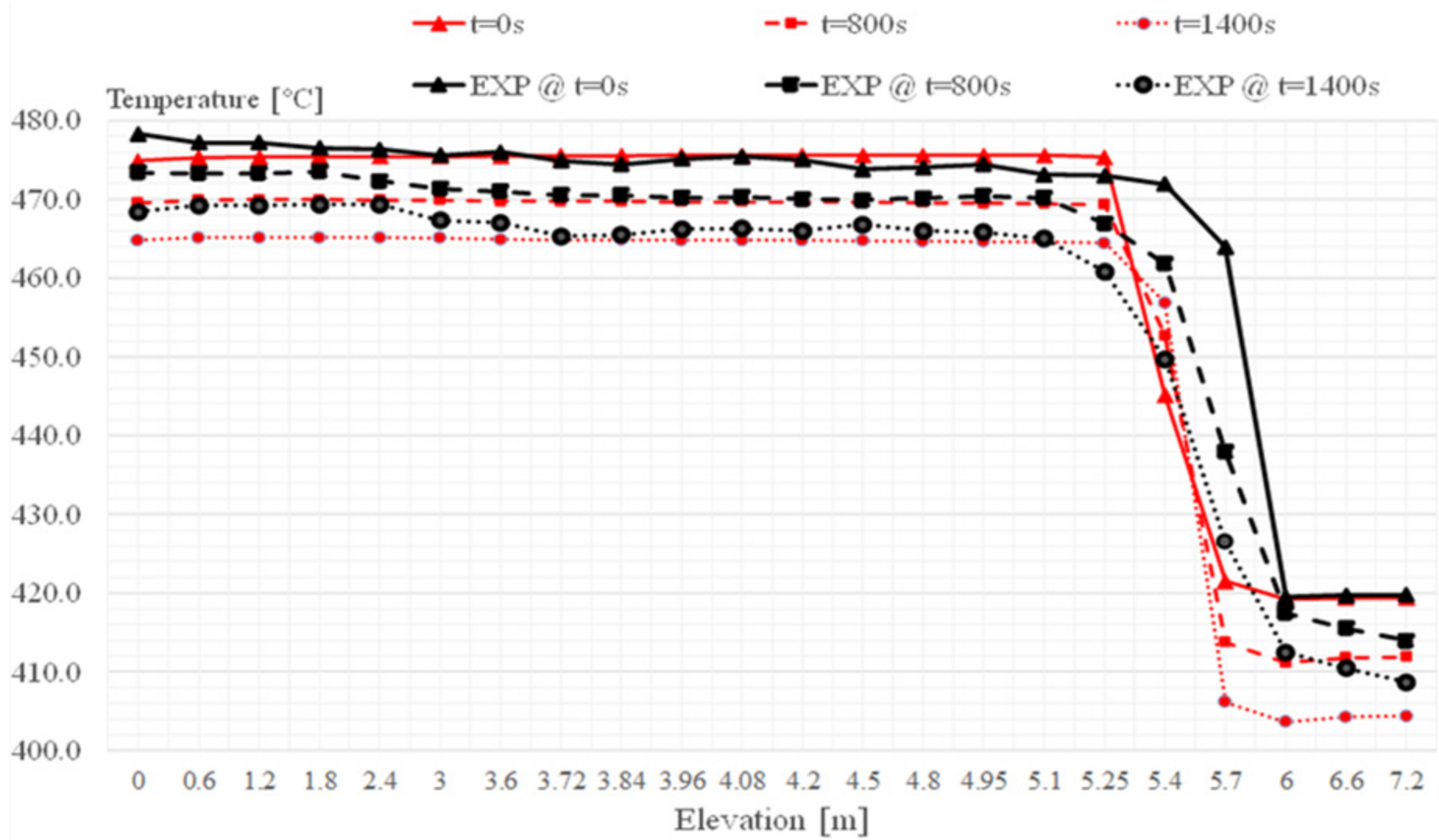

- Narcisi, V.; Giannetti, F.; Tarantino, M.; Martelli, D.; Caruso, G. Pool temperature stratification analysis in CIRCE-ICE facility with RELAP5-3D © model and comparison with experimental tests. J. Phys. Conf. Ser. 2017, 923, 012006. [Google Scholar] [CrossRef]

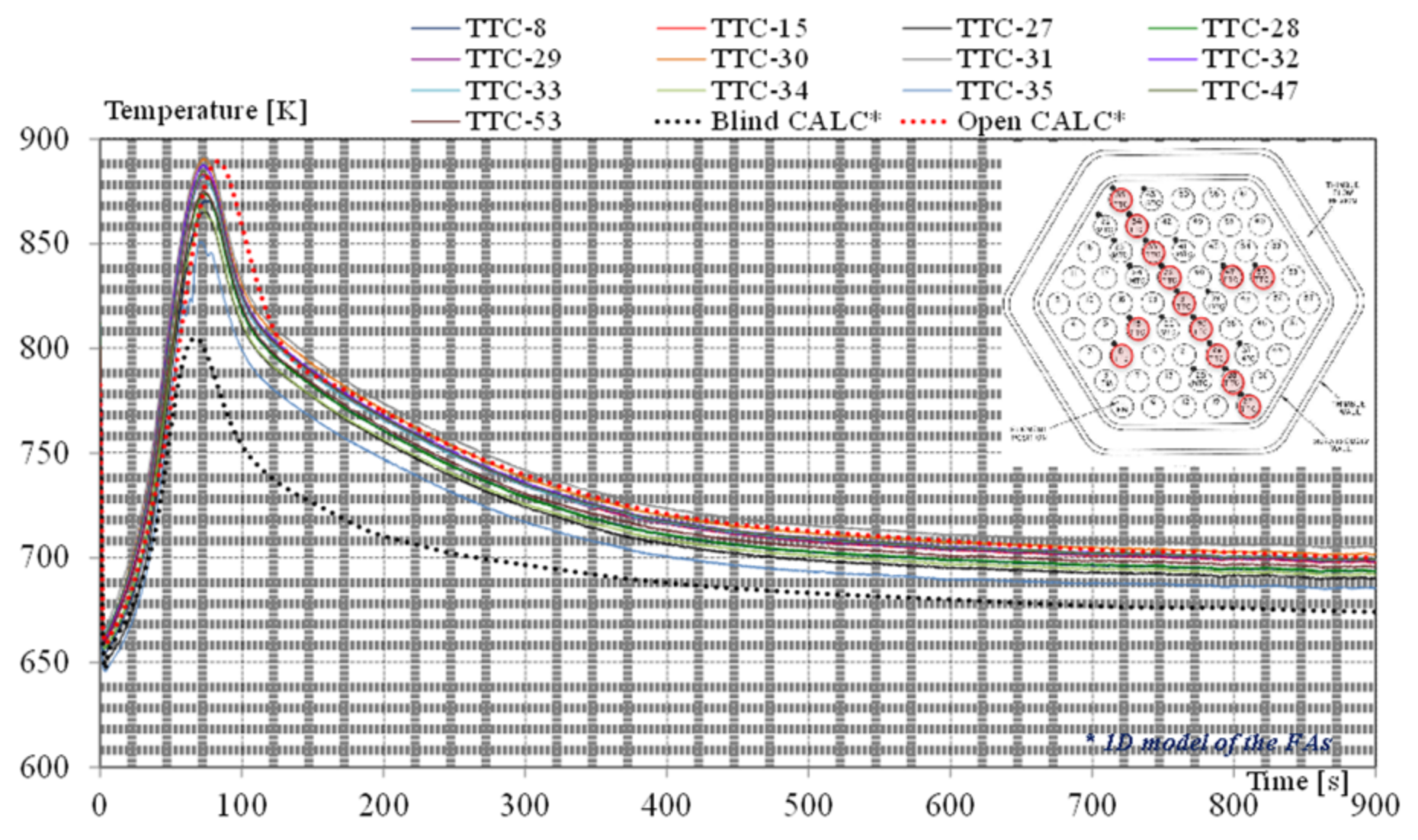

- Forgione, N.; Martelli, D.; Barone, G.; Giannetti, F.; Lorusso, P.; Hollands, T.; Papukchiev, A.; Polidori, M.; Cervone, A.; Di Piazza, I. Post-test simulations for the NACIE-UP benchmark by STH codes. Nucl. Eng. Des. 2019, 353, 1102789. [Google Scholar] [CrossRef]

- Narcisi, V.; Lorusso, P.; Giannetti, F.; Alfonsi, A.; Caruso, G. Uncertainty quantification method for RELAP5-3D© using RAVEN and application on NACIE experiments. Ann. Nucl. Energy 2019, 127, 419–432. [Google Scholar] [CrossRef]

- Forgione, N.; Angelucci, M.; Barone, G.; Polidori, M.; Cervone, A.; Di Piazza, I.; Giannetti, F.; Lorusso, P.; Hollands, T.; Papukchiev, A. Blind Simulations of NACIE-UP Experimental Tests by STH Codes. In Proceedings of the 26th International Conference on Nuclear Engineering(ICONE26), London, UK, 22–26 July 2018. [Google Scholar] [CrossRef]

- Tarantino, M.; Del Nevo, A.; Forgione, N.; Bandini, G. Post Test Analysis of ICE Tests. In Proceedings of the 20th International Conference on Nuclear Engineering (ICONE20), Anaheim, CA, USA, 30 July–3 August 2012; Volume 2, pp. 703–712. [Google Scholar]

- Gonfiotti, B.; Barone, G.; Angelucci, M.; Martelli, D.; Forgione, N.; Del Nevo, A.; Tarantino, M. Thermal Hydraulic Analysis of the CIRCE-HERO Pool-Type Facility. In Proceedings of the 26th International Conference on Nuclear Engineering (ICONE26), London, UK, 22–26 July 2018. [Google Scholar] [CrossRef]

- Del Nevo, A.; Martelli, E. Validation of a Three-Dimensional Model of EBR-II and Assessment of RELAP5-3D Based on SHRT-17 Test. Nucl. Technol. 2016, 193, 1–14. [Google Scholar] [CrossRef]

- Giannetti, F.; Narcisi, V.; Subioli, A.; Del Nevo, A. PHÉNIX Transient Analysis for the Assessment of RELAP5-3D based on Dissymmetric Test Benchmark. In Proceedings of the 26th International Conference on Nuclear Engineering (ICONE26), London, UK, 22–26 July 2018. [Google Scholar] [CrossRef]

- Rozzia, D.; Del Nevo, A.; Tarantino, N.; Forgione, N. Preliminary Discussion on LFR Fuel Pin Design: Current Status, Fuel Modeling and Open Issues. In Proceedings of the 20th International Conference on Nuclear Engineering (ICONE20), Anaheim, CA, USA, 30 July–3 August 2012; Volume 1, pp. 467–473. [Google Scholar] [CrossRef]

- Lassmann, K. TRANSURANUS: A fuel rod analysis code ready for use. J. Nucl. Mater. 1992, 188, 295–302. [Google Scholar] [CrossRef]

- Magni, A.; Del Nevo, A.; Luzzi, L.; Rozzia, D.; Adorni, M.; Schubert, A.; Van Uffelen, P. The TRANSURANUS fuel performance code. In Nuclear Power Plant Design and Analysis Code; Wang, J., Li, X., Allison, C., Hohorst, J., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 161–205. [Google Scholar] [CrossRef]

- PELGRIMM Project, FP7-EURATOM-FISSION, Grant Agreement N. 295664. 2012. Available online: https://cordis.europa.eu/project/id/295664/it (accessed on 30 September 2019).

- INSPYRE Project, H2020-EURATOM-FISSION, Grant Agreement N. 754329, 2017 Investigations Supporting MOX Fuel Licensing in ESNII Prototype Reactors. Use Fundamental Research to Improve the Simulation of Nuclear Fuels: The Path towards Safer Reactors. Available online: http://www.eera-jpnm.eu/inspyre/ (accessed on 30 September 2019).

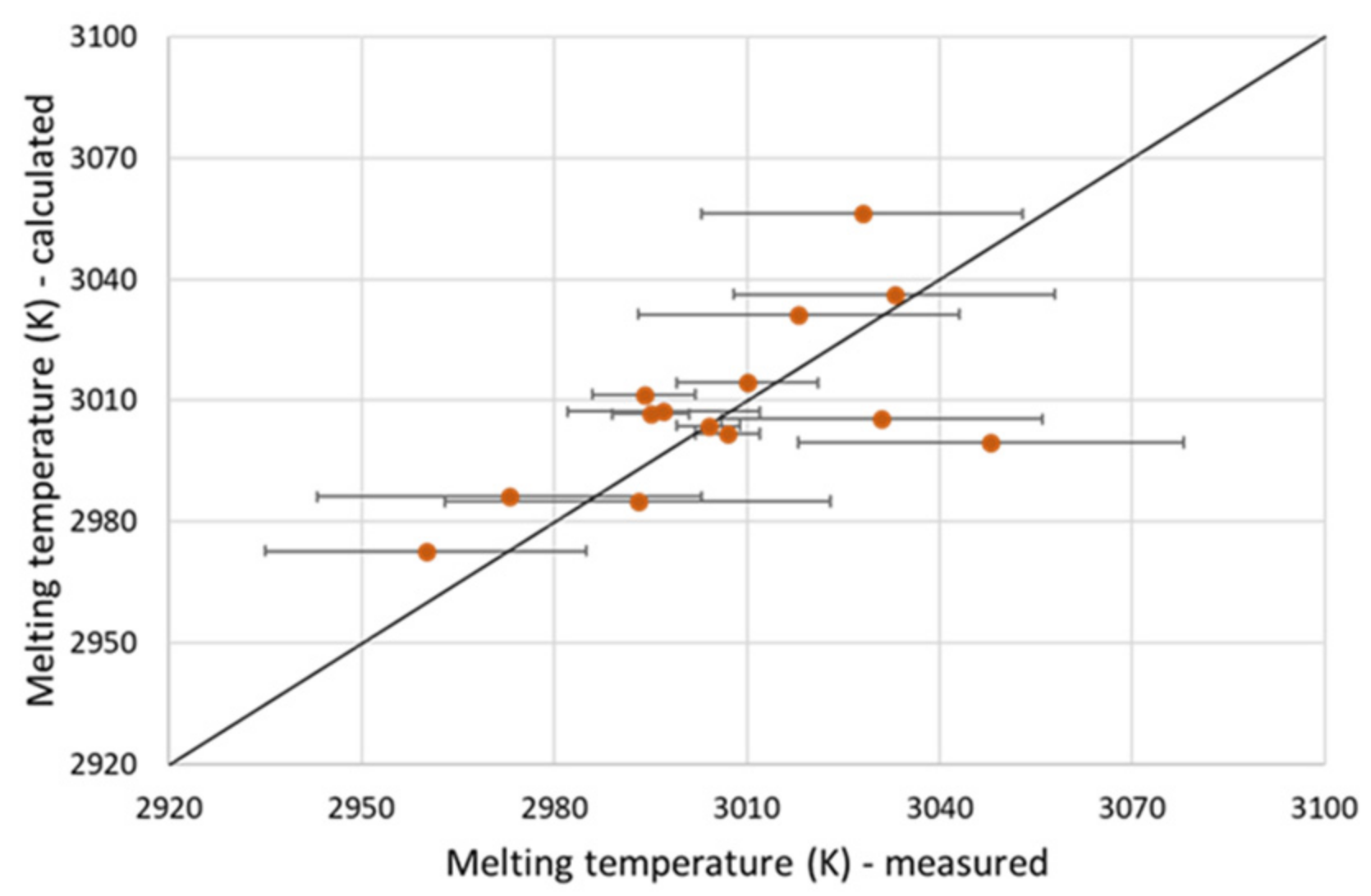

- Luzzi, L.; Barani, T.; Boer, B.; Cognini, L.; Del Nevo, A.; Lainet, M.; Lemehov, S.; Magni, A.; Marelle, V.; Michel, B.; et al. Assessment of three European fuel performance codes against the SUPERFACT-1 fast reactor irradiation experiment. Nucl. Eng. Technol. 2021, 53, 3367–3378. [Google Scholar] [CrossRef]

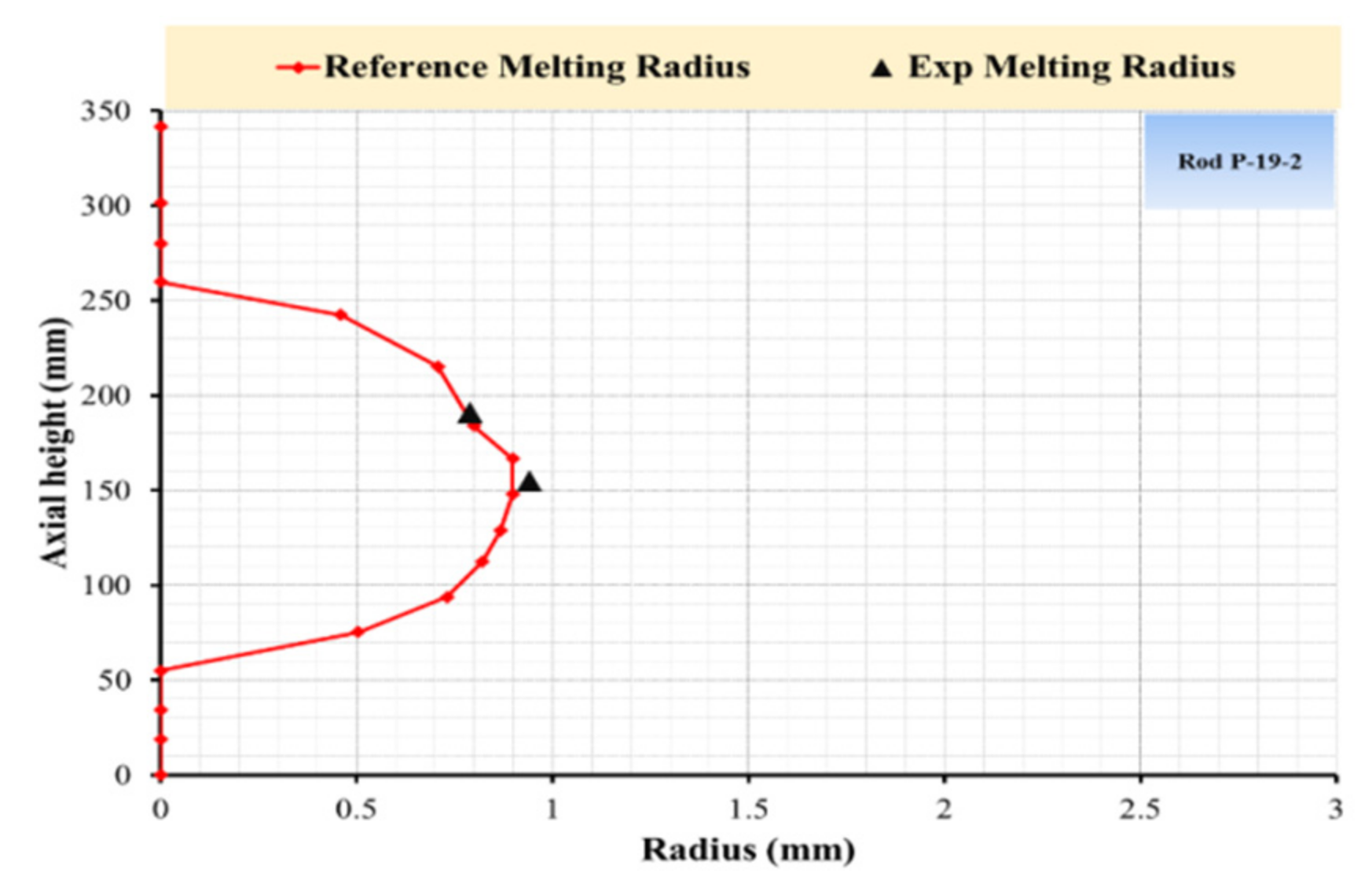

- Magni, A.; Barani, T.; Del Nevo, A.; Pizzocri, D.; Staicu, D.; Van Uffelen, P.; Luzzi, L. Modelling and assessment of thermal conductivity and melting behaviour of MOX fuel for fast reactor applications. J. Nucl. Mater. 2020, 541, 152410. [Google Scholar] [CrossRef]

- Del Nevo, A.; Cervone, A.; Grasso, G.; Tarantino, M.; Barani, T.; Cammi, A.; Cerini, M.; Cervino, S.; Cognini, L.; De Luca, L.; et al. Development of Best Estimate Numerical Tools for LFR Design and Safety Analysis; AdP MISE-ENEA, ENEA report ADPFISS-LP2-144 Rev. 0; ENEA: Rome, Italy, 2017; 300p. [Google Scholar]

- Rozzia, D.; Del Nevo, A.; Ardizzone, A.; Tarantino, M.; Agostini, P. Capabilities of TRANSURANUS code in simulating inception of melting in FBR MOX fuel. In Proceedings of the 22nd International Conference Nuclear Energy for New Europe (NENE), Bled, Slovenia, 9–13 September 2013; p. 609. [Google Scholar]

- Luzzi, L.; Barani, T.; Bruschi, E.; Pizzocri, D.; Rozzia, D.; Del Nevo, A. Advancements in FGR Modelling for Transient Analysis of FR Fuel, AdP MISE-ENEA, ENEA Report; ADPFISS-LP2-118 Rev. 0; ENEA: Rome, Italy, September 2016; 116p. [Google Scholar]

- Barani, T.; Cammi, A.; Castagna, C.; Cognini, L.; Lorenzi, S.; Luzzi, L.; Magni, A.; Pizzocri, D.; Abrate, N.; Dulla, S.; et al. Development of Best Estimate Numerical Tools for LFR Design and Safety Analysis; AdP MISE-ENEA, ENEA report; ADPFISS-LP2-158 Rev. 0; ENEA: Rome, Italy, 2018; 213p. [Google Scholar]

- Tachibana, T.; Ohmori, T.; Yamanouchi, S.; Itaki, T. Determination of melting point of mixed-oxide fuel irradiated in fast breeder reactor. J. Nucl. Sci. Technol. 1985, 22, 155–157. [Google Scholar] [CrossRef][Green Version]

- Komatsu, J.; Tachibana, T.; Konashi, K. The melting temperature of irradiated oxide fuel. J. Nucl. Mater. 1988, 154, 38–44. [Google Scholar] [CrossRef]

- Konno, K.; Hirosawa, T. Melting temperature of mixed oxide fuels for fast reactors. J. Nucl. Sci. Technol. 2002, 39, 771–777. [Google Scholar] [CrossRef][Green Version]

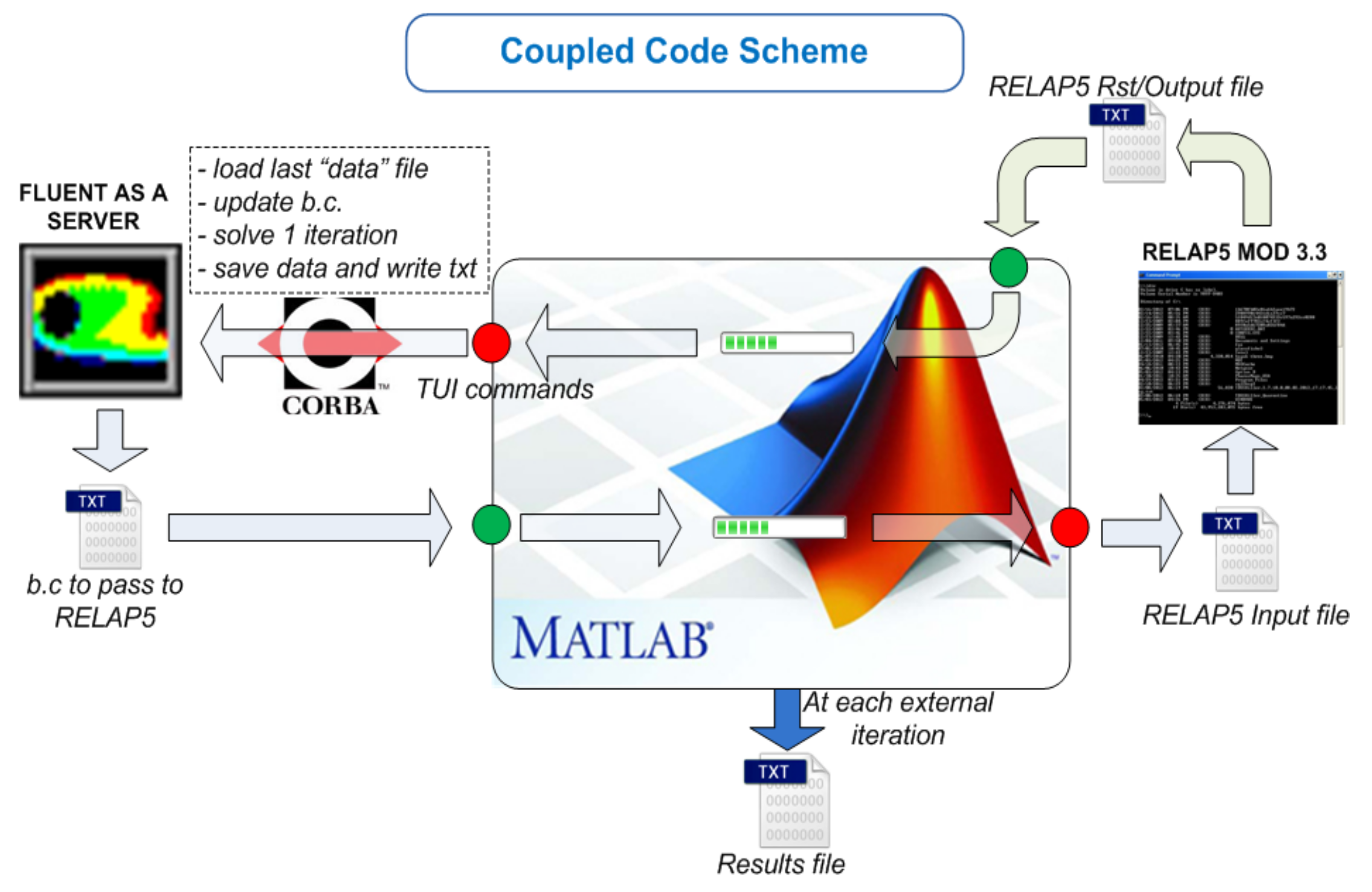

- Pucciarelli, A.; Toti, A.; Castelliti, D.; Belloni, F.; Van Tichelen, K.; Moscardini, M.; Galleni, F.; Forgione, N. Coupled system thermal hydraulics/CFD model: General guidelines and application to heavy liquid metals. Ann. Nucl. Energy 2021, 153, 107990. [Google Scholar] [CrossRef]

- Martelli, D.; Forgione, N.; Barone, G.; Di Piazza, I. Coupled simulations of the NACIE facility using RELAP5 and ANSYS FLUENT codes. Ann. Nucl. Energy 2017, 101, 408–418. [Google Scholar] [CrossRef]

- Angelucci, M.; Martelli, D.; Barone, G.; Di Piazza, I.; Forgione, N. STH-CFD codes coupled calculations applied to HLM loop and pool systems. Sci. Technol. Nucl. Install. 2017, 2017, 1936894. [Google Scholar] [CrossRef]

- Guidez, J.; Prele, G. Superphenix Technical and Scientific Achievements; Atlantis Press: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Kasahara, N. Fast Reactor System Design; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Иванoвич, С.И. Гoлoвнoй блoк нoвoгo пoкoления БН-800. Гoлoвнoй блoк нoвoгo пoкoления БН-800. Осoбеннoсти ввoда в эксплуатацию. 2016. Available online: http://mntk.rosenergoatom.ru/mediafiles/u/files/2016/Materials_2016/Plenar_rus/Golovnoj_blok_novogo_pokoleniya._Osobennosti_VE.pdf (accessed on 30 September 2019).

- Kamdar, M.H. Fracture in Liquid Metal Environments; Technical Report ARLCB-TR-85013; US ARMY Armament R&D Center: Watervliet, NY, USA, 1985. [Google Scholar]

- Prusek, S.; Lubosik, Z.; Rajwa, S.; Walentek, A.; Wrana, A. Geotechnical monitoring of rock mass and support behaviour around the UCG georeactor: Two case studies in Polish coal mining industry. Int. Conf. Ground Control Min. 2017, 321–328. [Google Scholar]

- Bondarenko, V.; Dychkovskiy, R.; Falshtynskiy, V. Synthetic Stowing of Rockmass at Borehole Underground Coal Gasification (BUCG). Deep Min. Chall. 2009, 169–177. [Google Scholar] [CrossRef]

- Jianu, A.; Mueller, G.; Weisenburger, A.; Heinzel, A.; Fazio, C.; Markov, V.G.; Kashtanov, A.D. Creep-to-rupture tests of T91 steel in flowing Pb–Bi eutectic melt at 550 °C. J. Nucl. Mater. 2009, 394, 102–108. [Google Scholar] [CrossRef]

- Angiolini, M.; Agostini, P.; Pilloni, L.; Utili, M. Towards a new approach for structural materials of Lead Fast Reactors. In Proceedings of the International Conference on Fast Reactors and Related Fuel Cycles: Next Generation Nuclear Systems for Sustainable Development (FR17), Yekaterinburg, Russia, 26–29 June 2017. [Google Scholar]

- Singh, L. A Review on Detonation Gun Sprayed Coatings. J. Miner. Mater. Charact. Eng. 2012, 11, 243–265. [Google Scholar] [CrossRef]

- Di Fonzo, F.; Tonini, D.; Li Bassi, A.; Casari, C.S.; Beghi, M.G.; Bottani, C.E.; Gastaldi, D.; Vena, P.; Contro, R. Growth regimes in pulsed laser deposition of aluminum oxide films. Appl. Phys. A 2008, 93, 765–769. [Google Scholar] [CrossRef]

- García Ferré, F.; Bertarelli, E.; Chiodoni, A.; Carrielli, D.; Gastaldi, D.; Vena, P.; Beghi, M.G.; Di Fonzo, F. The mechanical properties of a nanocrystalline Al2O3/a-Al2O3 composite coating measured by nanoindentation and Brillouin spectroscopy. Acta Mater. 2013, 61, 2662–2670. [Google Scholar] [CrossRef]

- Garcia Ferré, F.; Ormellese, M.; Di Fonzo, F.; Beghi, M.G. Advanced Al2O3 coatings for high temperature operation of steels in heavy liquid metals: A preliminary study. Corros. Sci. 2013, 77, 375–378. [Google Scholar] [CrossRef]

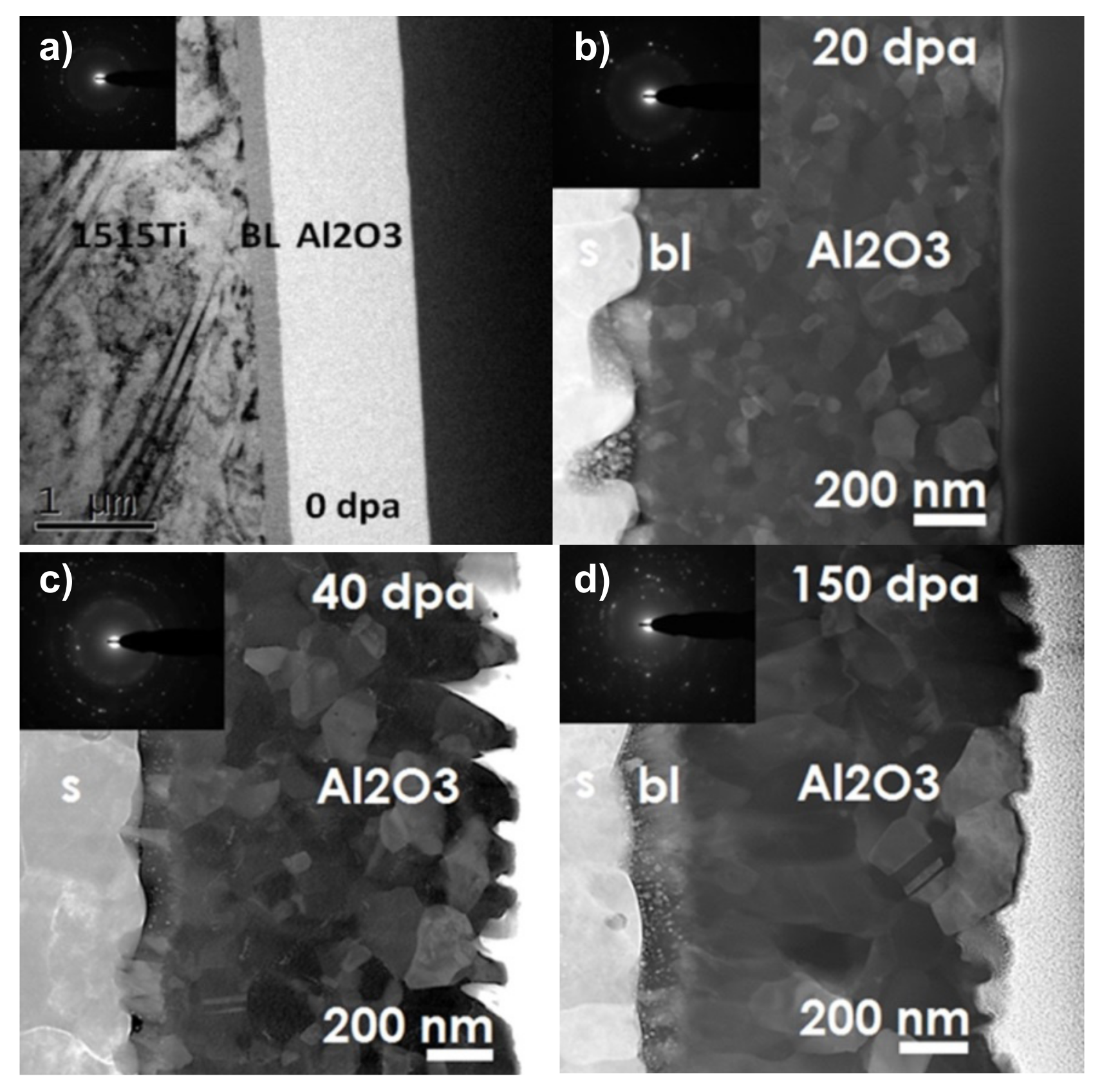

- García Ferré, F.; Mairov, A.; Ceseracciu, L.; Serruys, Y.; Trocellier, P.; Baumier, C.; Kaïtasov, O.; Brescia, R.; Gastaldi, D.; Vena, P.; et al. Radiation endurance in Al2O3 nanoceramics. Sci. Rep. 2016, 6, 33478. [Google Scholar] [CrossRef] [PubMed]

- OECD/NEA Nuclear Science Committee. Handbook on Lead-bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermal-hydraulics and Technologies. 2015. Available online: https://www.oecd-nea.org/science/pubs/2015/7268-leadbismuth-2015.pdf (accessed on 30 September 2019).

- Frignani, M.; Alemberti, A.; Tarantino, M.; Grasso, G. ALFRED staged approach. In Proceedings of the ICAPP 2019 Conference, Juan-Les-Pins, France, 12–15 May 2019. [Google Scholar]

- Tarantino, M.; Bassini, S.; Del Nevo, A.; Di Piazza, I. LFR-DEMO Development. Status & Perspectives of ALFRED Reactor. In Proceedings of the ANS Winter Meeting and Nuclear Technology Expo, Washington, DC, USA, 29 October–2 November 2017. [Google Scholar]

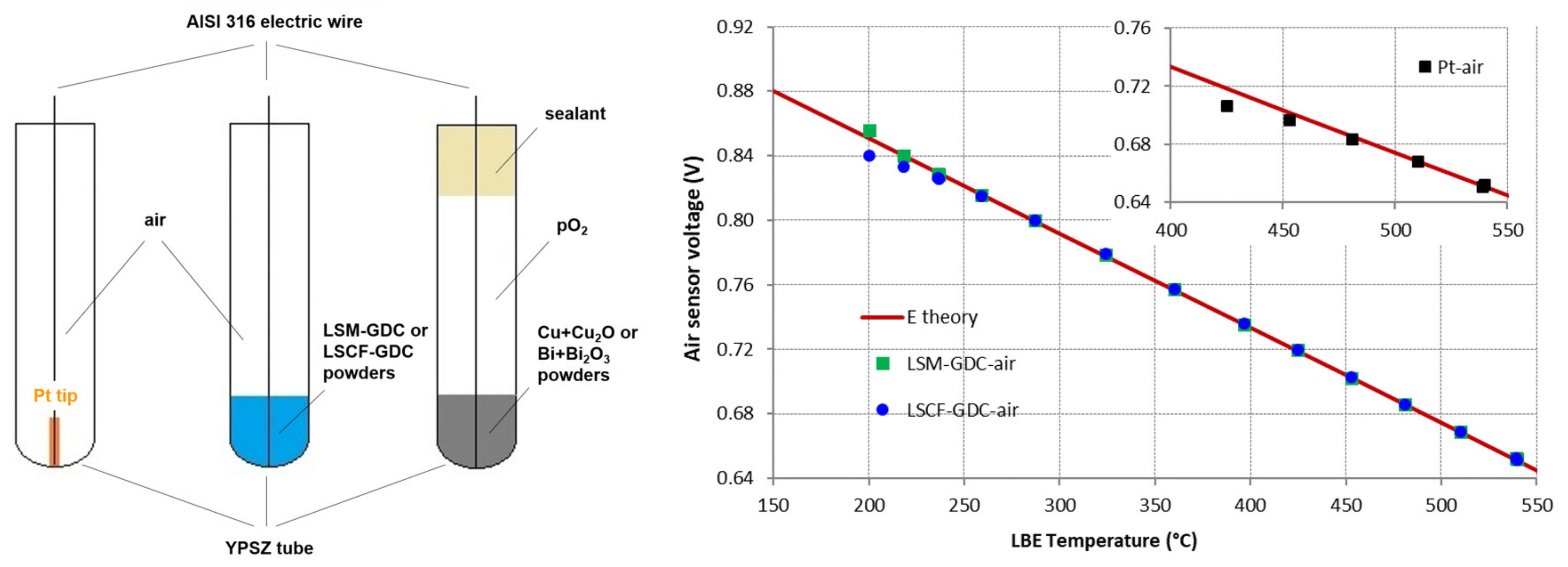

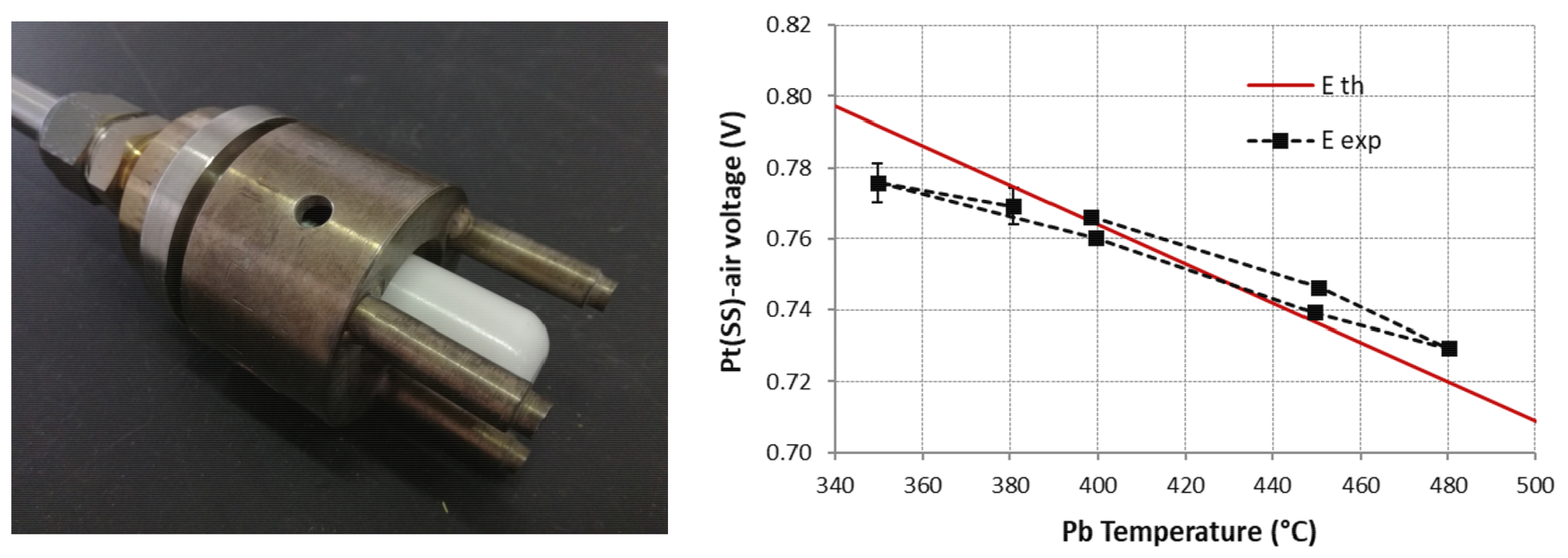

- Bassini, S.; Antonelli, A.; Di Piazza, I.; Tarantino, M. Oxygen sensors for Heavy Liquid Metal coolants: Calibration and assessment of the minimum reading temperature. J. Nucl. Mater. 2017, 486, 197–205. [Google Scholar] [CrossRef]

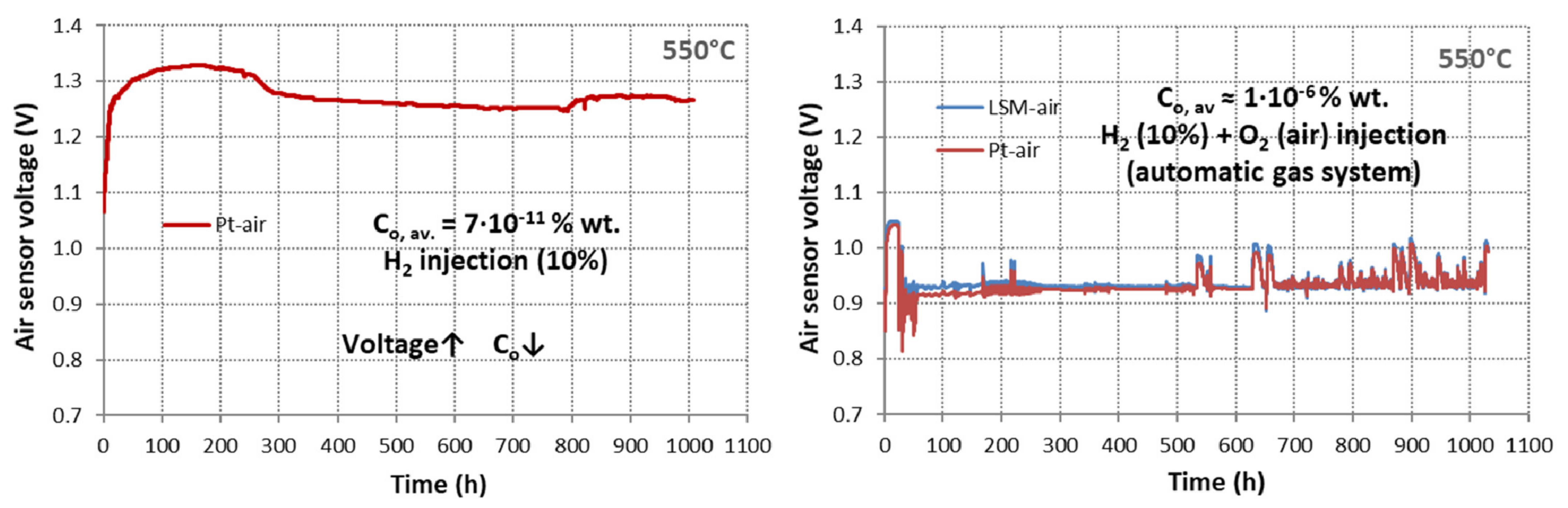

- Bassini, S.; Di Piazza, I.; Antonelli, A.; Angelucci, M.; Sermenghi, V.; Polazzi, G.; Tarantino, M. In-loop oxygen reduction in HLM thermal-hydraulic facility NACIE-UP. Prog. Nucl. Energy 2018, 105, 137–145. [Google Scholar] [CrossRef]

- Martelli, D.; Tarantino, M.; Forgione, N.; Bassini, S.; Di Piazza, I. CIRCE-ICE experimental activities in support of LMFR Design. In Proceedings of the 17th International Conference on Fast Reactors and Related Fuel Cycles (FR17), Yekaterinburg, Russia, 26–19 June 2017. [Google Scholar]

- Schroer, C.; Wedemeyer, O.; Konys, J. Gas/liquid oxygen-transfer to flowing lead alloys. Nucl. Eng. Des. 2011, 241, 1310–1318. [Google Scholar] [CrossRef]

- Nam, H.O.; Lim, J.; Han, D.Y.; Hwang, I.S. Dissolved oxygen control and monitoring implementation in the liquid lead-bismuth eutectic loop: HELIOS. J. Nucl. Mater. 2008, 376, 381–385. [Google Scholar] [CrossRef]

- Muller, G.; Heinzel, A.; Schumacher, G.; Weisenburger, A. Control of oxygen concentration in liquid lead and lead-bismuth. J. Nucl. Mater. 2003, 321, 256–262. [Google Scholar] [CrossRef]

- Kondo, M.; Takahashi, M.; Miura, K.; Onizawa, T. Study on control of oxygen concentration in lead-bismuth flow using lead oxide particles. J. Nucl. Mater. 2006, 357, 97–104. [Google Scholar] [CrossRef]

- Lim, J.; Marino, A.; Aerts, A. Active oxygen control by a PbO mass exchanger in the liquid lead-bismuth eutectic loop: MEXICO. J. Nucl. Sci. Technol. 2016, 54, 131–137. [Google Scholar] [CrossRef]

- Fazio, C.; Ricapito, I.; Scaddozzo, G.; Benamati, G. Corrosion behaviour of steels and refractory metals and tensile features of steels exposed to flowing PbBi in the LECOR loop. J. Nucl. Mater. 2003, 318, 325–332. [Google Scholar] [CrossRef]

| Parameter | BFPS | ALFRED FA (2016) |

|---|---|---|

| D [mm] | 10 | 10.5 |

| p/d | 1.4 | 1.32 |

| Q [kW] | 250 | 2330 |

| Q pin [kW] | 13 | 18.5 |

| Q″ [MW/m2] | 0.7 | 0.7–1 |

| v [m/s] | 0.8 | 1.1 |

| N pins | 19 | 127 |

| L active [mm] | 600 | 600 |

| L plenum [mm] | 500 | 500 |

| Component | Materials (Stage 1; Tin-Tout = 390–430 °C) | Materials and/or Coatings (Stage 2 and 3, Tin-Tout = 400–520 °C) |

|---|---|---|

| Fuel cladding | 15-15Ti 20% CW (AIM1) | 15-15Ti + Al2O3 by PLD |

| FA Structures | 15-15Ti 20% CW (AIM1) | 15-15Ti + Al2O3 by ALD/PLD |

| Internal structures | AISI 316LN (ASTM) | Al diff. coating, or AFA steel |

| Steam Generator | AISI 316LN (ASTM) | AFA steel, or T91 + Al diff. coat., or Alloy 800 + Al diff. coat. |

| DHR Heat Exchanger | AISI 316L (ASTM) 15-15Ti (DIN 1.4970) | Al diff. coating, or AFA steel |

| Primary Pumps (impellers) | AISI 300 series | Al diff. coating, or Maxphase coating, or AlTiN coating |

| Reactor Vessel | AISI 316LN (ASTM) | (Oxygen control) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarantino, M.; Angiolini, M.; Bassini, S.; Cataldo, S.; Ciantelli, C.; Cristalli, C.; Del Nevo, A.; Di Piazza, I.; Diamanti, D.; Eboli, M.; et al. Overview on Lead-Cooled Fast Reactor Design and Related Technologies Development in ENEA. Energies 2021, 14, 5157. https://doi.org/10.3390/en14165157

Tarantino M, Angiolini M, Bassini S, Cataldo S, Ciantelli C, Cristalli C, Del Nevo A, Di Piazza I, Diamanti D, Eboli M, et al. Overview on Lead-Cooled Fast Reactor Design and Related Technologies Development in ENEA. Energies. 2021; 14(16):5157. https://doi.org/10.3390/en14165157

Chicago/Turabian StyleTarantino, Mariano, Massimo Angiolini, Serena Bassini, Sebastiano Cataldo, Chiara Ciantelli, Carlo Cristalli, Alessandro Del Nevo, Ivan Di Piazza, Dario Diamanti, Marica Eboli, and et al. 2021. "Overview on Lead-Cooled Fast Reactor Design and Related Technologies Development in ENEA" Energies 14, no. 16: 5157. https://doi.org/10.3390/en14165157

APA StyleTarantino, M., Angiolini, M., Bassini, S., Cataldo, S., Ciantelli, C., Cristalli, C., Del Nevo, A., Di Piazza, I., Diamanti, D., Eboli, M., Fiore, A., Grasso, G., Lodi, F., Lorusso, P., Marinari, R., Martelli, D., Papa, F., Sartorio, C., Utili, M., & Venturini, A. (2021). Overview on Lead-Cooled Fast Reactor Design and Related Technologies Development in ENEA. Energies, 14(16), 5157. https://doi.org/10.3390/en14165157