Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties

Abstract

1. Introduction

2. Results and Discussion

2.1. Basic Composition of Raw Materials and Pasta

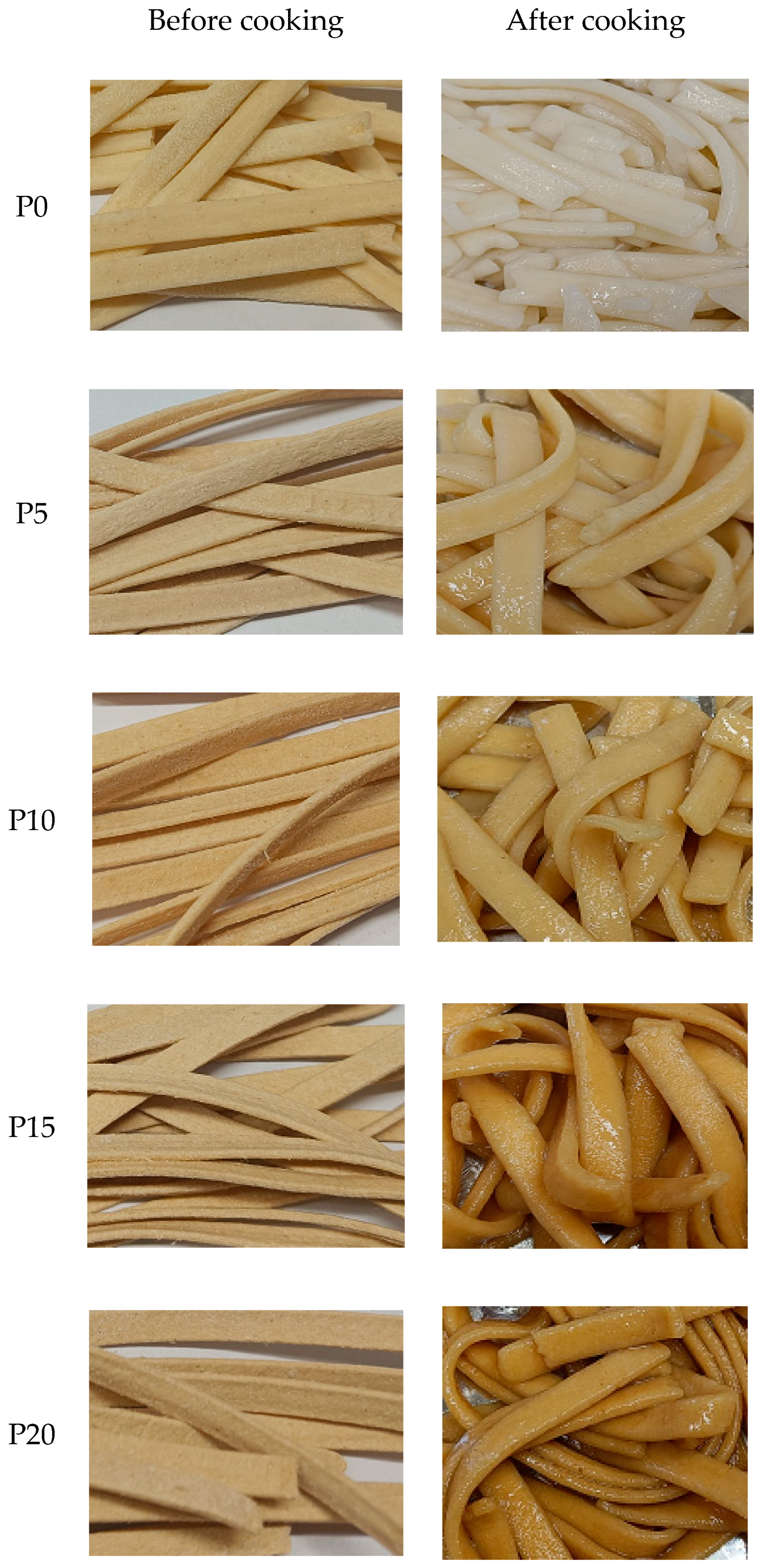

2.2. Color Parameters of Pasta

2.3. Cooking Properties of Pasta

2.4. Texture Properties

2.5. Total Phenolic Content and Antioxidant Activity of Cooked Pasta

2.6. LC-ESI-MS/MS Analysis of Phenolic Acids and Flavonoid Compounds

2.7. Sensory Properties

3. Materials and Methods

3.1. Basic Composition of Raw Materials

3.2. Research Materials and Preparation of Pasta

3.3. Evaluation of Chemical and Physical Properties of the Pasta

3.3.1. Determination of the Basic Chemical Composition

3.3.2. Measurement of Water Activity

3.3.3. Color Coordinates

3.4. Cooking Quality of Pasta

3.4.1. Optimal Cooking Time

3.4.2. Weight Increase Index and Cooking Loss

3.5. Texture Analysis

3.6. Total Phenolic Content and Antioxidant Activity

3.7. LC-ESI-MS/MS Analysis of Phenolic Acids and Flavonoid Compounds

3.8. Sensory Evaluation

3.9. Statistical Estimation of Research Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Jones, J.M. CODEX-Aligned Dietary Fiber Definitions Help to Bridge the ‘Fiber Gap’. Nutr. J. 2014, 13, 34. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Dietetic Products, Nutrition, and Allergies (NDA). Scientific Opinion on Dietary Reference Values for Carbohydrates and Dietary Fibre. EFSA J. 2010, 8, 1462. [Google Scholar] [CrossRef]

- McIntosh, G.H.; Noakes, M.; Royle, P.J.; Foster, P.R. Whole-Grain Rye and Wheat Foods and Markers of Bowel Health in Overweight Middle-Aged Men. Am. J. Clin. Nutr. 2003, 77, 967–974. [Google Scholar] [CrossRef] [PubMed]

- Xu, R. Oat Fibre: Overview on Their Main Biological Properties. Eur. Food Res. Technol. 2012, 234, 563–569. [Google Scholar] [CrossRef]

- Peterson, D.M. Oat Antioxidants. J. Cereal Sci. 2001, 33, 115–129. [Google Scholar] [CrossRef]

- Dziki, D.; Lisiecka, K.; Gawlik-Dziki, U.; Różyło, R.; Krajewska, A.; Cacak-Pietrzak, G. Shortbread Cookies Enriched with Micronized Oat Husk: Physicochemical and Sensory Properties. Appl. Sci. 2022, 12, 12512. [Google Scholar] [CrossRef]

- Różyło, R.; Schönlechner, R.; Pichler, E.C.; Dziki, D.; Matwijczuk, A.; Biernacka, B.; Świeca, M. Innovative High-Fiber Wheat Bread Fortified with Micronized Oat and Plantago Ovata Husks: Spectroscopic and Physicochemical Characteristics. Food Chem. 2023, 428, 136782. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, M.; Bhandari, B.; Yang, Z. Micronization and Nanosizing of Particles for an Enhanced Quality of Food: A Review. Crit. Rev. Food Sci. Nutr. 2018, 58, 993–1001. [Google Scholar] [CrossRef]

- Dziki, D.; Tarasiuk, W.; Gawlik-Dziki, U. Micronized Oat Husk: Particle Size Distribution, Phenolic Acid Profile and Antioxidant Properties. Materials 2021, 14, 5443. [Google Scholar] [CrossRef]

- Dziki, D.; Gawlik-Dziki, U.; Tarasiuk, W.; Różyło, R. Fiber Preparation from Micronized Oat By-Products: Antioxidant Properties and Interactions between Bioactive Compounds. Molecules 2022, 27, 2621. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.; Wierzbicka, A. Effect of Oat β-Glucan Fiber Powder and Vacuum-Drying on Cooking Quality and Physical Properties of Pasta. CyTA—J. Food 2016, 14, 101–108. [Google Scholar] [CrossRef]

- Astiz, V.; Guardianelli, L.M.; Salinas, M.V.; Brites, C.; Puppo, M.C. High β-Glucans Oats for Healthy Wheat Breads: Physicochemical Properties of Dough and Breads. Foods 2022, 12, 170. [Google Scholar] [CrossRef] [PubMed]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Różyło, R.; Siastała, M. Physical, Sensorial, and Antioxidant Properties of Common Wheat Pasta Enriched with Carob Fiber. LWT—Food Sci. Technol. 2017, 77, 186–192. [Google Scholar] [CrossRef]

- Leventa, H.; Koyuncub, M.; Bilgiçlic, N.; Adıgüzela, E.; Dedeoğlub, M. Improvement of chemical properties of noodle and pasta using dephytinized cereal brans. LWT—Food Sci. Technol. 2020, 128, 109470. [Google Scholar] [CrossRef]

- Espinosa-Solis, V.; Zamudio-Flores, P.B.; Tirado-Gallegos, J.M.; Ramírez-Mancinas, S.; Olivas-Orozco, G.I.; Espino-Díaz, M.; Hernández-González, M.; García-Cano, V.G.; Sánchez-Ortíz, O.; Buenrostro-Figueroa, J.J.; et al. Evaluation of Cooking Quality, Nutritional and Texture Characteristics of Pasta Added with Oat Bran and Apple Flour. Foods 2019, 8, 299. [Google Scholar] [CrossRef] [PubMed]

- Cafieri, S.; Mastromatteo, M.; Chillo, S.; Del Nobile, M.A. Modeling the mechanical properties of pasta cooked at different times. J. Food Eng. 2010, 100, 336–342. [Google Scholar] [CrossRef]

- Bustos, M.C.; Perez, G.T.; León, A.E. Sensory and Nutritional Attributes of Fibre-Enriched Pasta. LWT—Food Sci. Technol. 2011, 44, 1429–1434. [Google Scholar] [CrossRef]

- Cheung, P.C.K.; Mehta, B.M. (Eds.) Handbook of Food Chemistry; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-36604-8. [Google Scholar]

- Nurullaeva, D.; Farmanova, N.; Luzhanin, V.; Povidysh, M.; Orlova-Lebedkova, A. Chemical Components and Biological Activity of Oats Seed—Avena sativa L. Int. J. Pharm. Res. 2020, 12, 221–229. [Google Scholar] [CrossRef]

- Piątkowska, E.; Witkowicz, R.; Pisulewska, E. Antioxidant Properties of Selected Cultivars of Oats. Food Sci. Technol. Qual. 2010, 14, 100–107. [Google Scholar] [CrossRef]

- Emmons, C.L.; Peterson, D.M. Antioxidant Activity and Phenolic Contents of Oat Groats and Hulls. Cereal Chem. J. 1999, 76, 902–906. [Google Scholar] [CrossRef]

- Zhang, K.; Dong, R.; Hu, X.; Ren, C.; Li, Y. Oat-Based Foods: Chemical Constituents, Glycemic Index, and the Effect of Processing. Foods 2021, 10, 1304. [Google Scholar] [CrossRef] [PubMed]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta Fortification with Olive Pomace: Effects on the Technological Characteristics and Nutritional Properties. LWT 2019, 114, 108368. [Google Scholar] [CrossRef]

- Kwinda, O.; Onipe, O.O.; Jideani, A.I.O. The Effect of Oat Bran and Psyllium Husk Fibre on Oil Reduction and Some Physicochemical Properties of Magwinya—A Deep-Fried Dough. CyTA—J. Food 2018, 16, 247–254. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Różyło, R.; Gawlik-Dziki, U. Banana Powder as an Additive to Common Wheat Pasta. Foods 2020, 9, 53. [Google Scholar] [CrossRef] [PubMed]

- Horwitz, W.; Latimer, G.W., Jr. Offcial Methods of Analysis of AOAC International; AOAC International: Gaitherburg, MD, USA, 2011. [Google Scholar]

- Serin, S.; Turhan, K.N.; Turhan, M. Correlation between Water Activity and Moisture Content of Turkish Flower and Pine Honeys. Food Sci. Technol. 2018, 38, 238–243. [Google Scholar] [CrossRef]

- Miceli, A.; Francesca, N.; Moschetti, G.; Settanni, L. The Influence of Addition of Borago Officinalis with Antibacterial Activity on the Sensory Quality of Fresh Pasta. Int. J. Gastron. Food Sci. 2015, 2, 93–97. [Google Scholar] [CrossRef][Green Version]

- Monteiro, M.L.G.; Mársico, E.T.; Soares, M.S.; Magalhães, A.O.; Canto, A.C.V.C.S.; Costa-Lima, B.R.C.; Alvares, T.S.; Conte, C.A. Nutritional Profile and Chemical Stability of Pasta Fortified with Tilapia (Oreochromis niloticus) Flour. PLoS ONE 2016, 11, e0168270. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Bonomi, F.; D’Egidio, M.G.; Iametti, S.; Marengo, M.; Marti, A.; Pagani, M.A.; Ragg, E.M. Structure–Quality Relationship in Commercial Pasta: A Molecular Glimpse. Food Chem. 2012, 135, 348–355. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Wójtowicz, A. Influence of Extrusion-Cooking Process Parameters on Selected Mechanical Properties of Precooked Maize Pasta Products. TEKA Kom. Mot. Energ. Roln.—OL PAN 2011, 11, 430–440. [Google Scholar]

- Kasprzak-Drozd, K.; Oniszczuk, T.; Kowalska, I.; Mołdoch, J.; Combrzyński, M.; Gancarz, M.; Dobrzański, B., Jr.; Kondracka, A.; Oniszczuk, A. Effect of the production parameters and in vitro digestion on the content of polyphenolic compounds, phenolic acids, and antiradical properties of innovative snacks enriched with wild garlic (Allium ursinum L.) leaves. Int. J. Mol. Sci. 2022, 23, 14458. [Google Scholar] [CrossRef] [PubMed]

- Burda, S.; Oleszek, W. Antioxidant and antiradical activities of flavonoids. Agric. Food Chem. 2001, 49, 2774–2779. [Google Scholar] [CrossRef] [PubMed]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Singh, A.; Raju, R.; Mrad, M.; Reddell, P.; Münch, G. The Reciprocal EC50 Value as a Convenient Measure of the Potency of a Compound in Bioactivity-Guided Purification of Natural Products. Fitoterapia 2020, 143, 104598. [Google Scholar] [CrossRef]

- Nowacka, N.; Nowak, R.; Drozd, M.; Olech, M.; Los, R.; Malm, A. Antibacterial, Antiradical Potential and Phenolic Compounds of Thirty-One Polish Mushrooms. PLoS ONE 2015, 10, e0140355. [Google Scholar] [CrossRef]

- Pietrzak, W.; Nowak, R.; Gawlik-Dziki, U.; Lemieszek, M.K.; Rzeski, W. LC-ESI-MS/MS Identification of Biologically Active Phenolic Compounds in Mistletoe Berry Extracts from Different Host Trees. Molecules 2017, 22, 624. [Google Scholar] [CrossRef]

| Sample | Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Dry Matter (%) | Ash (%) | Protein (%) | Fat (%) | Fiber (%) | Water Activity (-) | Available Carbohydrates (%) | |

| CWF * | 86.15 ± 0.35 A** | 0.39 ± 0.12 A | 11.95 ± 0.09 A | 1.20 ± 0.12 A | 3.20 ± 0.63 B | 0.393 ± 0.054 B | 83.26 |

| MOH | 89.80 ± 0.11 A | 3.42 ± 0.11 B | 1.27 ± 0.08 B | - | 93.7 ± 1.23 A | 0.321 ± 0.040 A | 4.61 |

| P0 | 90.46 ± 0.16 a | 0.36 ± 0.17 a | 11.89 ± 0.11 b | 1.26 ± 0.17 a | 0.27 ± 0.17 a | 0.339 ± 0.011 c | 86.22 |

| P5 | 90.83 ± 0.45 a | 0.74 ± 0.22 a | 11.76 ± 0.39 b | 1.13 ± 0.19 a | 3.14 ± 0.83 b | 0.352 ± 0.003 cd | 83.23 |

| P10 | 90.82 ± 0.05 a | 0.63 ± 0.05 a | 11.47 ± 0.71 ab | 1.04 ± 0.16 a | 3.94 ± 0.84 b | 0.320 ± 0.006 d | 82.92 |

| P15 | 91.51 ± 0.30 a | 1.06 ± 0.82 b | 11.18 ± 0.64 ab | 0.97 ± 0.18 a | 6.55 ± 0.41 c | 0.298 ± 0.008 a | 80.24 |

| P20 | 92.25 ± 0.49 a | 1.41 ± 0.37 b | 10.34 ± 0.34 a | 0.96 ± 0.18 a | 7.05 ± 0.82 c | 0.302 ± 0.004 ab | 80.24 |

| Sample | Color Parameters | |||

|---|---|---|---|---|

| L* | a* | b* | ΔE | |

| CWF * | 90.76 ± 0.68 B** | 2.05 ± 0.07 A | 13.79 ± 0.05 A | - |

| MOH | 74.51 ± 0.14 A | 8.13 ± 0.07 B | 22.66 ± 0.06 B | - |

| P0 | 66.48 ± 4.37 d | 3.27 ± 0.29 a | 13.63 ± 1.04 a | - |

| P5 | 64.52 ± 0.63 cd | 3.97 ± 0.04 a | 14.45 ± 2.48 a | 4.70 ± 1.55 a |

| P10 | 60.07 ± 1.72 c | 5.03 ± 0.38 b | 15.00 ± 0.15 a | 7.38 ± 3.29 b |

| P15 | 55.54 ± 2.24 b | 5.62 ± 0.42 bc | 15.90 ± 1.10 a | 11.29 ± 5.49 bc |

| P20 | 48.66 ± 1.75 a | 6.09 ± 0.04 c | 16.67 ± 0.59 a | 18.02 ± 4.63 c |

| CP0 | 67.26 ± 0.89 b | 2.02 ± 0.18 a | 16.51 ± 0.05 a | - |

| CP5 | 66.45 ± 1.39 b | 5.38 ± 0.07 b | 20.44 ± 1.61 ab | 5.34 ± 1.33 a |

| CP10 | 62.97 ± 2.28 b | 7.59 ± 0.76 c | 22.02 ± 3.30 b | 9.20 ± 3.75 b |

| CP15 | 63.33 ± 3.17 b | 8.15 ± 0.55 cd | 23.69 ± 0.29 b | 10.48 ± 1.24 bc |

| CP20 | 53.17 ± 2.08 a | 9.62 ± 1.21 d | 22.04 ± 2.27 b | 16.96 ± 3.77 c |

| Sample | Parameters | ||

|---|---|---|---|

| OCT (min) | WI (kg CP/kg P) | CL (g/100 g of pasta) | |

| CP0 * | 10.50 ± 0.26 a** | 2.28 ± 0.02 c | 4.62 ± 0.02 a |

| CP5 | 10.90 ± 0.22 ab | 2.26 ± 0.03 c | 5.46 ± 0.03 b |

| CP10 | 11.50 ± 0.23 b | 2.22 ± 0.03 b | 5.49 ± 0.03 b |

| CP15 | 12.10 ± 0.13 c | 2.14 ± 0.02 ab | 5.57 ± 0.03 b |

| CP20 | 12.60 ± 0.21 c | 2.10 ± 0.01 a | 7.52 ± 0.01 c |

| Sample | Parameters | |

|---|---|---|

| Deformation (mm) | Stretching Force (N) | |

| CP0 * | 7.04 ± 3.15 b** | 1.06 ± 0.07 b |

| CP5 | 5.54 ± 1.34 ab | 0.83 ± 0.10 a |

| CP10 | 4.98 ± 1.79 ab | 0.75 ± 0.13 a |

| CP15 | 3.94 ± 1.13 ab | 0.74 ± 0.06 a |

| CP20 | 2.82 ± 0.69 a | 0.73 ± 0.06 a |

| Sample | Parameters | ||

|---|---|---|---|

| TPC (mg GEA/g d. m.) | ABTS EC50 (mg d. m./mL) | DPPH EC50 (mg d. m./mL) | |

| CWF * | 256.87 ± 10.06 A** | 242.69 ± 12.07 A | 355.12 ± 2.71 A |

| MOH | 628.32 ± 12.35 B | 35.62 ± 1.06 B | 55.22 ± 2.73 B |

| CP0 | 247.59 ± 1.12 a | 256.53 ± 2.01 e | 364.04 ± 10.99 e |

| CP5 | 263.24 ± 13.87 ab | 186.04 ± 5.10 d | 282.37 ± 3.05 d |

| CP10 | 279.61 ± 3.40 ab | 154.93 ± 7.62 c | 252.40 ± 2.20 c |

| CP15 | 291.37 ± 8.99 b | 136.85 ± 8.92 b | 206.23 ± 4.29 b |

| CP20 | 350.20 ± 24.49 c | 101.17 ± 1.56 a | 162.02 ± 8.45 a |

| Sample | Flavonoid Aglycones (µg/g d.m.) | Flavonoid Glycosides (µg/g d.m.) | ||

|---|---|---|---|---|

| Luteolina | Apigenina | Luteolin-7-O-glucoside (Luteoloside) | Apigenin-6-C-glucoside (Isovitexin)/ Apigenin-8-C-glucoside (Apigenin-6-C-glucoside (Vitexin) | |

| P0 * | trace | trace | trace | trace |

| P5 | trace | trace | nd | trace |

| P10 | trace | trace | nd | trace |

| P15 | trace | trace | nd | 19.75 ± 0.21 a** |

| P20 | trace | trace | nd | 28.40 ± 0.92 a |

| Phenolic Acids (µg/g d.m.) | Sample | ||||

|---|---|---|---|---|---|

| P0 * | P5 | P10 | P15 | P20 | |

| ** 3-O-caffeoylquinic acid (neochlorogenic acid) | nd | nd | trace | trace | trace |

| *** 5-caffeoylquinic acid (chlorogenic acid) | trace | trace | trace | trace | 4.35 ± 0.01 a** |

| 4-Hydroxybenzoic acid | trace | trace | trace | trace | trace |

| vanilic acid | trace | trace | trace | 8.25 ± 0.50 a | 19.33 ± 0.04 ab |

| syringic acid | nd | nd | trace | 15.95 ± 0.07 a | 31.85 ± 0.71 b |

| 4-Hydroxycinnamic acid (p-coumaric acid) | trace | 54.00 ± 4.21 a | 149.75 ± 1.06 a | 266.75 ± 3.18 b | 292.00 ± 0.71 c |

| ferulic acid | 643.50 ± 36.74 a | 1025.50 ± 9.19 b | 1227.50 ± 17.68 b | 1522.50 ± 31.82 c | 1517.50 ± 38.89 d |

| salicylic acid | trace | trace | trace | trace | trace |

| Sample | Sensory Attribute | |||||

|---|---|---|---|---|---|---|

| Appearance | Color | Smell | Taste | Texture | Overall | |

| CP0 * | 2.67 ± 0.58 a** | 2.33 ± 1.15 a | 6.33 ± 0.58 a | 5.67 ± 0.58 b | 6.00 ± 0.00 b | 4.67 ± 0.58 ab |

| CP5 | 4.33 ± 1.15 ab | 4.33 ± 0.58 ab | 6.00 ± 0.00 a | 5.67 ± 0.58 b | 5.67 ± 0.58 b | 6.00 ± 0.02 c |

| CP10 | 6.33 ± 0.58 c | 5.67 ± 1.15 b | 5.67 ± 0.58 a | 5.00 ± 0.03 ab | 4.67 ± 0.58 ab | 6.33 ± 0.58 c |

| CP15 | 6.00 ± 0.02 bc | 6.00 ± 0.02 b | 5.67 ± 0.58 a | 5.33 ± 0.58 b | 4.67 ± 0.58 ab | 5.00 ± 0.02 b |

| CP20 | 6.33 ± 0.58 c | 6.00 ± 0.03 b | 5.67 ± 0.58 a | 4.00 ± 0.02 a | 3.67 ± 0.58 a | 4.00 ± 0.03 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biernacka, B.; Dziki, D.; Różyło, R.; Gawlik-Dziki, U.; Nowak, R.; Pietrzak, W. Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties. Molecules 2023, 28, 7197. https://doi.org/10.3390/molecules28207197

Biernacka B, Dziki D, Różyło R, Gawlik-Dziki U, Nowak R, Pietrzak W. Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties. Molecules. 2023; 28(20):7197. https://doi.org/10.3390/molecules28207197

Chicago/Turabian StyleBiernacka, Beata, Dariusz Dziki, Renata Różyło, Urszula Gawlik-Dziki, Renata Nowak, and Wioleta Pietrzak. 2023. "Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties" Molecules 28, no. 20: 7197. https://doi.org/10.3390/molecules28207197

APA StyleBiernacka, B., Dziki, D., Różyło, R., Gawlik-Dziki, U., Nowak, R., & Pietrzak, W. (2023). Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties. Molecules, 28(20), 7197. https://doi.org/10.3390/molecules28207197