Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology

Abstract

:1. Introduction

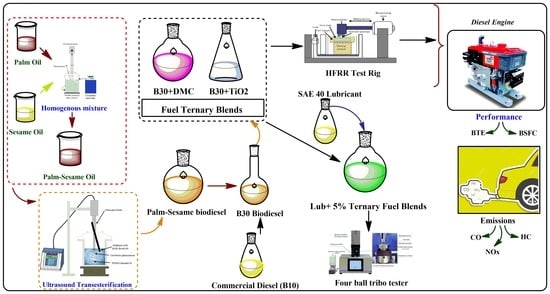

2. Materials and Methods

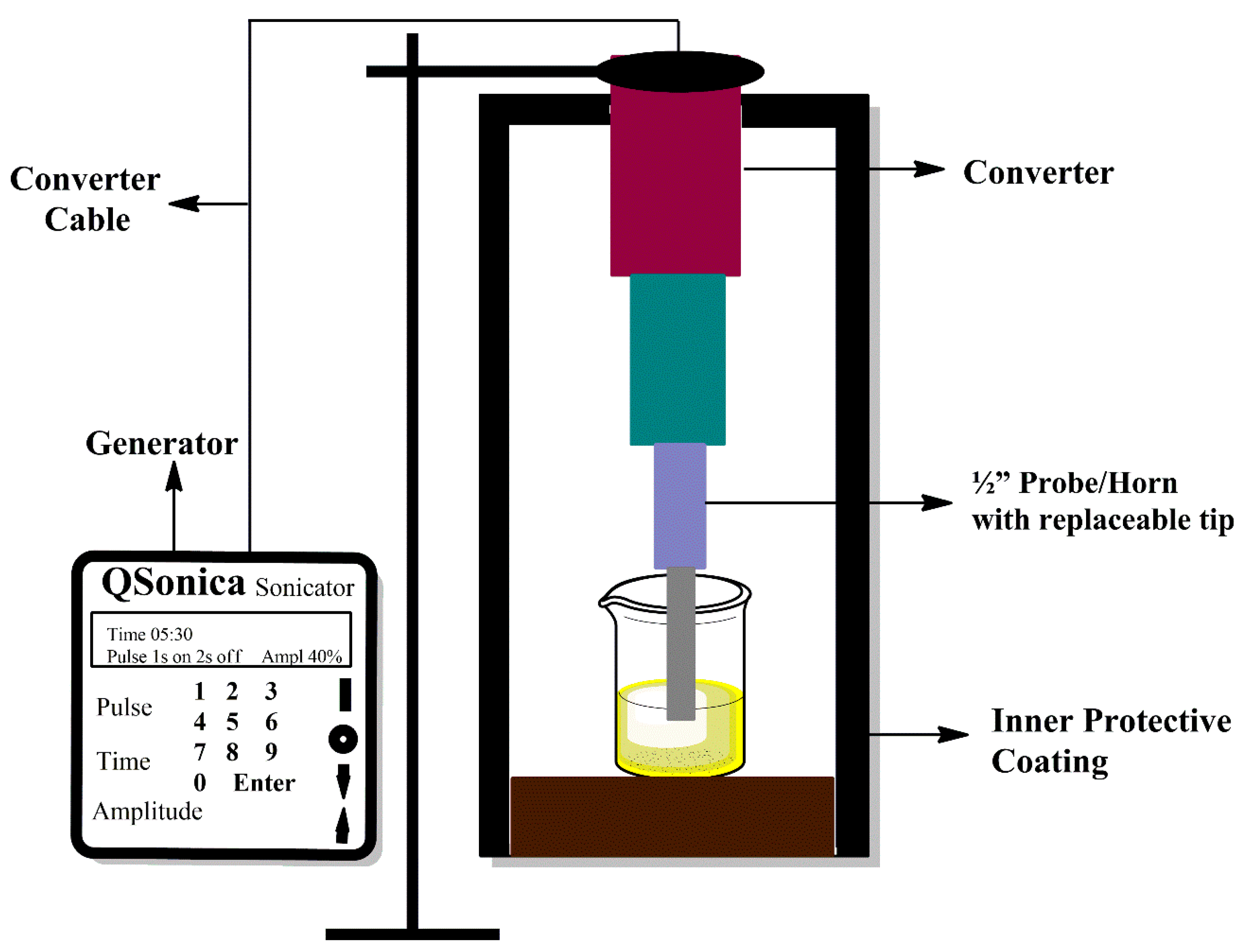

2.1. Biodiesel Production

2.2. Fuel Samples Preparation

2.2.1. Fuel Sample Preparation for HFRR and Engine Test Rig

2.2.2. Lubricant Sample Preparation

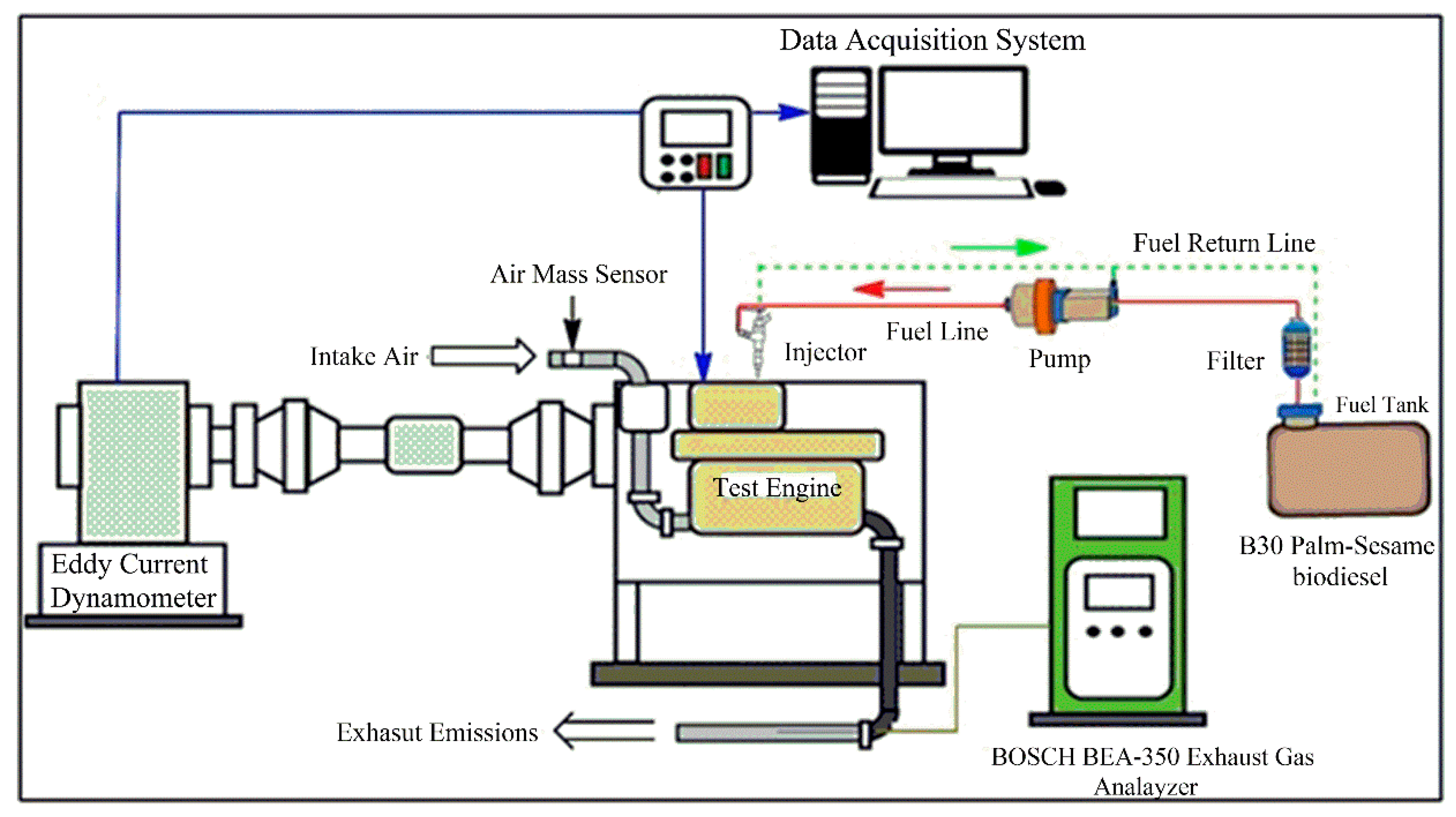

2.3. Experimental Set-Up

2.3.1. Diesel Engine Set-Up

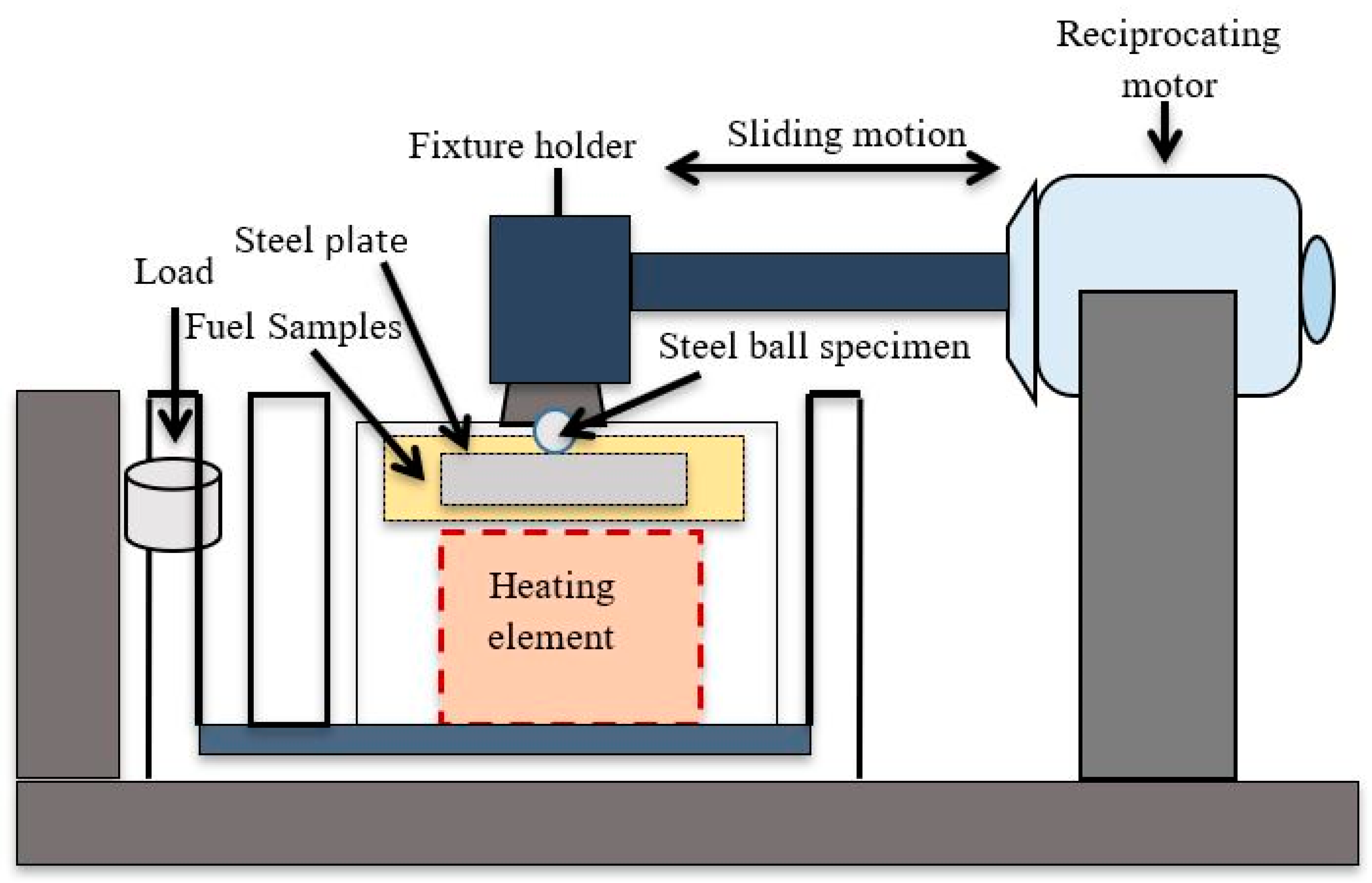

2.3.2. HFRR Test Rig

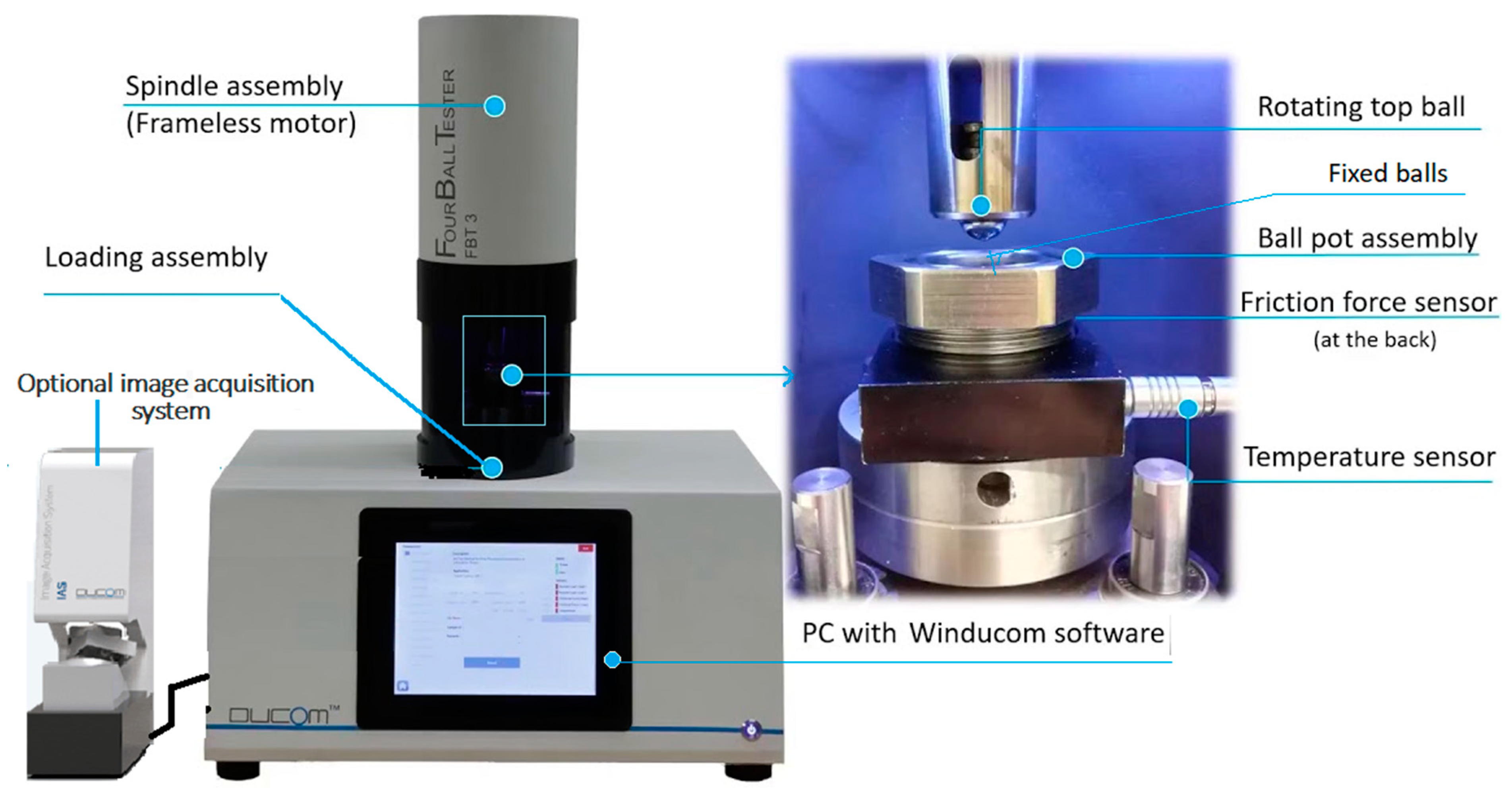

2.3.3. Four-Ball Tribo Tester Rig

3. Results and Discussion

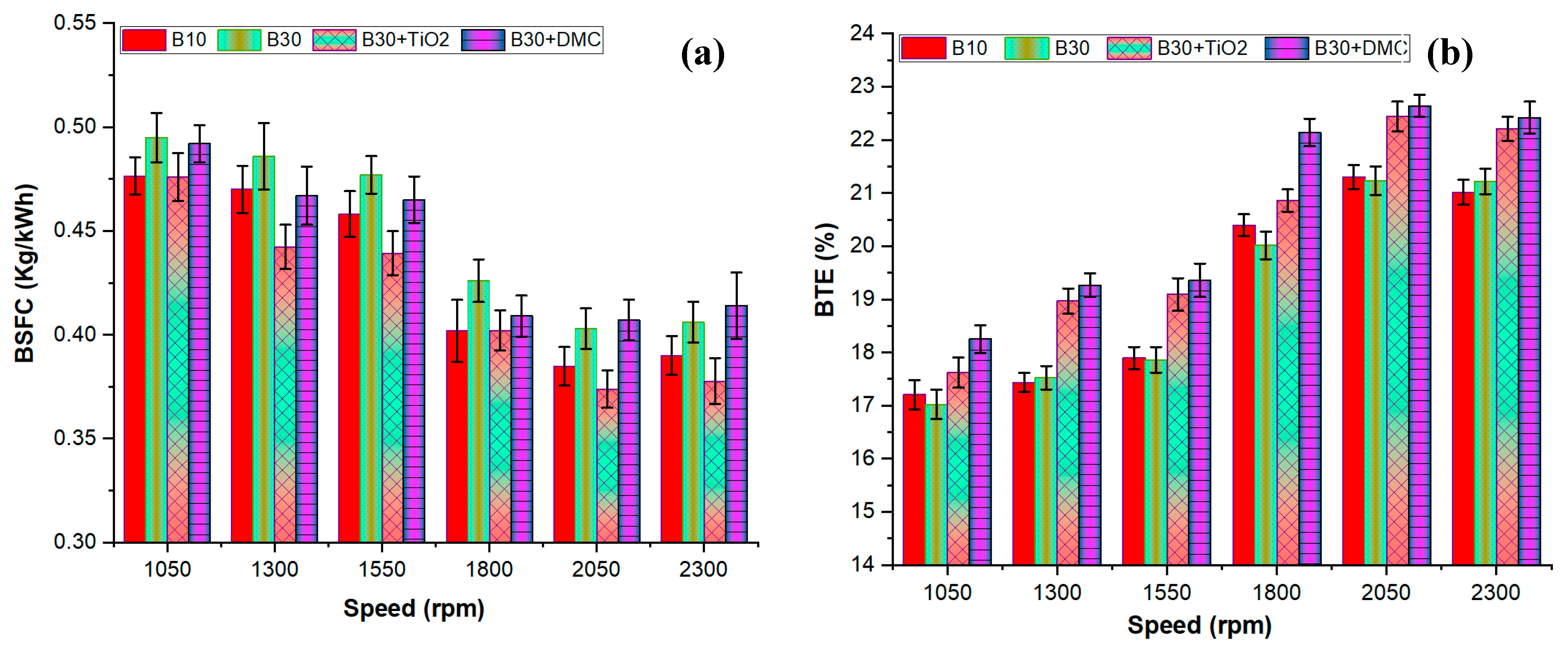

3.1. Engine Performance

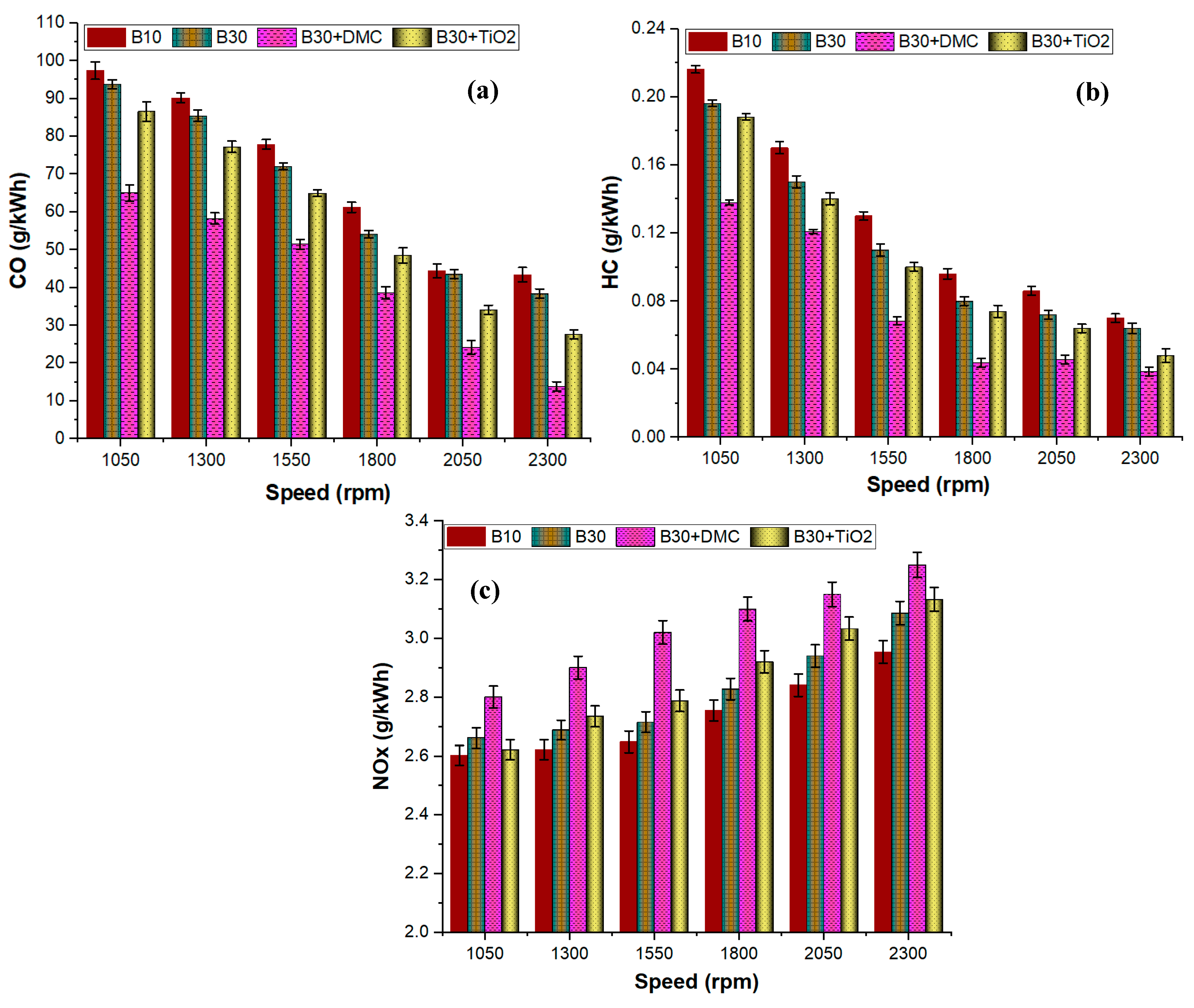

3.2. Engine Emissions

3.3. HFRR Tribological Study

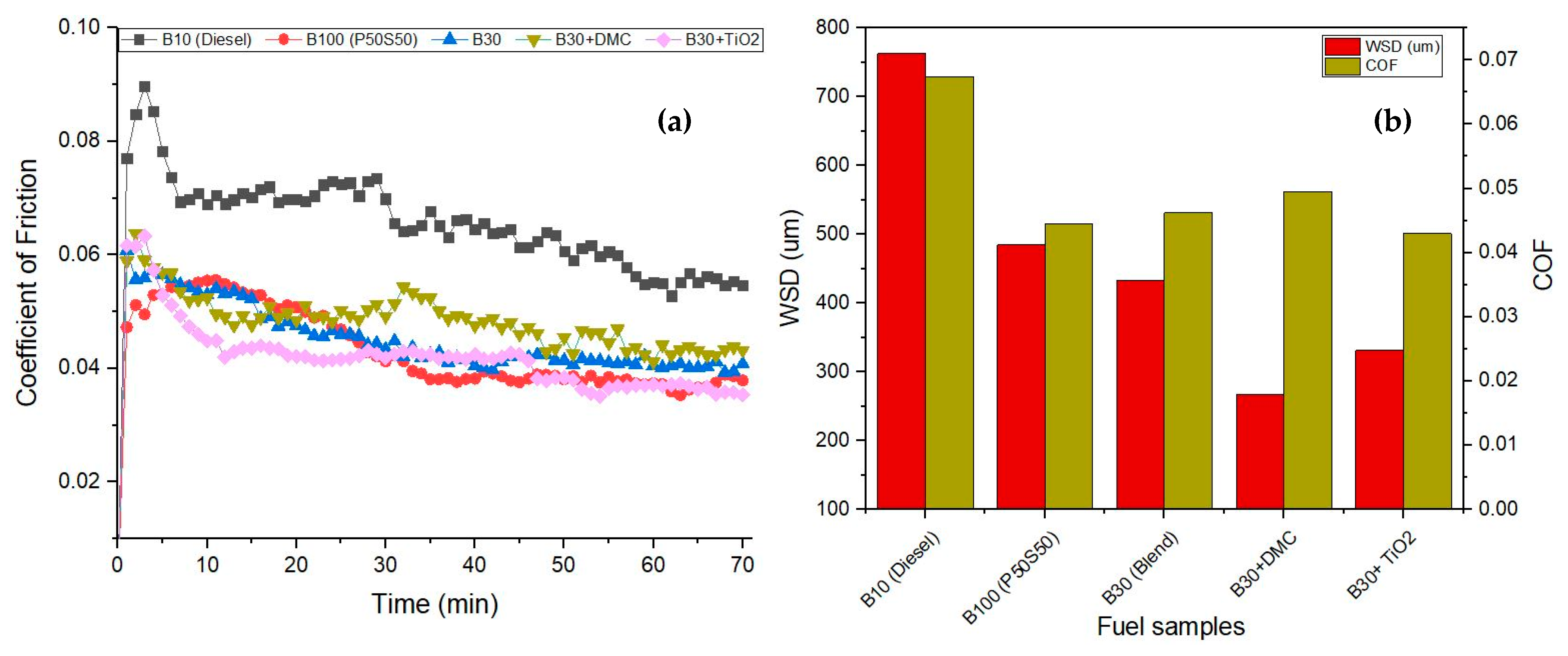

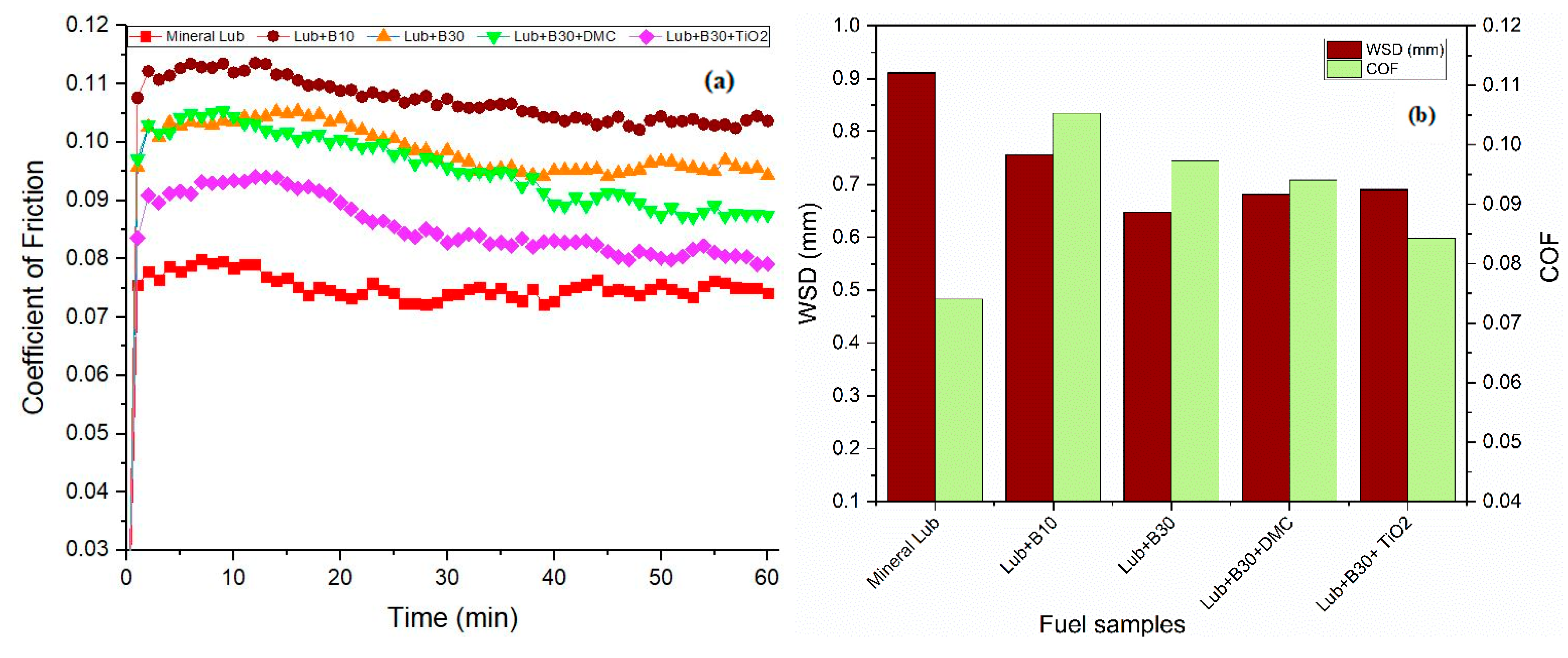

3.4. Four-Ball Tribological Study

4. Conclusions

- B10 (Malaysian commercial diesel) presented very poor lubricity. The B10 fuel blend showed very high COF and WSD values compared to other tested fuels.

- On average, B30 + TiO2 showed a reduction of 6.72% and B30 + DMC exhibited an increment of 7.15% in COF in comparison to B30 fuel. Both fuel additive blends showed a significant reduction in WSD by 38.4% and 23.5% for B30 fuel blended with DMC and TiO2 fuel additives in comparison with the neat B30 fuel blend.

- All contaminated samples showed increments in COF if 13.72%, 27%, 31.35%, and 42.29% for Lub + B30 + TiO2, Lub + B30 + DMC, and Lub + B10, respectively, compared to mineral lubricant.

- Ternary test fuels demonstrated an improvement in BSFC reduction of 6.76% and 1.45% for B30 fuel blended with DMC and TiO2 fuel additives in comparison with the neat B30 fuel blend.

- All ternary test fuels demonstrated a significant reduction in emissions of carbon monoxide upon adding fuel additives by 32.09% and 12.46% for B30 fuel blended with DMC and TiO2, respectively, in comparison with the B30 fuel blend.

- The B30 fuel blended with DMC and TiO2 nanoparticles showed a reduction in HC emissions of 25.4% and 8.63%, respectively, compared to B30 due to the presence of higher oxygen content.

- On average, the blends with fuel additives resulted in an increase in NOx emissions by 9.72% and 1.84% for B30 fuel blended with DMC and TiO2 in comparison with the B30 fuel blend.

5. Future Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ASTM | American Standard for Testing Materials |

| B100 | 100% biodiesel |

| EN | Europe Union |

| CI | Compression ignition |

| B30 | 70% diesel + 30% biodiesel |

| KOH | Potassium hydroxide |

| B10 | 10% biodiesel + 90% diesel |

| BTE | Brake thermal efficiency |

| HFRR | High-frequency reciprocating rig |

| BSFC | Brake-specific fuel consumption |

| TiO2 | Titanium oxide |

| BTDC | Before top dead center |

| P50S50 | 50% palm and 50% sesame |

| SO | Sesame oil |

| B30 + TiO2 | 70% diesel + 30% biodiesel + 100 ppm TiO2 by mass |

| COF | Coefficient of friction |

| ppm | Parts per million |

| HC | Hydrocarbon |

| DMC | Dimethyl carbonate |

| CO | Carbon monoxide |

| WSD | Wear scar diameter |

| NOx | Nitrogen oxides |

References

- Fattah, I.M.R.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8. [Google Scholar] [CrossRef]

- Ong, H.C.; Milano, J.; Silitonga, A.S.; Hassan, M.H.; Shamsuddin, A.H.; Wang, C.-T.; Indra Mahlia, T.M.; Siswantoro, J.; Kusumo, F.; Sutrisno, J. Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization. J. Clean. Prod. 2019, 219, 183–198. [Google Scholar] [CrossRef]

- Silitonga, A.; Shamsuddin, A.; Mahlia, T.; Milano, J.; Kusumo, F.; Siswantoro, J.; Dharma, S.; Sebayang, A.; Masjuki, H.; Ong, H.C. Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization. Renew. Energy 2020, 146, 1278–1291. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar] [CrossRef]

- Gad, M.S.; Jayaraj, S. A comparative study on the effect of nano-additives on the performance and emissions of a diesel engine run on Jatropha biodiesel. Fuel 2020, 267, 117168. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Syazmi, Z.A.H.S.; Mofijur, M.; Abas, A.E.P.; Bilad, M.R.; Ong, H.C.; Silitonga, A.S. Patent landscape review on biodiesel production: Technology updates. Renew. Sustain. Energy Rev. 2020, 118, 109526. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Chong, W.T.; Boosroh, M.H. Overview properties of biodiesel diesel blends from edible and non-edible feedstock. Renew. Sustain. Energy Rev. 2013, 22, 346–360. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Rizwanul Fattah, I.M.; Sajjad, H.; Arbab, M.I. Effect of n-butanol and diethyl ether as oxygenated additives on combustion–emission-performance characteristics of a multiple cylinder diesel engine fuelled with diesel–jatropha biodiesel blend. Energy Convers. Manag. 2015, 94, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Wakil, M.A.; Ashraful, A.M.; Shahir, S.A. Experimental investigation of performance and regulated emissions of a diesel engine with Calophyllum inophyllum biodiesel blends accompanied by oxidation inhibitors. Energy Convers. Manag. 2014, 83, 232–240. [Google Scholar] [CrossRef]

- Latiff, R. Malaysia to Implement B30 Biodiesel Mandate in Transport Sector before 2025; Sarkar, H., Ed.; REUTERS: Putrajaya, Malaysia, 2020. [Google Scholar]

- Elisha, O.; Fauzi, A.; Anggraini, E. Analysis of Production and Consumption of Palm-Oil Based Biofuel using System Dynamics Model: Case of Indonesia. Int. J. Sci. Eng. Technol. 2019, 6. [Google Scholar] [CrossRef]

- Coca, N. As Palm Oil for Biofuel Rises in Southeast Asia, Tropical Ecosystems Shrink; Chinadialogue China: Beijing, China, 2020. [Google Scholar]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Mofijur, M.; Abedin, M.J. Effect of antioxidant on the performance and emission characteristics of a diesel engine fueled with palm biodiesel blends. Energy Convers. Manag. 2014, 79, 265–272. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Muk Cho, H.; Masjuki, H.H.; Kalam, M.A.; Ong, H.C.; Gul, M.; Harith, M.H.; Yusoff, M.N.A.M. Critical review on sesame seed oil and its methyl ester on cold flow and oxidation stability. Energy Rep. 2020, 6, 40–54. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Masjuki, H.H.; Kalam, M.A.; Ong, H.C.; Gul, M.; Farooq, M.; Soudagar, M.E.M.; Ahmed, W.; Harith, M.H.; Yusoff, M.N.A.M. Ultrasound-assisted process optimization and tribological characteristics of biodiesel from palm-sesame oil via response surface methodology and extreme learning machine-Cuckoo search. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Gul, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Mujtaba, M.A. A Review: Role of Fatty Acids Composition in Characterizing Potential Feedstock for Sustainable Green Lubricants by Advance Transesterification Process and its Global as Well as Pakistani Prospective. BioEnergy Res. 2020, 13, 1–22. [Google Scholar] [CrossRef]

- Lapuerta, M.; García-Contreras, R.; Agudelo, J.R. Lubricity of Ethanol-Biodiesel-Diesel Fuel Blends. Energy Fuels 2010, 24, 1374–1379. [Google Scholar] [CrossRef]

- Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M. Impact of biodiesel blend on injector deposit formation. Energy 2014, 72, 813–823. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Experimental investigations of effect of Karanja biodiesel on tribological properties of lubricating oil in a compression ignition engine. Fuel 2014, 130, 112–119. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G. Preliminary study of nano-and microscale TiO2 additives on tribological behavior of chemically modified rapeseed oil. Tribol. Trans. 2013, 56, 797–805. [Google Scholar] [CrossRef]

- Agarwal, A.K. Lubricating Oil Tribology of a Biodiesel-Fuelled Compression Ignition Engine. Proceedings of ASME 2003 Internal Combustion Engine Division Spring Technical Conference, Erie, PA, USA, 7–10 September 2003. [Google Scholar]

- Gul, M.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam, M.A.; Mujtaba, M.A.; Harith, M.H.; Syahir, A.Z.; Ahmed, W.; Bari Farooq, A. Effect of TMP-based-cottonseed oil-biolubricant blends on tribological behavior of cylinder liner-piston ring combinations. Fuel 2020, 278, 118242. [Google Scholar] [CrossRef]

- Maleque, M.A.; Masjuki, H.H.; Haseeb, A.S.M.A. Effect of mechanical factors on tribological properties of palm oil methyl ester blended lubricant. Wear 2000, 239, 117–125. [Google Scholar] [CrossRef]

- Sulek, M.; Kulczycki, A.; Malysa, A. Assessment of lubricity of compositions of fuel oil with biocomponents derived from rape-seed. Wear 2010, 268, 104–108. [Google Scholar] [CrossRef]

- Singh, Y.; Singla, A.; Upadhyay, A.; Singh, A.K. Sustainability of Moringa-oil–based biodiesel blended lubricant. Energy Sources Part A: Recovery Util. Environ. Eff. 2017, 39, 313–319. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G. Effect of Bio-Lubricant and Biodiesel-Contaminated Lubricant on Tribological Behavior of Cylinder Liner–Piston Ring Combination. Tribol. Trans. 2012, 55, 438–445. [Google Scholar] [CrossRef]

- Mofijur, M.; Kusumo, F.; Fattah, I.; Mahmudul, H.; Rasul, M.; Shamsuddin, A.; Mahlia, T. Resource Recovery from Waste Coffee Grounds Using Ultrasonic-Assisted Technology for Bioenergy Production. Energies 2020, 13, 1770. [Google Scholar] [CrossRef] [Green Version]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crop. Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Murcak, A.; Haşimoğlu, C.; Çevik, İ.; Karabektaş, M.; Ergen, G. Effects of ethanol–diesel blends to performance of a DI diesel engine for different injection timings. Fuel 2013, 109, 582–587. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Rizwanul Fattah, I.M. Evaluation of n-butanol as an oxygenated additive to improve combustion-emission-performance characteristics of a diesel engine fuelled with a diesel-calophyllum inophyllum biodiesel blend. RSC Adv. 2015, 5, 17160–17170. [Google Scholar] [CrossRef]

- Nadeem, M.; Rangkuti, C.; Anuar, K.; Haq, M.; Tan, I.; Shah, S. Diesel engine performance and emission evaluation using emulsified fuels stabilized by conventional and gemini surfactants. Fuel 2006, 85, 2111–2119. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Demirbas, A.; Aghbashlo, M. Impacts of additives on performance and emission characteristics of diesel engines during steady state operation. Prog. Energy Combust. Sci. 2017, 59, 32–78. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Arbab, M.I.; Fattah, I.M.R. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Anbarasu, A.; Karthikeyan, A. Performance and emission characteristics of a diesel engine using cerium oxide nanoparticle blended biodiesel emulsion fuel. J. Energy Eng 2016, 142, 04015009. [Google Scholar] [CrossRef]

- Örs, I.; Sarıkoç, S.; Atabani, A.E.; Ünalan, S.; Akansu, S.O. The effects on performance, combustion and emission characteristics of DICI engine fuelled with TiO2 nanoparticles addition in diesel/biodiesel/n-butanol blends. Fuel 2018, 234, 177–188. [Google Scholar] [CrossRef]

- D’Silva, R.; Binu, K.; Bhat, T.J.M.T.P. Performance and Emission characteristics of a CI Engine fuelled with diesel and TiO2 nanoparticles as fuel additive. Mater. Today Proc. 2015, 2, 3728–3737. [Google Scholar] [CrossRef]

- Devarajan, Y. Experimental evaluation of combustion, emission and performance of research diesel engine fuelled di-methyl- carbonate and biodiesel blends. Atmos. Pollut. Res. 2019, 10, 795–801. [Google Scholar] [CrossRef]

- Saxena, V.; Kumar, N.; Saxena, V.K. Multi-objective optimization of modified nanofluid fuel blends at different TiO2 nanoparticle concentration in diesel engine: Experimental assessment and modeling. Appl. Energy 2019, 248, 330–353. [Google Scholar] [CrossRef]

- Prabu, A.; Anand, R.B. Emission control strategy by adding alumina and cerium oxide nano particle in biodiesel. J. Energy Inst. 2016, 89, 366–372. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Ebadi, M.T.; Mamat, R.; Yusaf, T. Biodiesels from three feedstock: The effect of graphene oxide (GO) nanoparticles diesel engine parameters fuelled with biodiesel. Renew. Energy 2020, 145, 190–201. [Google Scholar] [CrossRef]

- Anand, R.; Kannan, G.; Nagarajan, S.; Velmathi, S. Performance emission and combustion characteristics of a diesel engine fueled with biodiesel produced from waste cooking oil. SAE Tech. Pap. 2010. [Google Scholar] [CrossRef]

- Pan, M.; Qian, W.; Zheng, Z.; Huang, R.; Zhou, X.; Huang, H.; Li, M. The potential of dimethyl carbonate (DMC) as an alternative fuel for compression ignition engines with different EGR rates. Fuel 2019, 257, 115920. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H. Testing palm biodiesel and NPAA additives to control NOx and CO while improving efficiency in diesel engines. Bioenergy 2008, 32, 1116–1122. [Google Scholar] [CrossRef]

- Atmanli, A. Comparative analyses of diesel–waste oil biodiesel and propanol, n-butanol or 1-pentanol blends in a diesel engine. Fuel 2016, 176, 209–215. [Google Scholar] [CrossRef]

- Konishi, T.; Klaus, E.E.; Duda, J.L. Wear Characteristics of Aluminum-Silicon Alloy under Lubricated Sliding Conditions. Tribol. Trans. 1996, 39, 811–818. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Masum, B.M.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crop. Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

| Properties of Test Fuel | P50S50 | Malaysian Diesel | Equipment | Accuracy |

|---|---|---|---|---|

| Kinematic viscosity at 40 °C (mm2/s) | 4.43 | 2.88 | SVM 3000, (Anton Paar, Graz, Austria) | ±0.35% mm2/s |

| Acid Value (mg KOH/g) | 0.375 | 0.152 | - | - |

| Density at 15 °C (kg/m3) | 881 | 838.96 | SVM 3000, (Anton Paar, Graz, Austria) | ±0.1 kg/m3 |

| High heating value (MJ/kg) | 41.24 | 45.67 | C2000 basic calorimeter, IKA, Staufen, Germany | ±0.1% MJ/kg |

| Cetane number | 53.37 | 48.50 | - | - |

| Cold filter plugging point (°C ) | −1.714 | 0 | CFFP NTL 450, Compass Instruments, IL, USA | - |

| Flash point (°C ) | >151 | 77.90 | Pensky-Martens closed cup tester NPM 440, Normalab, Valliquerville, France | ±0.1 °C |

| Cloud point (°C ) | 7.82 | 2.05 | Cloud and pour point tester NTE 450, Normalab, Valliquerville, France | ±0.1 °C |

| Pour point (°C ) | 3.821 | 2.1 | Cloud and pour point tester NTE 450, Normalab, Valliquerville, France | - |

| Oxidation stability (h) | 6.89 | 13.20 | 873 Biodiesel Rancimat, Metrohm, Herisau, Switzerland | ±0.01 h |

| Test Fuel Blends | Density at 15 °C | Kinematic Viscosity at 40 °C | Calorific Value | Viscosity Index |

|---|---|---|---|---|

| kg/m3 | mm2/s | MJ/kg | ||

| B10 | 855.9 | 3.153 | 43.92 | 81.2 |

| B100 (P50S50 biodiesel) | 880 | 4.420 | 41.25 | 186.2 |

| B30 | 852.6 | 3.348 | 43.14 | 164.2 |

| B30 + DMC | 878 | 2.457 | 39.78 | - |

| B30 + TiO2 | 853 | 3.364 | 42.93 | 208.3 |

| Lubricant Samples | Physicochemical Properties of Lubricant Samples | ||

|---|---|---|---|

| Density at 15 °C (kg/m3) | Viscosity at 40 °C (mm2/s) | Viscosity Index | |

| 100% Lubricant (SAE 40) | 873.7 | 87,022 | 201.3 |

| Lubricant + 5% B10 | 872.0 | 71,072 | 205.3 |

| Lubricant + 5% B30 | 873.3 | 76,652 | 221.6 |

| Lubricant + 5% B30 + DMC | 872.0 | 64,509 | - |

| Lubricant + 5% B30 + TiO2 | 872.1 | 69,311 | 205.4 |

| Measurement | Measurement Range | Accuracy (±) |

|---|---|---|

| Speed | 60–10,000 rpm | ±10 rpm |

| Load | ±120 Nm | ±0.1 Nm |

| Flow Measurement | 0.5–36 L/h | ±0.01 L/h |

| CO | 0–10 vol.% | ±0.001 vol.% |

| HC | 0–9999 ppm | ±1 ppm |

| NOx | 0–5000 ppm | ±1 ppm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mujtaba, M.A.; Masjuki, H.H.; Kalam, M.A.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Rizwanul Fattah, I.M.; et al. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies 2020, 13, 3375. https://doi.org/10.3390/en13133375

Mujtaba MA, Masjuki HH, Kalam MA, Noor F, Farooq M, Ong HC, Gul M, Soudagar MEM, Bashir S, Rizwanul Fattah IM, et al. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies. 2020; 13(13):3375. https://doi.org/10.3390/en13133375

Chicago/Turabian StyleMujtaba, M. A., H. H. Masjuki, M. A. Kalam, Fahad Noor, Muhammad Farooq, Hwai Chyuan Ong, M. Gul, Manzoore Elahi M. Soudagar, Shahid Bashir, I. M. Rizwanul Fattah, and et al. 2020. "Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology" Energies 13, no. 13: 3375. https://doi.org/10.3390/en13133375

APA StyleMujtaba, M. A., Masjuki, H. H., Kalam, M. A., Noor, F., Farooq, M., Ong, H. C., Gul, M., Soudagar, M. E. M., Bashir, S., Rizwanul Fattah, I. M., & Razzaq, L. (2020). Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies, 13(13), 3375. https://doi.org/10.3390/en13133375