Performance Evaluation of a Stator Modular Ring Generator for a Shrouded Wind Turbine

Abstract

:1. Introduction

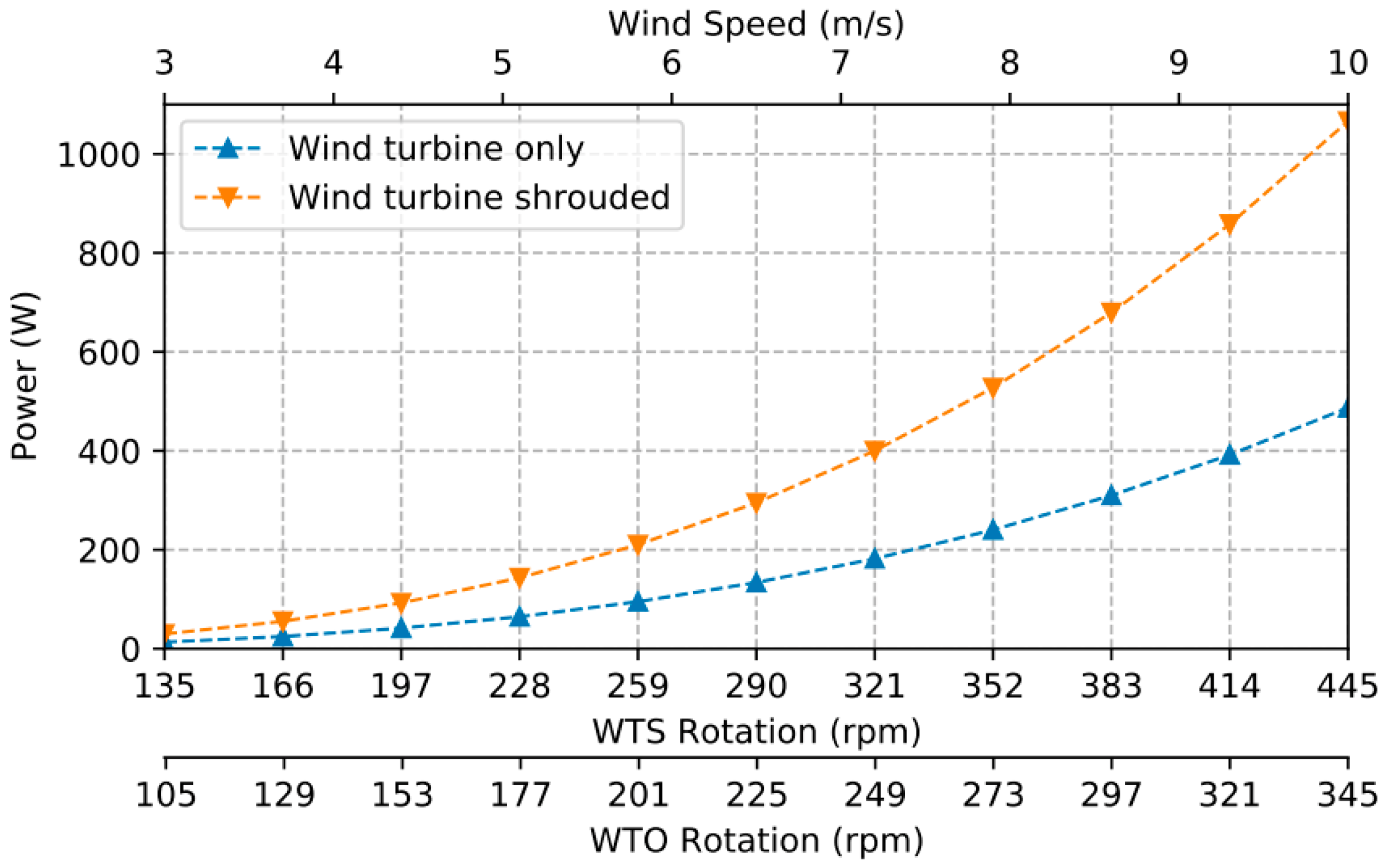

2. Methodology

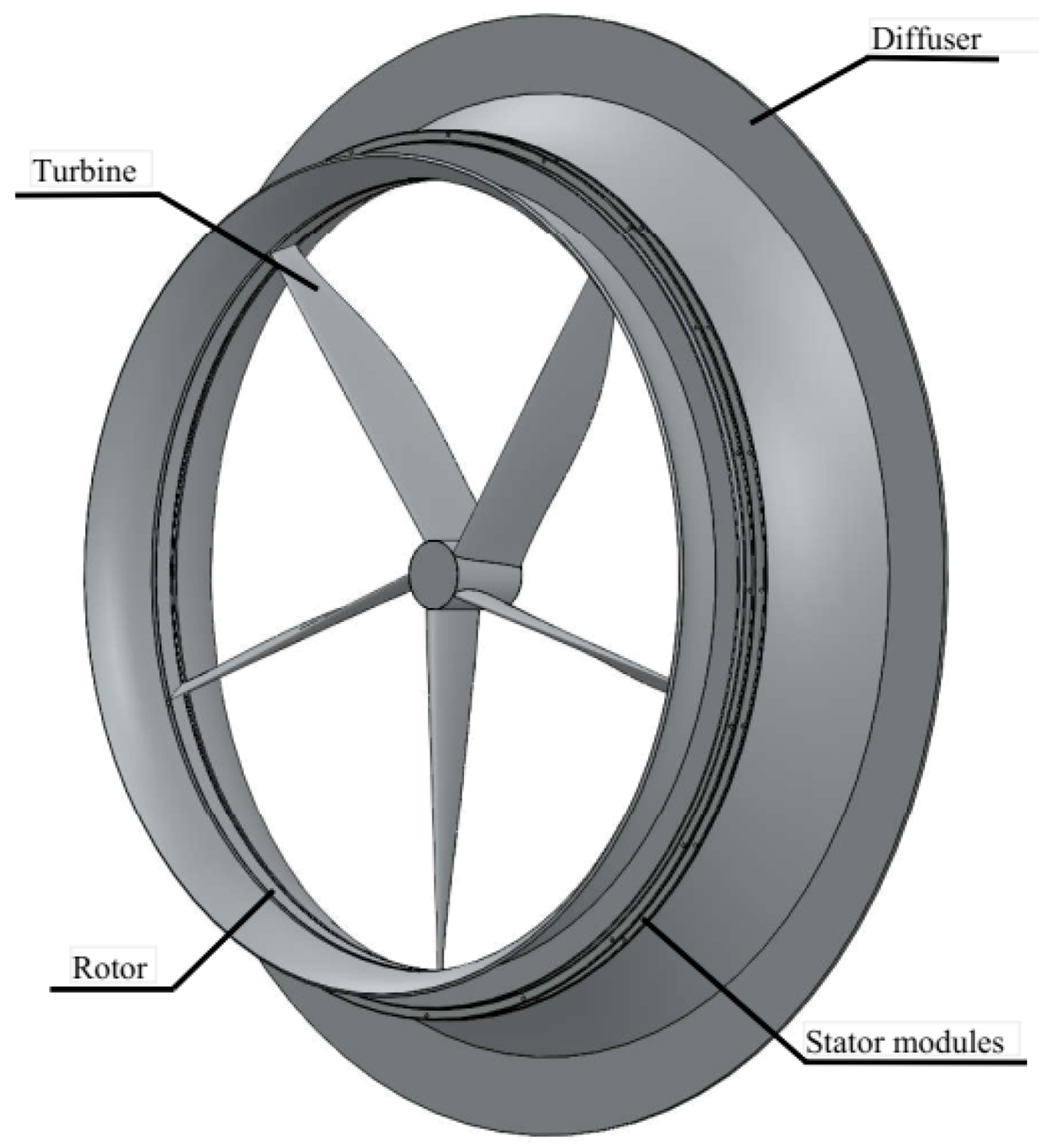

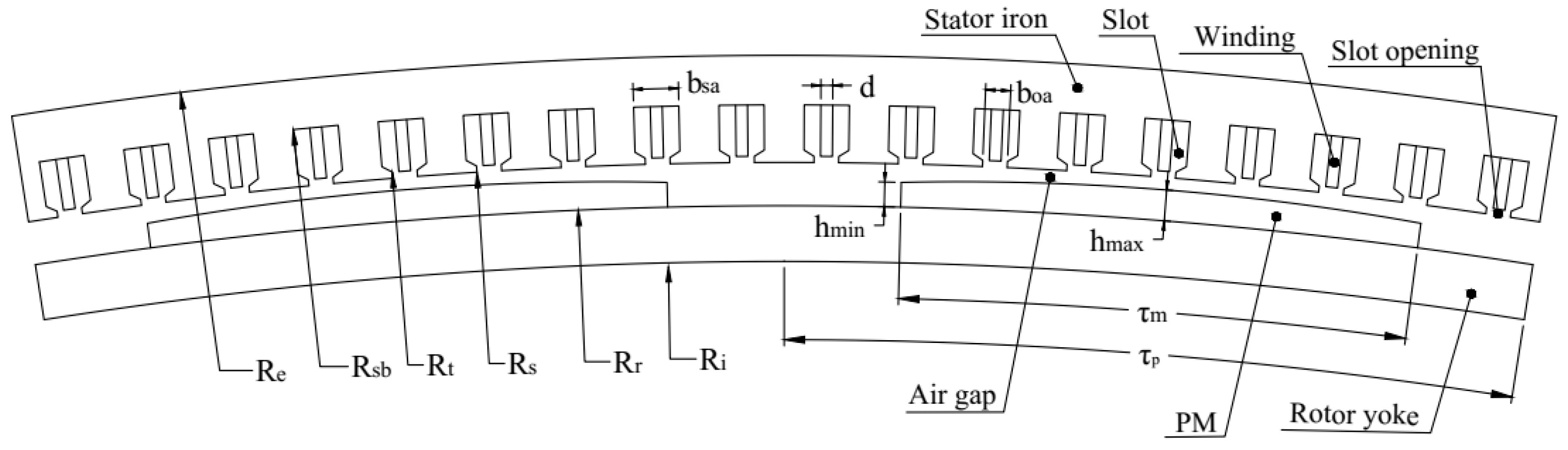

2.1. Stator Modular Ring Generator Model

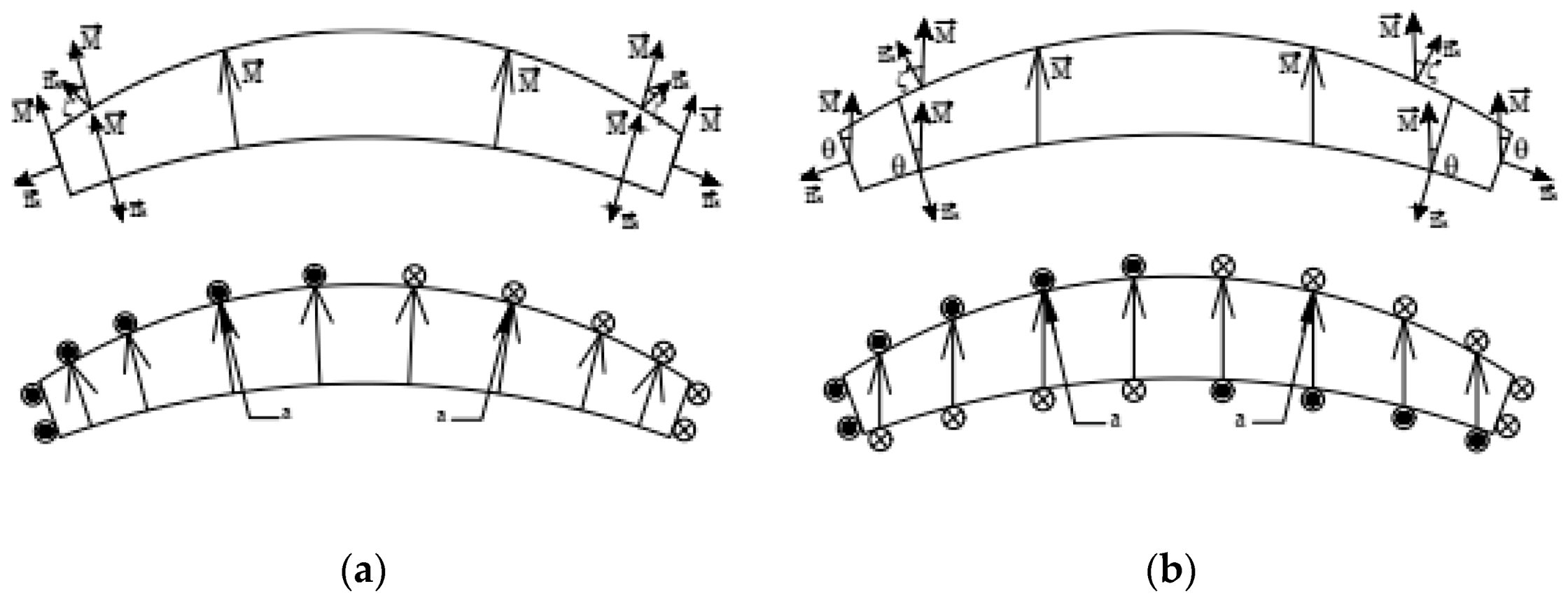

2.2. Analytical Model

- infinite permeable iron materials.

- nonconductive stator/rotor laminations.

- negligible end effect.

- uniform distributed current density in conductor area.

- relative permeability of the permanent magnets equals 1.

- opening slot and slots have radial sides.

2.3. FEM Simulation

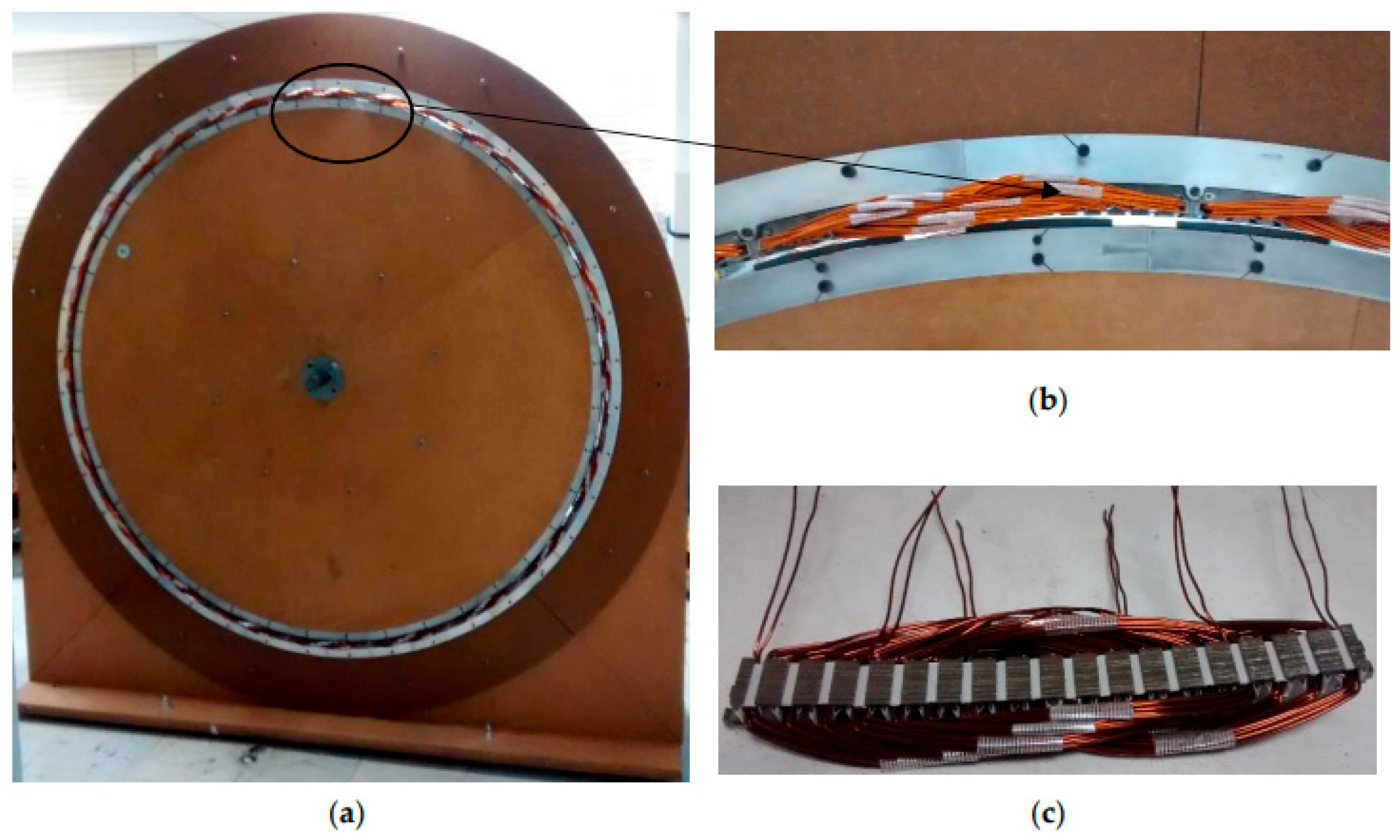

2.4. Prototype Structure

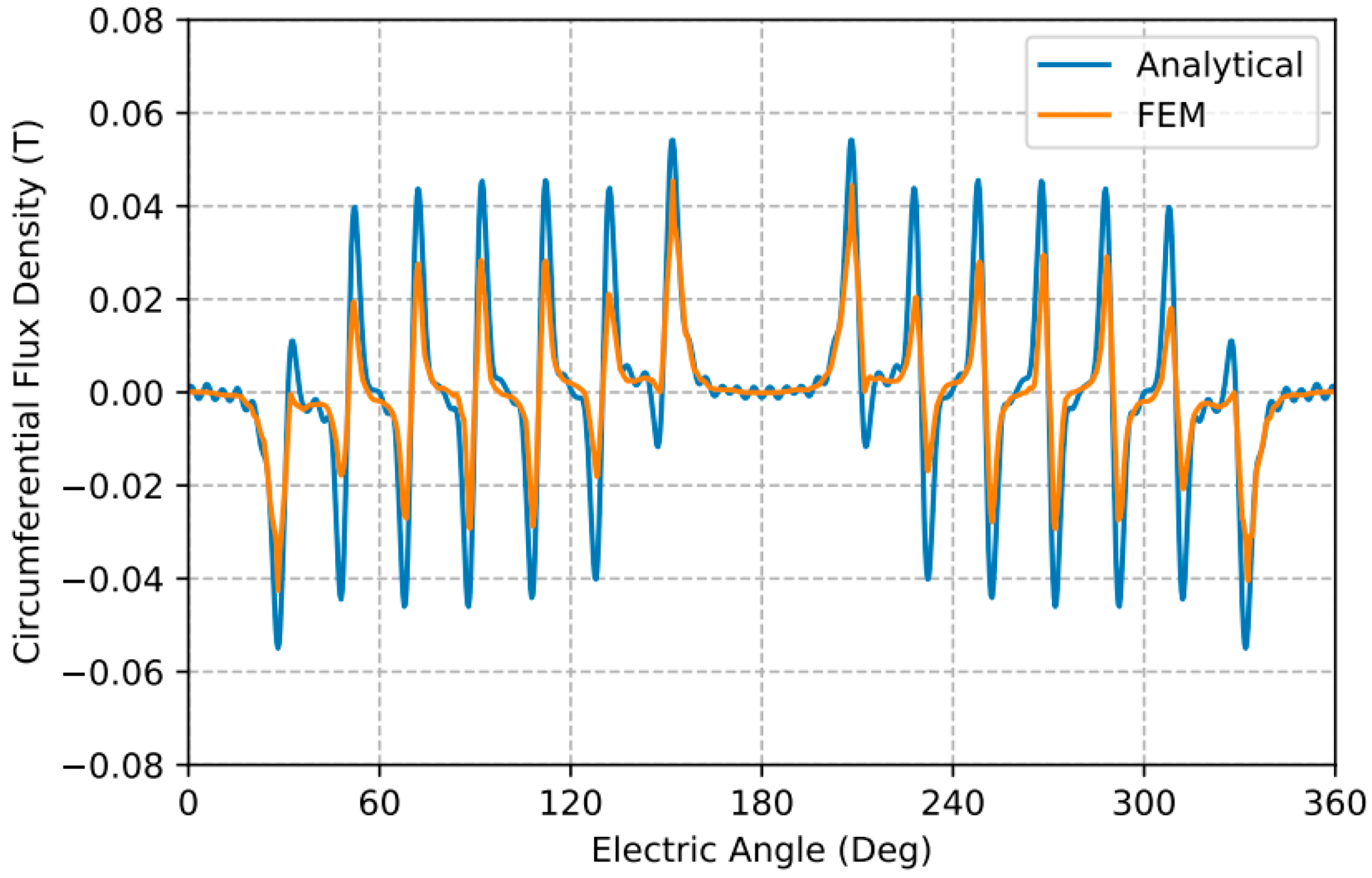

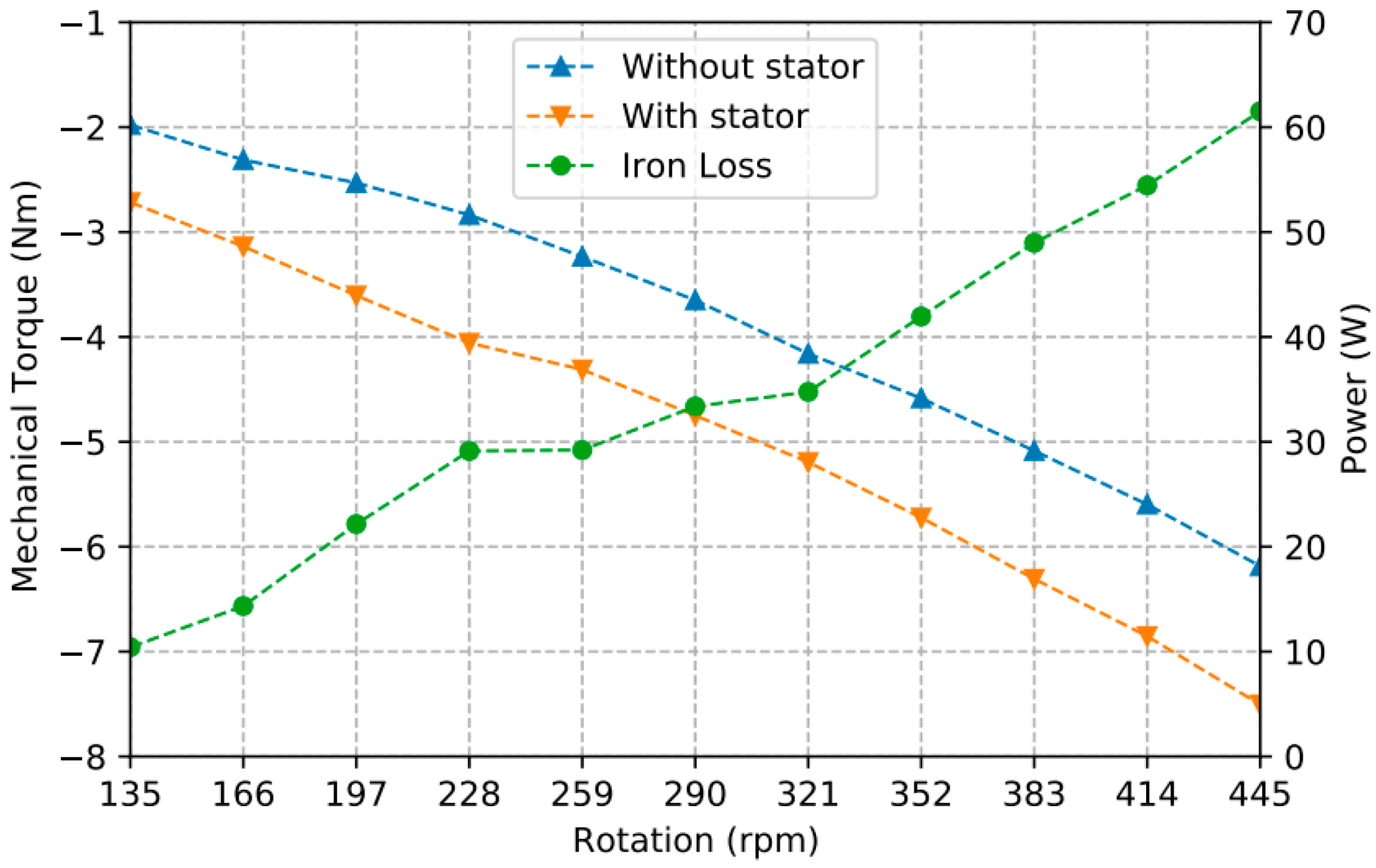

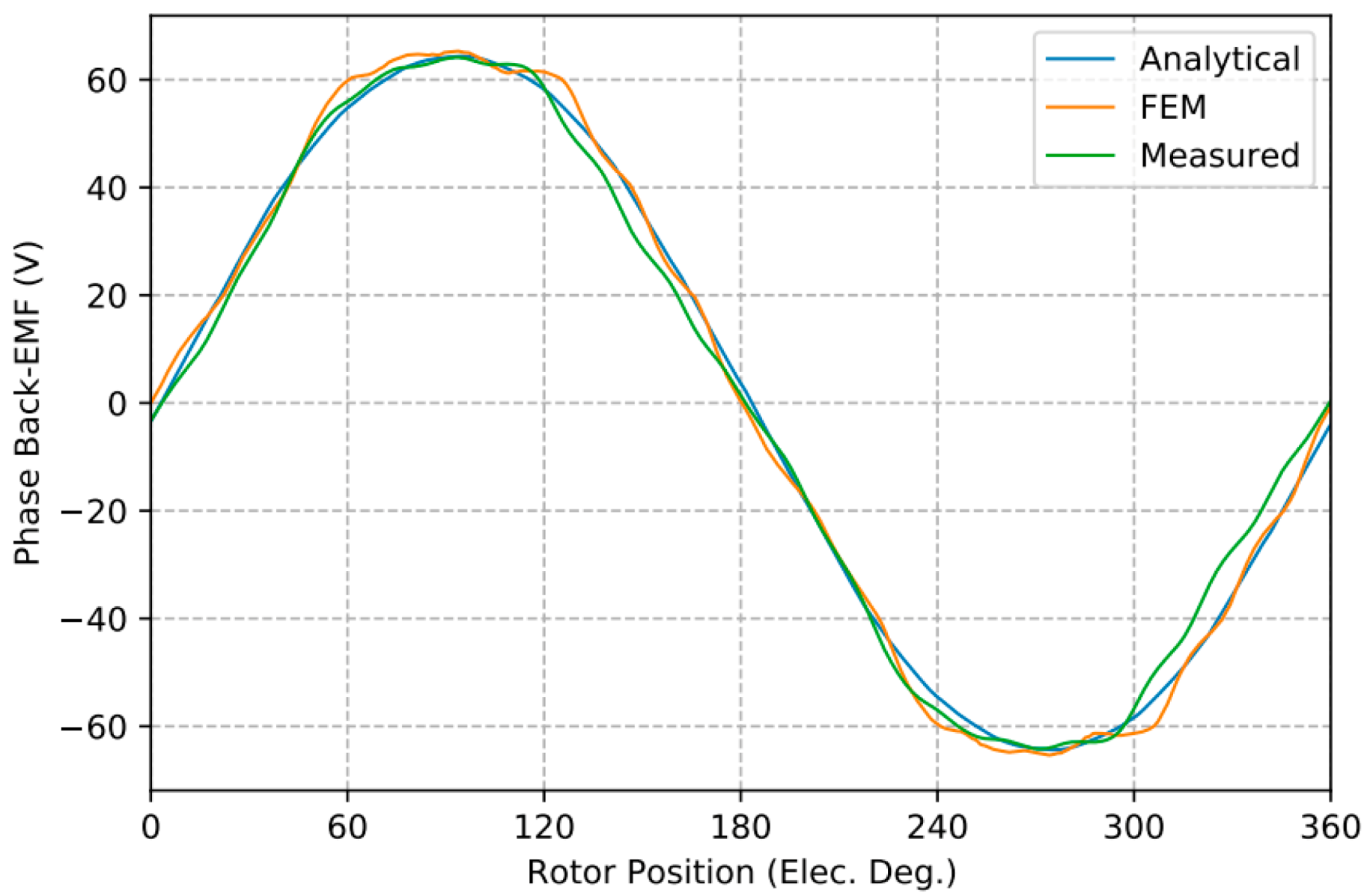

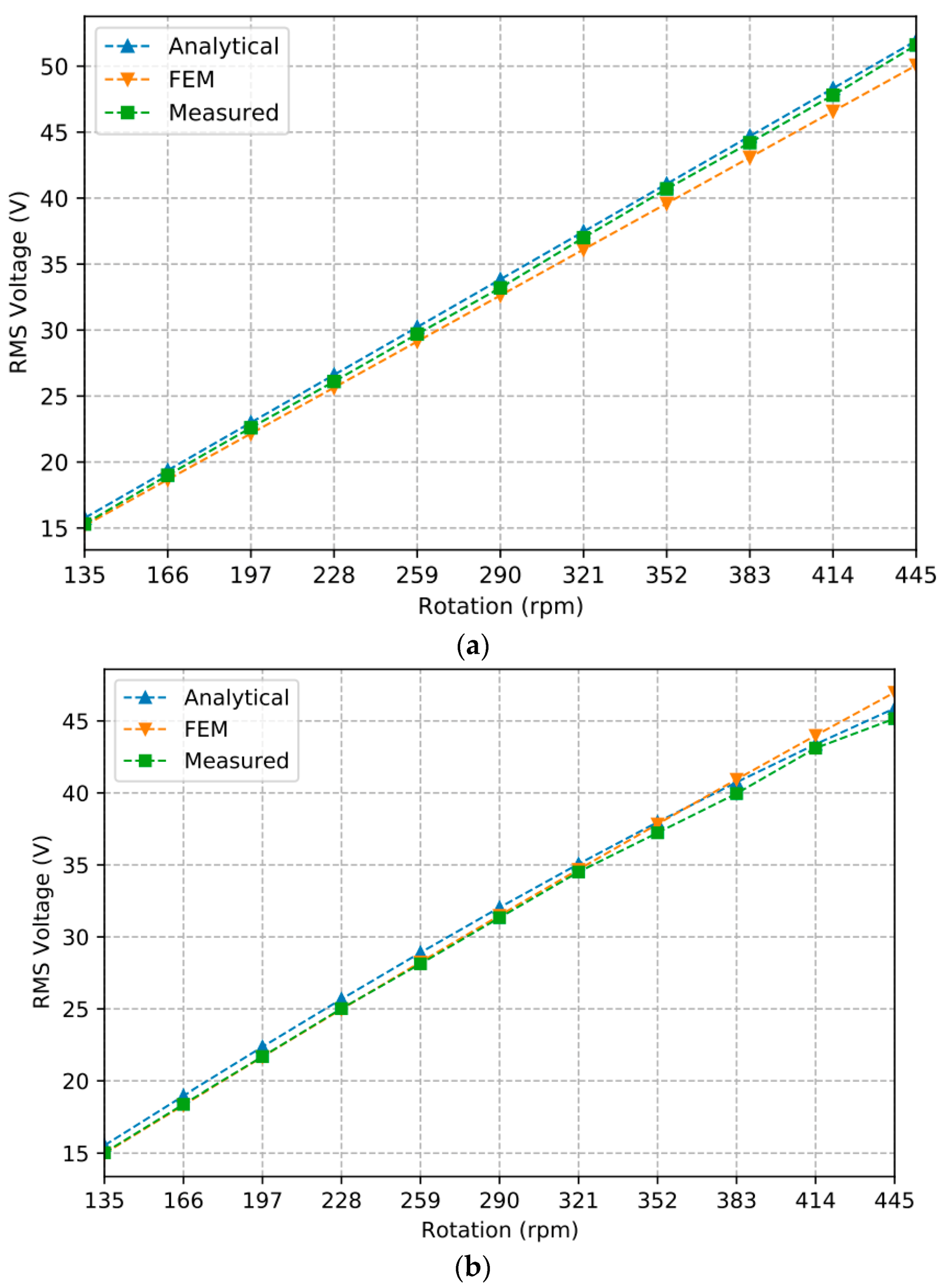

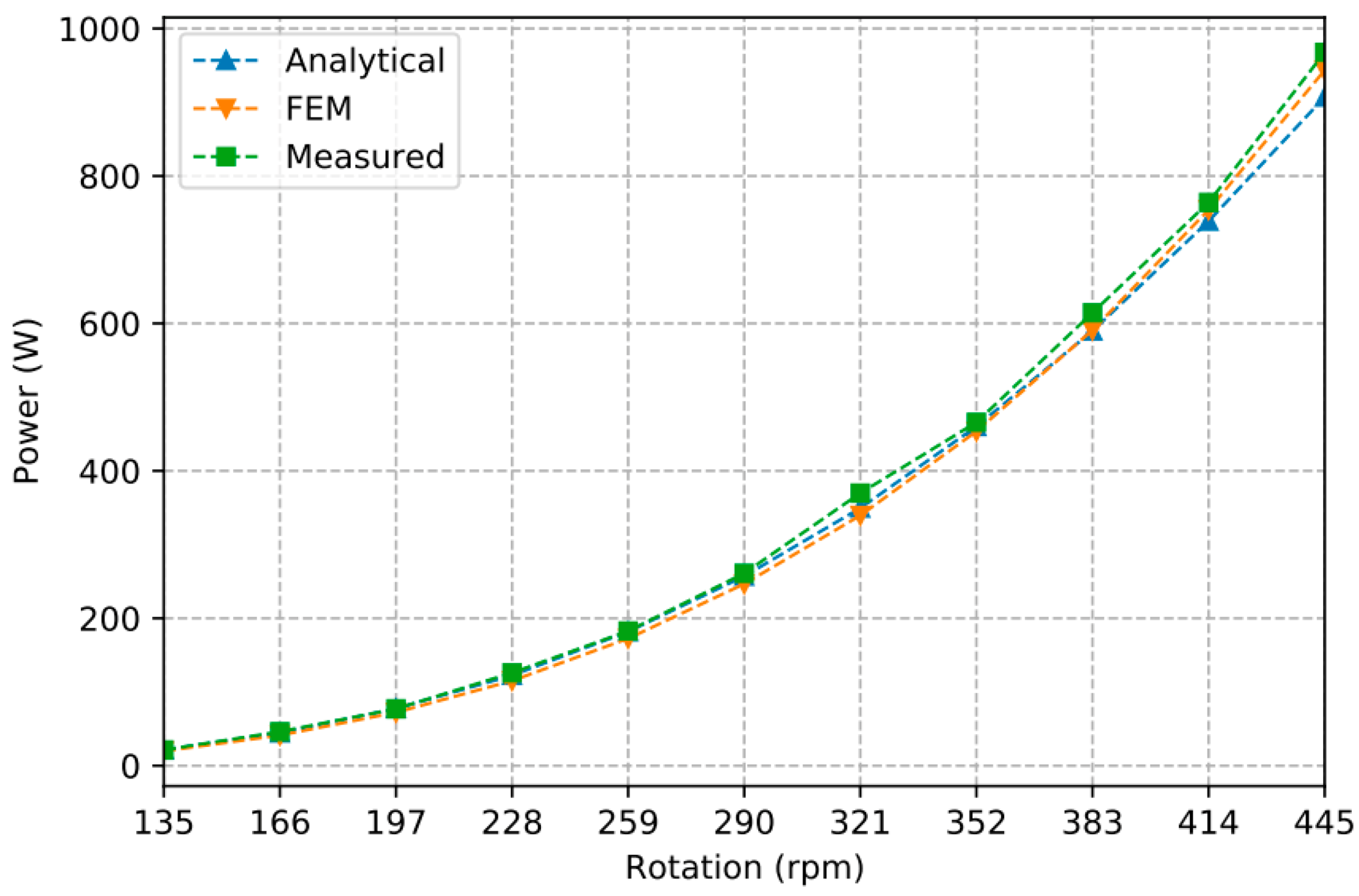

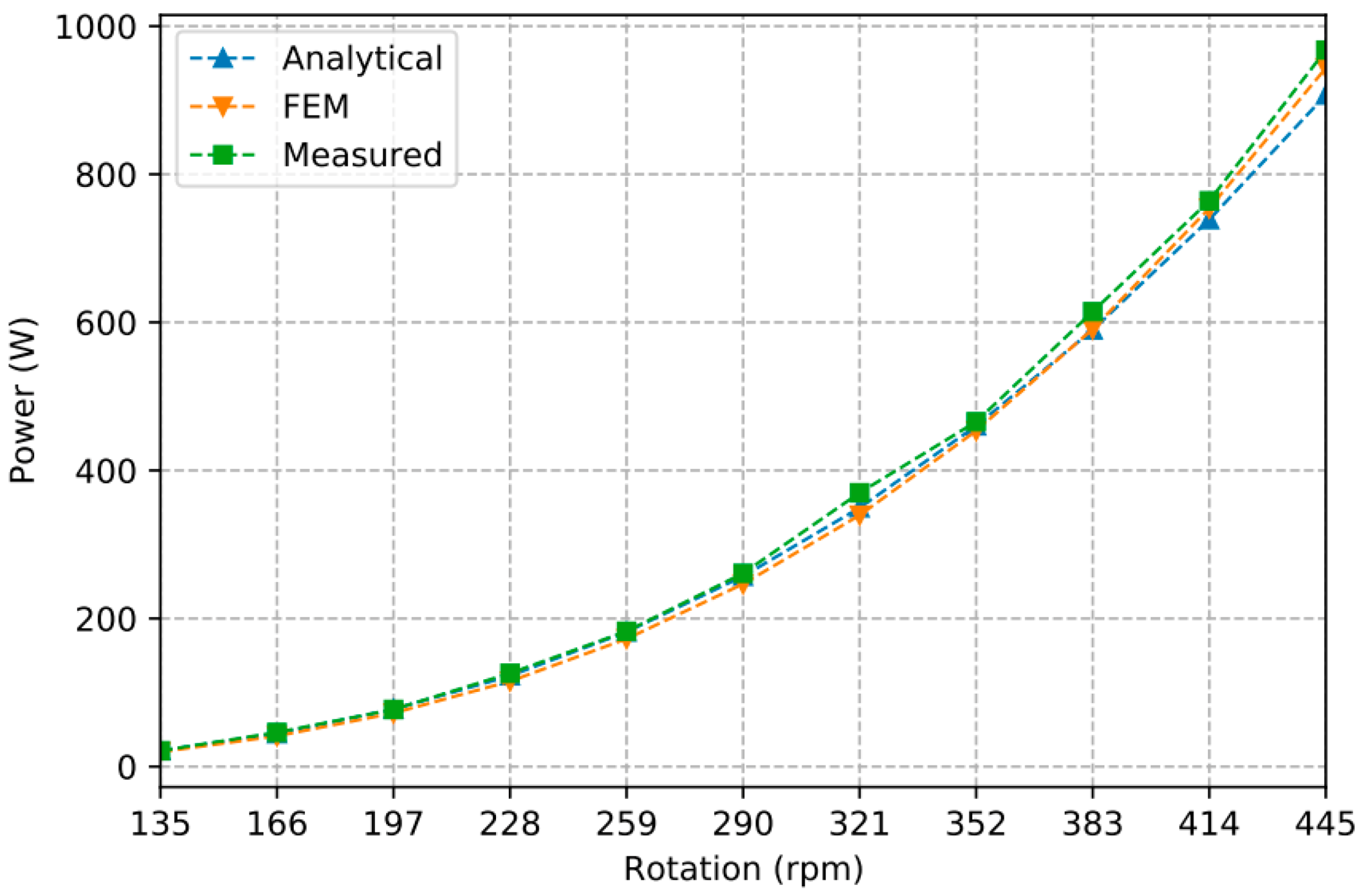

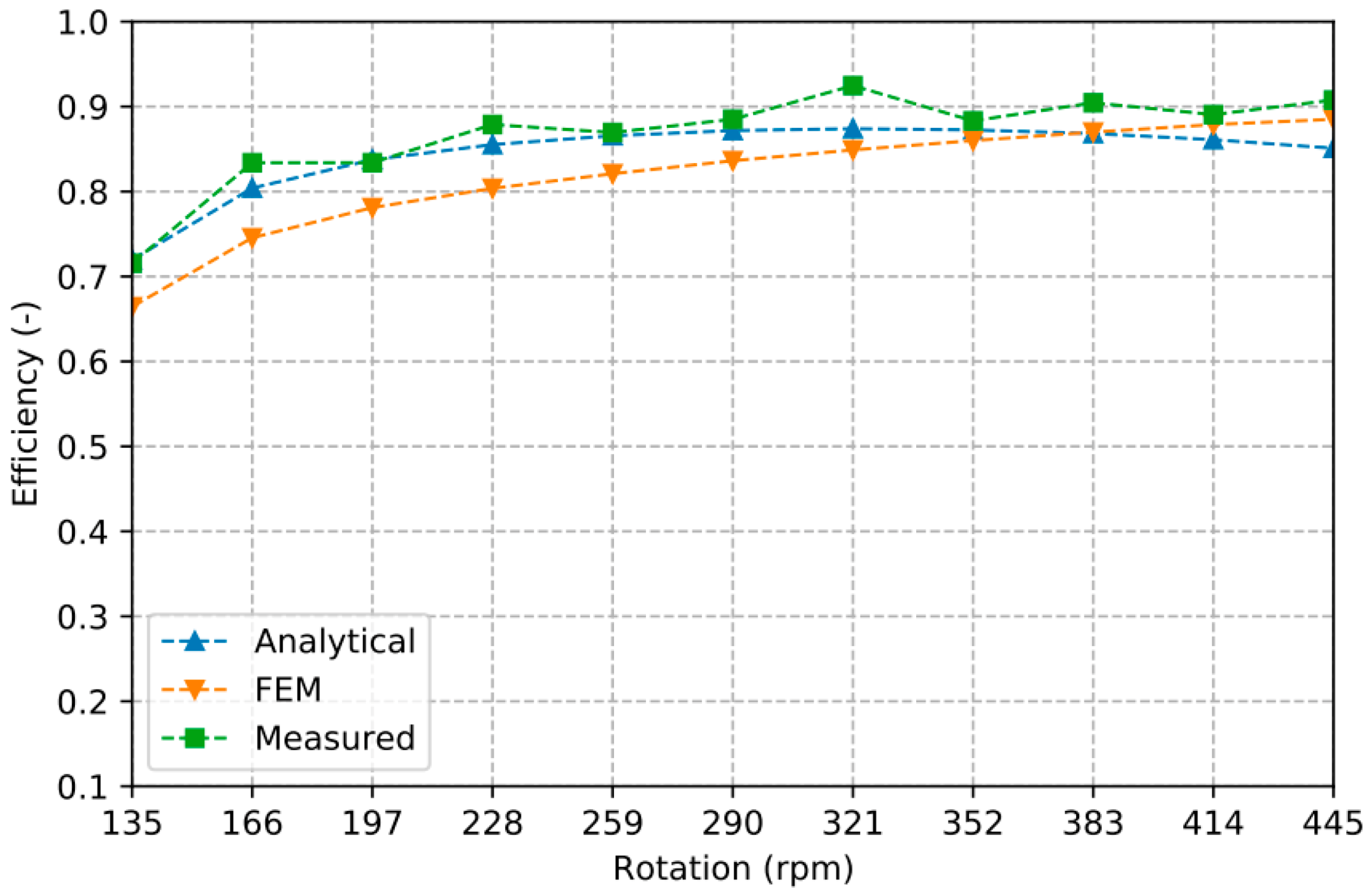

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Components of the Magnetic Flux Density

Appendix A.2. Interface Conditions

Appendix A.2.1. Interface between Air Gap and Slot Opening

Appendix A.2.2. Interface between Slot Opening and Slot Region

References

- Dilimulati, A.; Stathopoulos, T.; Paraschivoiu, M. Wind turbine designs for urban applications: A case study of shrouded diffuser casing for turbines. J. Wind Eng. Ind. Aerodyn. 2018, 175, 179–192. [Google Scholar] [CrossRef] [Green Version]

- Ohya, Y.; Karasudani, T.; Sakurai, A.; Abe, K.; Inoue, M. Development of a shrouded wind turbine with a flanged diffuser. J. Wind Eng. Ind. Aerodyn. 2008, 96, 524–539. [Google Scholar] [CrossRef]

- Ohya, Y.; Karasudani, T. A shrouded wind turbine generating high output power with wind-lens technology. Energies 2010, 3, 634–649. [Google Scholar] [CrossRef] [Green Version]

- Verdum, V.; Homrich, R.P.; Flores Filho, A.F.; Dorrell, D.G. Ironless Machine Design for Wind-Based Microgeneration. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Spooner, E.; Williamson, A.C.; Catto, G. Modular design of permanent-magnet generators for wind turbines. IEE Proc. Electr. Power Appl. 1996, 143, 388. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Z.; Cheng, M. Design and comparison of a novel stator interior permanent magnet generator for direct-drive wind turbines. IET Renew. Power Gener. 2007, 1, 203–210. [Google Scholar] [CrossRef]

- Ditmanson, C.; Hein, P.; Kolb, S.; Molck, J.; Bernet, S. A new modular flux-switching permanent-magnet drive for large wind turbines. IEEE Trans. Ind. Appl. 2014, 50, 3787–3794. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, Y.; Zhu, C.; Liu, X.; Li, B. A novel modular-stator outer-rotor flux-switching permanent-magnet motor. Energies 2017, 10, 937. [Google Scholar] [CrossRef]

- Li, Y.X.; Zhu, Z.Q.; Thomas, A.S.; Wu, Z.Y.; Wu, X.M. Novel Modular Fractional Slot Permanent Magnet Machines With Redundant Teeth. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Petrov, I.; Di, C.; Lindh, P.; Niemela, M.; Repo, A.K.; Pyrhonen, J. Fault-tolerant modular stator concentrated winding permanent magnet machine. IEEE Access 2020, 8, 7806–7816. [Google Scholar] [CrossRef]

- Oliveira, J.A.; Filho, A.F.F.; Dorrell, D.G. Ring-shaped surface-mounted permanent magnet generators with modular stator for small wind turbines. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Oliveira, J.A.; Filho, A.F.F. Parameters evaluation of a permanent magnet synchronous generator with modular stator. IEEE Lat. Am. Trans. 2019, 17, 1678–1685. [Google Scholar] [CrossRef]

- Lubin, T.; Mezani, S.; Rezzoug, A. 2D Exact Analytical Model for Surface-Mounted Permanent Magnet Motors with Semi-Closed Slots. IEEE Trans. Magn. 2011, 2, 1–15. [Google Scholar]

- Wu, L.J.; Zhu, Z.Q.; Staton, D.; Popescu, M.; Hawkins, D. Analytical prediction of electromagnetic performance of surface-mounted PM machines based on subdomain model accounting for tooth-tips. IET Electr. Power Appl. 2011, 5, 597. [Google Scholar] [CrossRef]

- Boutora, Y.; Takorabet, N.; Ibtiouen, R. Analytical model on real geometries of magnet bars of surface permanent magnet slotless machine. Prog. Electromagn. Res. B 2016, 66, 31–47. [Google Scholar] [CrossRef] [Green Version]

- Binns, K.J.; Lawrenson, P.J.; Trowbridge, C.W. The Analytical and Numerical Solution of Electric and Magnetic Fields; John Wiley & Sons: New York, NY, USA, 1993. [Google Scholar]

- Zhou, Y.; Li, H.; Meng, G.; Zhou, S.; Cao, Q. Analytical calculation of magnetic field and cogging torque in surface-mounted permanent-magnet machines accounting for any eccentric rotor shape. IEEE Trans. Ind. Electron. 2015, 62, 3438–3447. [Google Scholar] [CrossRef]

- Xue, Z.; Li, H.; Zhou, Y.; Ren, N.; Wen, W. Analytical Prediction and Optimization of Cogging Torque in Surface-Mounted Permanent Magnet Machines with Modified Particle Swarm Optimization. IEEE Trans. Ind. Electron. 2017, 64, 9795–9805. [Google Scholar] [CrossRef]

- Wu, L.J.; Zhu, Z.Q.; Staton, D.; Popescu, M.; Hawkins, D. Subdomain model for predicting armature reaction field of surface-mounted permanent-magnet machines accounting for tooth-tips. IEEE Trans. Magn. 2012, 48, 107–117. [Google Scholar] [CrossRef]

- Meessen, K.J.; Paulides, J.J.H.; Lomonova, E.A. Force calculations in 3-D cylindrical structures using fourier analysis and the maxwell stress tensor. IEEE Trans. Magn. 2013, 49, 536–545. [Google Scholar] [CrossRef]

| Parameters | Dimensions | Parameters | Dimensions |

|---|---|---|---|

| Stator outer diameter (Re) | 797 | Pole-arc to pole pitch ratio (τm/τp) | 0.7 |

| Stator yoke height | 6.7 | Slot-width (bsa) | 0.53 |

| Stator inner diameter (RS) | 781 | Slot-opening (boa) | 0.29 |

| Tooth tip edge | 1 | Winding turn/phase | 12 |

| Magnet thickness (hmax) | 5 | Axial length | 20 |

| Magnet thickness (hmin) | 4 | Coercive force (kA/m) | 212 |

| Rotor outer diameter (Rr) | 774 | Magnetization | Parallel |

| Rotor inner diameter (Ri) | 765 | Winding-width (d) | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, J.A.; Filho, Á.F.F. Performance Evaluation of a Stator Modular Ring Generator for a Shrouded Wind Turbine. Energies 2021, 14, 67. https://doi.org/10.3390/en14010067

Oliveira JA, Filho ÁFF. Performance Evaluation of a Stator Modular Ring Generator for a Shrouded Wind Turbine. Energies. 2021; 14(1):67. https://doi.org/10.3390/en14010067

Chicago/Turabian StyleOliveira, Jefferson A., and Ály F. Flores Filho. 2021. "Performance Evaluation of a Stator Modular Ring Generator for a Shrouded Wind Turbine" Energies 14, no. 1: 67. https://doi.org/10.3390/en14010067

APA StyleOliveira, J. A., & Filho, Á. F. F. (2021). Performance Evaluation of a Stator Modular Ring Generator for a Shrouded Wind Turbine. Energies, 14(1), 67. https://doi.org/10.3390/en14010067