Two-Color-Thermography for Temperature Determination in Laser Beam Welding of Low-Melting Materials

Abstract

1. Introduction

Temperature Determination in Laser Beam Welding

2. Materials and Methods

2.1. Two-Color-Thermography

2.1.1. Physical Background

2.1.2. Experimental Set-Up and Combined Optical Path Efficiency

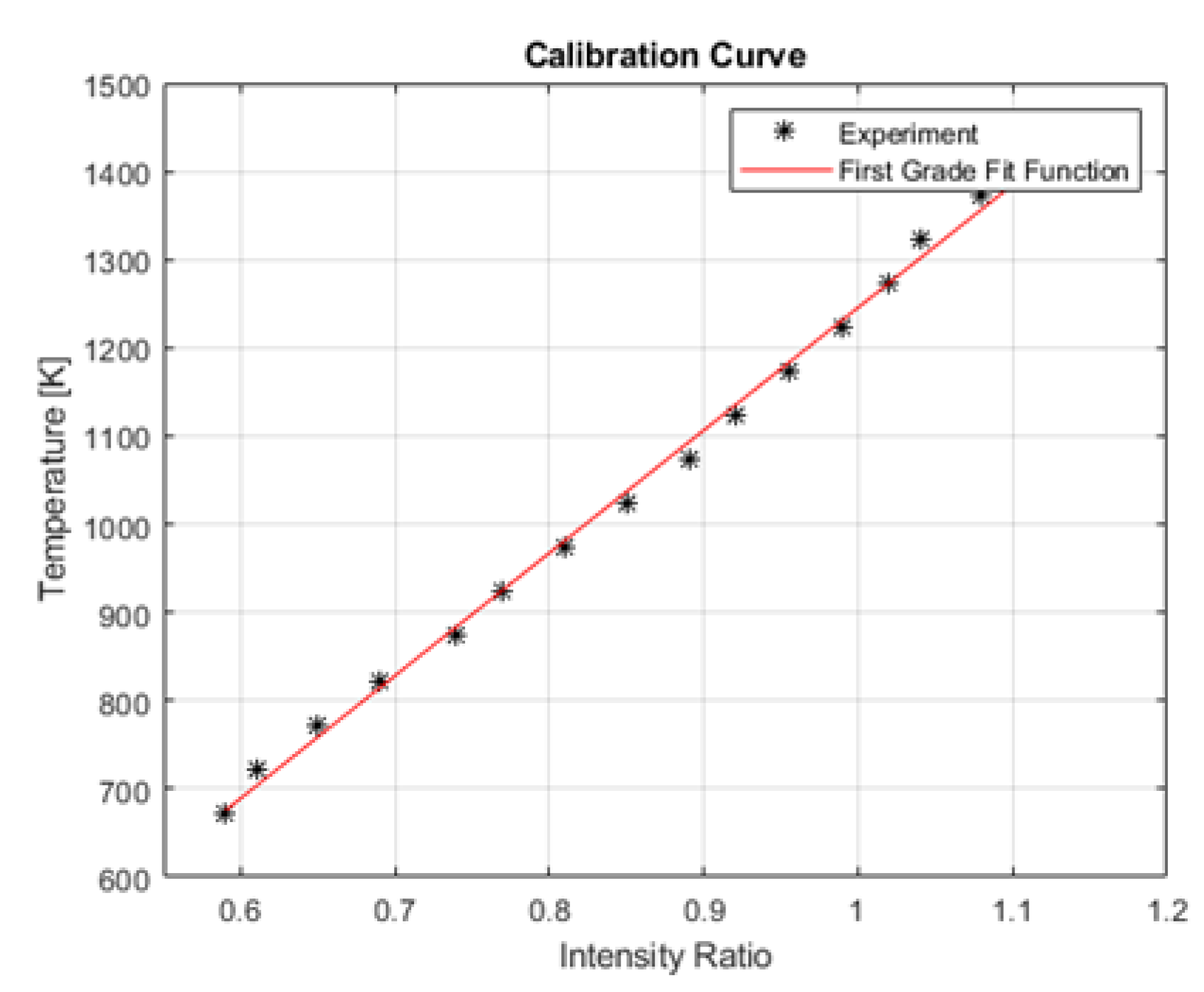

2.2. Calibration

2.3. Image Processing

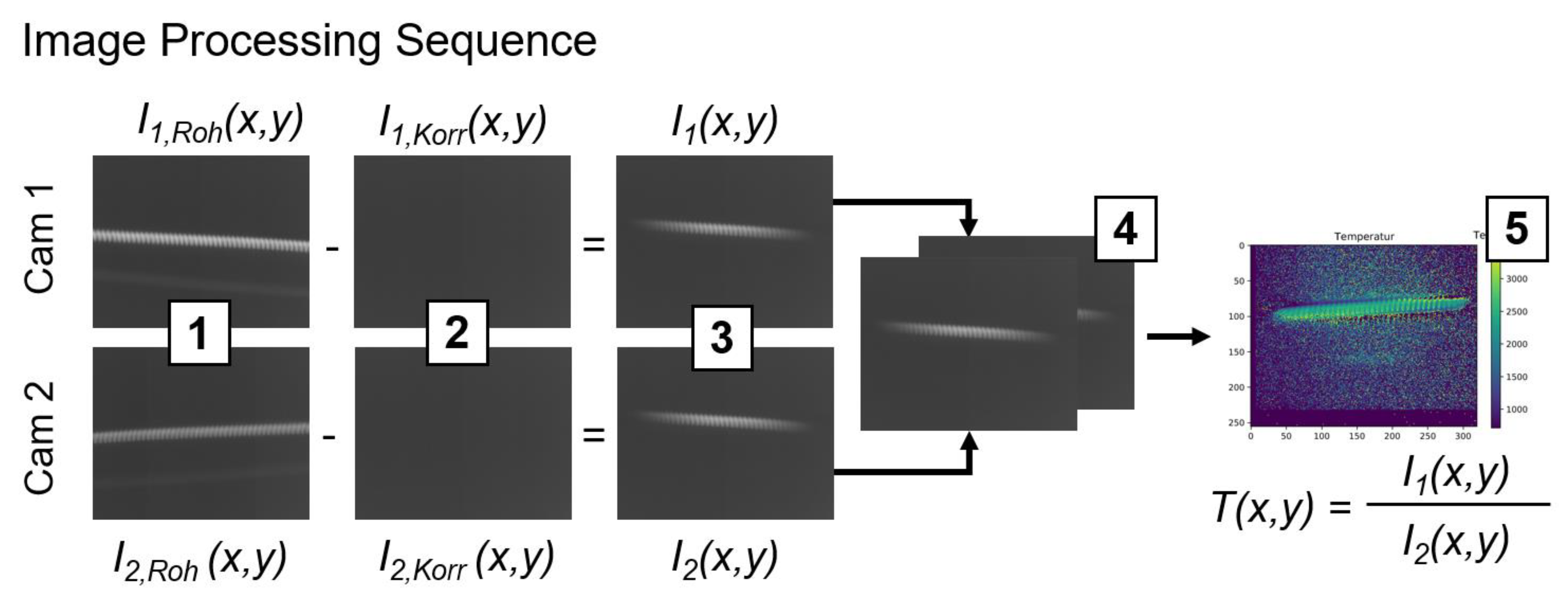

- Initial raw images:

- 2.

- Subtraction of dark-frame images from raw images:

- 3.

- Noise-corrected images (elimination of dark current and fixed-pattern noise):

- 4.

- Image alignment based on a similarity measure (cross-correlation)

- 5.

- Calculation of intensity ratio and temperature assignment for each pixel

2.4. Proof-of-Concept at Constant Temperature

- A variation of signal intensity does not affect the temperature determination based on the two-color-thermography system.

- A variation of emissivity does not affect the temperature determination based on the two-color-thermography system.

2.5. Experimental Set-Up for Laser Beam Welding

3. Results

3.1. Proof-of-Concept at Constant Temperature

3.1.1. Influence of Signal Intensity Variation

3.1.2. Influence of Emissivity Variation

3.2. Dynamic Temperature Evolution during Laser Beam Welding

4. Discussion

4.1. Proof-of-Concept at Constant Temperature

4.2. Dynamic Temperature Evolution during Laser Beam Welding

5. Conclusions

- A spatial and temporal temperature determination set-up based on the ratio principle is presented. The developed two-color-thermography set-up is designed to measure temperature in the region of low-melting materials (< 1200 K) based on InGaAs-sensors.

- For process conditions employing constant thermal radiation, it is demonstrated that temperature determination is possible despite the signal intensity variation with the two-color-thermography system. The calculated mean temperature is reported to differ by <0.007% from the defined temperature despite doubling the exposure time of the camera sensors.

- For process conditions employing constant thermal radiation, it is demonstrated that temperature determination is possible despite variation of emissivity with the two-color-thermography system. The calculated mean temperature of a custom-made checkerboard consisting of tiles with different emissivity deviated by less than 0.01% from the defined temperature value.

- Image artifacts presumably caused by internal reflections inside the optical path of the two-color-thermography system restrict the direct transition of the set-up into a commercial laser welding machine.

- Further investigations and optimization of the optical beam path design will be conducted to allow for reliable temperature measurement during the dynamic temperature evolution in laser beam welding of low-melting materials.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sokolov, M.; Salminen, A. Improving Laser Beam Welding Efficiency. Engineering 2014, 6, 559–571. [Google Scholar] [CrossRef]

- Svenungsson, J.; Choquet, I.; Kaplan, A. Laser Welding Process—A Review of Keyhole Welding Modelling. Phys. Procedia 2015, 78, 182–191. [Google Scholar] [CrossRef]

- Hakem, M.; Lebaili, S.; Mathieu, S.; Miroud, D.; Lebaili, A.; Cheniti, B. Effect of microstructure and precipitation phenomena on the mechanical behavior of AA6061-T6 aluminum alloy weld. Int. J. Adv. Manuf. Technol. 2019, 102, 2907–2918. [Google Scholar] [CrossRef]

- Gref, W. Laserstrahlschweißen von Aluminiumwerkstoffen mit der Fokusmatrixtechnik. Ph.D. Thesis, Stuttgart University, Stuttgart, Germany, 2015. [Google Scholar]

- Mohr, G.; Nowakowski, S.; Altenburg, S.J.; Maierhofer, C.; Hilgenberg, K. Experimental Determination of the Emissivity of Powder Layers and Bulk Material in Laser Powder Bed Fusion Using Infrared Thermography and Thermocouples. Metals 2020, 10, 1546. [Google Scholar] [CrossRef]

- Davies, M.A.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A.L. On The Measurement of Temperature in Material Removal Processes. CIRP Ann. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Novasens Sensortechnik Heuer. Emissionsgradtabelle für die Infrarot Temperaturmessung. Available online: https://www.novasens.de/wp-content/uploads/Emissionsgradtabellenovasens.pdf (accessed on 11 April 2023).

- Pavlov, M.; Doubenskaia, M.; Smurov, I. Pyrometric analysis of thermal processes in SLM technology. Phys. Procedia 2010, 5, 523–531. [Google Scholar] [CrossRef]

- Heigel, J.; Lane, B. The effect of powder on cooling rate and melt pool length measurements using in situ thermographic techniques. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=923988 (accessed on 11 April 2023).

- Herman, I.P. Optical Diagnostics for Thin Film Processing: Chapter 13—Pyrometry; Academic Press: San Diego, CA, USA, 1996. [Google Scholar]

- Müller, B.; Renz, U. Development of a fast fiber-optic two-color pyrometer for the temperature measurement of surfaces with varying emissivities. Rev. Sci. Instrum. 2001, 72, 3366–3374. [Google Scholar] [CrossRef]

- Furumoto, T.; Ueda, T.; Alkahari, M.; Hosokawa, A. Investigation of laser consolidation process for metal powder by two-color pyrometer and high-speed video camera. CIRP Ann. 2013, 62, 223–226. [Google Scholar] [CrossRef]

- Gutknecht, K.; Haferkamp, L.; Cloots, M.; Wegener, K. Determining process stability of Laser Powder Bed Fusion using pyrometry. Procedia CIRP 2020, 95, 127–132. [Google Scholar] [CrossRef]

- Mitchell, J.; Ivanoff, T.; Dagel, D.; Madison, J.; Jared, B. Linking pyrometry to porosity in additively manufactured metals. Addit. Manuf. 2020, 31, 100946. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Vallabh, C.; Zhao, X. Melt pool temperature measurement and monitoring during laser powder bed fusion based additive manufacturing via single-camera two-wavelength imaging pyrometry (STWIP). J. Manuf. Process. 2022, 79, 486–500. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, Y. Effect of surface oxidation on emissivity properties of pure aluminum in the near infrared region. Mater. Res. Express 2017, 4, 086501. [Google Scholar] [CrossRef]

- ISOTECH. Blackbody Source Pegasus R. Available online: https://www.klasmeier.com/wp-content/uploads/2018/03/Datenblatt-Pegasus-R.pdf (accessed on 11 April 2023).

- Shapiro, J.H.; Boyd, R.W. The physics of ghost imaging. Quantum Inf. Process 2012, 11, 949–993. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwarzkopf, K.; Rothfelder, R.; Rasch, M.; Schmidt, M. Two-Color-Thermography for Temperature Determination in Laser Beam Welding of Low-Melting Materials. Sensors 2023, 23, 4908. https://doi.org/10.3390/s23104908

Schwarzkopf K, Rothfelder R, Rasch M, Schmidt M. Two-Color-Thermography for Temperature Determination in Laser Beam Welding of Low-Melting Materials. Sensors. 2023; 23(10):4908. https://doi.org/10.3390/s23104908

Chicago/Turabian StyleSchwarzkopf, Karen, Richard Rothfelder, Michael Rasch, and Michael Schmidt. 2023. "Two-Color-Thermography for Temperature Determination in Laser Beam Welding of Low-Melting Materials" Sensors 23, no. 10: 4908. https://doi.org/10.3390/s23104908

APA StyleSchwarzkopf, K., Rothfelder, R., Rasch, M., & Schmidt, M. (2023). Two-Color-Thermography for Temperature Determination in Laser Beam Welding of Low-Melting Materials. Sensors, 23(10), 4908. https://doi.org/10.3390/s23104908