Deep Learning Aided Data-Driven Fault Diagnosis of Rotatory Machine: A Comprehensive Review

Abstract

:1. Introduction

- Alternating current (AC) motors, synchronous AC motors, and induction AC motors;

- Direct current (DC) motors and brushless DC motors;

- Hermetic motors.

- A detailed analysis of a standard bearing fault diagnosis pipeline is given;

- An overview of shallow machine learning techniques used in the field of bearing fault diagnosis and their limitations;

- A systematic review of the literature available on bearing fault diagnosis in the last decade mainly focusing on the application of deep learning algorithms;

- Discussion on the future directions in the field of bearing fault diagnosis.

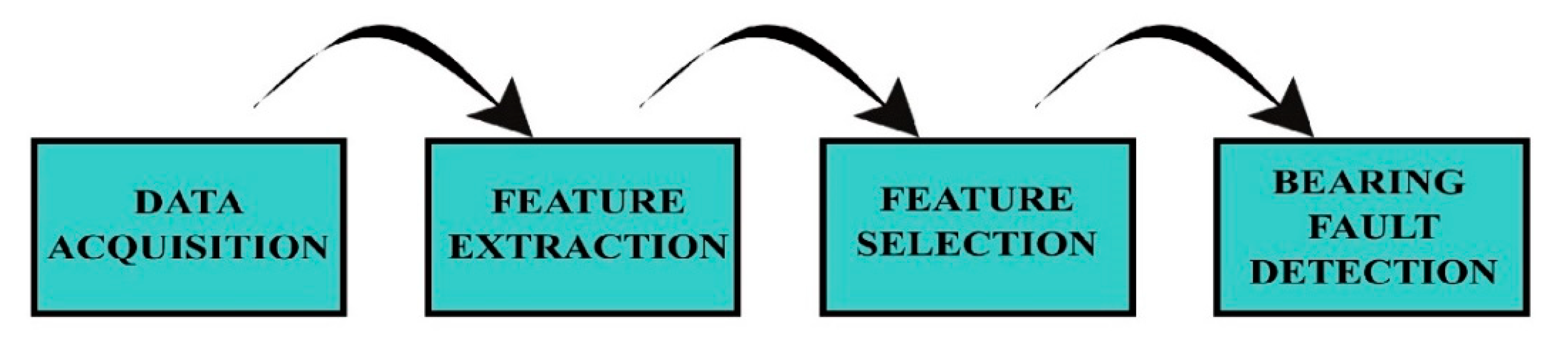

2. A Standard Pipeline of Bearing Fault Diagnosis

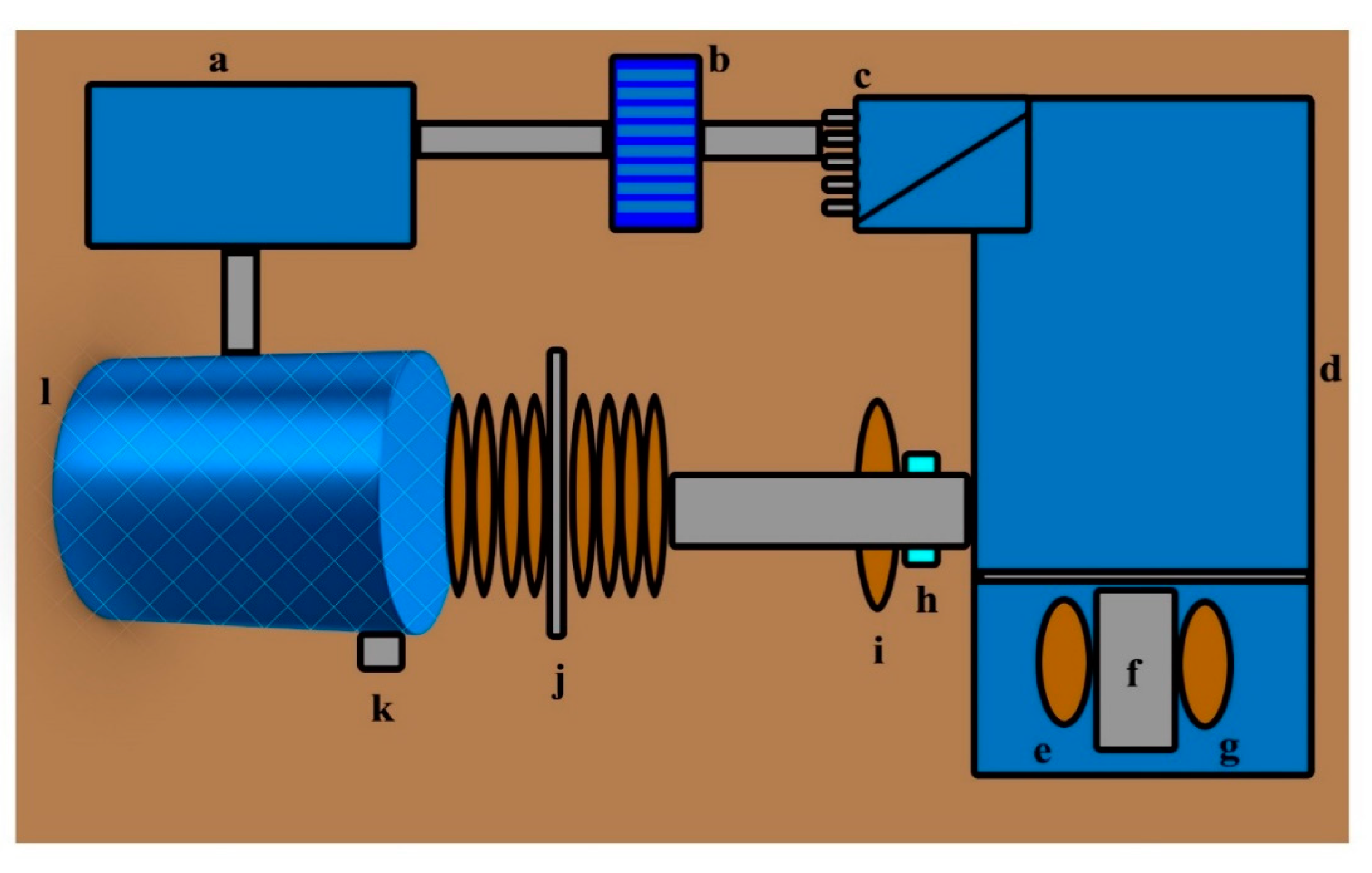

2.1. Data Acquisition

2.2. Feature Extraction

2.3. Feature Selection

2.4. Bearing Fault Diagnosis/Classification

3. Dataset for Fault Bearing Experiment

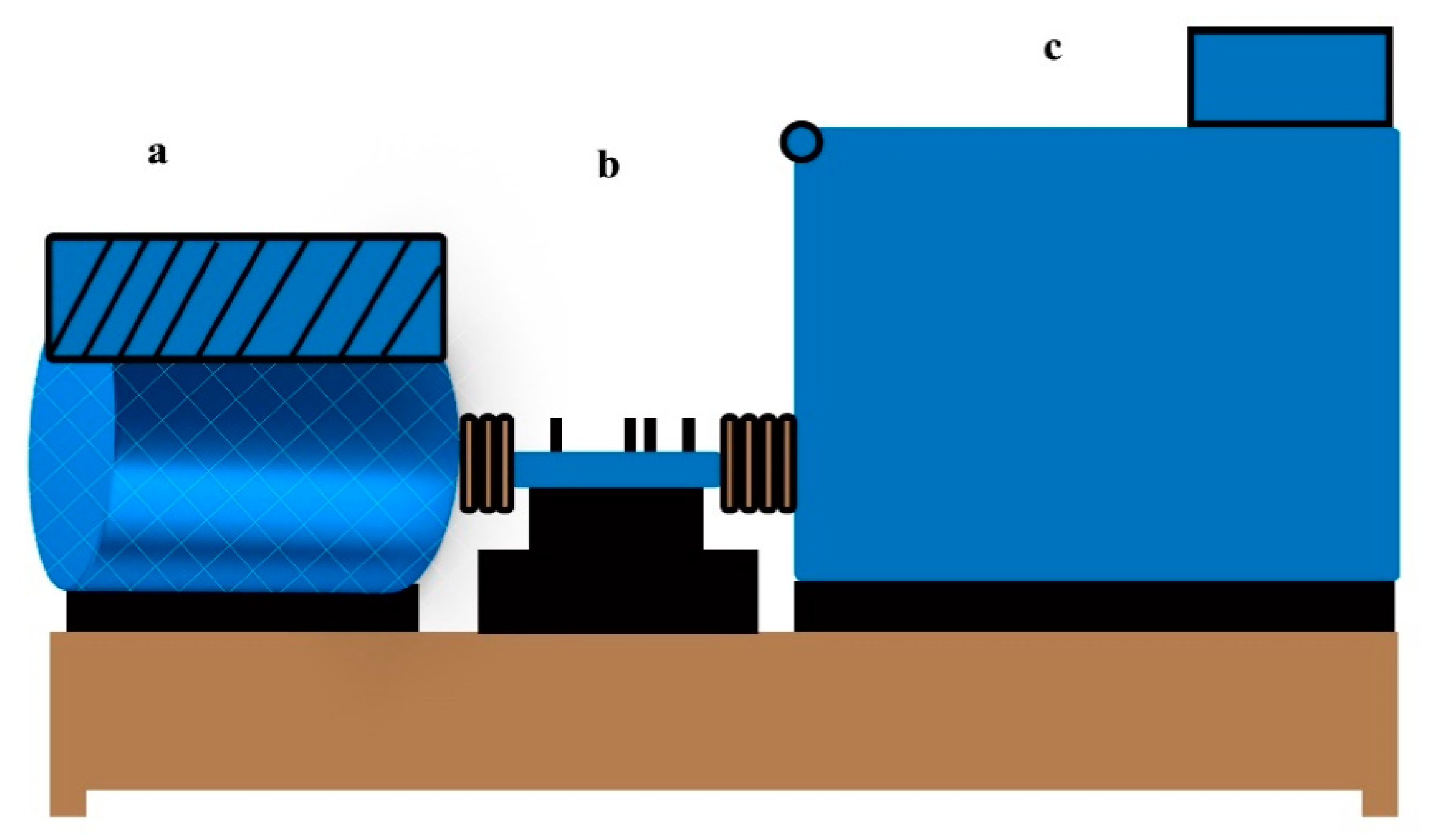

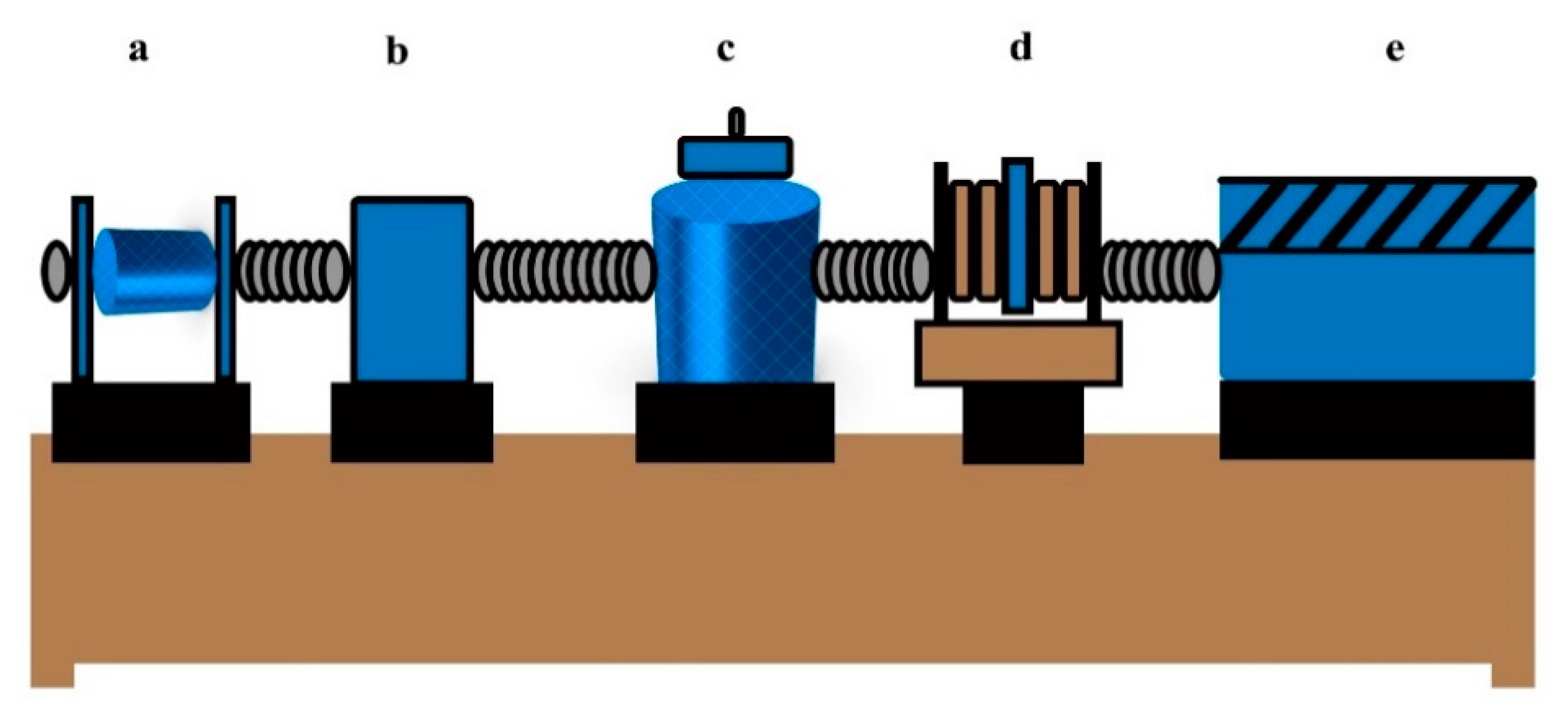

3.1. Case Western Reserve University Bearing Dataset

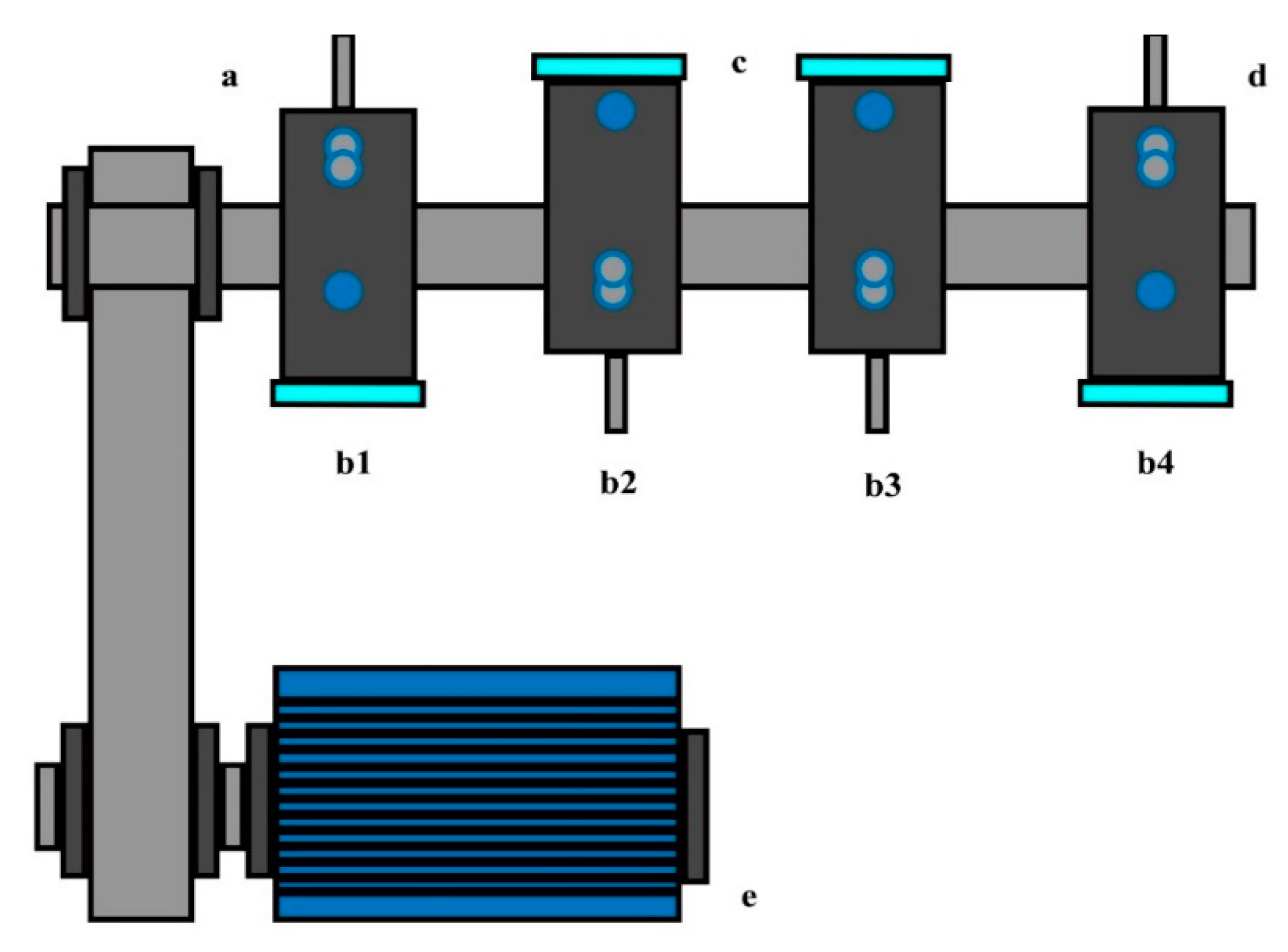

3.2. Paderborn University Bearing Dataset

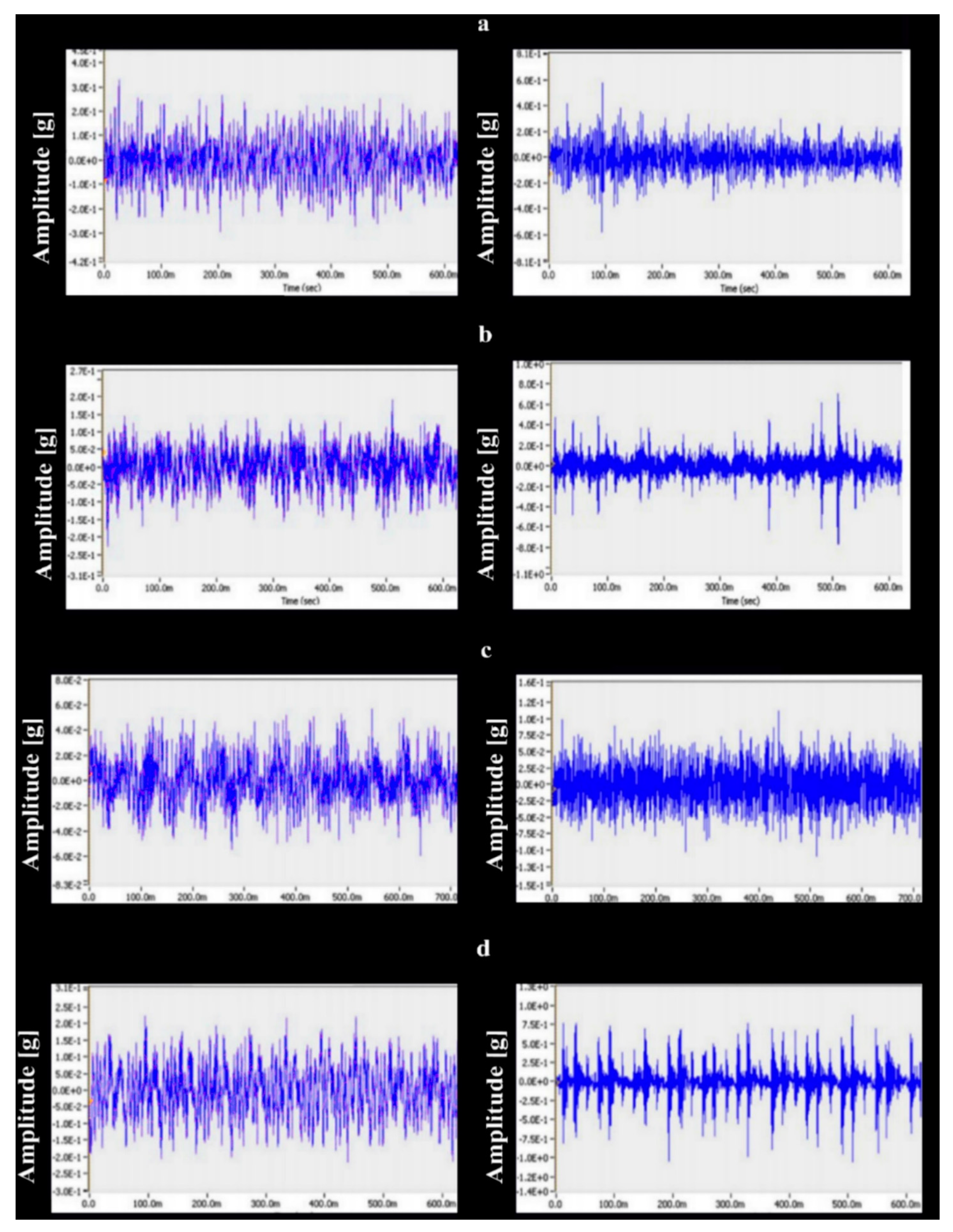

3.3. PRONOSTIA Dataset

3.4. IMS Dataset

3.5. Highlights of the Datasets

3.6. Effects of the Datasets

4. Shallow Learning for Bearing Fault Diagnosis

Classical ML Algorithms for Fault Bearing Diagnosis

5. Deep Learning Algorithms Used for Fault Bearing Diagnosis

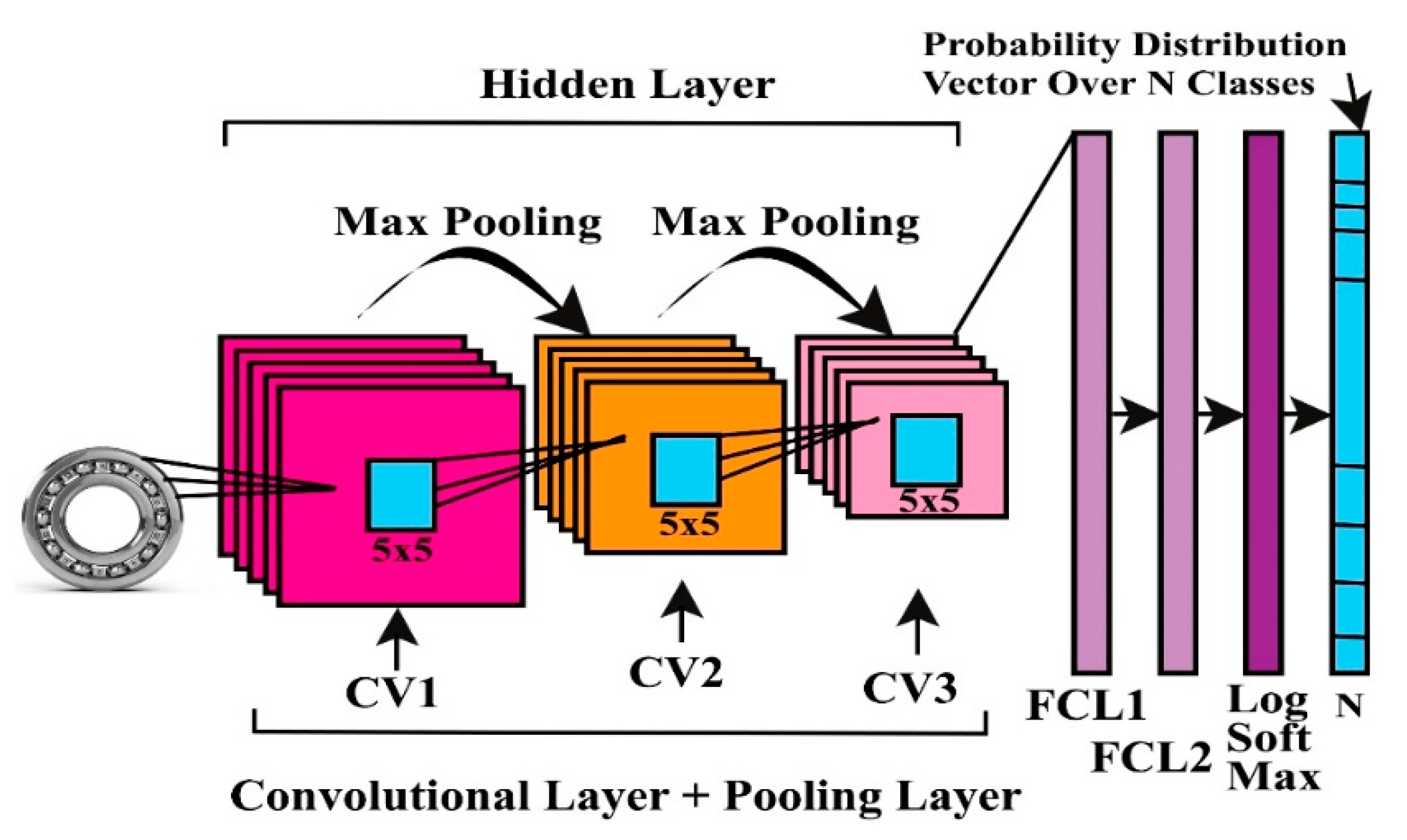

5.1. Convolutional Neural Network (CNN)-Based Bearing Fault Diagnosis

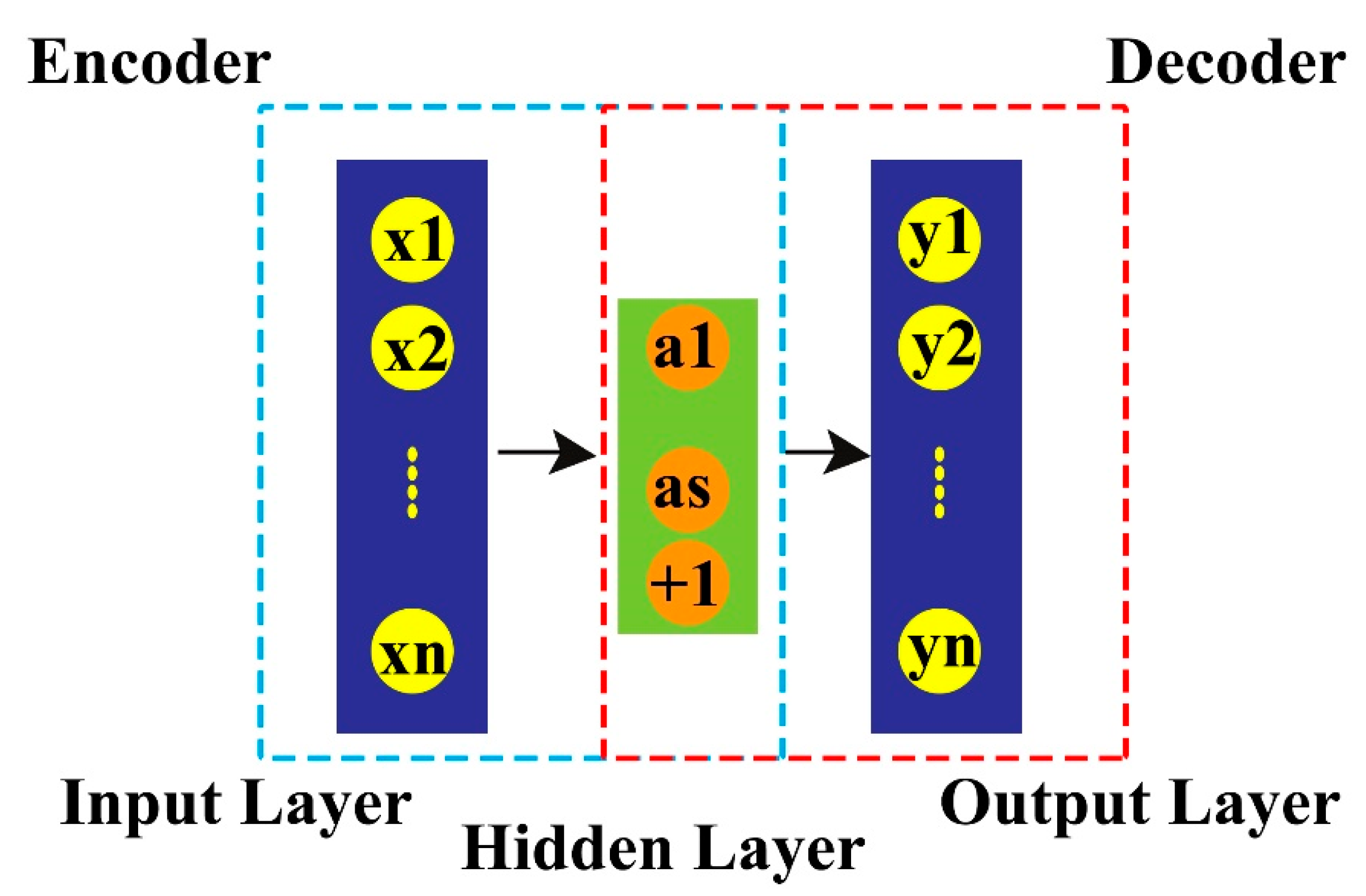

5.2. Auto-Encoders-Based Bearing Fault Diagnosis

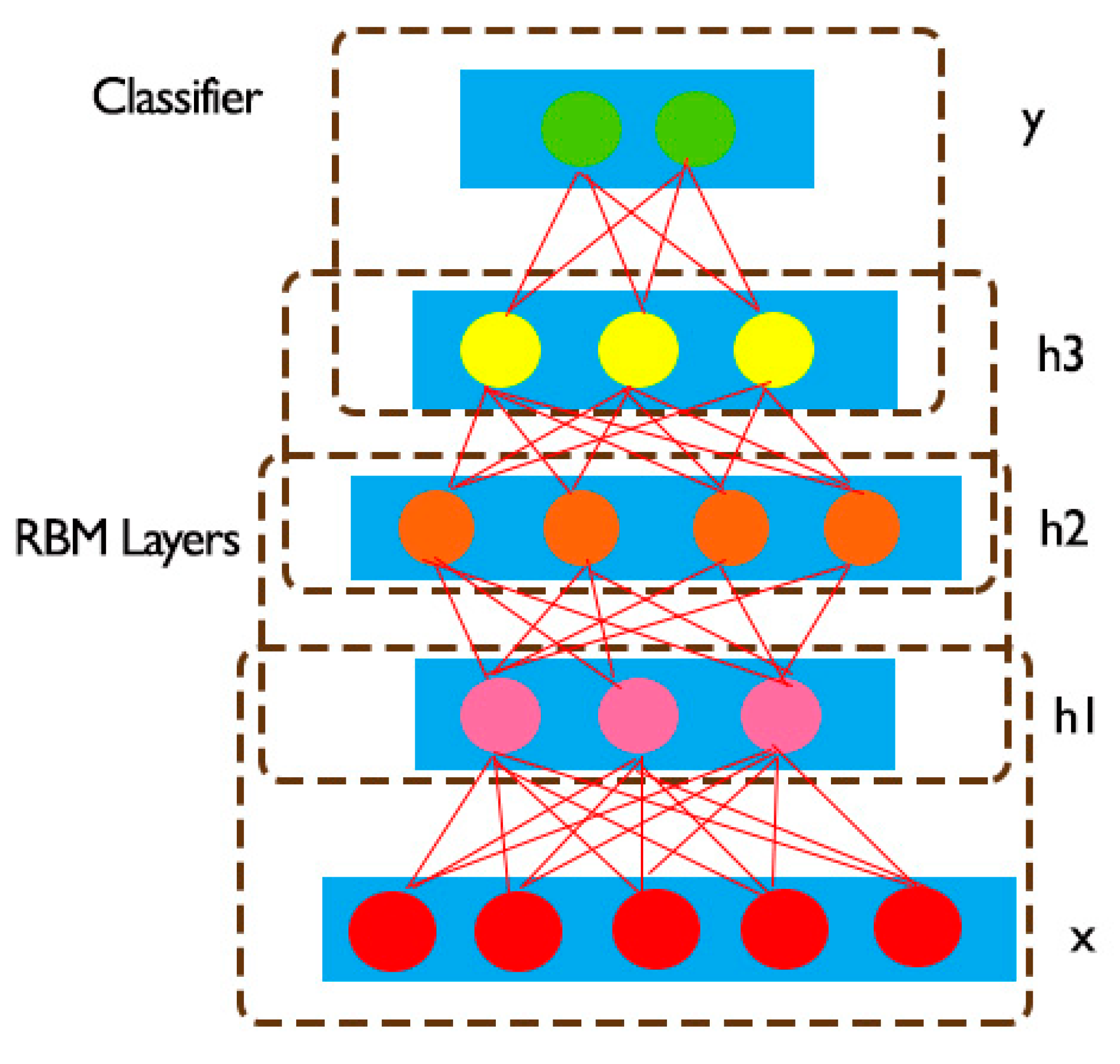

5.3. Deep Belief Network (DBN)-Based Methods for Bearing Fault Diagnosis

5.4. Recurrent Neural Network (RNN)-Based Methodologies

5.5. Other Methods

6. Discussion

6.1. Limitations

Classical Machine Learning

- Generalizability

- 2.

- Domain-Related Knowledge

- 3.

- Learning Ability, Reliability and Performance

- 4.

- Cross-Domain Analysis

6.2. Advantages and Disadvantages of Deep Learning

6.2.1. Advantages

- The automated learning of structures from new data is the main benefit of using a deep learning system. The hierarchical order of nonlinear transformations makes it simple to extrapolate information from coarse data without the requirement for feature extraction and selection.

- Because the overhead of feature engineering and selection is not required, developing condition monitoring, fault detection and diagnosis, and prognosis strategies for predictive maintenance is quite simple.

- Transfer learning is better served by deep learning algorithms. It paves the way for cross-domain data-driven predictive maintenance solutions to be developed.

- When compared to machine-learning-based predictive maintenance strategies, deep-learning-based predictive maintenance strategies have a higher generalization potential.

- The bigger the number of layers and neurons in a deep learning network, the more complicated the problems can be that are conceived, resulting in a performance improvement.

- The most appealing aspect of using deep learning in predictive maintenance is that these networks can automatically extract the relevant feature from data, obviating the need for manual feature engineering.

- When deep learning is up to date, it can predict failures and cover every new event or behavior.

6.2.2. Disadvantages

- To perform better than other strategies, it necessitates a big volume of data.

- Because of the complicated data models, training is exceedingly costly. Deep learning also necessitates the use of pricey GPUs and hundreds of workstations. The users’ costs will rise as a result of this.

- Because it necessitates knowledge of topology, the training method, and other characteristics, there is no standard theory to aid you in choosing the correct deep learning tools. As a result, it is difficult for less skilled people to adopt it.

- It is difficult to grasp output based just on learning, and therefore, this necessitates the use of classifiers. Such tasks are carried out using algorithms based on convolutional neural networks.

6.3. Comparison of Deep Learning Models

6.4. Future Perspectives of Deep Learning

6.4.1. Enhanced Generalization

6.4.2. Explain-Ability

6.4.3. Multimodal and Multisensor Data Fusion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

List of Symbols

| AE | Auto-encoder |

| AE-DNN | Auto-encoder Deep Neural Network |

| AFSA | Artificial Fish Swarm Algorithm |

| ANN | Artificial Neural Network |

| CNN | Convolutional Neural Network |

| DBN | Deep Belief Network |

| DCNN | Deep Convolutional Neural Network |

| DL | Deep Learning |

| DRN | Deep Residual Networks |

| DT-CWT | Dual tree- Complex Wavelet Transform |

| DWWC | Dynamical Weighted Wavelet Connected |

| DWT | Discrete Wavelet Transform |

| ELM | Extreme Learning Machine |

| FC | Fully Connected Layer |

| FFT | Fast Fourier Transform |

| FT | Fourier Transform |

| GA-PSO | Genetic Algorithms-Practical Swarm Optimization |

| ICA | Independent Component Analysis |

| IMS | Intelligent Maintenance System |

| KSVD | K means singular value decomposition |

| KNN | k-Nearest Neighbor |

| LAMSTAR | Large Memory Storage and Retrieval |

| LSTM | Long Short-Term Memory |

| ML | Machine Learning |

| PCA | Principal Component Analysis |

| PSD | Photoshop |

| RBM | Restricted Boltzmann Machine |

| REB’s | Rolling Elements Bearings |

| RNN | Recurrent Neural Network |

| RMS | Root Mean Square Value |

| RPM | Revolutions per minute |

| RTD | Resistance Temperature Detector |

| SDAE | Stacked Denoising Auto-encoder |

| STFT | Short -time Fourier Transform |

| S-Transform | Stock well Transform |

| SVM | Support Vector Machine |

| WPT | Wavelet Packet Transform |

| WTA | Winner Take All Auto-encoder |

References

- Saidur, R. A review on electrical motors energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 877–898. [Google Scholar] [CrossRef]

- Allied Market Research, Electric Motors Market Overview. Available online: https://www.alliedmarketresearch.com/electric-motor-market (accessed on 16 July 2021).

- Jian, Y.; Qing, X.; He, L.; Zhao, Y.; Qi, X.; Du, M. Fault diagnosis of motor bearing based on deep learning. Adv. Mech. Eng. 2019, 11, 1687814019875620. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Nandi, S.; Toliyat, H.A.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Case Western Reserve University (CWRU) Bearing Data Center. Available online: https://csegroups.case.edu/bearingdatacenter/pages/download-data-file (accessed on 16 July 2021).

- Lessmeier, C.; Kimotho, J.K.; Zimmer, D.; Sextro, W. KAt-DataCenter. Available online: https://mb.uni-paderborn.de/kat/forschung/datacenter/bearing-datacenter (accessed on 16 July 2021).

- Nectoux, P.; Gouriveau, R.; Medjaher, K.; Ramasso, E.; Chebel-Morello, B.; Noureddine Zerhouni, C.V. Pronostia: An experimental platform for bearings accelerated life test. In Proceedings of the IEEE Conference on Prognostics and Health Management, Denver, CO, USA, 18–21 June 2012; p. 18. [Google Scholar]

- Qiu, H.; Lee, J.; Lin, J. Wavelet Filter-based Weak Signature Detection Method and its Application on Roller Bearing Prognostics. J. Sound Vib. 2006, 289, 1066–1090. [Google Scholar] [CrossRef]

- Kankar, P.; Sharma, S.C.; Harsha, S. Fault diagnosis of ball bearings using machine learning methods. Expert Syst. Appl. 2011, 38, 1876–1886. [Google Scholar] [CrossRef]

- Qiu, H.; Lee, J.; Lin, J.; Yu, G. Robust performance degradation assessment methods for enhanced rolling element bearing prognostics. Adv. Eng. Inform. 2003, 17, 127–140. [Google Scholar] [CrossRef]

- Zhang, R.; Fang, Y.; Zhou, Z. Fault diagnosis of rolling bearing based on k-SVD dictionary learning algorithm and BP Neural Network. In Proceedings of the 2019 International Conference on Robotics, Intelligent Control and Artificial Intelligence, Shanghai, China, 20–22 September 2019. [Google Scholar]

- Khan, S.A.; Kim, J.M. Automated Bearing Fault Diagnosis Using 2D Analysis of Vibration Acceleration Signals under Variable Speed Conditions. Shock Vib. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Mehta, A.; Goyal, D.; Choudhary, A.; Pabla, B.S.; Belghith, S. Machine Learning-Based Fault Diagnosis of Self-Aligning Bearings for Rotating Machinery Using Infrared Thermograpgy. Math. Probl. Eng. 2021, 2021, 9947300. [Google Scholar] [CrossRef]

- Chen, Z. Bearing fault diagnosis with compressed data based on two-stage matching pursuit. In Proceedings of the 2017 Prognostics and System Health Management Conference, Harbin, China, 9–12 July 2017. [Google Scholar]

- Ding, X.; He, Q. Energy-Fluctuated Multiscale Feature Learning with Deep ConvNet for Intelligent Spindle Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Ding, Q. Deep residual learning-based fault diagnosis method for rotating machinery. ISA Trans. 2019, 95, 295–305. [Google Scholar] [CrossRef]

- Luo, P.; Hu, Y. Research on Rolling Bearing Fault Identification Method Based on LSTM Neural Network. In Proceedings of the 2018 the 6th International Conference on Mechanical Engineering, Materials Science and Civil Engineering, Xiamen, China, 21–22 December 2018. [Google Scholar]

- Wu, C.; Chen, T.; Jiang, R. Bearing fault diagnosis via kernel matrix construction based support vector machine. J. Vibroeng. 2017, 19, 3445–3461. [Google Scholar] [CrossRef] [Green Version]

- Tyagi, S.; Panigrahi, S.K. A DWT and SVM based method for rolling element bearing fault diagnosis and its comparison with Artificial Neural Networks. J. Appl. Comput. Mech. 2017, 3, 80–91. [Google Scholar] [CrossRef]

- Fernández-Francos, D.; Marténez-Rego, D.; Fontenla-Romero, O.; Alonso-Betanzos, A. Automatic bearing fault diagnosis based on one-class m-SVM. Comput. Ind. Eng. 2013, 64, 357–365. [Google Scholar] [CrossRef]

- Yadav, O.P.; Joshi, D.; Pahuja, G.L. Support Vector Machine based Bearing Fault Detection of Induction Motor. Indian J. Adv. Electron. Eng. 2013, 1, 34–39. [Google Scholar]

- Deng, W.; Li, X.; Zhao, H. Study on A Fault Diagnosis Method of Rolling Element Bearing Based on Improved ACO and SVM Model. Int. J. Future Gener. Commun. Netw. 2016, 9, 167–180. [Google Scholar] [CrossRef]

- Janssens, O.; Slavkovikj, V.; Vervisch, B.; Stockman, K.; Loccufier, M.; Verstockt, S.; van de Walle, R.; van Hoecke, S. Convolutional Neural Network Based Fault Detection for Rotating Machinery. J. Sound Vib. 2016, 377, 331–345. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Meas. J. Int. Meas. Confed. 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.; Zhou, B. Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv. Eng. Inform. 2017, 32, 139–151. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Zilong, Z.; Wei, Q. Intelligent fault diagnosis of rolling bearing using one-dimensional multi-scale deep convolutional neural network based health state classification. In Proceedings of the ICNSC 2018—15th IEEE International Conference on Networking, Sensing and Control, Zhuhai, China, 27–29 March 2018. [Google Scholar]

- Fuan, W.; Hongkai, J.; Haidong, S.; Wenjing, D.; Shuaipeng, W. An adaptive deep convolutional neural network for rolling bearing fault diagnosis. Meas. Sci. Technol. 2017, 28, 095005. [Google Scholar] [CrossRef]

- Ince, T.; Kiranyaz, S.; Eren, L.; Askar, M.; Gabbouj, M. Real-Time Motor Fault Detection by 1-D Convolutional Neural Networks. IEEE Trans. Ind. Electron. 2016, 63, 7067–7075. [Google Scholar] [CrossRef]

- Eren, L. Bearing fault detection by one-dimensional convolutional neural networks. Math. Probl. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wen, L.; Gao, L.; Li, X.; Wang, L.; Zhu, J. A Jointed Signal Analysis and Convolutional Neural Network Method for Fault Diagnosis. Procedia CIRP 2018, 72, 1084–1087. [Google Scholar] [CrossRef]

- Zhuang, Z.; Lv, H.; Xu, J.; Huang, Z.; Qin, W. A deep learning method for bearing fault diagnosis through stacked residual dilated convolutions. Appl. Sci. 2019, 9, 1823. [Google Scholar] [CrossRef] [Green Version]

- Sohaib, M.; Kim, J.-M. Fault diagnosis of rotary machine bearings under inconsistent working conditions. IEEE Trans. Instrum. Meas. 2019, 69, 3334–3347. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y.; Zhang, Z. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load. Mech. Syst. Signal Process. 2018, 100, 439–453. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network-Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Oh, J.W.; Jeong, J. Convolutional neural network and 2-D image based fault diagnosis of bearing without retraining. In Proceedings of the 2019 the 3rd International Conference on Compute and Data Analysis, Kahului, HI, USA, 14–17 March 2019. [Google Scholar]

- Zhao, C.; Sun, J.; Lin, S.; Peng, Y. Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset. Sensors 2021, 21, 5494. [Google Scholar] [CrossRef]

- Hao, S.; Ge, F.X.; Li, Y.; Jiang, J. Multisensor bearing fault diagnosis based on one-dimensional convolutional long short-term memory networks. Meas. J. Int. Meas. Confed. 2020, 159, 107802. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep Learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ballard, D.H. Modular Learning in Neural Networks. AAAI 1987, 647, 279–284. [Google Scholar]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72–73, 303–315. [Google Scholar] [CrossRef]

- Wang, F.; Dun, B.; Deng, G.; Li, H.; Han, Q. A deep neural network based on kernel function and auto-encoder for bearing fault diagnosis. In Proceedings of the I2MTC 2018—2018 IEEE International Instrumentation and Measurement Technology Conference: Discovering New Horizons in Instrumentation and Measurement, Houston, TX, USA, 14–17 May 2018. [Google Scholar]

- Islam, M.M.M.; Kim, J.-M. Automated bearing fault diagnosis scheme using 2D representation of wavelet packet transform and deep convolutional neural network. Comput. Ind. 2019, 106, 142–153. [Google Scholar] [CrossRef]

- Mao, W.; He, J.; Li, Y.; Yan, Y. Bearing fault diagnosis with auto-encoder extreme learning machine: A comparative study. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 1560–1578. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.Y.; Qin, W.L.; Ma, J. Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Signal Process 2017, 130, 377–388. [Google Scholar] [CrossRef]

- Guo, X.; Shen, C.; Chen, L. Deep fault recognizer: An integrated model to denoise and extract features for fault diagnosis in rotating machinery. Appl. Sci. 2017, 7, 41. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhao, H.; Wang, F. A novel deep autoencoder feature learning method for rotating machinery fault diagnosis. Mech. Syst. Signal Process 2017, 95, 187–204. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W. Multisensor feature fusion for bearing fault diagnosis using sparse autoencoder and deep belief network. IEEE Trans. Instrum. Meas. 2017, 66, 1693–1702. [Google Scholar] [CrossRef]

- Verma, N.K.; Gupta, V.K.; Sharma, M.; Sevakula, R.K. Intelligent condition based monitoring of rotating machines using sparse auto-encoders. In Proceedings of the PHM 2013—2013 IEEE International Conference on Prognostics and Health Management, Gaithersburg, MD, USA, 24–27 June 2013. [Google Scholar]

- Li, C.; Zhang, W.; Peng, G.; Liu, S. Bearing Fault Diagnosis Using Fully-Connected Winner-Take-All Autoencoder. IEEE Access 2017, 6, 6103–6115. [Google Scholar] [CrossRef]

- Fischer, A.; Igel, C. An introduction to restricted Boltzmann machines. In Iberoamerican Congress on Pattern Recognition; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Sohaib, M.; Kim, C.-H.; Kim, J.-M. A hybrid feature model and deep-learning-based bearing fault diagnosis. Sensors 2017, 17, 2876. [Google Scholar] [CrossRef] [Green Version]

- Shen, C.; Xie, J.; Wang, D.; Jiang, X.; Shi, J.; Zhu, Z. Improved hierarchical adaptive deep belief network for bearing fault diagnosis. Appl. Sci. 2019, 9, 3374. [Google Scholar] [CrossRef] [Green Version]

- Tao, J.; Liu, Y.; Yang, D. Bearing Fault Diagnosis Based on Deep Belief Network and Multisensor Information Fusion. Shock Vib. 2016, 2016, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Lin, T.R.; Tan, J. A bearing fault and severity diagnostic technique using adaptive deep belief networks and Dempster–Shafer theory. Struct. Health Monit. 2020, 19, 240–261. [Google Scholar] [CrossRef]

- Liang, T.; Wu, S.; Duan, W.; Zhang, R. Bearing fault diagnosis based on improved ensemble learning and deep belief network. J. Phys. Conf. Ser. 2018, 1074, 012154. [Google Scholar] [CrossRef]

- Gan, M.; Wang, C.; Zhu, C. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Process. 2016, 72–73, 92–104. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Wang, F.; Wang, Y. Rolling bearing fault diagnosis using adaptive deep belief network with dual-tree complex wavelet packet. ISA Trans. 2017, 69, 187–201. [Google Scholar] [CrossRef]

- Li, M.; Wei, Q.; Wang, H.; Zhang, X. Research on fault diagnosis of time-domain vibration signal based on convolutional neural networks. Syst. Sci. Control Eng. 2019, 7, 73–81. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.; Huang, M.; Lu, Q.; Zhong, M. Rotating Machinery Fault Diagnosis Using Long-short-term Memory Recurrent Neural Network. IFAC-PapersOnLine 2018, 51, 228–232. [Google Scholar] [CrossRef]

- Abed, W.; Sharma, S.; Sutton, R.; Motwani, A. A Robust Bearing Fault Detection and Diagnosis Technique for Brushless DC Motors Under Non-stationary Operating Conditions. J. Control. Autom. Electr. Syst. 2015, 26, 241–254. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Ouyang, M.; Yong, C.; Chen, D.; Guo, J.; Zhou, Y. A novel intelligent fault diagnosis method for rolling bearing based on integrated weight strategy features learning. Sensors 2020, 20, 1774. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, M.; Kang, M.; Tang, B.; Pecht, M. Multiple Wavelet Coefficients Fusion in Deep Residual Networks for Fault Diagnosis. IEEE Trans. Ind. Electron. 2019, 66, 4696–4706. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Ma, J. Rolling Bearing Fault Diagnosis Based on STFT-Deep Learning and Sound Signals. Shock Vib. 2016, 2016, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Deng, S.; Chen, X.; Li, C.; Sanchez, R.V.; Qin, H. Deep neural networks-based rolling bearing fault diagnosis. Microelectron. Reliab. 2017, 75, 327–333. [Google Scholar] [CrossRef]

- Zhao, M.; Kang, M.; Tang, B.; Pecht, M. Deep Residual Networks with Dynamically Weighted Wavelet Coefficients for Fault Diagnosis of Planetary Gearboxes. IEEE Trans. Ind. Electron. 2018, 65, 4290–4300. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Lv, F.; Wen, C.; Bao, Z.; Liu, M. Fault diagnosis based on deep learning. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016. [Google Scholar] [CrossRef]

- Hasan, M.J.; Sohaib, M.; Kim, J.M. 1D CNN-based transfer learning model for bearing fault diagnosis under variable working conditions. In International Conference on Computational Intelligence in Information System; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

| SL | Dataset | Total Sensors | Sensors Type | Sample Frequency |

|---|---|---|---|---|

| 1 | Case Western Reserve University | 2 | Accelerometer | 12 and 48 kHz |

| 2 | Paderborn University Dataset | 1/2/1 | Accelerometer, Current sensor, and thermocouple | 64 kHz |

| 3 | PRONOSTIA Dataset | 2/1 | Accelerometer and thermocouple | 25.6 kHz |

| 4 | Intelligent Maintenance Systems Dataset | 2 | Accelerometer | 20 Hz |

| S. NO. | Parameters |

|---|---|

| 1 | Bearing specification (brand/model) |

| 2 | Outer race diameter |

| 3 | Inner race diameter |

| 4 | Ball diameter |

| 5 | Ball number |

| 6 | Contact angle |

| 7 | Clearance |

| 8 | Noise |

| 9 | Phase angle |

| 10 | Change in amplitude |

| 11 | Change in sampling frequency |

| Author | Year | Learning Method | Average Accuracy | Data Set |

|---|---|---|---|---|

| R. Zhang et al. [12] | 2019 | KSVD | 70% | ABLT—a bearing life enhancement test bench |

| Khan and Kim [13] | 2016 | ANN-LBP histogram | 100% | CRWU |

| Ankush Mehta et al. [14] | 2021 | KNN-SVM-LDA | 90% | Experimental Setup |

| Zihan Chen. [15] | 2017 | 2-stage matching pursuit | 99.69% | CWRU |

| Ding and He. [16] | 2017 | EFMF-ConvNet | 98.8% | CWRU |

| W. Zhang et al. [17] | 2018 | Residual learning algorithm | 99.99% | CWRU |

| Luo and Hu [18] | 2019 | LSTM-NN | 98% | CWRU |

| Wu et al. [19] | 2017 | KMCSVM | 99.1% | CWRU |

| Tyagi and Panigrahi [20] | 2017 | ANN-SVM | 97.9% | Experimental Setup |

| Fernández-Francos et al. [21] | 2013 | SVM | 99% 100% | ISM and CWRU |

| Yadav et al. [22] | 2013 | LS-SVM | 87% | 3-Phase Squirrel cage induction |

| Deng et al. [23] | 2016 | IMASFD | 97.67% | CWRU |

| Refs. | Year | Learning Method | Average Accuracy | Dataset |

|---|---|---|---|---|

| Guo et al. [25] | 2016 | ADCNN | 99.3% | CWRU |

| Lu et al. [26] | 2017 | CNN | 90% | QPZ-II |

| Xia et al. [27] | 2017 | CNN | 99.89% | CWRU |

| Zilong and Wei [28] | 2018 | MS-DCNN | 99.27% | CWRU |

| Fuan et al. [29] | 2017 | DCNN | 100% | CWRU |

| Ince et al. [30] | 2016 | 1D-CNN | 97.4% | Real-time motor data |

| Eren et al. [31] | 2017 | 1D-CNN | 97% | IMS |

| Wen, Gao et al. [32] | 2018 | JCNN | 99.94% | CWRU |

| Zhuang et al. [33] | 2019 | SRDCNN | 95% | CWRU |

| Sohaib and Kim [34] | 2019 | CNN | 90% | CWRU |

| W. Zhang et al. [35] | 2018 | TICNN | 95.5% | CRWU |

| Wen et al. [36] | 2017 | LeNet-5 CNN | 99.79% | Famous motor bearing dataset |

| 99.481% | Self-priming centrifugal pump dataset | |||

| 100% | Axial piston hydraulic pump dataset | |||

| Oh and Jeong [37] | 2019 | SRDCNN | 95% | CWRU |

| Hasan et al. [38] | 2019 | CNN | 90% | CWRU |

| Hao et al. [39] | 2018 | TICNN | 95.5% | CRWU |

| Refs. | Year | Learning Method | Average Accuracy | Dataset |

|---|---|---|---|---|

| Feng Jia et al. [42] | 2016 | DNN-AE | 99.6% | Rolling element bearing and Planetary Gearbox |

| Wang et al. [43] | 2018 | DNN-Gaussian radial basis kernel function and AE | 86.75% | The aeroengine of aircraft |

| Sohaib et al. [44] | 2017 | SSAE-DNN | 99.1% | CWRU |

| Mao et al. [45] | 2017 | AE-ELM | 100% | CWRU |

| Lu et al. [46] | 2017 | SDA | 84.01% | CWRU |

| Guo et al. [47] | 2017 | SDAE | 100% | CWRU |

| Shao et al. [48] | 2017 | AFSA-SDAE | 87.8% | Gearbox Electrical Locomotive roller bearing |

| Zhuyun Chen et al. [49] | 2017 | SAE-DBN | 91.76% | Rolling element bearing |

| Verma et al. [50] | 2013 | SAE | 97.22% | Air compressor |

| Chuanhao Li et al. [51] | 2017 | FC-WTA-AE | 98.47% | CWRU |

| Fischer and Igel [52] | 2017 | LAMSTAR | 96% | Bearing seeded |

| Refs. | Year | Learning Method | Average Accuracy | Dataset |

|---|---|---|---|---|

| Shen et al. [54] | 2019 | HA-DBN | 99.96% | Bearing Test rig |

| Tao et al. [55] | 2016 | DBN | 94.73% | QPZ-II |

| Yu et al. [56] | 2020 | DBN-DS | 99.69% | Qingdao University of Technology Bearing Fault Test rig |

| Liang et al. [57] | 2018 | DBN | 84.2% | CWRU |

| Gan et al. [58] | 2016 | HDN-DBN | 99.78% | CWRU |

| Shao et al. [59] | 2017 | Adaptive-DBN | 96.89% | CWRU |

| Refs. | Year | Learning Method | Average Accuracy | Data Set |

|---|---|---|---|---|

| M. Li et al. [60] | 2019 | RNN-LSTM | 98% | CWRU |

| Yang et al. [61] | 2018 | LSTM-RNN | 99.9% | Wind Turbine Driven Train Diagnostic Simulator |

| Abed et al. [62] | 2019 | RNN | 97% | Experimental Setup |

| Refs. | Year | Learning Method | Average Accuracy | Data Set |

|---|---|---|---|---|

| J. He et al. [63] | 2020 | ESSAE | 99.71% | CWRU |

| M. Zhao et al. [64] | 2019 | Multiple Wavelet Coefficients Fusion and deep residual network | 96.29% | The rolling bearing test stand |

| Liu et al. [65] | 2018 | STFT-DL and Sound Signals | 99.82 | CWRU |

| Zhiqiang Chen et al. [66] | 2017 | DBM-DBN-Stack Auto-encoder | 99% | Experimental Setup fabricated by Universidad Politecnia Salesiana Ecuador |

| M. Zhao et al. [67] | 2018 | DRN-DWWC | 99.60% | Planetary Gearbox |

| SL# | Model | Description | Pros | Cons |

|---|---|---|---|---|

| 1 | Deep Neural Network (DNN) | More than two layers are present. This allows for sophisticated non-linear relationships to be created. It is utilized for both classification and regression. | It is frequently utilized and has a high level of accuracy. | Because the error is propagated back to the previous one layer, the training process is not straightforward. The model’s learning process is likewise far too slow. |

| 2 | Convolutional Neural Network (CNN) | With two-dimensional data, this network performs well. It is made up of convolutional filters that turn two-dimensional data into three-dimensional data. | Very good performance, and the model learns quickly. | For categorization, it requires a large amount of labeled data. |

| 3 | Recurrent Neural Network (RNN) | It has the ability to learn and remember sequences. All of the weights are shared throughout all of the stages and neurons. | LSTM, BLSTM, MDLSTM, and HLSTM are some of the versions that can learn sequential events and reflect time dependencies. These provide cutting-edge accuracy in speech recognition, character recognition, and a number of other natural language processing applications. | Due of gradient vanishing and the necessity for large datasets, there are numerous difficulties. |

| 4 | Deep Belief Network (DBN) | DBNs are probabilistic generative models that give a combined probability distribution across observable data and labels. | It addresses the problem of parameter selection, which can lead to poor local optima in some circumstances, and ensures that the network is properly established. Because the procedure is unsupervised, no tagged data are required. However, DBNs have a number of flaws, such as the high computational cost of training a DBN and the lack of clarity surrounding the processes for further network optimization based on maximum likelihood training approximation. | They do not account for the two-dimensional structure of an input image, which may significantly affect their performance and applicability in computer vision and multimedia analysis problems. |

| 5 | Auto-Encoders | Auto-encoders are a type of unsupervised learning technology in which neural networks are used to learn representations. We will create a neural network architecture in such a way that we force a compressed knowledge representation of the original input due to a bottleneck in the network. | They are particularly useful in feature extraction, since they can represent data as nonlinear representations. | An auto-encoder must be trained. Before you even start developing the real model, that is a lot of data, processing time, hyper parameter adjustment, and model validation. Instead of capturing as much information as possible, an auto-encoder learns to capture as much relevant information as feasible. |

| 6 | Deep Boltzmann Machine (DBMs) | The DBM has entirely undirected connections, whereas the top two layers constitute an undirected graphical model and the lower layers form a directed generative model. Units in odd-numbered levels are conditionally independent on units in even-numbered layers, and vice versa, in DBMs with several layers of hidden units. | They can capture multiple layers of complicated input data representations and are suitable for unsupervised learning, since they can be trained on unlabeled data, but they can also be fine-tuned for a specific job in a supervised manner. | One of the most significant is the high computing cost of inference, which makes collaborative optimization on large datasets nearly impossible. Several strategies for improving the effectiveness of DBMs have been presented. These include employing distinct models to initialize the values of the hidden units in all layers to speed up inference. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mushtaq, S.; Islam, M.M.M.; Sohaib, M. Deep Learning Aided Data-Driven Fault Diagnosis of Rotatory Machine: A Comprehensive Review. Energies 2021, 14, 5150. https://doi.org/10.3390/en14165150

Mushtaq S, Islam MMM, Sohaib M. Deep Learning Aided Data-Driven Fault Diagnosis of Rotatory Machine: A Comprehensive Review. Energies. 2021; 14(16):5150. https://doi.org/10.3390/en14165150

Chicago/Turabian StyleMushtaq, Shiza, M. M. Manjurul Islam, and Muhammad Sohaib. 2021. "Deep Learning Aided Data-Driven Fault Diagnosis of Rotatory Machine: A Comprehensive Review" Energies 14, no. 16: 5150. https://doi.org/10.3390/en14165150

APA StyleMushtaq, S., Islam, M. M. M., & Sohaib, M. (2021). Deep Learning Aided Data-Driven Fault Diagnosis of Rotatory Machine: A Comprehensive Review. Energies, 14(16), 5150. https://doi.org/10.3390/en14165150