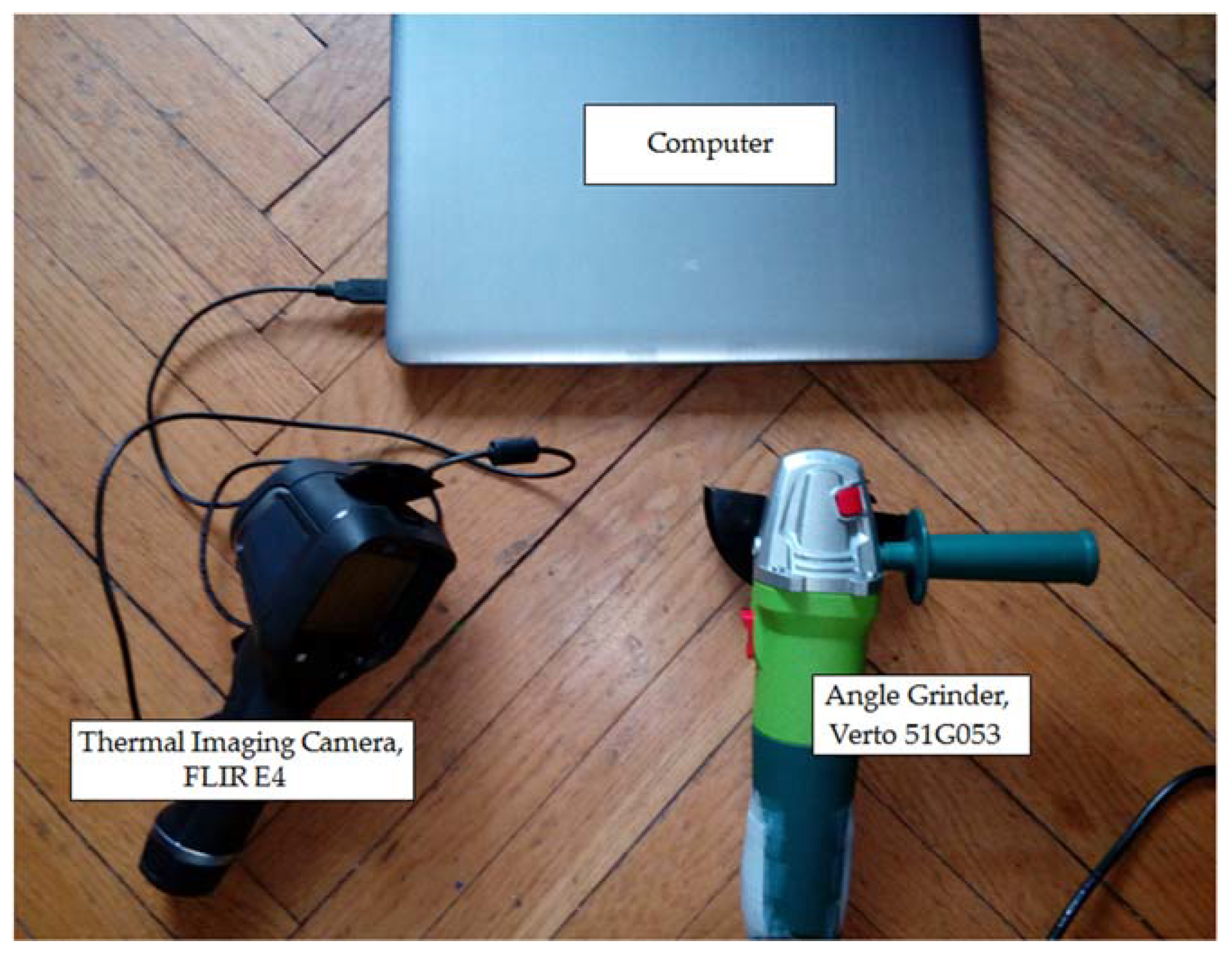

Ventilation Diagnosis of Angle Grinder Using Thermal Imaging

Abstract

1. Introduction

2. Theoretical Background

3. Processing and Recognition of the Thermal Image

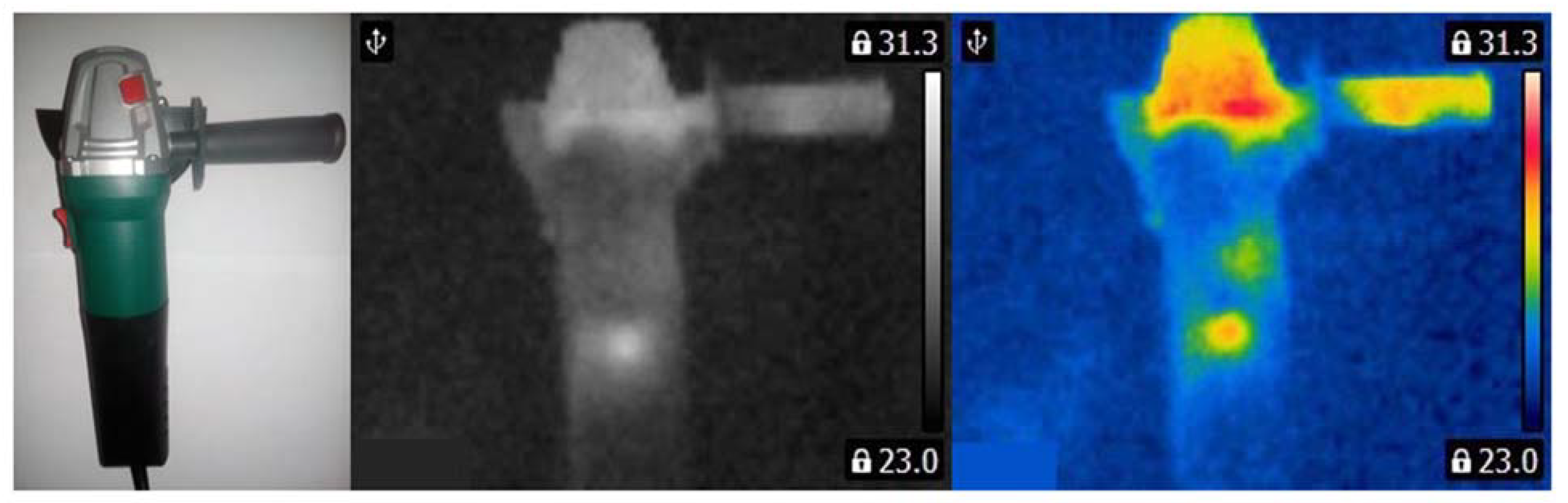

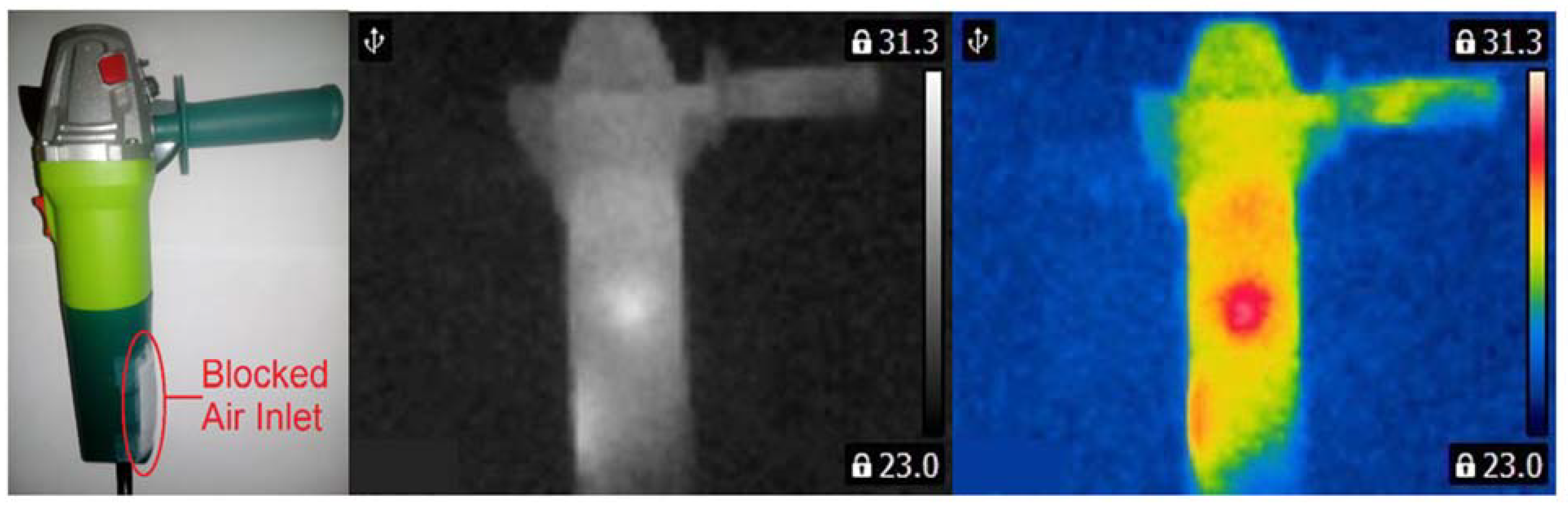

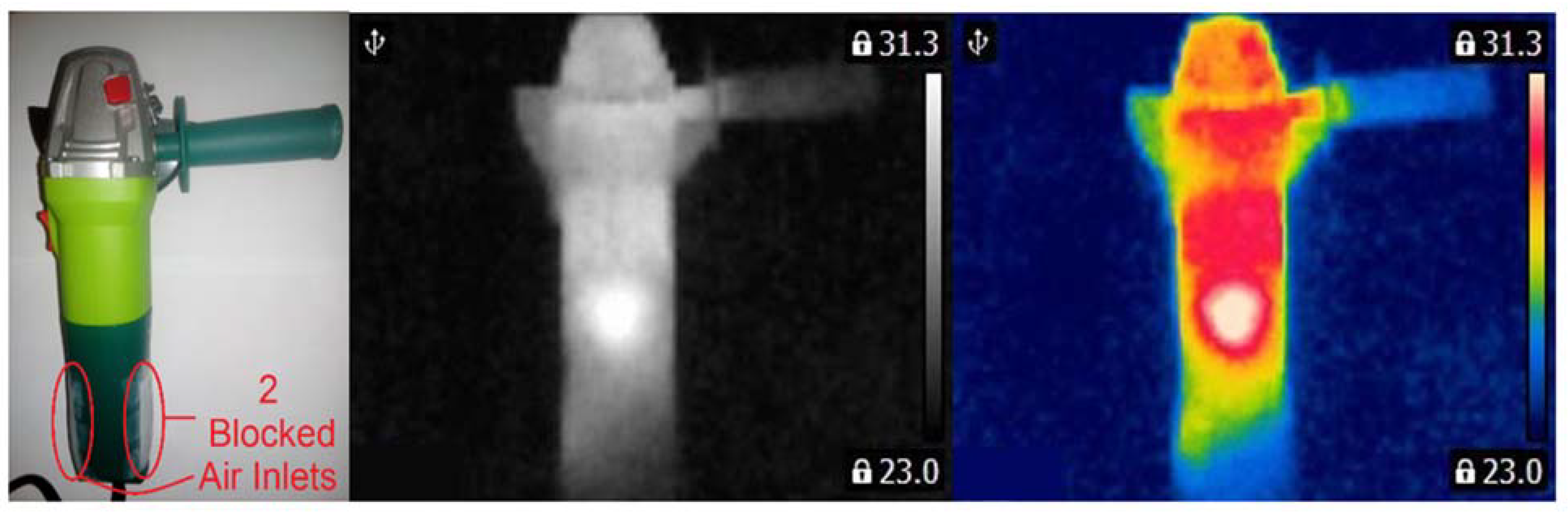

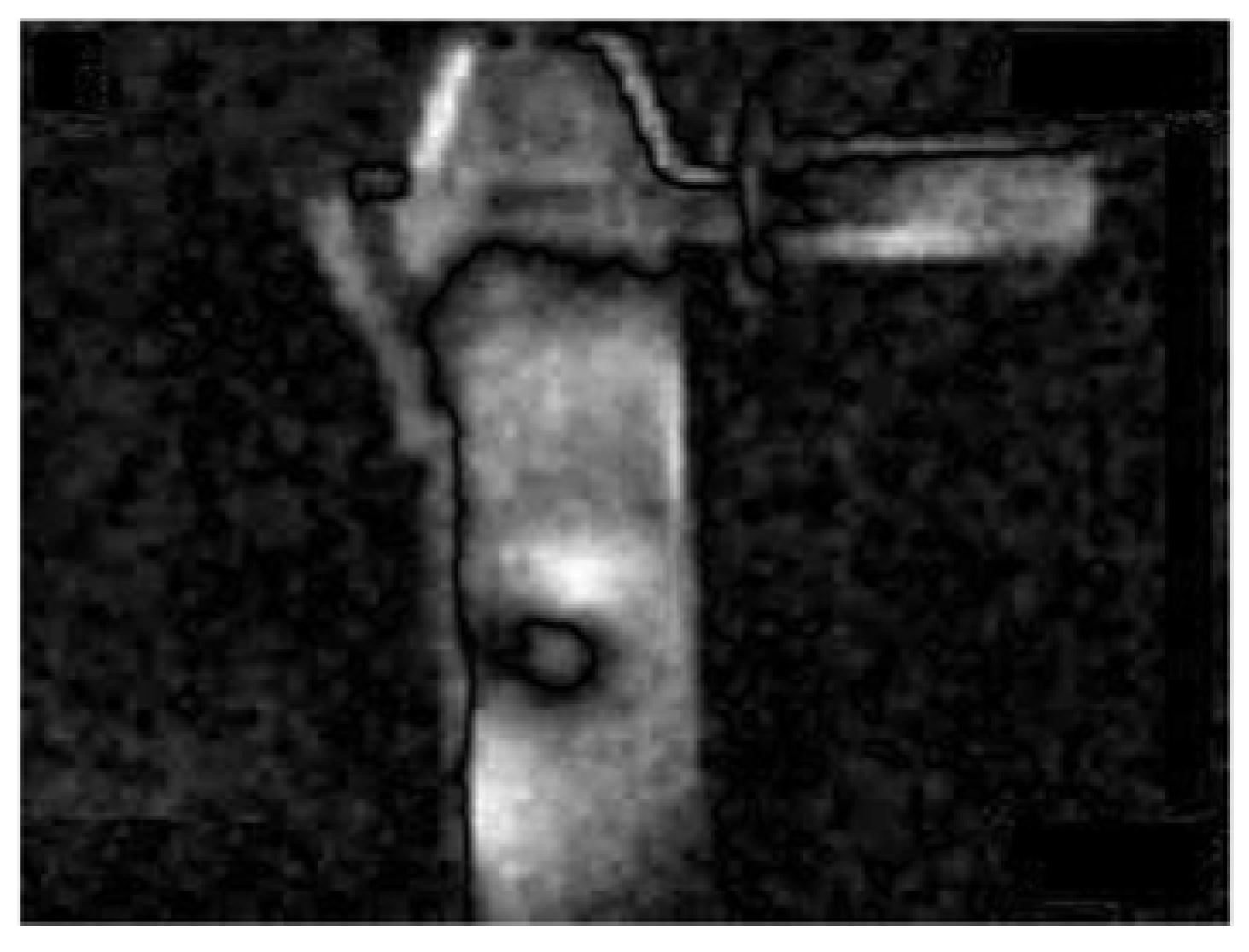

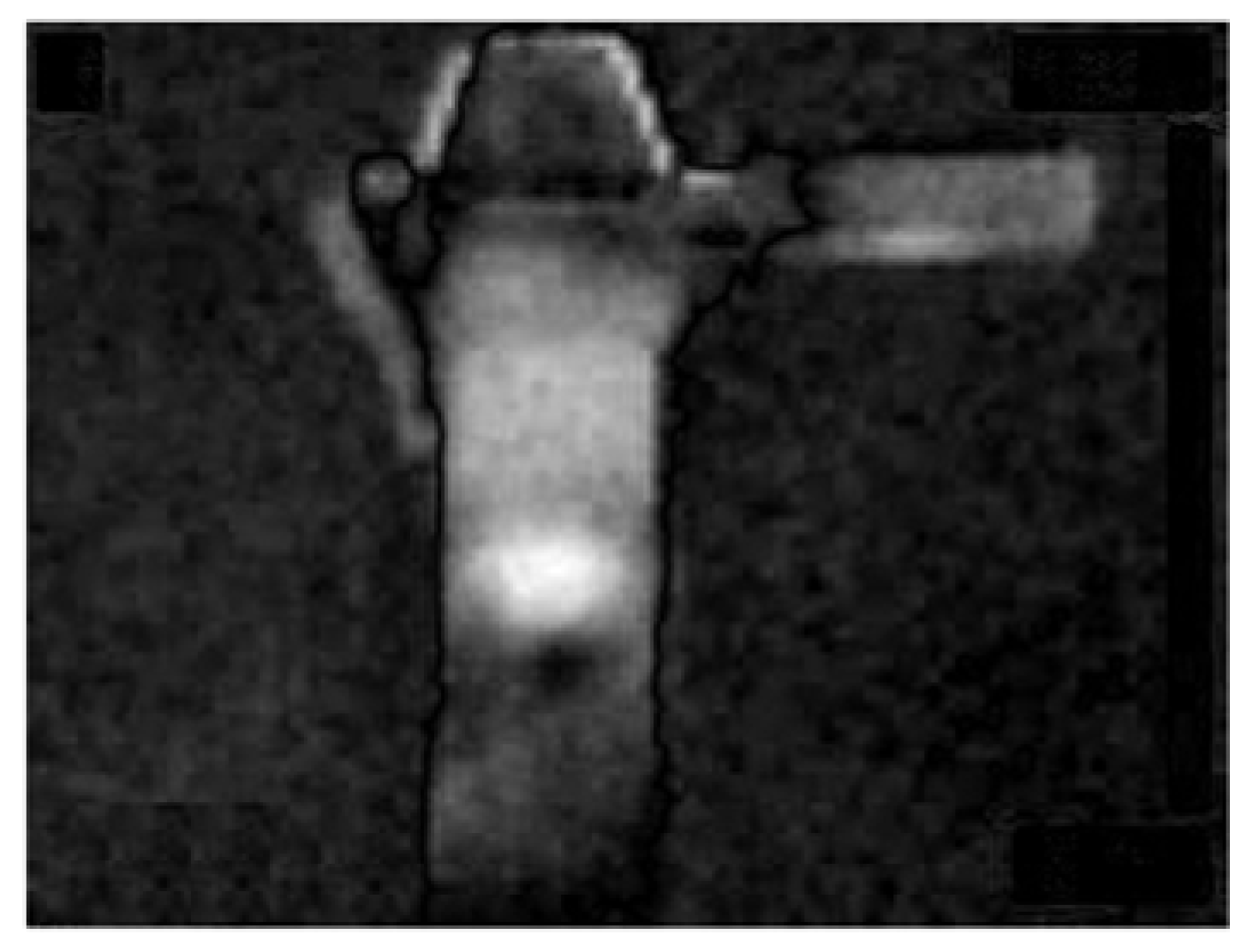

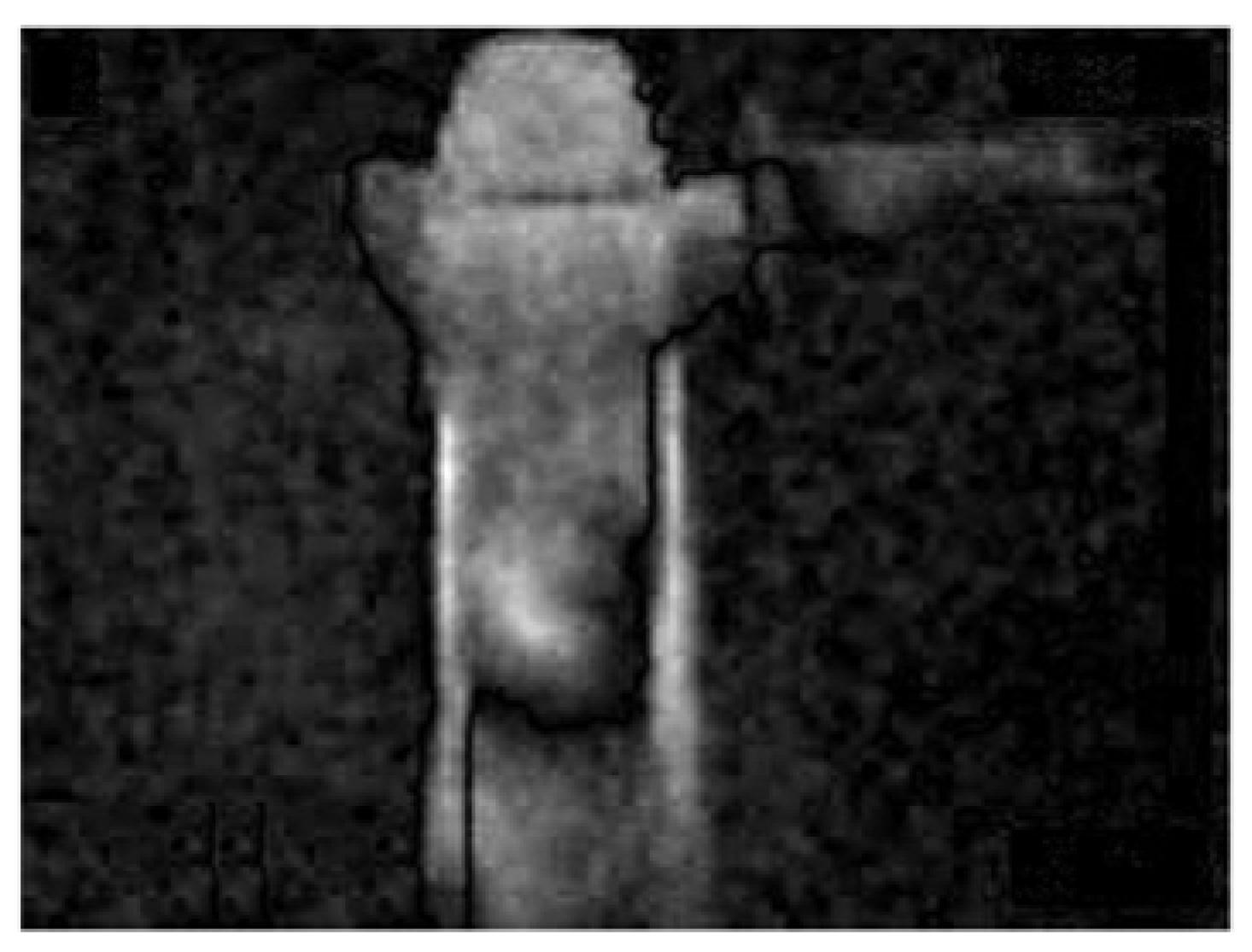

4. Analyzed States of the Angle Grinder

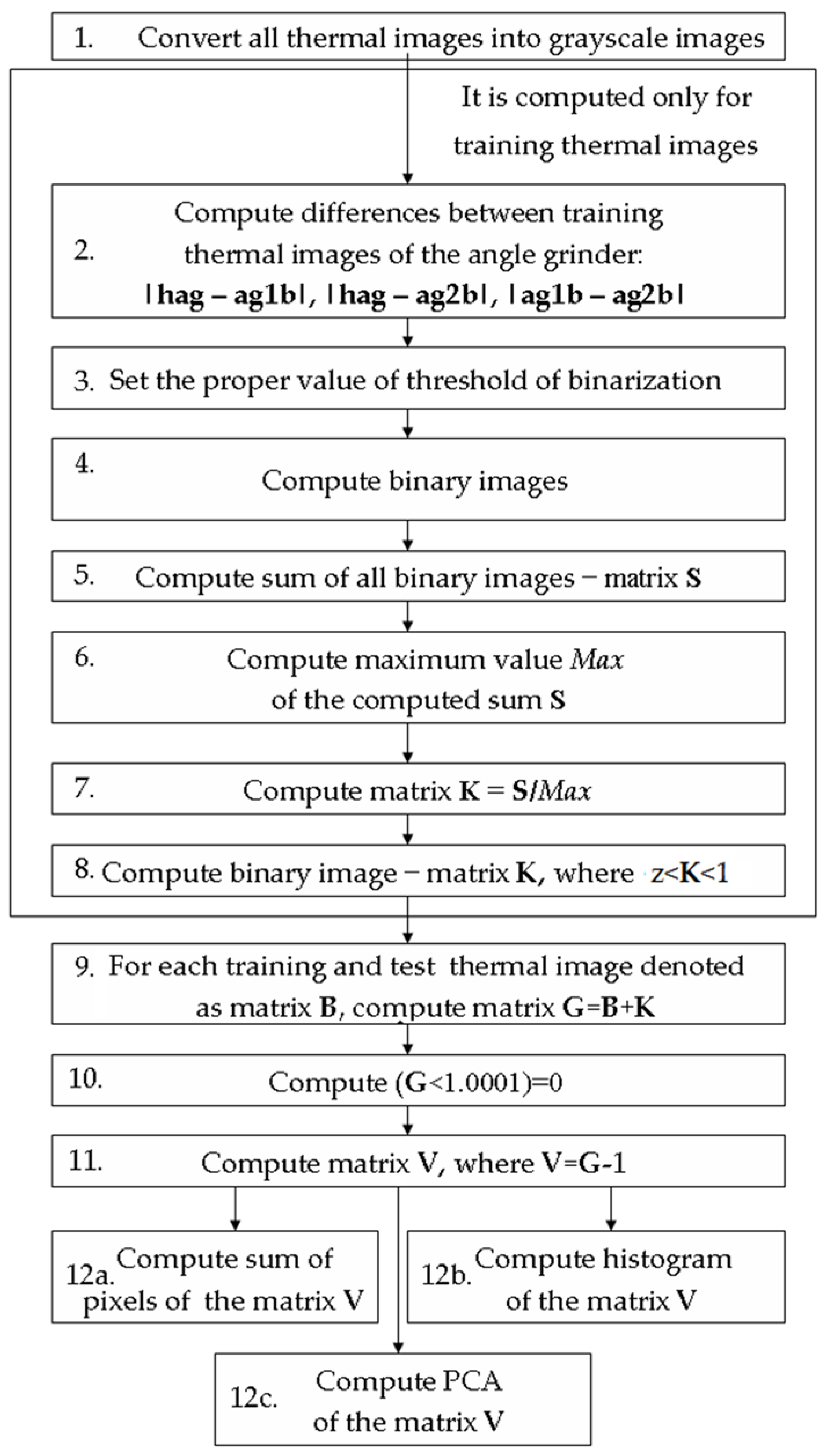

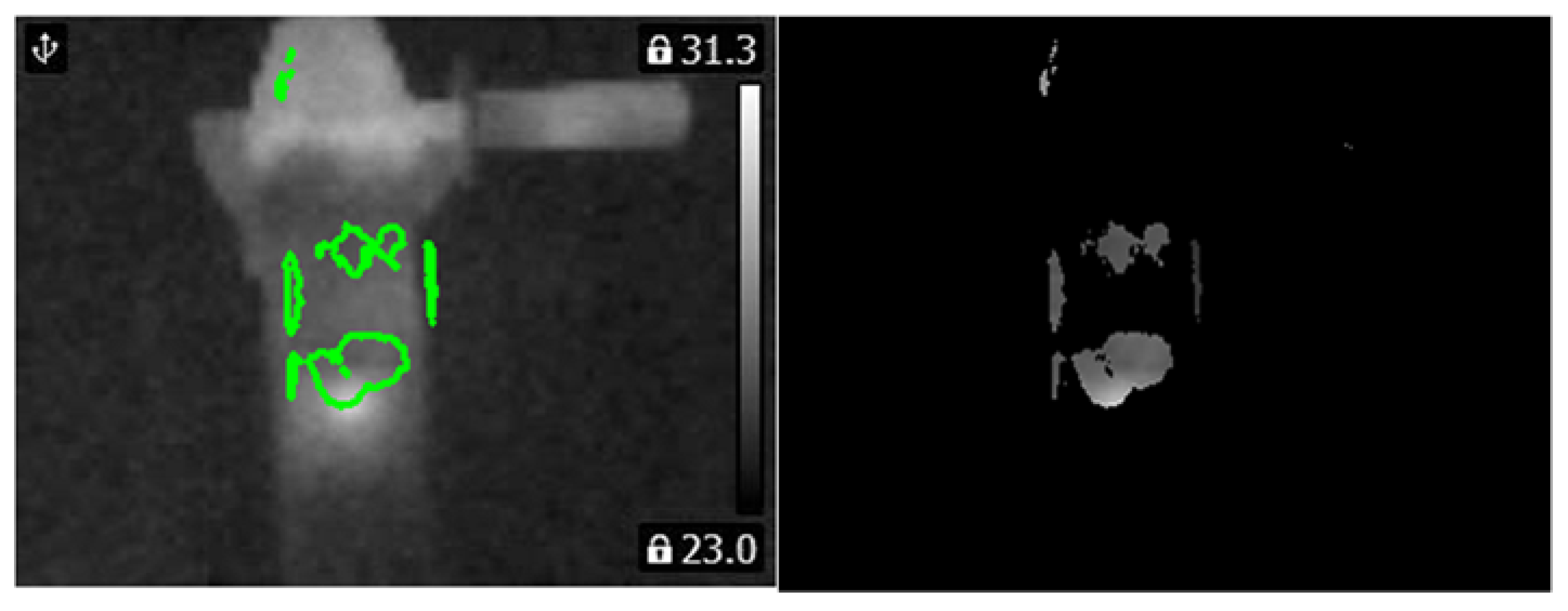

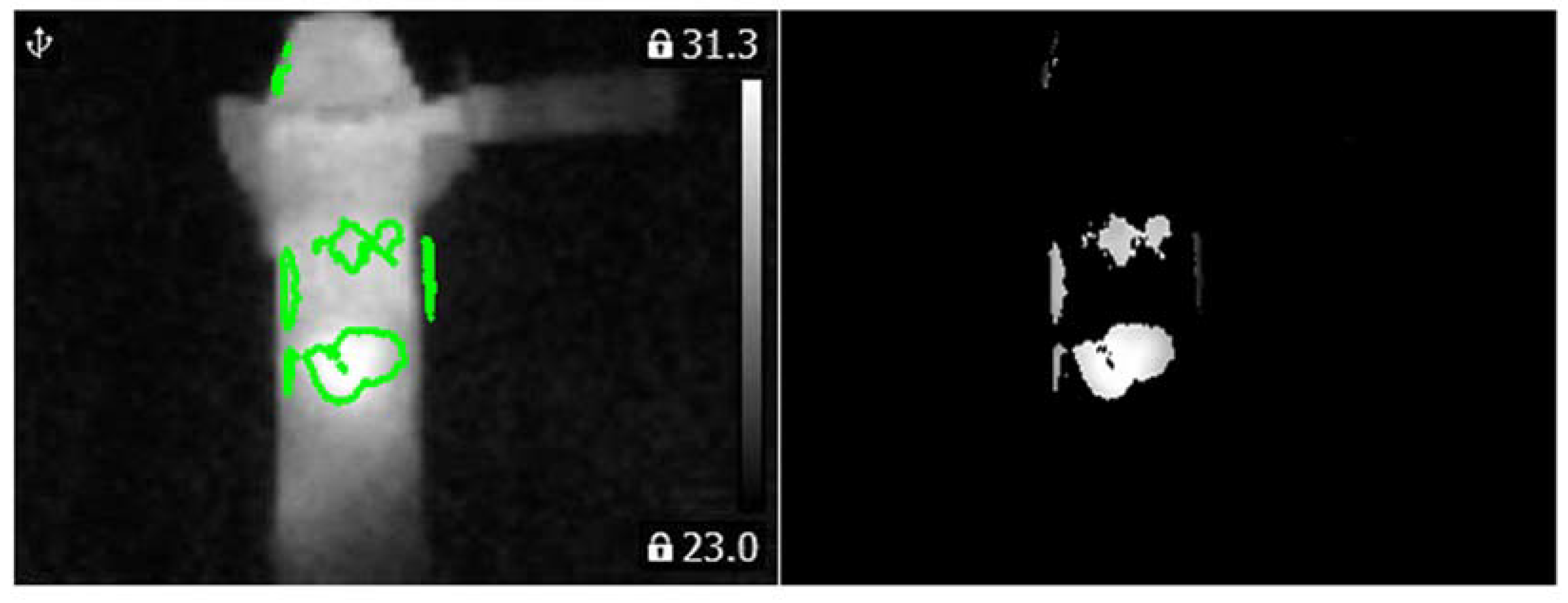

4.1. BCAoMID−F (Binarized Common Areas of Maximum Image Differences−Fusion)

- Convert all thermal images into grayscale images (256 colors, value of the pixel is in the range of <0–1>).

- Compute differences between training thermal images of the angle grinder: |hag-ag1b|, |hag-ag2b|, |ag1b-ag2b|, where hag − matrix (320 × 240) of the thermal image of the healthy angle grinder, ag1b−matrix (320 × 240) of the thermal image of the angle grinder with 1 blocked air inlet, ag2b−matrix (320 × 240) of the thermal image of the angle grinder with 2 blocked air inlets.

- For computed differences |hag-ag1b|, |hag-ag2b|, |ag1b-ag2b|, set the proper value of threshold of binarization (t<|hag-ag1b|<u, for example: t = 0.1, u = 1).

- Compute binary images (binarization threshold = 0.1).

- Compute the sum of all binary images of the computed differences. It is denoted as matrix S.

- Compute maximum value (Max) of the computed sum S.

- Compute matrix K = S/Max.

- Compute binary image−matrix K, where z < K < 1 (set 0 for values of matrix K less than z, set 1 for values of matrix K greater than z), z is set experimentally <0, 1>. For the analysis, the author set z = 0.5. Computed binary image K has values 0 and 1.

- For each training and test thermal image denoted as matrix B, compute matrix G = B + K.

- Compute matrix (G < 1.001) = 0 (set 0 for values of matrix G less than 1.001).

- Compute matrix V, where V = G − 1

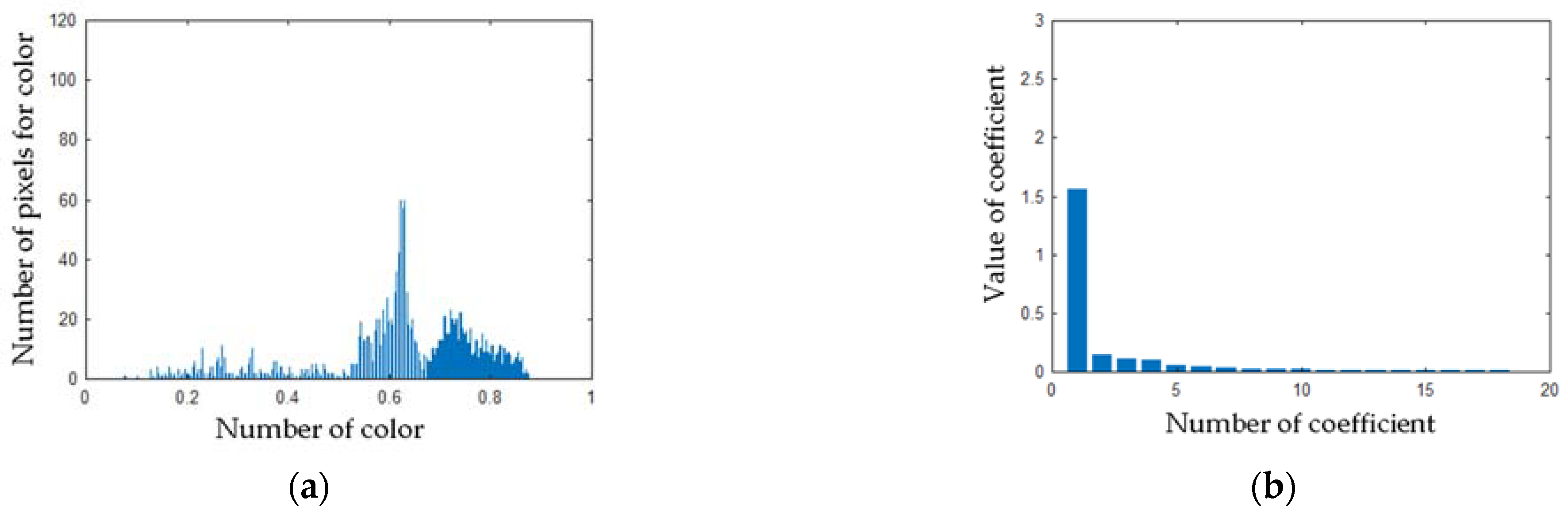

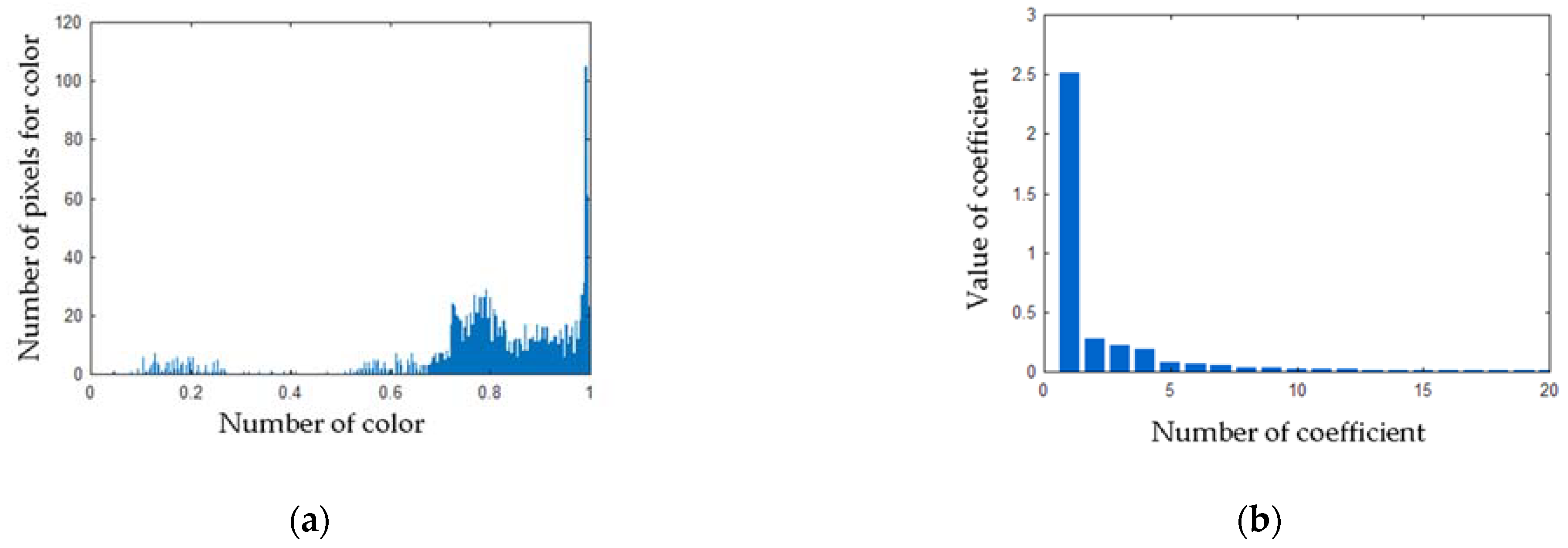

- Compute three features: compute the sum of pixels of the matrix V, compute a histogram of the matrix V, compute PCA (Principal Component Analysis) of the matrix V.

4.2. Principal Component Analysis

4.3. Classification Using the Nearest Neighbor

- (1)

- load training and test feature vectors,

- (2)

- set k = 1 (k − number of nearest neighbors),

- (3)

- Compute the distance d, where d = Σ|a-b|, a—test feature vector, b—training feature vector,

- (4)

- for all computed distances d, select the nearest distance,

- (5)

- select the label of the predicted class.

4.4. Support Vector Machine

5. Results of the Analysis of Thermal Images

6. Conclusions

- (1)

- Thermal images should be captured at the same distance (thermal imaging camera–analyzed motor).

- (2)

- The proposed method is efficient for measurement distance equal to 0.4 m. Slight shifts of thermal imaging camera(+/−0.1 m) do not cause major changes for recognition results.

- (3)

- Recognition rate for considered states was high (TRAG is in the range of 98.5–100%).

- (4)

- The same conditions and equipment should be used for measurements. The temperature of air in a room should be similar for all training and test thermal images.

- (5)

- Different types of motors can be diagnosed by the proposed method successfully.

- (6)

- The proposed method is fast. It can be implemented as a condition online monitoring system.

- (7)

- The method is non-invasive. It can be used for conditions of difficult access.

- (8)

- The proposed method uses a computer and thermal imaging camera. The cost of the experimental setup is low (about 1400–1600$).

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jafari, A.; Faiz, J.; Jarrahi, M.A. A Simple and Efficient Current-Based Method for Interturn Fault Detection in BLDC Motors. IEEE Trans. Ind. Inform. 2021, 17, 2707–2715. [Google Scholar] [CrossRef]

- Purbowaskito, W.; Lan, C.Y.; Liu, M.K.; Fuh, K. A Novel Scheme on Fault Diagnosis of Induction Motors using Current per Voltage Bode Diagram. J. Chin. Soc. Mech. Eng. 2020, 41, 781–790. [Google Scholar]

- Liu, L.S.; Chen, L.Q.; Wang, Z.L.; Liu, D.T. Early Fault Detection of Planetary Gearbox Based on Acoustic Emission and Improved Variational Mode Decomposition. IEEE Sens. J. 2021, 21, 1735–1745. [Google Scholar] [CrossRef]

- Chen, L.; Choy, Y.S.; Tam, K.C.; Fei, C.W. Hybrid microphone array signal processing approach for faulty wheel identification and ground impedance estimation in wheel/rail system. Appl. Acoust. 2021, 172, 107633. [Google Scholar] [CrossRef]

- Meserkhani, A.; Jafari, S.M.; Rahi, A. Experimental comparison of acoustic emission sensors in the detection of outer race defect of angular contact ball bearings by artificial neural network. Measurement 2021, 168, 108198. [Google Scholar] [CrossRef]

- Motahari-Nezhad, M.; Jafari, S.M. ANFIS system for prognosis of dynamometer high-speed ball bearing based on frequency domain acoustic emission signals. Measurement 2020, 166, 108154. [Google Scholar] [CrossRef]

- Chen, B.; Xie, L.; Li, Y.Z.; Gao, B.C. Acoustical damage detection of wind turbine yaw system using Bayesian network. Renew. Energy 2020, 160, 1364–1372. [Google Scholar] [CrossRef]

- Glowacz, A. Recognition of acoustic signals of induction motor using Fft, Smofs-10 and LSVM. Eksploat. I Niezawodn. Maint. Reliab. 2015, 17, 569–574. [Google Scholar] [CrossRef]

- Glowacz, A. Fault diagnostics of acoustic signals of loaded synchronous motor using SMOFS-25-EXPANDED and selected classifiers. Teh. Vjesn. Tech. Gaz. 2016, 23, 1365–1372. [Google Scholar] [CrossRef]

- Glowacz, A.; Tadeusiewicz, R.; Legutko, S.; Caesarendra, W.; Irfan, M.; Liu, H.; Brumercik, F.; Gutten, M.; Sulowicz, M.; Daviu, J.A.; et al. Fault diagnosis of angle grinders and electric impact drills using acoustic signals. Applied Acoustics 2021, 179. [Google Scholar] [CrossRef]

- Inturi, V.; Shreyas, N.; Chetti, K.; Sabareesh, G.R. Comprehensive fault diagnostics of wind turbine gearbox through adaptive condition monitoring scheme. Appl. Acoust. 2021, 174, 107738. [Google Scholar] [CrossRef]

- Xing, S.B.; Lei, Y.G.; Wang, S.H.; Jia, F. Distribution-Invariant Deep Belief Network for Intelligent Fault Diagnosis of Machines Under New Working Conditions. IEEE Trans. Ind. Electron. 2021, 68, 2617–2625. [Google Scholar] [CrossRef]

- Ma, S.L.; Yuan, Y.; Wu, J.W.; Jiang, Y.; Jia, B.W.; Li, W.X. Multisensor Decision Approach for HVCB Fault Detection Based on the Vibration Information. IEEE Sens. J. 2021, 21, 985–994. [Google Scholar] [CrossRef]

- Barusu, M.R.; Deivasigamani, M. Non-Invasive Vibration Measurement for Diagnosis of Bearing Faults in 3-Phase Squirrel Cage Induction Motor Using Microwave Sensor. IEEE Sens. J. 2021, 21, 1026–1039. [Google Scholar] [CrossRef]

- Jeffali, F.; Ouariach, A.; El Kihel, B.; Nougaoui, A. Diagnosis of three-phase induction motor and the impact on the kinematic chain using non-destructive technique of infrared thermography. Infrared Phys. Technol. 2019, 102. [Google Scholar] [CrossRef]

- Li, Y.B.; Gu, J.X.; Zhen, D.; Xu, M.Q.; Ball, A. An Evaluation of Gearbox Condition Monitoring Using Infrared Thermal Images Applied with Convolutional Neural Networks. Sensors 2019, 19, 2205. [Google Scholar] [CrossRef]

- Al-Musawi, A.K.; Anayi, F.; Packianather, M. Three-phase induction motor fault detection based on thermal image segmentation. Infrared Phys. Technol. 2020, 104, 103140. [Google Scholar] [CrossRef]

- Morales-Perez, C.; Rangel-Magdaleno, J.; Peregrina-Barreto, H.; Ramirez-Cortes, J.; Vazquez-Pacheco, E. Bearing Fault Detection Technique by using Thermal Images: A case of Study. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1797–1802. [Google Scholar]

- Misra, R.; Agarwal, A. Improving Motor Reliability by Thermal Imaging. In Proceedings of the IEEE International Conference on Sustainable Energy, Electronics, and Computing Systems (SEEMS), Greater Noida, India, 26–27 October 2018. [Google Scholar]

- Choudhary, A.; Shimi, S.L.; Akula, A. Bearing Fault Diagnosis of Induction Motor Using Thermal Imaging. In Proceedings of the International Conference on Computing, Power and Communication Technologies (GUCON), Greater Noida, India, 28–29 September 2018; pp. 950–955. [Google Scholar]

- Quattrocchi, A.; Freni, F.; Montanini, R. Self-heat generation of embedded piezoceramic patches used for fabrication of smart materials. Sens. Actuators A Phys. 2018, 280, 513–520. [Google Scholar] [CrossRef]

- Freni, F.; Quattrocchi, A.; Piccolo, S.A.; Montanini, R. Quantitative evaluation of eggs freshness using flash thermography. Quant. Infrared Thermogr. J. 2020, 17, 13–25. [Google Scholar] [CrossRef]

- Rani, M.F.H.; Razlan, Z.M.; Shahriman, A.B.; Ibrahim, Z.; Wan, W.K. Comparative study of surface temperature of lithium-ion polymer cells at different discharging rates by infrared thermography and thermocouple. Int. J. Heat Mass Transf. 2020, 153. [Google Scholar] [CrossRef]

- Duan, Z.H.; Wu, T.H.; Guo, S.W.; Shao, T.; Malekian, R.; Li, Z.X. Development and trend of condition monitoring and fault diagnosis of multi-sensors information fusion for rolling bearings: A review. Int. J. Adv. Manuf. Technol. 2018, 96, 803–819. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Chen, B.; Pan, G.F.; Zhao, Y. A novel hybrid model based on VMD-WT and PCA-BP-RBF neural network for short-term wind speed forecasting. Energy Convers. Manag. 2019, 195, 180–197. [Google Scholar] [CrossRef]

- Gajewski, J.; Valis, D. The determination of combustion engine condition and reliability using oil analysis by MLP and RBF neural networks. Tribol. Int. 2017, 115, 557–572. [Google Scholar] [CrossRef]

- Nurmaini, S.; Partan, R.U.; Caesarendra, W.; Dewi, T.; Rahmatullah, M.N.; Darmawahyuni, A.; Bhayyu, V.; Firdaus, F. An Automated ECG Beat Classification System Using Deep Neural Networks with an Unsupervised Feature Extraction Technique. Appl. Sci. 2019, 9, 2921. [Google Scholar] [CrossRef]

- Sun, S.; Przystupa, K.; Wei, M.; Yu, H.; Ye, Z.; Kochan, O. Fast bearing fault diagnosis of rolling element using Levy Moth-Flame optimization algorithm and Naive Bayes. Eksploat. I Niezawodn. Maint. Reliab. 2020, 22, 730–740. [Google Scholar] [CrossRef]

- Ranjan, J.; Patra, K.; Szalay, T.; Mia, M.; Gupta, M.K.; Song, Q.H.; Krolczyk, G.; Chudy, R.; Pashnyov, V.A.; Pimenov, D.Y. Artificial Intelligence-Based Hole Quality Prediction in Micro-Drilling Using Multiple Sensors. Sensors 2020, 20, 885. [Google Scholar] [CrossRef]

- Peng, Y.H.; Albuquerque, P.H.M.; do Nascimento, I.F.; Machado, J.V.F. Between Nonlinearities. Complexity, and Noises: An Application on Portfolio Selection Using Kernel Principal Component Analysis. Entropy 2019, 21, 376. [Google Scholar] [CrossRef]

- Ye, B.G.; Qiu, T.R.; Bai, X.M.; Liu, P. Research on Recognition Method of Driving Fatigue State Based on Sample Entropy and Kernel Principal Component Analysis. Entropy 2018, 20, 701. [Google Scholar] [CrossRef]

- Li, Z.; Guan, X.R.; Zou, K.F.; Xu, C. Estimation of Knee Movement from Surface EMG Using Random Forest with Principal Component Analysis. Electronics 2020, 9, 43. [Google Scholar] [CrossRef]

- Geler, Z.; Kurbalija, V.; Ivanovic, M.; Radovanovic, M. Weighted kNN and constrained elastic distances for time-series classification. Expert Syst. Appl. 2020, 162, 113829. [Google Scholar] [CrossRef]

- Dong, Y.X.; Ma, X.J.; Fu, T.L. Electrical load forecasting: A deep learning approach based on K-nearest neighbors. Appl. Soft Comput. 2021, 99, 106900. [Google Scholar] [CrossRef]

- Ferreira, P.J.S.; Cardoso, J.M.P.; Mendes-Moreira, J. kNN Prototyping Schemes for Embedded Human Activity Recognition with Online Learning. Computers 2020, 9, 96. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Recognition of images of finger skin with application of histogram. image filtration and K-NN classifier. Biocybern. Biomed. Eng. 2016, 36, 95–101. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, D.R.; Min, T.; Ou, Y.H. A Fault Diagnosis Method of Rolling Bearing Integrated with Cooperative Energy Feature Extraction and Improved Least-Squares Support Vector Machine. Math. Probl. Eng. 2020, 6643167. [Google Scholar] [CrossRef]

- Song, Q.S.; Yan, G.P.; Tang, G.W.; Ansari, F. Robust principal component analysis and support vector machine for detection of microcracks with distributed optical fiber sensors. Mech. Syst. Signal Process. 2021, 146, 107019. [Google Scholar] [CrossRef]

- Wang, J.; Shen, L.Z.; Bi, Y.H.; Lei, J.L. Modeling and optimization of a light-duty diesel engine at high altitude with a support vector machine and a genetic algorithm. Fuel 2021, 285, 119137. [Google Scholar] [CrossRef]

- Kim, J.S.; Choi, K.N.; Kang, S.W. Infrared Thermal Image-Based Sustainable Fault Detection for Electrical Facilities. Sustainability 2021, 13, 557. [Google Scholar] [CrossRef]

- Glowacz, A. Fault diagnosis of electric impact drills using thermal imaging. Measurement 2021, 171. [Google Scholar] [CrossRef]

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 100 |

| AG with 2 blocked air inlets | 100 |

| TRAG [%] | |

| 3 states of the AG | 100 |

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 100 |

| AG with 2 blocked air inlets | 100 |

| TRAG [%] | |

| 3 states of the AG | 100 |

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 100 |

| AG with 2 blocked air inlets | 100 |

| TRAG [%] | |

| 3 states of the AG | 100 |

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 100 |

| AG with 2 blocked air inlets | 100 |

| TRAG [%] | |

| 3 states of the AG | 100 |

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 100 |

| AG with 2 blocked air inlets | 100 |

| TRAG [%] | |

| 3 states of the AG | 100 |

| State of the Angle Grinder | RAG [%] |

|---|---|

| Healthy AG | 100 |

| AG with 1 blocked air inlet | 97.7 |

| AG with 2 blocked air inlets | 97.7 |

| TRAG [%] | |

| 3 states of the AG | 98.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glowacz, A. Ventilation Diagnosis of Angle Grinder Using Thermal Imaging. Sensors 2021, 21, 2853. https://doi.org/10.3390/s21082853

Glowacz A. Ventilation Diagnosis of Angle Grinder Using Thermal Imaging. Sensors. 2021; 21(8):2853. https://doi.org/10.3390/s21082853

Chicago/Turabian StyleGlowacz, Adam. 2021. "Ventilation Diagnosis of Angle Grinder Using Thermal Imaging" Sensors 21, no. 8: 2853. https://doi.org/10.3390/s21082853

APA StyleGlowacz, A. (2021). Ventilation Diagnosis of Angle Grinder Using Thermal Imaging. Sensors, 21(8), 2853. https://doi.org/10.3390/s21082853