A Fault Diagnosis Approach for Rolling Bearing Integrated SGMD, IMSDE and Multiclass Relevance Vector Machine

Abstract

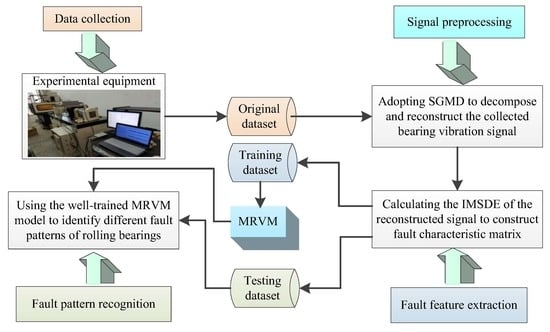

1. Introduction

- (1)

- A new method called SGMD is employed for preprocessing of bearing vibration data, which can obtain a superior noise reduction effect via signal decomposition and reconstruction.

- (2)

- The BA-based optimized IMSDE is proposed to extract bearing fault features at multiscale scales, which can not only overcome the shortcomings of MSDE in description of signal complexity, but also avoid the dependence of parameter selection of MSDE on expert experience.

- (3)

- MRVM is introduced for automatic identification of bearing fault patterns, which has fewer parameters than other classifiers (e.g., BPNN and SVM).

- (4)

- The efficacy and superiority of the proposed method is verified by the experimental investigation and comparative analysis of various methods.

2. The Proposed Method

2.1. Signal Preprocessing

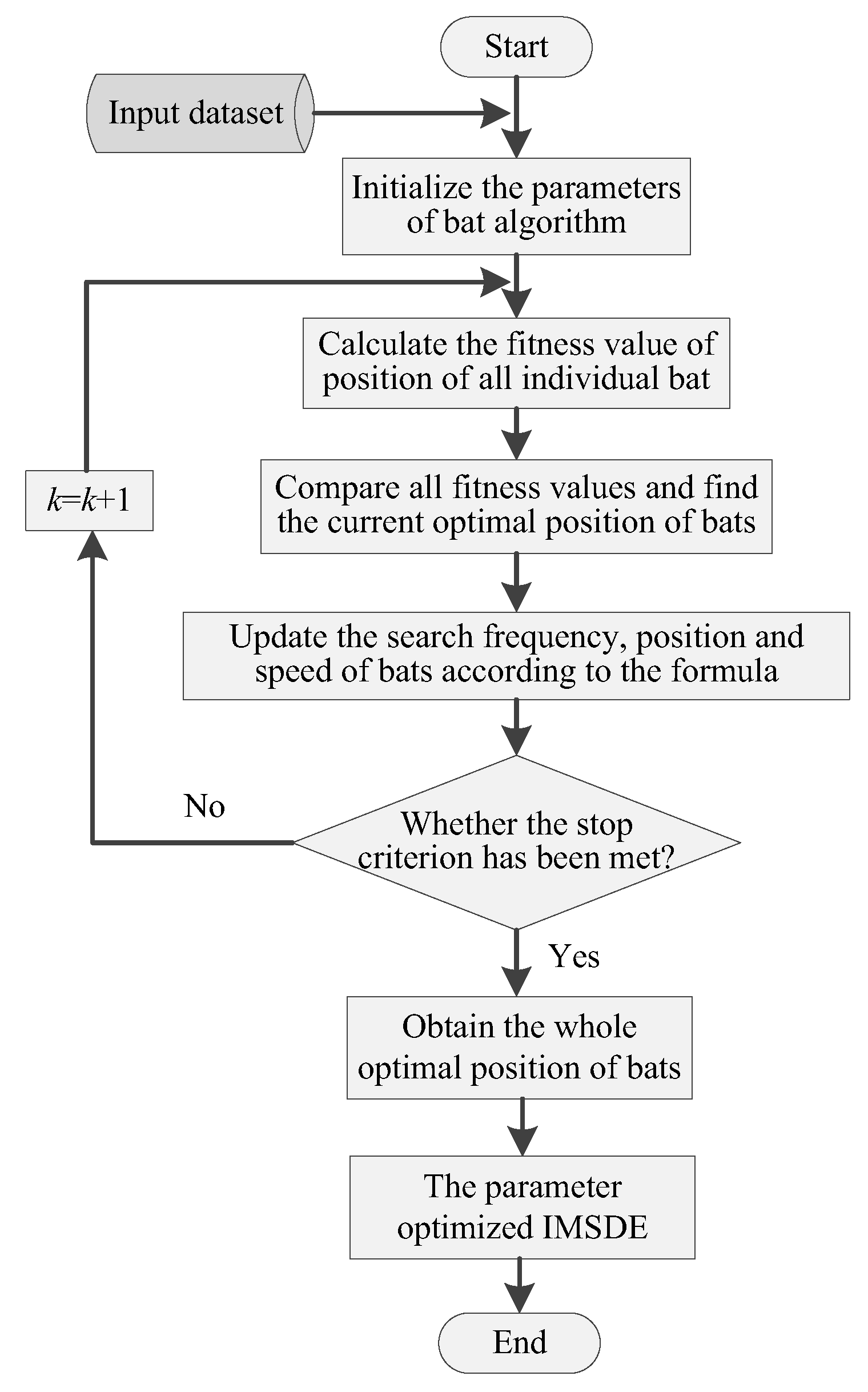

2.2. Fault Feature Extraction

- (1)

- Initialize the parameters of BA. Specifically, set maximum number of iterations M = 50, set the population number N = 1000, search frequency range , speed and position of bats. Due to the four parameters (, m, , ) of IMSDE need to be optimized, so the position of each bats is defined as , where , , , and are the scale factor, embedding dimension, time delay and the number of symbol, respectively. The upper and lower limits of are and , respectively.

- (2)

- Define the fitness function of BA as the accuracy rate between the correctly classified samples and total samples, calculate and compare the fitness value of position of all bats, find the current optimal position of bats according to maximum fitness function.

- (3)

- Update search frequency, speed and position of bats according to the following formula:where is a random variable satisfying uniform distribution, represents the current global optimal position of bats, and the search frequency assigned to each bat needs to satisfy the uniform distribution of .

- (4)

- Determine if the iteration stopping criterion has been met. If the stopping criterion is reached, we will obtain the overall optimal position (i.e., the optimal parameters of IMSDE) of bats. Otherwise, repeat step 2 and 3 until the stop criterion is met. Finally, the parameter optimized IMSDE is used for fault feature extraction.

2.3. Fault Pattern Recognition

2.4. Flowchart of the Proposed Method

3. Experimental Verification

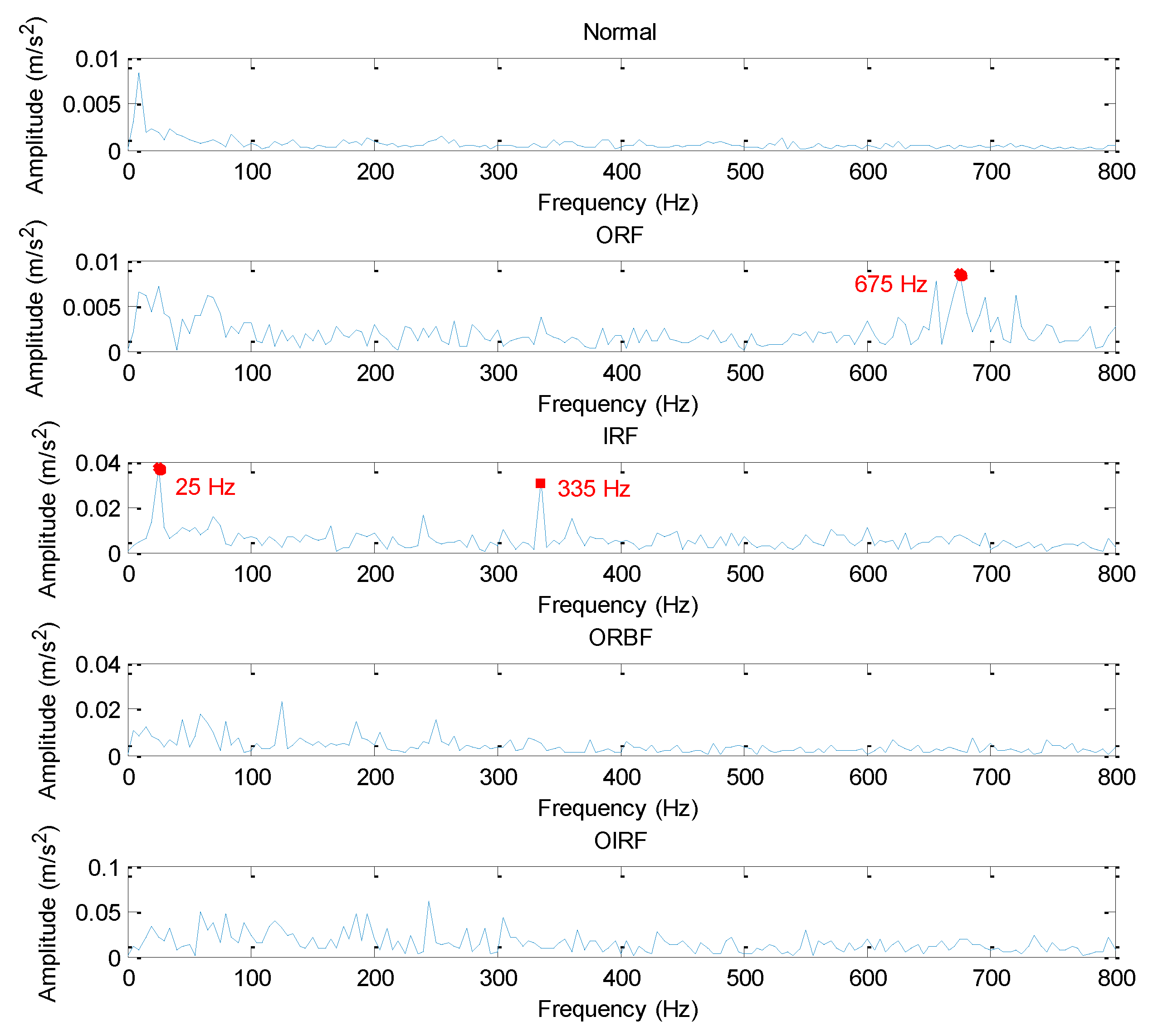

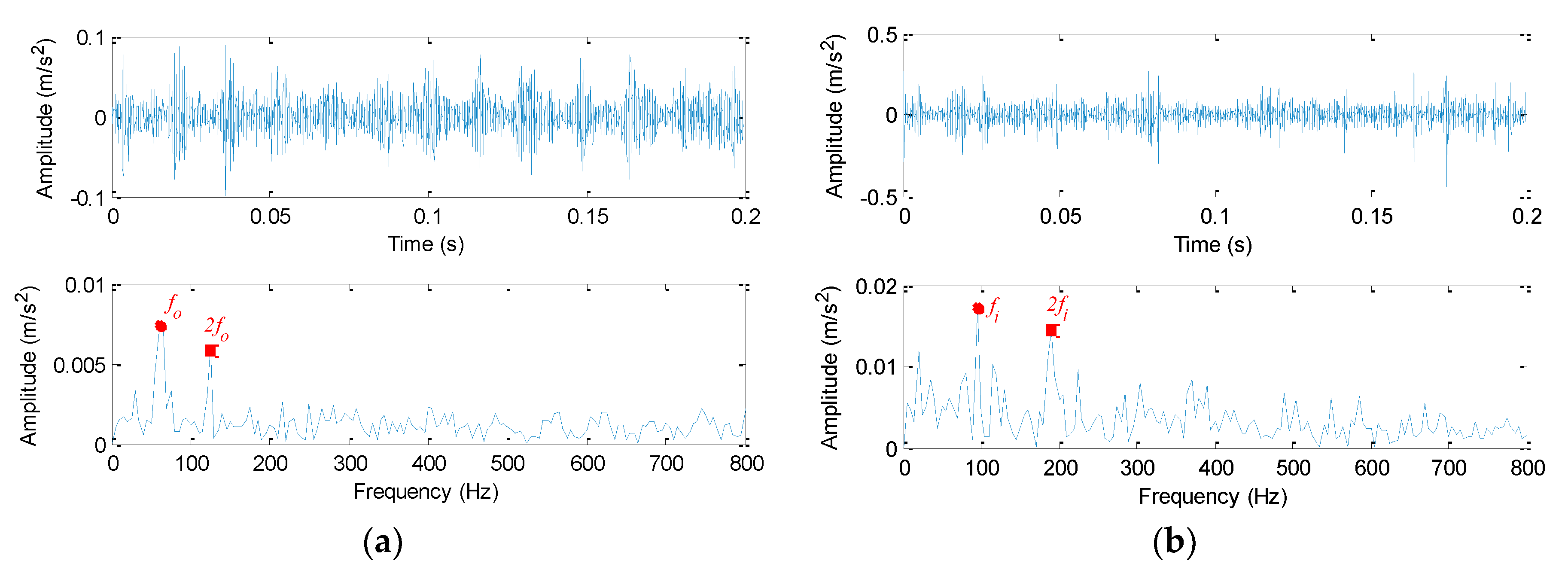

3.1. Experimental Setup and Data Description

3.2. The Proposed Method Analysis

3.3. Comparison among Various Methods

4. Conclusions

- (1)

- SGMD is applied for signal preprocessing, which can remove noise interference hidden in the original bearing vibration signal and reveal fault symptoms.

- (2)

- The BA-based optimized IMSDE is proposed for fault feature extraction, which can determine automatically its important parameters and avoid the disadvantage of information loss of MSDE.

- (3)

- MRVM classifier is introduced for fault pattern recognition, which can achieve better multi-classification performance than other involved classifiers.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Related Theory

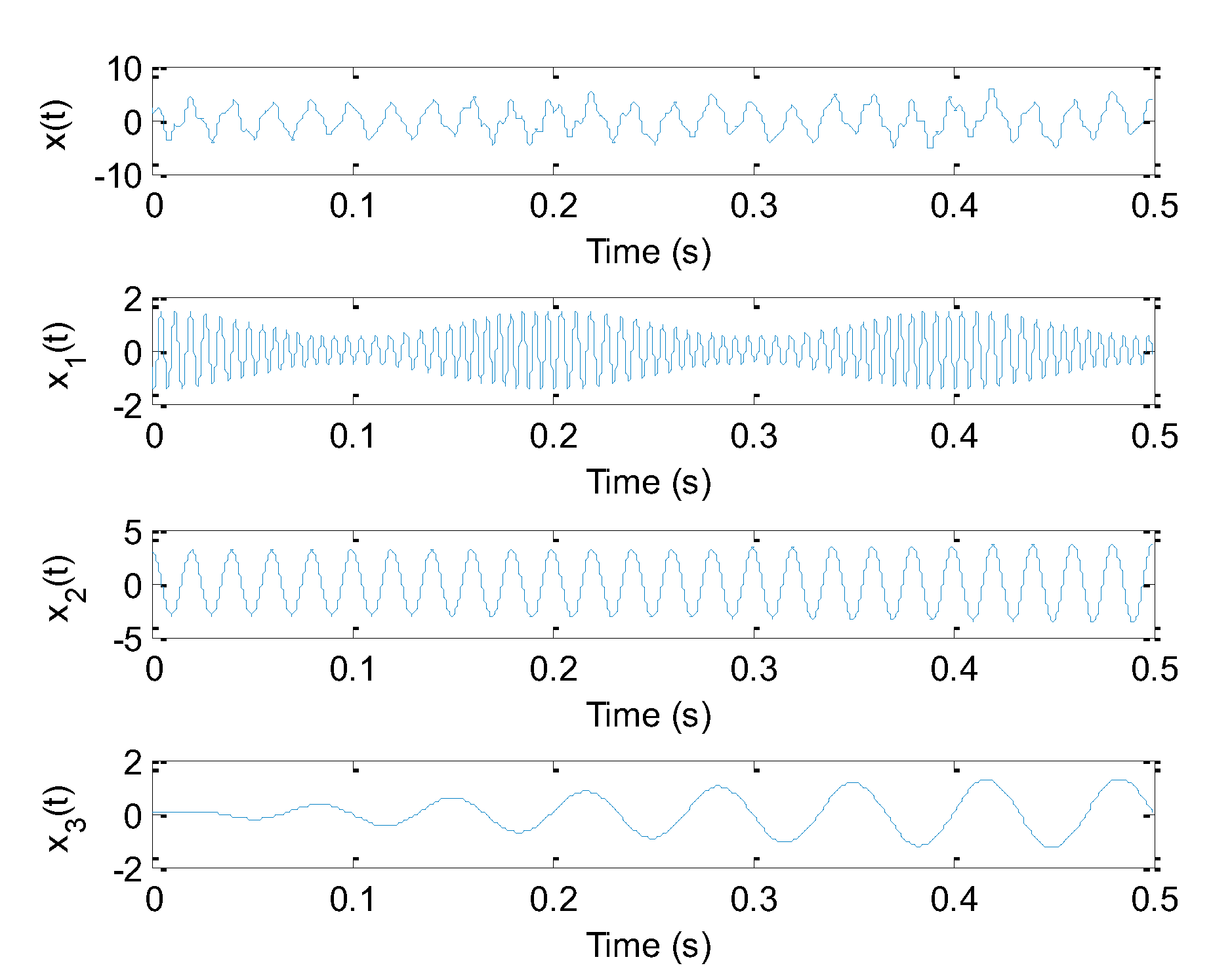

Appendix A.1. SGMD

- (1)

- Phase space reconstruction. Supposing that there is a one-dimensional discrete original signal , then we havewhere k is the embedding dimension, is the time delay and . Due to the two parameters (i.e., embedding dimension k and time delay ) have certain influence on the reconstruction results, so we need to choose them carefully. In this paper, considering the influence of time delay on the analysis results is much smaller than the embedding dimension. Hence, in this paper, time delay is empirically selected as = 1, whereas the embedding dimension k is determined adaptively by calculating power spectral density (PSD) based on the idea of literature [37]. Specifically, PSD of the original signal x is firstly calculated, then the frequency corresponding to the maximum peak in PSD is estimated, if the normalized frequency is less than the given threshold 0.001, the embedding dimension k is set as n/3, where n is the data length. Otherwise, the embedding dimension is set as , where Fs is the sampling frequency.

- (2)

- QR decomposition of symplectic orthogonal matrix. Assuming that the covariance symmetric matrix , the Hamilton matrix M can be constructed asIf , then both M and N are Hamiltonian matrices. Symplectic orthogonal matrix Q can be constructed, such thatwhere B is the upper triangular matrix and . Besides, B can be obtained by transforming N into two symplectic orthogonal matrices, whose eigenvalues are , ,..., . According to the property, . is the eigenvector of matrix A corresponding to . According to and , we can get the matrix . The original phase space reconstruction matrix X is composed of d components, which can be rewritten as .

- (3)

- Diagonal average operation. In this step, the one given components (1 ≤ k ≤ d) can be transformed into a time series with the length n, so the original time series amounts to the sum of d time series with the length n. Assuming that , , , .According to Equation (A4), the time series can be obtained from , finally the original vibration signal can be divided successively into d independent mono-component signals named symplectic geometry component (SGC).

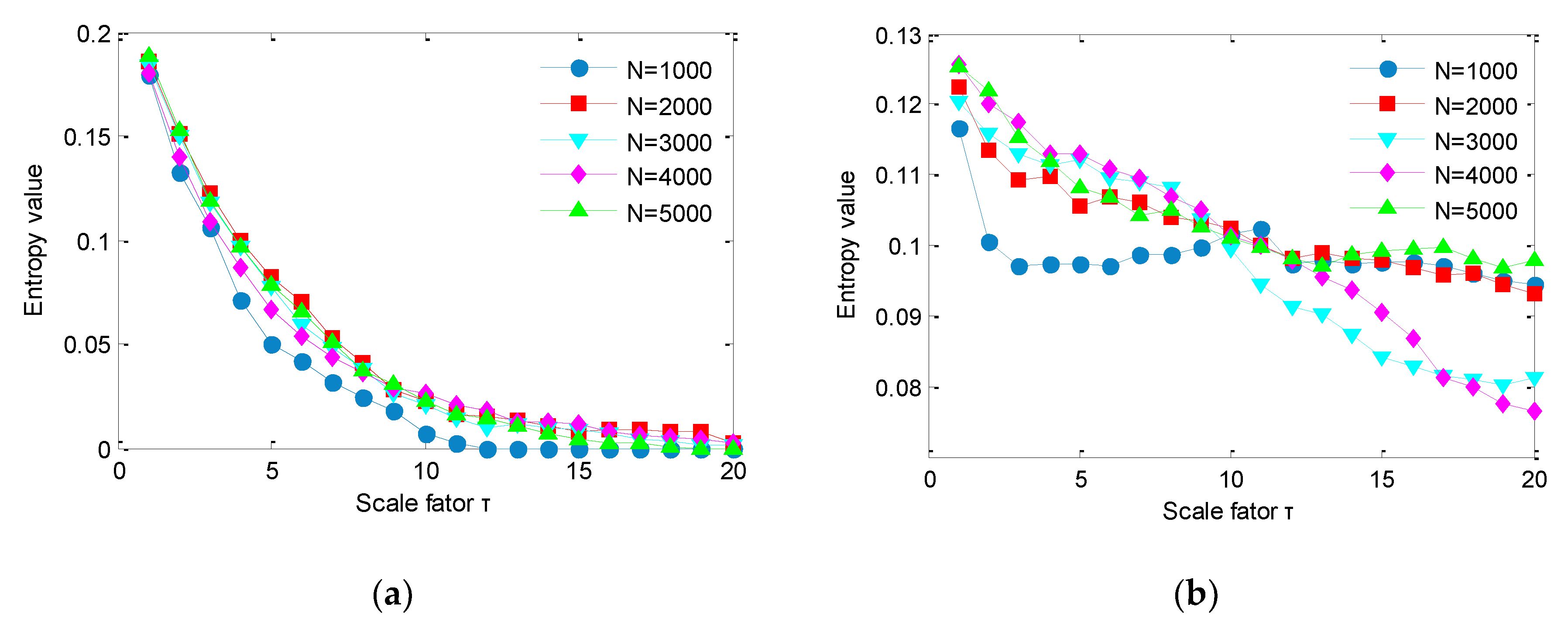

Appendix A.2. IMSDE

- (1)

- For the scale factor of time series , using Equation (A5) to obtain the coarse-grained time series . Specifically, in IMSDE, if the scale factor = 1, we can acquire one coarse-graining time series . If the scale factor = 2, we can acquire two coarse-graining time series and . However, in MSDE, when the scale factor = 2, only one coarse-graining time series is acquired.

- (2)

- Calculating the symbolic dynamic entropy (SDE) of each coarse-grained time series , and conducting the average operation of all SDE to obtain the final results of IMSDE (see Equation (A6)).where represents the scale factor, m denotes the embedding dimension, means the time delay, represents the number of symbols. denotes the operator of symbolic dynamic entropy. Detailed calculation procedure of SDE is available at [14], where the performance of SDE has been proved better than other entropies (e.g., SE and PE) at describing the frequency and amplitude change of signal. Given these facts, theoretically speaking, due to the superiority of SDE in describing the complexity of signal, and the application of data sliding and average operation, the modified coarse-grained procedure can more comprehensively describe signal’s amplitude information at different scales, so IMSDE can obtain more abundant fault characteristic information than MSDE and some existing multiscale entropies (e.g., MSE and MPE). Note that the modified coarse-grained procedure in IMSDE can also be found in literature [38,39]. If one wants to implement this algorithm, its MATLAB code are available from the corresponding author upon request, or you can also download it from the Supplementary Materials.

Appendix A.3. MRVM

References

- Wang, X.; Zheng, Y.; Zhao, Z.; Wang, J. Bearing fault diagnosis based on statistical locally linear embedding. Sensors 2015, 15, 16225–16247. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Feng, F.; Zhang, B. Weak fault feature extraction of rolling bearings based on an improved kurtogram. Sensors 2016, 16, 1482. [Google Scholar] [CrossRef] [PubMed]

- Pang, B.; Tang, G.; Tian, T.; Zhou, C. Rolling bearing fault diagnosis based on an improved HTT transform. Sensors 2018, 18, 1203. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Liu, Y.; Jia, M. Multiscale cascading deep belief network for fault identification of rotating machinery under various working conditions. Knowl. Based Syst. 2020, 193, 105484. [Google Scholar] [CrossRef]

- Hu, A.; Yan, X.; Xiang, L. A new wind turbine fault diagnosis method based on ensemble intrinsic time-scale decomposition and WPT-fractal dimension. Renew. Energy 2015, 83, 767–778. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Huang, Y.; Lu, R.; Chen, K. Detection of internal defect of apples by a multichannel Vis/NIR spectroscopic system. Postharvest Biol. Technol. 2020, 161, 111065. [Google Scholar] [CrossRef]

- Yan, R.; Liu, Y.; Gao, R.X. Permutation entropy: A nonlinear statistical measure for status characterization of rotary machines. Mech. Syst. Signal Process. 2012, 29, 474–484. [Google Scholar] [CrossRef]

- Yan, S.; Nguang, S.K.; Zhang, L. Nonfragile integral-based event-triggered control of uncertain cyber-physical systems under cyber-attacks. Complexity 2019, 2019, 14. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, F. Fault feature extraction of reciprocating compressor based on adaptive waveform decomposition and Lempel-Ziv complexity. IEEE Access 2019, 7, 82522–82531. [Google Scholar] [CrossRef]

- Zhou, R.; Yang, C.; Wan, J.; Zhang, W.; Guan, B.; Xiong, N. Measuring complexity and predictability of time series with flexible multiscale entropy for sensor networks. Sensors 2017, 17, 787. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Wu, P.H.; Wu, C.W.; Ding, J.J.; Wang, C.C. Bearing fault diagnosis based on multiscale permutation entropy and support vector machine. Entropy 2012, 14, 1343–1356. [Google Scholar] [CrossRef]

- Zheng, J.; Pan, H.; Cheng, J. Rolling bearing fault detection and diagnosis based on composite multiscale fuzzy entropy and ensemble support vector machines. Mech. Syst. Signal Process. 2017, 85, 746–759. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Li, G.; Xu, M.; Huang, W. A fault diagnosis scheme for planetary gearboxes using modified multi-scale symbolic dynamic entropy and mRMR feature selection. Mech. Syst. Signal Process. 2017, 91, 295–312. [Google Scholar] [CrossRef]

- Yang, X.; Gandomi, A.H. Bat algorithm: A novel approach for global engineering optimization. Eng. Comput. 2012, 29, 464–483. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Cerrada, M.; Sanchez, R.V.; Cabrera, D.; Zurita, G.; Li, C. Multi-stage feature selection by using genetic algorithms for fault diagnosis in gearboxes based on vibration signal. Sensors 2015, 15, 23903–23926. [Google Scholar] [CrossRef]

- Dorigo, M.; Blum, C. Ant colony optimization theory: A survey. Theor. Comput. Sci. 2005, 344, 243–278. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Zhou, J. A novel bearing fault diagnosis model integrated permutation entropy, ensemble empirical mode decomposition and optimized SVM. Measurement 2015, 69, 164–179. [Google Scholar] [CrossRef]

- Cao, H.; Fan, F.; Zhou, K.; He, Z. Wheel-bearing fault diagnosis of trains using empirical wavelet transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- An, X.; Jiang, D.; Chen, J.; Liu, C. Application of the intrinsic time-scale decomposition method to fault diagnosis of wind turbine bearing. J. Vib. Control 2012, 18, 240–245. [Google Scholar] [CrossRef]

- Yan, X.; Liu, Y.; Zhang, W.; Jia, M.; Wang, X. Research on a novel improved adaptive variational mode decomposition method in rotor fault diagnosis. Appl. Sci. 2020, 10, 1696. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. Improved singular spectrum decomposition-based 1. 5-dimensional energy spectrum for rotating machinery fault diagnosis. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 50. [Google Scholar]

- Pan, H.; Yang, Y.; Li, X.; Zheng, J.; Cheng, J. Symplectic geometry mode decomposition and its application to rotating machinery compound fault diagnosis. Mech. Syst. Signal Process. 2019, 114, 189–211. [Google Scholar] [CrossRef]

- Kavaz, A.G.; Barutcu, B. Fault detection of wind turbine sensors using artificial neural networks. J. Sens. 2018, 2018, 11. [Google Scholar] [CrossRef]

- Mao, W.; He, L.; Yan, Y.; Wang, J. Online sequential prediction of bearings imbalanced fault diagnosis by extreme learning machine. Mech. Syst. Signal Process. 2017, 83, 450–473. [Google Scholar] [CrossRef]

- Zhu, K.; Song, X.; Xue, D. A roller bearing fault diagnosis method based on hierarchical entropy and support vector machine with particle swarm optimization algorithm. Measurement 2014, 47, 669–675. [Google Scholar] [CrossRef]

- Tipping, M.E. Sparse bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar]

- Widodo, A.; Kim, E.Y.; Son, J.D.; Yang, B.S.; Tan, A.C.; Gu, D.S.; Choi, B.K.; Mathew, J. Fault diagnosis of low speed bearing based on relevance vector machine and support vector machine. Expert Syst. Appl. 2009, 36, 7252–7261. [Google Scholar] [CrossRef]

- Psorakis, I.; Damoulas, T.; Girolami, M.A. Multiclass relevance vector machines: Sparsity and accuracy. IEEE Trans. Neural Netw. 2010, 21, 1588–1598. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Zhong, Y.; Tang, H. A data indicator-based deep belief networks to detect multiple faults in axial piston pumps. Mech. Syst. Signal Process. 2018, 112, 154–170. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Zhong, Y.; Zhou, Y. Convolutional neural network-based hidden Markov models for rolling element bearing fault identification. Knowl. Based Syst. 2017, 144, 65–76. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, J.; Xu, Y.; Zheng, Y.; Peng, X.; Jiang, W. Unsupervised fault diagnosis of rolling bearings using a deep neural network based on generative adversarial networks. Neurocomputing 2018, 315, 412–424. [Google Scholar] [CrossRef]

- Li, J.; Yao, X.; Wang, H.; Zhang, J. Periodic impulses extraction based on improved adaptive VMD and sparse code shrinkage denoising and its application in rotating machinery fault diagnosis. Mech. Syst. Signal Process. 2019, 126, 568–589. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. Application of CSA-VMD and optimal scale morphological slice bispectrum in enhancing outer race fault detection of rolling element bearings. Mech. Syst. Signal Process. 2019, 122, 56–86. [Google Scholar] [CrossRef]

- Bonizzi, P.; Karel, J.; Meste, O.; Peeters, R.L. Singular spectrum decomposition: A new method for time series decomposition. Adv. Adapt. Data Anal. 2014, 6, 1450011. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, T.; Zhao, W.; Luo, Z.; Lin, H. Rotating machinery fault diagnosis based on improved multiscale amplitude-aware permutation entropy and multiclass relevance vector machine. Sensors 2019, 19, 4542. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. Intelligent fault diagnosis of rotating machinery using improved multiscale dispersion entropy and mRMR feature selection. Knowl. Based Syst. 2019, 163, 450–471. [Google Scholar] [CrossRef]

| Methods | RMSE | Computing Time (s) | |||

|---|---|---|---|---|---|

| SGMD | 0.9987 | 0.9998 | 0.9942 | 0.0741 | 1.1749 |

| EEMD | 0.4901 | 0.8215 | 0.9905 | 0.0985 | 3.2671 |

| EWT | 0.7424 | 0.0147 | 0.0207 | 2.7231 | 1.0938 |

| EITD | 0.8435 | 0.7298 | 0.1721 | 0.1965 | 1.0142 |

| Bearing Type | Ball Diameter (mm) | Pitch Diameter (mm) | Number of Balls | Contact Angle (°) |

|---|---|---|---|---|

| HRB6205 | 7.94 | 39.04 | 9 | 0 |

| Rotation Frequency fr | Inner Race Fault fi | Outer Race Fault fo | Ball Fault fb | Cage Fault fc |

|---|---|---|---|---|

| 17.5 | 94.76 | 62.73 | 41.24 | 6.97 |

| Fault Type | Number of Training Samples | Number of Testing Samples | Class Labels |

|---|---|---|---|

| Normal | 30 | 30 | 1 |

| ORF | 30 | 30 | 2 |

| IRF | 30 | 30 | 3 |

| OIRF | 30 | 30 | 4 |

| ORBF | 30 | 30 | 5 |

| Number of Symbols | Diagnosis accuracy and CPU Time Obtained Using Our Method for Four Trials | Average Accuracy and CPU Time | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| = 3 | 95.33%/18.25 s | 94.67%/18.83 s | 94.67%/17.96 s | 94.00%/17.07 s | 94.67%/18.02 s |

| = 6 | 98.00%/26.72 s | 97.33%/27.13 s | 97.33%/26.94 s | 98.00%/25.08 s | 97.67%/26.46 s |

| = 12 | 100%/33.89 s | 100%/34.13 s | 99.33%/33.52 s | 100%/34.38 s | 99.83%/33.98 s |

| = 18 | 96.67%/41.33 s | 96.00%/42.05 s | 97.33%/41.26.s | 97.33%/41.47 s | 96.83%/41.52 s |

| Different Classifiers | Main Parameter Setting |

|---|---|

| MRVM | Kernel parameters of radial basis function g = 0.05 |

| BPNN | Number of hidden nodes N = 20, the training number I = 500, the learning rate σ = 0.1, and the training error e = 0.001 |

| SVM | Penalty factor c = 1, kernel parameters of radial basis function g = 0.05 |

| ELM | Number of hidden neurons N = 20 |

| KNN | Number of neighbors is set as 3 |

| Different Classifiers | Testing Accuracy Obtained Using IMSDE with Different Preprocessors | Average Accuracy | |||

|---|---|---|---|---|---|

| SGMD-IMSDE | EEMD-IMSDE | EWT-IMSDE | EITD-IMSDE | ||

| MRVM | 100% (150/150) | 95.33% (143/150) | 97.33% (146/150) | 94.67% (142/150) | 96.83% (581/600) |

| BPNN | 98.67% (148/150) | 94.00% (140/150) | 96.00% (144/150) | 92.67% (139/150) | 95.16% (571/600) |

| SVM | 99.33% (149/150) | 94.67% (142/150) | 96.67% (145/150) | 94.00% (140/150) | 96.00% (576/600) |

| ELM | 99.33% (149/150) | 94.00% (140/150) | 96.67% (145/150) | 93.33% (140/150) | 95.67% (574/600) |

| KNN | 99.33% (149/150) | 94.67% (142/150) | 96.00% (144/150) | 92.00% (138/150) | 95.50% (573/600) |

| Average accuracy | 99.33% (745/750) | 94.26% (707/750) | 96.53% (724/750) | 93.20% (699/750) | —— |

| Different Classifiers | Testing Accuracy Obtained Using SGMD with Different Feature Extractors | Average Accuracy | |||

|---|---|---|---|---|---|

| SGMD-IMSDE | SGMD-MSDE | SGMD-MSE | SGMD-MPE | ||

| MRVM | 100% (150/150) | 98.67% (148/150) | 92.67% (139/150) | 96.00% (144/150) | 96.83% (581/600) |

| BPNN | 98.67% (148/150) | 97.33% (146/150) | 91.33% (137/150) | 94.67% (142/150) | 95.50% (573/600) |

| SVM | 99.33% (149/150) | 98.00% (147/150) | 91.33% (137/150) | 94.67% (142/150) | 95.83% (575/600) |

| ELM | 99.33% (149/150) | 97.33% (146/150) | 92.00% (138/150) | 95.33% (143/150) | 96.00% (576/600) |

| KNN | 99.33% (149/150) | 97.33% (146/150) | 91.33% (137/150) | 95.33% (143/150) | 95.83% (575/600) |

| Average accuracy | 99.33% (745/750) | 97.73% (733/750) | 91.73% (688/750) | 95.20% (714/750) | —— |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Liu, Y.; Jia, M. A Fault Diagnosis Approach for Rolling Bearing Integrated SGMD, IMSDE and Multiclass Relevance Vector Machine. Sensors 2020, 20, 4352. https://doi.org/10.3390/s20154352

Yan X, Liu Y, Jia M. A Fault Diagnosis Approach for Rolling Bearing Integrated SGMD, IMSDE and Multiclass Relevance Vector Machine. Sensors. 2020; 20(15):4352. https://doi.org/10.3390/s20154352

Chicago/Turabian StyleYan, Xiaoan, Ying Liu, and Minping Jia. 2020. "A Fault Diagnosis Approach for Rolling Bearing Integrated SGMD, IMSDE and Multiclass Relevance Vector Machine" Sensors 20, no. 15: 4352. https://doi.org/10.3390/s20154352

APA StyleYan, X., Liu, Y., & Jia, M. (2020). A Fault Diagnosis Approach for Rolling Bearing Integrated SGMD, IMSDE and Multiclass Relevance Vector Machine. Sensors, 20(15), 4352. https://doi.org/10.3390/s20154352