AI/Machine Learning and Sol-Gel Derived Hybrid Materials: A Winning Coupling

Abstract

1. Introduction

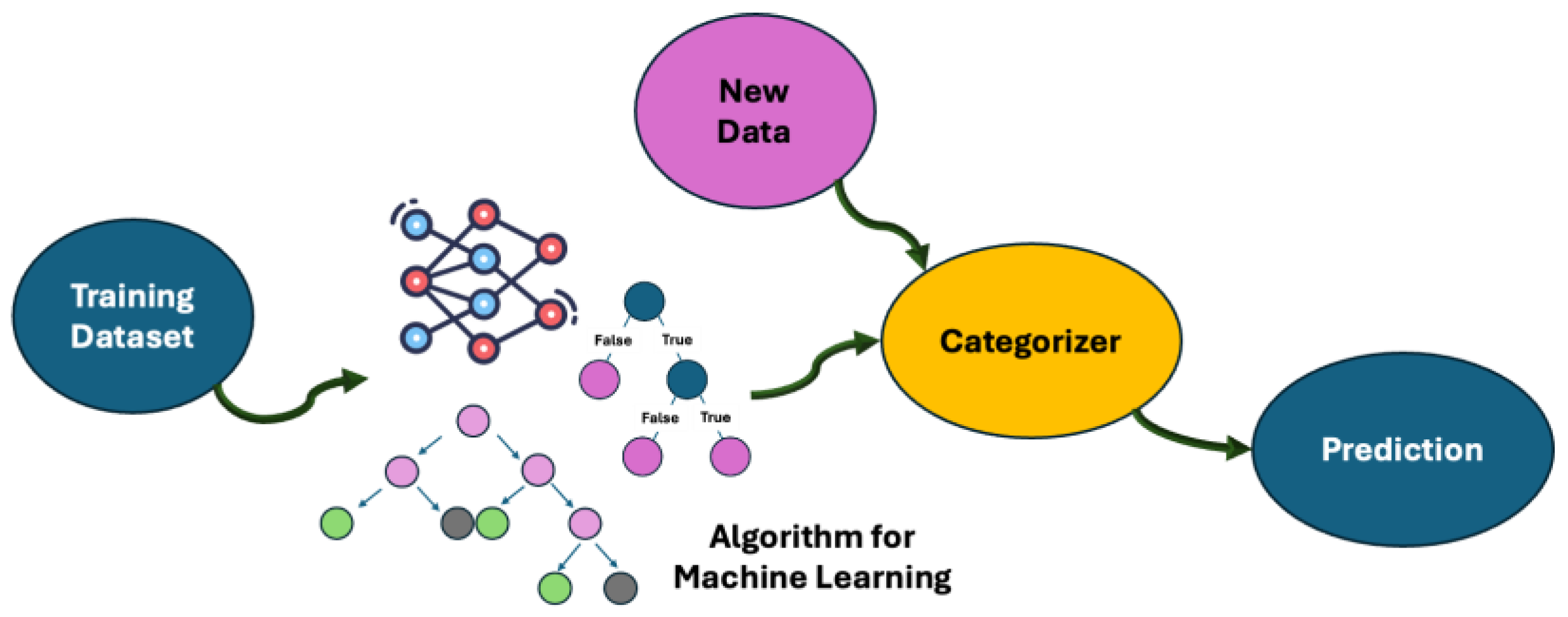

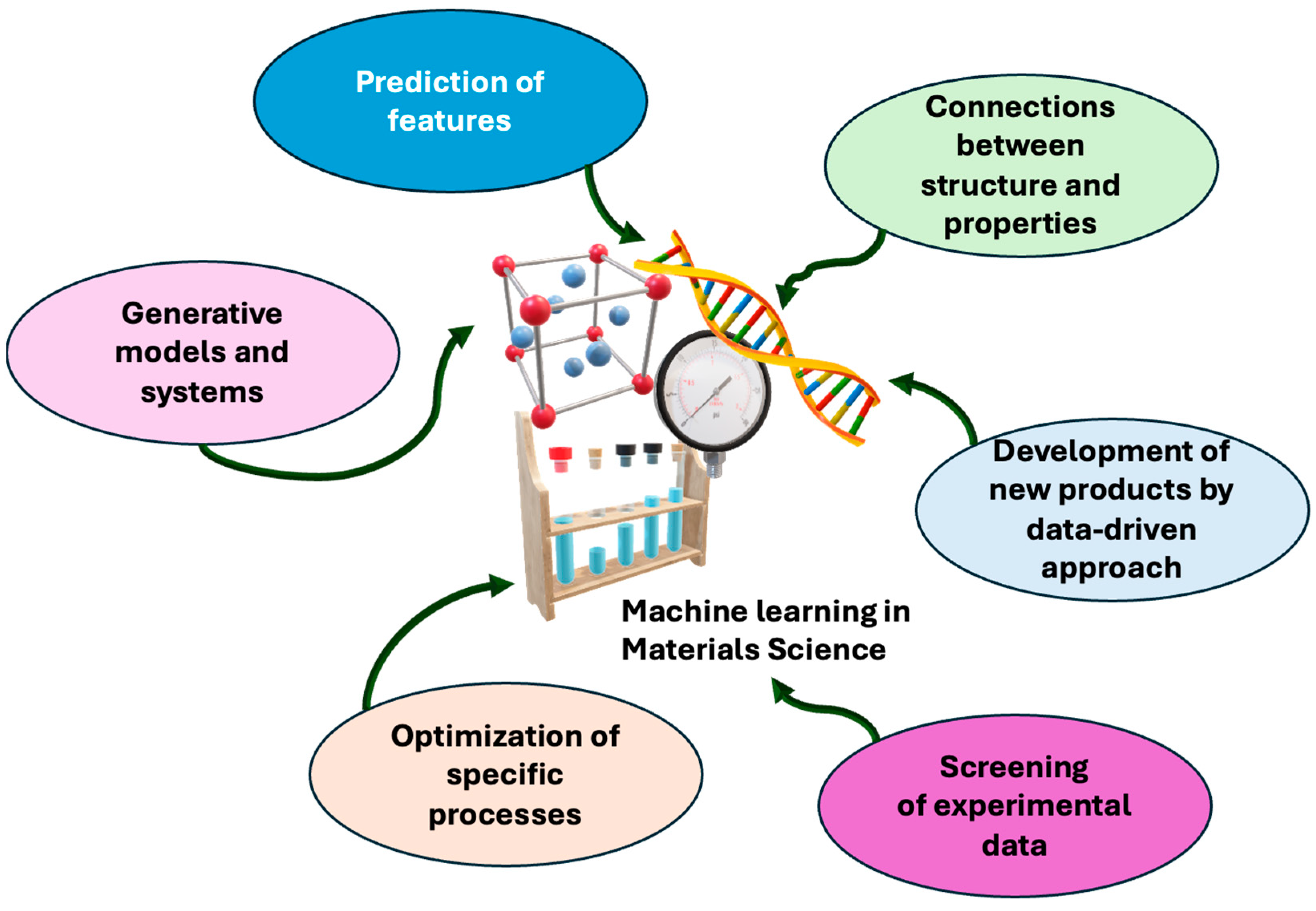

2. Artificial Intelligence and Machine Learning in Materials Science: An Overview

2.1. Supervised Learning Approaches

2.2. Unsupervised Learning Methods

2.3. Deep Learning Methodologies and Bayesian Methods for Optimization

2.4. Artificial Intelligence in Materials Science and Property Prediction

2.5. Other Machine Learning Algorithms and Statistical Tools for Data Optimization

2.6. Statistical Metrics and Performance Parameters for Prediction Evaluation and Data Correlation

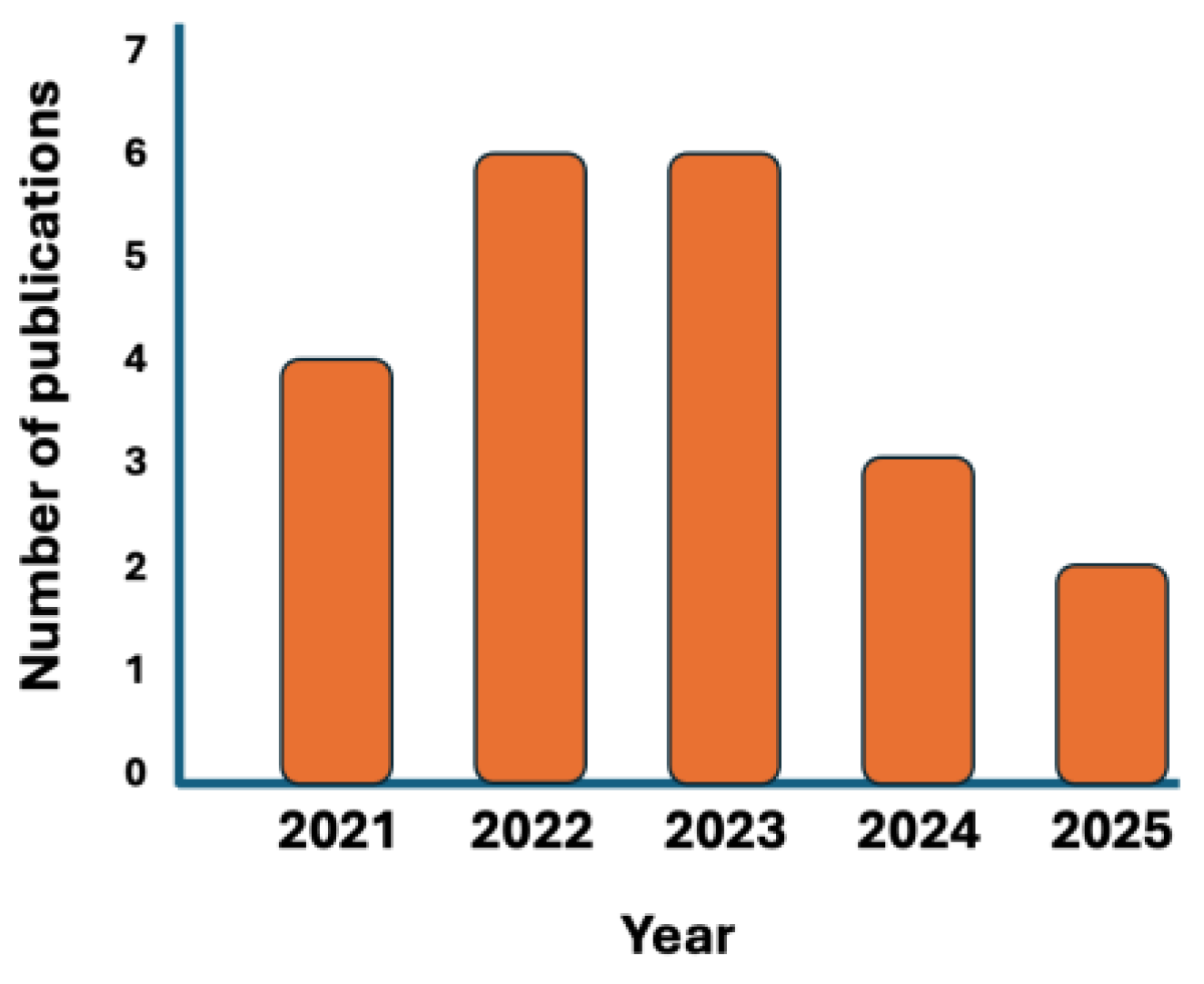

3. Current State-of-the-Art in the Use of AI/ML Approaches for Predicting Key Properties of Hybrid Sol-Gel-Derived Materials

3.1. Sol-Gel-Derived Aerogels: Machine Learning Prediction of Their Physico-Chemical Features

3.2. Sol-Gel Derived Hybrid Nanofluids: Machine Learning Prediction of Their Physico-Chemical Properties

3.3. Machine Learning Assisted Sol-Gel Methodologies for the Preparation and Characterization of Functional Polymeric Products

3.4. Sol-Gel Derived Metal Oxides, Organic Structures, and Inorganic Materials for Several ML-Optimized Technologies

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Adaptive boosting | AdBoost |

| Artificial Intelligence | AI |

| Artificial neural network | ANN |

| Bayesian optimized boosted regression trees | BoA-BRT |

| Bayesian optimized support vector machine | BoASVM |

| Bayesian optimized wide neural network | BoWNN |

| Boosted regression tree | BRT |

| Decision tree | DT |

| Deep convolutional neural network | DCNN |

| Diffusion-limited cluster–cluster aggregation | DLCA |

| Gaussian process regression | GPR |

| Gradient boost | GB |

| Graphene oxide | GO |

| Graphitic carbon nitride | g-C3N4 |

| Heat release capacity | HRC |

| K-nearest neighbor | KNN |

| Long short-term memory | LSTM |

| Machine learning | ML |

| Mean absolute error | MAE |

| Mean absolute percentage error | MAPE |

| Mean square error | MSE |

| Multiwall carbon nanotubes | MWCNTs |

| One-dimensional convolutional neural network | 1DCNN |

| Oxidized multi-walled carbon nanotubes | O-MWCNTs |

| Peak of heat release rate | pkHRR |

| Principal component analysis | PCA |

| Random forest | RF |

| Root main square error | RMSE |

| Support vector machine | SVM |

| Tetraethylorthosilicate | TEOS |

| Time to ignition | TTI |

References

- Barrino, F. Hybrid Organic–Inorganic Materials Prepared by Sol–Gel and Sol–Gel-Coating Method for Biomedical Use: Study and Synthetic Review of Synthesis and Properties. Coatings 2024, 14, 425. [Google Scholar] [CrossRef]

- Zarkov, A. Sol–Gel Technology Applied to Materials Science: Synthesis, Characterization and Applications. Materials 2024, 17, 462. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Huang, Y.; Xie, Q.; Liu, G.; Ma, C.; Zhang, G. Functional Polymer–Ceramic Hybrid Coatings: Status, Progress, and Trend. Prog. Polym. Sci. 2024, 154, 101840. [Google Scholar] [CrossRef]

- Letailleur, A.A.; Ribot, F.; Boissière, C.; Teisseire, J.; Barthel, E.; Desmazieres, B.; Chemin, N.; Sanchez, C. Sol–Gel Derived Hybrid Thin Films: The Chemistry behind Processing. Chem. Mater. 2011, 23, 5082–5089. [Google Scholar] [CrossRef]

- Schottner, G. Hybrid Sol− Gel-Derived Polymers: Applications of Multifunctional Materials. Chem. Mater. 2001, 13, 3422–3435. [Google Scholar] [CrossRef]

- Figueira, R.B. Hybrid Sol–Gel Coatings for Corrosion Mitigation: A Critical Review. Polymers 2020, 12, 689. [Google Scholar] [CrossRef] [PubMed]

- Biglari, L.; Naghdi, M.; Poursamar, S.A.; Nilforoushan, M.R.; Bigham, A.; Rafienia, M. A Route toward Fabrication of 3D Printed Bone Scaffolds Based on Poly (Vinyl Alcohol)–Chitosan/Bioactive Glass by Sol–Gel Chemistry. Int. J. Biol. Macromol. 2024, 258, 128716. [Google Scholar] [CrossRef] [PubMed]

- Boukhriss, A.; Roblin, J.-P.; Aaboub, T.; Boyer, D.; Gmouh, S. Luminescent Hybrid Coatings Prepared by a Sol–Gel Process for a Textile-Based PH Sensor. Mater. Adv. 2020, 1, 918–925. [Google Scholar] [CrossRef]

- Balbay, S.; Acıkgoz, C. Anti-Yellowing UV-Curable Hybrid Coatings Prepared by the Sol–Gel Method on Polystyrene. Prog. Org. Coat. 2020, 140, 105499. [Google Scholar] [CrossRef]

- Bifulco, A.; Imparato, C.; Aronne, A.; Malucelli, G. Flame Retarded Polymer Systems Based on the Sol-Gel Approach: Recent Advances and Future Perspectives. J. Sol-Gel Sci. Technol. 2022, 115, 226–250. [Google Scholar] [CrossRef]

- Arya, M.; Heera, S.; Meenu, P.; Deepa, K.G. Organic-Inorganic Hybrid Materials and Architectures in Optoelectronic Devices: Recent Advancements. ChemPhysMater 2024, 3, 252–272. [Google Scholar] [CrossRef]

- Waqar, M.A.; Mubarak, N.; Khan, A.M.; Khan, R.; Khan, I.N.; Riaz, M.; Ahsan, A.; Munir, M. Sol-Gel for Delivery of Molecules, Its Method of Preparation and Recent Applications in Medicine. Polym. Technol. Mater. 2024, 63, 1564–1581. [Google Scholar] [CrossRef]

- Onishi, B.S.D.; Costa, B.H.; Marchiori, L.; de Freitas, B.D.; Pugina, R.S.; Bartlett, J.R.; Carlos, L.D.; Ferreira-Neto, E.P.; Ribeiro, S.J.L. Organic–Inorganic Hybrid Silica Systems: Synthesis Strategies and Optical Applications. J. Sol-Gel Sci. Technol. 2025, 113, 86–108. [Google Scholar] [CrossRef]

- Samuneva, B.; Kabaivanova, L.; Chernev, G.; Djambaski, P.; Kashchieva, E.; Emanuilova, E.; Miranda Salvado, I.M.; Fernandes, M.H.V.; Wu, A. Sol–Gel Synthesis and Structure of Silica Hybrid Materials. J. Sol-Gel Sci. Technol. 2008, 48, 73–79. [Google Scholar] [CrossRef]

- Faustini, M.; Nicole, L.; Ruiz-Hitzky, E.; Sanchez, C. History of Organic–Inorganic Hybrid Materials: Prehistory, Art, Science, and Advanced Applications. Adv. Funct. Mater. 2018, 28, 1704158. [Google Scholar] [CrossRef]

- Gross, S.; Müller, K. Sol–Gel Derived Silica-Based Organic–Inorganic Hybrid Materials as “Composite Precursors” for the Synthesis of Highly Homogeneous Nanostructured Mixed Oxides: An Overview. J. Sol-Gel Sci. Technol. 2011, 60, 283–298. [Google Scholar] [CrossRef]

- Wen, J.; Wilkes, G.L. Organic/Inorganic Hybrid Network Materials by the Sol−Gel Approach. Chem. Mater. 1996, 8, 1667–1681. [Google Scholar] [CrossRef]

- Jiju, A. Design of Experiments for Engineers and Scientists, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2023; pp. i–iii. ISBN 978-0-443-15173-6. [Google Scholar]

- Mahmoodian, M.; Arya, A.B.; Pourabbas, B. Synthesis of Organic–Inorganic Hybrid Compounds Based on Bis-GMA and Its Sol–Gel Behavior Analysis Using Taguchi Method. Dent. Mater. 2008, 24, 514–521. [Google Scholar] [CrossRef] [PubMed]

- Najafabadi, A.H.; Mozaffarinia, R.; Rahimi, H.; Razavi, R.S.; Paimozd, E. Sol–Gel Processing of Hybrid Nanocomposite Protective Coatings Using Experimental Design. Prog. Org. Coat. 2013, 76, 293–301. [Google Scholar] [CrossRef]

- Roy, R.K. Taguchi Method, 2nd ed.; JUSE Press, Ltd.: Tokyo, Japan, 2010; ISBN 9780872638648. [Google Scholar]

- Rahimi, H.; Mozaffarinia, R.; Najafabadi, A.H.; Razavi, R.S.; Paimozd, E. Optimization of Process Factors for the Synthesis of Advanced Chrome-Free Nanocomposite Sol–Gel Coatings for Corrosion Protection of Marine Aluminum Alloy AA5083 by Design of Experiment. Prog. Org. Coat. 2013, 76, 307–317. [Google Scholar] [CrossRef]

- Yahyaei, H.; Mohseni, M.; Bastani, S. Using Taguchi Experimental Design to Reveal the Impact of Parameters Affecting the Abrasion Resistance of Sol–Gel Based UV Curable Nanocomposite Films on Polycarbonate. J. Sol-Gel Sci. Technol. 2011, 59, 95–105. [Google Scholar] [CrossRef]

- Ooi, K.-B.; Tan, G.W.-H.; Al-Emran, M.; Al-Sharafi, M.A.; Capatina, A.; Chakraborty, A.; Dwivedi, Y.K.; Huang, T.-L.; Kar, A.K.; Lee, V.-H. The Potential of Generative Artificial Intelligence across Disciplines: Perspectives and Future Directions. J. Comput. Inf. Syst. 2025, 65, 76–107. [Google Scholar] [CrossRef]

- Gama, F.; Magistretti, S. Artificial Intelligence in Innovation Management: A Review of Innovation Capabilities and a Taxonomy of AI Applications. J. Prod. Innov. Manag. 2025, 42, 76–111. [Google Scholar] [CrossRef]

- Gursoy, D.; Cai, R. Artificial Intelligence: An Overview of Research Trends and Future Directions. Int. J. Contemp. Hosp. Manag. 2025, 37, 1–17. [Google Scholar] [CrossRef]

- Barbierato, E.; Gatti, A. The Challenges of Machine Learning: A Critical Review. Electronics 2024, 13, 416. [Google Scholar] [CrossRef]

- Worden, K.; Tsialiamanis, G.; Cross, E.J.; Rogers, T.J. Artificial Neural Networks; Springer: Berlin, Germany, 2023; ISBN 9783031366444. [Google Scholar]

- Meier, R.J. A Way towards Reliable Predictive Methods for the Prediction of Physicochemical Properties of Chemicals Using the Group Contribution and Other Methods. Appl. Sci. 2019, 9, 1700. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data Fusion and Machine Learning for Industrial Prognosis: Trends and Perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mishra, D.; Agarwal, R. An Artificial Intelligence-Powered Approach to Material Design. In Cutting-Edge Research in Chemical and Material Science; Bhumi: Kolhapur, India, 2024; Volume I, pp. 62–89. [Google Scholar]

- Plathottam, S.J.; Rzonca, A.; Lakhnori, R.; Iloeje, C.O. A Review of Artificial Intelligence Applications in Manufacturing Operations. J. Adv. Manuf. Process. 2023, 5, e10159. [Google Scholar] [CrossRef]

- Osisanwo, F.Y.; Akinsola, J.E.T.; Awodele, O.; Hinmikaiye, J.O.; Olakanmi, O.; Akinjobi, J. Supervised Machine Learning Algorithms: Classification and Comparison. Int. J. Comput. Trends Technol. 2017, 48, 128–138. [Google Scholar] [CrossRef]

- Burkart, N.; Huber, M.F. A Survey on the Explainability of Supervised Machine Learning. J. Artif. Intell. Res. 2021, 70, 245–317. [Google Scholar] [CrossRef]

- Polce, E.M.; Kunze, K.N.; Fu, M.C.; Garrigues, G.E.; Forsythe, B.; Nicholson, G.P.; Cole, B.J.; Verma, N.N. Development of Supervised Machine Learning Algorithms for Prediction of Satisfaction at 2 Years Following Total Shoulder Arthroplasty. J. shoulder Elb. Surg. 2021, 30, e290–e299. [Google Scholar] [CrossRef] [PubMed]

- Shetty, S.H.; Shetty, S.; Singh, C.; Rao, A. Supervised Machine Learning: Algorithms and Applications. In Fundamentals and Methods of Machine and Deep Learning: Algorithms, Tools, and Applications; Scrivener Publishing LLC: Beverly, MA, USA, 2022; pp. 1–16. [Google Scholar]

- Terlapu, P.; Sadi, R.P.; Pondreti, R.; Tippana, C. Intelligent Identification of Liver Diseases Based on Incremental Hidden Layer Neurons ANN Model. Int. J. Comput. Digit. Syst. 2022, 11, 1027–1050. [Google Scholar] [CrossRef] [PubMed]

- Brereton, R.G.; Lloyd, G.R. Support Vector Machines for Classification and Regression. Analyst 2010, 135, 230–267. [Google Scholar] [CrossRef] [PubMed]

- Ortegon, J.; Ledesma-Alonso, R.; Barbosa, R.; Castillo, J.V.; Atoche, A.C. Material Phase Classification by Means of Support Vector Machines. Comput. Mater. Sci. 2018, 148, 336–342. [Google Scholar] [CrossRef]

- Deng, J. Structural Reliability Analysis for Implicit Performance Function Using Radial Basis Function Network. Int. J. Solids Struct. 2006, 43, 3255–3291. [Google Scholar] [CrossRef]

- Usama, M.; Qadir, J.; Raza, A.; Arif, H.; Yau, K.-L.A.; Elkhatib, Y.; Hussain, A.; Al-Fuqaha, A. Unsupervised Machine Learning for Networking: Techniques, Applications and Research Challenges. IEEE Access 2019, 7, 65579–65615. [Google Scholar] [CrossRef]

- Kalusivalingam, A.K.; Sharma, A.; Patel, N.; Singh, V. Enhancing Customer Segmentation through AI: Leveraging K-Means Clustering and Neural Network Classifiers. Int. J. AI ML 2020, 1. Available online: https://cognitivecomputingjournal.com/index.php/IJAIML-V1/article/view/49 (accessed on 23 June 2025).

- Mishra, C.; Gupta, D.L. Deep Machine Learning and Neural Networks: An Overview. IAES Int. J. Artif. Intell. 2017, 6, 66. [Google Scholar] [CrossRef]

- Misra, A.; Vojinovic, Z.; Ramakrishnan, B.; Luijendijk, A.; Ranasinghe, R. Shallow Water Bathymetry Mapping Using Support Vector Machine (SVM) Technique and Multispectral Imagery. Int. J. Remote Sens. 2018, 39, 4431–4450. [Google Scholar] [CrossRef]

- Kumari, P.; Swarnalatha, K.S.; Pandey, P. Deep Learning: Foundations, Architectures, and Transformative Applications. In Neural Network Advancements in the Age of AI; IGI Global: Hershey, PA, USA, 2025; pp. 33–98. [Google Scholar]

- Shakya, A.; Biswas, M.; Pal, M. Classification of Radar Data Using Bayesian Optimized Two-Dimensional Convolutional Neural Network. In Radar Remote Sensing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 175–186. [Google Scholar]

- Zhou, J.; Mourelatos, Z.P.; Ellis, C. Design under Uncertainty Using a Combination of Evidence Theory and a Bayesian Approach. SAE Int. J. Mater. Manuf. 2009, 1, 122–135. [Google Scholar] [CrossRef]

- Rupp, A.A.; Dey, D.K.; Zumbo, B.D. To Bayes or Not to Bayes, from Whether to When: Applications of Bayesian Methodology to Modeling. Struct. Equ. Model. 2004, 11, 424–451. [Google Scholar] [CrossRef]

- Schmidt, J.; Marques, M.R.G.; Botti, S.; Marques, M.A.L. Recent Advances and Applications of Machine Learning in Solid-State Materials Science. npj Comput. Mater. 2019, 5, 83. [Google Scholar] [CrossRef]

- Chen, L.; Pilania, G.; Batra, R.; Huan, T.D.; Kim, C.; Kuenneth, C.; Ramprasad, R. Polymer Informatics: Current Status and Critical next Steps. Mater. Sci. Eng. R Rep. 2021, 144, 100595. [Google Scholar] [CrossRef]

- Medasani, B.; Gamst, A.; Ding, H.; Chen, W.; Persson, K.A.; Asta, M.; Canning, A.; Haranczyk, M. Predicting Defect Behavior in B2 Intermetallics by Merging Ab Initio Modeling and Machine Learning. npj Comput. Mater. 2016, 2, 1. [Google Scholar] [CrossRef]

- Pilania, G.; Iverson, C.N.; Lookman, T.; Marrone, B.L. Machine-Learning-Based Predictive Modeling of Glass Transition Temperatures: A Case of Polyhydroxyalkanoate Homopolymers and Copolymers. J. Chem. Inf. Model. 2019, 59, 5013–5025. [Google Scholar] [CrossRef] [PubMed]

- De Jong, M.; Chen, W.; Notestine, R.; Persson, K.; Ceder, G.; Jain, A.; Asta, M.; Gamst, A. A Statistical Learning Framework for Materials Science: Application to Elastic Moduli of k-Nary Inorganic Polycrystalline Compounds. Sci. Rep. 2016, 6, 34256. [Google Scholar] [CrossRef] [PubMed]

- Seko, A.; Togo, A.; Hayashi, H.; Tsuda, K.; Chaput, L.; Tanaka, I. Prediction of Low-Thermal-Conductivity Compounds with First-Principles Anharmonic Lattice-Dynamics Calculations and Bayesian Optimization. Phys. Rev. Lett. 2015, 115, 205901. [Google Scholar] [CrossRef] [PubMed]

- Weng, B.; Song, Z.; Zhu, R.; Yan, Q.; Sun, Q.; Grice, C.G.; Yan, Y.; Yin, W.-J. Simple Descriptor Derived from Symbolic Regression Accelerating the Discovery of New Perovskite Catalysts. Nat. Commun. 2020, 11, 3513. [Google Scholar] [CrossRef] [PubMed]

- Walker, K.W.; Jiang, Z. Application of Adaptive Boosting (AdaBoost) in Demand-Driven Acquisition (DDA) Prediction: A Machine-Learning Approach. J. Acad. Librariansh. 2019, 45, 203–212. [Google Scholar] [CrossRef]

- Nie, P.; Roccotelli, M.; Fanti, M.P.; Ming, Z.; Li, Z. Prediction of Home Energy Consumption Based on Gradient Boosting Regression Tree. Energy Rep. 2021, 7, 1246–1255. [Google Scholar] [CrossRef]

- Cunningham, P.; Delany, S.J. K-Nearest Neighbour Classifiers-a Tutorial. ACM Comput. Surv. 2021, 54, 1–25. [Google Scholar] [CrossRef]

- Bansal, M.; Goyal, A.; Choudhary, A. A Comparative Analysis of K-Nearest Neighbor, Genetic, Support Vector Machine, Decision Tree, and Long Short Term Memory Algorithms in Machine Learning. Decis. Anal. J. 2022, 3, 100071. [Google Scholar] [CrossRef]

- Greenacre, M.; Groenen, P.J.F.; Hastie, T.; d’Enza, A.I.; Markos, A.; Tuzhilina, E. Principal Component Analysis. Nat. Rev. Methods Prim. 2022, 2, 100. [Google Scholar] [CrossRef]

- Plevris, V.; Solorzano, G.; Bakas, N.P.; Ben Seghier, M.E.A. Investigation of Performance Metrics in Regression Analysis and Machine Learning-Based Prediction Models. In Proceedings of the 8th European Congress on Computational Methods in Applied Sciences and Engineering, Oslo, Norway, 5–9 June 2022. [Google Scholar]

- Rainio, O.; Teuho, J.; Klén, R. Evaluation Metrics and Statistical Tests for Machine Learning. Sci. Rep. 2024, 14, 6086. [Google Scholar] [CrossRef] [PubMed]

- Du, Z. The Relationship between Prediction Accuracy and Correlation Coefficient. Sol. Phys. 2011, 270, 407–416. [Google Scholar] [CrossRef]

- Pool, S.; Vis, M.; Seibert, J. Evaluating Model Performance: Towards a Non-Parametric Variant of the Kling-Gupta Efficiency. Hydrol. Sci. J. 2018, 63, 1941–1953. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, G.; Li, P.; Wang, H.; Zhang, M.; Liang, X. An Improved Random Forest Based on the Classification Accuracy and Correlation Measurement of Decision Trees. Expert Syst. Appl. 2024, 237, 121549. [Google Scholar] [CrossRef]

- Abdusalamov, R.; Pandit, P.; Milow, B.; Itskov, M.; Rege, A. Machine Learning-Based Structure–Property Predictions in Silica Aerogels. Soft Matter 2021, 17, 7350–7358. [Google Scholar] [CrossRef] [PubMed]

- Meakin, P. Diffusion-Limited Aggregation in Three Dimensions: Results from a New Cluster-Cluster Aggregation Model. J. Colloid Interface Sci. 1984, 102, 491–504. [Google Scholar] [CrossRef]

- Scherdel, C.; Miller, E.; Reichenauer, G.; Schmitt, J. Advances in the Development of Sol-Gel Materials Combining Small-Angle X-Ray Scattering (SAXS) and Machine Learning (ML). Processes 2021, 9, 672. [Google Scholar] [CrossRef]

- Walker, R.C.; Hyer, A.P.; Guo, H.; Ferri, J.K. Silica Aerogel Synthesis/Process–Property Predictions by Machine Learning. Chem. Mater. 2023, 35, 4897–4910. [Google Scholar] [CrossRef]

- Chen, Y.X.; Klima, K.M.; Brouwers, H.J.H.; Yu, Q. Effect of Silica Aerogel on Thermal Insulation and Acoustic Absorption of Geopolymer Foam Composites: The Role of Aerogel Particle Size. Compos. Part B Eng. 2022, 242, 110048. [Google Scholar] [CrossRef]

- Chaouk, H.; Obeid, E.; Halwani, J.; Arayro, J.; Mezher, R.; Mouhtady, O.; Gazo-Hanna, E.; Amine, S.; Younes, K. Machine Learning Techniques to Analyze the Influence of Silica on the Physico-Chemical Properties of Aerogels. Gels 2024, 10, 554. [Google Scholar] [CrossRef] [PubMed]

- Sheikholeslami, M.; Farshad, S.A.; Gerdroodbary, M.B.; Alavi, A.H. Impact of New Multiple Twisted Tapes on Treatment of Solar Heat Exchanger. Eur. Phys. J. Plus 2022, 137, 86. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Farshad, S.A. Investigation of Solar Collector System with Turbulator Considering Hybrid Nanoparticles. Renew. Energy 2021, 171, 1128–1158. [Google Scholar] [CrossRef]

- Said, Z.; Cakmak, N.K.; Sharma, P.; Sundar, L.S.; Inayat, A.; Keklikcioglu, O.; Li, C. Synthesis, Stability, Density, Viscosity of Ethylene Glycol-Based Ternary Hybrid Nanofluids: Experimental Investigations and Model-Prediction Using Modern Machine Learning Techniques. Powder Technol. 2022, 400, 117190. [Google Scholar] [CrossRef]

- Kanti, P.K.; Sharma, P.; Sharma, K.V.; Maiya, M.P. The Effect of PH on Stability and Thermal Performance of Graphene Oxide and Copper Oxide Hybrid Nanofluids for Heat Transfer Applications: Application of Novel Machine Learning Technique. J. Energy Chem. 2023, 82, 359–374. [Google Scholar] [CrossRef]

- Kanti, P.K.; Sharma, P.; Maiya, M.P.; Sharma, K.V. The Stability and Thermophysical Properties of Al2O3-Graphene Oxide Hybrid Nanofluids for Solar Energy Applications: Application of Robust Autoregressive Modern Machine Learning Technique. Sol. Energy Mater. Sol. Cells 2023, 253, 112207. [Google Scholar] [CrossRef]

- Hashjin, R.R.; Ranjbar, Z.; Yari, H.; Momen, G. Tuning up Sol-Gel Process to Achieve Highly Durable Superhydrophobic Coating. Surf. Interfaces 2022, 33, 102282. [Google Scholar] [CrossRef]

- Manoharan, K.; Anwar, M.T.; Bhattacharya, S. Development of Hydrophobic Paper Substrates Using Silane and Sol–Gel Based Processes and Deriving the Best Coating Technique Using Machine Learning Strategies. Sci. Rep. 2021, 11, 11352. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xing, W.; Tang, G. Advances in Novel Flame-Retardant Technologies for Fire-Safe Polymeric Materials. Molecules 2024, 29, 573. [Google Scholar] [CrossRef] [PubMed]

- Huo, S.; Guo, Y.; Yang, Q.; Wang, H.; Song, P. Two-Dimensional Nanomaterials for Flame Retardant Polymer Composites: A Mini Review. Adv. Nanocomposites 2024, 1, 240–247. [Google Scholar] [CrossRef]

- Branda, F.; Passaro, J.; Pauer, R.; Gaan, S.; Bifulco, A. Solvent-Free One-Pot Synthesis of Epoxy Nanocomposites Containing Mg (OH) 2 Nanocrystal–Nanoparticle Formation Mechanism. Langmuir 2022, 38, 5795–5802. [Google Scholar] [CrossRef] [PubMed]

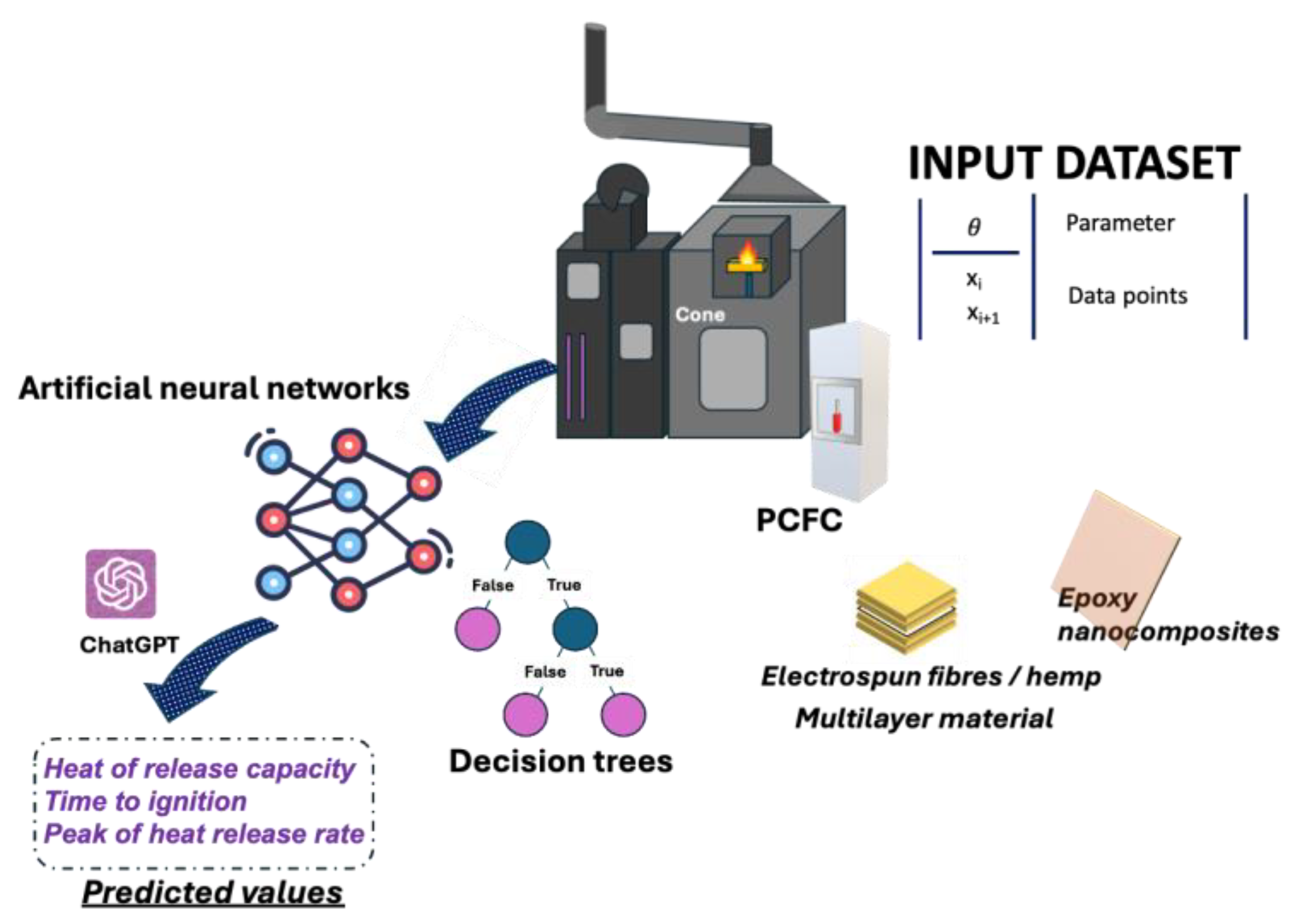

- Bifulco, A.; Casciello, A.; Imparato, C.; Forte, S.; Gaan, S.; Aronne, A.; Malucelli, G. A Machine Learning Tool for Future Prediction of Heat Release Capacity of In-Situ Flame Retardant Hybrid Mg (OH) 2-Epoxy Nanocomposites. Polym. Test. 2023, 127, 108175. [Google Scholar] [CrossRef]

- Kiranyaz, S.; Avci, O.; Abdeljaber, O.; Ince, T.; Gabbouj, M.; Inman, D.J. 1D Convolutional Neural Networks and Applications: A Survey. Mech. Syst. Signal Process. 2021, 151, 107398. [Google Scholar] [CrossRef]

- Ma, P.; Jia, X.; Xu, W.; He, Y.; Tarwa, K.; Alharbi, M.O.; Wei, C.-I.; Wang, Q. Enhancing Salmon Freshness Monitoring with Sol-Gel Cellulose Nanocrystal Colorimetric Paper Sensors and Deep Learning Methods. Food Biosci. 2023, 56, 103313. [Google Scholar] [CrossRef]

- Bifulco, A.; Climaco, I.; Casciello, A.; Passaro, J.; Battegazzore, D.; Nebbioso, V.; Russo, P.; Imparato, C.; Aronne, A.; Malucelli, G. Prediction and Validation of Fire Parameters for a Self-Extinguishing and Smoke Suppressant Electrospun PVP-Based Multilayer Material through Machine Learning Models. J. Mater. Sci. 2025, 60, 1019–1040. [Google Scholar] [CrossRef]

- Moreno, J.J.M.; Pol, A.P.; Abad, A.S.; Blasco, B.C. Using the R-MAPE Index as a Resistant Measure of Forecast Accuracy. Psicothema 2013, 25, 500–506. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-C.; Young, G.; Iqbal, H.; Kondarage, A.I.; Karunaratne, A.; Jones, J.R.; Tallia, F. Effect of Process Variables on Optimisation of Mechanical Properties of Silica/Poly (Tetrahydrofuran) Sol-Gel Hybrids. J. Sol-Gel Sci. Technol. 2025. [Google Scholar] [CrossRef]

- Berg, S.; Kutra, D.; Kroeger, T.; Straehle, C.N.; Kausler, B.X.; Haubold, C.; Schiegg, M.; Ales, J.; Beier, T.; Rudy, M. Ilastik: Interactive Machine Learning for (Bio) Image Analysis. Nat. Methods 2019, 16, 1226–1232. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Zhou, Y.; Liu, X.; Zhou, Q.; Huang, B.; Zhang, E.; Chen, Q.; Shen, J. Wettability and Corrosion Performance of Arc-Sprayed Fe-Based Amorphous Coatings. Surf. Coat. Technol. 2022, 433, 128129. [Google Scholar] [CrossRef]

- Misyura, S.Y.; Morozov, V.S.; Orlova, E.G.; Andryushchenko, V.A. Wetting, Droplet Evaporation and Corrosion Behavior of Various Composite and Textured Materials. Ceram. Int. 2024, 50, 19269–19282. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Akbarzadeh, K.; Ramezanzadeh, M.; Naderi, R.; Mahdavian, M.; Olivier, M.-G. Corrosion Resistance Enhancement of a Sol-Gel Coating by Incorporation of Modified Carbon Nanotubes: Artificial Neural Network (ANN) Modeling and Experimental Explorations. Prog. Org. Coat. 2023, 174, 107296. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, K.; Zhang, M.; Xu, T.; Du, H.; Pang, B.; Si, C. Sustainable Polysaccharide-Based Materials for Intelligent Packaging. Carbohydr. Polym. 2023, 313, 120851. [Google Scholar] [CrossRef] [PubMed]

- Zalke, J.B.; Bhaiyya, M.L.; Jain, P.A.; Sakharkar, D.N.; Kalambe, J.; Narkhede, N.P.; Thakre, M.B.; Rotake, D.R.; Kulkarni, M.B.; Singh, S.G. A Machine Learning Assisted Non-Enzymatic Electrochemical Biosensor to Detect Urea Based on Multi-Walled Carbon Nanotube Functionalized with Copper Oxide Micro-Flowers. Biosensors 2024, 14, 504. [Google Scholar] [CrossRef] [PubMed]

- Adesibikan, A.A.; Emmanuel, S.S.; Nafiu, S.A.; Tachia, M.J.; Iwuozor, K.O.; Emenike, E.C.; Adeniyi, A.G. A Review on Sustainable Photocatalytic Degradation of Agro-Organochlorine and Organophosphorus Water Pollutants Using Biogenic Iron and Iron Oxide-Based Nanoarchitecture Materials. Desalin. Water Treat. 2024, 320, 100591. [Google Scholar] [CrossRef]

- Kistan, A.; Mohan, S.; Mahalakshmi, S.; Jayanthi, A.; Ramya, A.J.; Karthik, P.S. Sol-Gel Technique, Characterization and Photocatalytic Degradation Activity of Manganese Doped ZnO Nanoparticles. Main Gr. Chem. 2024, 23, 17–30. [Google Scholar] [CrossRef]

- Chelghoum, H.; Nasrallah, N.; Tahraoui, H.; Seleiman, M.F.; Bouhenna, M.M.; Belmeskine, H.; Zamouche, M.; Djema, S.; Zhang, J.; Mendil, A. Eco-Friendly Synthesis of ZnO Nanoparticles for Quinoline Dye Photodegradation and Antibacterial Applications Using Advanced Machine Learning Models. Catalysts 2024, 14, 831. [Google Scholar] [CrossRef]

- Ricciarelli, D.; Kaiser, W.; Mosconi, E.; Wiktor, J.; Ashraf, M.W.; Malavasi, L.; Ambrosio, F.; De Angelis, F. Reaction Mechanism of Photocatalytic Hydrogen Production at Water/Tin Halide Perovskite Interfaces. ACS Energy Lett. 2022, 7, 1308–1315. [Google Scholar] [CrossRef]

- Koyale, P.A.; Mulik, S.V.; Gunjakar, J.L.; Dongale, T.D.; Koli, V.B.; Mullani, N.B.; Sutar, S.S.; Kapdi, Y.G.; Soni, S.S.; Delekar, S.D. Synergistic Enhancement of Water-Splitting Performance Using Mof-Derived Ceria-Modified g-C3N4 Nanocomposites: Synthesis, Performance Evaluation, and Stability Prediction with Machine Learning. Langmuir 2024, 40, 13657–13668. [Google Scholar] [CrossRef] [PubMed]

- Seitz, P.; Scherdel, C.; Reichenauer, G.; Schmitt, J. Machine Learning in the Development of Si-Based Anodes Using Small-Angle X-Ray Scattering for Structural Property Analysis. Comput. Mater. Sci. 2023, 218, 111984. [Google Scholar] [CrossRef]

- Mu, S.; Shen, W.; Lv, D.; Song, W.; Tan, R. Inkjet-Printed MOS-Based MEMS Sensor Array Combined with One-Dimensional Convolutional Neural Network Algorithm for Identifying Indoor Harmful Gases. Sens. Actuators A Phys. 2024, 369, 115210. [Google Scholar] [CrossRef]

| Sol-Gel System | Machine Learning and Optimization Tools | Predicted Parameters and Characteristics | Statistical Indices for Efficiency | Ref. |

|---|---|---|---|---|

| Silica aerogels | ANN |

| R2 = 0.973 | [66] |

| Silica aerogels |

| Solid-phase thermal conductivity |

| [68] |

| Silica aerogels |

| Surface area |

| [69] |

| rGO-Fe3O4-TiO2 hybrid nanofluids |

| Influence of temperature and volume concentration on the viscosity and density | R-values of BRT-based density (0.9989) and viscosity (0.9979) higher than those of the ANN-based and SVM-based models | [74] |

| Hybrid nanofluids based on CuO and GO at different ratios |

|

|

| [75] |

| Hybrid nanofluids composed of alumina (Al2O3) and graphene oxide (GO) at different mixing ratios |

|

| Prognostic efficiency of 97.15–99.91% | [76] |

| Mg(OH)2-epoxy nanocomposite | ANN | HRC | MAE and RMSE equal to 145.6 and 186.1, respectively | [82] |

| Sol-gel functionalized paper sensor |

| Non-destructive estimation of the salmon freshness | Accuracy up to 99.2% | [84] |

| Coated hemp blankets with cross-linked electrospun polyvinylpyrrolidone-silica blankets and TiO2 nanoparticles |

|

|

| [85] |

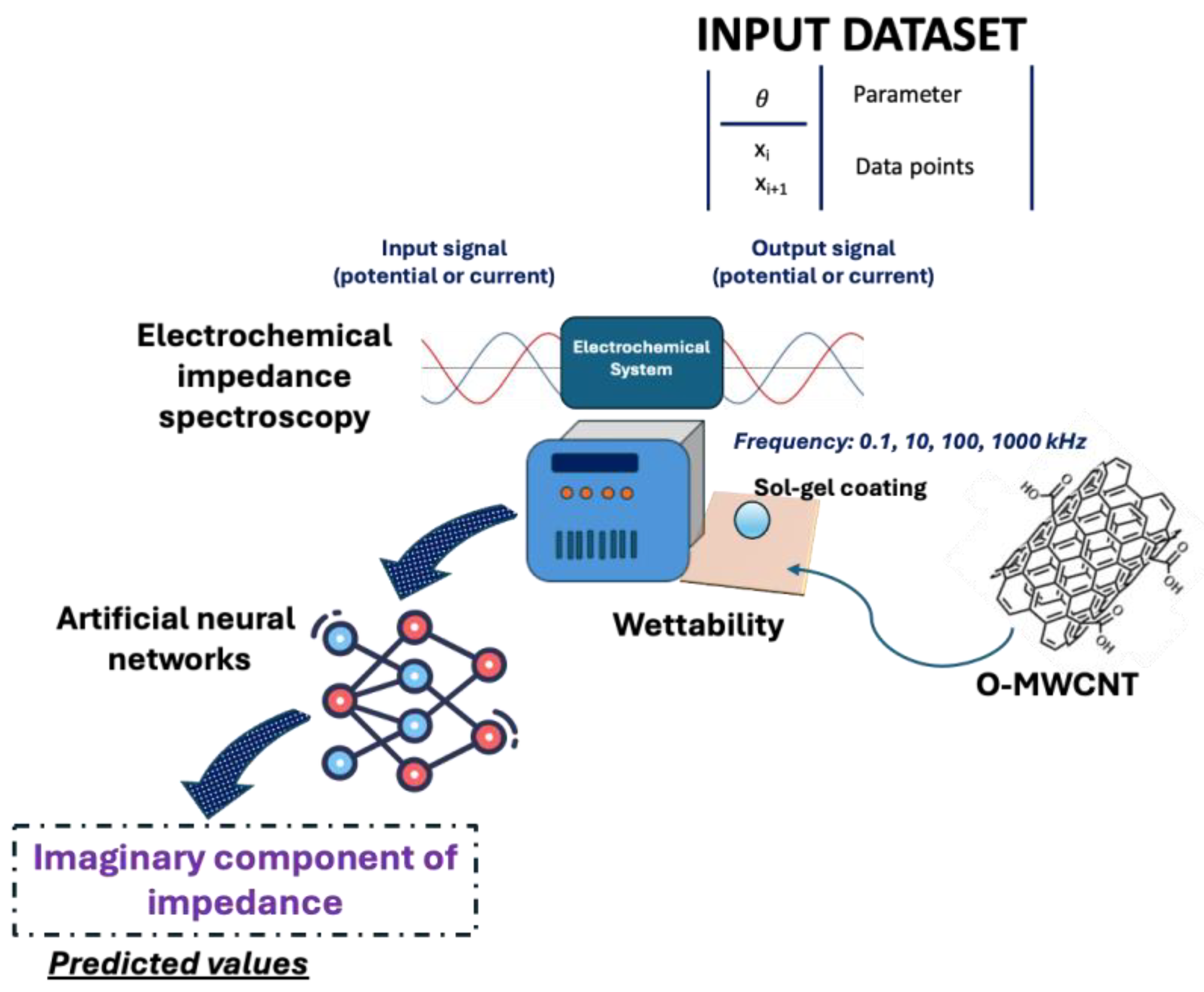

| Sol-gel coatings containing O-MWCNT nanotubes |

| Imaginary part of the impedance |

| [91] |

| Xanthine biosensor based on Co3O4 nanoparticles and MWCNTs (tailored by a MWCNT-ZnO nanocomposite functionalized with CuO-MFs) |

|

| KNN model gave lower RMSE (0.0004) than linear regression (0.0006), together with a higher (0.981) R2 compared to linear regression (0.953) | [93] |

| ZnO-based nanoparticles |

| Photodegradation rates of quinoline yellow | RMSE values along all phases (i.e., training (0.0160), testing (0.0250), validation (0.0244), and the whole dataset (0.0179)) | [96] |

| ZnO/SnO2-based micro-electromechanical system gas sensor array | 1DCNN | Classification of mixed gases | The conventional SVM model gave an 80% recognition accuracy of the gas mixtures, while the 1DCNN provided 99.8% | [100] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bifulco, A.; Malucelli, G. AI/Machine Learning and Sol-Gel Derived Hybrid Materials: A Winning Coupling. Molecules 2025, 30, 3043. https://doi.org/10.3390/molecules30143043

Bifulco A, Malucelli G. AI/Machine Learning and Sol-Gel Derived Hybrid Materials: A Winning Coupling. Molecules. 2025; 30(14):3043. https://doi.org/10.3390/molecules30143043

Chicago/Turabian StyleBifulco, Aurelio, and Giulio Malucelli. 2025. "AI/Machine Learning and Sol-Gel Derived Hybrid Materials: A Winning Coupling" Molecules 30, no. 14: 3043. https://doi.org/10.3390/molecules30143043

APA StyleBifulco, A., & Malucelli, G. (2025). AI/Machine Learning and Sol-Gel Derived Hybrid Materials: A Winning Coupling. Molecules, 30(14), 3043. https://doi.org/10.3390/molecules30143043