Bollinger Bands Based on Exponential Moving Average for Statistical Monitoring of Multi-Array Photovoltaic Systems

Abstract

1. Introduction

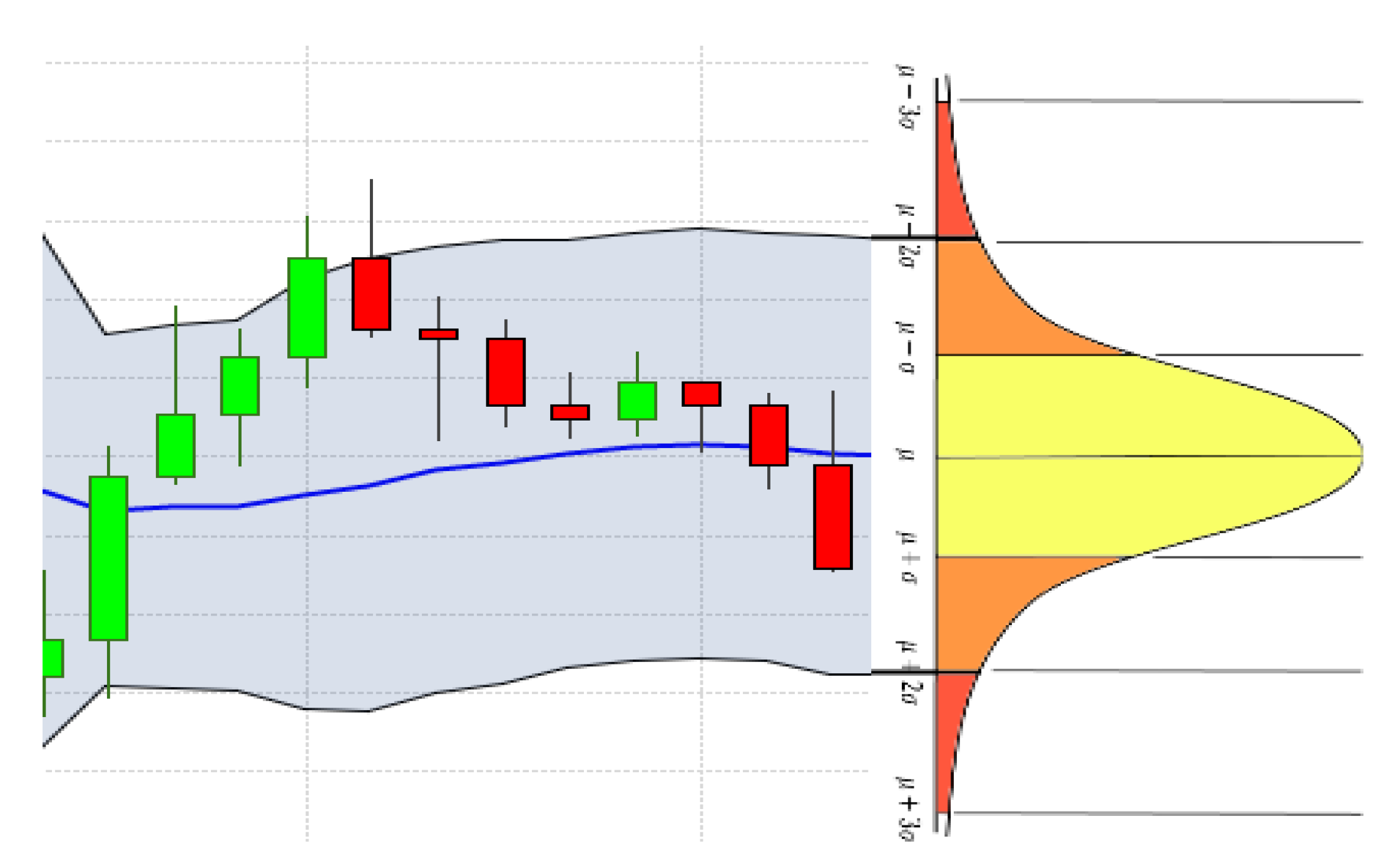

2. Bollinger Bands, SMA and EMA

3. PV Plant under Examination

4. Case Study: Results

- quarter analysis (January–March 2016);

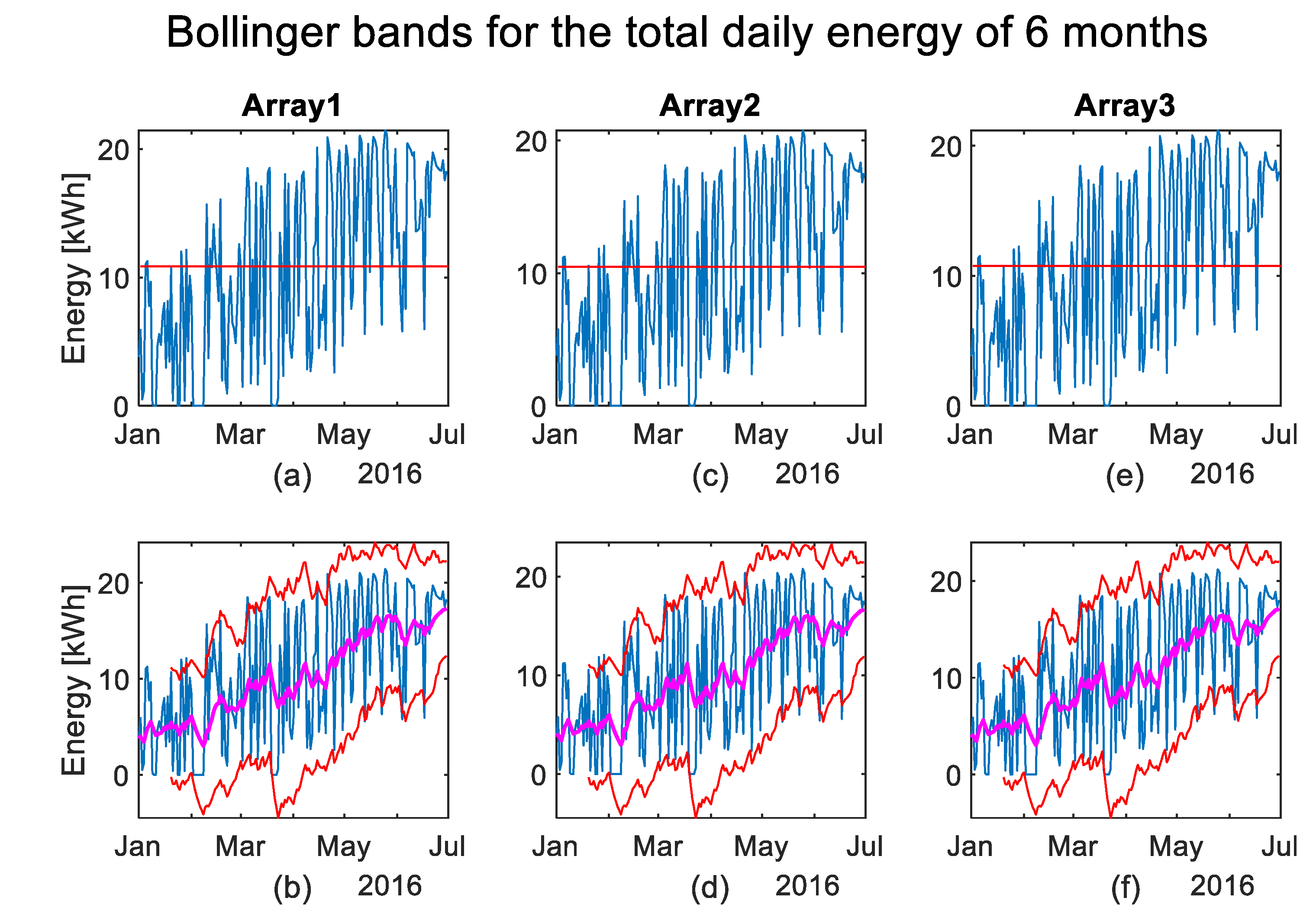

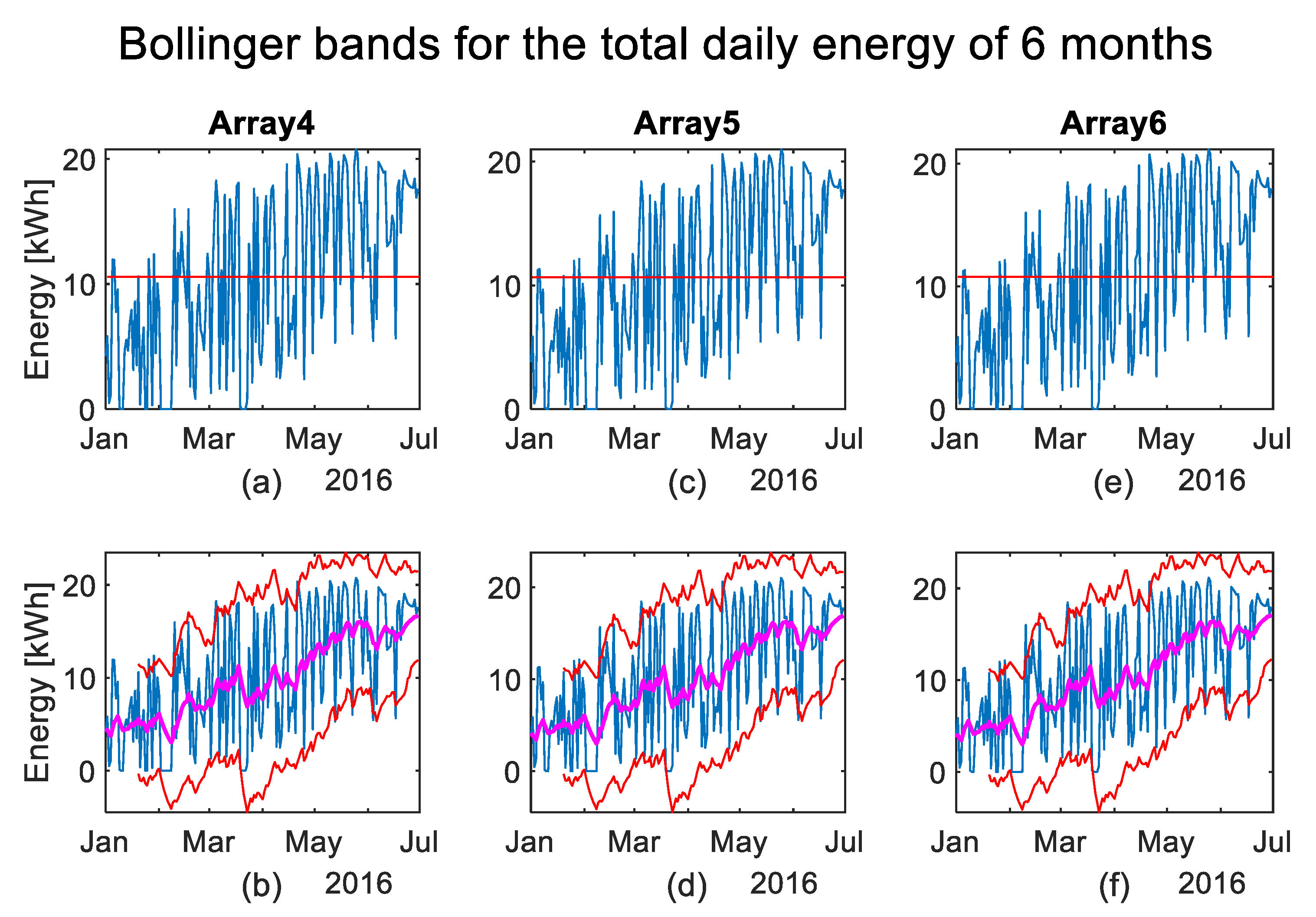

- semester analysis (January–June 2016);

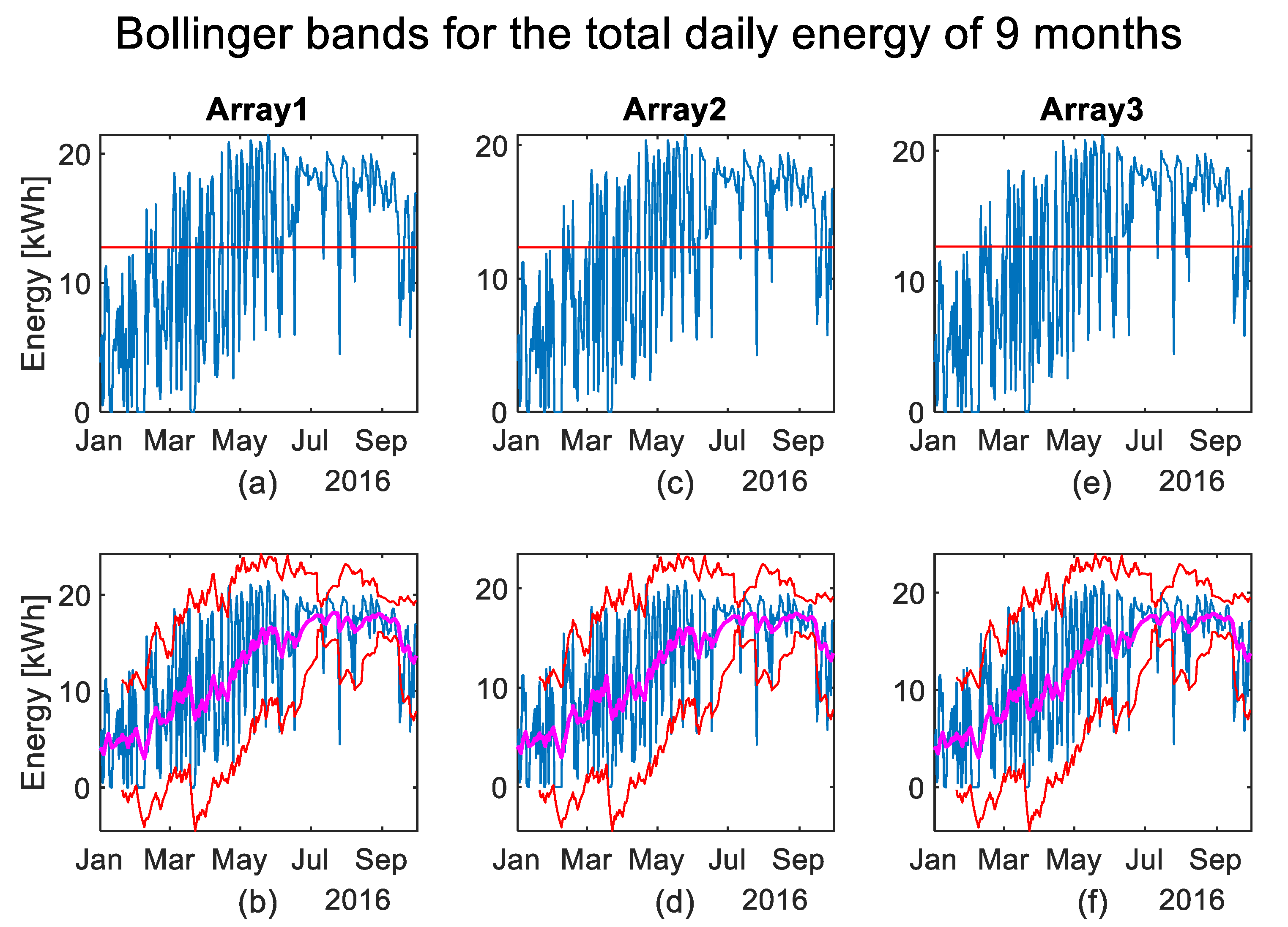

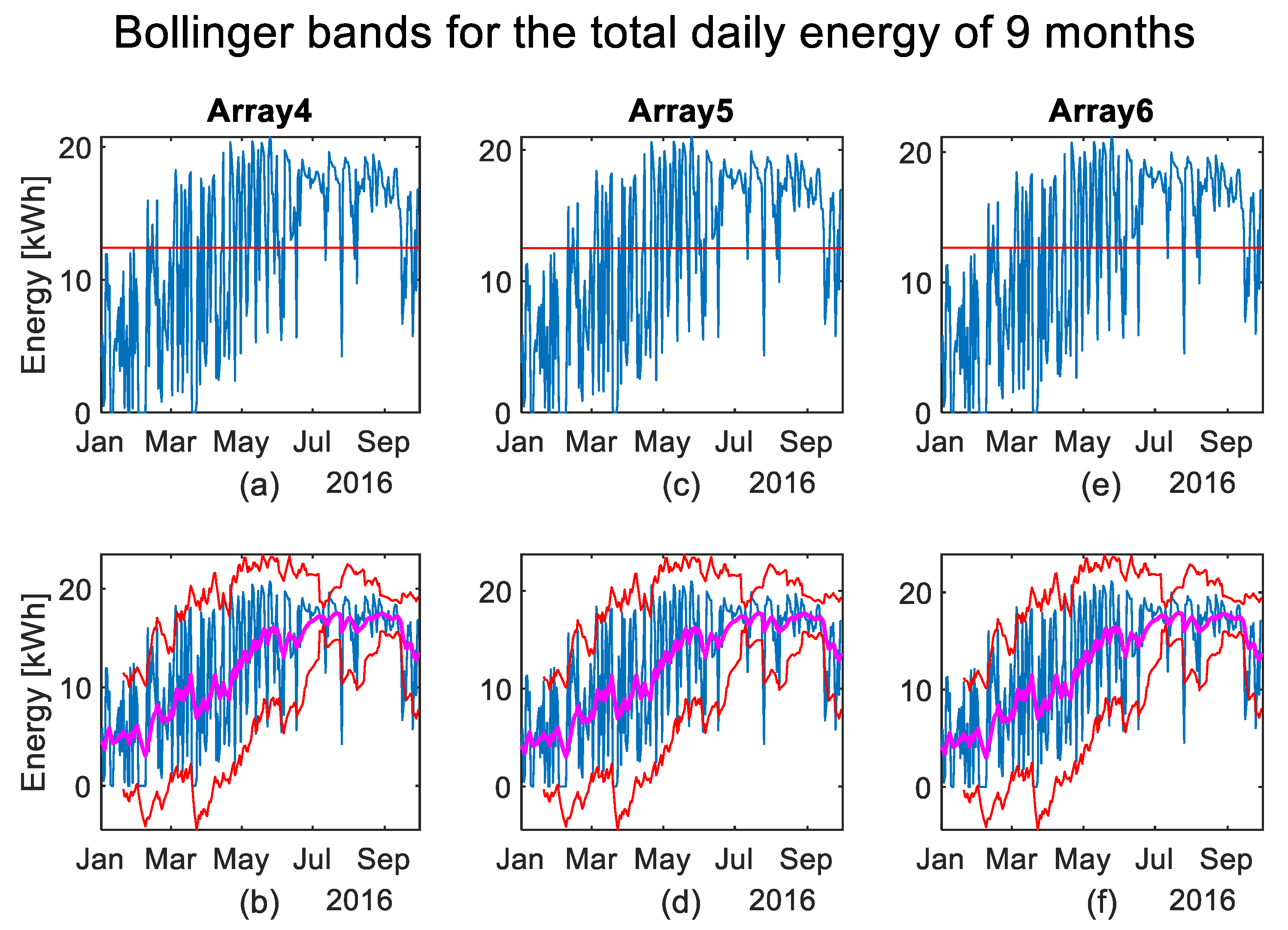

- nine-months analysis (January–September 2016);

- twelve-months analysis (January–December 2016).

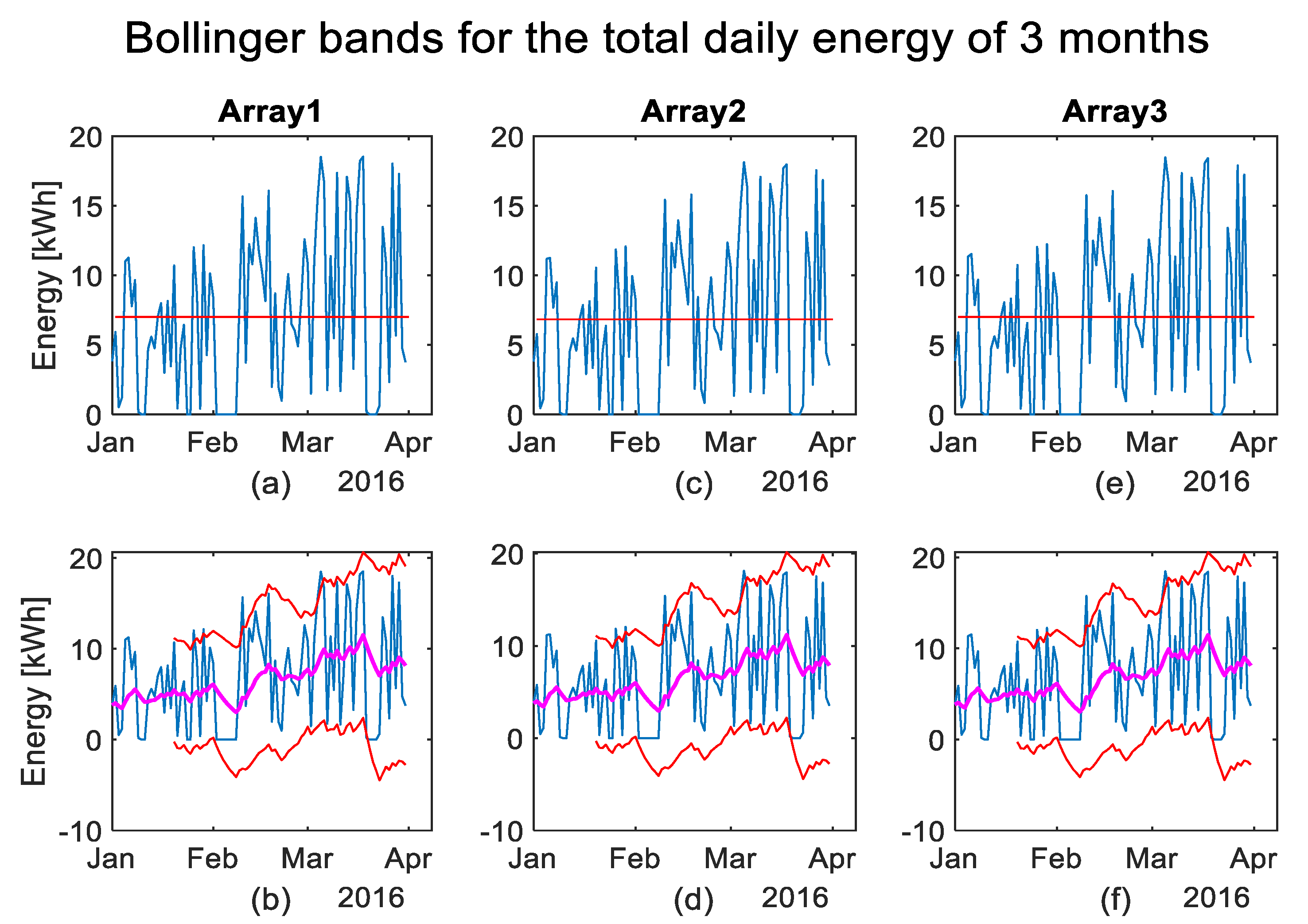

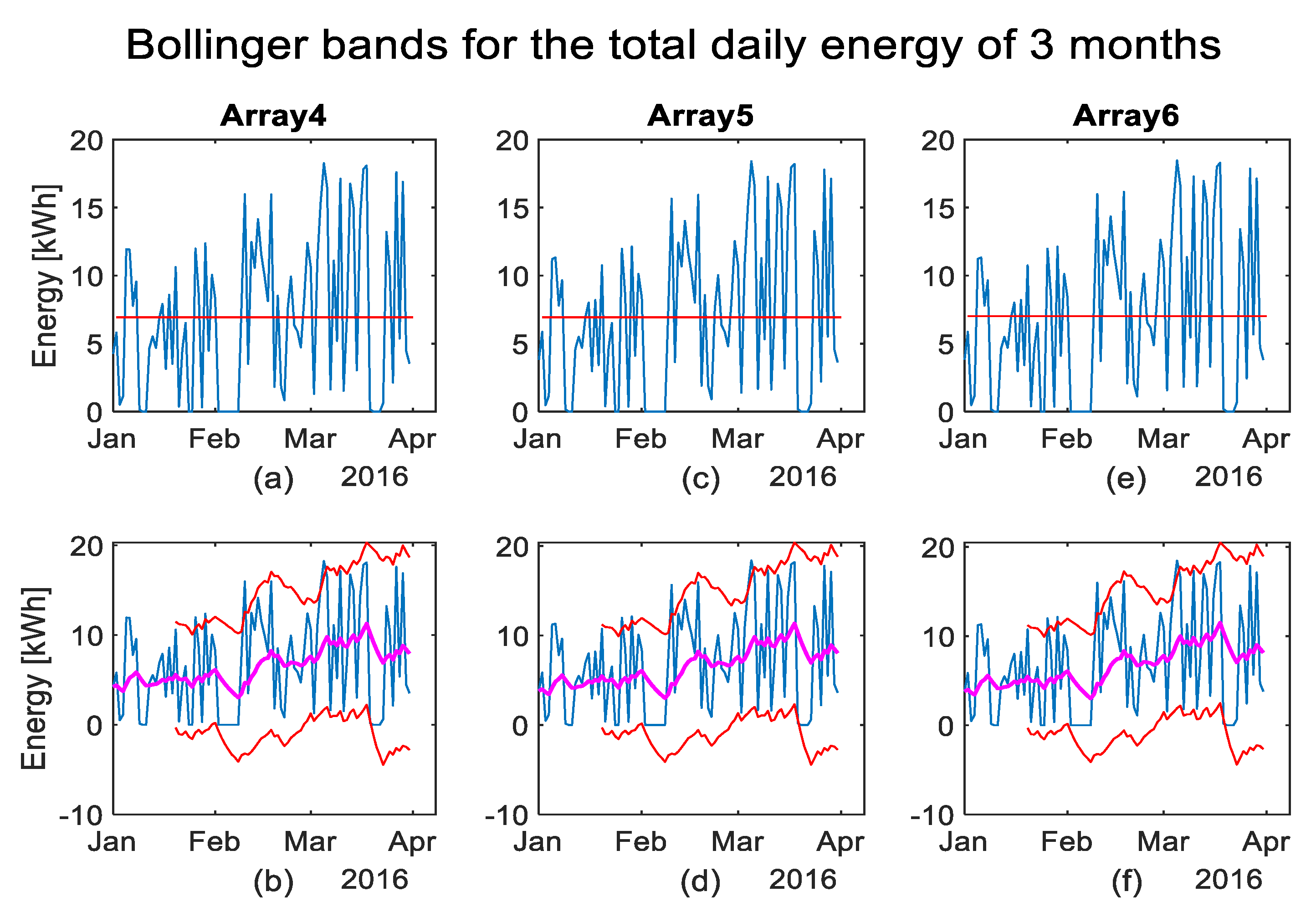

4.1. Three-Months Analysis (January–March 2016)

4.2. Six-Months Analysis (January–June 2016)

4.3. Nine-Months Analysis (January–September 2016)

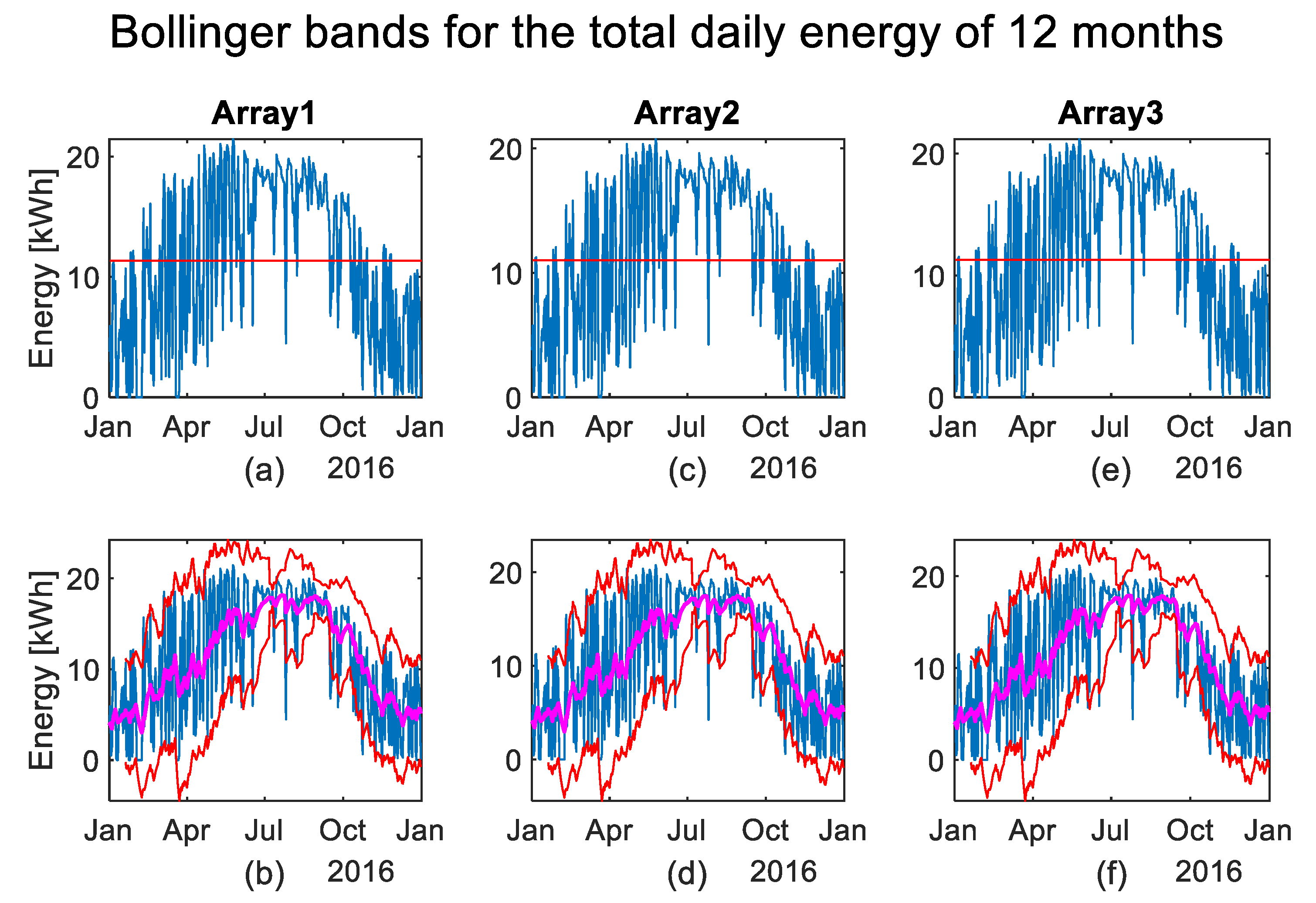

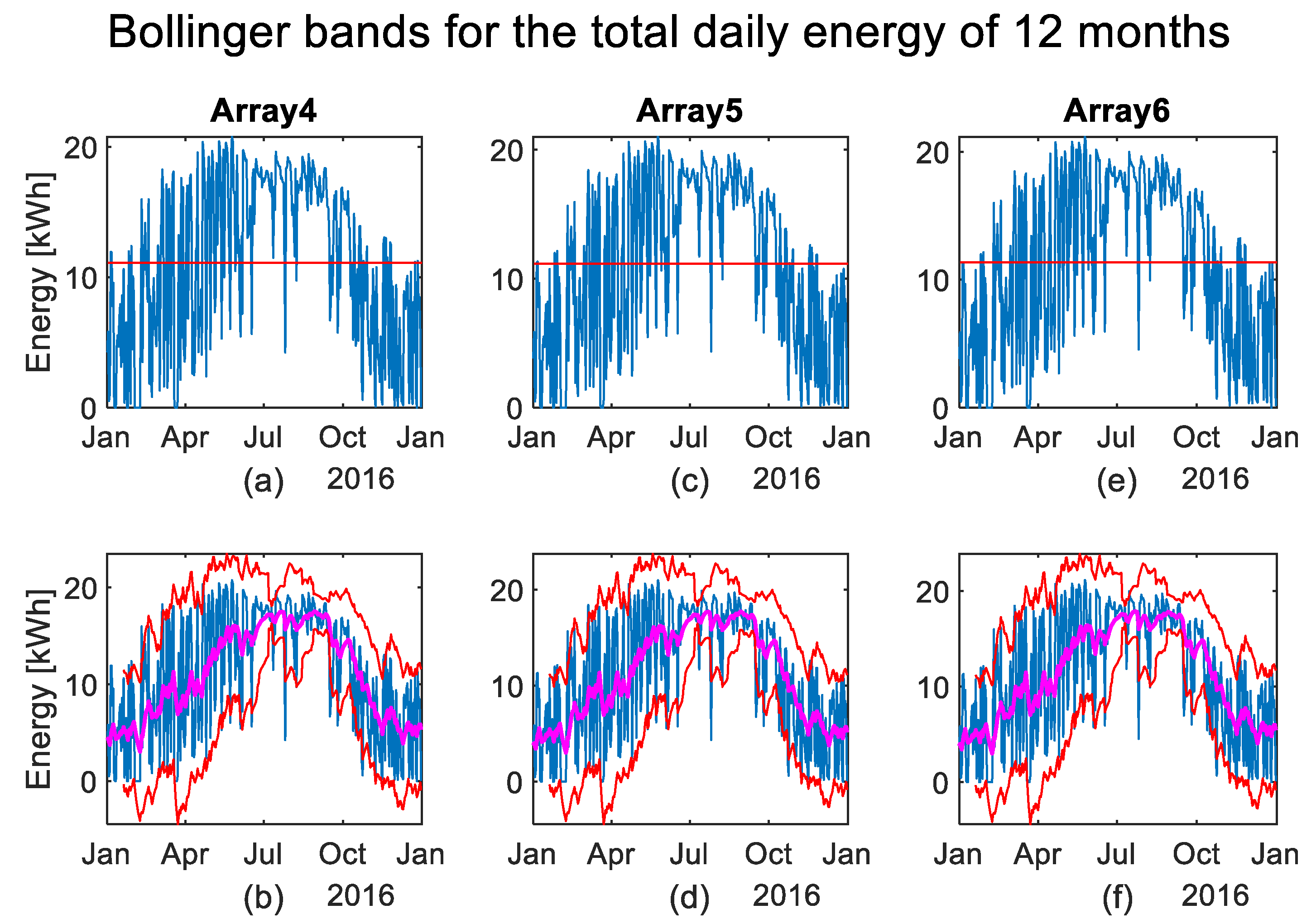

4.4. Twelve-Months Analysis (January–December 2016)

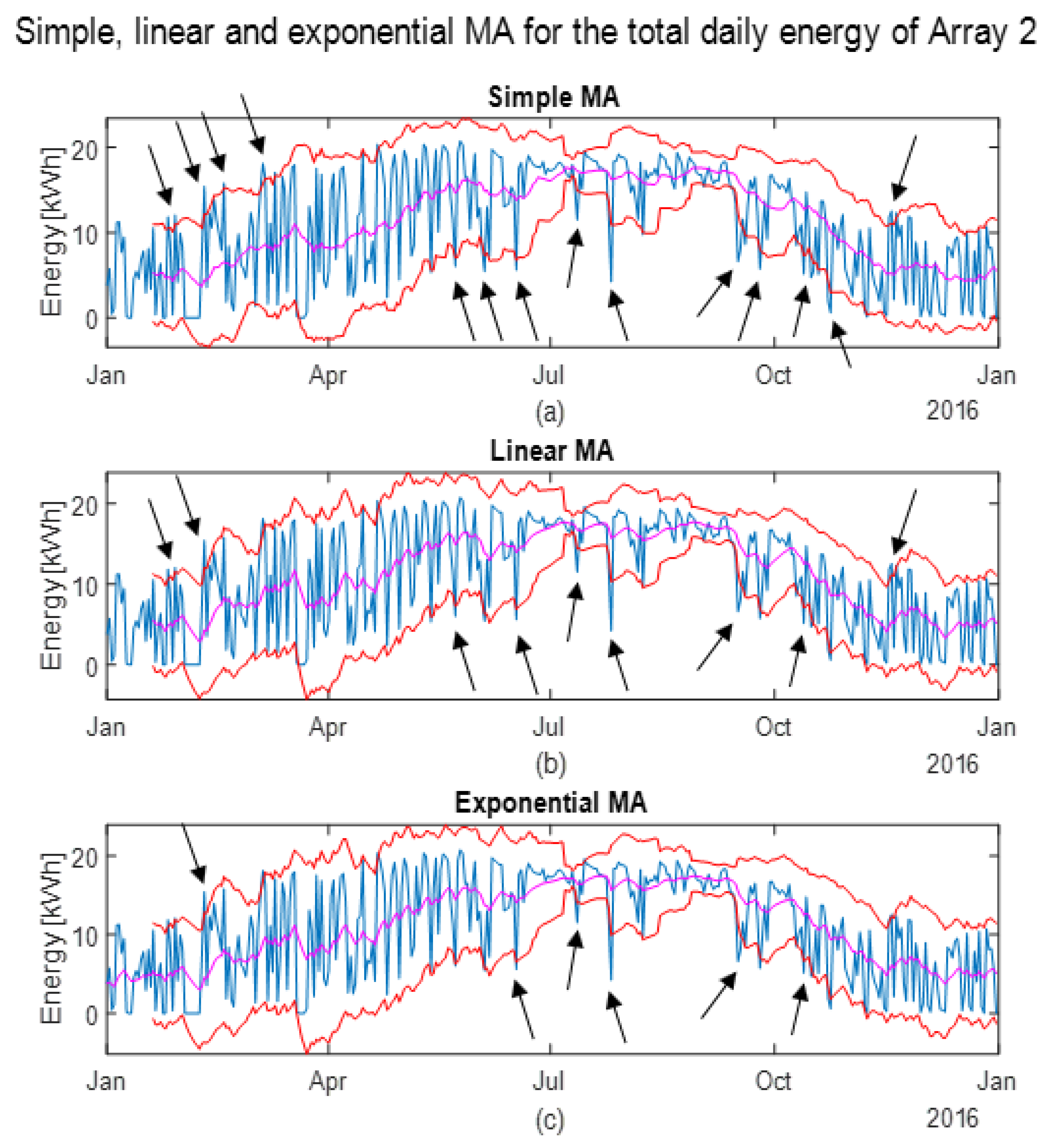

4.5. Comparison among Simple, Linear and Exponential MA

5. Conclusions

Funding

Conflicts of Interest

References

- Xiao, W.; Ozog, N.; Dundorf, W.G. Topology study of photovoltaic interface for maximum power point tracking. IEEE Trans. Ind. Electron. 2007, 54, 1696–1704. [Google Scholar] [CrossRef]

- Mutoh, N.; Inoue, T. A control method to charge series- connected ultraelectric double- layer capacitors suitable for photovoltaic generation systems combining MPPT control method. IEEE Trans. Ind. Electron. 2007, 54, 374–383. [Google Scholar] [CrossRef]

- Grimaccia, F.; Leva, S.; Mussetta, M.; Ogliari, E. ANN Sizing Procedure for the Day-Ahead Output Power Forecast of a PV Plant. Appl. Sci. 2017, 7, 622. [Google Scholar] [CrossRef]

- Acciani, G.; Chiarantoni, E.; Fornarelli, G.; Vergura, S. A feature extraction unsupervised neural network for an environmental data set. Neural Netw. 2003, 16, 427–436. [Google Scholar] [CrossRef]

- Vergura, S.; Pavan, A.M. On the photovoltaic explicit empirical model: Operations along the current-voltage curve. In Proceedings of the 2015 International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015. [Google Scholar]

- Pavan, A.M.; Vergura, S.; Mellit, A.; Lughi, V. Explicit empirical model for photovoltaic devices. Experimental validation. Sol. Energy 2017, 155, 647–653. [Google Scholar] [CrossRef]

- Guerriero, P.; di Napoli, F.; Vallone, G.; D’Alessandro, V.; Daliento, S. Monitoring and diagnostics of PV plants by a wireless self-powered sensor for individual panels. IEEE J. Photovolt. 2015, 6, 286–294. [Google Scholar] [CrossRef]

- Takashima, T.; Yamaguchi, J.; Otani, K.; Kato, K.; Ishida, M. Experimental Studies of Failure Detection Methods in PV module strings. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 2227–2230. [Google Scholar]

- Breitenstein, O.; Rakotoniaina, J.P.; Al Rifai, M.H. Quantitative evaluation of shunts in solar cells by lock-in thermography. Prog. Photovolt. Res. Appl. 2003, 11, 515–526. [Google Scholar] [CrossRef]

- Vergura, S.; Marino, F.; Carpentieri, M. Carpentieri, Processing Infrared Image of PV Modules for Defects Classification. In Proceedings of the International Conference on Renewable Energy Research and Applications (ICRERA 2015), Palermo, Italy, 22–25 November 2015; ISBN 978-1-4799-9981-1. [Google Scholar]

- Grimaccia, F.; Leva, S.; Dolara, A.; Aghaei, M. Survey on PV Modules’ Common Faults after an O&M Flight Extensive Campaign over Different Plants in Italy. IEEE J. Photovolt. 2017, 7, 810–816. [Google Scholar]

- Johnston, S.; Guthrey, H.; Yan, F.; Zaunbrecher, K.; Al-Jassim, M.; Rakotoniaina, P.; Kaes, M. Correlating multicrystalline silicon defect types using photoluminescence, defect-band emission, and lock-in thermography imaging techniques. IEEE J. Photovolt. 2014, 4, 348–354. [Google Scholar] [CrossRef]

- Peloso, M.P.; Meng, L.; Bhatia, C.S. Combined thermography and luminescence imaging to characterize the spatial performance of multicrystalline Si wafer solar cells. IEEE J. Photovolt. 2015, 5, 102–111. [Google Scholar] [CrossRef]

- Vergura, S.; Marino, F. Quantitative and Computer Aided Thermography-based Diagnostics for PV Devices: Part I—Framework. IEEE J. Photovolt. 2017, 7, 822–827. [Google Scholar] [CrossRef]

- Vergura, S.; Colaprico, M.; de Ruvo, M.F.; Marino, F. A Quantitative and Computer Aided Thermography-based Diagnostics for PV Devices: Part II—Platform and Results. IEEE J. Photovolt. 2017, 7, 237–243. [Google Scholar] [CrossRef]

- Mekki, H.; Mellit, A.; Salhi, H. Artificial neural network-based modelling and fault detection of partial shaded photovoltaic modules. Simul. Model. Pract. Theory 2016, 67, 1–13. [Google Scholar] [CrossRef]

- Harrou, F.; Sun, Y.; Kara, K.; Chouder, A.; Silvestre, S.; Garoudja, E. Statistical fault detection in photovoltaic systems. Sol. Energy 2017, 150, 485–499. [Google Scholar]

- Vergura, S. Hypothesis Tests-Based Analysis for Anomaly Detection in Photovoltaic Systems in the Absence of Environmental Parameters. Energies 2018, 11, 485. [Google Scholar] [CrossRef]

- Cristaldi, L.; Faifer, M.; Leone, G.; Vergura, S. Reference Strings for Statistical Monitoring of the Energy Performance of Photovoltaic Fields. In Proceedings of the IEEE-ICCEP 2015 International Conference on Clean Electrical Power, Taormina, Italy, 16–18 June 2015. [Google Scholar]

- Ventura, C.; Tina, G.M. Development of models for online diagnostic and energy assessment analysis of PV power plants: The study case of 1 MW Sicilian PV plant. Energy Procedia 2015, 83, 248–257. [Google Scholar] [CrossRef]

- Silvestre, S.; Kichou, S.; Chouder, A.; Nofuentes, G.; Karatepe, E. Analysis of current and voltage indicators in grid connected PV (photovoltaic) systems working in faulty and partial shading conditions. Energy 2015, 86, 42–50. [Google Scholar] [CrossRef]

- Vergura, S. Scalable Model of PV Cell in Variable Environment Condition based on the Manufacturer Datasheet for Circuit Simulation. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Roma, Italy, 10–13 June 2015. [Google Scholar]

- Chao, K.H.; Ho, S.H.; Wang, M.H. Modeling and fault diagnosis of a photovoltaic system. Electr. Power Syst. Res. 2008, 78, 97–105. [Google Scholar] [CrossRef]

- Hamdaoui, M.; Rabhi, A.; Hajjaji, A.; Rahmoum, M.; Azizi, M. Monitoring and control of the performances for photovoltaic systems. In Proceedings of the International Renewable Energy Congress, Sousse, Tunisia, 5–7 November 2009. [Google Scholar]

- Kim, I.-S. On-line fault detection algorithm of a photovoltaic system using wavelet transform. Sol. Energy 2016, 226, 137–145. [Google Scholar] [CrossRef]

- Rabhia, A.; El Hajjajia, A.; Tinab, M.H.; Alia, G.M. Real time fault detection in photovoltaic systems. Energy Procedia 2017, 11, 914–923. [Google Scholar]

- Plato, R.; Martel, J.; Woodruff, N.; Chau, T.Y. Online fault detection in PV systems. IEEE Trans. Sustain. Energy 2015, 6, 1200–1207. [Google Scholar] [CrossRef]

- Ando, B.; Bagalio, A.; Pistorio, A. Sentinella: Smart monitoring of photovoltaic systems at panel level. IEEE Trans. Instrum. Meas. 2015, 64, 2188–2199. [Google Scholar] [CrossRef]

- Harrou, F.; Sun, Y.; Taghezouit, B.; Saidi, A.; Hamlati, M.E. Reliable fault detection and diagnosis of photovoltaic systems based on statistical monitoring approaches. Renew. Energy 2018, 116, 22–37. [Google Scholar] [CrossRef]

- Photovoltaic Geographical Information System. Available online: http://re.jrc.ec.europa.eu/pvg_tools/en/tools.html (accessed on 18 July 2020).

- Murphy, J. Technical Analysis of the Financial Markets: A Comprehensive Guide to Trading Methods and Applications; New York Institute of Finance Serie: New York, NY, USA, 1999. [Google Scholar]

- De Giorgi, M.G.; Congedo, P.M.; Malvoni, M. Photovoltaic power forecasting using statistical methods: Impact of weather data. IET Sci. Measure. Technol. 2014, 8, 90–97. [Google Scholar] [CrossRef]

- Congedo, P.M.; Malvoni, M.; Mele, M.; De Giorgi, M.G. Performance measurements of mono-crystalline silicon PV modules in South-eastern Italy. Energy Convers. Manag. 2013, 68, 1–10. [Google Scholar] [CrossRef]

- Malvoni, M.; Leggieri, A.; Maggiotto, G.; Congedo, P.M.; De Giorgi, M.G. Long term performance, losses and efficiency analysis of a 960 kWP photovoltaic system in the Mediterranean climate. Energy Convers. Manag. 2017, 145, 169–181. [Google Scholar]

- Yadav, S.K.; Bajpai, U. Performance evaluation of a rooftop solar photovoltaic power plant in Northern India. Energy Sustain. Dev. 2018, 43, 130–138. [Google Scholar]

- Bollinger, J. Bollinger on Bollinger Bands; Professional Finance & Investment; McGraw-Hill Education: New York, NY, USA, 2002. [Google Scholar]

- Bollinger Bands. Available online: https://www.bollingerbands.com/ (accessed on 18 July 2020).

- Rajput, P.; Malvoni, M.; Manoj Kumar, N.; Sastry, O.S.; Tiwari, G.N. Risk priority number for understanding the severity of photovoltaic failure modes and their impacts on performance degradation. Case Stud. Therm. Eng. 2019, 16, 100563. [Google Scholar] [CrossRef]

- Makrides, G.; Bastian, Z.; Markus, S.; George, E.G. Performance loss rate of twelve photovoltaic technologies under field conditions using statistical techniques. Sol. Energy 2014, 103, 28–42. [Google Scholar] [CrossRef]

- Demir, S.; Mincev, K.; Kok, K.; Paterakis, N.G. Introducing Technical Indicators to Electricity Price Forecasting: A Feature Engineering Study for Linear, Ensemble, and Deep Machine Learning Models. Appl. Sci. 2019, 10, 255. [Google Scholar] [CrossRef]

- Rajput, V.N.; Pandya, K.S.; Hong, J.; Geem, Z.W. A Novel Protection Scheme for Solar Photovoltaic Generator Connected Networks Using Hybrid Harmony Search Algorithm-Bollinger Bands Approach. Energies 2020, 13, 2439. [Google Scholar] [CrossRef]

- Thakkar, A.; Kotecha, K. A new Bollinger Band based energy efficient routing for clustered wireless sensor network. Appl. Soft. Comput. 2015, 32, 144–153. [Google Scholar] [CrossRef]

| Array | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Mean (kWh) | 7.00 | 6.83 | 7.00 | 6.92 | 6.93 | 7.01 |

| Global mean | 6.95 | |||||

| Spread % | 0.76 | −1.73 | 0.76 | −0.40 | −0.28 | 0.91 |

| Array | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Mean (kWh) | 10.85 | 10.49 | 10.77 | 10.56 | 10.64 | 10.77 |

| Global mean | 10.68 | |||||

| Spread % | 1.54 | −1.75 | 0.86 | −1.16 | −0.35 | 0.86 |

| Array | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Mean (kWh) | 12.74 | 12.35 | 12.66 | 12.41 | 12.53 | 12.66 |

| Global mean | 12.56 | |||||

| Spread % | 1.46 | −1.65 | 0.81 | −1.18 | −0.25 | 0.81 |

| Array | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Mean (kWh) | 11.59 | 11.01 | 11.28 | 11.10 | 11.17 | 11.33 |

| Global mean | 11.21 | |||||

| Spread % | 1.20 | −1.72 | 0.66 | −0.94 | −0.35 | 1.15 |

| 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|

| 3 months | 0.76 | −1.73 | 0.76 | −0.40 | −0.28 | 0.91 |

| 6 months | 1.54 | −1.75 | 0.86 | −1.16 | −0.35 | 0.86 |

| 9 months | 1.46 | −1.65 | 0.81 | −1.18 | −0.25 | 0.81 |

| 12 months | 1.20 | −1.72 | 0.66 | −0.94 | −0.35 | 1.15 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vergura, S. Bollinger Bands Based on Exponential Moving Average for Statistical Monitoring of Multi-Array Photovoltaic Systems. Energies 2020, 13, 3992. https://doi.org/10.3390/en13153992

Vergura S. Bollinger Bands Based on Exponential Moving Average for Statistical Monitoring of Multi-Array Photovoltaic Systems. Energies. 2020; 13(15):3992. https://doi.org/10.3390/en13153992

Chicago/Turabian StyleVergura, Silvano. 2020. "Bollinger Bands Based on Exponential Moving Average for Statistical Monitoring of Multi-Array Photovoltaic Systems" Energies 13, no. 15: 3992. https://doi.org/10.3390/en13153992

APA StyleVergura, S. (2020). Bollinger Bands Based on Exponential Moving Average for Statistical Monitoring of Multi-Array Photovoltaic Systems. Energies, 13(15), 3992. https://doi.org/10.3390/en13153992