A Fault Diagnosis Mechanism with Power Generation Improvement for a Photovoltaic Module Array

Abstract

1. Introduction

2. Effect of Array Configuration on Output Performance

3. Particle Swarm Optimization Algorithm

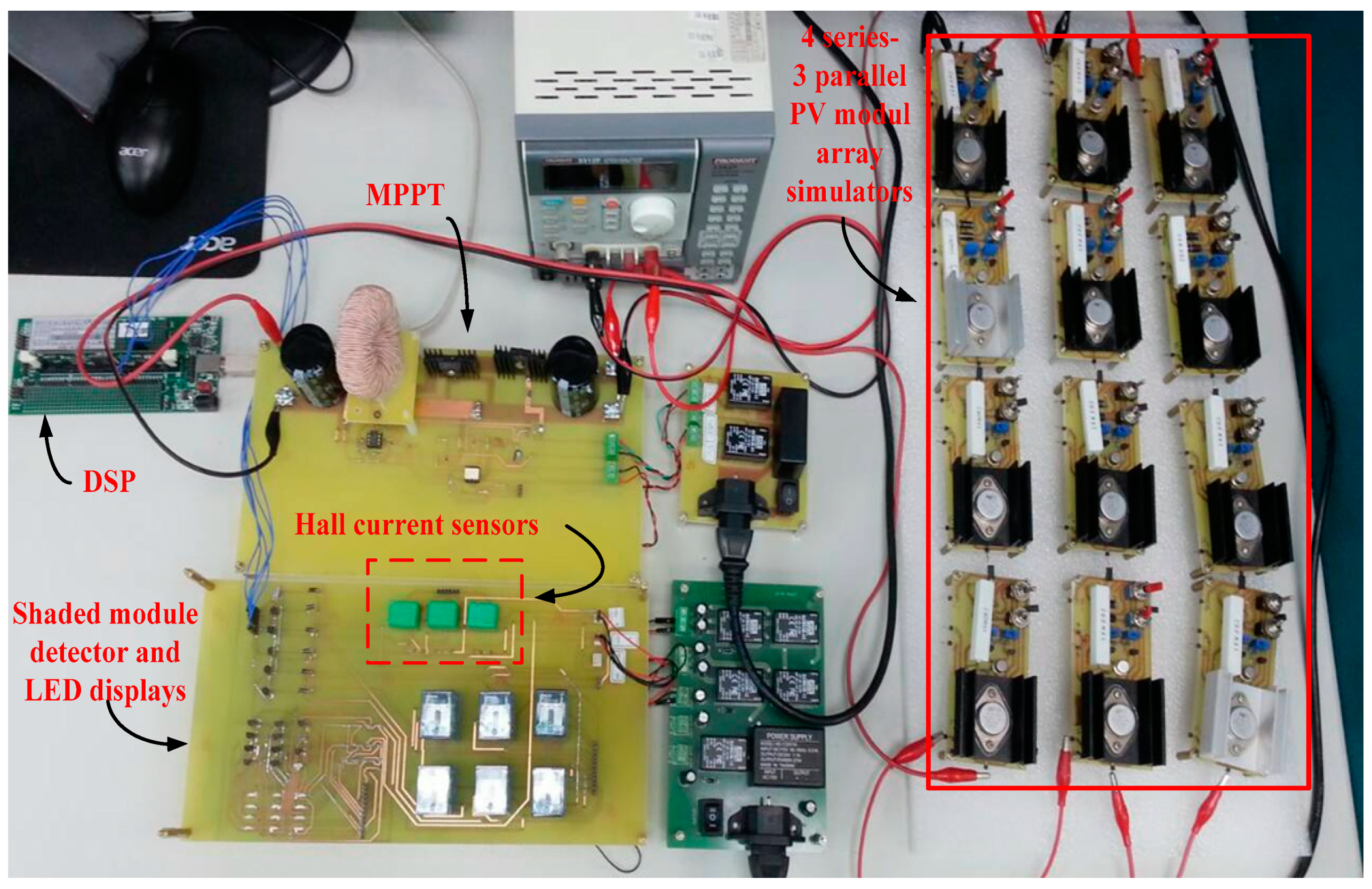

4. Online Fault Diagnosis System

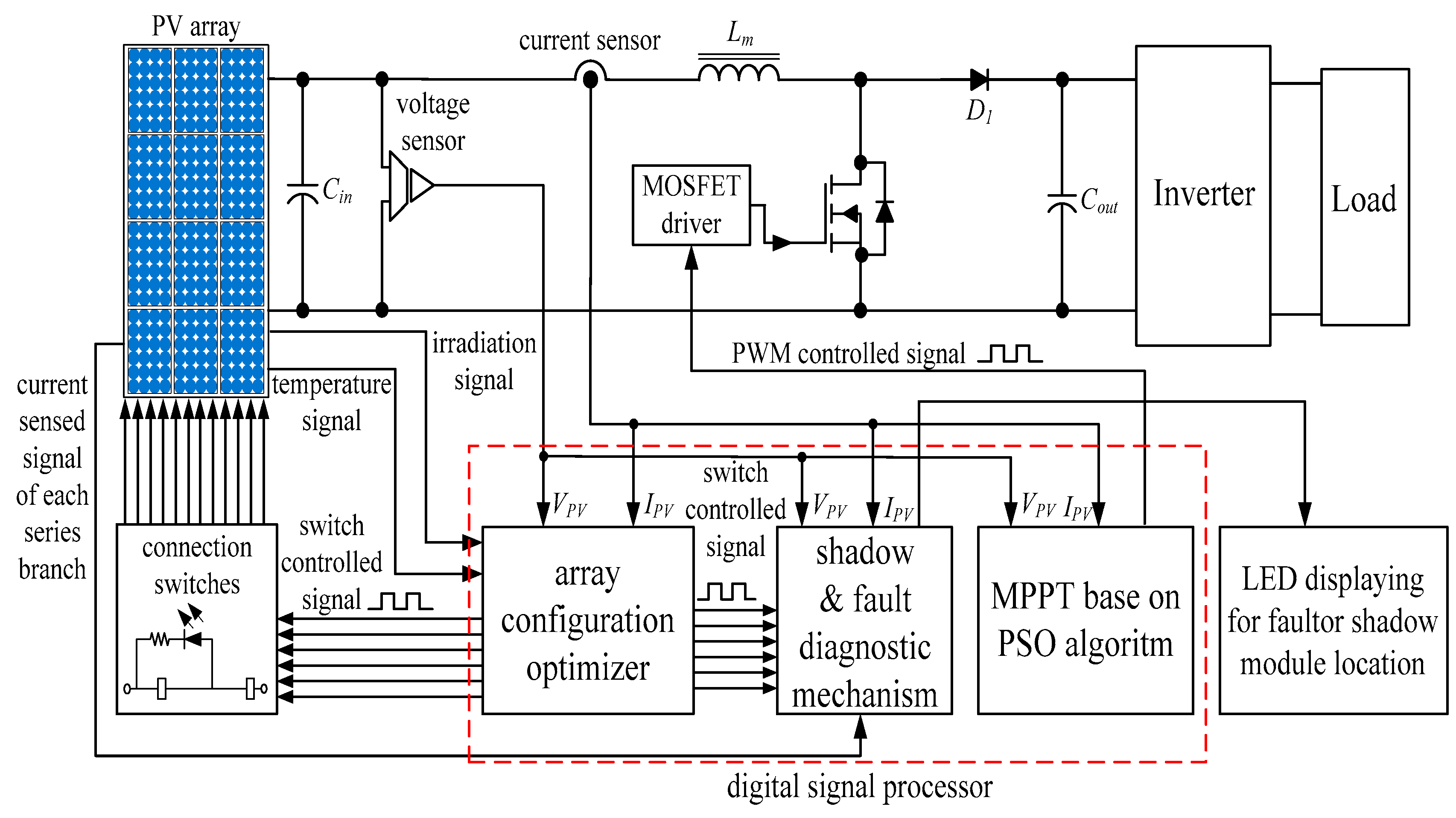

4.1. System Framework

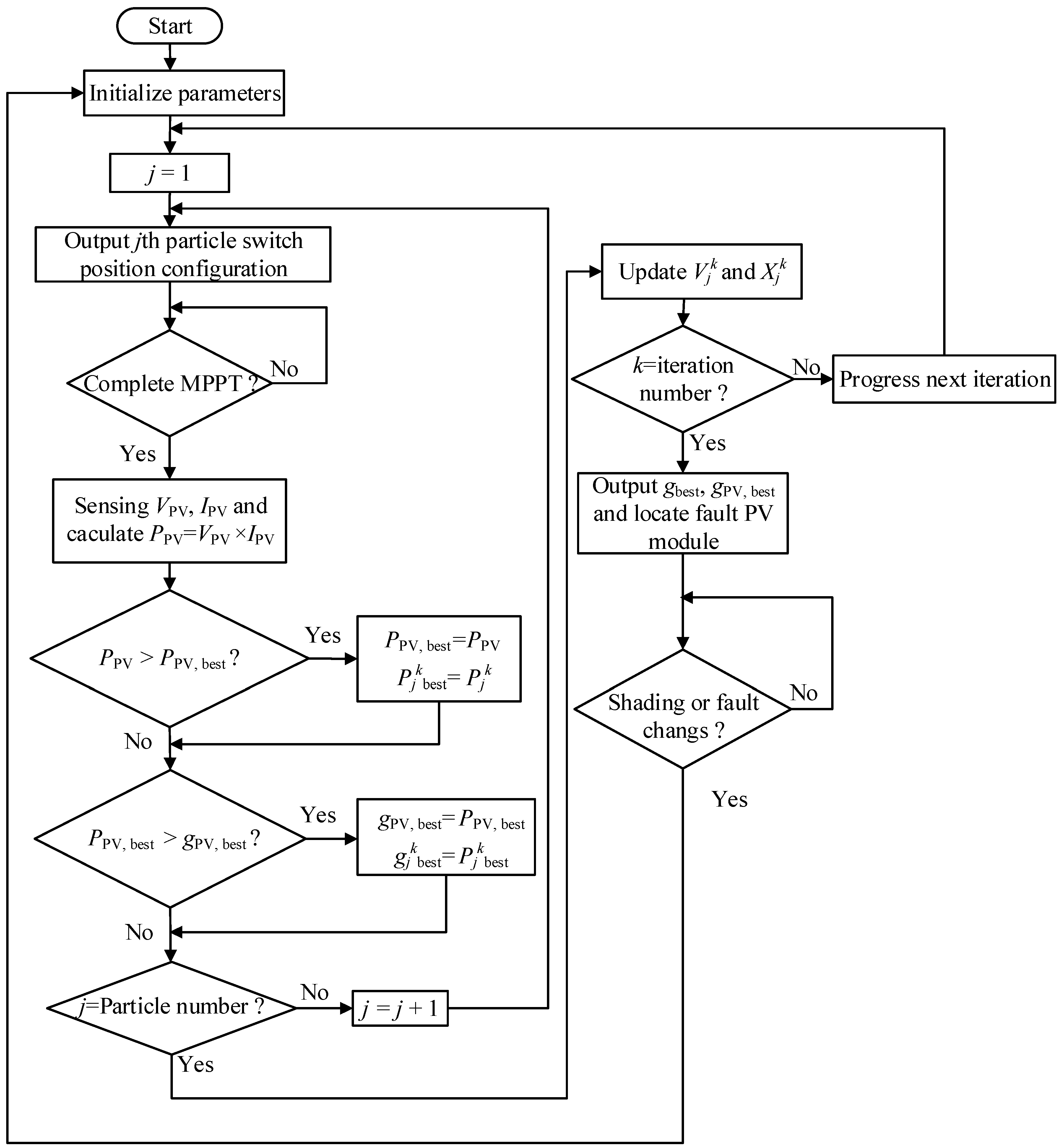

4.2. MPPT under Shaded Conditions

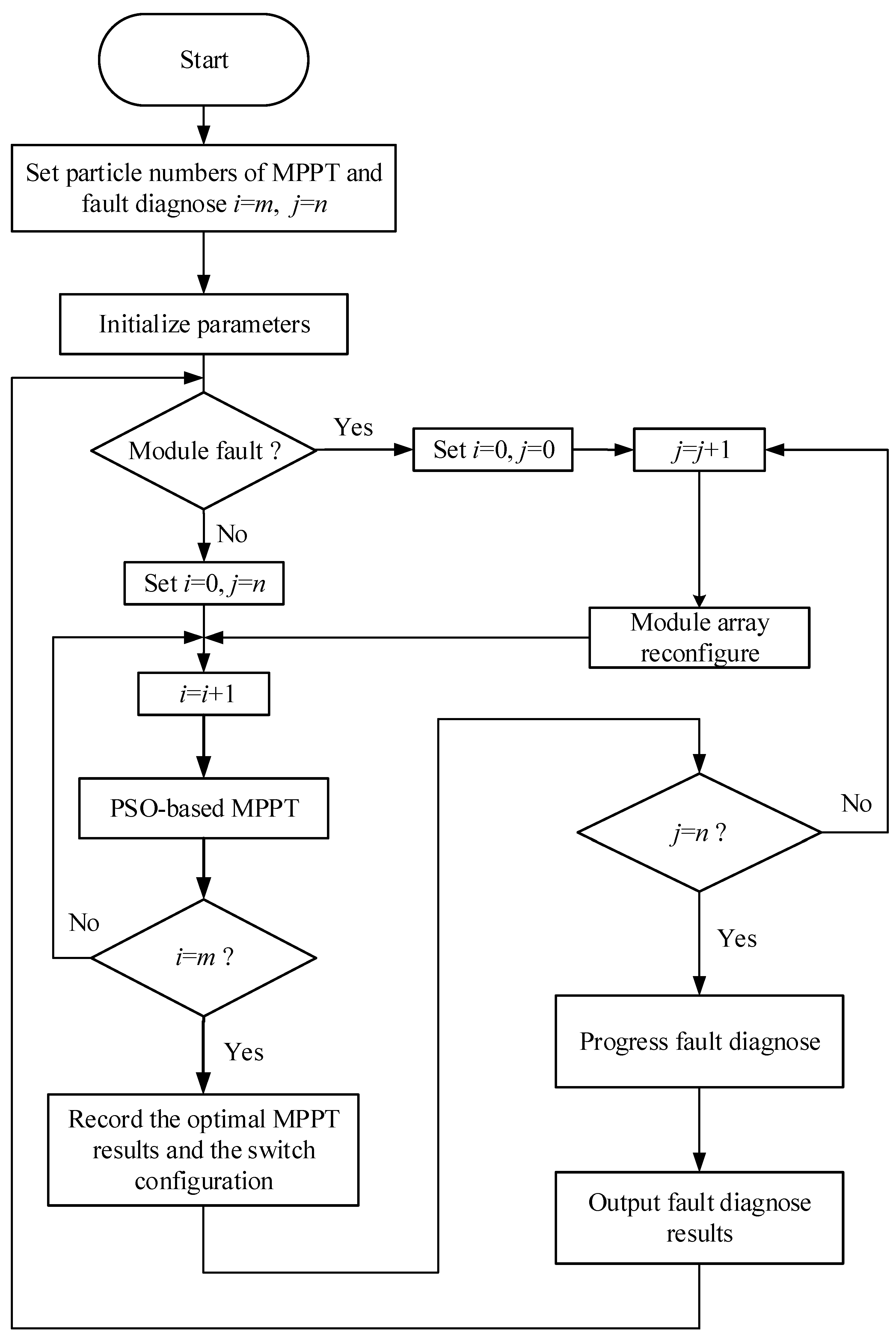

4.3. Integration between MPPT and Array Configuration Optimization

4.4. Online Fault Detection Mechanism

- step 1:

- Initialize all the PSO parameters, including the controlled signal (i.e., the configuration of switch position) of all the switches (here using relays as switches) pbest and gbest. The controlled signal of all the switches are set as the positions of particles, and the output power of a PV module array is defined as the objective function, that is, .

- step 2:

- The configuration of switch positions of particles is employed as the switch control signals in the progress of an MPP tracking event.

- step 3:

- The output power of the PV module array is evaluated as the output voltage times the output current at the end of a tracking event.

- step 4:

- Compare the current output power with PPV,best. In case the current output power is superior to PPV,best, then PPV,best is updated. At the same time, the optimal configuration of switch position Pbest is also update. Then, further compare PPV,best with gPV,best. If PPV,best is superior to gPV,best, then gPV,best is replaced with PPV,best. Meanwhile, the global optimal configuration of switch position gbest is also updated.

- step 5:

- The positions and velocities of all the particles are updated according to Equations (1) and (2). The indicates the switch positions of particle j at kth iteration.

- step 6:

- Repeat steps 2 to 5 until the maximum number of iterations is reached.

- step 7:

- The malfunction diagnostic block takes the switch control signals (configuration of switch positions) and the measured output power as inputs and locates and displays the non-well-operated PV modules on an LED array.

- step 8:

- In case of any change in the state of a malfunction event, go back to step 1 for a new run. Otherwise, remain idle.

5. Experimental Results

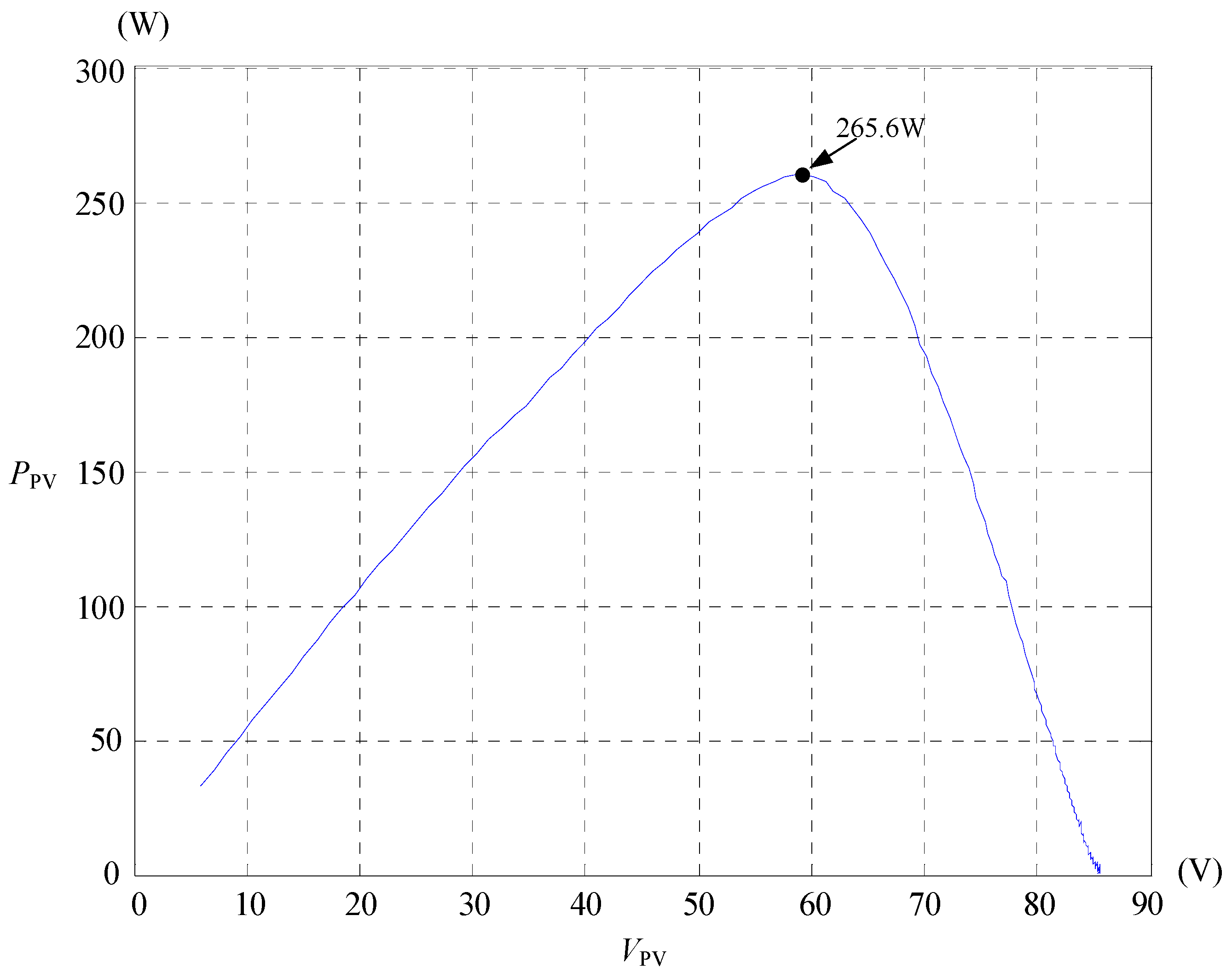

5.1. Optimized Configurations for Different Shaded Cases

5.1.1. Case 1: A 30% Shaded PV Module in Row 1 (Module 1, 5, or 9)

5.1.2. Case 2: A 30% shaded PV Module in Row 2 (Module 2, 6, or 10)

5.1.3. Case 3: A 30% Shaded PV Module in Row 3 (Module 3, 7, or 11)

5.1.4. Case 4: A 30% Shaded PV Module in Row 4 (Module 4, 8, or 12)

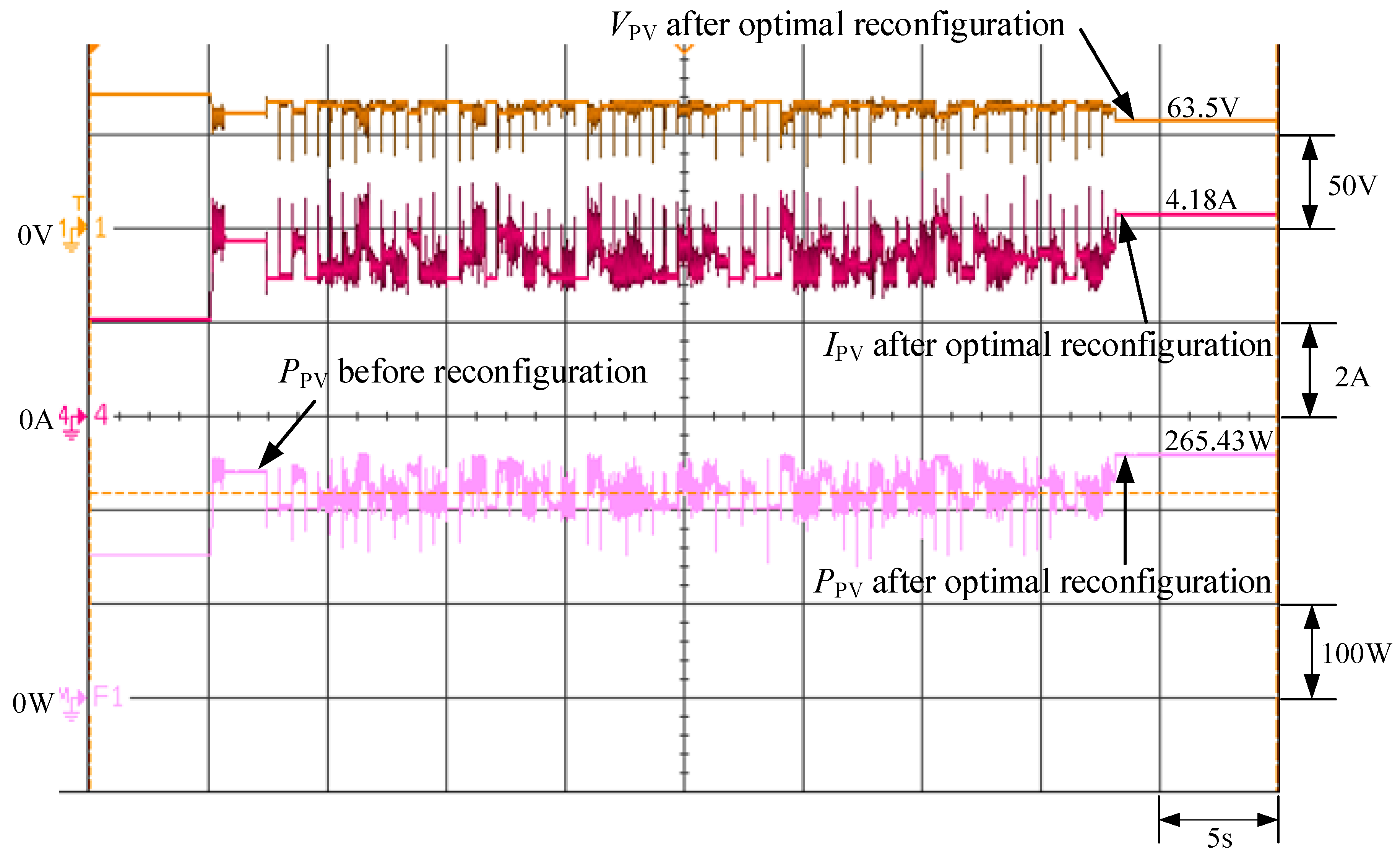

5.2. On-Line Tests of Duo Purpose Mechanism

5.2.1. Case 1: Module 1 with a 30% Shadow

5.2.2. Case 2: Module 6 with a 30% Shadow

5.2.3. Case 3: Module 11 with a 30% Shadow

5.2.4. Case 4: Module 8 with a 30% Shadow

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Tang, K.H.; Chao, K.H.; Chao, Y.W.; Chen, J.P. Design and implementation of a simulator for photovoltaic modules. Int. J. Photoenergy 2012, 2012, 1–6. [Google Scholar] [CrossRef]

- Patel, H.; Agarwal, V. Maximum power point tracking scheme for PV systems operating under partially shaded conditions. IEEE Trans. Ind. Electron. 2008, 55, 1689–1698. [Google Scholar] [CrossRef]

- Bradai, R.; Boukenoui, R.; Kheldoun, A.; Salhi, H.; Ghanes, M.; Barbot, J.-P.; Mellit, A. Experimental assessment of new fast MPPT algorithm for PV systems under non-uniform irradiance conditions. Appl. Energy 2017, 199, 416–429. [Google Scholar] [CrossRef]

- Gosumbonggot, J.; Fujita, G. Partial shading detection and global maximum power point tracking algorithm for photovoltaic with the variation of irradiation and temperature. Energies 2019, 12, 202. [Google Scholar] [CrossRef]

- Dzung, N.L.B. An adaptive solar photovoltaic array using model-based reconfiguration algorithm. IEEE Trans. Ind. Electron. 2008, 55, 2644–2654. [Google Scholar]

- Sharm El-Dein, M.Z.; Kazerani, M.; Salama, M.M.A. Novel configurations for photovoltaic farms to reduce partial shading losses. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; pp. 1–5. [Google Scholar]

- Alahmad, M.; Chaaban, M.A.; Lau, S.K.; Shi, J.; Neal, J. An adaptive utility interactive photovoltaic system based on a flexible switch matrix to optimize performance in real-time. Sol. Energy 2012, 86, 951–963. [Google Scholar] [CrossRef]

- Malathy, S.R.; Ramaprabha, R. Reconfiguration strategies to extract maximum power from photovoltaic array under partially shaded conditions. Renew. Sust. Energy Rev. 2018, 81, 2922–2934. [Google Scholar] [CrossRef]

- Niazi, K.A.K.; Yang, Y.H.; Sera, D. Review of mismatch mitigation techniques for PV modules. IET Renew. Power Gener. 2019, 13, 2035–2050. [Google Scholar] [CrossRef]

- Niazi, K.A.K.; Yang, Y.H.; Nasir, M.; Sera, D. Evaluation of interconnection configuration schemes for PV modules with switched-inductor converters under partial shading conditions. Energies 2019, 12, 2802. [Google Scholar] [CrossRef]

- Hariharan, R.; Chakkarapani, M.; Saravana Ilango, G.; Nagamani, C. A method to detect photovoltaic array faults and partial shading in PV systems. IEEE J. Photovolt. 2016, 6, 1278–1285. [Google Scholar] [CrossRef]

- Kumar, B.P.; Ilango, G.S.; Reddy, M.J.B.; Chilakapati, N. Nagamani Chilakapati. Online fault detection and diagnosis in photovoltaic systems using wavelet packets. IEEE J. Photovolt. 2018, 8, 257–265. [Google Scholar] [CrossRef]

- Rivai, A.; Rahim, N.A.; Elias, M.F.M.; Jamaludin, J. Analysis of photovoltaic string failure and health monitoring with module fault identification. Energies 2020, 13, 100. [Google Scholar] [CrossRef]

- Alam, M.K.; Khan, F.; Johnson, J.; Flicker, J. A comprehensive review of catastrophic faults in PV arrays: Types, detection, and mitigation techniques. IEEE J. Photovolt. 2015, 5, 982–997. [Google Scholar] [CrossRef]

- Zhao, Y.; Palma, J.F.; Mosesian, J.; Lyons, L.; Lehman, B. Line–line fault analysis and protection challenges in solar photovoltaic arrays. IEEE Trans. Ind. Electron. 2013, 60, 3784–3795. [Google Scholar] [CrossRef]

- Chen, Z.C.; Wu, L.J.; Cheng, S.Y.; Lin, P.J.; Wu, Y.; Lin, W.C. Intelligent fault diagnosis of photovoltaic arrays based on optimized kernel extreme learning machine and I-V characteristics. Appl. Energy 2017, 204, 912–931. [Google Scholar] [CrossRef]

- Chao, K.H.; Ho, S.H.; Wang, M.H. Modeling and fault diagnosis of a photovoltaic system. Elec. Power Syst. Res. 2008, 78, 97–105. [Google Scholar] [CrossRef]

- PVSAT Website. Available online: http://pvsat.de/rahmen.html (accessed on 20 August 2020).

- Lorenz, E.; Betcke, J.; Drews, A.; Heinemann, D.; Toggweiler, P.; Stettler, S.; Van Sark, W.; Heilscher, G.; Schneider, M.; Wiemken, E.; et al. PVSAT-2: Intelligent performance check of PV system operation based on satellite data. In Proceedings of the 19th European Photovolatic Solar Energy Conference, Paris, France, 7–11 June 2004; pp. 3069–3072. [Google Scholar]

- Drews, A.; Keizer, A.C.; Beyer, H.G.; Lorenz, E.; Betcke, J.; Van Sark, W.G.J.H.M.; Heydenreich, W.; Wiemken, E.; Stettler, S.; Toggweiler, P.; et al. Monitoring and remote failure detection of grid-connected PV systems based on satellite observations. Sol. Energy 2007, 81, 548–564. [Google Scholar] [CrossRef]

- De Keizer, A.C.; Van Sark, W.G.J.H.M.; Stettler, S.; Toggweiler, P.; Lorenz, E.; Drews, A.; Heinemann, D.; Heilscher, G.; Schneider, M.; Wiemken, E.; et al. PVSAT-2: Results of field test of the satellite-based PV system performance check. In Proceedings of the 21th European Photovolatic Solar Energy Conference, Dresden, Germany, 4–8 September 2006; pp. 2681–2685. [Google Scholar]

- Zhiqiang, H.; Li, G. Research and implementation of microcomputer online fault detection of solar array. In Proceedings of the 4th International Conference on Computer Science & Education, Nanning, China, 25–28 July 2009; pp. 1052–1055. [Google Scholar]

- Chao, K.H.; Chen, P.Y.; Wang, M.H.; Chen, C.T. An intelligent fault detection method of a photovoltaic module array using wireless sensor networks. Int. J. Distrib. Sens. Netw. 2014. [Google Scholar] [CrossRef]

- Chao, K.H.; Lai, P.L.; Liao, B.J. The optimal configuration of photovoltaic module arrays based on adaptive switching controls. Energy Convers. Manag. 2015, 100, 157–167. [Google Scholar] [CrossRef]

- Chao, K.H.; Tsai, J.H.; Chen, Y.H. Development of a low-cost fault detector for photovoltaic module array. Electronics 2019, 8, 255. [Google Scholar] [CrossRef]

- Grimaccia, F.; Leva, S.; Niccolai, A. PV plant digital mapping for modules defects detection by unmanned aerial vehicles. IET Renew. Power Gener. 2017, 11, 1221–1228. [Google Scholar] [CrossRef]

- Li, X.; Yang, Q.; Chen, Z.; Luo, X.; Yan, W. Visible defects detection based on UAV-based inspection in Iarge-scale photovoltaic systems. IET Renew. Power Gener. 2017, 11, 1234–1244. [Google Scholar] [CrossRef]

- Menéndez, O.; Guamán, R.; Pérez, M.; Cheein, F.A. Photovoltaic modules diagnosis using artificial vision techniques for artifact minimization. Energies 2018, 11, 1688. [Google Scholar] [CrossRef]

- Ramaprabha, R.; Mathur, B.L. A comprehensive review and analysis of solar photovoltaic array configurations under partial shaded conditions. Int. J. Photoenergy 2012. [Google Scholar] [CrossRef]

- Wang, Y.J.; Hsu, P.C. An investigation on partial shading of PV modules with different connection configurations of PV Cells. Energy 2011, 36, 3069–3078. [Google Scholar] [CrossRef]

- Satpathy, P.R.; Jena, S.; Sharma, R. Power enhancement from partially shaded modules of solar PV arrays. Energy 2018, 144, 839–850. [Google Scholar] [CrossRef]

- Deshpande, V.P.; Bodkhe, S.B. Analysis of various connection configuration of photovoltaic module under different shading conditions. Int. J. Appl. Eng. Res. 2017, 12, 5715–5720. [Google Scholar]

- Eberhart, R.C.; Kennedy, R.C. A new optimizer using particle swarm theory. In Proceedings of the 6th International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar]

- Kennedy, J.; Eberhart, R.C. Particle swarm optimization. In Proceedings of the International Neural Networks Conference, Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Liu, Y.; Niu, B. A novel PSO model based on simulating human social communication behavior. Int. J. Photoenergy 2012. [Google Scholar] [CrossRef]

- Liu, A.; Zahara, E.; Yang, M.T. A modified NM-PSO method for parameter estimation problems of models. Int. J. Photoenergy 2012. [Google Scholar] [CrossRef]

- Ishaque, K.; Salam, Z.; Amjad, M.; Mekhilef, S. An improved particle swarm optimization (PSO)—Based MPPT for PV with reduced steady-state oscillation. IEEE Trans. Power Electron. 2012, 27, 3627–3638. [Google Scholar] [CrossRef]

- Chao, K.H.; Lee, Y.H. A maximum power point tracker with automatic step size tuning scheme for photovoltaic systems. Int. J. Photoenergy 2012. [Google Scholar] [CrossRef]

- Liu, Y.H.; Huang, S.C.; Huang, J.W.; Liang, W.C. A particle swarm optimization-based maximum power point tracking algorithm for PV systems operating under partially shaded conditions. IEEE Trans. Energy Convers. 2012, 27, 1027–1035. [Google Scholar] [CrossRef]

- SANYO HIP 2717 Datasheet. Available online: http://iris.nyit.edu/~mbertome/solardecathlon/SDClerical/SD_DESIGN+DEVELOPMENT/091804_Sanyo190HITBrochure.pdf (accessed on 18 December 2019).

- MP-170 Brochure. Available online: http://www.environmental-expert.com/products/model-mp-170-iv.checker-80092 (accessed on 21 August 2020).

| Parameter Items | |

|---|---|

| Particle amount | 4 |

| Cognition learning factor (C1) | 1 |

| Social learning factor (C2) | 2 |

| Weighting (w) | 0.8 |

| Iterations | 8 |

| Switch NO. | Switch S1 | Switch S2 | Switch S3 | Switch S6 | Switch S7 | Switch S8 | |

|---|---|---|---|---|---|---|---|

| Shadow

Position | |||||||

| Shaded PV module in row 1 (module 1, 5 or 9) | 1 | 0 | 0 | 1 | 0 | 0 | |

| 1 | 1 | 0 | 1 | 0 | 0 | ||

| 1 | 0 | 1 | 1 | 0 | 0 | ||

| 1 | 1 | 1 | 1 | 0 | 0 | ||

| 1 | 0 | 0 | 1 | 1 | 0 | ||

| Shaded PV module in row 2 (module 2, 6 or 10) | 1 | 1 | 0 | 1 | 1 | 0 | |

| 1 | 1 | 1 | 1 | 1 | 0 | ||

| 1 | 1 | 0 | 1 | 1 | 1 | ||

| 1 | 1 | 1 | 1 | 1 | 1 | ||

| Shaded PV module in row 3 (module 3, 7 or 11) | 0 | 1 | 1 | 0 | 1 | 1 | |

| 1 | 1 | 1 | 0 | 1 | 1 | ||

| 0 | 1 | 1 | 1 | 1 | 1 | ||

| 1 | 1 | 1 | 1 | 1 | 1 | ||

| Shaded PV module in row 4 (module 4, 8 or 12) | 0 | 0 | 1 | 0 | 0 | 1 | |

| 1 | 0 | 1 | 0 | 0 | 1 | ||

| 0 | 1 | 1 | 0 | 0 | 1 | ||

| 1 | 1 | 1 | 0 | 0 | 1 | ||

| 0 | 0 | 1 | 1 | 0 | 1 | ||

| 1 | 0 | 1 | 1 | 0 | 1 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, K.-H.; Lai, P.-L. A Fault Diagnosis Mechanism with Power Generation Improvement for a Photovoltaic Module Array. Energies 2021, 14, 598. https://doi.org/10.3390/en14030598

Chao K-H, Lai P-L. A Fault Diagnosis Mechanism with Power Generation Improvement for a Photovoltaic Module Array. Energies. 2021; 14(3):598. https://doi.org/10.3390/en14030598

Chicago/Turabian StyleChao, Kuei-Hsiang, and Pei-Lun Lai. 2021. "A Fault Diagnosis Mechanism with Power Generation Improvement for a Photovoltaic Module Array" Energies 14, no. 3: 598. https://doi.org/10.3390/en14030598

APA StyleChao, K.-H., & Lai, P.-L. (2021). A Fault Diagnosis Mechanism with Power Generation Improvement for a Photovoltaic Module Array. Energies, 14(3), 598. https://doi.org/10.3390/en14030598