Scale-Fractal Detrended Fluctuation Analysis for Fault Diagnosis of a Centrifugal Pump and a Reciprocating Compressor

Abstract

1. Introduction

- 1.

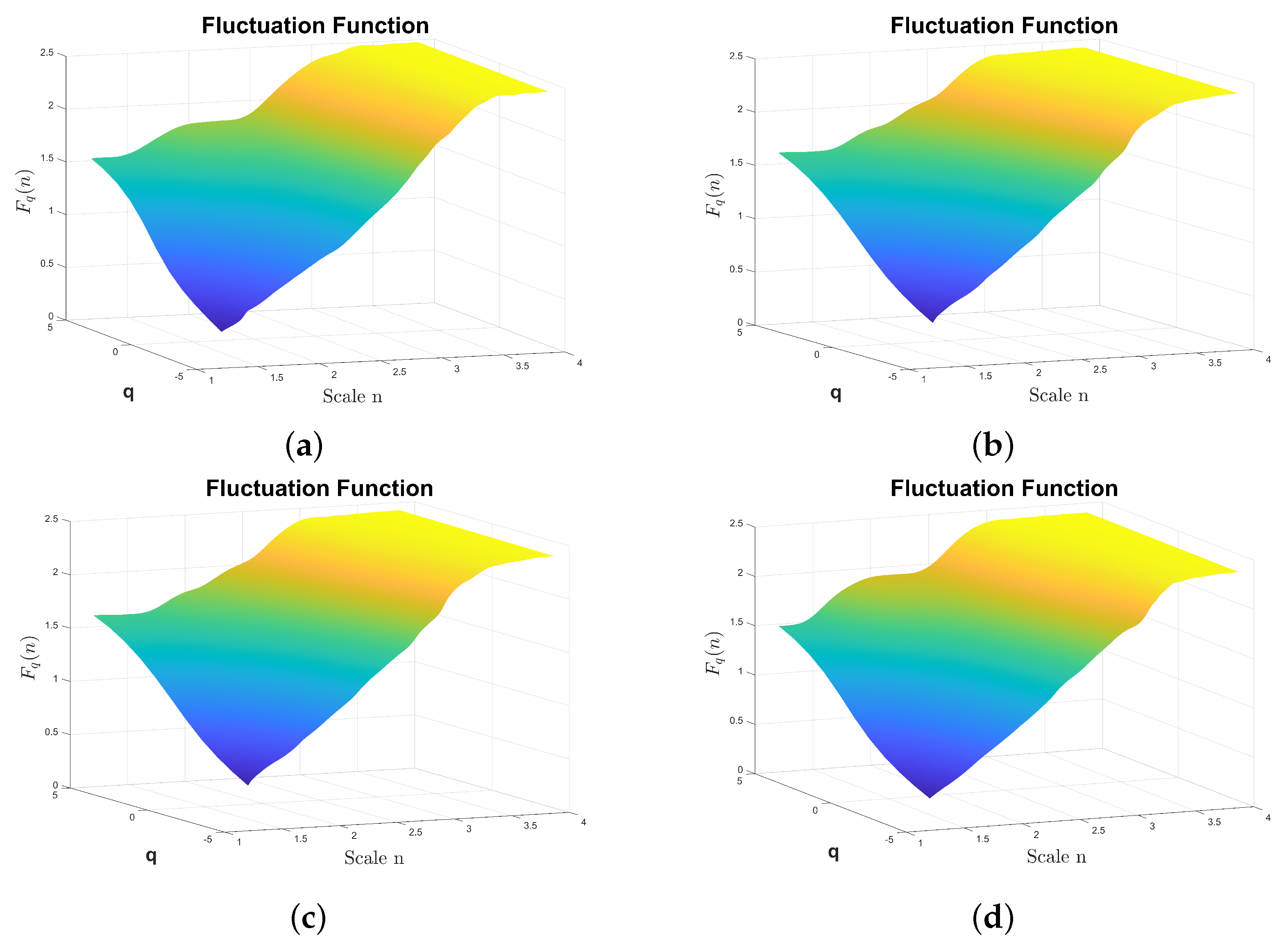

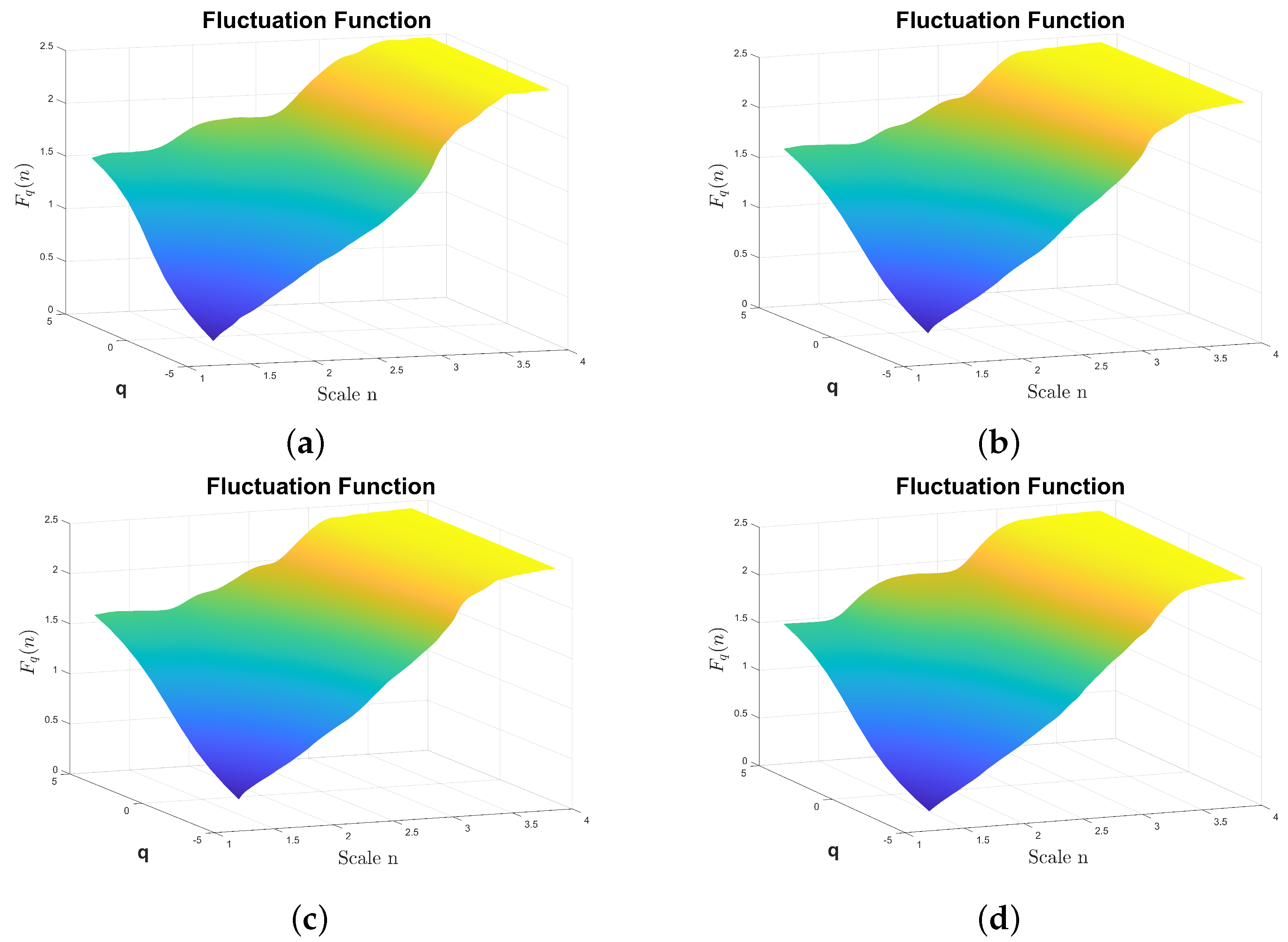

- A novel bidimensional feature extracted from the multi-scale, multi-fractal DFA analysis of raw vibration signals was proposed. Such a 2D surface can capture the fault signature’s scale or fractal features from the vibration signals without requiring the application of preprocessing or denoising methodologies.

- 2.

- This scale-fractal DFA representation extracted from the raw vibration signals efficiently diagnoses faults in a reciprocating compressor and a centrifugal pump. The performance of this novel feature was evaluated by classifying faults using three different vibration signal datasets: (a) a dataset with 17 multi-valve fault conditions, and (b) a dataset with 13 multi-fault conditions, both acquired from a reciprocating compressor. Additionally, we considered a dataset with 13 fault conditions recorded from a multi-stage centrifugal pump.

- 3.

- We propose a 2D robust scale-fractal feature representation extracted from vibration signals that can be easily adapted for fault classification using either deep learning-based or classical machine learning models.

2. Theoretical Background

2.1. Multi-Fractal Time Series

2.2. Detrended Fluctuation Analysis

- Step 1: The profile or accumulation sum is determined as [40]:where is the mean of the time series .

- Step 2: The profile accumulation is subdivided into segments of equal length n, , which are not overlapped. This procedure is applied to the signal in the forward time direction and, starting from the end and going backward, resulting in a total number of segments corresponding to .

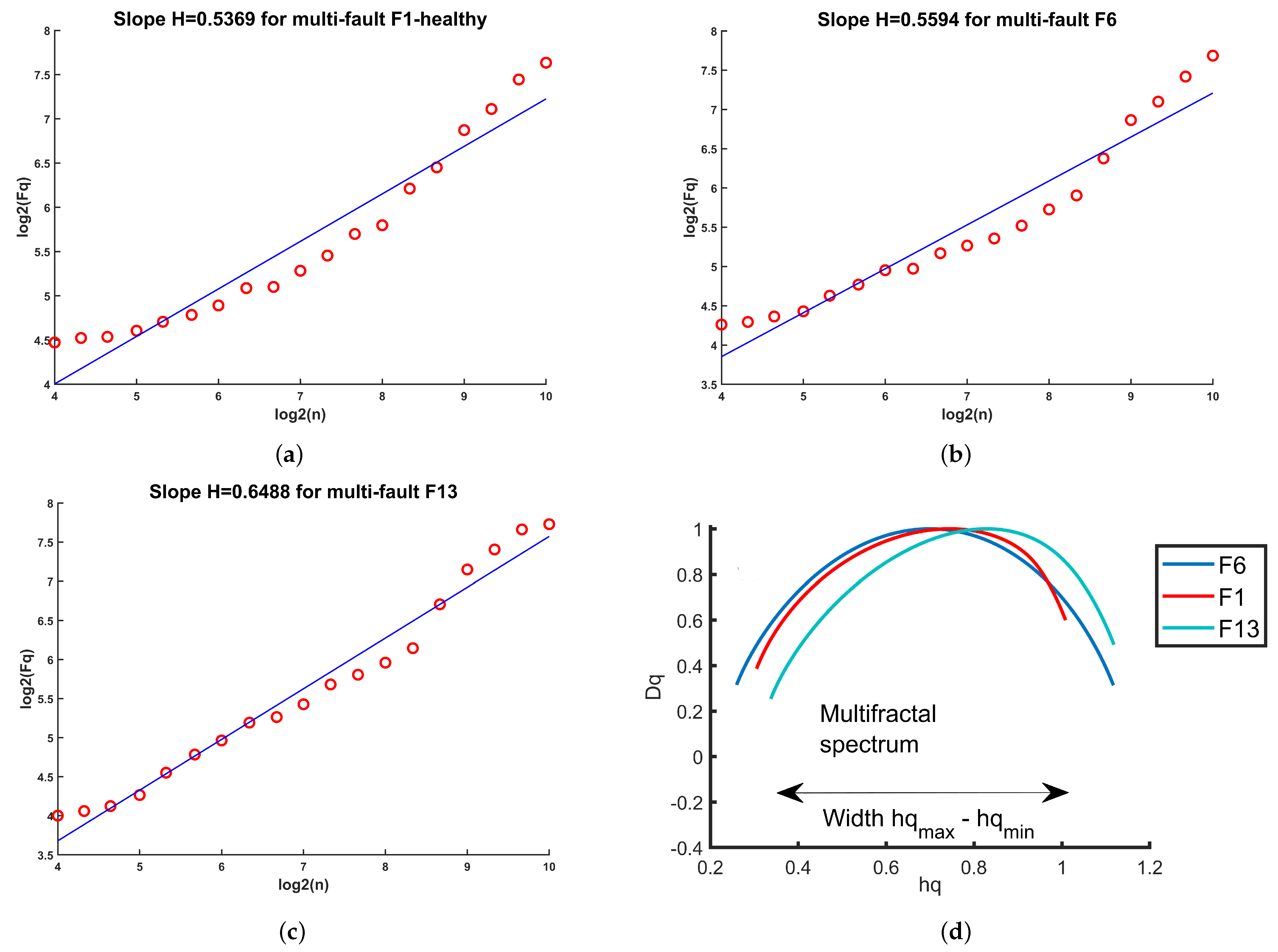

- Step 3: The trend is estimated in each segment. This trend calculation is conducted by the least-squares fit of the time series and subsequent estimation of the variance as [40]:for each signal segment , andfor . In both cases, represents a fitting polynomial in segment . The possibilities for the polynomial order are linear, quadratic, cubic, or higher-order polynomial. This fitting polynomial leads to different orders of DFA known as DFA1, DFA2, DFA3, … [45]. An example of DFA of order one, or linear DFA, is shown in Figure 1c, and the corresponding DFA of order two, or quadratic DFA, is shown in Figure 1d for a vibration signal.

- Step 4: The fluctuation function of q order is the average over all segments, as [40]:where q is a real number with values different from zero, if m represents the order of DFA, then is defined for .

- Step 5: The scaling structure of the fluctuation function can be estimated from the log-log plots of as a function of n considering several values of q. In time series long-range power-law correlated, when n has a large value, increases as a power-law [46]:where the generalized Hurst exponent corresponds to the slope in the log–log plot, usually denoted as H.

- Step 6: The time series multi-fractal spectrum can also be calculated as [47]:where .

2.3. Multi-Fractal Detrended Fluctuation Analysis

2.4. Algorithm for Fast Calculation of

3. Centrifugal Pump and Reciprocating Compressor Datasets

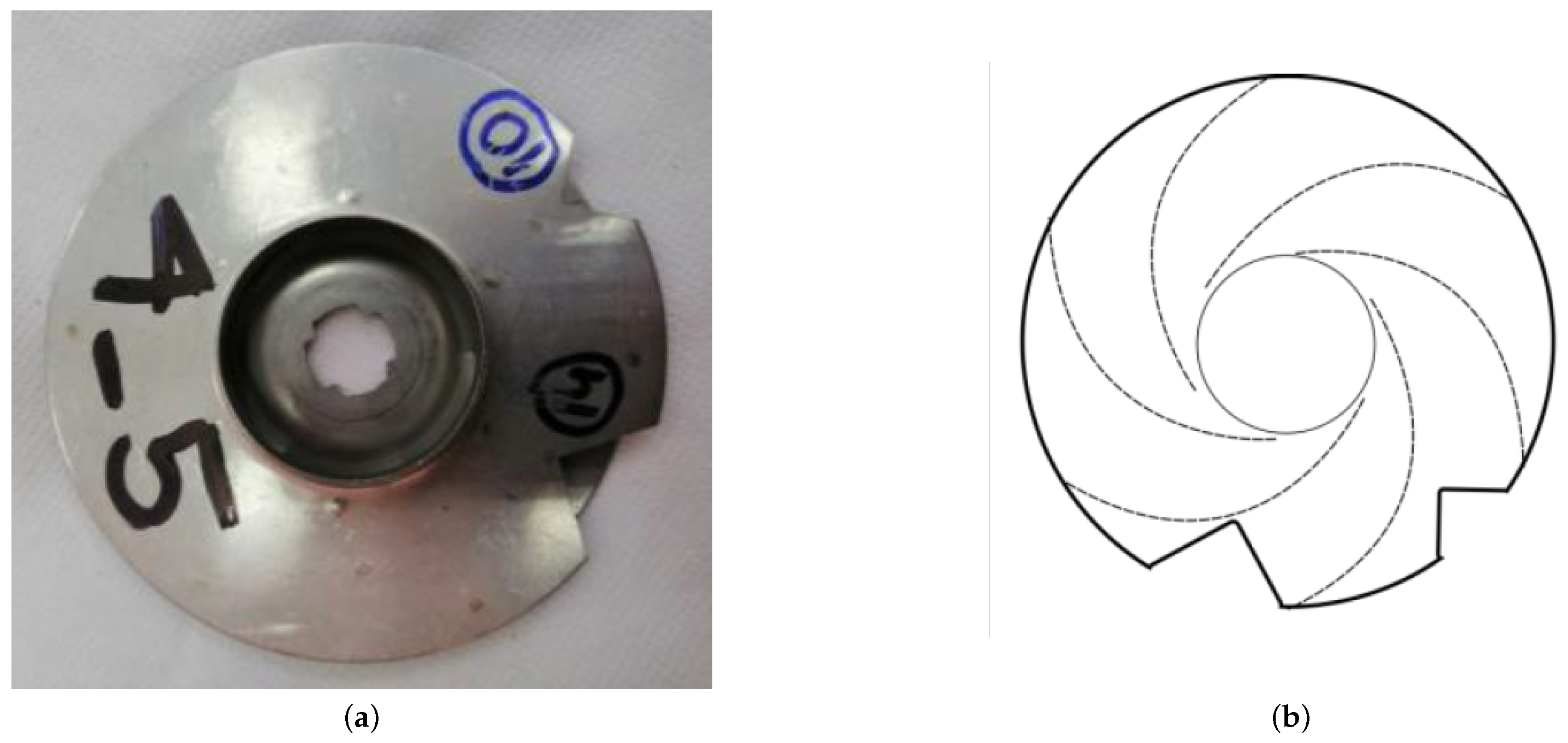

3.1. Centrifugal Pump Dataset

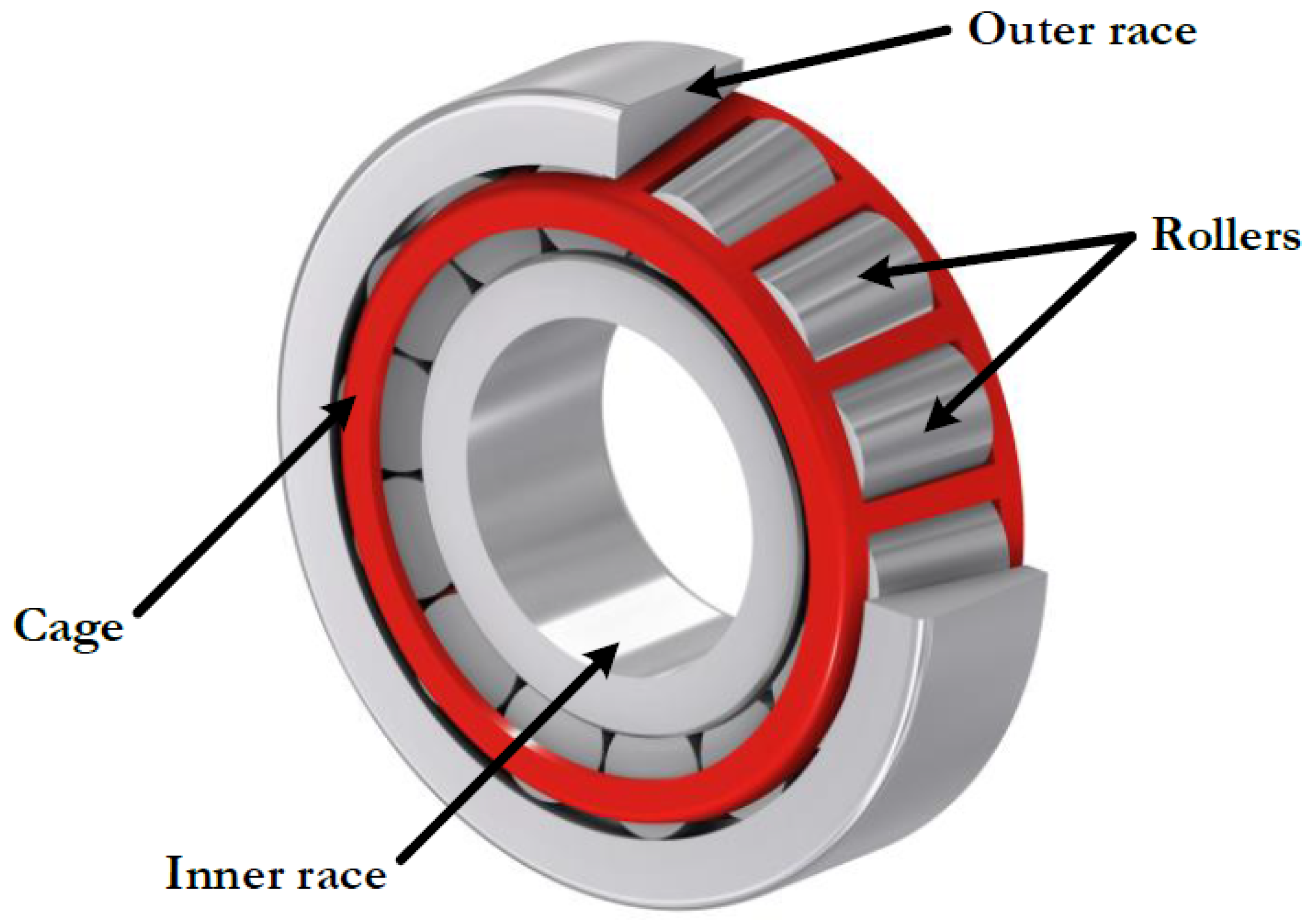

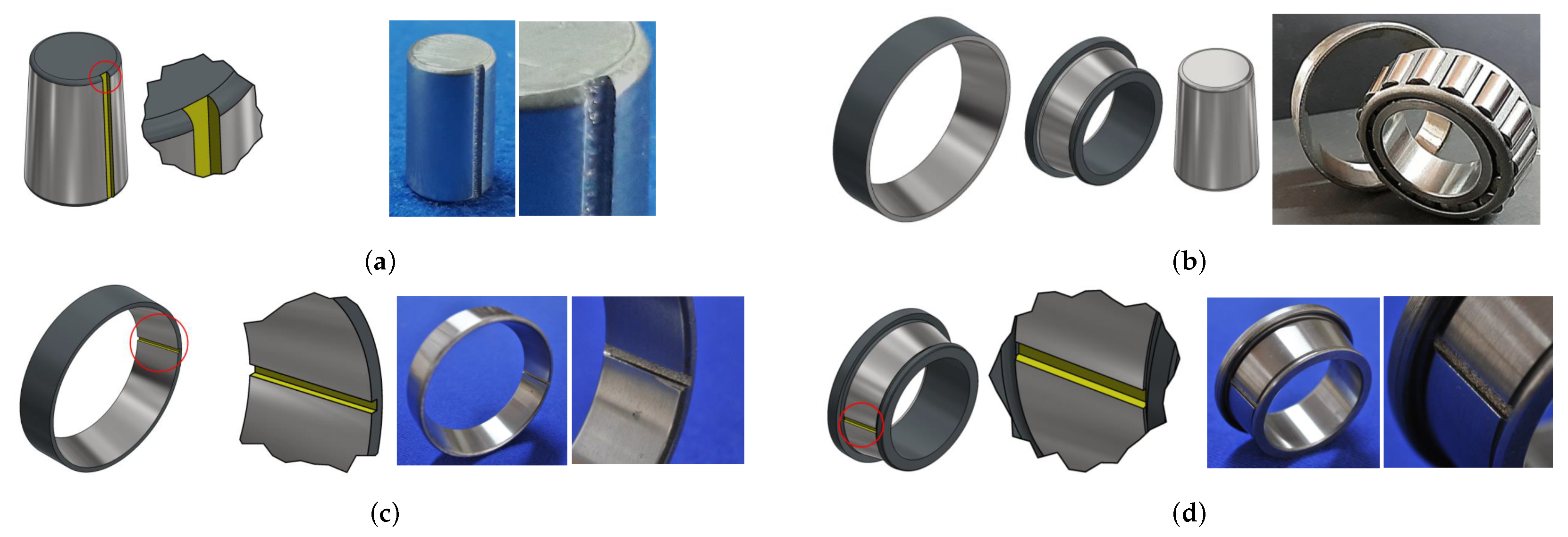

3.2. Reciprocating Compressor Dataset

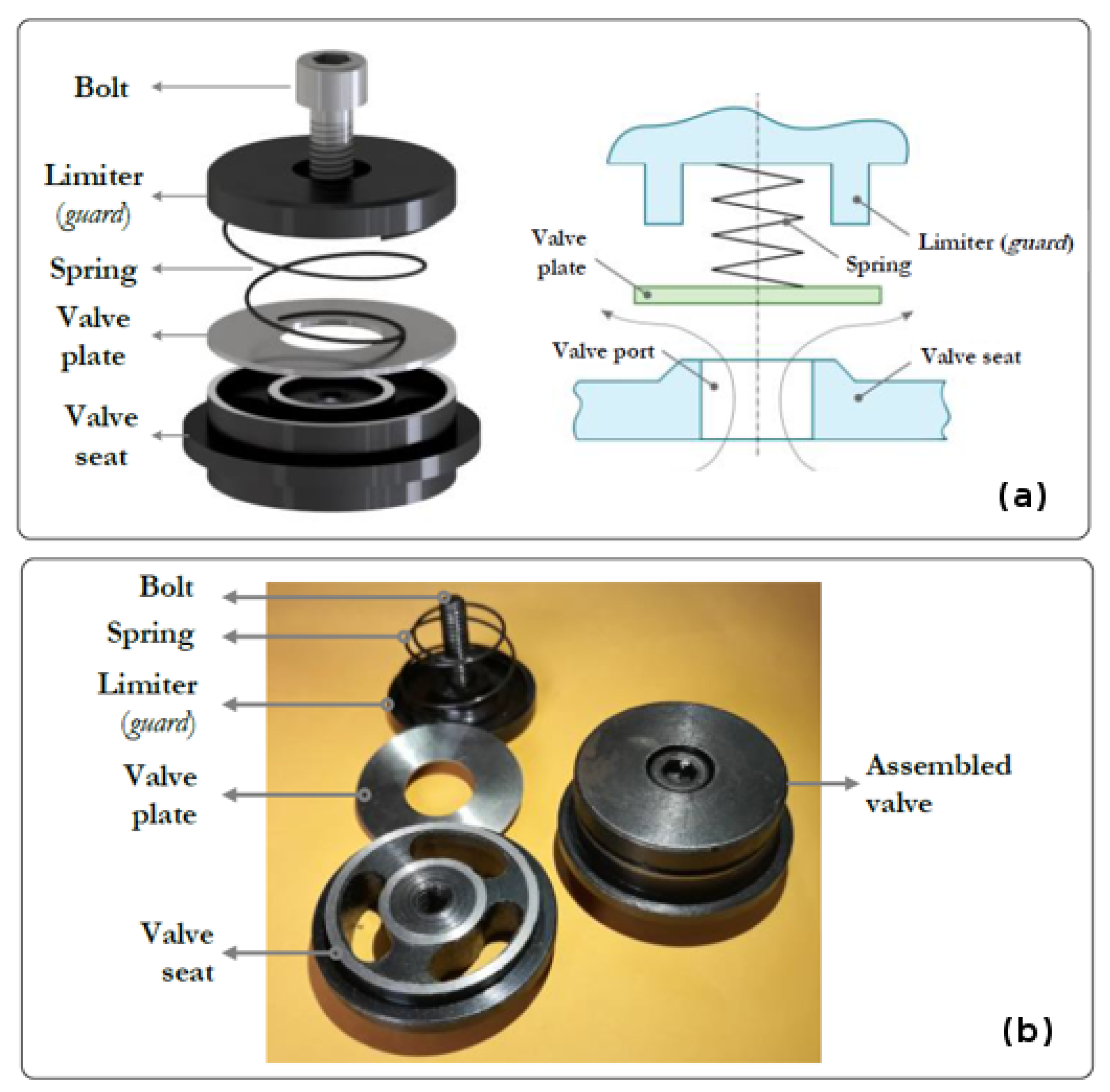

Multi-Valve Fault Dataset

3.3. Multi-Fault Dataset

4. Methodology

4.1. Feature Extraction from the Vibration Signals

4.2. Fault Classification Using Classical Machine Learning Models

4.3. Fault Classification Using Convolutional Neural Network Models

5. Results

5.1. Classification Results for the Centrifugal Pump

5.2. Classification Results for the Reciprocating Compressor

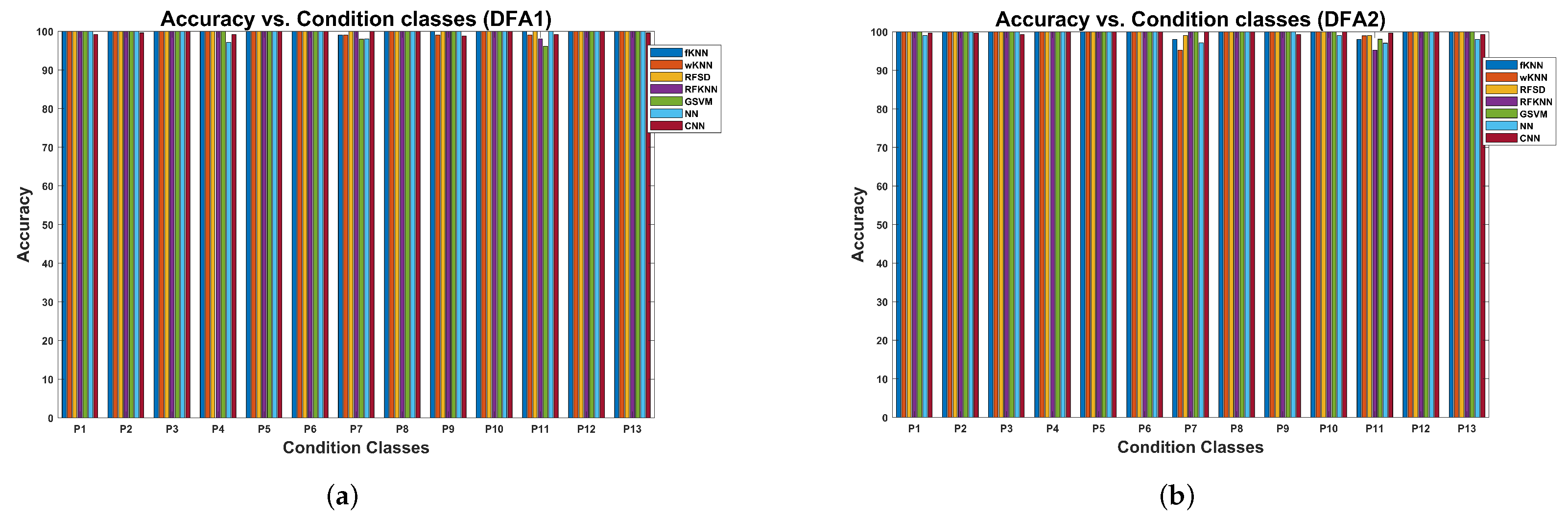

5.2.1. Results for the Multi-Faults Vibration Dataset

5.2.2. Results for the Multi-Valve Vibration Dataset

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BS | Broken Spring |

| CBR | Convolutional, Batch normalization, and ReLU layer |

| CNN | Convolutional neural networks |

| CP | Centrifugal Pump |

| D | Dropout layer |

| DFA | Detrended fluctuation analysis |

| DFA2 | Detrended fluctuation analysis with quadratic approximation |

| DV | Discharge valve |

| EDM | Electrical Discharge Machining |

| EWT | Empirical Wavelet Transform |

| FC | Full connected layer |

| GSVM | Support vector machine with Gaussian kernel |

| GSVM | Gaussian support vector machines |

| HTH | Healthy |

| IB | Imbalance impeller |

| ICB | Impeller channel blockage |

| IMF | Intrinsic mode function |

| IRC | Inner race crack |

| IV | Inlet valve |

| kNN | k-Nearest Neighbors |

| MFDFA | Multi-fractal detrended fluctuation analysis |

| MP | Max-pooling layer |

| MSB | Modulation signal bispectrum |

| NN | Neural network |

| ORC | Outer race crack |

| PCA | Principal component analysis |

| PEB | Pitting at the entrance of the impeller blades |

| POB | Pitting at the output of the impeller blades |

| RC | Reciprocating Compressor |

| REC | Roller element crack |

| ReLU | Rectified linear unit |

| RF | Random Forests |

| RFKNN | Random forest subspace k-nearest neighbor |

| RFKNN | Random forest subspace kNN |

| RFSD | Random forest subspace discriminant |

| ROC | Receiver operator curve |

| SMF | State-adaptive morphological filter |

| SOFT | Softmax layer |

| SVM | Support vector machine |

| VMD | Variational mode decomposition |

| VPC | Valve plate corrosion |

| VPF | Valve plate fracture |

| VSW | Valve seat wear |

| wKNN | Weighted k-nearest neighbor |

Appendix A. Tables and Figures

Appendix A.1. Tables

| Parameter | Units | Limit | Value |

|---|---|---|---|

| Room temperature | °C | Min | 14 |

| Room temperature | °C | Max | 24 |

| Relative Humidity | Percent | Min | 42% |

| Relative Humidity | Percent | Max | 60% |

| Environmental noise before starting compressor | dBA | Max | 48 |

| Environmental noise during experiment | dBA | Max | 80 |

| Experimental Conditions | Description | Discharge Pressure (bar) |

|---|---|---|

| C1 | Regulated discharge valve up to 5.5 bar | |

| C2 | Regulated discharge valve up to 6.5 bar | |

| C3 | Regulated discharge valve up to 7.5 bar | |

| C4 | Regulated discharge valve up to 8.5 bar | |

| C5 | Regulated discharge valve up to 9.5 bar | |

| C6 | Regulated discharge valve up to 10.4 bar |

| Parameter | Units | First Stage | Second Stage | Tank |

|---|---|---|---|---|

| Tank pressure | bar | - | - | 2.9 to 3.1 |

| Inlet pressure | bar | −0.1 to 0.1 | Variable | - |

| Discharge pressure | bar | 1.3 to 2.5 | 2.9 to 4.1 | - |

| Surface temperature | °C | 37 to 65 | 38 to 72 | - |

| in the intake valve cover | ||||

| Surface temperature | °C | 42 to 50 | 40 to 62 | - |

| in the discharge valve cover |

Appendix A.2. Figures

References

- Zhou, H.; Huang, X.; Wen, G.; Lei, Z.; Dong, S.; Zhang, P.; Chen, X. Construction of health indicators for condition monitoring of rotating machinery: A review of the research. Expert Syst. Appl. 2022, 203, 117297. [Google Scholar] [CrossRef]

- Vishwakarma, M.; Purohit, R.; Harshlata, V.; Rajput, P. Vibration Analysis & Condition Monitoring for Rotating Machines: A Review. Mater. Today Proc. 2017, 4, 2659–2664. [Google Scholar] [CrossRef]

- Tiboni, M.; Remino, C.; Bussola, R.; Amici, C. A review on vibration-based condition monitoring of rotating machinery. Appl. Sci. 2022, 12, 972. [Google Scholar] [CrossRef]

- Holzenkamp, M.; Kolodziej, J.R.; Boedo, S.; Delmotte, S. An experimentally validated model for reciprocating compressor main bearings for applications in health monitoring. In Proceedings of the Dynamic Systems and Control Conference, Palo Alto, CA, USA, 21–23 October 2013; Volume 56130, p. V002T24A002. [Google Scholar] [CrossRef]

- Pichler, K.; Lughofer, E.; Pichler, M.; Buchegger, T.; Klement, E.P.; Huschenbett, M. Fault detection in reciprocating compressor valves under varying load conditions. Mech. Syst. Signal Process. 2016, 70, 104–119. [Google Scholar] [CrossRef]

- AlThobiani, F.; Ball, A. An approach to fault diagnosis of reciprocating compressor valves using Teager–Kaiser energy operator and deep belief networks. Expert Syst. Appl. 2014, 41, 4113–4122. [Google Scholar] [CrossRef]

- Dutta, A.; Karimi, I.A.; Farooq, S. PROAD (Process Advisor): A health monitoring framework for centrifugal pumps. Comput. Chem. Eng. 2022, 163, 107825. [Google Scholar] [CrossRef]

- Jamadar, I.; Bellary, S.; Kanai, R.; Alrobaian, A. Model-based condition monitoring for the detection of failure of a ball bearing in a centrifugal pump. J. Fail. Anal. Prev. 2019, 19, 1556–1568. [Google Scholar] [CrossRef]

- Luo, Y.; Han, Y.; Yuan, S.; Yuan, J. Research on the single-value indicators for centrifugal pump based on vibration signals. Sensors 2020, 20, 3283. [Google Scholar] [CrossRef]

- Ahmad, Z.; Rai, A.; Hasan, M.J.; Kim, C.H.; Kim, J.M. A Novel Framework for Centrifugal Pump Fault Diagnosis by Selecting Fault Characteristic Coefficients of Walsh Transform and Cosine Linear Discriminant Analysis. IEEE Access 2021, 9, 150128–150141. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R. Time-frequency analysis and support vector machine in automatic detection of defect from vibration signal of centrifugal pump. Measurement 2017, 108, 119–133. [Google Scholar] [CrossRef]

- Salehi, S.; Raisee, M.; Cervantes, M.J.; Nourbakhsh, A. On the flow field and performance of a centrifugal pump under operational and geometrical uncertainties. Appl. Math. Model. 2018, 61, 540–560. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, D.; Ma, K.; Gao, K. Descriptions of entropy with fractal dynamics and their applications to the flow pressure of centrifugal compressor. Entropy 2019, 21, 266. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, Z.; Rai, A.; Maliuk, A.S.; Kim, J.M. Discriminant feature extraction for centrifugal pump fault diagnosis. IEEE Access 2020, 8, 165512–165528. [Google Scholar] [CrossRef]

- Hasan, M.J.; Rai, A.; Ahmad, Z.; Kim, J.M. A fault diagnosis framework for centrifugal pumps by scalogram-based imaging and deep learning. IEEE Access 2021, 9, 58052–58066. [Google Scholar] [CrossRef]

- Fausing Olesen, J.; Shaker, H.R. Predictive Maintenance for Pump Systems and Thermal Power Plants: State-of-the-Art Review, Trends and Challenges. Sensors 2020, 20, 2425. [Google Scholar] [CrossRef] [PubMed]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine Learning Approach Using MLP and SVM Algorithms for the Fault Prediction of a Centrifugal Pump in the Oil and Gas Industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, J.; Ma, B. Fault diagnosis of reciprocating compressor using a novel ensemble empirical mode decomposition-convolutional deep belief network. Measurement 2020, 156, 107619. [Google Scholar] [CrossRef]

- Lu, K.; Sultan, I.A.; Phung, T.H. A Literature Review of the Positive Displacement Compressor: Current Challenges and Future Opportunities. Energies 2023, 16, 7035. [Google Scholar] [CrossRef]

- Lv, Q.; Yu, X.; Ma, H.; Ye, J.; Wu, W.; Wang, X. Applications of machine learning to reciprocating compressor fault diagnosis: A review. Processes 2021, 9, 909. [Google Scholar] [CrossRef]

- Mondal, D.; Haba, U.; Gu, F.; Ball, A. Airborne Acoustic Signature Analysis for Fault Diagnosis of Reciprocating Compressors Using Modulation Signal Bi-spectrum. In Proceedings of the 2019 25th International Conference on Automation and Computing (ICAC), Lancaster, UK, 5–7 September 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Li, Y.; Pan, Y.; Liu, Y.; Ba, P.; Wu, S. Research on non-parametric prediction method of reciprocating compressor time series based on prediction credibility scale. Adv. Mech. Eng. 2022, 14, 16878132221142114. [Google Scholar] [CrossRef]

- Cabrera, D.; Guamán, A.; Zhang, S.; Cerrada, M.; Sánchez, R.V.; Cevallos, J.; Long, J.; Li, C. Bayesian approach and time series dimensionality reduction to LSTM-based model-building for fault diagnosis of a reciprocating compressor. Neurocomputing 2019, 380, 51–66. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Xu, M.; Huang, W. A review of early fault diagnosis approaches and their applications in rotating machinery. Entropy 2019, 21, 409. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lin, C.; Peng, D.; Ge, H. Fault diagnosis of rotating machinery: A review and bibliometric analysis. IEEE Access 2020, 8, 224985–225003. [Google Scholar] [CrossRef]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Abraham, A. Multi-fault diagnosis of Industrial Rotating Machines using Data-driven approach: A review of two decades of research. Eng. Appl. Artif. Intell. 2023, 123, 106139. [Google Scholar] [CrossRef]

- Yang, B.S.; Han, T.; An, J.L.; Kim, H.C.; Ahn, B.H. A condition classification system for reciprocating compressors. Struct. Health Monit. 2004, 3, 277–284. [Google Scholar] [CrossRef]

- Azizi, R.; Attaran, B.; Hajnayeb, A.; Ghanbarzadeh, A.; Changizian, M. Improving accuracy of cavitation severity detection in centrifugal pumps using a hybrid feature selection technique. Measurement 2017, 108, 9–17. [Google Scholar] [CrossRef]

- Nourmohammadzadeh, A.; Hartmann, S. Fault classification of a centrifugal pump in normal and noisy environment with artificial neural network and support vector machine enhanced by a genetic algorithm. In Proceedings of the Theory and Practice of Natural Computing, Mieres, Spain, 15–16 December 2015; pp. 58–70. [Google Scholar] [CrossRef]

- Duan, Q.; Lu, R.; Xie, H.; Ping, J.; Lu, C.; Zhou, X.; Gao, J.; Li, J. Fault Diagnosis of Air Compressor in Nuclear Power Plant Based on Vibration Observation Window. IEEE Access 2020, 8, 222274–222284. [Google Scholar] [CrossRef]

- Cerrada, M.; Macancela, J.C.; Cabrera, D.; Estupiñan, E.; Sánchez, R.V.; Medina, R. Reciprocating Compressor Multi-Fault Classification Using Symbolic Dynamics and Complex Correlation Measure. Appl. Sci. 2020, 10, 2512. [Google Scholar] [CrossRef]

- Qiu, G.; Huang, S.; Gu, Y. Experimental investigation and multi-conditions identification method of centrifugal pump using Fisher discriminant ratio and support vector machine. Adv. Mech. Eng. 2019, 11, 1687814019878041. [Google Scholar] [CrossRef]

- Panda, A.K.; Rapur, J.S.; Tiwari, R. Prediction of flow blockages and impending cavitation in centrifugal pumps using support vector machine (SVM) algorithms based on vibration measurements. Measurement 2018, 130, 44–56. [Google Scholar] [CrossRef]

- Hamomd, O.; Alabied, S.; Xu, Y.; Daraz, A.; Gu, F.; Ball, A. Vibration based centrifugal pump fault diagnosis based on modulation signal bispectrum analysis. In Proceedings of the 2017 23rd International Conference on Automation and Computing (ICAC), Huddersfield, UK, 7–8 September 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Tan, M.; Lu, Y.; Wu, X.; Liu, H.; Tian, X. Investigation on performance of a centrifugal pump with multi-malfunction. J. Low Freq. Noise, Vib. Act. Control 2020, 40, 740–752. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhao, H.; Zhang, L.; Ou, L. Fault feature extraction method based on EWT-SMF and MF-DFA for valve fault of reciprocating compressor. J. Vibroeng. 2019, 21, 639–653. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Li, Y.; Zhao, H.; Chen, S. Feature extraction method based on VMD and MFDFA for fault diagnosis of reciprocating compressor valve. J. Vibroeng. 2017, 19, 6007–6020. [Google Scholar] [CrossRef]

- Liang, X.; Luo, Y.; Deng, F.; Li, Y. Application of Improved MFDFA and D-S Evidence Theory in Fault Diagnosis. Appl. Sci. 2022, 12, 4976. [Google Scholar] [CrossRef]

- Chen, G.; Yan, C.; Meng, J.; Wang, Z.; Wu, L. Health condition monitoring of bearings based on multifractal spectrum feature with modified empirical mode decomposition-multifractal detrended fluctuation analysis. Struct. Health Monit. 2022, 21, 2618–2640. [Google Scholar] [CrossRef]

- Kantelhardt, J.W.; Zschiegner, S.A.; Koscielny-Bunde, E.; Havlin, S.; Bunde, A.; Stanley, H.E. Multifractal detrended fluctuation analysis of nonstationary time series. Phys. A Stat. Mech. Its Appl. 2002, 316, 87–114. [Google Scholar] [CrossRef]

- Lu, B.; Feng, Y.; Zhang, D. Multifractal manifold for rotating machinery fault diagnosis based on detrended fluctuation analysis. J. Vibroeng. 2016, 18, 5153–5173. [Google Scholar] [CrossRef][Green Version]

- Castiglioni, P.; Lazzeroni, D.; Coruzzi, P.; Faini, A. Multifractal-multiscale analysis of cardiovascular signals: A DFA-based characterization of blood pressure and heart-rate complexity by gender. Complexity 2018, 2018, 4801924. [Google Scholar] [CrossRef]

- de Melo Barros Junior, P.R.; Bunge, K.L.; Serravalle Reis Rodrigues, V.H.; Ferreira Santiago, M.T.; dos Santos Marinho, E.B.; Lima de Jesus Silva, J.L. Multi-fractal detrended cross-correlation heatmaps for time series analysis. Sci. Rep. 2022, 12, 21655. [Google Scholar] [CrossRef]

- Castiglioni, P.; Parati, G.; Civijian, A.; Quintin, L.; Di Rienzo, M. Local scale exponents of blood pressure and heart rate variability by detrended fluctuation analysis: Effects of posture, exercise, and aging. IEEE Trans. Biomed. Eng. 2008, 56, 675–684. [Google Scholar] [CrossRef]

- Hu, K.; Ivanov, P.C.; Chen, Z.; Carpena, P.; Stanley, H.E. Effect of trends on detrended fluctuation analysis. Phys. Rev. E 2001, 64, 011114. [Google Scholar] [CrossRef]

- Movahed, M.S.; Jafari, G.; Ghasemi, F.; Rahvar, S.; Tabar, M.R.R. Multifractal detrended fluctuation analysis of sunspot time series. J. Stat. Mech. Theory Exp. 2006, 2006, P02003. [Google Scholar] [CrossRef]

- Ihlen, E.A. Introduction to multifractal detrended fluctuation analysis in Matlab. Front. Physiol. 2012, 3, 141. [Google Scholar] [CrossRef]

- Castiglioni, P.; Faini, A. A Fast DFA Algorithm for Multifractal Multiscale Analysis of Physiological Time Series. Front. Physiol. 2019, 10. [Google Scholar] [CrossRef]

- Medina, R.; Cerrada, M.; Yang, S.; Cabrera, D.; Estupiñan, E.; Sánchez, R.V. Fault Classification in a Reciprocating Compressor and a Centrifugal Pump Using Non-Linear Entropy Features. Mathematics 2022, 10, 3033. [Google Scholar] [CrossRef]

- Zaman, W.; Ahmad, Z.; Siddique, M.F.; Ullah, N.; Kim, J.M. Centrifugal Pump Fault Diagnosis Based on a Novel SobelEdge Scalogram and CNN. Sensors 2023, 23, 5255. [Google Scholar] [CrossRef]

- Rapur, J.S.; Tiwari, R. Automation of multi-fault diagnosing of centrifugal pumps using multi-class support vector machine with vibration and motor current signals in frequency domain. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 278. [Google Scholar] [CrossRef]

- Guerra, C.J.; Kolodziej, J.R. A data-driven approach for condition monitoring of reciprocating compressor valves. J. Eng. Gas Turbines Power 2014, 136, 041601. [Google Scholar] [CrossRef]

- Lv, Q.; Cai, L.; Yu, X.; Ma, H.; Li, Y.; Shu, Y. An automatic fault diagnosis method for the reciprocating compressor based on HMT and ANN. Appl. Sci. 2022, 12, 5182. [Google Scholar] [CrossRef]

- Hu, L.; Wang, L.; Chen, Y.; Hu, N.; Jiang, Y. Bearing fault diagnosis using piecewise aggregate approximation and complete ensemble empirical mode decomposition with adaptive noise. Sensors 2022, 22, 6599. [Google Scholar] [CrossRef]

- Holzenkamp, M.; Kolodziej, J.R.; Boedo, S.; Delmontte, S. Seeded fault testing and classification of dynamically loaded floating ring compressor bearings. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2016, 2, 021003. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Suykens, J.A.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Dudani, S.A. The distance-weighted k-nearest-neighbor rule. IEEE Trans. Syst. Man. Cybern. 1976, 325–327. [Google Scholar] [CrossRef]

- Zhang, G.P. Neural networks for classification: A survey. IEEE Trans. Syst. Man, Cybern. Part C (Appl. Rev.) 2000, 30, 451–462. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Wen, S.; Tang, C. A strategy on selecting performance metrics for classifier evaluation. Int. J. Mob. Comput. Multimed. Commun. (IJMCMC) 2014, 6, 20–35. [Google Scholar] [CrossRef]

- Sokolova, M.; Lapalme, G. A systematic analysis of performance measures for classification tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

- Maaten, L.v.d.; Hinton, G. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- Medina, R.; Cerrada, M.; Cabrera, D.; Sánchez, R.V. Poincaré Images Extracted from Vibration Signals are Useful Features for Fault Classification in a Reciprocating Compressor. In Proceedings of the Proceedings of 19th Latin American Control Congress (LACC 2022), La Habana, Cuba, 30 November–4 December 2022; Llanes-Santiago, O., Ed.; Springer: Cham, Switzerland, 2023; pp. 119–128. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, H.; Mao, Y. Analysis of vibration and noise induced by unsteady flow inside a centrifugal compressor. Aerosp. Sci. Technol. 2020, 107, 106286. [Google Scholar] [CrossRef]

| Fault Label | Impeller Fault | Stage 10 | Stage 9 | Stage 8 | Stage 7 | Stage 6 | Stage 5 | Rest of Stages |

|---|---|---|---|---|---|---|---|---|

| P1 | ||||||||

| P2 | PEB | 2 | 1 | |||||

| P3 | PEB | 5 | 4 | 3 | 2 | 1 | ||

| P4 | PEB | 8 | 7 | 6 | 5 | 4 | 3 | |

| P5 | POB | 2 | 1 | |||||

| P6 | POB | 5 | 4 | 3 | 2 | 1 | ||

| P7 | POB | 8 | 7 | 6 | 5 | 4 | 3 | |

| P8 | ICB | 1 | ||||||

| P9 | ICB | 4 | 3 | 2 | 1 | |||

| P10 | ICB | 6 | 5 | 4 | 3 | 2 | 1 | |

| P11 | IB | 1 | ||||||

| P12 | IB | 4 | 3 | 2 | 1 | |||

| P13 | IB | 6 | 5 | 4 | 3 | 2 | 1 |

| Stage and Valve Type | Fault Type | Fault Label |

|---|---|---|

| All stages | HTH | S1 |

| 2, DV | VSW | S2 |

| 2, DV | VPC | S3 |

| 2, DV | VPF | S4 |

| 2, DV | BS | S5 |

| 2,IV | VSW | S6 |

| 2, IV | VPC | S7 |

| 2, IV | VPF | S8 |

| 2, IV | BS | S9 |

| 1, DV | VSW | S10 |

| 1, DV | VPC | S11 |

| 1, DV | VPF | S12 |

| 1, DV | BS | S13 |

| 1, IV 2 | VSW | S14 |

| 1, IV 2 | VPC | S15 |

| 1, IV 2 | VPF | S16 |

| 1, IV 2 | BS | S17 |

| Label | Valve, 2S–DV | Bearings, B1 |

|---|---|---|

| F1 | Healthy | Healthy |

| F2 | Valve seat wear | IRC |

| F3 | Corrosion | IRC |

| F4 | Fracture | IRC |

| F5 | Broken Spring | IRC |

| F6 | Valve seat wear | REC |

| F7 | Corrosion | REC |

| F8 | Fracture | REC |

| F9 | Broken Spring | REC |

| F10 | Valve seat wear | ORC |

| F11 | Corrosion | ORC |

| F12 | Fracture | ORC |

| F13 | Broken Spring | ORC |

| Features | Model | Accuracy | Sensitivity | Specificity | FPR | -Score |

|---|---|---|---|---|---|---|

| DFA1 | kNN | 99.85 | 99.85 | 99.99 | 0.01 | 99.85 |

| wKNN | 99.85 | 99.85 | 99.99 | 0.01 | 99.85 | |

| RFSD | 100.00 | 100.00 | 100.00 | 0.00 | 100.00 | |

| RFKNN | 99.92 | 99.92 | 99.99 | 0.00 | 99.92 | |

| GSVM | 99.69 | 99.69 | 99.97 | 0.03 | 99.69 | |

| NN | 99.62 | 99.62 | 99.97 | 0.03 | 99.61 | |

| CNN | 99.67 | 99.67 | 99.97 | 0.03 | 99.67 | |

| DFA2 | kNN | 99.62 | 99.62 | 99.97 | 0.03 | 99.62 |

| wKNN | 99.62 | 99.63 | 99.97 | 0.03 | 99.62 | |

| RFSD | 100.00 | 100.00 | 100.00 | 0.00 | 100.00 | |

| RFKNN | 99.77 | 99.77 | 99.98 | 0.02 | 99.77 | |

| GSVM | 99.92 | 99.92 | 99.99 | 0.00 | 99.92 | |

| NN | 99.08 | 99.09 | 99.92 | 0.08 | 99.08 | |

| CNN | 99.73 | 99.73 | 99.98 | 0.03 | 99.73 |

| Features | Model | Mean | Std | Min | Max |

|---|---|---|---|---|---|

| DFA1 | kNN | 99.85 | 0.24 | 99.23 | 100 |

| wKNN | 99.85 | 0.37 | 99.23 | 100 | |

| RFSD | 100.00 | 0.00 | 100.00 | 100 | |

| RFKNN | 99.92 | 0.32 | 99.23 | 100 | |

| GSVM | 99.69 | 0.40 | 99.23 | 100 | |

| NN | 99.62 | 0.54 | 98.46 | 100 | |

| CNN | 99.67 | 0.44 | 98.77 | 100 | |

| DFA2 | kNN | 99.62 | 0.40 | 99.23 | 100 |

| wKNN | 99.62 | 0.40 | 99.23 | 100 | |

| RFSD | 100.00 | 0.00 | 100.00 | 100 | |

| RFKNN | 99.77 | 0.54 | 98.46 | 100 | |

| GSVM | 99.92 | 0.32 | 99.23 | 100 | |

| NN | 99.08 | 0.73 | 97.69 | 100 | |

| CNN | 99.73 | 0.27 | 99.39 | 100 |

| Features | Model | Accuracy | Sensitivity | Specificity | FPR | -Score |

|---|---|---|---|---|---|---|

| DFA1 | kNN | 77.95 | 79.02 | 98.17 | 1.83 | 77.70 |

| wKNN | 77.18 | 78.65 | 98.12 | 1.89 | 77.18 | |

| RFSD | 95.38 | 95.71 | 99.62 | 0.38 | 95.36 | |

| RFKNN | 81.03 | 81.48 | 98.42 | 1.58 | 81.08 | |

| GSVM | 88.21 | 89.27 | 99.02 | 0.98 | 88.34 | |

| NN | 84.10 | 85.09 | 98.68 | 1.32 | 84.33 | |

| CNN | 88.63 | 88.63 | 99.05 | 0.95 | 89.64 | |

| DFA2 | kNN | 87.94 | 88.23 | 99.01 | 0.99 | 87.42 |

| wKNN | 86.67 | 88.01 | 98.90 | 1.10 | 86.56 | |

| RFSD | 97.44 | 97.69 | 99.79 | 0.21 | 97.45 | |

| RFKNN | 84.87 | 85.06 | 98.75 | 1.26 | 84.60 | |

| GSVM | 91.79 | 92.64 | 99.32 | 0.68 | 91.99 | |

| NN | 88.71 | 89.41 | 99.06 | 0.94 | 88.73 | |

| CNN | 97.78 | 97.78 | 99.81 | 0.19 | 97.78 |

| Algorithm | Mean | Std | min | max | |

|---|---|---|---|---|---|

| MFDFA1 | kNN | 77.95 | 5.30 | 71.79 | 87.18 |

| wKNN | 77.18 | 7.30 | 64.10 | 87.18 | |

| RFSD | 95.38 | 3.15 | 89.74 | 100.00 | |

| RFKNN | 81.03 | 4.55 | 74.36 | 89.74 | |

| GSVM | 88.21 | 5.01 | 74.36 | 92.31 | |

| NN | 84.10 | 6.14 | 74.36 | 92.31 | |

| CNN | 88.63 | 3.49 | 86.75 | 94.87 | |

| MFDFA2 | kNN | 87.95 | 2.43 | 84.62 | 92.31 |

| wKNN | 86.67 | 3.15 | 82.05 | 92.31 | |

| RFSD | 97.44 | 2.09 | 94.87 | 100.00 | |

| RFKNN | 84.87 | 4.90 | 76.92 | 92.31 | |

| GSVM | 91.79 | 3.38 | 84.62 | 97.44 | |

| NN | 88.72 | 5.16 | 79.49 | 94.87 | |

| CNN | 97.78 | 2.33 | 94.02 | 99.57 |

| Features | Model | Accuracy | Sensitivity | Specificity | FPR | -Score |

|---|---|---|---|---|---|---|

| DFA1 | kNN | 95.10 | 95.75 | 99.70 | 0.30 | 95.01 |

| wKNN | 96.86 | 96.91 | 99.80 | 0.20 | 96.85 | |

| RFSD | 99.61 | 99.62 | 99.97 | 0.02 | 99.61 | |

| RFKNN | 91.76 | 91.72 | 99.49 | 0.51 | 91.61 | |

| GSVM | 87.25 | 87.21 | 99.25 | 0.75 | 87.20 | |

| NN | 97.45 | 97.53 | 99.84 | 0.16 | 97.46 | |

| CNN | 97.58 | 97.58 | 99.85 | 0.15 | 97.57 | |

| DFA2 | kNN | 93.92 | 94.22 | 99.62 | 0.38 | 93.96 |

| wKNN | 95.49 | 95.66 | 99.72 | 0.28 | 95.43 | |

| RFSD | 99.02 | 99.16 | 99.94 | 0.06 | 99.01 | |

| RFKNN | 94.71 | 94.69 | 99.67 | 0.33 | 94.65 | |

| GSVM | 99.02 | 99.10 | 99.94 | 0.06 | 99.02 | |

| NN | 98.04 | 98.18 | 99.88 | 0.12 | 98.03 | |

| CNN | 99.80 | 99.80 | 99.99 | 0.01 | 99.80 |

| Algorithm | Mean | Std | min | max | |

|---|---|---|---|---|---|

| MFDFA1 | kNN | 95.10 | 2.96 | 90.20 | 100.00 |

| wKNN | 96.86 | 2.11 | 94.12 | 100.00 | |

| RFSD | 99.61 | 1.24 | 96.08 | 100.00 | |

| RFKNN | 91.76 | 3.18 | 88.24 | 98.04 | |

| GSVM | 87.25 | 1.39 | 84.31 | 88.24 | |

| NN | 97.45 | 2.45 | 94.12 | 100.00 | |

| CNN | 97.58 | 1.45 | 95.75 | 99.35 | |

| MFDFA2 | kNN | 93.92 | 3.51 | 88.24 | 100.00 |

| wKNN | 95.49 | 2.08 | 92.16 | 98.04 | |

| RFSD | 99.02 | 1.03 | 98.04 | 100.00 | |

| RFKNN | 94.71 | 2.93 | 88.24 | 98.04 | |

| GSVM | 99.02 | 1.03 | 98.04 | 100.00 | |

| NN | 98.04 | 2.07 | 94.12 | 100.00 | |

| CNN | 99.80 | 0.18 | 99.67 | 100.00 |

| Machine | Accuracy Statistical +SVM [49] | Accuracy InfoEntropy +SVM [49] | Accuracy Entropy +SVM [49] | Accuracy AllFeat +SVM [49] | Accuracy +CNN | Accuracy Spectrogram +CNN [49] |

|---|---|---|---|---|---|---|

| CP | 71.03 | 96.32 | 97.30 | 99.81 | 99.73 | 98.61 |

| RC | 86.91 | 96.83 | 97.57 | 97.90 | 99.80 | 96.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina, R.; Sánchez, R.-V.; Cabrera, D.; Cerrada, M.; Estupiñan, E.; Ao, W.; Vásquez, R.E. Scale-Fractal Detrended Fluctuation Analysis for Fault Diagnosis of a Centrifugal Pump and a Reciprocating Compressor. Sensors 2024, 24, 461. https://doi.org/10.3390/s24020461

Medina R, Sánchez R-V, Cabrera D, Cerrada M, Estupiñan E, Ao W, Vásquez RE. Scale-Fractal Detrended Fluctuation Analysis for Fault Diagnosis of a Centrifugal Pump and a Reciprocating Compressor. Sensors. 2024; 24(2):461. https://doi.org/10.3390/s24020461

Chicago/Turabian StyleMedina, Ruben, René-Vinicio Sánchez, Diego Cabrera, Mariela Cerrada, Edgar Estupiñan, Wengang Ao, and Rafael E. Vásquez. 2024. "Scale-Fractal Detrended Fluctuation Analysis for Fault Diagnosis of a Centrifugal Pump and a Reciprocating Compressor" Sensors 24, no. 2: 461. https://doi.org/10.3390/s24020461

APA StyleMedina, R., Sánchez, R.-V., Cabrera, D., Cerrada, M., Estupiñan, E., Ao, W., & Vásquez, R. E. (2024). Scale-Fractal Detrended Fluctuation Analysis for Fault Diagnosis of a Centrifugal Pump and a Reciprocating Compressor. Sensors, 24(2), 461. https://doi.org/10.3390/s24020461