Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil

Abstract

:1. Introduction

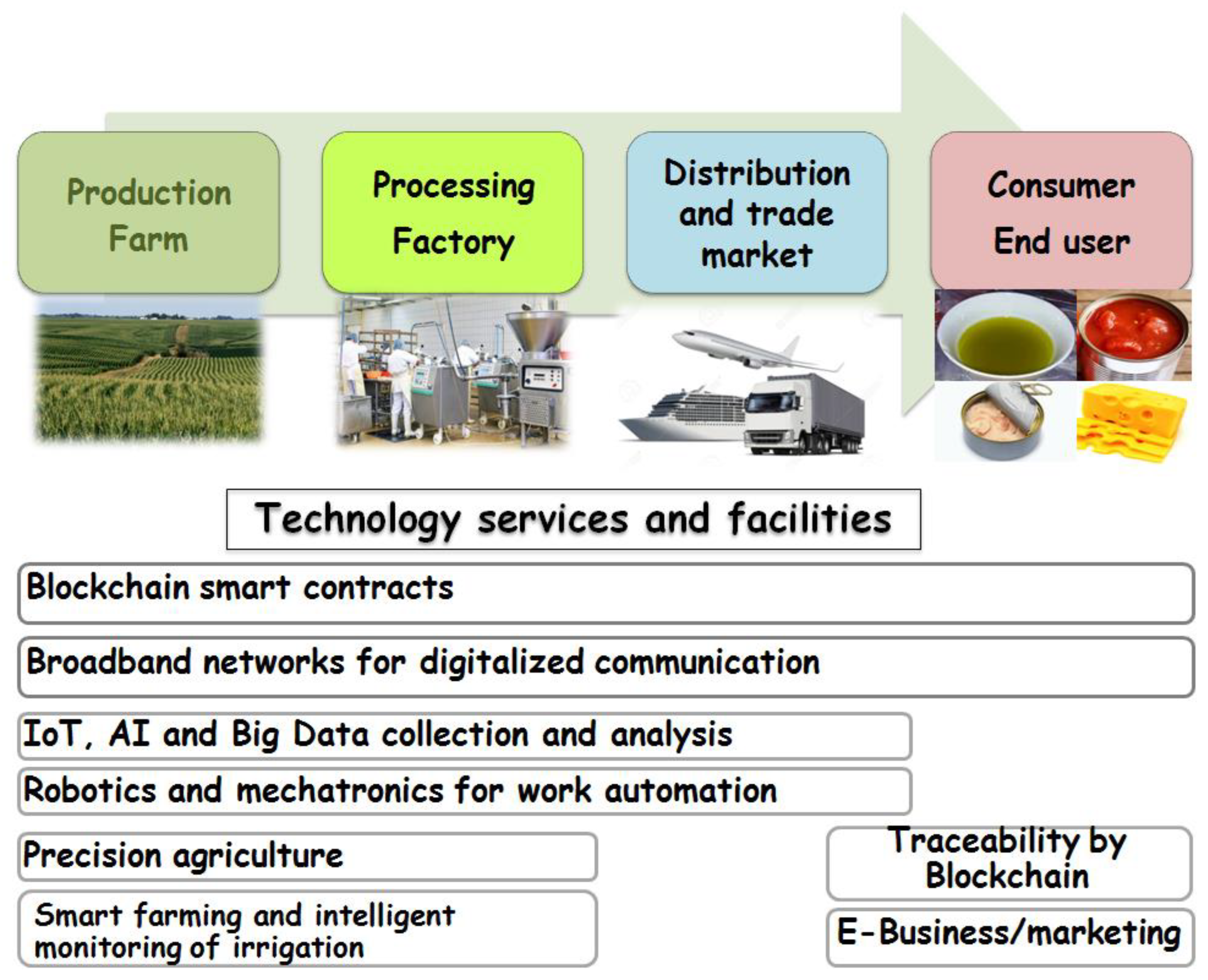

2. Agri-Food 4.0

Agri-Food 4.0 Technologies

| Sector | Application | Tool/Technology | References |

|---|---|---|---|

| Farming | Improvement of the resilience of agriculture production systems | Remote sensing, unmanned vehicle, unmanned aerial systems, next-generation sequencing, high throughput phenotyping | [67,68] |

| Yield and productivity prediction | Field imaging, deep learning approach, biological and environmental indicators integration | [69,70,71] | |

| Intelligent control system for the determination of the watering time of turfgrass plants | Computer vision system, artificial neural network | [72] | |

| Grain crops: disease detection, grain quality, phenotyping | Computer vision, graphics processing unit, deep belief networks, artificial bee colony, extreme learning machine | [73,74] | |

| Energy consumption forecasting | Mathematical models | [75] | |

| Determining the precise work area of agriculture machinery | IoT | [76] | |

| In-field estimation of strawberry ripeness | Hyperspectral imaging, deep learning approach | [77] | |

| Weed management | Machine vision, graphics processing unit | [78,79] | |

| Crop evapotranspiration equations and modeling | Symbolic regression technique, artificial neural network, extreme learning machine, meteorological data | [80,81,82,83] | |

| Prediction of the hydration characteristics of wheat | Adaptive neuro-fuzzy inference system, artificial neural network | [84] | |

| Water detection on the Earth’s surface | Remote sensing technique, reflectometry data | [85] | |

| Optimization of irrigation monitoring, pesticides and herbicides applications | Automated robotic systems, machine learning algorithms, wireless sensor network | [86,87] | |

| Non-destructive determination of the soluble solids content of citrus | Near infrared transmittance technology, variable selection algorithm | [88] | |

| Disease diagnosis, detection and control (paddy crop, olive, grapevine, apple and orchards) | Automated vision, image processing, neural network architectures | [89,90,91,92,93,94] | |

| Irrigation water demand forecasting | Runoff simulation method | [95] | |

| Soil temperature assessment | Satellite imagery, regression-based models | [96] | |

| Health diagnosis of agriculture vehicles | Lightweight artificial intelligence technology, artificial neural networks, genetic algorithm | [97] | |

| Obstacle detection for agricultural machinery vehicle | Infrared binocular stereo vision system | [98] | |

| Perception of tractor implement performance in the plowing process | Soft computing workplace, non-linear equations | [99] | |

| Mechanical transplantation of pot seedlings | Robotics, mechatronics | [100] | |

| Crop damage avoidance during weed eradication | Mechatronics | [101] | |

| Citrus rootstock evaluation | Unmanned aerial vehicle-based remote sensing | [102] | |

| Detection of seed germination | Low-power embedded system | [103] | |

| Detection of post-harvest apple pesticide residues | Machine vision technology, AlexNet–CNN deep learning network | [104] | |

| Non-destructive detection of seed viability | Near infrared spectroscopy, infrared thermography, multispectral imaging | [105] | |

| Determination of the best drought tolerance indices | Artificial neural network | [106] | |

| Carbon sequestration and emissions mitigation in paddy fields | Denitrification–decomposition model | [107] | |

| Plant identification | Visual features of leaves, artificial neural network, support vector machine, algorithms | [108] | |

| Livestock monitoring | Poultry monitoring | Computer vision systems | [109] |

| Bird nest localization | Drone-borne thermal imaging | [110] | |

| Fishing/ Aquaculture | Separation of dead and live rainbow trout fish eggs | Visual machine technology-based intelligent system, imagery processing | [111] |

| Fisheries management | Data collection and interpretation | [112] | |

| Forestry | Spatial prediction of wildfire probability | neuro-fuzzy system and metaheuristic optimization algorithms, mathematical modeling | [113,114] |

| Tree volume prediction | Machine learning | [115] | |

| Trade marketing | Prediction of agricultural produce prices | Convolutional neural networks, artificial neural networks | [116,117] |

| Input–output analysis of agricultural economic benefits | Big data | [118] | |

| Food industry and transformation | Predicting optimum moisture content reduction in drying potato slices | Adaptive neuro fuzzy inference systems, artificial neural network, response surface methodology | [119] |

| Modeling and optimization of Terminalia catappa L. kernel oil extraction | Artificial neural network | [120] | |

| Optimization of refrigerated transport | Computational fluid dynamics turbulence | [121] | |

| Applications for the food of electronic noses and tongues | Biosensors, chemical sensors | [122,123,124] | |

| Climatology | Early warning of agricultural meteorological disasters | Big data | [125] |

3. Advantages in Adopting DNA-Based Technologies in Agri-Food Supply Chain Traceability

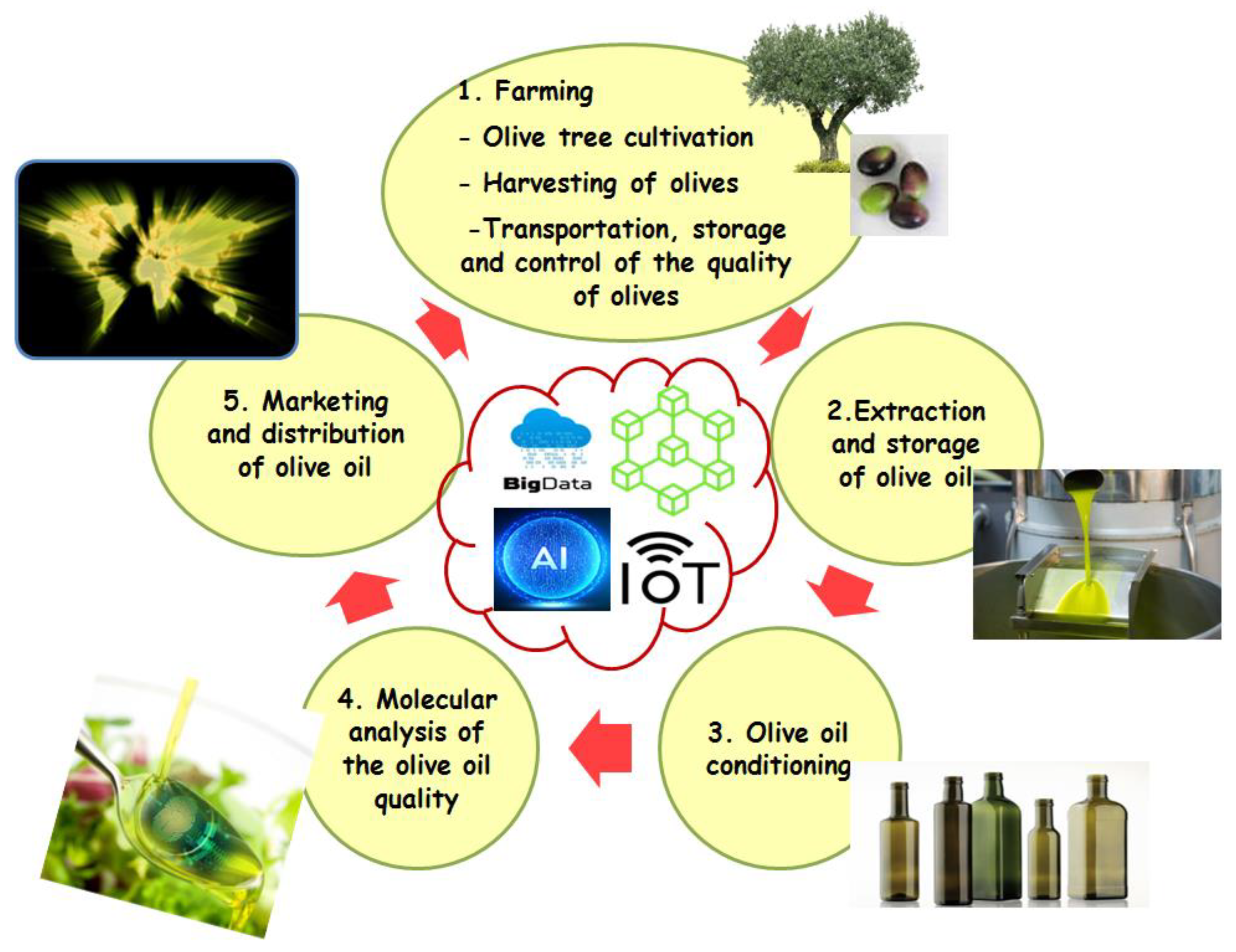

The Case of Olive Oil

4. Conclusions, Vision and Key Advice

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Agriculture: Towards 2030/2050—The 2012 Revision | Etudes Prospectives Mondiales | Organisation des Nations Unies pour L’Alimentation et L’Agriculture. Available online: http://www.fao.org/global-perspectives-studies/resources/detail/fr/c/411108/ (accessed on 7 March 2021).

- Lezoche, M.; Hernandez, J.E.; Díaz, M.D.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- The Future of Food and Agriculture | FAO | Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/publications/fofa/en/ (accessed on 8 March 2021).

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldú, F.X. The Rise of Blockchain Technology in Agriculture and Food Supply Chains. Trends Food Sci. Technol. 2019, 91, 640. [Google Scholar] [CrossRef] [Green Version]

- Chammem, N.; Issaoui, M.; De Almeida, A.I.D.; Delgado, A.M. Food Crises and Food Safety Incidents in European Union, United States, and Maghreb Area: Current Risk Communication Strategies and New Approaches. J. AOAC Int. 2018, 101, 923–938. [Google Scholar] [CrossRef]

- The Most Common Food Safety Incidents Related to Developing Countries. Available online: https://www.food-safety.com/articles/6307-the-most-common-food-safety-incidents-related-to-developing-countries (accessed on 30 March 2022).

- Vellinga, A.; Van Loock, F. The dioxin crisis as experiment to determine poultry-related campylobacter enteritis. Emerg. Infect. Dis. 2002, 8, 19–22. [Google Scholar] [CrossRef] [PubMed]

- Wilesmith, J.W.; Wells, G.A.; Cranwell, M.P.; Ryan, J.B. Bovine spongiform encephalopathy: Epidemiological studies. Vet. Rec. 1988, 123, 638–644. [Google Scholar] [CrossRef]

- Dona, A.; Arvanitoyannis, I.S. Health Risks of Genetically Modified Foods. Crit. Rev. Food Sci. Nutr. 2009, 49, 164–175. [Google Scholar] [CrossRef]

- Keatley, K.L. Controversy over genetically modified organisms: The governing laws and regulations. Qual. Assur. 2000, 8, 33–36. [Google Scholar] [CrossRef]

- Oeschger, M.P.; Silva, C.E. Genetically modified organisms in the United States: Implementation, concerns, and public perception. Adv. Biochem. Eng. Biotechnol. 2007, 107, 57–68. [Google Scholar] [CrossRef]

- Splitter, J. How A Decade Of GMO Controversy Changed The Dialogue About Food. Available online: https://www.forbes.com/sites/jennysplitter/2019/12/20/how-a-decade-of-gmo-controversy-changed-the-dialogue-about-food/ (accessed on 19 July 2021).

- Belaud, J.-P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Corallo, A.; Latino, M.E.; Menegoli, M. Agriculture 4.0: How Use Traceability Data to Tell Food Product to the Consumers. In Proceedings of the 2020 9th International Conference on Industrial Technology and Management (ICITM), Oxford, UK, 11–13 February 2020; pp. 197–201. [Google Scholar]

- Miranda, J.; Ponce, P.; Molina, A.; Wright, P. Sensing, smart and sustainable technologies for Agri-Food 4. Comput. Ind. 2019, 108, 21–36. [Google Scholar] [CrossRef]

- Espitia, A.; Rocha, N.; Ruta, M. COVID-19 and Food Protectionism: The Impact of the Pandemic and Export Restrictions on World Food Markets; Policy Research Working Papers; The World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Evenett, S.; Fiorini, M.; Fritz, J.; Hoekman, B.; Lukaszuk, P.; Rocha, N.; Ruta, M.; Santi, F.; Shingal, A. Trade Policy Responses to the COVID-19 Pandemic: Evidence from a New Dataset. VoxEU.org 2020. Available online: https://voxeu.org/article/trade-policy-responses-covid-19-pandemic-new-dataset (accessed on 18 April 2021).

- Hoekman, B.M.; Fiorini, M.; Yildirim, A. Learning from Trade Policy Responses in the COVID-19 Pandemic. 2020. Available online: https://euideas.eui.eu/2020/05/04/learning-from-trade-policy-responses-in-the-covid-19-pandemic/ (accessed on 18 April 2021).

- Fiorini, M.; Hoekman, B.M.; Yildirim, A. COVID-19: Expanding Access to Essential Supplies in a Value Chain World; CEPR Press: Washington, DC, USA, 2020; ISBN 978-1-912179-30-5. [Google Scholar]

- Hoekman, B.M.; Fiorini, M.; Yildirim, A. COVID-19: Export Controls and International Cooperation; CEPR Press: Washington, DC, USA, 2020; ISBN 978-1-912179-30-5. [Google Scholar]

- Hoekman, B.M.; Fiorini, M.; Yildirim, A. Export Restrictions: A Negative-Sum Policy Response to the COVID-19 Crisis; European University Institute: San Domenico di Fiesole, Italy, 2020. [Google Scholar]

- COVID-19 and the Food and Agriculture Sector: Issues and Policy Responses. Available online: https://www.oecd.org/coronavirus/policy-responses/covid-19-and-the-food-and-agriculture-sector-issues-and-policy-responses-a23f764b/ (accessed on 18 April 2021).

- Building a Resilient Recovery: How We Can Emerge Stronger from the COVID-19 Pandemic. Available online: http://www.oecd.org/coronavirus/en/ (accessed on 19 July 2021).

- Schmidt, L.B. The History of American Agriculture as a Field of Research. Agric. Hist. 1940, 14, 117–126. [Google Scholar]

- Gorlinski, G. (Ed.) The History of Agriculture: 1; Illustrated edition; Rosen Education Service: New York, NY, USA, 2012; ISBN 978-1-61530-919-1. [Google Scholar]

- Taylor, F.W. The Principles of Scientific Management; Dover Publications Inc.: Mineola, NY, USA, 2003; ISBN 978-0-486-29988-4. [Google Scholar]

- Why the Internet of Things Is Called Internet of Things: Definition, History, Disambiguation. IoT Analytics. 2014. Available online: https://iot-analytics.com/internet-of-things-definition/ (accessed on 19 July 2021).

- The Internet of Things | McKinsey. Available online: https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/the-internet-of-things# (accessed on 19 July 2021).

- Colizzi, L.; Caivano, D.; Ardito, C.; Desolda, G.; Castrignanò, A.; Matera, M.; Khosla, R.; Moshou, D.; Hou, K.-M.; Pinet, F.; et al. Chapter 1: Introduction to agricultural IoT. In Agricultural Internet of Things and Decision Support for Precision Smart Farming; Castrignanò, A., Buttafuoco, G., Khosla, R., Mouazen, A.M., Moshou, D., Naud, O., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 1–33. ISBN 978-0-12-818373-1. [Google Scholar]

- Chakraborty, S.; Das, P.; Pal, S. IoT Foundations and Its Application. In IoT and Analytics for Agriculture; Pattnaik, P.K., Kumar, R., Pal, S., Panda, S.N., Eds.; Springer: Singapore, 2020; pp. 51–68. ISBN 9789811391767. [Google Scholar]

- Nakamatsu, K.; Kountchev, R.; Aharari, A.; El-Bendary, N.; Hu, B. New Developments of IT, IoT and ICT Applied to Agriculture: Proceedings of ICAIT 2019; Springer: Singapore, 2020; ISBN 9789811550720. [Google Scholar]

- Violino, S.; Ortenzi, L.; Antonucci, F.; Pallottino, F.; Benincasa, C.; Figorilli, S.; Costa, C. An Artificial Intelligence Approach for Italian EVOO Origin Traceability through an Open Source IoT Spectrometer. Foods 2020, 9, 834. [Google Scholar] [CrossRef] [PubMed]

- Jellali, A.; Hachicha, W.; Aljuaid, A.M. Sustainable Configuration of the Tunisian Olive Oil Supply Chain Using a Fuzzy TOPSIS-Based Approach. Sustainability 2021, 13, 722. [Google Scholar] [CrossRef]

- Bui, V.; Nguyen, L.-H.T. Blockchain in Agri-Food Supply Chains Management: Opportunities and Challenges. In E-Business in the 21st Century; Intelligent Information Systems; World Scientific Publishing: Singapore, 2020; Volume 7, pp. 365–395. ISBN 9789811231834. [Google Scholar]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture, Tuscany, Italy, 8–9 May 2018; pp. 1–4. [Google Scholar]

- Kramer, M.; Bitsch, L.; Hanf, J. Blockchain and Its Impacts on Agri-Food Supply Chain Network Management. Sustainability 2021, 13, 2168. [Google Scholar] [CrossRef]

- LAMPARTE, A.M.G. Use of Blockchain Technologies in the Agri-Food Sector. Available online: https://ec.europa.eu/eip/agriculture/en/event/use-blockchain-technologies-agri-food-sector (accessed on 4 April 2021).

- Marchesi, L.; Mannaro, K.; Porcu, R. Automatic Generation of Blockchain Agri-food Traceability Systems. arXiv 2021, arXiv:210307315Cs. [Google Scholar]

- Motta, G.A.; Tekinerdogan, B.; Athanasiadis, I.N. Blockchain Applications in the Agri-Food Domain: The First Wave. Front. Blockchain 2020, 3, 6. [Google Scholar] [CrossRef]

- Patelli, N.; Mandrioli, M. Blockchain technology and traceability in the agrifood industry. J. Food Sci. 2020, 85, 3670–3678. [Google Scholar] [CrossRef]

- Rana, R.L.; Tricase, C.; De Cesare, L. Blockchain technology for a sustainable agri-food supply chain. Br. Food J. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Shahid, A.; Almogren, A.S.; Javaid, N.; Al-Zahrani, F.; Zuair, M.; Alam, M. Blockchain-Based Agri-Food Supply Chain: A Complete Solution. IEEE Access 2020, 8, 69230–69243. [Google Scholar] [CrossRef]

- Tripoli, M.; Schmidhuber, J. Emerging Opportunities for the Application of Blockchain in the Agri-Food Industry; FAO and ICTSD: Rome, Italy, 2018. [Google Scholar]

- Zarpelão, B.B.; Junior, S.B.; Badaró, A.T.; Barbin, D.F. 10. On the use of blockchain for agrifood traceability. In Food Authentication and Traceability; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 279–302. ISBN 978-0-12-821104-5. [Google Scholar]

- Arena, A.; Bianchini, A.; Perazzo, P.; Vallati, C.; Dini, G. BRUSCHETTA: An IoT Blockchain-Based Framework for Certifying Extra Virgin Olive Oil Supply Chain. In Proceedings of the 2019 IEEE International Conference on Smart Computing (SMARTCOMP), Washington, DC, USA, 12–15 June 2019; pp. 173–179. [Google Scholar]

- Violino, S.; Pallottino, F.; Sperandio, G.; Figorilli, S.; Ortenzi, L.; Tocci, F.; Vasta, S.; Imperi, G.; Costa, C. A Full Technological Traceability System for Extra Virgin Olive Oil. Foods 2020, 9, 624. [Google Scholar] [CrossRef]

- Guido, R.; Mirabelli, G.; Palermo, E.; Solina, V. A framework for food traceability: Case study—Italian extra-virgin olive oil supply chain. Int. J. Ind. Eng. Manag. 2020, 11, 50–60. [Google Scholar] [CrossRef]

- Big Data: What It Is and Why It Matters. Available online: https://www.sas.com/en_us/insights/big-data/what-is-big-data.html (accessed on 23 July 2021).

- Le Big Data Expliqué. Available online: https://www.mongodb.com/fr-fr/big-data-explained (accessed on 25 July 2021).

- De Mauro, A.; Greco, M.; Grimaldi, M. What is Big Data? A Consensual Definition and a Review of Key Research Topics. 2014. Available online: https://www.researchgate.net/publication/265775800_What_is_Big_Data_A_Consensual_Definition_and_a_Review_of_Key_Research_Topics (accessed on 23 July 2021).

- The Impact of the Internet of Things on Data Centers. Available online: https://www.gartner.com/en/documents/2672920/the-impact-of-the-internet-of-things-on-data-centers (accessed on 24 July 2021).

- Sicular, S. Gartner’s Big Data Definition Consists of Three Parts, Not to Be Confused with Three “V”s. 2013. Available online: https://blogs.gartner.com/svetlana-sicular/gartners-big-data-definition-consists-of-three-parts-not-to-be-confused-with-three-vs/#:~:text=Gartner’s%20Big%20Data%20Definition%20Consists,Confused%20with%20Three%20%E2%80%9CV%E2%80%9Ds&text=This%20is%20my%20article%2C%20published,one%2C%20and%20oftentimes%2C%20misunderstood. (accessed on 23 July 2021).

- BBVA The Five V’s of Big Data | BBVA. NEWS BBVA 2017. Available online: https://www.bbva.com/en/five-vs-big-data/ (accessed on 23 July 2021).

- Reilly, K. From Automata to Automation: The Birth of the Robot in R.U.R. (Rossum’s Universal Robots). In Automata and Mimesis on the Stage of Theatre History; Reilly, K., Ed.; Palgrave Macmillan: London, UK, 2011; pp. 148–176. ISBN 978-0-230-34754-0. [Google Scholar]

- Ben Ayed, R.; Hanana, M. Artificial Intelligence to Improve the Food and Agriculture Sector. J. Food Qual. 2021, 2021, e5584754. [Google Scholar] [CrossRef]

- Tzachor, A. Artificial Intelligence for Agricultural Supply Chain Risk Management: Constraints and Potentials. 2020. Available online: https://cgspace.cgiar.org/handle/10568/108709 (accessed on 18 July 2021).

- Jha, K.; Doshi, A.; Patel, P.; Shah, M. A comprehensive review on automation in agriculture using artificial intelligence. Artif. Intell. Agric. 2019, 2, 1–12. [Google Scholar] [CrossRef]

- Agriculture Trends Disrupting the Food Value Chain | McKinsey. Available online: https://www.mckinsey.com/industries/agriculture/our-insights/agriculture-sector-preparing-for-disruption-in-the-food-value-chain# (accessed on 18 April 2021).

- Ordukaya, E.; Karlik, B. Quality control of olive oils using machine learning and electronic nose. J. Food Qual. 2017, 2017, 9272404. [Google Scholar] [CrossRef] [Green Version]

- Zarezadeh, M.R.; Aboonajmi, M.; Ghasemi Varnamkhasti, M. Fraud detection and quality assessment of olive oil using ultrasound. Food Sci. Nutr. 2021, 9, 180–189. [Google Scholar] [CrossRef] [PubMed]

- Soltani, M.; Rashvand, M.; Teimouri, N.; Omid, M. Authentication of Virgin Olive Oil by Using Dielectric spectroscopy combined with Some Artificial Intelligence Methods. Agric. Eng. Int. CIGR J. 2019, 21, 224–230. [Google Scholar]

- Venturini, F.; Sperti, M.; Michelucci, U.; Herzig, I.; Baumgartner, M.; Caballero, J.P.; Jimenez, A.; Deriu, M.A. Exploration of Spanish Olive Oil Quality with a Miniaturized Low-Cost Fluorescence Sensor and Machine Learning Techniques. Foods 2021, 1000, 1010. [Google Scholar] [CrossRef]

- Asharindavida, F.; Nibouche, O.; Uhomoibhi, J.; Wang, H.; Vincent, J. Evaluation of olive oil quality using a miniature spectrometer: A machine learning approach. In Proceedings of the Sensing for Agriculture and Food Quality and Safety XIII, Online Only, 12–16 April 2021; Volume 11754, pp. 17–28. [Google Scholar]

- Violino, S.; Benincasa, C.; Taiti, C.; Ortenzi, L.; Pallottino, F.; Marone, E.; Mancuso, S.; Costa, C. AI-based hyperspectral and VOCs assessment approach to identify adulterated extra virgin olive oil. Eur. Food Res. Technol. 2021, 247, 1013–1022. [Google Scholar] [CrossRef]

- Gazeli, O.; Bellou, E.; Stefas, D.; Couris, S. Laser-based classification of olive oils assisted by machine learning. Food Chem. 2020, 302, 125329. [Google Scholar] [CrossRef]

- Gyftokostas, N.; Stefas, D.; Kokkinos, V.; Bouras, C.; Couris, S. Laser-induced breakdown spectroscopy coupled with machine learning as a tool for olive oil authenticity and geographic discrimination. Sci. Rep. 2021, 11, 5360. [Google Scholar] [CrossRef]

- Jung, J.; Maeda, M.; Chang, A.; Bhandari, M.; Ashapure, A.; Landivar-Bowles, J. The potential of remote sensing and artificial intelligence as tools to improve the resilience of agriculture production systems. Curr. Opin. Biotechnol. 2021, 70, 15–22. [Google Scholar] [CrossRef]

- Dobrota, C.T.; Carpa, R.; Butiuc-Keul, A. Analysis of designs used in monitoring crop growth based on remote sensing methods. Turk. J. Agric. For. 2021, 45, 730–742. [Google Scholar] [CrossRef]

- Anami, B.S.; Malvade, N.N.; Palaiah, S. Deep learning approach for recognition and classification of yield affecting paddy crop stresses using field images. Artif. Intell. Agric. 2020, 4, 12–20. [Google Scholar] [CrossRef]

- Kouadio, L.; Deo, R.C.; Byrareddy, V.; Adamowski, J.F.; Mushtaq, S.; Phuong Nguyen, V. Artificial intelligence approach for the prediction of Robusta coffee yield using soil fertility properties. Comput. Electron. Agric. 2018, 155, 324–338. [Google Scholar] [CrossRef]

- Köksal, E.S.; Erdem, C.; Taşan, M.; Temízel, K.E. Developing new hyperspectral vegetation indexes sensitive to yield and evapotranspiration of dry beans. Turk. J. Agric. For. 2021, 45, 743–749. [Google Scholar] [CrossRef]

- Nadafzadeh, M.; Abdanan Mehdizadeh, S. Design and fabrication of an intelligent control system for determination of watering time for turfgrass plant using computer vision system and artificial neural network. Precis. Agric. 2019, 20, 857–879. [Google Scholar] [CrossRef]

- Patrício, D.I.; Rieder, R. Computer vision and artificial intelligence in precision agriculture for grain crops: A systematic review. Comput. Electron. Agric. 2018, 153, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Sabanci, K. Detection of sunn pest-damaged wheat grains using artificial bee colony optimization-based artificial intelligence techniques. J. Sci. Food Agric. 2020, 100, 817–824. [Google Scholar] [CrossRef]

- Bolandnazar, E.; Rohani, A.; Taki, M. Energy consumption forecasting in agriculture by artificial intelligence and mathematical models. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 42, 1618–1632. [Google Scholar] [CrossRef]

- Waleed, M.; Um, T.-W.; Kamal, T.; Khan, A.; Iqbal, A. Determining the Precise Work Area of Agriculture Machinery Using Internet of Things and Artificial Intelligence. Appl. Sci. 2020, 10, 3365. [Google Scholar] [CrossRef]

- Gao, Z.; Shao, Y.; Xuan, G.; Wang, Y.; Liu, Y.; Han, X. Real-time hyperspectral imaging for the in-field estimation of strawberry ripeness with deep learning. Artif. Intell. Agric. 2020, 4, 31–38. [Google Scholar] [CrossRef]

- Partel, V.; Charan Kakarla, S.; Ampatzidis, Y. Development and evaluation of a low-cost and smart technology for precision weed management utilizing artificial intelligence. Comput. Electron. Agric. 2019, 157, 339–350. [Google Scholar] [CrossRef]

- Su, W.-H. Crop plant signaling for real-time plant identification in smart farm: A systematic review and new concept in artificial intelligence for automated weed control. Artif. Intell. Agric. 2020, 4, 262–271. [Google Scholar] [CrossRef]

- Pandey, P.K.; Pandey, V. Development of reference evapotranspiration equations using an artificial intelligence-based function discovery method under the humid climate of Northeast India. Comput. Electron. Agric. 2020, 179, 105838. [Google Scholar] [CrossRef]

- Soh, Y.W.; Koo, C.H.; Huang, Y.F.; Fung, K.F. Application of artificial intelligence models for the prediction of standardized precipitation evapotranspiration index (SPEI) at Langat River Basin, Malaysia. Comput. Electron. Agric. 2018, 144, 164–173. [Google Scholar] [CrossRef]

- Tang, D.; Feng, Y.; Gong, D.; Hao, W.; Cui, N. Evaluation of artificial intelligence models for actual crop evapotranspiration modeling in mulched and non-mulched maize croplands. Comput. Electron. Agric. 2018, 152, 375–384. [Google Scholar] [CrossRef]

- Yu, H.; Wen, X.; Li, B.; Yang, Z.; Wu, M.; Ma, Y. Uncertainty analysis of artificial intelligence modeling daily reference evapotranspiration in the northwest end of China. Comput. Electron. Agric. 2020, 176, 105653. [Google Scholar] [CrossRef]

- Shafaei, S.M.; Nourmohamadi-Moghadami, A.; Kamgar, S. Development of artificial intelligence based systems for prediction of hydration characteristics of wheat. Comput. Electron. Agric. 2016, 128, 34–45. [Google Scholar] [CrossRef]

- Favenza, A.; Imam, R.; Dovis, F.; Pini, M. Detecting water using UAV-based GNSS-Reflectometry data and Artificial Intelligence. In Proceedings of the 2019 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Portici, Italy, 24–26 October 2019; pp. 7–12. [Google Scholar]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Vij, A.; Vijendra, S.; Jain, A.; Bajaj, S.; Bassi, A.; Sharma, A. IoT and Machine Learning Approaches for Automation of Farm Irrigation System. Procedia Comput. Sci. 2020, 167, 1250–1257. [Google Scholar] [CrossRef]

- Tian, X.; Li, J.; Yi, S.; Jin, G.; Qiu, X.; Li, Y. Nondestructive determining the soluble solids content of citrus using near infrared transmittance technology combined with the variable selection algorithm. Artif. Intell. Agric. 2020, 4, 48–57. [Google Scholar] [CrossRef]

- Partel, V.; Nunes, L.; Stansly, P.; Ampatzidis, Y. Automated vision-based system for monitoring Asian citrus psyllid in orchards utilizing artificial intelligence. Comput. Electron. Agric. 2019, 162, 328–336. [Google Scholar] [CrossRef]

- Tewari, V.K.; Pareek, C.M.; Lal, G.; Dhruw, L.K.; Singh, N. Image processing based real-time variable-rate chemical spraying system for disease control in paddy crop. Artif. Intell. Agric. 2020, 4, 21–30. [Google Scholar] [CrossRef]

- Cruz, A.; Ampatzidis, Y.; Pierro, R.; Materazzi, A.; Panattoni, A.; De Bellis, L.; Luvisi, A. Detection of grapevine yellows symptoms in Vitis vinifera L. with artificial intelligence. Comput. Electron. Agric. 2019, 157, 63–76. [Google Scholar] [CrossRef]

- Cruz, A.C.; Luvisi, A.; De Bellis, L.; Ampatzidis, Y. X-FIDO: An Effective Application for Detecting Olive Quick Decline Syndrome with Deep Learning and Data Fusion. Front. Plant Sci. 2017, 8, 1741. [Google Scholar] [CrossRef]

- Özden, C. Apple leaf disease detection and classification based on transfer learning. Turk. J. Agric. For. 2021, 45, 775–783. [Google Scholar] [CrossRef]

- Alkan, A.; Abdullah, M.U.; Abdullah, H.O.; Assaf, M.; Zhou, H. A smart agricultural application: Automated detection of diseases in vine leaves using hybrid deep learning. Turk. J. Agric. For. 2021, 45, 717–729. [Google Scholar] [CrossRef]

- Lou, S.; Mo, L.; Zhou, J.; Wang, Y.; He, W. Supply and Demand Forecasting of Water Resource Coupling System in Upstream Yangtze River under Changing Environmental Conditions. Water 2021, 13, 640. [Google Scholar] [CrossRef]

- Singh, V.K.; Singh, B.P.; Kisi, O.; Kushwaha, D.P. Spatial and multi-depth temporal soil temperature assessment by assimilating satellite imagery, artificial intelligence and regression based models in arid area. Comput. Electron. Agric. 2018, 150, 205–219. [Google Scholar] [CrossRef]

- Gupta, N.; Khosravy, M.; Gupta, S.; Dey, N.; Crespo, R.G. Lightweight Artificial Intelligence Technology for Health Diagnosis of Agriculture Vehicles: Parallel Evolving Artificial Neural Networks by Genetic Algorithm. Int. J. Parallel Program. 2020, 50, 1–26. [Google Scholar] [CrossRef]

- Fei, Y.; Liu, X.; Zhao, Q.; Zhuang, Y.; Liao, G.; Fu, Q. Obstacle Detection for Agricultural Machinery Vehicle. In Proceedings of the Proceedings of the 2019 International Conference on Artificial Intelligence and Computer Science, ACM, Wuhan, China, 12–13 July 2019; pp. 126–131. [Google Scholar]

- Shafaei, S.M.; Loghavi, M.; Kamgar, S. Reliable execution of a robust soft computing workplace found on multiple neuro-fuzzy inference systems coupled with multiple nonlinear equations for exhaustive perception of tractor-implement performance in plowing process. Artif. Intell. Agric. 2019, 2, 38–84. [Google Scholar] [CrossRef]

- Raheman, K.R.; Paradkar, H.V. Design of a 4 DOF parallel robot arm and the firmware implementation on embedded system to transplant pot seedlings. Artif. Intell. Agric. 2020, 4, 172–183. [Google Scholar] [CrossRef]

- Kumar, S.P.; Tewari, V.K.; Chandel, A.K.; Mehta, C.R.; Nare, B.; Chethan, C.R.; Mundhada, K.; Shrivastava, P.; Gupta, C.; Hota, S. A fuzzy logic algorithm derived mechatronic concept prototype for crop damage avoidance during eco-friendly eradication of intra-row weeds. Artif. Intell. Agric. 2020, 4, 116–126. [Google Scholar] [CrossRef]

- Ampatzidis, Y.; Partel, V.; Meyering, B.; Albrecht, U. Citrus rootstock evaluation utilizing UAV-based remote sensing and artificial intelligence. Comput. Electron. Agric. 2019, 164, 104900. [Google Scholar] [CrossRef]

- Shadrin, D.; Menshchikov, A.; Ermilov, D.; Somov, A. Designing Future Precision Agriculture: Detection of Seeds Germination Using Artificial Intelligence on a Low-Power Embedded System. IEEE Sens. J. 2019, 19, 11573–11582. [Google Scholar] [CrossRef]

- Jiang, B.; He, J.; Yang, S.; Fu, H.; Li, T.; Song, H.; He, D. Fusion of machine vision technology and AlexNet-CNNs deep learning network for the detection of postharvest apple pesticide residues. Artif. Intell. Agric. 2019, 1, 1–8. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y.; Li, J.; Zhang, C.; Fan, S. Recent advances in emerging techniques for non-destructive detection of seed viability: A review. Artif. Intell. Agric. 2019, 1, 35–47. [Google Scholar] [CrossRef]

- Etminan, A.; Pour-Aboughadareh, A.; Mohammadi, R.; Shooshtari, L.; Yousefiazarkhanian, M.; Moradkhani, H. Determining the best drought tolerance indices using Artificial Neural Network (ANN): Insight into application of intelligent agriculture in agronomy and plant breeding. Cereal Res. Commun. 2019, 47, 170–181. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, X.; Lyu, J.; Zhi, Y.; Chen, F.; Wang, L.; Liu, C.; Zhou, S. Carbon sequestration and emissions mitigation in paddy fields based on the DNDC model: A review. Artif. Intell. Agric. 2020, 4, 140–149. [Google Scholar] [CrossRef]

- Yigit, E.; Sabanci, K.; Toktas, A.; Kayabasi, A. A study on visual features of leaves in plant identification using artificial intelligence techniques. Comput. Electron. Agric. 2019, 156, 369–377. [Google Scholar] [CrossRef]

- Okinda, C.; Nyalala, I.; Korohou, T.; Okinda, C.; Wang, J.; Achieng, T.; Wamalwa, P.; Mang, T.; Shen, M. A review on computer vision systems in monitoring of poultry: A welfare perspective. Artif. Intell. Agric. 2020, 4, 184–208. [Google Scholar] [CrossRef]

- Santangeli, A.; Chen, Y.; Kluen, E.; Chirumamilla, R.; Tiainen, J.; Loehr, J. Integrating drone-borne thermal imaging with artificial intelligence to locate bird nests on agricultural land. Sci. Rep. 2020, 10, 10993. [Google Scholar] [CrossRef] [PubMed]

- Rohani, A.; Taki, M.; Bahrami, G. Application of artificial intelligence for separation of live and dead rainbow trout fish eggs. Artif. Intell. Agric. 2019, 1, 27–34. [Google Scholar] [CrossRef]

- Gebremedhin, S.; Bruneel, S.; Getahun, A.; Anteneh, W.; Goethals, P. Scientific Methods to Understand Fish Population Dynamics and Support Sustainable Fisheries Management. Water 2021, 13, 574. [Google Scholar] [CrossRef]

- Jaafari, A.; Zenner, E.K.; Panahi, M.; Shahabi, H. Hybrid artificial intelligence models based on a neuro-fuzzy system and metaheuristic optimization algorithms for spatial prediction of wildfire probability. Agric. For. Meteorol. 2019, 266–267, 198–207. [Google Scholar] [CrossRef]

- Güllüce, Y.; Çelik, R.N. FireAnalyst: An effective system for detecting fire geolocation and fire behavior in forests using mathematical modeling. Turk. J. Agric. For. 2020, 44, 127–139. [Google Scholar] [CrossRef]

- Schikowski, A.B.; Corte, A.P.D.; Ruza, M.S.; Sanquetta, C.R.; Montaño, R.A.N.R. Modeling of stem form and volume through machine learning. An. Acad. Bras. Ciênc. 2018, 90, 3389–3401. [Google Scholar] [CrossRef]

- Anggraeni, W.; Mahananto, F.; Rofiq, M.A.; Andri, K.B.; Sumaryanto; Zaini, Z.; Subriadi, A.P. Agricultural Strategic Commodity Price Forecasting Using Artificial Neural Network. In Proceedings of the 2018 International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 21–22 November 2018; pp. 347–352. [Google Scholar]

- Guo, H.; Woodruff, A.; Yadav, A. Improving Lives of Indebted Farmers Using Deep Learning: Predicting Agricultural Produce Prices Using Convolutional Neural Networks. Proc. AAAI Conf. Artif. Intell. 2020, 34, 13294–13299. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, S. Input-output Analysis of Agricultural Economic Benefits Based on Big Data and Artificial Intelligence. J. Phys. Conf. Ser. 2020, 1574, 012121. [Google Scholar] [CrossRef]

- Elijah, O.; Philomena, K.; Joseph, T.; Nwajinka, C.; Ohale, P. Evaluation of optimization techniques in predicting optimum moisture content reduction in drying potato slices. Artif. Intell. Agric. 2020, 4, 39–47. [Google Scholar] [CrossRef]

- Agu, C.M.; Menkiti, M.C.; Ekwe, E.B.; Agulanna, A.C. Modeling and optimization of Terminalia catappa L. kernel oil extraction using response surface methodology and artificial neural network. Artif. Intell. Agric. 2020, 4, 1–11. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhu, W.-Y.; Ji, Z.-T. Comparison of veracity and application of different CFD turbulence models for refrigerated transport. Artif. Intell. Agric. 2019, 3, 11–17. [Google Scholar] [CrossRef]

- Aouadi, B.; Zaukuu, J.-L.Z.; Vitális, F.; Bodor, Z.; Fehér, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical Evolution and Food Control Achievements of Near Infrared Spectroscopy, Electronic Nose, and Electronic Tongue-Critical Overview. Sensors 2020, 20, 5479. [Google Scholar] [CrossRef] [PubMed]

- Minaev, G.; Müller, P.; Salminen, K.; Rantala, J.; Surakka, V.; Visa, A. A Comparison of Various Algorithms for Classification of Food Scents Measured with an Ion Mobility Spectrometry. Sensors 2021, 21, 361. [Google Scholar] [CrossRef] [PubMed]

- Sipos, L.; Végh, R.; Bodor, Z.; Zaukuu, J.-L.Z.; Hitka, G.; Bázár, G.; Kovacs, Z. Classification of Bee Pollen and Prediction of Sensory and Colorimetric Attributes—A Sensometric Fusion Approach by e-Nose, e-Tongue and NIR. Sensors 2020, 20, 6768. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liao, S. Quality Control Framework of Big Data for Early Warning of Agricultural Meteorological Disasters. In Proceedings of the 2019 International Conference on Artificial Intelligence and Computer Science, Wuhan, China, 12–13 July 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 74–78. [Google Scholar]

- Ayed, R.B.; Grati-Kamoun, N.; Moreau, F.; Rebaï, A. Comparative study of microsatellite profiles of DNA from oil and leaves of two Tunisian olive cultivars. Eur. Food Res. Technol. 2009, 229, 757–762. [Google Scholar] [CrossRef]

- Kane, D.; Hellberg, R. Identification of Species in Ground Meat Products Sold on the U.S. Commercial Market Using DNA-Based Methods. Food Control 2016, 59, 158–163. [Google Scholar] [CrossRef]

- Chang, C.-H.; Lin, H.-Y.; Ren, Q.; Lin, Y.-S.; Shao, K.-T. DNA barcode identification of fish products in Taiwan: Government-commissioned authentication cases. Food Control 2016, 66, 38–43. [Google Scholar] [CrossRef]

- Xiong, X.; Yuan, F.; Huang, M.; Lu, L.; Xiong, X.; Wen, J. DNA Barcoding Revealed Mislabeling and Potential Health Concerns with Roasted Fish Products Sold across China. J. Food Prot. 2019, 82, 1200–1209. [Google Scholar] [CrossRef]

- Silletti, S.; Morello, L.; Gavazzi, F.; Gianì, S.; Braglia, L.; Breviario, D. Untargeted DNA-based methods for the authentication of wheat species and related cereals in food products. Food Chem. 2018, 271, 410–418. [Google Scholar] [CrossRef]

- Gonzalvez, A.; Armenta, S.; de la Guardia, M. Trace-element composition and stable-isotope ratio for discrimination of foods with Protected Designation of Origin. TrAC Trends Anal. Chem. 2009, 28, 1295–1311. [Google Scholar] [CrossRef]

- Del Coco, L.; Schena, F.P.; Fanizzi, F.P. 1H nuclear magnetic resonance study of olive oils commercially available as Italian products in the United States of America. Nutrients 2012, 4, 343–355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Janin, M.; Medini, S.; Técher, I. Methods for PDO olive oils traceability: State of art and discussion about the possible contribution of strontium isotopic tool. Eur. Food Res. Technol. 2014, 5, 745–754. [Google Scholar] [CrossRef] [Green Version]

- Perri, E.; Benincasa, C.; Muzzalupo, I. Olive Oil Traceability; IntechOpen: London, UK, 2012; ISBN 978-953-51-0883-2. [Google Scholar]

- Girelli, C.R.; Del Coco, L.; Zelasco, S.; Salimonti, A.; Conforti, F.L.; Biagianti, A.; Barbini, D.; Fanizzi, F.P. Traceability of “Tuscan PGI” Extra Virgin Olive Oils by 1H NMR Metabolic Profiles Collection and Analysis. Metabolites 2018, 8, 60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rongai 13C NMR Analysis for the Geographical Characterization of Extra Virgin Olive Oil (EVOO) Produced in Some Italian Regions. Available online: https://www.semanticscholar.org/paper/13C-NMR-Analysis-for-the-Geographical-of-Extra-Oil-Rongai/d7c221ea4a006f8accff7d6c2798aa525a1b64ca (accessed on 22 March 2022).

- Alonso-Salces, R.; Moreno-Rojas, J.M.; Holland, M.V.; Guillou, C. Authentication of Virgin Olive Oil Using NMR and Isotopic Fingerprinting; Nova Science Publishers: Hauppauge, NY, USA, 2011; pp. 1–60. [Google Scholar]

- Petrakis, P.V.; Agiomyrgianaki, A.; Christophoridou, S.; Spyros, A.; Dais, P. Geographical characterization of greek virgin olive oils (cv. Koroneiki) using 1H and 31P NMR fingerprinting with canonical discriminant analysis and classification binary trees. J. Agric. Food Chem. 2008, 56, 3200–3207. [Google Scholar] [CrossRef]

- Girelli, C.R.; Calò, F.; Angilè, F.; Mazzi, L.; Barbini, D.; Fanizzi, F.P. 1H NMR Spectroscopy to Characterize Italian Extra Virgin Olive Oil Blends, Using Statistical Models and Databases Based on Monocultivar Reference Oils. Foods 2020, 9, 1797. [Google Scholar] [CrossRef]

- Gradišek, A.; Cifelli, M.; Ancora, D.; Sepe, A.; Zalar, B.; Apih, T.; Domenici, V. Analysis of Extra Virgin Olive Oils from Two Italian Regions by Means of Proton Nuclear Magnetic Resonance Relaxation and Relaxometry Measurements. J. Agric. Food Chem. 2021, 69, 12073–12080. [Google Scholar] [CrossRef]

- Calò, F.; Girelli, C.R.; Wang, S.C.; Fanizzi, F.P. Geographical Origin Assessment of Extra Virgin Olive Oil via NMR and MS Combined with Chemometrics as Analytical Approaches. Foods 2022, 11, 113. [Google Scholar] [CrossRef]

- Ben Ayed, R.; Kallel, I.; Ben Hassen, H.; Rebai, A. SNP marker analysis for validating the authenticity of Tunisian olive oil. J. Genet. 2014, 93, e148–e154. [Google Scholar] [CrossRef]

- Pasqualone, A.; Caponio, F.; Blanco, A. Inter-simple sequence repeat DNA markers for identification of drupes from different Olea europaea L. cultivars. Eur. Food Res. Technol. 2001, 213, 240–243. [Google Scholar] [CrossRef]

- Muzzalupo, I.; Perri, E. Recovery and characterisation of DNA from virgin olive oil. Eur. Food Res. Technol. 2002, 214, 528–531. [Google Scholar] [CrossRef] [Green Version]

- Pafundo, S.; Agrimonti, C.; Marmiroli, N. Traceability of plant contribution in olive oil by amplified fragment length polymorphisms. J. Agric. Food Chem. 2005, 53, 6995–7002. [Google Scholar] [CrossRef] [PubMed]

- Testolin, R.; Lain, O. DNA Extraction from Olive Oil and PCR Amplification of Microsatellite Markers. J. Food Sci. 2005, 70, C108–C112. [Google Scholar] [CrossRef]

- Muzzalupo, I.; Pellegrino, M.; Perri, E. Detection of DNA in virgin olive oils extracted from destoned fruits. Eur. Food Res. Technol. 2007, 224, 469–475. [Google Scholar] [CrossRef]

- Rallo, P.; Dorado, G.; Martín, A. Development of simple sequence repeats (SSRs) in olive tree (Olea europaea L.). Theor. Appl. Genet. 2000, 101, 984–989. [Google Scholar] [CrossRef]

- Diaz, A.; Martín, A.; Rallo, P.; Diego, B.; de la Rosa, R. Self-incompatibility of ‘Arbequina’ and ‘Picual’ Olive Assessed by SSR Markers. J. Am. Soc. Hortic. Sci. 2006, 131, 250–255. [Google Scholar] [CrossRef] [Green Version]

- Mookerjee, S.; Guerin, J.; Collins, G.; Ford, C.; Sedgley, M. Paternity analysis using microsatellite markers to identify pollen donors in an olive grove. TAG Theor. Appl. Genet. Theor. Angew. Genet. 2005, 111, 1174–1182. [Google Scholar] [CrossRef]

- Ben Ayed, R.; Ben Hassen, H.; Ennouri, K.; Ben Marzoug, R.; Rebai, A. OGDD (Olive Genetic Diversity Database): A microsatellite markers’ genotypes database of worldwide olive trees for cultivar identification and virgin olive oil traceability. Database J. Biol. Databases Curation 2016, 2016, bav090. [Google Scholar] [CrossRef] [Green Version]

- Pasqualone, A.; Montemurro, C.; Caponio, F.; Blanco, A. Identification of virgin olive oil from different cultivars by analysis of DNA microsatellites. J. Agric. Food Chem. 2004, 52, 1068–1071. [Google Scholar] [CrossRef]

- Doveri, S.; Gil, F.; Diaz, A.; Reale, S.; Busconi, M.; Machado, A.; Martín, A.; Fogher, C.; Donini, P.; Lee, D. Standardization of a set of microsatellite markers for use in cultivar identification studies in olive (Olea europaea L.). Sci. Hortic. 2008, 116, 367–373. [Google Scholar] [CrossRef]

- Busconi, M.; Foroni, C.; Corradi, M.; Bongiorni, C.; Cattapan, F.; Fogher, C. DNA extraction from olive oil and its use in the identification of the production cultivar. Food Chem. 2003, 83, 127–134. [Google Scholar] [CrossRef]

| Technology | Challenges | ||

|---|---|---|---|

| Social | Organizational | Technological | |

| IoT |

|

|

|

| Blockchain |

|

|

|

| BD |

|

|

|

| AI |

|

| |

| DNA Marker Technologies | Advantages | Limits | References |

|---|---|---|---|

| Random Amplified Polymorphic DNA (RAPD) | The Polymerase Chain Reaction (PCR) is realized by using short primers (8–12 nucleotides) and amplifying random segments of DNA. | Very sensitive to DNA concentration and amplification conditions. Lack of reproducibility. | [143,144] |

| Amplified Fragment Length Polymorphism (AFLP) | AFLP is possible with a smaller quantity of the genomic template. As restriction sites are present across the entire genome of an individual, which allows the AFLP marker to analyze multiple loci at once. | Inconsistent results and unreliable AFLP profiles. AFLP cannot be performed with poor quality DNA or degraded DNA. As AFLP are dominant markers in nature, they cannot detect homozygous or heterozygous individuals. | [145] |

| Simple Sequence Repeats (SSRs) | Codominant, multi-allelic and highly abundant in the genomes of eukaryotes. High discriminatory power between the varieties. The results are highly reproducible, but this depends on the quality of DNA as the input. | The extraction of DNA from a liquid lipid matrix. The selection of appropriate molecular markers that can lead to significant results. | [126,142,143,144,145,146,147,148,149,150,151,152,153] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Ayed, R.; Hanana, M.; Ercisli, S.; Karunakaran, R.; Rebai, A.; Moreau, F. Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil. Plants 2022, 11, 1230. https://doi.org/10.3390/plants11091230

Ben Ayed R, Hanana M, Ercisli S, Karunakaran R, Rebai A, Moreau F. Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil. Plants. 2022; 11(9):1230. https://doi.org/10.3390/plants11091230

Chicago/Turabian StyleBen Ayed, Rayda, Mohsen Hanana, Sezai Ercisli, Rohini Karunakaran, Ahmed Rebai, and Fabienne Moreau. 2022. "Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil" Plants 11, no. 9: 1230. https://doi.org/10.3390/plants11091230

APA StyleBen Ayed, R., Hanana, M., Ercisli, S., Karunakaran, R., Rebai, A., & Moreau, F. (2022). Integration of Innovative Technologies in the Agri-Food Sector: The Fundamentals and Practical Case of DNA-Based Traceability of Olives from Fruit to Oil. Plants, 11(9), 1230. https://doi.org/10.3390/plants11091230