Expedient Prediction of the Fuel Properties of Carbonized Woody Biomass Based on Hue Angle

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Carbonization Process

2.2. Fuel Property Measurements

2.3. Color Measurements

3. Results and Discussion

3.1. Properties of Carbonized WB

3.2. Color Changes of Carbonized WB

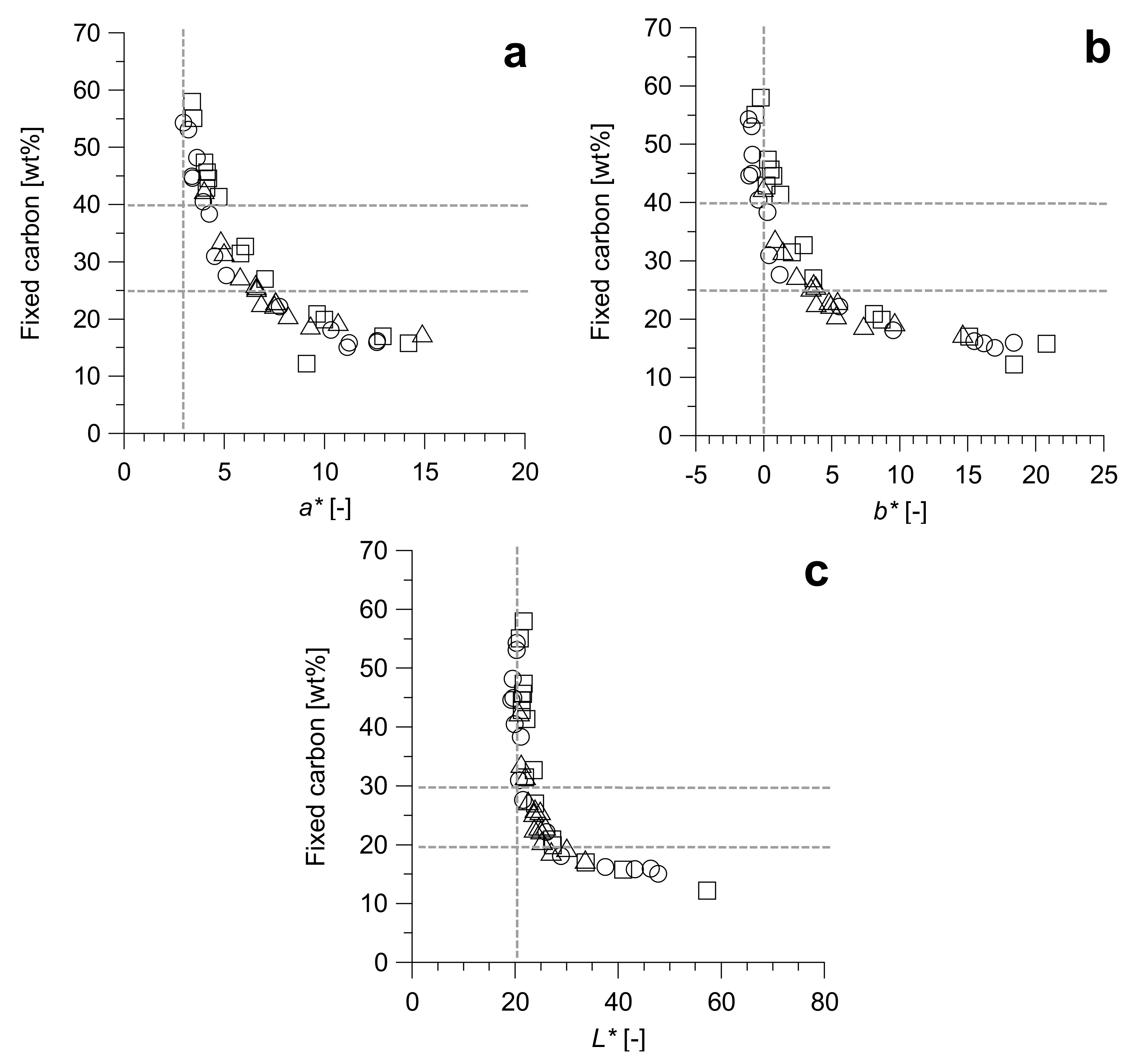

3.3. Relationship between the Color and Properties of Carbonized WB

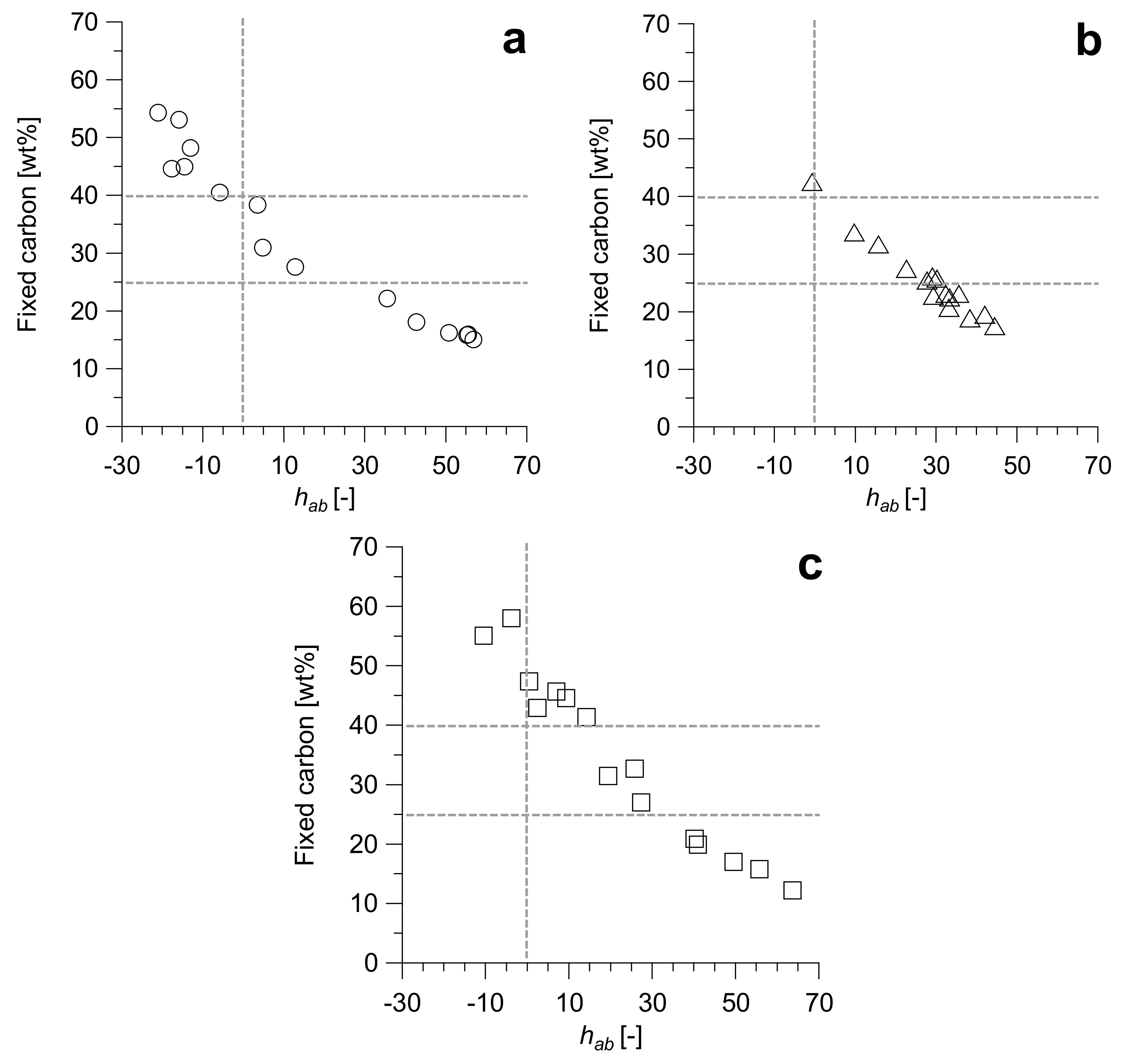

3.4. Hue Angle and Fuel Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody biomass energy potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- Colin, B.; Dirion, J.-L.; Arlabosse, P.; Salvador, S. Quantification of the torrefaction effects on the grindability and the hygroscopicity of wood chips. Fuel 2017, 197, 232–239. [Google Scholar] [CrossRef]

- Biswas, A.K.; Umeki, K.; Yang, W.; Blasiak, W. Change of pyrolysis characteristics and structure of woody biomass due to steam explosion pretreatment. Fuel Process. Technol. 2011, 92, 1849–1854. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl. Energy 2014, 135, 182–191. [Google Scholar] [CrossRef]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Gil, M.V.; García, R.; Pevida, C.; Rubiera, F. Grindability and combustion behavior of coal and torrefied biomass blends. Bioresour. Technol. 2015, 191, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Sun, R.; Chi, H.H.; Meng, X.; Li, Y.; Levendis, Y.A. Hydrogen chloride emissions from combustion of raw and torrefied biomass. Fuel 2017, 200, 37–46. [Google Scholar] [CrossRef]

- Ciolkosz, D.; Wallace, R. A review of torrefaction for bioenergy feedstock production. Biofuels Bioprod. Biorefin. 2011, 5, 317–329. [Google Scholar] [CrossRef]

- Koppejan, J.; Sokhansanj, S.; Melin, S.; Madrali, S. Status overview of torrefaction technologies. IEA Bioenergy Task Rep. 2015, 32, 1–54. [Google Scholar]

- Li, J.; Brzdekiewicz, A.; Yang, W.; Blasiak, W. Co-firing based on biomass torrefaction in a pulverised coal boiler with aim of 100% fuel switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; Energy Centre of Netherlands Report No. ECN-C-05-013; Energy Research Centre of The Netherlands (ECN): Petten, The Netherlands, 2005. [Google Scholar]

- Correia, R.; Gonçalves, M.; Nobre, C.; Mendes, B. Impact of torrefaction and low-temperature carbonization on the properties of biomass wastes from Arundo donax L. and Phoenix canariensis. Bioresour. Technol. 2017, 223, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, F.; San Miguel, G. Improved fuel properties of whole table olive stones via pyrolytic processing. Biomass Bioenergy 2016, 92, 1–11. [Google Scholar] [CrossRef]

- Sadaka, S.; Liechty, H.; Pelkki, M.; Blazier, M. Pyrolysis and combustion kinetics of raw and carbonized cottonwood and switchgrass agroforest. BioResources 2015, 10, 4498–4518. [Google Scholar] [CrossRef]

- Sadaka, S.; Sharara, M.A.; Ashworth, A.; Keyser, P.; Allen, F.; Wright, A. Characterization of biochar from switchgrass carbonisation. Energies 2014, 7, 548–567. [Google Scholar] [CrossRef]

- Kubojima, Y.; Yanagida, T.; Yoshida, T.; Kiguchi, M. Simple estimation method for determining weight reduction in torrefied wood chips by color date. Mokuzai Gakkaishi 2017, 63, 176–182. [Google Scholar] [CrossRef]

- Strandberg, A.; Holmgren, P.; Broström, M. Predicting fuel properties of biomass using thermogravimetry and multivariate data analysis. Fuel Process. Technol. 2017, 156, 107–112. [Google Scholar] [CrossRef]

- Lestander, T.A.; Rudolfsson, M.; Pommer, L.; Nordin, A. NIR provides excellent predictions of properties of biocoal from torrefaction and pyrolysis of biomass. Green Chem. 2014, 16, 4906–4913. [Google Scholar] [CrossRef]

- Lindström, S.W.; Nilsson, D.; Nordin, A.; Nordwaeger, M.; Olofsson, I.; Pommer, L.; Geladi, P. Quality assurance of torrefied biomass using RGB, visual and near infrared (hyper) spectral image data. J. Near Infrared Spectrosc. 2014, 22, 129–139. [Google Scholar] [CrossRef]

- Tooyserkani, Z.; Sokhansanj, S.; Bi, X.; Lim, J.; Lau, A.; Saddler, J.; Kumar, L.; Lam, P.S.; Melin, S. Steam treatment of four softwood species and bark to produce torrefied wood. Appl. Energy 2013, 103, 514–521. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Straka, R. Combustion process of torrefied wood biomass. J. Therm. Anal. Calorim. 2017, 127, 1339–1349. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Kalemba, I. Characterisation of renewable fuels’ torrefaction process with different instrumental techniques. Energy 2015, 87, 259–269. [Google Scholar] [CrossRef]

- Endo, Y.; Otaka, M. Development of energy self-sustained production process of Bio Upgraded CoalTM (BUC) with high co-firing rate in Pulverised Coal boilers. In Proceedings of the 9th i-CIPEC, Kyoto, Japan, 20–23 September 2016. [Google Scholar]

- Yana, W.; Perezb, S.; Shenga, K. Upgrading fuel quality of moso bamboo via low temperature thermochemical treatments: Dry torrefaction and hydrothermal carbonisation. Fuel 2017, 196, 473–480. [Google Scholar] [CrossRef]

- Chen, W.-H.; Cheng, W.-Y.; Lu, K.-M.; Huang, Y.-P. An evaluation on improvement of pulverised biomass property for solid fuel through torrefaction. Appl. Energy 2011, 88, 3636–3644. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, L. Effects of steam explosion on wood appearance and structure of sub-alpine fir. Wood Sci. Technol. 2006, 40, 427–436. [Google Scholar] [CrossRef]

- Dhyania, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2017, in press. [Google Scholar] [CrossRef]

| Sample | No. | Moisture | Ash | VM | FC | C | H | N | O | S | HHV | Temp. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (wt %) | (wt %) | (wt %) | (wt %) | (wt %) | (wt %) | (wt %) | (wt %) | (wt %) | (MJ/kg) | (°C) | ||

| Untreated rubber tree | R-1 | 28.9 | 1.3 | 83.6 | 15.1 | 49.9 | 6.6 | 0.4 | 41.9 | 0.02 | 19.8 | - |

| Carbonized rubber tree | R-2 | 0.2 | 1.6 | 82.2 | 16.3 | 51.7 | 6.6 | 0.4 | 41.3 | 0.06 | 20.2 | 304 |

| R-3 | 0.6 | 1.5 | 82.6 | 16.0 | 51.0 | 6.6 | 0.4 | 40.6 | 0.04 | 19.8 | 318 | |

| R-4 | 0.3 | 1.6 | 80.3 | 18.1 | 53.8 | 6.3 | 0.4 | 39.4 | 0.04 | 21.2 | 320 | |

| R-5 | 0.3 | 1.5 | 82.7 | 15.9 | 51.6 | 6.4 | 0.4 | 41.6 | 0.03 | 20.2 | 321 | |

| R-6 | 0.3 | 2.6 | 69.8 | 27.6 | 58.4 | 5.8 | 0.5 | 35.3 | 0.03 | 23.1 | 338 | |

| R-7 | 0.2 | 1.8 | 76.1 | 22.2 | 55.7 | 6.2 | 0.4 | 37.7 | 0.03 | 21.9 | 339 | |

| R-8 | 0.8 | 3.7 | 65.3 | 31.0 | 59.2 | 5.7 | 0.5 | 34.6 | 0.03 | 23.5 | 339 | |

| R-9 | 0.6 | 2.4 | 59.3 | 38.4 | 64.0 | 5.3 | 0.5 | 30.1 | 0.03 | 25.1 | 341 | |

| R-10 | 0.6 | 5.6 | 53.9 | 40.5 | 64.3 | 5.1 | 0.6 | 30.0 | 0.04 | 25.3 | 344 | |

| R-11 | 0.5 | 3.4 | 48.4 | 48.2 | 67.7 | 4.8 | 0.6 | 26.8 | 0.04 | 26.9 | 345 | |

| R-12 | 0.1 | 3.6 | 51.8 | 44.6 | 66.3 | 5.1 | 0.6 | 27.9 | 0.05 | 25.9 | 345 | |

| R-13 | 0.4 | 3.1 | 42.6 | 54.3 | 71.2 | 4.5 | 0.6 | 23.6 | 0.05 | 27.6 | 354 | |

| R-14 | 0.2 | 4.5 | 42.4 | 53.1 | 70.3 | 4.5 | 0.7 | 24.5 | 0.05 | 27.3 | 355 | |

| R-15 | 0.4 | 3.5 | 51.5 | 45.0 | 66.3 | 5.0 | 0.7 | 28.0 | 0.04 | 25.9 | 355 | |

| Untreated softwood bark | B-1 | 46.3 | 4.1 | 78.9 | 17.0 | 51.3 | 6.7 | 0.2 | 37.7 | 0.02 | 21.1 | - |

| Carbonized softwood bark | B-2 | <0.1 | 10.6 | 70.4 | 19.0 | 51.3 | 6.0 | 0.4 | 42.4 | 0.03 | 20.4 | 293 |

| B-3 | <0.1 | 10.0 | 69.8 | 20.2 | 52.9 | 5.9 | 0.4 | 40.8 | 0.03 | 20.9 | 303 | |

| B-4 | <0.1 | 8.5 | 69.0 | 22.6 | 55.8 | 6.0 | 0.4 | 37.8 | 0.03 | 21.8 | 305 | |

| B-5 | <0.1 | 14.5 | 67.2 | 18.4 | 50.0 | 5.6 | 0.4 | 44.0 | 0.03 | 19.8 | 305 | |

| B-6 | <0.1 | 10.3 | 67.0 | 22.6 | 52.8 | 5.7 | 0.4 | 41.1 | 0.03 | 21.6 | 309 | |

| B-7 | <0.1 | 5.5 | 69.3 | 25.2 | 57.6 | 5.9 | 0.3 | 36.1 | 0.03 | 22.8 | 310 | |

| B-8 | <0.1 | 5.7 | 72.0 | 22.3 | 57.4 | 6.0 | 0.3 | 36.3 | 0.03 | 22.6 | 311 | |

| B-9 | 0.1 | 8.0 | 60.8 | 31.2 | 60.9 | 5.4 | 0.3 | 33.3 | 0.03 | 24.2 | 315 | |

| B-10 | <0.1 | 7.5 | 67.6 | 25.0 | 57.0 | 6.0 | 0.4 | 36.6 | 0.03 | 22.7 | 316 | |

| B-11 | <0.1 | 5.0 | 72.9 | 22.0 | 56.4 | 6.1 | 0.3 | 32.2 | 0.04 | 22.6 | 317 | |

| B-12 | <0.1 | 8.0 | 65.0 | 27.0 | 57.8 | 5.8 | 0.4 | 36.1 | 0.03 | 23.4 | 319 | |

| B-13 | <0.1 | 15.8 | 58.5 | 25.6 | 54.1 | 5.3 | 0.4 | 40.2 | 0.03 | 21.1 | 319 | |

| B-14 | <0.1 | 7.7 | 50.2 | 42.0 | 67.0 | 4.8 | 0.4 | 27.8 | 0.03 | 26.4 | 330 | |

| B-15 | <0.1 | 6.5 | 60.2 | 33.3 | 62.2 | 5.5 | 0.3 | 31.9 | 0.04 | 24.6 | 337 | |

| Untreated lumber waste | W-1 | 59.5 | 0.1 | 87.7 | 12.2 | 50.3 | 6.6 | 0.1 | 42.9 | <0.01 | 19.8 | - |

| Carbonized lumber waste | W-2 | <0.1 | 0.2 | 82.8 | 17.0 | 53.5 | 6.4 | 0.1 | 39.8 | <0.01 | 20.5 | 337 |

| W-3 | <0.1 | 0.2 | 84.0 | 15.8 | 52.6 | 6.6 | 0.1 | 40.8 | <0.01 | 20.6 | 350 | |

| W-4 | <0.1 | 0.3 | 79.8 | 19.9 | 56.1 | 6.3 | 0.1 | 37.5 | <0.01 | 21.8 | 359 | |

| W-5 | <0.1 | 0.3 | 78.8 | 20.9 | 56.8 | 6.3 | 0.1 | 36.8 | <0.01 | 22.6 | 361 | |

| W-6 | 0.2 | 0.6 | 56.5 | 42.9 | 67.6 | 5.2 | 0.1 | 27.1 | <0.01 | 27.0 | 373 | |

| W-7 | 0.5 | 0.5 | 68.0 | 31.5 | 61.9 | 5.8 | 0.1 | 32.2 | <0.01 | 24.7 | 381 | |

| W-8 | 0.2 | 0.6 | 54.8 | 44.6 | 69.9 | 5.4 | 0.1 | 24.7 | <0.01 | 27.9 | 395 | |

| W-9 | 0.3 | 0.5 | 72.5 | 27.0 | 60.7 | 6.0 | 0.1 | 33.2 | <0.01 | 24.6 | 395 | |

| W-10 | 0.5 | 0.4 | 66.9 | 32.7 | 62.7 | 5.7 | 0.1 | 31.5 | <0.01 | 24.9 | 396 | |

| W-11 | 0.3 | 0.8 | 57.8 | 41.4 | 68.2 | 5.5 | 0.1 | 26.3 | <0.01 | 26.9 | 401 | |

| W-12 | 0.3 | 0.7 | 51.9 | 47.4 | 71.0 | 5.2 | 0.1 | 23.7 | <0.01 | 28.1 | 401 | |

| W-13 | <0.1 | 0.8 | 41.2 | 58.0 | 75.5 | 4.6 | 0.1 | 19.9 | <0.01 | 30.5 | 404 | |

| W-14 | 0.3 | 0.7 | 53.6 | 45.7 | 69.7 | 5.4 | 0.1 | 24.8 | <0.01 | 27.5 | 405 | |

| W-15 | <0.1 | 0.8 | 44.1 | 55.1 | 75.1 | 4.8 | 0.1 | 20.0 | <0.01 | 29.9 | 407 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saito, Y.; Sakuragi, K.; Shoji, T.; Otaka, M. Expedient Prediction of the Fuel Properties of Carbonized Woody Biomass Based on Hue Angle. Energies 2018, 11, 1191. https://doi.org/10.3390/en11051191

Saito Y, Sakuragi K, Shoji T, Otaka M. Expedient Prediction of the Fuel Properties of Carbonized Woody Biomass Based on Hue Angle. Energies. 2018; 11(5):1191. https://doi.org/10.3390/en11051191

Chicago/Turabian StyleSaito, Yuta, Kiyoshi Sakuragi, Tetsuya Shoji, and Maromu Otaka. 2018. "Expedient Prediction of the Fuel Properties of Carbonized Woody Biomass Based on Hue Angle" Energies 11, no. 5: 1191. https://doi.org/10.3390/en11051191

APA StyleSaito, Y., Sakuragi, K., Shoji, T., & Otaka, M. (2018). Expedient Prediction of the Fuel Properties of Carbonized Woody Biomass Based on Hue Angle. Energies, 11(5), 1191. https://doi.org/10.3390/en11051191