The H2020 McSAFER Project: Main Goals, Technical Work Program, and Status

Abstract

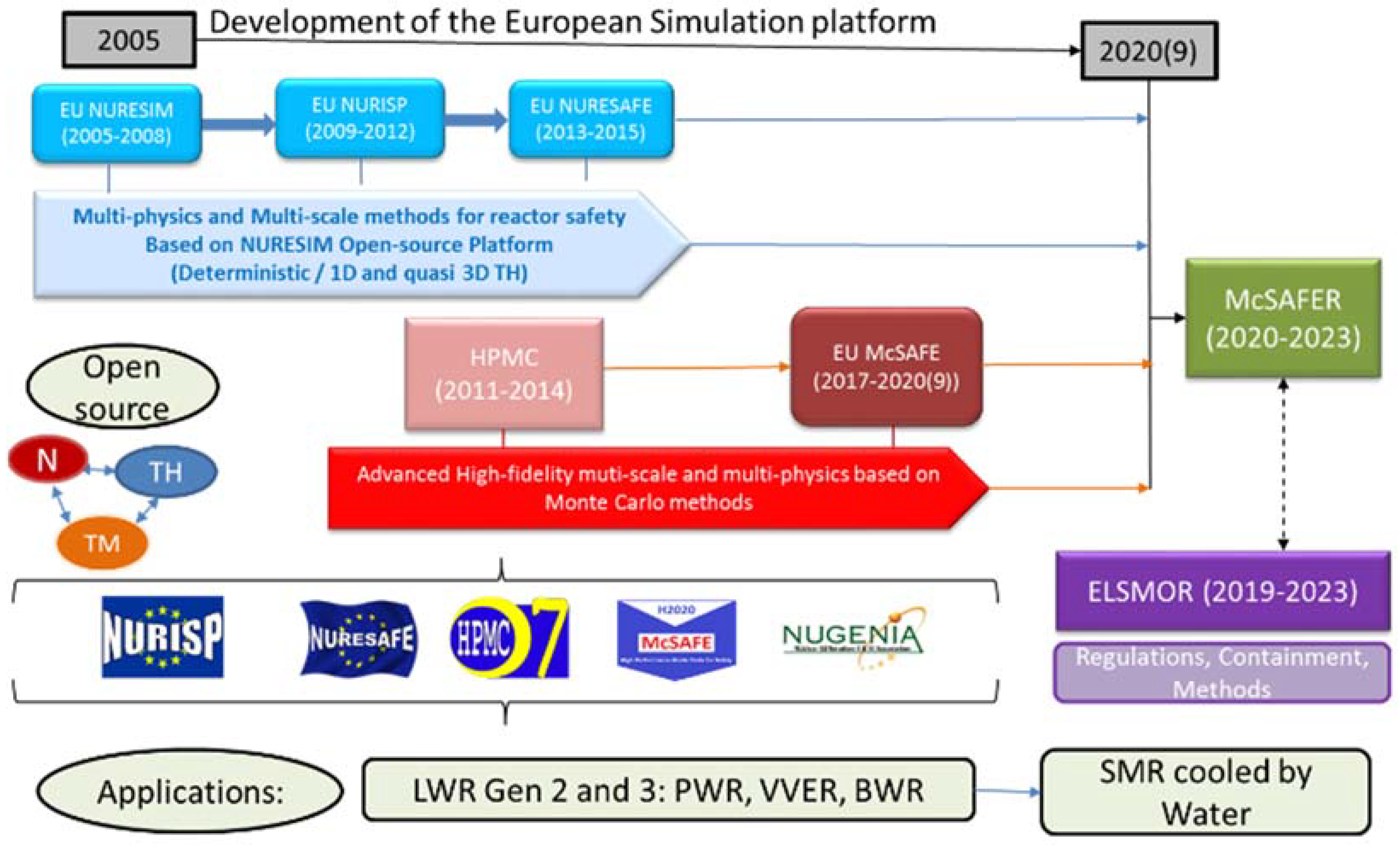

1. Introduction

1.1. Challenges for Numerical Tools

1.2. Advanced Tools for Safety Evaluations

1.3. Validation of Numerical Tools

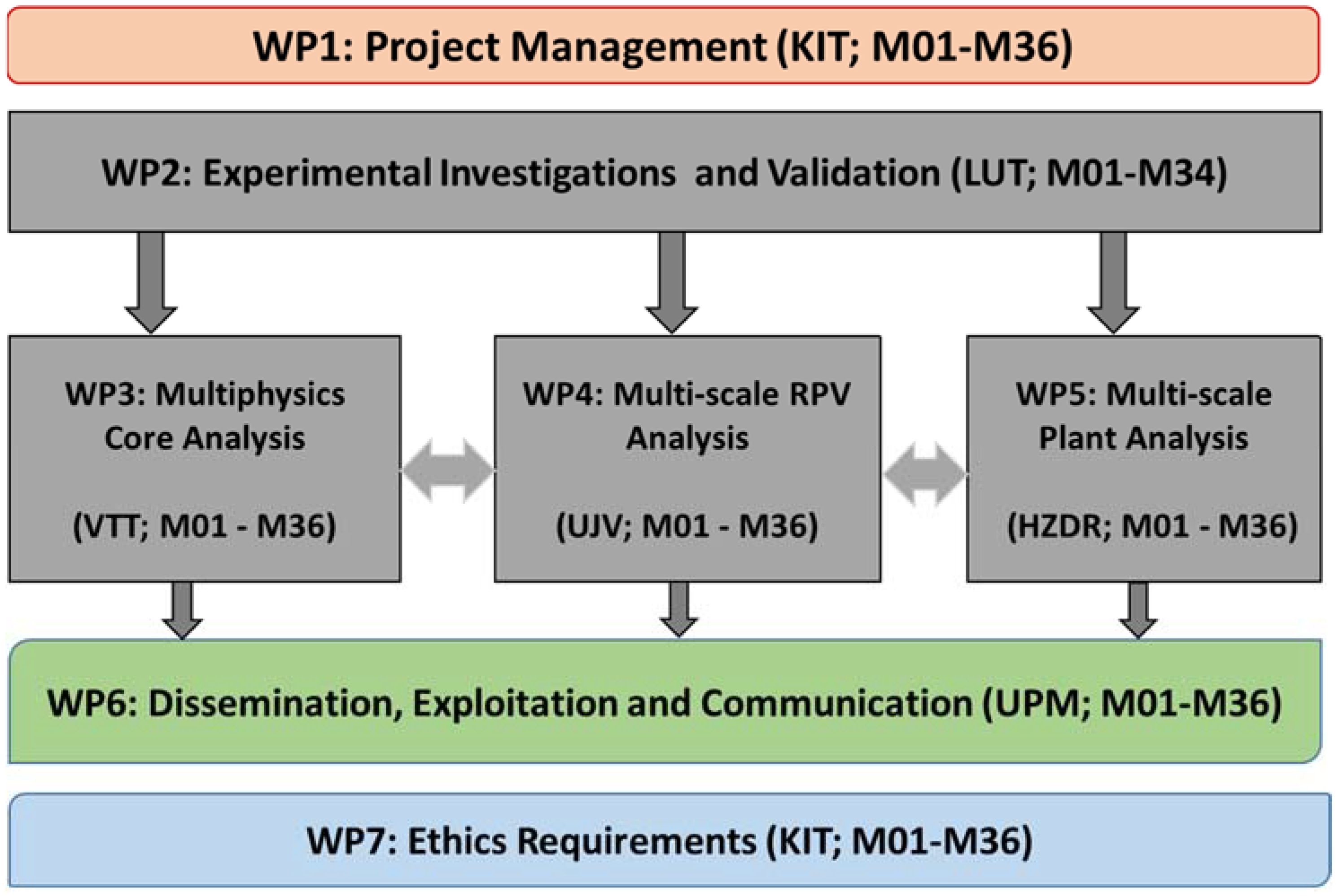

2. McSAFER Partners and Structure

2.1. Project Partners

2.2. McSAFER Structure

3. Main Goals and Content of the Technical Work Packages

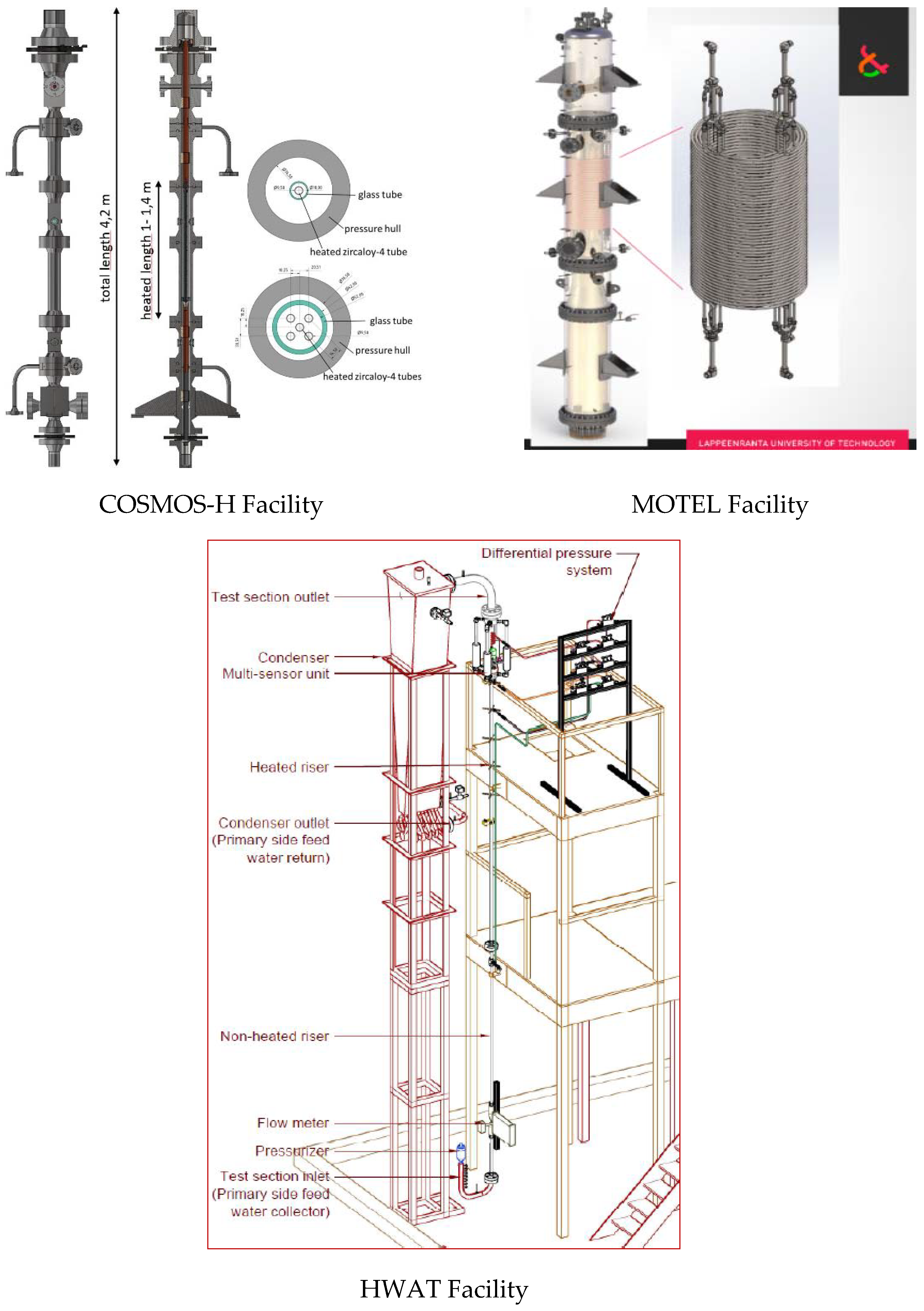

3.1. Experimental Investigations and Validation

- Fundamental heat transfer experiments at the COSMOS-H facility using a heated tube in an annular gap and a heated rod bundle (five tubes) of dimensions similar to the ones of SMRs to study CHF phenomena at three different pressure levels (from 5 to 15 MPa) [28].

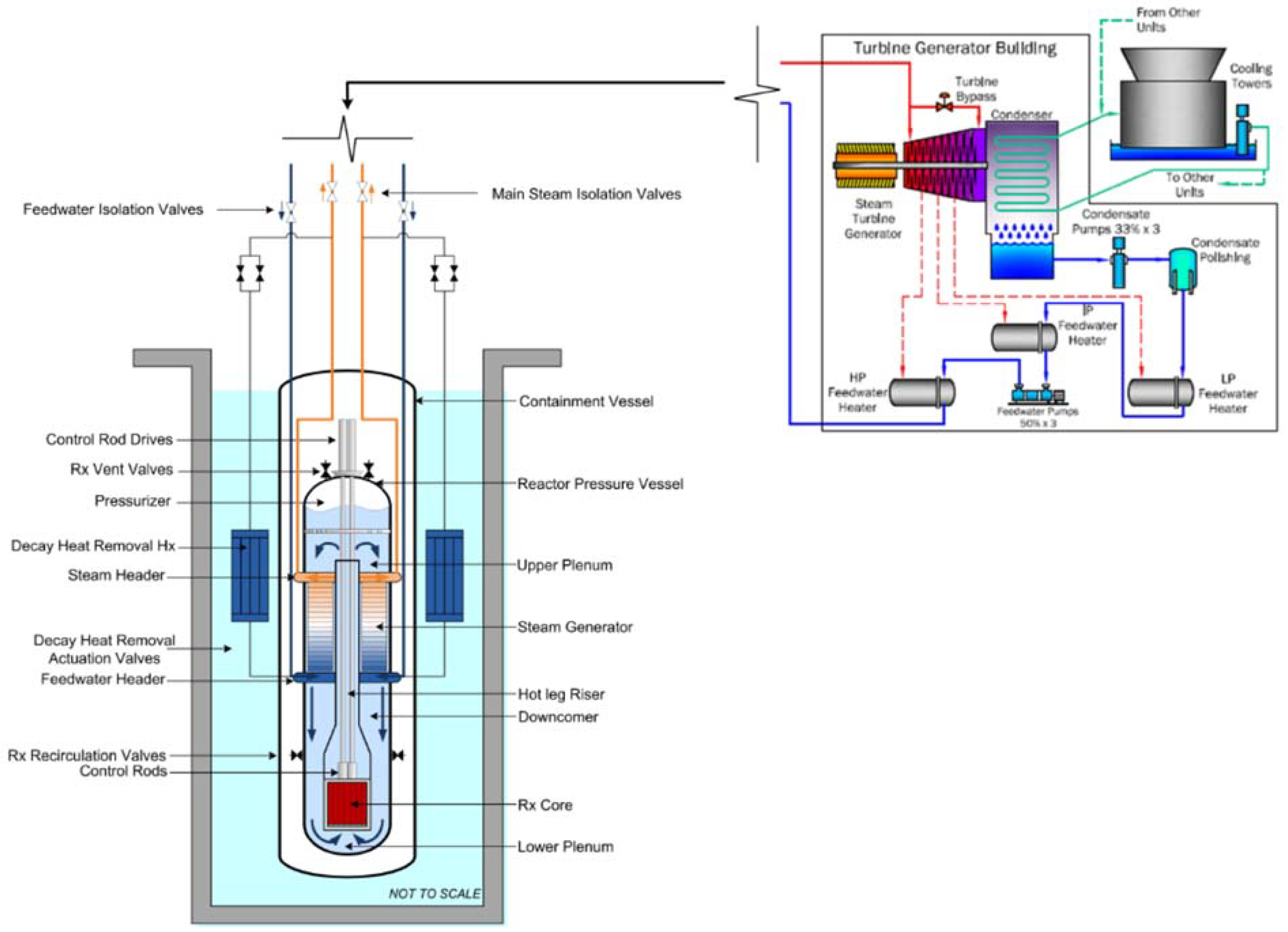

- Experiments at the MOTEL facility, which is designed for SMR-relevant tests and includes essential components of SMR, e.g., a helical coil heat exchanger, core, and pressurizer (representative for NuScale). A test series is dedicated to investigate the behavior of the helical steam generator and another one to study the cross-flow phenomena [29].

- Tests at the HWAT facility including a two-phase heat transfer under forced circulation and the transition to natural convection considering SMR-relevant thermal hydraulic conditions.

- Validation of CFD codes using the experimental data of COSMOS-H, MOTEL, and HWAT.

- Validation of subchannel thermal hydraulic codes with the experimental data obtained with the proposed tests.

- Validation of system thermal hydraulic codes using the test data generated.

- Serie 1: Tests with a single Zircaloy tube in an annular gap of 4 m height. Different CHF tests are foreseen in order to quantify the measurement uncertainty. In addition to sensors for pressure, temperature, and mass flow, imaging measurement techniques is also be used;

- Serie 2: Rod bundle experiments with five Zircaloy tubes arranged in a square geometry with one at the center. A tube length of 1 m has been considered. Only the methods based on the backscattering of light such as Laser Dopper Anemometrie (LDA) are used, since the optical accessibility is limited.

- Forced circulation steady-state tests: measurement of the distribution of the flow with a multi-sensor probe, measurement of the heat transfer under different flow conditions inside the heater riser.

- Forced-to-natural circulation transients in a ca. 8.8 m high closed loop including the riser, a return line and a condenser test section. Transient local flow characteristics, natural circulation stability, and transient local flow characteristics during natural circulation are measured.

- Series 1: MOTEL helical coil steam generator experiments to study the behavior of the helical coil SG, i.e., steady-state heat transfer, temperature distributions along the SG tubes, steady states with different power levels;

- Series 2: MOTEL cross-flow experiments: mixing between subchannels with even and skewed radial power distributions in the core by adjusting the powers of the 12 radial heating regions.

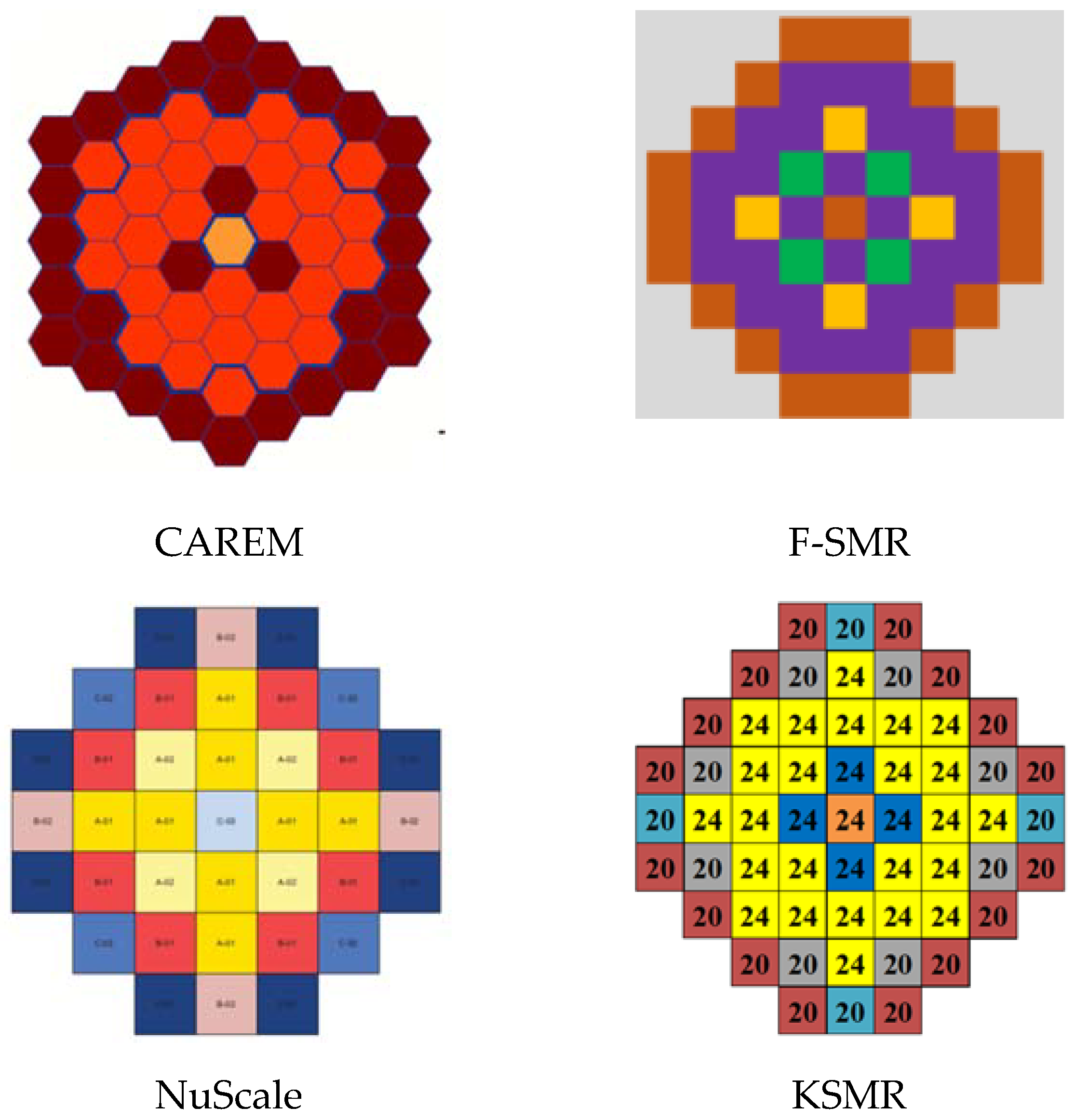

3.2. Multiphysics Core Analysis

- Develop advanced deterministic solvers (SP3-pin-by-pin/subchannel) for improving core analysis achieving higher prediction accuracy, i.e., at the pin-level compared to the traditional lower-fidelity codes (nodal solutions);

- Demonstrate the need for high-fidelity novel multiphysics and multiscale codes to improve the traditional low-fidelity codes and methods which are currently in use by both the industry and regulators for routine simulations;

- Show the appropriateness of the high-fidelity multiphysics solutions based on Monte Carlo methods developed within the McSAFE project as the reference solution for the reduced-order solutions, especially in cases where no experimental data are available;

- Extend the core analysis tools (neutronic, thermal hydraulic, and thermo-mechanics) for the simulation of a SMR core loaded with accident tolerant fuel (ATF).

3.3. Multiscale Reactor Pressure Vessel Analysis

- Selection of appropriate Design Basis Accident (DBA) sequences, e.g., steam line break, boron dilution, and Anticipated Transients Without Scram (ATWS);

- Application of multiscale thermal hydraulic methods, including the coupling of system thermal hydraulic and subchannel codes for the analysis of the RPV.

- Application of novel multiscale thermal hydraulic methods, including the coupling of CFD and system thermal hydraulic codes for the analysis of the RPV.

3.4. Multiscale Plant Analysis

- The selection of the SMR-relevant design basis accidents for the analysis with traditional methods, e.g., steam line break, ATWS, or boron dilution when applicable;

- The analysis of the selected design basis accidents using advanced safety analysis methodologies based on a multiscale and multiphysics approach;

- A comparison of the different safety analysis approaches.

3.5. Dissemination, Exploitation and Communication

- Organization of workshops;

- Dedicated training courses including massive open online course (MOOC).

- Creation of a User Group (UG);

- Creation of a technical Advisory Board (AB);

- Public project website;

- Regular project Newsletter issues;

- Publications of Press releases;

- Presentations in conferences and publications.

4. Status of the Project

4.1. The Experimental and Validation Program

- HWAT facility: Heat transfer for subcooled boiling and CHF; study of the appropriateness of two critical components (heated riser and pool type condenser) for future transient tests [33];

- MOTEL: The first test series are focused on the helical coil steam generator behavior. The primary/secondary heat transfer is studied on different steady states with different core power levels [34];

- COSMOS-H: The first test planned consists of a single heated tube made of Zircalloy-4 arranged in an annular gap with an outer glass tube [35]. The heat transfer between the cladding and the coolant is measured for an increasing heat flux. It ranges from subcooled boiling until critical heat flux conditions.

4.2. Multiphysics Core Analysis

4.3. Multiphysics and Multiscale Reactor Pressure Vessel (RPV) Analysis

- One-dimensional system thermal hydraulic codes (TRACE, ATHLET, RELAP5);

- Tridimensional system thermal hydraulic codes (TRACE, ATHLET-3D, RELAP-3D);

- Subchannel codes (SUBCHANFLOW, ARTHUR);

- CFD-codes (OpenFOAM, Fluent).

4.4. Multiscale Plant Analysis

4.5. Dissemination, Exploitation and Communication

5. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Disclaimer

References

- OECD. Small Modular Reactors: Challenges and Opportunities; NEA Nr. 7560; OECD: Paris, France, 2021. [Google Scholar]

- OECD. SMall Modular Reactors: Nuclear Energy Market Potential for Near-Term Deployment; NEA Nr. 7213; OECD: Paris, France, 2016. [Google Scholar]

- Reyes, J. NuScale Plant Safety in Response to Extreme. Nucl. Technol. 2012, 178, 153–163. [Google Scholar] [CrossRef]

- Halfinger, J.A.; Haggerty, M.D. The B&W mPower™ Scalable, Practical Nuclear Reactor Design. Nucl. Technol. 2012, 178, 164–169. [Google Scholar]

- Petrovic, B.; Ricotti, M.; Monti, S.; Čavlina, N.; Hisashi, N. Pioneering Role of IRIS in the Resur-gence of Small Modular Reactors. Nucl. Technol. 2012, 178, 2126–2152. [Google Scholar] [CrossRef]

- Kim, K.K.; Lee, W.; Choi, S.; Kim, H.R.; Ha, J. SMART: The First Licensed Advanced Integral Reactor. J. Energy Power Eng. 2014, 8, 94–102. [Google Scholar]

- Delmastro, D.; Gimenez, M.; Florido, P.; Daverio, H.; Serra, O.; Blanco, A.; Mueller, P. CAREM Concept: A Competitive SMR. In Proceedings of the ICONE12, Arlington, VA, USA, 25–29 April 2004. [Google Scholar]

- Reitsma, F. The IAEA Activities on Advance Reactor technology and SMRs. In Proceedings of the Joint IAEA-ICTP Worhkshop on the Physics and Technology of the Innovative High Temperature Nuclear Energy Systems, Vienna, Austria, 20–24 August 2018. [Google Scholar]

- IAEA. Small Modular Reactor (SMR) Regulator’s Forum. 2021. Available online: https://www.iaea.org/topics/small-modular-reactors/smr-regulators-forum (accessed on 23 August 2021).

- Alzaben, Y.; Sanchez-Espinoza, V.; Stieglitz, R. Core neutronics and safety characteristics of a boron-free core for Small Modular Reactors. Ann. Nucl. Energy 2019, 132, 70–81. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, W.S.; Shi, S.; Ishii, M. A core Design study for a small modular nboiling water reactor with long life core. Nucl. Technol. 2016, 193, 364–374. [Google Scholar] [CrossRef]

- Zhang, K. Development of Multi-Scale Thermal Hydraulic Methods for Reactor Safety. Doctoral Thesis, KIT, Karlsruhe, Germany, 2019. [Google Scholar]

- Zhang, K.; Sanchez-Espinoza, V. Multi-Scale Coupling of TRACE and SUBCHANFLOW based on ECI for the Analysis of 3D Phenomena inside the PWR RPV. In Proceedings of the 12th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics, Operation and Safety, Qingdao, China, 14–18 October 2019. [Google Scholar]

- Hoehne, T.; Krepper, E.; Rohde, U. Application of CFD Codes in Nuclear Reactor Safety Analysis. Sci. Technol. Nucl. Install. 2010, 2010, 198758. [Google Scholar]

- Böttcher, M. Detailed CFX-5 study of the coolant mixing within the reactor pressure vessel of a VVER-1000 reactor during a non-symmetrical heat-up test. Nucl. Eng. Des. 2008, 238, 445–452. [Google Scholar] [CrossRef]

- Böttcher, M.; Krüßmann, R. Primary loop study of a VVER-1000 reactor with special focus on coolant mixing. Nucl. Eng. Des. 2010, 240, 2244–2253. [Google Scholar] [CrossRef][Green Version]

- Bestion, D.; Lucas, D.; Anglart, H.; Niceno, B.; Vyskocil, L. Multi-scale thermalhydraulic analysis performed in the NURESIM and NURISP Projects. In Proceedings of the ICONE-20, Anaheim, CA, USA, 30 July–3 August 2012. [Google Scholar]

- Sheng, D.-Y.; Seidl, M. Towards the development of a full-scale transient CFD model to simulate the static and dynamic in-core mass flux distribution in a classical German PWR. In Proceedings of the NURETH-16, Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- Trikouros, N.G. A Perspective on Small Reactor Licensing and Implementation. Nucl. Technol. 2012, 178, 233–239. [Google Scholar] [CrossRef]

- CORDIS. Towards European Licencing of Small Modular Reactors (ELSMOR). EU Fresearch. 2021. Available online: https://cordis.europa.eu/project/id/847553/fr (accessed on 20 July 2021).

- Daeubler, M.; Trost, N.; Jimenez, J.; Sanchez, V.; Stieglitz, R.; Macian-Juan, R. Static and transient pin-by-pin simulations of a full PWR core with the extended coupled code system DYNSUB. Ann. Nucl. Energy 2015, 84, 31–44. [Google Scholar] [CrossRef]

- Dugan, K. Developing a Multiphysics Solver in APOLLO3 and Appalicatioons to Cross Section Homogenization. Doctoral Thesis, Universite Paris-Saclay, Saclay, France, 2017. [Google Scholar]

- Ferraro, D.; Garcia, M.; Valtavirta, V.; Imke, U.; Tuominen, R.; Leppännen, J.; Sanchez-Espinoza, V. Serpent/SUBCHANFLOW pin-by-pin coupled transient calculations for the SPERT-IIIE hot full power tests. ANE 2020, 142, 107387. [Google Scholar] [CrossRef]

- García, M.; Tuominen, R.; Gommlich, A.; Ferraro, D.; Valtavirta, V.; Imke, U.; Uffelen, P.V.; Mercatali, L.; Sanchez-Espinoza, V.; Leppänen, J.; et al. Serpent2-SUBCHANFLOW-TRANSURANUS coupling for pin-by-pin depletion calculations in Light Water Reactors. ANE 2020, 139, 107213. [Google Scholar] [CrossRef]

- Demazière, C.; Sanchez-Espinoza, V.H.; Chanaron, A.B. EPJ Nucl. Sci. Technol. 2020, 42, 6. [Google Scholar]

- European Commission. The Sustainable Nuclear Energy Technology Platform. A Vision Report; EUR 22842; European Comission: Brussels, Belgium, 2007. [Google Scholar]

- NUGENIA. NUGENIA Roadmap 2013; European Comission: Brussels, Belgium, 2013. [Google Scholar]

- Telkka, J. Development of thermal-hydraulic infrastructure at LUT. In Proceedings of the SAFARI-2018 Final Seminar, Espoo, Finland, 21–22 March 2019. [Google Scholar]

- Tromm, T.W.; Kaiser, F.; Gabriel, S.; Heiler, W.; Albrecht, G. Investigations on Flow Boiling under forced Convection on Zircaloy Tubes up to Critical Heat Flux. In Proceedings of the International Conference Nuclear Energy for New Europe (NENE2019), Portoroz, Slovenia, 12–19 September 2019. [Google Scholar]

- Hyvärinen, J.; Telkkä, J.; Kauppinen, O.; Purhonen, H. MOTEL—Modular design and physical principles of the next gen-eration thermal hydraulics test facility at LUT. In Proceedings of the 17th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-17), Xi’an, China, 3–8 September 2017; pp. 5128–5141. [Google Scholar]

- Bae, K. Safety Analysis for the Major DBAs in Passive PWR SMART (Presentation). In Proceedings of the Nuclear Safety Analysis Symposium of KAERI-KACARE, Daecheon, Korea, 28–29 June 2018. [Google Scholar]

- NuScale Power LLC. NuScale Standard Plant: Design Certification Application; Chapter 5: Reactor Coolant System and Connection Systems; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2020.

- Grishchenko, D. HWAT Experimental Setup and Test Matrix for First Test Series; McSAFER Project, Deliverable Nr. 2.7; CORDIS: Stockholm, Sweden, 2021. [Google Scholar]

- Tielinen, K.; Telkkä, J.; Kotro, E.; Kouhia, V.; Suikkanen, H. Description of the MOTEL Facility and Instrumentation; McSAFER, Deliverable 2.4; CORDIS: Helsinki, Finland, 2021. [Google Scholar]

- Gabriel, S.; Albrecht, G.; Heiler, W.; Heineken, F. COSMOS-H Experimental Setup and Tests; McSAFER, Deliverable Number 2.1; CORDIS: Karlsruhe, Germany, 2021. [Google Scholar]

- Ville, V.; Anthime, F.; Emil, F.; Héctor, L.; Luigi, M. Specifications for the Reactivity Transients Scenarios in the Four SMR Cores; McSAFER, Deliverable NUmber 3.1; CORDIS: Helsinki, Finland, 2021. [Google Scholar]

- Fridman, E.; Ferraro, D.; Valtavirta, V.; Lestani, H.; Mercatali, L.; Vocka, R.; Bilodid, Y.; Seidl, M.; Farda, A. Group Constant Generation for the State-of-the-Art Codes; McSAFER, Deliverable Number 3.2; CORDIS: Dresden, Germany, 2021. [Google Scholar]

| System TH-Codes | CFD-Codes | Core Simulator |

|---|---|---|

| ATHLET | FLUENT | DYN3D |

| ATHLET | OpenFOAM | DYN3D |

| TRACE | OpenFOAM | ANTS |

| TRACE | OpenFOAM | PARCS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez-Espinoza, V.H.; Gabriel, S.; Suikkanen, H.; Telkkä, J.; Valtavirta, V.; Bencik, M.; Kliem, S.; Queral, C.; Farda, A.; Abéguilé, F.; et al. The H2020 McSAFER Project: Main Goals, Technical Work Program, and Status. Energies 2021, 14, 6348. https://doi.org/10.3390/en14196348

Sanchez-Espinoza VH, Gabriel S, Suikkanen H, Telkkä J, Valtavirta V, Bencik M, Kliem S, Queral C, Farda A, Abéguilé F, et al. The H2020 McSAFER Project: Main Goals, Technical Work Program, and Status. Energies. 2021; 14(19):6348. https://doi.org/10.3390/en14196348

Chicago/Turabian StyleSanchez-Espinoza, Victor Hugo, Stephan Gabriel, Heikki Suikkanen, Joonas Telkkä, Ville Valtavirta, Marek Bencik, Sören Kliem, Cesar Queral, Anthime Farda, Florian Abéguilé, and et al. 2021. "The H2020 McSAFER Project: Main Goals, Technical Work Program, and Status" Energies 14, no. 19: 6348. https://doi.org/10.3390/en14196348

APA StyleSanchez-Espinoza, V. H., Gabriel, S., Suikkanen, H., Telkkä, J., Valtavirta, V., Bencik, M., Kliem, S., Queral, C., Farda, A., Abéguilé, F., Smith, P., Uffelen, P. V., Ammirabile, L., Seidl, M., Schneidesch, C., Grishchenko, D., & Lestani, H. (2021). The H2020 McSAFER Project: Main Goals, Technical Work Program, and Status. Energies, 14(19), 6348. https://doi.org/10.3390/en14196348