The Impact of the Thermal Comfort Models on the Prediction of Building Energy Consumption

Abstract

:1. Introduction

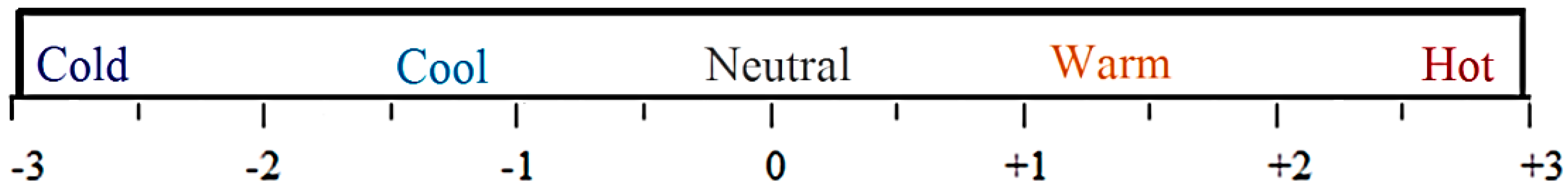

- The predicted mean vote (PMV) and the predicted percentage dissatisfied (PPD) models, which are also adopted by Comité European de Normalization (CEN) and by International Standardization Organization (ISO) standards.

- Adaptive thermal comfort models.

2. Methodology

2.1. The Mathematics Behind PMV

- ta: Air temperature [°C]

- V: Relative air velocity inside the room [m/s]

- fcl: Clothing factor, accounting for the relative increase in the clothed body surface over that of the unclothed body

- Icl: Clothing insulation [clo]

- Rcl: Clothing thermal insulation (m2 K/W)

- hc: Convective heat transfer coefficient (W/m2)

- e: 10

- W: External work (assumed = 0 W/m2)

- tr: Mean radiant temperature [°C]

- Met: Metabolic index [58.2 W/m2] or [met]

- tcl: Surface temperature of clothing [°C]

- pa: Partial pressure of water [KPa].

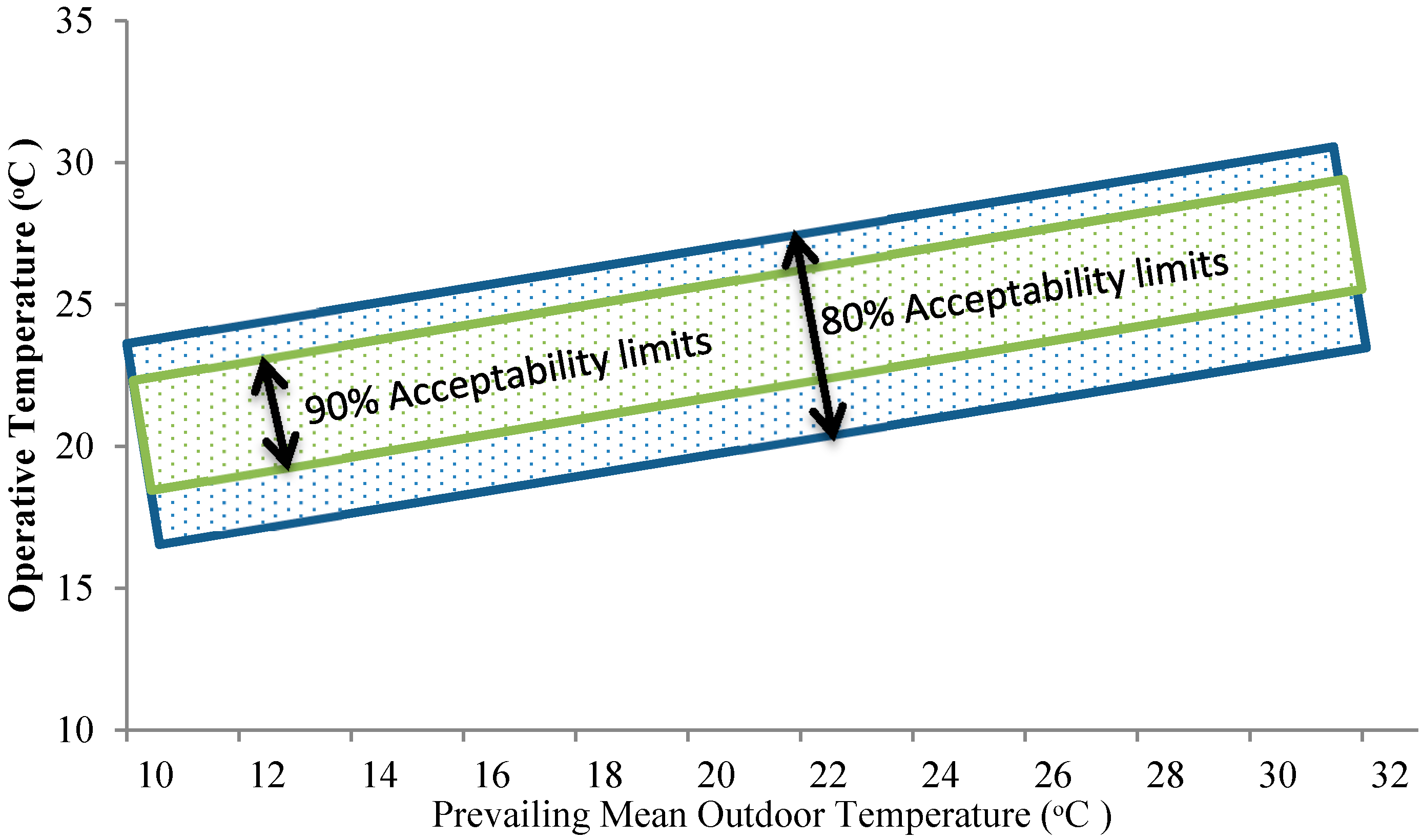

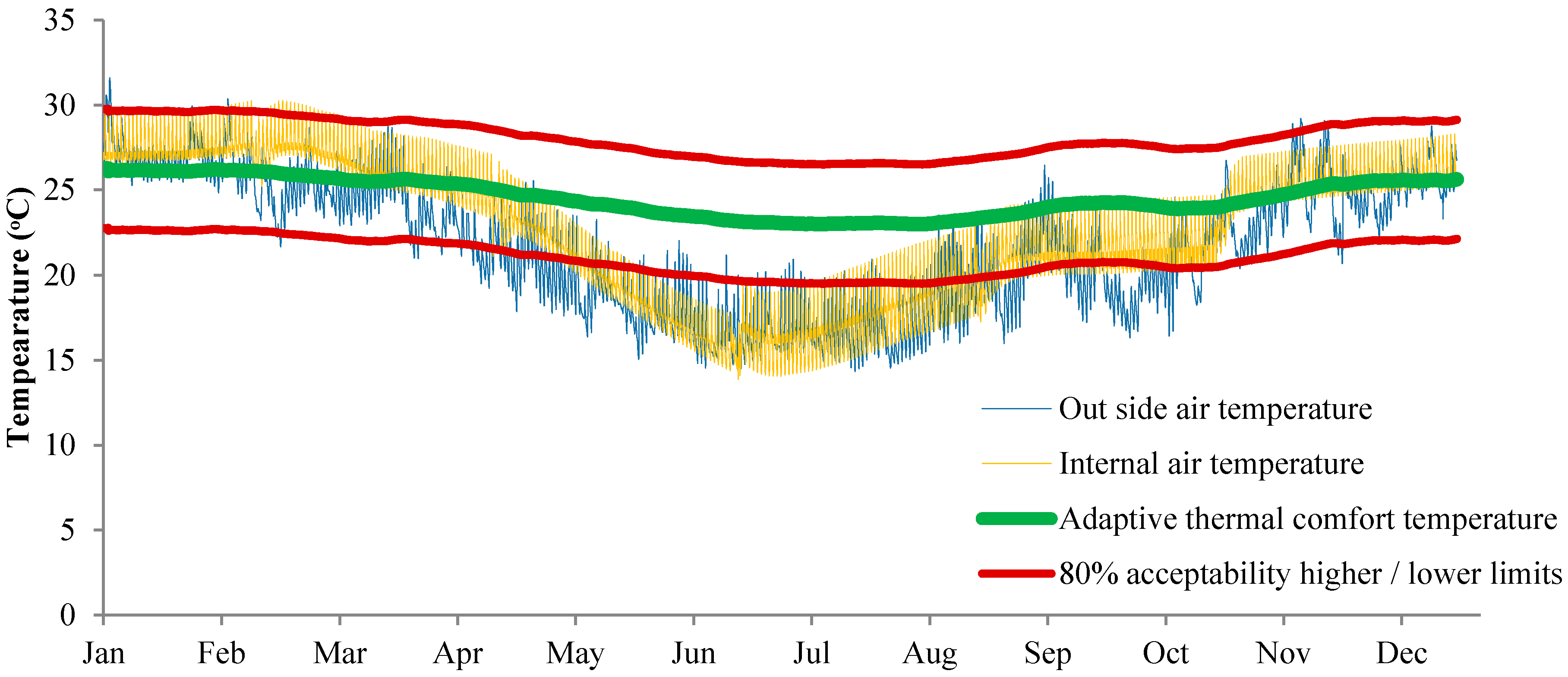

2.2. Adaptive Thermal Comfort

- To: The average of the outdoor air temperature for the previous 30 days (°C).

- Tc: Comfortable temperature (°C).

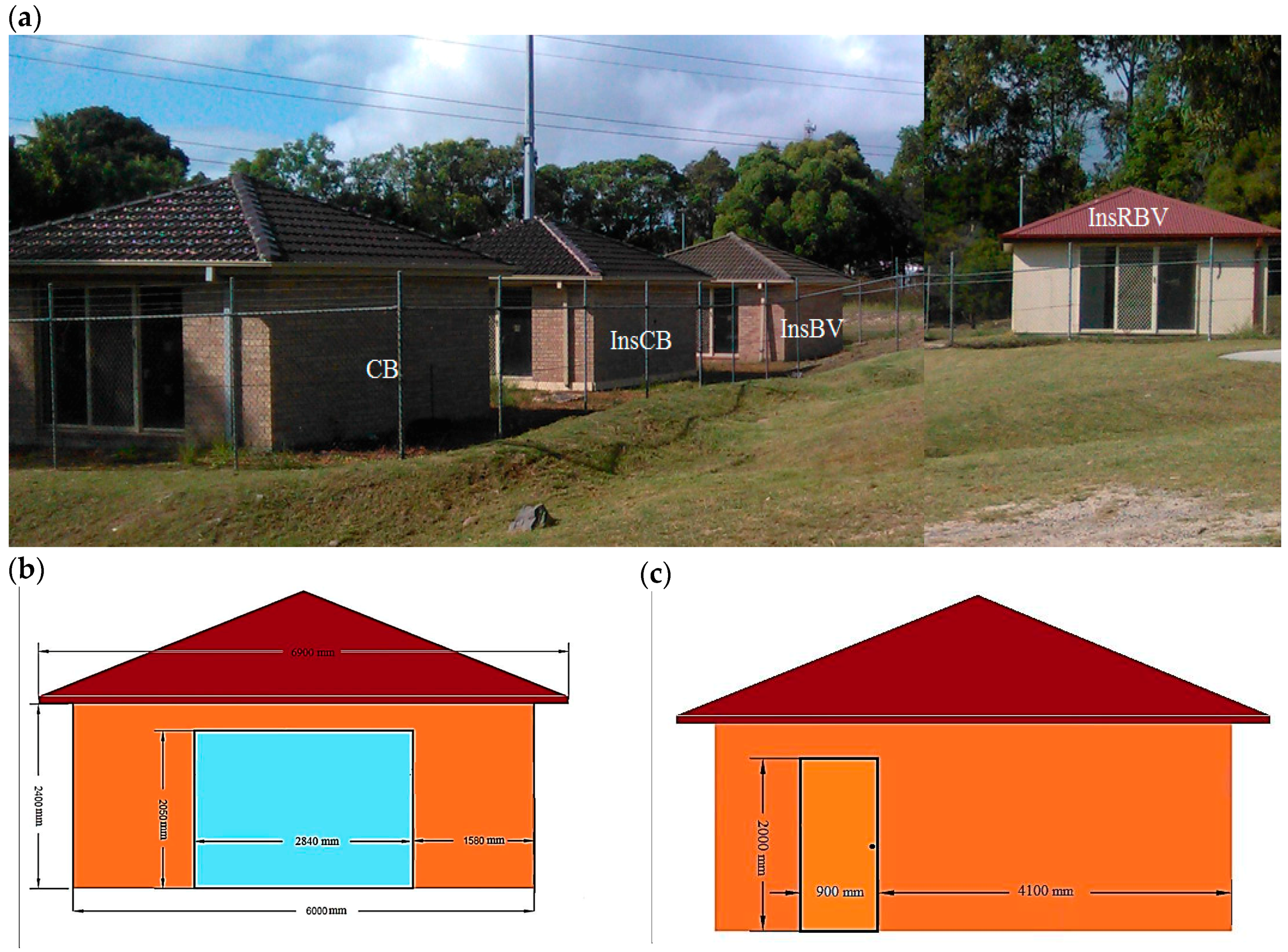

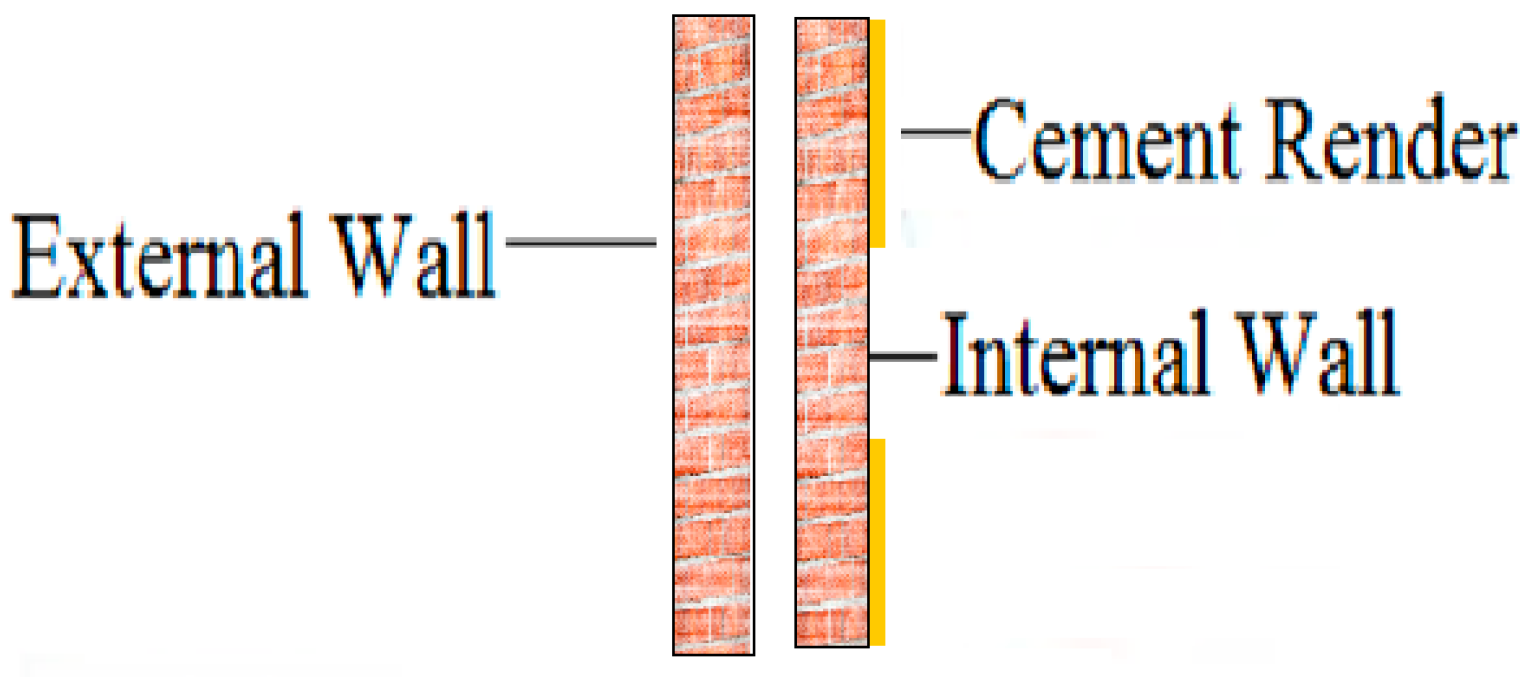

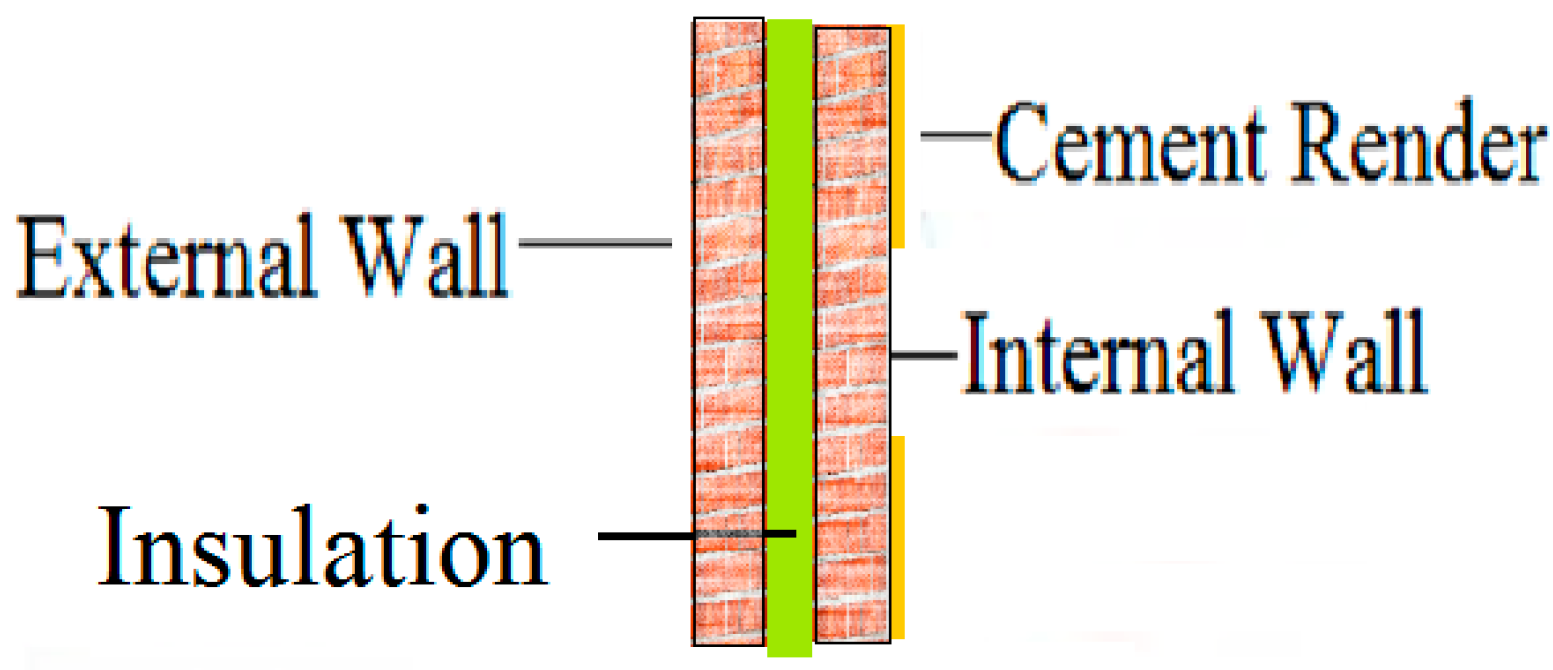

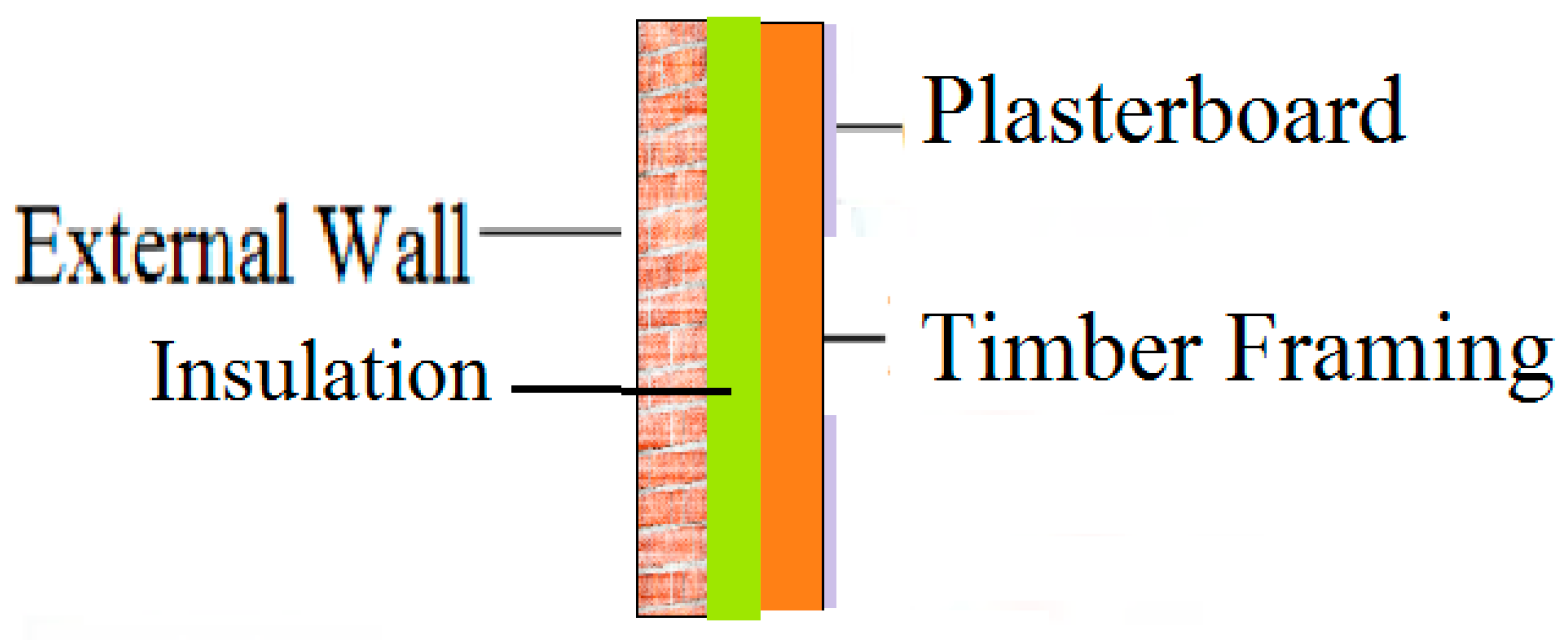

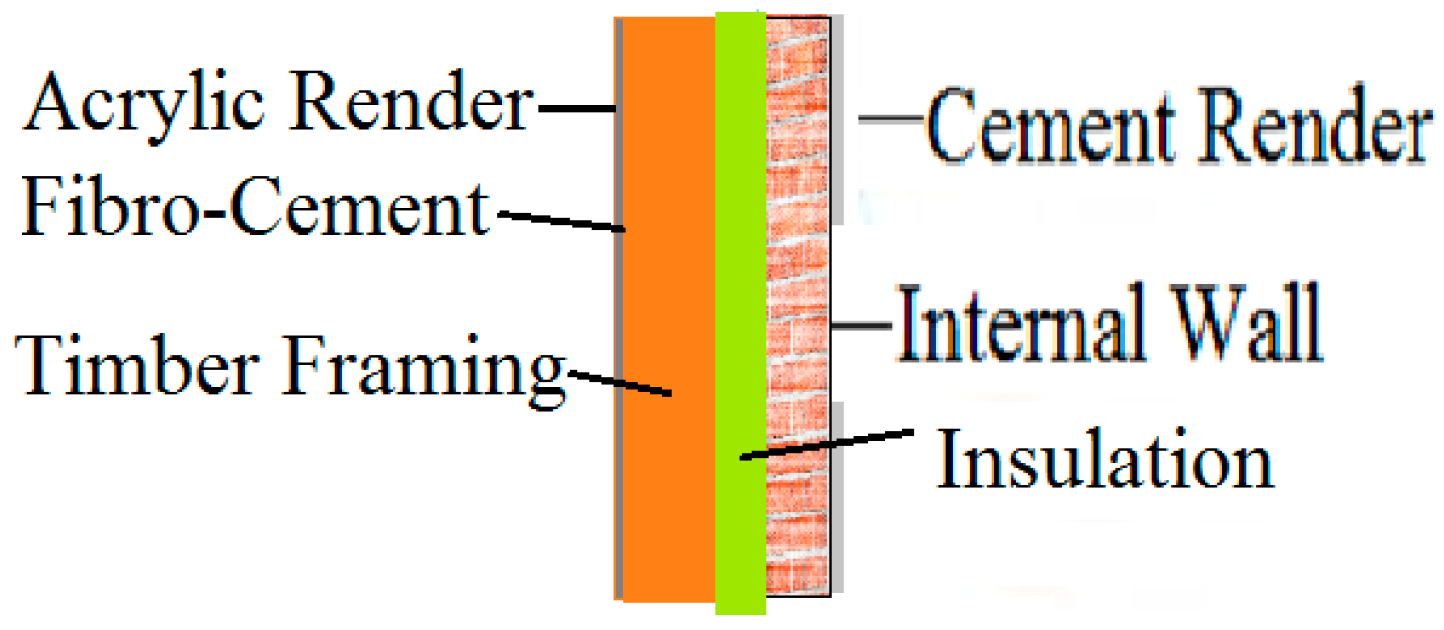

2.3. Full-Scale Test Modules

- Door; heavily insulated door in the southern wall, to eliminate any heat losses and allow easy access to the module.

- Window; in the northern wall of each module is a 6.38-mm laminated clear glass window, in a light-colored aluminum frame.

- Roof; 10 mm plasterboard ceiling with R3.5 glass wool batt insulation (thermal resistance of 3.5 m2·K/W) between rafters. Concrete and clay tiled roof with sarking insulation.

- Slab; concrete covers the whole building floor, with 100-mm thickness.

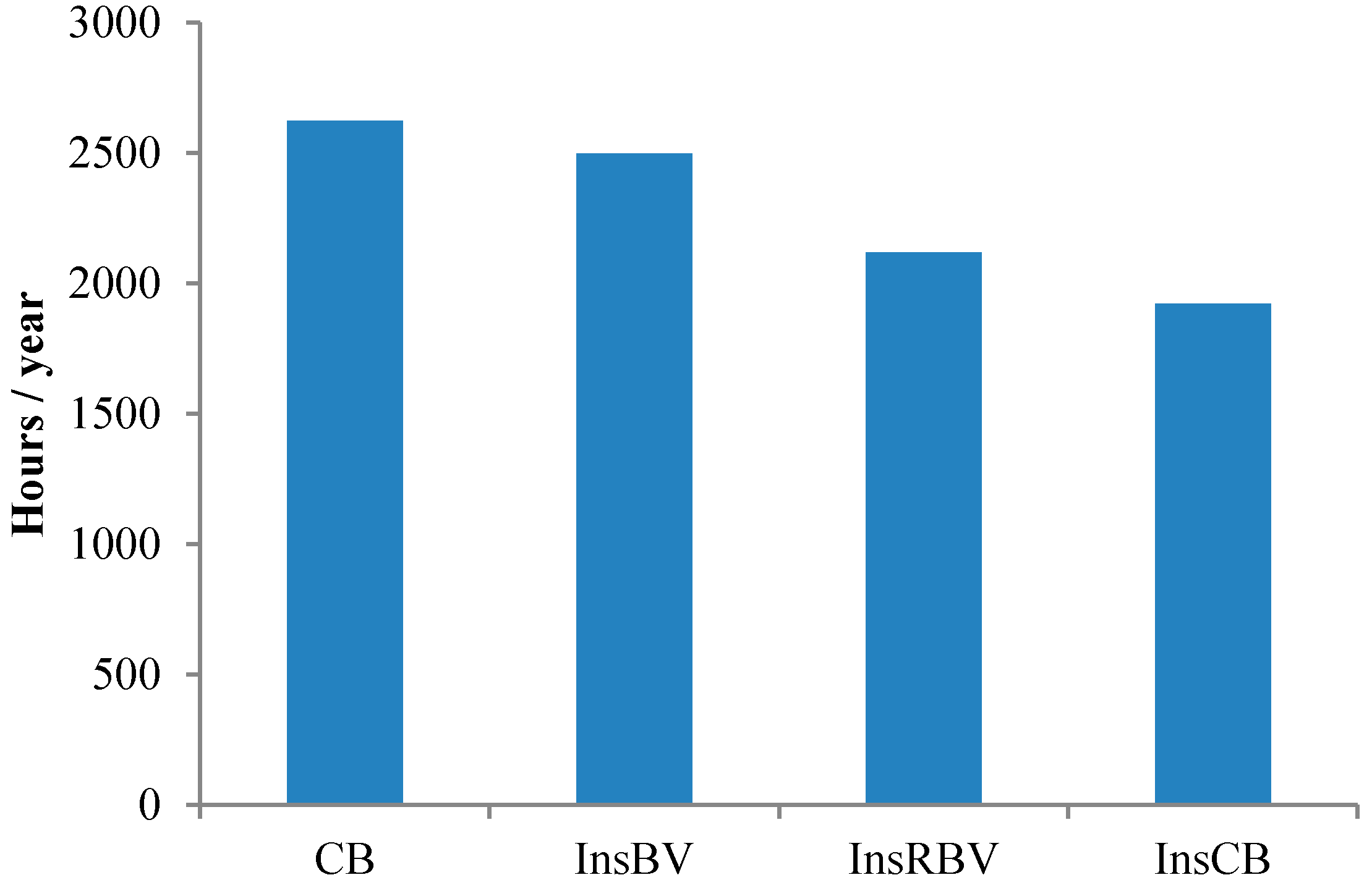

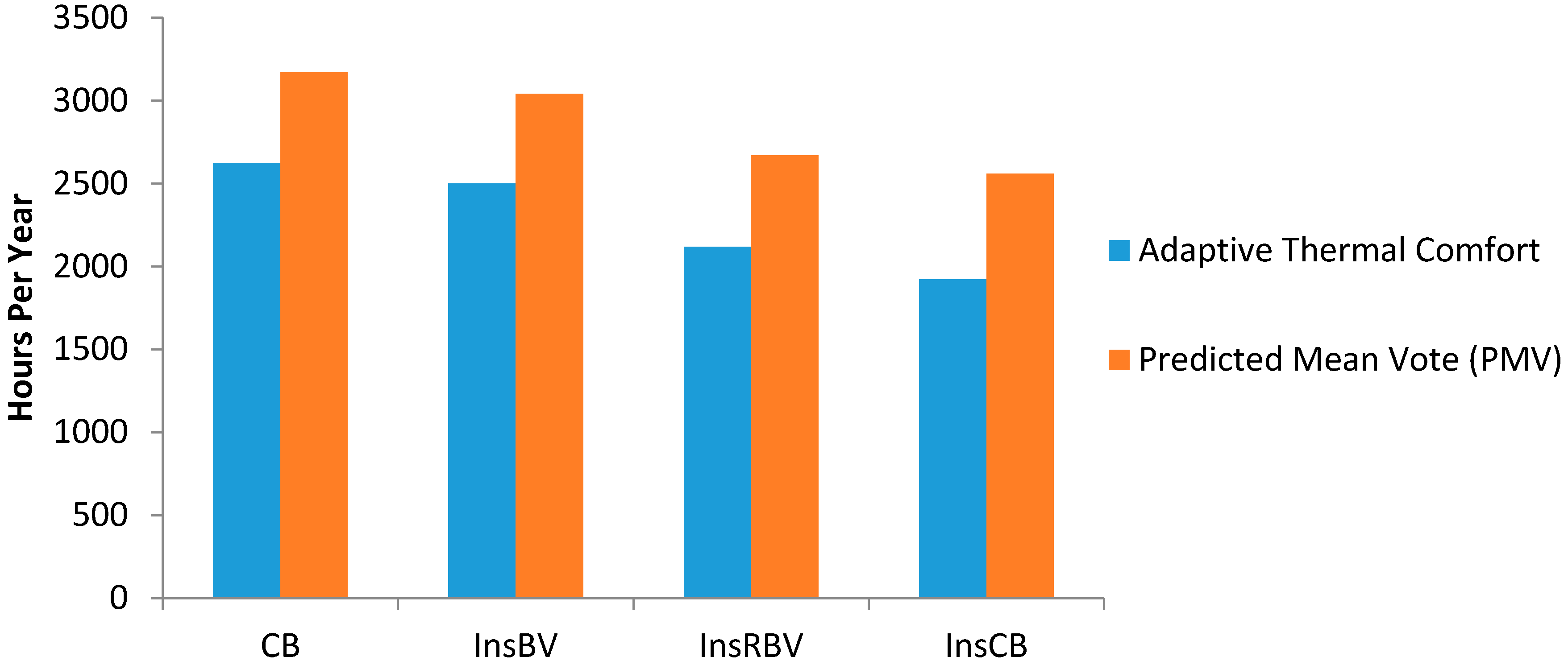

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Office of Energy Efficiency & Renewable Energy (EERE). Buildings Energy Data Book; US Department of Energy: Washington, DC, USA, 2009.

- Maleviti, E.; Wehrmeyer, W.; Mulugetta, Y. An Empirical Assessment to Express the Variability of Buildings’ Energy Consumption. Int. J. Energy Optim. Eng. 2013, 2, 55–67. [Google Scholar] [CrossRef]

- Yao, R.; Costanzo, V.; Li, X.; Zhang, Q.; Li, B. The effect of passive measures on thermal comfort and energy conservation. A case study of the hot summer and cold winter climate in the Yangtze River region. J. Build. Eng. 2018, 15, 298–310. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Ruano, A.E.; Silva, S.; Conceicao, E.Z.E. Neural networks based predictive control for thermal comfort and energy savings in public buildings. Energy Build. 2012, 55, 238–251. [Google Scholar] [CrossRef] [Green Version]

- Yun, G.Y. Influences of perceived control on thermal comfort and energy use in buildings. Energy Build. 2018, 158, 822–830. [Google Scholar] [CrossRef]

- d’Ambrosio Alfano, F.R.; Olesen, B.W.; Palella, B.I.; Riccio, G. Thermal comfort: Design and Assessment of Energy Saving. Energy Build. 2014, 81, 326–336. [Google Scholar] [CrossRef]

- Yang, W.; Moon, H.J. Cross-modal effects of noise and thermal conditions on indoor environmental perception and speech recognition. Appl. Acoust. 2018, 141, 1–8. [Google Scholar] [CrossRef]

- De Dear, R.; Brager, G.S. Developing an Adaptive Model of Thermal Comfort and Preference; American Society of Heating, Refrigerating and Air-Conditioning Engineers: New York, NY, USA, 1998; Volume 104. [Google Scholar]

- Parsons, K. Human Thermal Environments: The effects of Hot, Moderate, and Cold Environments on Human Health, Comfort, and Performance; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- ASHRAE Handbook. Fundamentals; American society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2009; Available online: http://shop.iccsafe.org/media/wysiwyg/material/8950P217-toc.pdf (accessed on 9 October 2017).

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.156.01.0075.01.ENG&toc=OJ:L:2018:156:FULL (accessed on 29 September 2018).

- Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/buildings (accessed on 30 September 2018).

- EN 15251: 2007 Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics.

- Olesen, B.W. Revision of EN 15251: Indoor environmental criteria. REHVA J. 2012, 49, 6–12. [Google Scholar]

- Moore, T.; Ridley, I.; Strengers, Y.; Maller, C.; Horne, R. Dwelling performance and adaptive summer comfort in low-income Australian households. Build. Res. Inf. 2016, 45, 443–456. [Google Scholar] [CrossRef]

- Jorissen, F.; Himpe, E.; Picard, D.; Buso, T.; Laverge, J.; Boydens, W.; Helsen, L. hybridGEOTABS project-MPC for controlling the power of the ground by integration. REHVA Eur. HVAC J. 2018, 55, 58–64. [Google Scholar]

- Zuhaib, S.; Manton, R.; Griffin, C.; Goggins, J. An Indoor Environmental Quality (IEQ) assessment of a partially-retrofitted university building. Build. Environ. 2018, 139, 49–85. [Google Scholar] [CrossRef]

- Ricciardi, P.; Buratti, C. Environmental quality of university classrooms: Subjective and objective evaluation of the thermal, acoustic, and lighting comfort conditions. Build. Environ. 2018, 127, 23–36. [Google Scholar] [CrossRef]

- ISO. ISO 17772-1—Energy performance of Buildings—Indoor Environmental Quality—Part 1: Indoor Environmental Input Parameters for the Design and Assessment of Energy Performance of Buildings. 2017. Available online: https://www.iso.org/standard/60498.html (accessed on 30 September 2018).

- International Standardization Organization. ISO 7730. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort; International Standardization Organization: Geneva, Switzerland, 2005. [Google Scholar]

- Van Hoof, J. Forty years of Fanger’s model of thermal comfort: Comfort for all? Indoor Air 2008, 18, 182–201. [Google Scholar] [CrossRef] [PubMed]

- Nicol, J.F.; Humphreys, M.A. Adaptive thermal comfort and sustainable thermal standards for buildings. Energy Build. 2002, 34, 563–572. [Google Scholar] [CrossRef]

- Wu, T.; Cao, B.; Zhu, Y. A field study on thermal comfort and air-conditioning energy use in an office building in Guangzhou. Energy Build. 2018, 168, 428–437. [Google Scholar] [CrossRef]

- Mora, R.; Bean, R. Thermal Comfort: Designing for People. ASHRAE J. 2018, 60, 40–46. [Google Scholar]

- ASHRAE. Thermal environmental conditions for human occupancy. In ANSI/ASHRAE Standard 55; American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2017. [Google Scholar]

- ASHRAE. Guideline 10-2016—Interactions Affecting the Achievement of Acceptable Indoor Environments; American Society of Heating, Refrigerating and Air Conditioning: Atlanta, GA, USA, 2016. [Google Scholar]

- d’Ambrosio Alfano, F.R.; Olesen, B.W.; Palella, B.I.; Riccio, G. Povl Ole Fanger’s impact ten years later. Energy Build. 2017, 152, 243–249. [Google Scholar] [CrossRef]

- Soebarto, V.; Bennetts, H. Thermal comfort and occupant responses during summer in a low to middle income housing development in South Australia. Build. Environ. 2014, 75, 19–29. [Google Scholar] [CrossRef]

- De Dear, R.J.; Brager, G.S.; Reardon, J.; Nicol, F. Developing an adaptive model of thermal comfort and preference/discussion. ASHRAE Trans. 1998, 104, 145. [Google Scholar]

- Nicol, F.; Humphreys, M. Derivation of the adaptive equations for thermal comfort in free-running buildings in European standard EN15251. Build. Environ. 2010, 45, 11–17. [Google Scholar] [CrossRef]

- Ren, Z.; Chen, D. Modelling study of the impact of thermal comfort criteria on housing energy use in Australia. Appl. Energy 2018, 210, 152–166. [Google Scholar] [CrossRef]

- Hwang, R.L.; Lin, T.P.; Kuo, N.J. Field experiments on thermal comfort in campus classrooms in Taiwan. Energy Build. 2006, 38, 53–62. [Google Scholar] [CrossRef]

- Fanger, P.O. The effect of air humidity in buildings on man’s comfort and health. In Proceedings of the CISCO-ITBTP Seminar Humidity in Building, Saint Remy les Chevreuse, France, November 1982. [Google Scholar]

- Fanger, P.O. Air humidity, comfort and health. In Proceedings of the IIR Commission E1, Paris, France, 1983; pp. 192–195. [Google Scholar]

- Fanger, P.O.; Toftum, J. Extension of the PMV model to non-air-conditioned buildings in warm climates. Energy Build. 2002, 34, 533–536. [Google Scholar] [CrossRef]

- Moujalled, B.; Cantin, R.; Guarracino, G. Comparison of thermal comfort algorithms in naturally ventilated office buildings. Energy Build. 2008, 40, 2215–2223. [Google Scholar] [CrossRef]

- Holopainen, R.; Tuomaala, P.; Hernandez, P.; Häkkinen, T.; Piira, K.; Piippo, J. Comfort assessment in the context of sustainable buildings: Comparison of simplified and detailed human thermal sensation methods. Build. Environ. 2014, 71, 60–70. [Google Scholar] [CrossRef]

- Ji, W.; Cao, B.; Luo, M.; Zhu, Y. Influence of short-term thermal experience on thermal comfort evaluations: A climate chamber experiment. Build. Environ. 2017, 114, 246–256. [Google Scholar] [CrossRef]

- Castaño-Rosa, R.; Rodríguez-Jiménez, C.; Rubio-Bellido, C. Adaptive Thermal Comfort Potential in Mediterranean Office Buildings: A Case Study of Torre Sevilla. Sustainability 2018, 10, 3091. [Google Scholar] [CrossRef]

- Human Thermal Comfort Sustainability Workshop. Available online: sustainabilityworkshop.autodesk.com/buildings/human-thermal-comfort#sthash.sQcMOvnS.dpuf (accessed on 27 September 2017).

- Bureau of Meteorology Australia, Newcastle University Weather Station for Humidity, Site Number: 061390. Available online: http://www.bom.gov.au/climate/averages/tables/cw_061390.shtml (accessed on 28 September 2017).

- CEAE, Engineering Center. Predicting Thermal Comfort. University of Colorado at Boulder. Civil, Environmental, and Architectural Engineering ECCE 246, 428 UCB. Available online: http://ceae.colorado.edu/~brandem/aren3050/docs/ThermalComfort.pdf (accessed on 28 September 2017).

- Albatayneh, A.; Alterman, D.; Page, A.W.; Moghtaderi, B. Warming issues associated with the long term simulation of housing using cfd analysis. J. Green Build. 2016, 11, 57–74. [Google Scholar] [CrossRef]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. The significance of time step size in simulating the thermal performance of buildings. Adv. Res. 2015, 5, 1–12. [Google Scholar] [CrossRef]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. Assessment of the Thermal Performance of Complete Buildings Using Adaptive Thermal Comfort. Procedia-Soc. Behav. Sci. 2016, 216, 655–661. [Google Scholar] [CrossRef]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. The Significance of Temperature Based Approach Over the Energy Based Approaches in the Buildings Thermal Assessment. Environ. Clim. Technol. 2017, 19, 39–50. [Google Scholar] [CrossRef] [Green Version]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. Thermal Assessment of Buildings Based on Occupants Behavior and the Adaptive Thermal Comfort Approach. Energy Procedia 2017, 115, 265–271. [Google Scholar] [CrossRef]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. Discrepancies in Peak Temperature Times using Prolonged CFD Simulations of Housing Thermal Performance. Energy Procedia 2017, 115, 253–264. [Google Scholar] [CrossRef]

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. Temperature versus energy based approaches in the thermal assessment of buildings. Energy Procedia 2017, 128, 46–50. [Google Scholar] [CrossRef]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. The role of measurement accuracy on the thermal environment assessment by means of PMV index. Build. Environ. 2011, 46, 1361–1369. [Google Scholar] [CrossRef]

- Walikewitz, N.; Jänicke, B.; Langner, M.; Meier, F.; Endlicher, W. The difference between the mean radiant temperature and the air temperature within indoor environments: A case study during summer conditions. Build. Environ. 2015, 84, 151–161. [Google Scholar] [CrossRef]

- Tyler, H.; Stefano, S.; Alberto, P.; Dustin, M.; Kyle, S. CBE Thermal Comfort Tool. Center for the Built Environment, University of California Berkeley. 2013. Available online: http://cbe.berkeley.edu/comforttool (accessed on 28 September 2017).

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. Notes on the calculation of the PMV index by means of apps. Energy Procedia 2016, 101, 249–256. [Google Scholar] [CrossRef]

- Pieroni, A.; Iazeolla, G. Engineering QoS and Energy Saving in the Delivery of ICT Services. In Sustaining Power Resources through Energy Optimization and Engineering; IGI Global: Hershey, PA, USA, 2016; pp. 208–226. [Google Scholar]

| Parameter | Unit | Range of PMV/PPD (ISO Standard 7730) | Note |

|---|---|---|---|

| Metabolic rate | Met (W/m2) | 0.8–4.0 | 1 for seated and 1.7 for cooking |

| Clothing insulation | Clo (m2 K/W) | 0.0–2.0 | 0.5 for the hot days and 1.3 for the cold |

| Mean radiant temperature | °C | 10.0–30.0 | Close to the outside air temperature |

| Air temperature | °C | 10.0–30.0 | Recorded inside each module |

| Air velocity | m/s | 0.0–1.0 | Main driver for air is natural circulation |

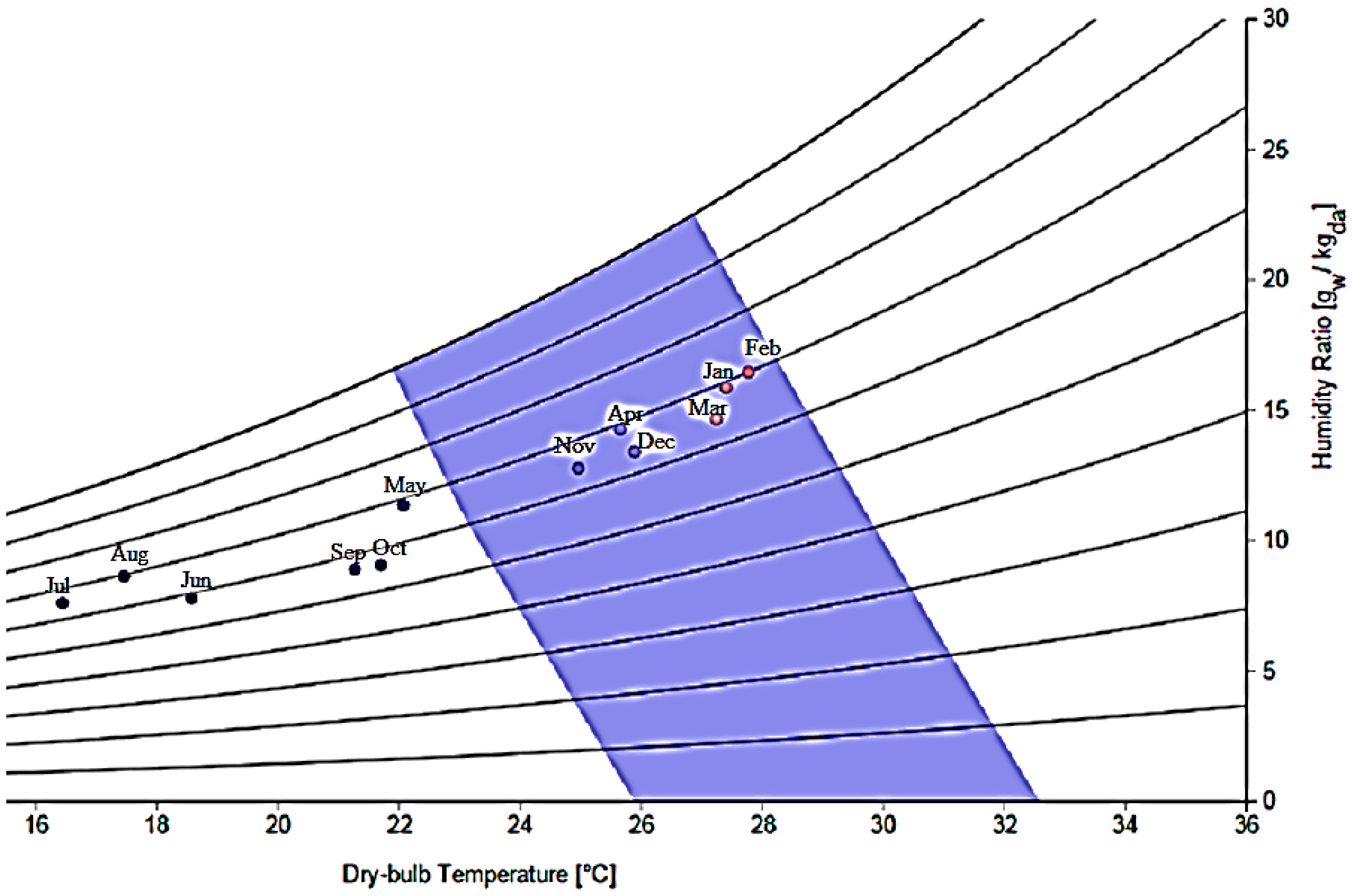

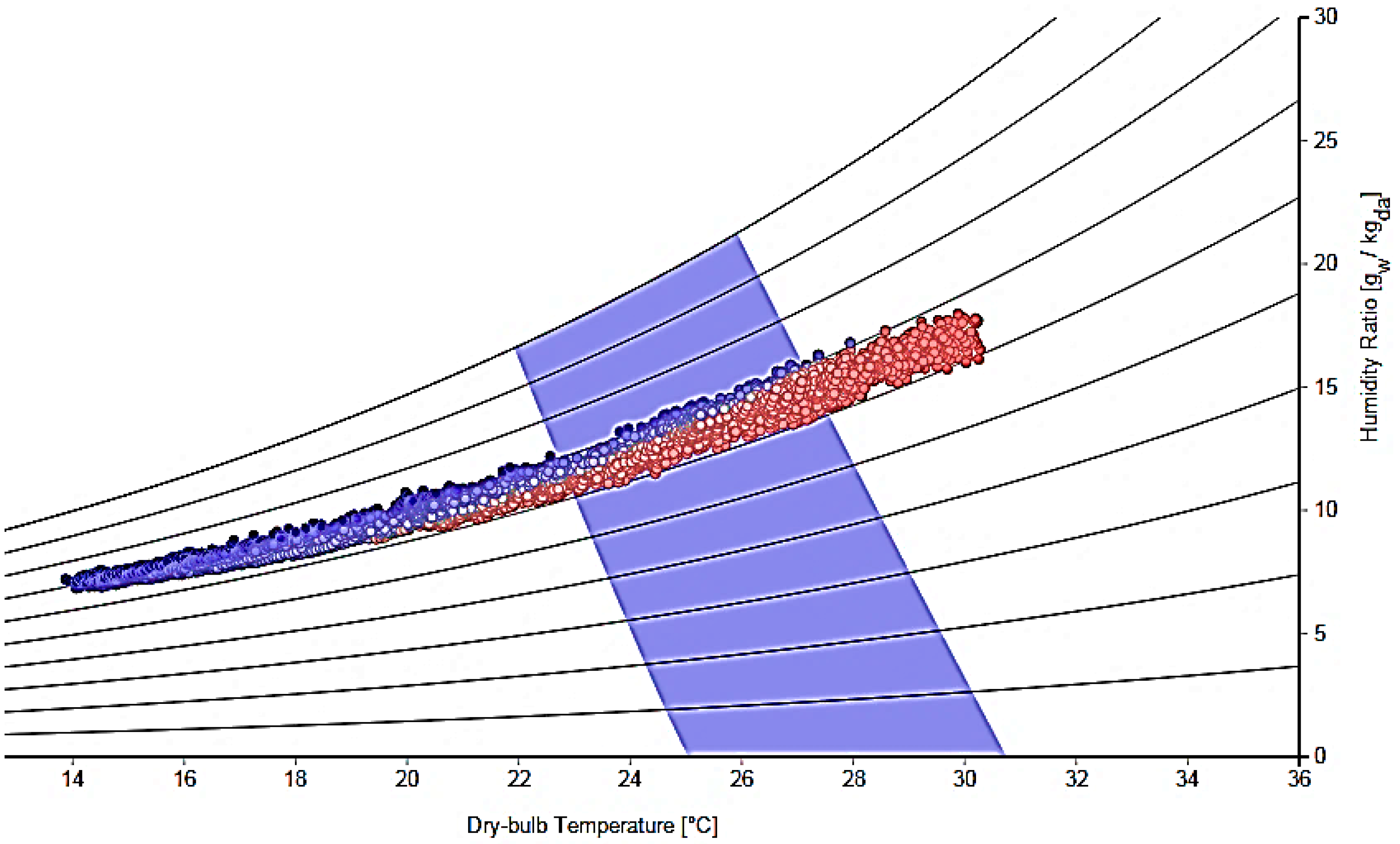

| Air humidity | % | 55–80 | Recorded at 9 a.m. and 3 p.m. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. The Impact of the Thermal Comfort Models on the Prediction of Building Energy Consumption. Sustainability 2018, 10, 3609. https://doi.org/10.3390/su10103609

Albatayneh A, Alterman D, Page A, Moghtaderi B. The Impact of the Thermal Comfort Models on the Prediction of Building Energy Consumption. Sustainability. 2018; 10(10):3609. https://doi.org/10.3390/su10103609

Chicago/Turabian StyleAlbatayneh, Aiman, Dariusz Alterman, Adrian Page, and Behdad Moghtaderi. 2018. "The Impact of the Thermal Comfort Models on the Prediction of Building Energy Consumption" Sustainability 10, no. 10: 3609. https://doi.org/10.3390/su10103609