A Method for Pipeline Leak Detection Based on Acoustic Imaging and Deep Learning

Abstract

:1. Introduction

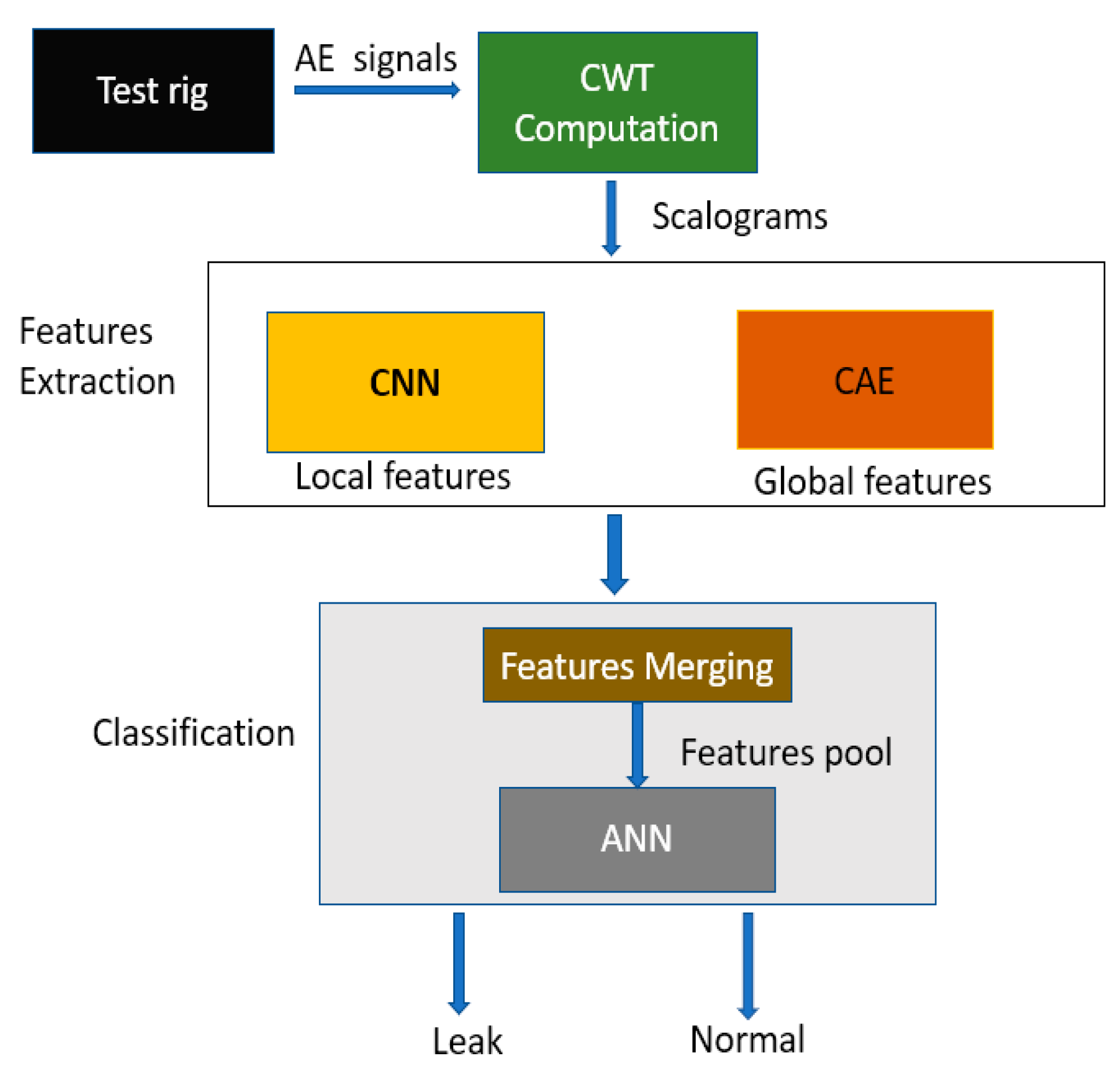

- The visualization and separation of the leak features from noisy data; the time-domain AE signals were transformed into AE images using CWT. From these AE images, leak-related features could be extracted. To surpass the traditional feature extraction techniques, a novel deep neural framework of CNN–CAE was proposed to extract the features autonomously. To the best of the author’s knowledge, CNN–CAE-based leak-related feature extraction has not been presented in the literature so far;

- The feature space obtained from the CNN–CAE was classified into “leak” and “no leak” states of the pipeline under variable leak and pressure conditions using a shallow ANN;

- Real-world pipeline data were used for the validation of the proposed method.

2. Proposed Method

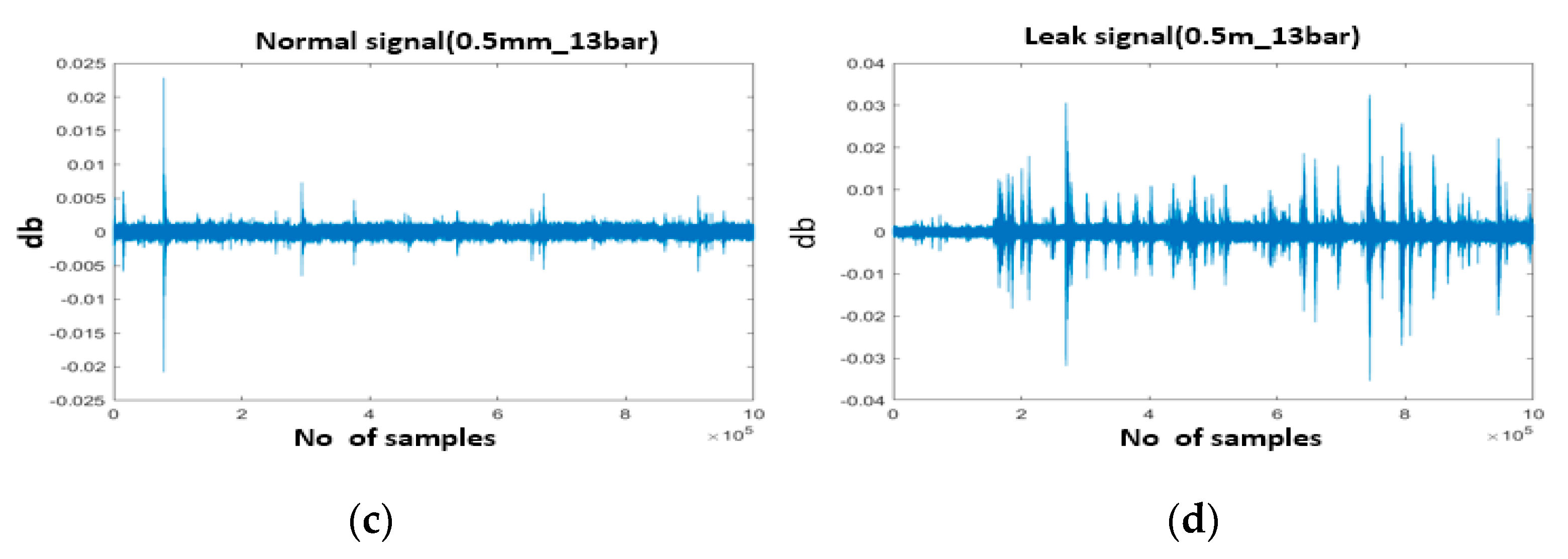

2.1. Continuous Wavelet Transform-Based Acoustic Emission Images

2.2. Global Feature Extraction Using CAE

2.2.1. Autoencoder Background

2.2.2. Convolutional Autoencoder Background

2.3. Local Feature Extraction Using CNN

2.4. Pipeline Leak State Identification Using ANN

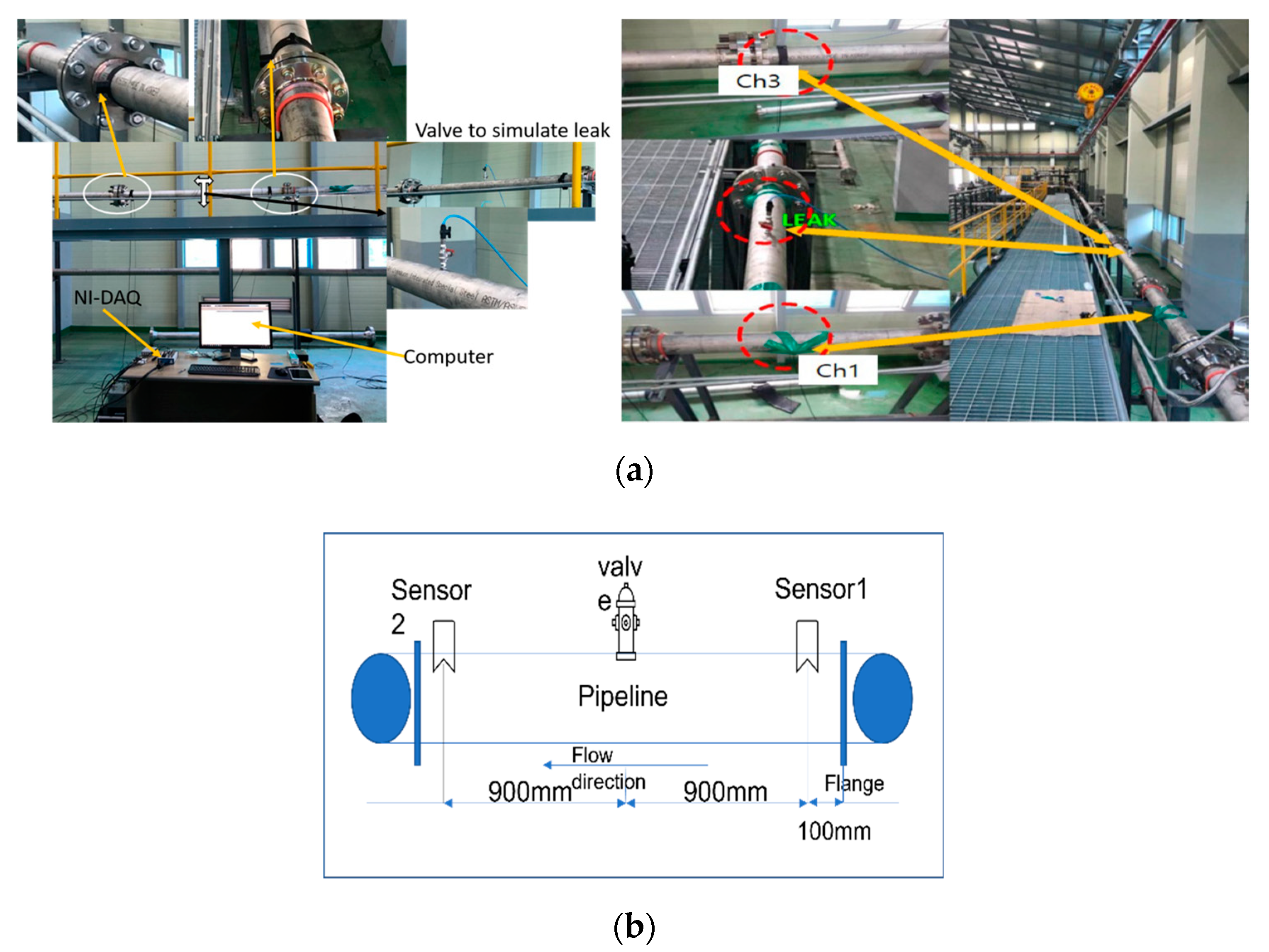

3. Experimental Setup

4. Results and Discussion

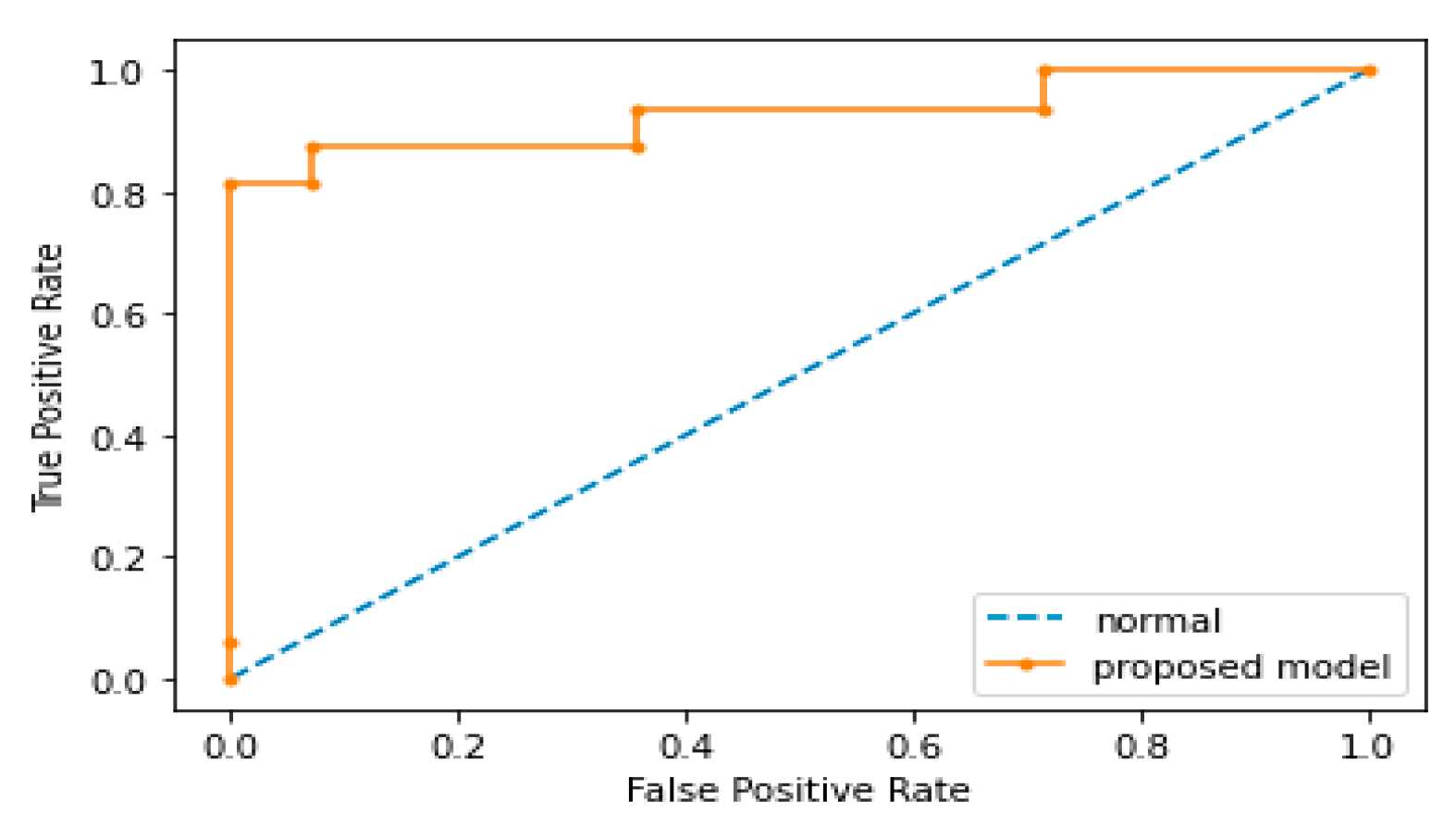

Proposed Method: Performance and Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Z.; Tariq, S.; Zayed, T. A comprehensive review of acoustic based leak localization method in pressurized pipelines. Mech. Syst. Signal Processing 2021, 161, 107994. [Google Scholar] [CrossRef]

- Wang, L.; Narasimman, S.C.; Ravula, S.R.; Ukil, A. Water Ingress Detection in Low-Pressure Gas Pipelines Using Distributed Temperature Sensing System. IEEE Sens. J. 2017, 17, 3165–3173. [Google Scholar] [CrossRef]

- Cataldo, A.; Cannazza, G.; de Benedetto, E.; Giaquinto, N. Underground Water Pipelines. IEEE Sens. J. 2012, 12, 1660–1667. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, L.; Liang, W.; Ding, Q. Integrated leakage detection and localization model for gas pipelines based on the acoustic wave method. J. Loss Prev. Process Ind. 2014, 27, 74–88. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, Q.; Wen, J.; Wang, F. Natural gas pipeline small leakage feature extraction and recognition based on LMD envelope spectrum entropy and SVM. Meas. J. Int. Meas. Confed. 2014, 55, 434–443. [Google Scholar] [CrossRef]

- Li, J.; Zheng, Q.; Qian, Z.; Yang, X. A novel location algorithm for pipeline leakage based on the attenuation of negative pressure wave. Process Saf. Environ. Prot. 2019, 123, 309–316. [Google Scholar] [CrossRef]

- Feng, J.; Li, F.; Lu, S.; Liu, J.; Ma, D. Injurious or noninjurious defect identification from MFL images in pipeline inspection using convolutional neural network. IEEE Trans. Instrum. Meas. 2017, 66, 1883–1892. [Google Scholar] [CrossRef]

- Luong, T.T.N.; Kim, J.M. The enhancement of leak detection performance for water pipelines through the renovation of training data. Sensors 2020, 20, 2542. [Google Scholar] [CrossRef]

- Chan, T.K.; Chin, C.S.; Zhong, X. Review of Current Technologies and Proposed Intelligent Methodologies for Water Distributed Network Leakage Detection. IEEE Access 2019, 6, 78846–78867. [Google Scholar] [CrossRef]

- Quy, T.B.; Kim, J.M. Real-time leak detection for a gas pipeline using a k-nn classifier and hybrid ae features. Sensors 2021, 21, 367. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Ahmad, Z.; Kim, J.M. A scheme with acoustic emission hit removal for the remaining useful life prediction of concrete structures. Sensors 2021, 21, 7761. [Google Scholar] [CrossRef] [PubMed]

- Caesarendra, W.; Kosasih, B.; Tieu, A.K.; Zhu, H.; Moodie, C.A.S.; Zhu, Q. Acoustic emission-based condition monitoring methods: Review and application for low speed slew bearing. Mech. Syst. Signal Processing 2016, 72–73, 134–159. [Google Scholar] [CrossRef]

- Elforjani, M.; Mba, D. Detecting natural crack initiation and growth in slow speed shafts with the Acoustic Emission technology. Eng. Fail. Anal. 2009, 16, 2121–2129. [Google Scholar] [CrossRef] [Green Version]

- Banjara, N.K.; Sasmal, S.; Voggu, S. Machine learning supported acoustic emission technique for leakage detection in pipelines. Int. J. Press. Vessel. Pip. 2020, 188, 104243. [Google Scholar] [CrossRef]

- Rai, A.; Kim, J.M. A novel pipeline leak detection approach independent of prior failure information. Meas. J. Int. Meas. Confed. 2021, 167, 108284. [Google Scholar] [CrossRef]

- Rai, A.; Ahmad, Z.; Hasan, J.; Kim, J.-M.; Jha, S. A Novel Pipeline Leak Detection Technique Based on Acoustic Emission Features and Two-Sample Kolmogorov–Smirnov Test. Sensors 2021, 21, 8247. [Google Scholar] [CrossRef]

- Li, S.; Song, Y.; Zhou, G. Leak detection of water distribution pipeline subject to failure of socket joint based on acoustic emission and pattern recognition. Meas. J. Int. Meas. Confed. 2017, 115, 39–44. [Google Scholar] [CrossRef]

- Xu, C.; Du, S.; Gong, P.; Li, Z.; Chen, G.; Song, G. An Improved Method for Pipeline Leakage Localization with a Single Sensor Based on Modal Acoustic Emission and Empirical Mode Decomposition with Hilbert Transform. IEEE Sens. J. 2020, 20, 5480–5491. [Google Scholar] [CrossRef]

- Xu, T.; Zeng, Z.; Huang, X.; Li, J.; Feng, H. Pipeline leak detection based on variational mode decomposition and support vector machine using an interior spherical detector. Process Saf. Environ. Prot. 2021, 153, 167–177. [Google Scholar] [CrossRef]

- Hasan, M.J.; Rai, A.; Ahmad, Z.; Kim, J.M. A Fault Diagnosis Framework for Centrifugal Pumps by Scalogram-Based Imaging and Deep Learning. IEEE Access 2021, 9, 58052–58066. [Google Scholar] [CrossRef]

- Nguyen, C.D.; Ahmad, Z.; Kim, J.M. Gearbox fault identification framework based on novel localized adaptive denoising technique, wavelet-based vibration imaging, and deep convolutional neural network. Appl. Sci. 2021, 11, 7575. [Google Scholar] [CrossRef]

- Jiao, J.; Zhao, M.; Lin, J.; Liang, K. A comprehensive review on convolutional neural network in machine fault diagnosis. Neurocomputing 2020, 417, 36–63. [Google Scholar] [CrossRef]

- Song, Y.; Li, S. Gas leak detection in galvanised steel pipe with internal flow noise using convolutional neural network. Process Saf. Environ. Prot. 2021, 146, 736–744. [Google Scholar] [CrossRef]

- Nam, Y.W.; Arai, Y.; Kunizane, T.; Koizumi, A. Water leak detection based on convolutional neural network using actual leak sounds and the hold-out method. Water Supply 2021, 21, 3477–3485. [Google Scholar] [CrossRef]

- Zhou, M.; Pan, Z.; Liu, Y.; Zhang, Q.; Cai, Y.; Pan, H. Leak Detection and Location Based on ISLMD and CNN in a Pipeline. IEEE Access 2019, 7, 30457–30464. [Google Scholar] [CrossRef]

- Rahimi, M.; Alghassi, A.; Ahsan, M.; Haider, J. Deep Learning Model for Industrial Leakage Detection Using Acoustic Emission Signal. Informatics 2020, 7, 49. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, Y.; Xu, Y.; Hu, Y.; Cai, Y.; Lin, J.; Pan, H. A Pipeline Leak Detection and Localization Approach Based on Ensemble TL1DCNN. IEEE Access 2021, 9, 47565–47578. [Google Scholar] [CrossRef]

- Jiao, J.; Zhao, M.; Lin, J.; Liang, K. Residual joint adaptation adversarial network for intelligent transfer fault diagnosis. Mech. Syst. Signal Processing 2020, 145, 106962. [Google Scholar] [CrossRef]

- Jiao, J.; Zhao, M.; Lin, J.; Ding, C. Deep coupled dense convolutional network with complementary data for intelligent fault diagnosis. IEEE Trans. Ind. Electron. 2019, 66, 9858–9867. [Google Scholar] [CrossRef]

- Cody, R.A.; Tolson, B.A.; Orchard, J. Detecting Leaks in Water Distribution Pipes Using a Deep Autoencoder and Hydroacoustic Spectrograms. J. Comput. Civ. Eng. 2020, 34, 04020001. [Google Scholar] [CrossRef]

- Piñal-Moctezuma, F.; Delgado-Prieto, M.; Romeral-Martínez, L. An acoustic emission activity detection method based on short-term waveform features: Application to metallic components under uniaxial tensile test. Mech. Syst. Signal Processing 2020, 142, 106753. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.; Lin, M.; Wu, J.; Zhu, H.; Shao, X. Intelligent fault diagnosis of rotating machinery based on continuous wavelet transform-local binary convolutional neural network. Knowl. Based Syst. 2021, 216, 106796. [Google Scholar] [CrossRef]

- Hunaidi, O.; Chu, W.; Wang, A.; Guan, W. Detecting leaks in plastic pipes. J. Am. Water Work. Assoc. 2000, 92, 82–94. [Google Scholar] [CrossRef] [Green Version]

- Martini, A.; Troncossi, M.; Rivola, A. Leak detection in water-filled small-diameter polyethylene pipes by means of acoustic emission measurements. Appl. Sci. 2017, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Lilly, J.M. Element analysis: A wavelet-based method for analysing time-localized events in noisy time series. Proc. R. Soc. A Math. Phys. Eng. Sci. 2017, 473, 20160776. [Google Scholar] [CrossRef] [PubMed]

- Zeiler, M.D.; Taylor, G.W.; Fergus, R. Adaptive deconvolutional networks for mid and high level feature learning. In Proceedings of the IEEE International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011; pp. 2018–2025. [Google Scholar] [CrossRef]

- Dumoulin, V.; Visin, F. A Guide to Convolution Arithmetic for Deep Learning. Available online: http://arxiv.org/abs/1603.07285 (accessed on 15 June 2021).

| Layers | Filters | Kernel Size | Output | Activation |

|---|---|---|---|---|

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 128 × 128 × 8/64 × 64 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 64 × 64 × 8/32 × 32 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 32 × 32 × 8/16 × 16 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 16 × 16 × 8/8 × 8 × 8 | ReLU/- |

| Flatten | 512 | - | 512 | ReLU/- |

| Reshape | - | - | 8 × 8 × 8 | |

| 4 covT | 8 | 3 × 3 | 128 × 128 × 8 | ReLU |

| Conv | 3 | 3 × 3 | 128 × 128 × 3 | ReLU |

| Layers | Filters | Kernel Size | Output | Activation |

|---|---|---|---|---|

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 128 × 128 × 8/64 × 64 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 64 × 64 × 8/32 × 32 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 32 × 32 × 8/16 × 16 × 8 | ReLU/- |

| Conv/MaxPool | 8 | 3 × 3/2 × 2 | 16 × 16 × 8/8 × 8 × 8 | ReLU/- |

| Flatten | 512 | - | 512 | |

| output | 4 | - | 4 | SoftMax |

| Layers | Nodes | Activation | Dropout Rate |

|---|---|---|---|

| Input | 1024 | - | 0.2 |

| Hidden | 512 | - | 0.2 |

| Output | 2 | SoftMax | - |

| Metric | Leak Size 0.3 mm, Pressure 7 bar | |||

| Proposed | FFT-CNN | CWT-LSTM | CWT-SVM | |

| Accuracy | 98.4% | 96.67% | 90.1% | 90.33% |

| Precision | 96.8% | 96.69% | 91.0% | 91.0% |

| Recall | 97% | 96.6% | 90.5% | 91.93% |

| F1 Score | 97.63% | 96.67% | 90.7% | 91.53% |

| Metric | Leak Size 0.5 mm, Pressure 13 bar | |||

| Proposed | FFT-CNN | CWT-LSTM | CWT-SVM | |

| Accuracy | 96.67% | 93.33% | 87.67% | 95.33% |

| Precision | 95% | 94.0% | 85.0% | 94.1% |

| Recall | 95.27% | 93.33% | 88.27% | 93.33% |

| F1 Score | 95.3% | 93.27% | 86.3% | 94.27% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, S.; Ahmad, Z.; Kim, C.-H.; Kim, J.-M. A Method for Pipeline Leak Detection Based on Acoustic Imaging and Deep Learning. Sensors 2022, 22, 1562. https://doi.org/10.3390/s22041562

Ahmad S, Ahmad Z, Kim C-H, Kim J-M. A Method for Pipeline Leak Detection Based on Acoustic Imaging and Deep Learning. Sensors. 2022; 22(4):1562. https://doi.org/10.3390/s22041562

Chicago/Turabian StyleAhmad, Sajjad, Zahoor Ahmad, Cheol-Hong Kim, and Jong-Myon Kim. 2022. "A Method for Pipeline Leak Detection Based on Acoustic Imaging and Deep Learning" Sensors 22, no. 4: 1562. https://doi.org/10.3390/s22041562

APA StyleAhmad, S., Ahmad, Z., Kim, C.-H., & Kim, J.-M. (2022). A Method for Pipeline Leak Detection Based on Acoustic Imaging and Deep Learning. Sensors, 22(4), 1562. https://doi.org/10.3390/s22041562