1. Introduction

Every year, road traffic accidents kill approximately 1.32 million people worldwide, and more than 50 million people sustain non-fatal injuries. Low- and middle-income (LMI) countries account for more than 90% of the world’s fatalities, although they own 60% of the world’s vehicles. The road fatality rate in LMI countries was at 27.5 per 100,000 populations while in high-income countries the road fatality rate was 8.3 per 100,000 [

1]. Africa has a fatality rate of 26.6 per 100,000 people while the European region has 9.3 per 100,000 [

2]. Road safety brings significant costs to the economy and trauma to society. The average cost of road traffic accidents in LMI countries was estimated to be between 3% and 5% of their gross domestic product (GDP).

In Rwanda, motorcycle drivers represent one of the most at-risk occupational groups, with a significant burden of disability-related vehicular incidents and permanent injuries. Among the motorcycle drivers surveyed, 38.7% said they had been in an accident in their lifetime, and 8.5% said they had gone to the hospital [

3]. According to the World Health Organization (WHO), global road traffic crashes in 2018 were the 8th and the 1st leading cause of death for children and young adults, respectively. In the same year, the fatality rate per 100,000 people was 29 for Uganda, 34.7 for Burundi, 29.2 for Tanzania, 27.4 for the Democratic Republic of the Congo (DRC), 27.8 for Kenya, and 29.7 for Rwanda. Considering the fatality rate per 100,000 people, Rwanda was ranked 7th in the world [

4]. According to the Rwanda National Police (RNP) for the past four years, reckless driving, wrong maneuvering and excessive speeding have been the major causes of traffic accidents. They account for 32.64%, 25.36%, and 13% of traffic accidents, respectively.

Figure 1 depicts the cause factors of road accident cases for the past four years. In a typical year, there have been 5595 road accidents on average, with 603 deaths, 789 serious injuries, 1765 minor injuries, and 2437 property damage.

An increase in average speed is relatively associated with an increase in collision frequency [

5].

Figure 2 shows that for the last 4 years, road accidents caused by excessive speeding increased in mean per month with 37.9, 51.1, 68 and 84.6 cases, respectively.

The United States of America (USA) started installing a chip in every entity on the Internet, including vehicles, which will facilitate the Internet of Vehicles (IoV) [

6]. The integration of technologies expands the Intelligent Transportation System (ITS) framework, wireless access protocols [

7] and GSM [

8]. Today’s real-time traffic data available for moving vehicles have enabled the development of ITS applications for traffic control services [

9]. The IoT is revolutionizing research by integrating smartness into the existing areas. ITS is tremendously promising to minimize road traffic safety challenges [

10]. The IoV allows both collecting and storing vehicles’ movement data in the Cloud [

11]. Vehicle data are being sent to the web from any device that can communicate using the representational state transfer application programming interface (REST API) [

12]. Building a sensor network for IoT applications implies a higher initial cost.

The GSM cellular network covers 96.4% of Rwanda. The fourth-generation long-term evolution (4G LTE) technology was deployed across 94.2% of its geographic coverage. Developing an application that is cellular communication-based is cost-effective [

13]. The in-car navigation system to provide traffic reports through vehicle-to-Cloud communication is crucial in ITS [

14]. Police forces along the roads keep continue being employed as the major solution to ensure that road users adhere to the set rules. Nowadays, ITS-based solutions facilitate traveling in a more organized way. One of the approaches has been the variable speed limit (VSL) to optimize traffic flow by adapting the speed limit to real-time conditions [

15]. VSL has been used in conjunction with other traffic flow control strategies to improve traffic throughput while reducing bottlenecks [

16]. Variable message signs are installed on motorways to notify drivers about the current speed limits [

17]. Their contributions are significant in terms of speed harmonization [

18]. The presence of an active VSL in the region results in increased traffic density as well as a reduction in flow [

19]. The VSL has shown its high influence on traffic flow dynamics such as congestion management [

20]. VSLs are being used as an approach to optimize traffic flow in terms of flow harmonization.

The speed of road vehicles is subjected to various parameters such as traffic conditions, vehicle conditions, weather, road curvature, driver behavior, and many others factors [

21]. Vehicle speed control can be implemented using the in-vehicle system, e.g., adaptive cruise control (ACC) [

22]. Intelligent speed adaptation (ISA) can also be used at a macroscopic level for a whole road segment. Vehicle speed control in related works was based on environment perception [

23], road conditions [

24], and driver state detection [

25]. A gear shift method for the dual clutch transmission (DCT) was proposed for the speed control of automotive motors [

26]. However, road traffic accidents are avoidable, and Sub-Saharan African countries lack adequate methods of reporting the tangible and intangible costs of road accidents. This leads to the inappropriate consideration of road accident costs [

27]. Human factors related to driving behavior, the driver’s attitude, and driving experience have been demonstrated to have relevant impacts on accident severity [

28,

29]. Every 1% increase in average speed increases the fatal crash risk by 4%. Hence, there is a need to develop an intelligent system to avoid excessive speeding. Investigating the effect of the change of speed on accidents has shown a strong relationship between speed and road safety [

30]. Despite the existing approaches, the variety of factors still challenges the drivers and road accidents keep increasing exponentially. Hence, there is a need to find a reliable and cost-effective system to limit the driver to the specific speed of a particular zone. Speed reduction needs a special focus since it is a priority strategy to reduce the rising fatalities associated with excessive speeding.

This paper was driven by the fact that Rwanda is taking advantage of emerging technologies to address road safety. The transportation sector is one of the major contributors to road safety problems [

31]. As a solution, the government has encouraged the use of electric vehicles in its 2050 vision to reduce pollution by up to 38%. Electric vehicles will account for 9% of this target [

32]. Various policies are being implemented for the electrification of transport [

33]. Electric car sales in 2019 were 2.1 million [

34]. Electric vehicles are categorized into battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs) based on the energy type [

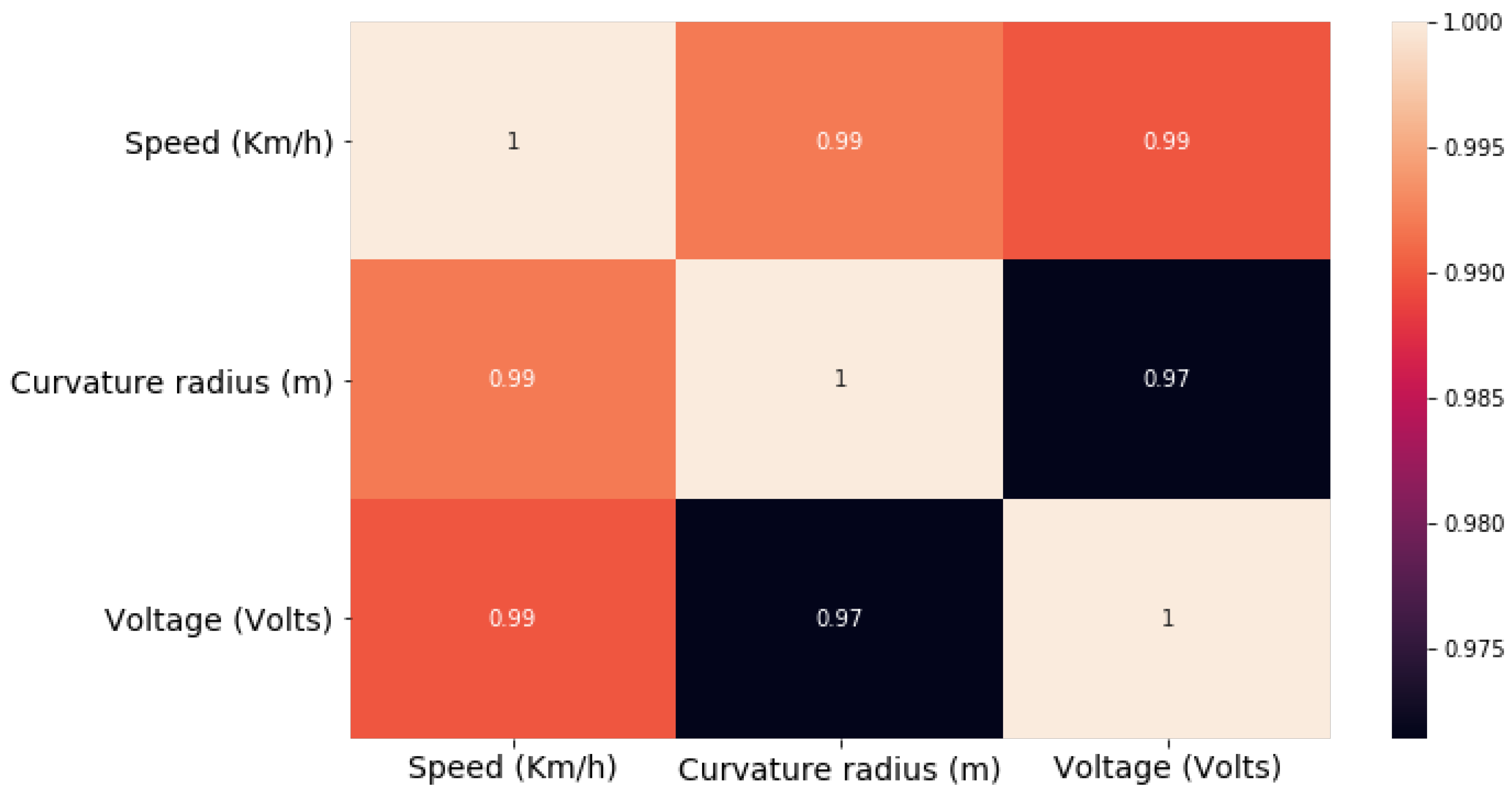

35]. This paper proposes a dynamic speed adaptation (DAS) method for controlling the operating speed at which the vehicle is observed operating under free flow conditions. Together with the speed sensing module for sensing the maximum lawful speed and predefined road curvature data for a particular zone, the vehicle’s speed limit is adjusted accordingly. The output from the speed limits and road curvature information parameters are presented as explanatory variables to predict the outcome of the response variable, which is the voltage supplied to the electric motor of the vehicle. The data generated by the small setup device was used to evaluate the MLR and RF regression approaches to compute the needed speed limit. The idea of speed control proposed in this paper is based on the working principles of BEVs, where only batteries feed the electric motor. The vehicle thus solely relies on the energy stored in the batteries pack [

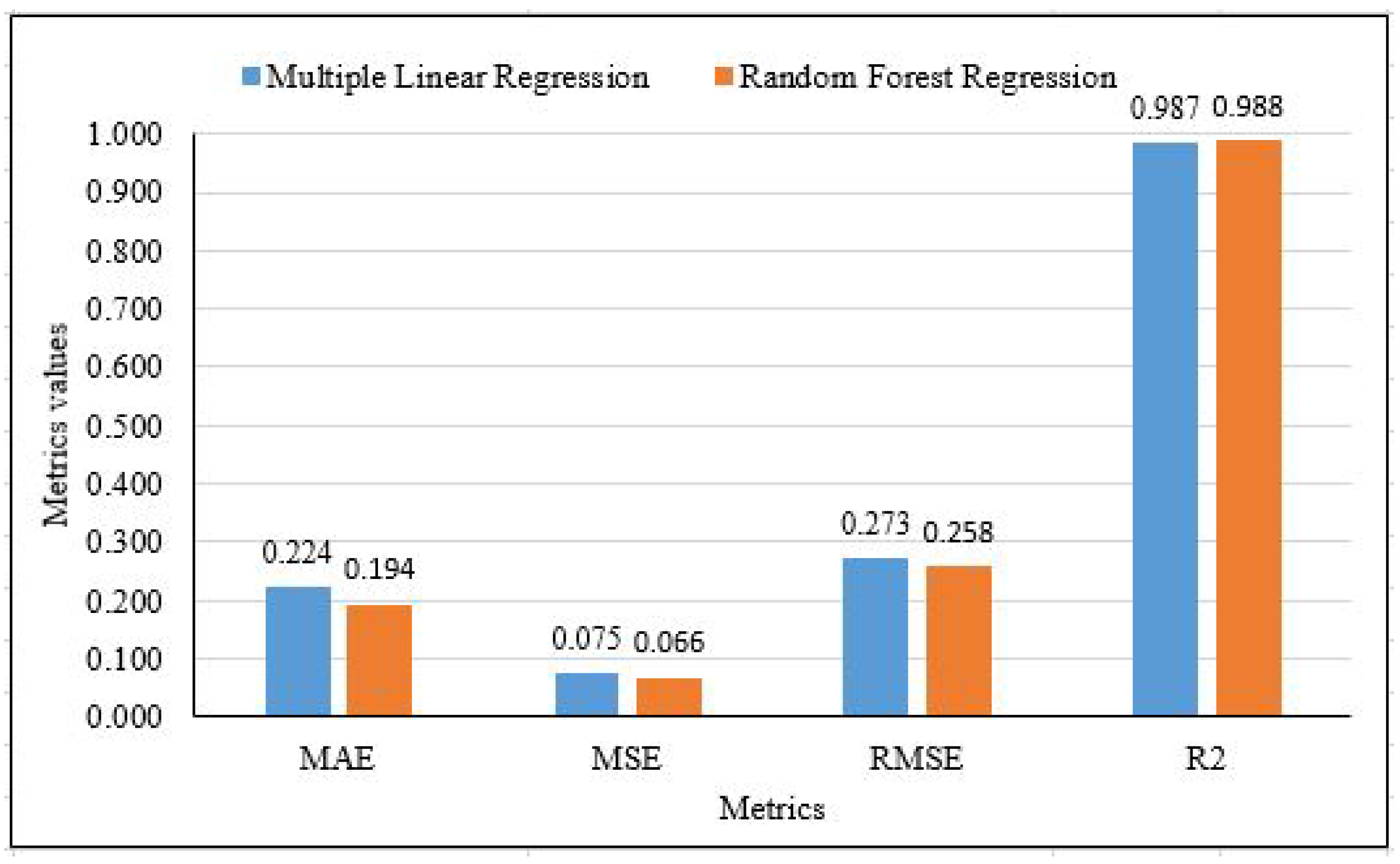

36].

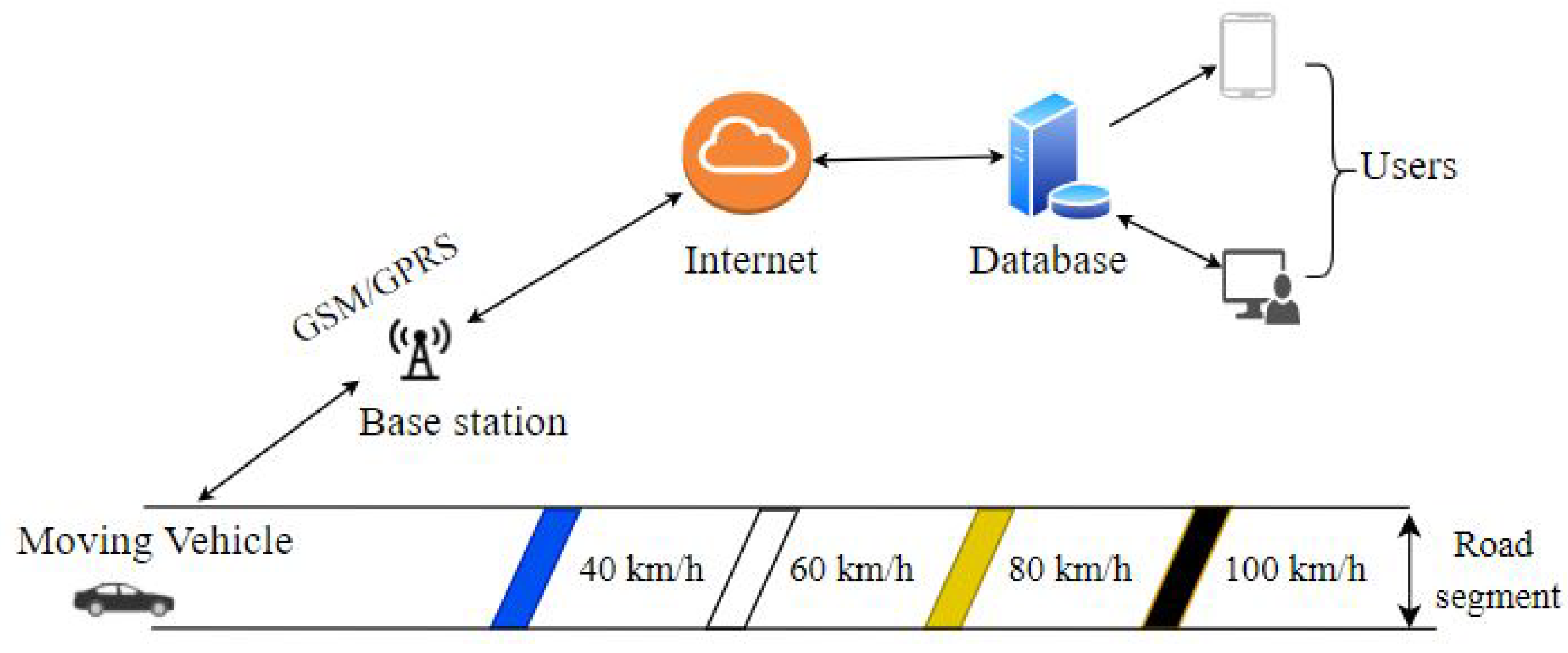

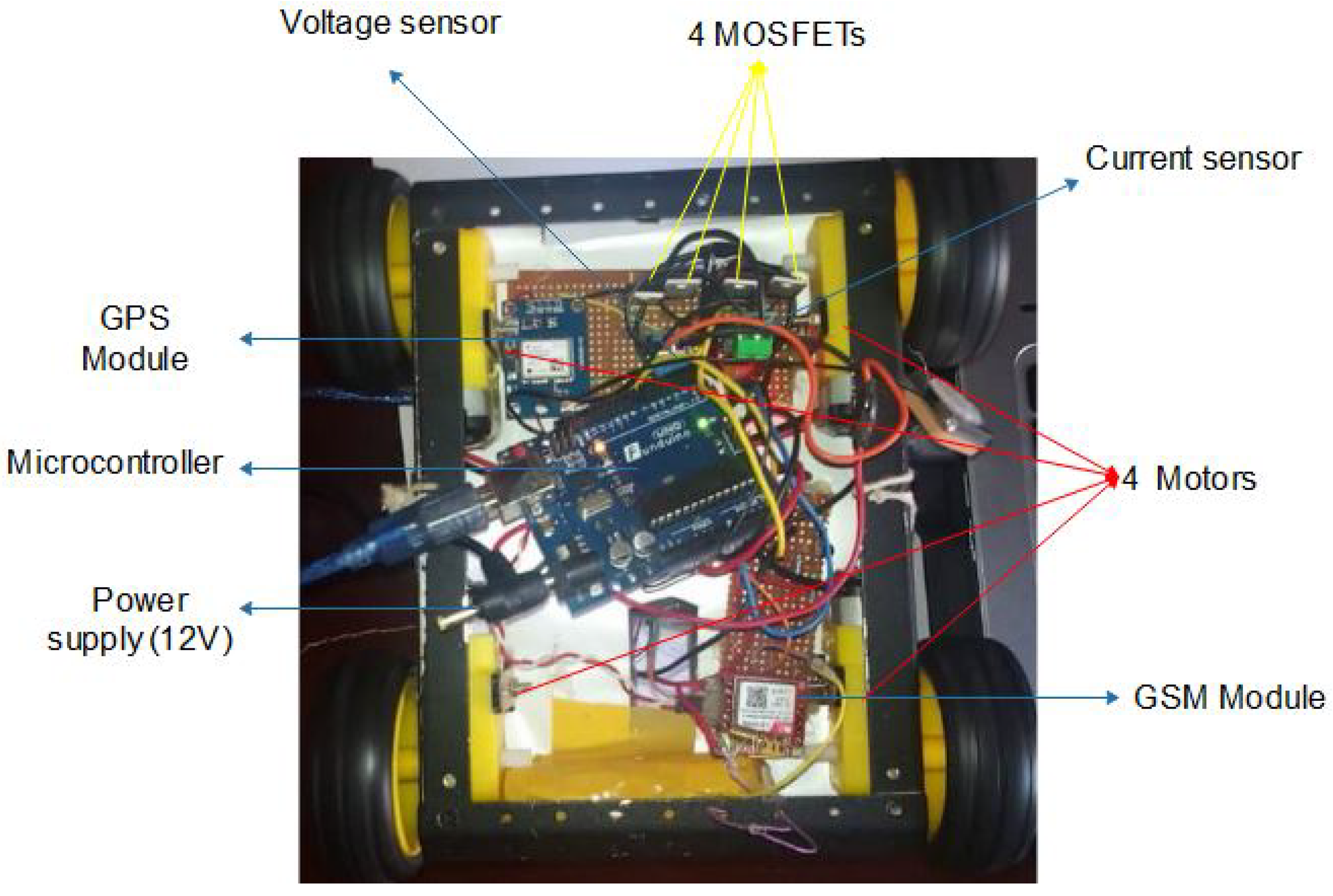

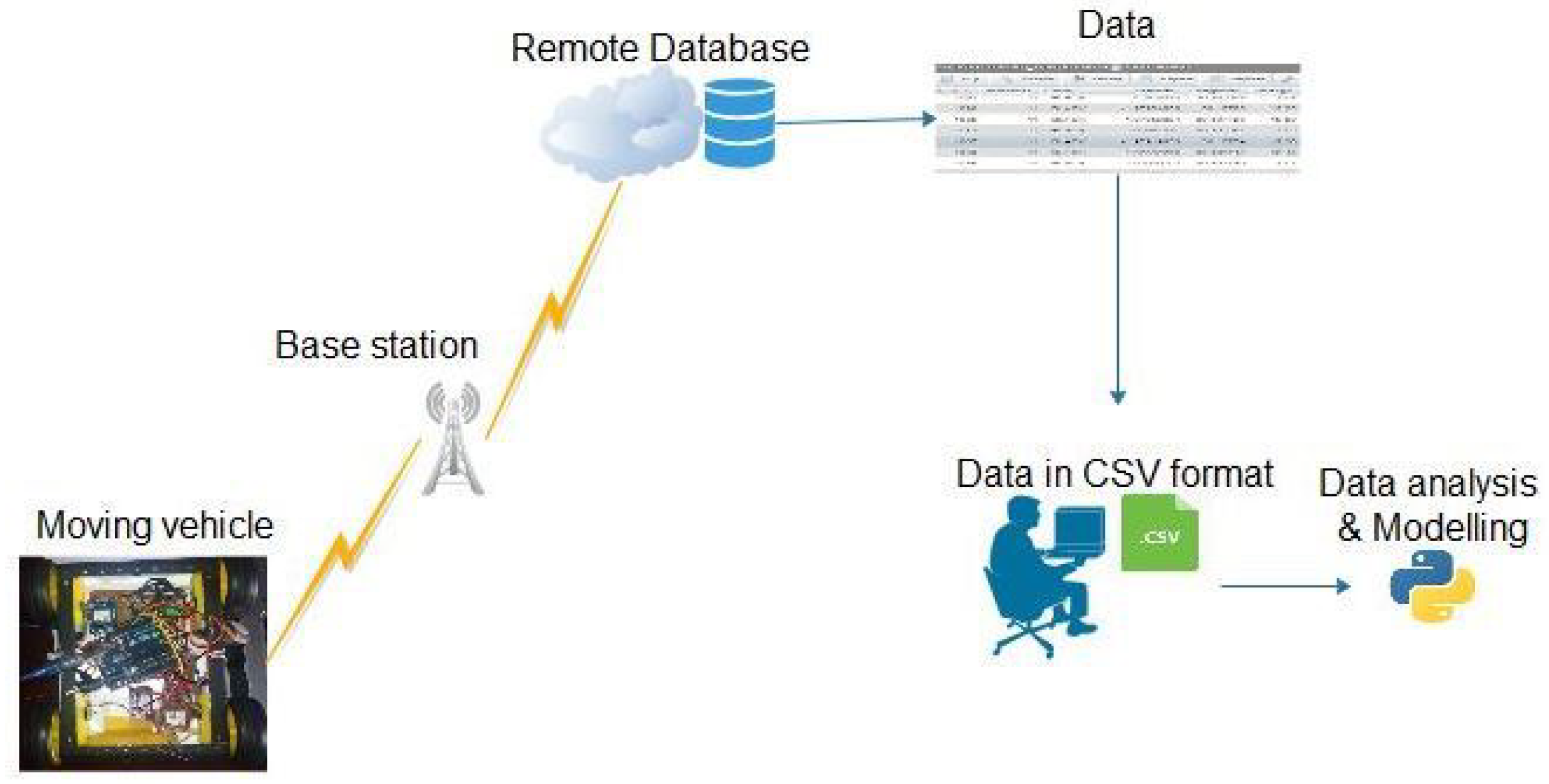

Motivated by the aforementioned matters, this paper aimed to investigate an adaptive speed control system for road safety. This research provides a data acquisition architecture using IoT technology. It also conducts a comparative analysis of regression models to predict the voltage. The key contributions of this paper are as follows: (i) proposing a hierarchical framework to control the speed and intelligently monitor the vehicle’s data; (ii) validating the efficiency of the proposed speed control system using the developed prototype; (iii) evaluating the effectiveness of the proposed vehicle data logging and monitoring; and (iv) proposing a machine learning model embedded in an in-vehicle device to predict the voltage to be supplied to the motor.

The rest of the paper is organized into the following sections.

Section 1 discusses the related literature,

Section 2 gives the detailed speed controlling system and an in-depth discussion of the implementation components.

Section 3 discusses the experiment and their results. Finally, in

Section 4, the conclusion with the future work directions is given.