Automobile Tires’ High-Carbon Steel Wire

Definition

1. Introduction

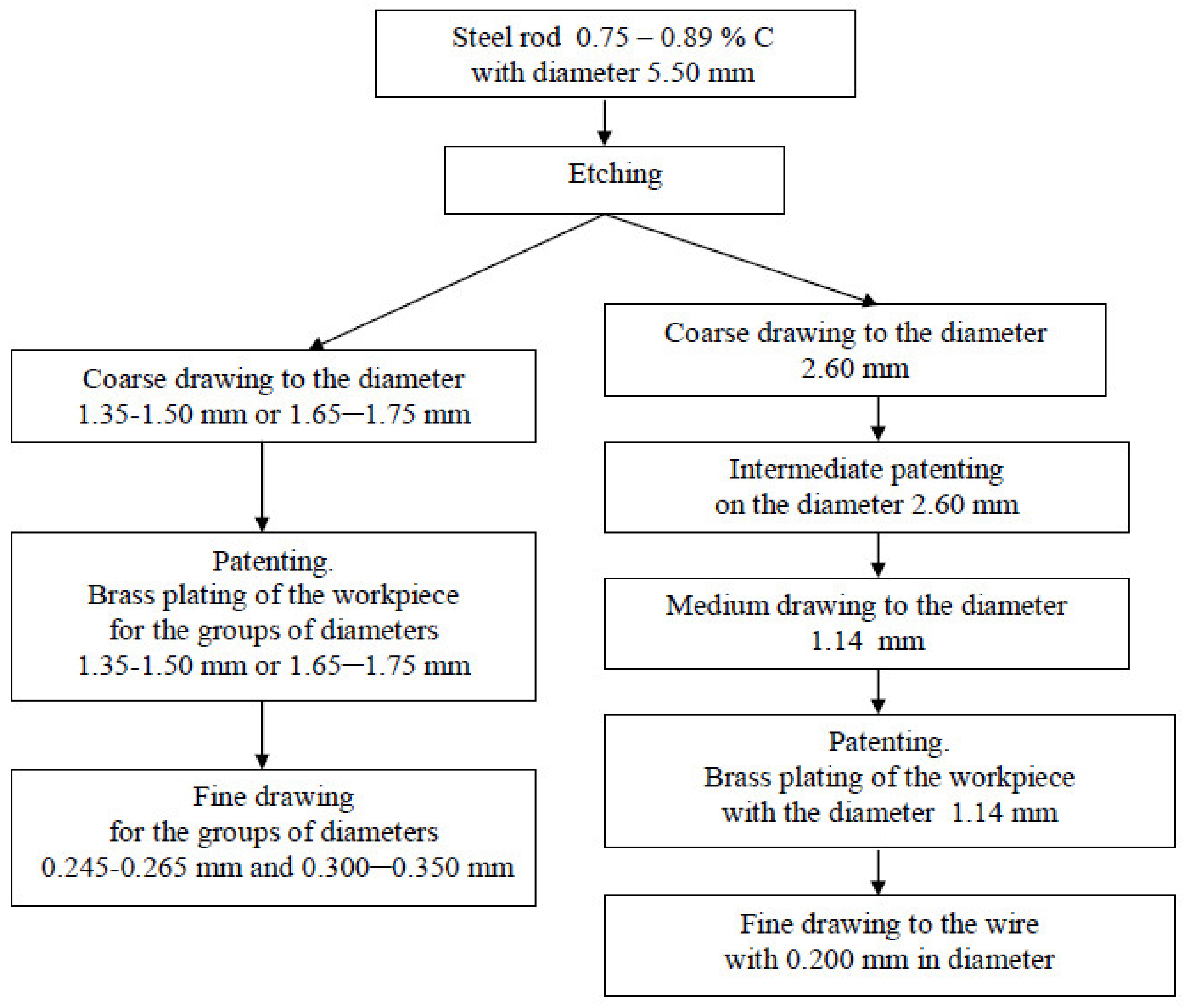

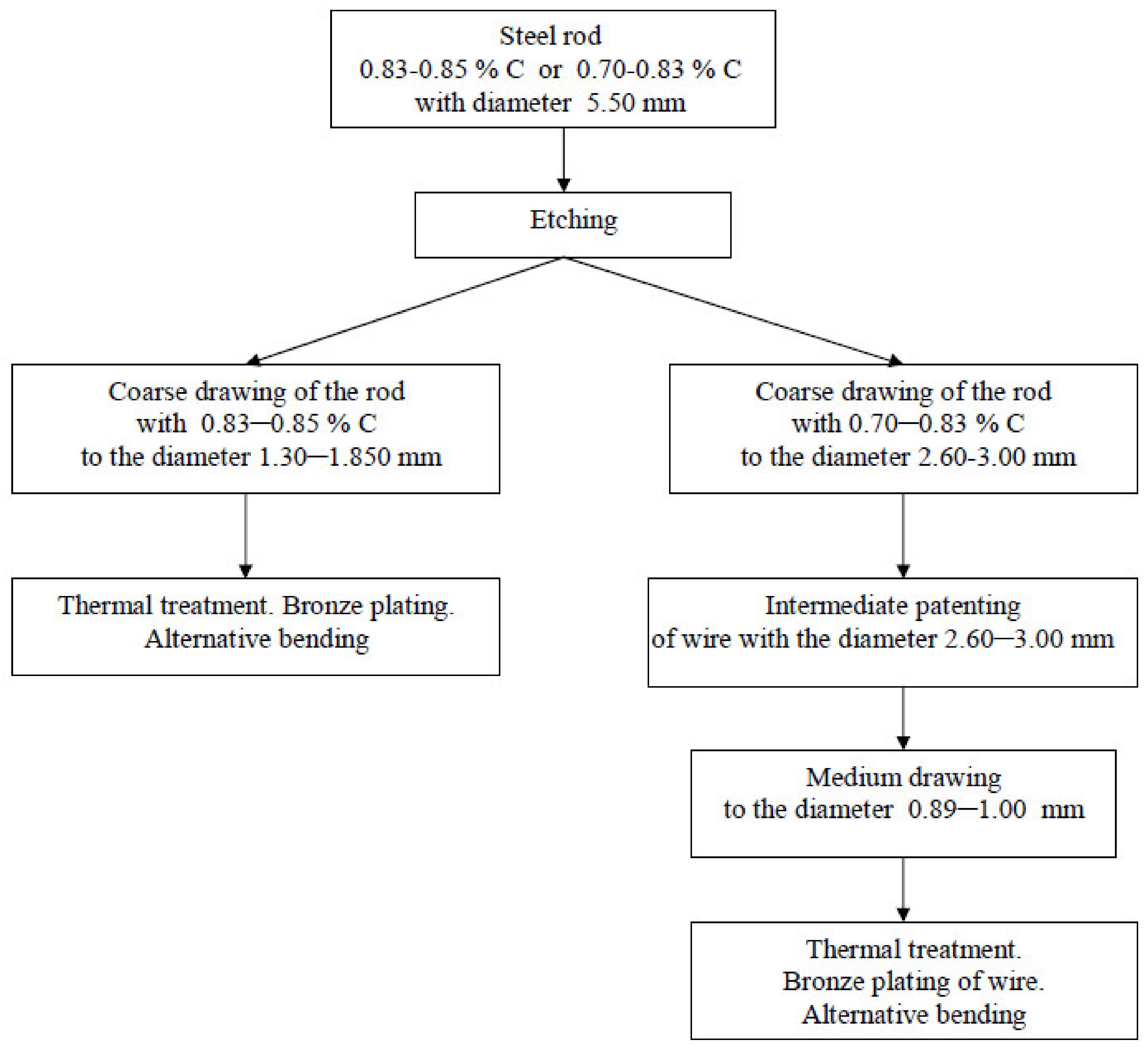

2. Structure, Role, and Demands of the Technological Process of High-Carbon Steel Wire Manufacturing

- -

- surface preparation and “rough-medium” drawing of sorbitized wire rod;

- -

- patenting of cold deformed workpiece. Patenting can be a transitory operation used for the formation of the final properties of the wire;

- -

- brass plating to ensure the adhesion of the metal cord to rubber;

- -

- finishing drawing;

- -

- laying of the metal cord;

- -

- annealing, processing in alternative deformation (if necessary for bead rings of tires).

2.1. Steel Rod for High-Strength Wire Manufacturing

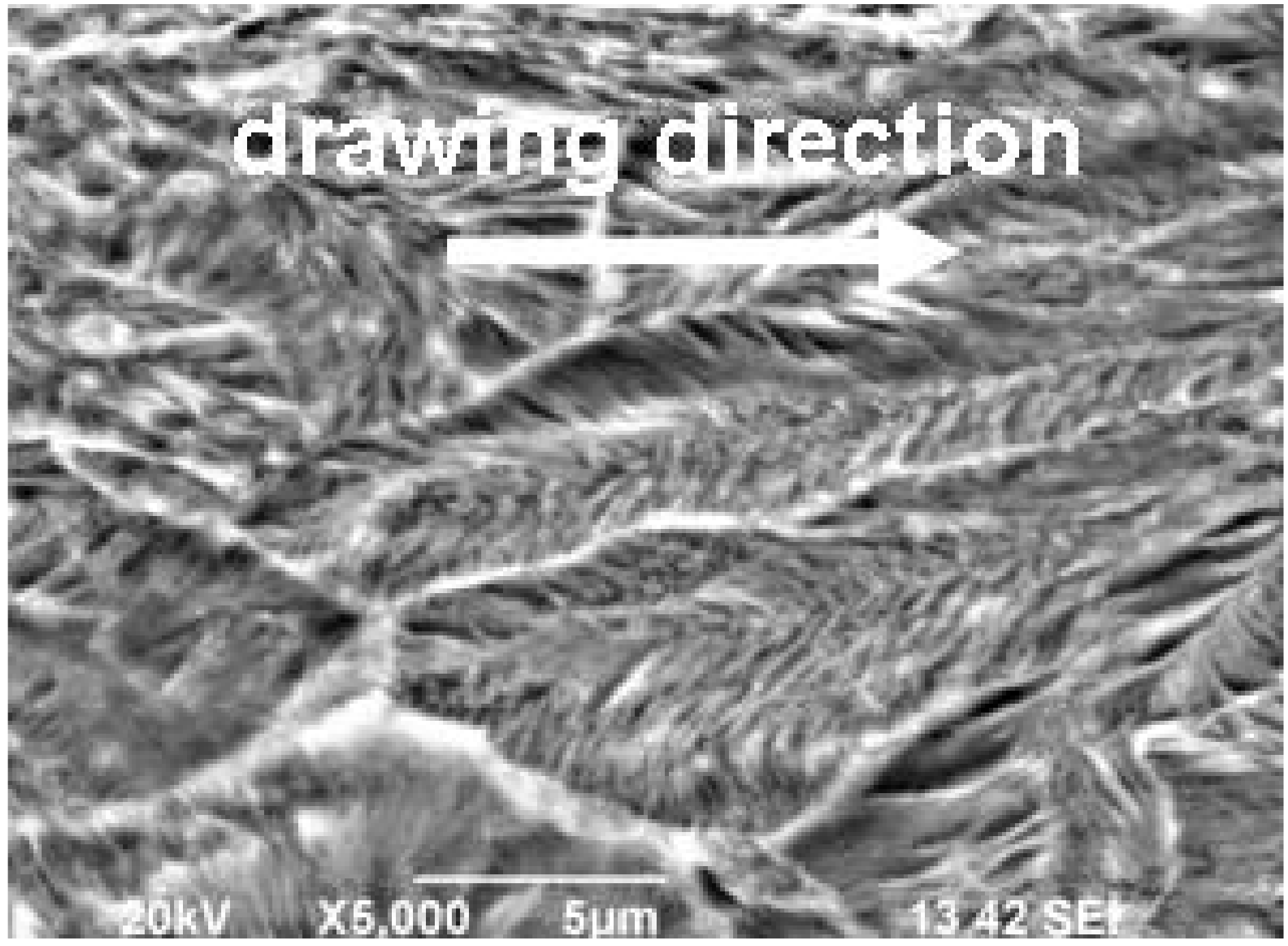

2.2. Role of Drawing in the Technological Process of High-Strength Wire Manufacturing

- rod—workpiece for the final wire (rough process stage)

- brass-plated wire after patenting—thin bras-plated wire (final process stage).

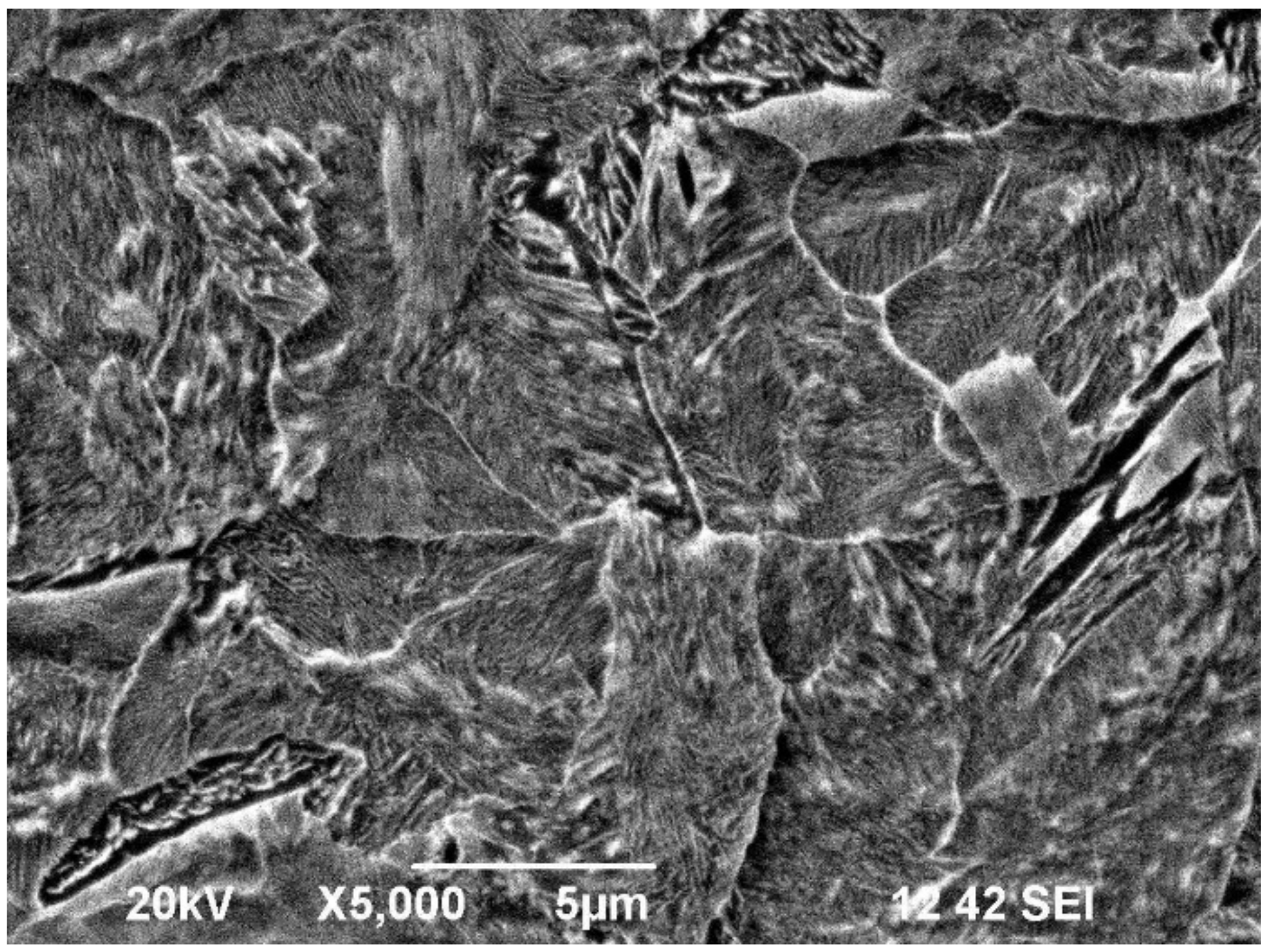

2.3. Role of Thermal Treatment in the Technological Process of High-Strength Wire Manufacturing

2.4. Deposition of Adhesive Coatings on the Metal Cord Wire

2.5. Use of Setups for Alternative Bending to Increase the Ductility of Bead Wire

2.6. Laying

3. Conclusions and Prospects

- -

- development of a methodology for calculating the drawing modes of high-carbon wire based on the selection and use of the fracture criterion and assessment of the influence of the deformation zone shape factor on its destruction;

- -

- investigation of the nature of metal flow in the near-surface layer during drawing, assessment of the influence of drawing factors on its depth, and development of practical recommendations for calculating deformation modes of thin high strength brass plated, and bronze coated wire for metal cord and bead wire.

Author Contributions

Funding

Conflicts of Interest

Entry Link on the Encyclopedia Platform:

References

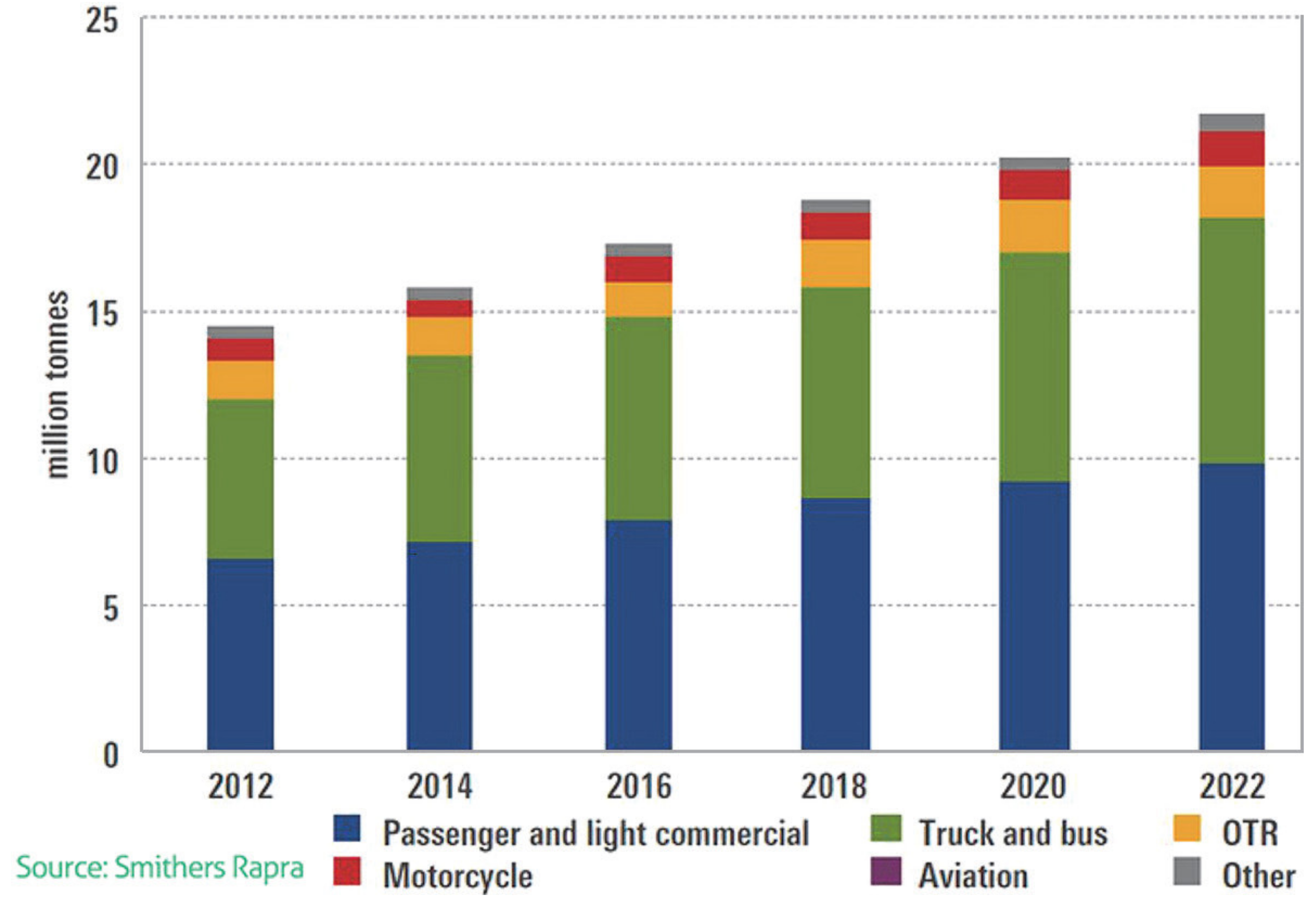

- Smithers Rapra. Available online: https://www.smithersrapra.com/resources/2017/april/tire-industry-in-boom-cycle (accessed on 30 June 2021).

- Fleming, R.A.; Livinsto, D.I. Tire Reinforcement and Tire Performance; American Society for Testing and Materials: Philadelphia, PA, USA, 1979; pp. 112–134. [Google Scholar]

- Vedeneev, A.V.; Bobarikin, Y.A.; Zalewski, V.P. Analysis of the development of consumption and production of steel cord. Foundry Prod. Metall. 2019, 48–59. [Google Scholar] [CrossRef]

- AZoM Materials. Available online: https://www.azom.com/ (accessed on 1 August 2021).

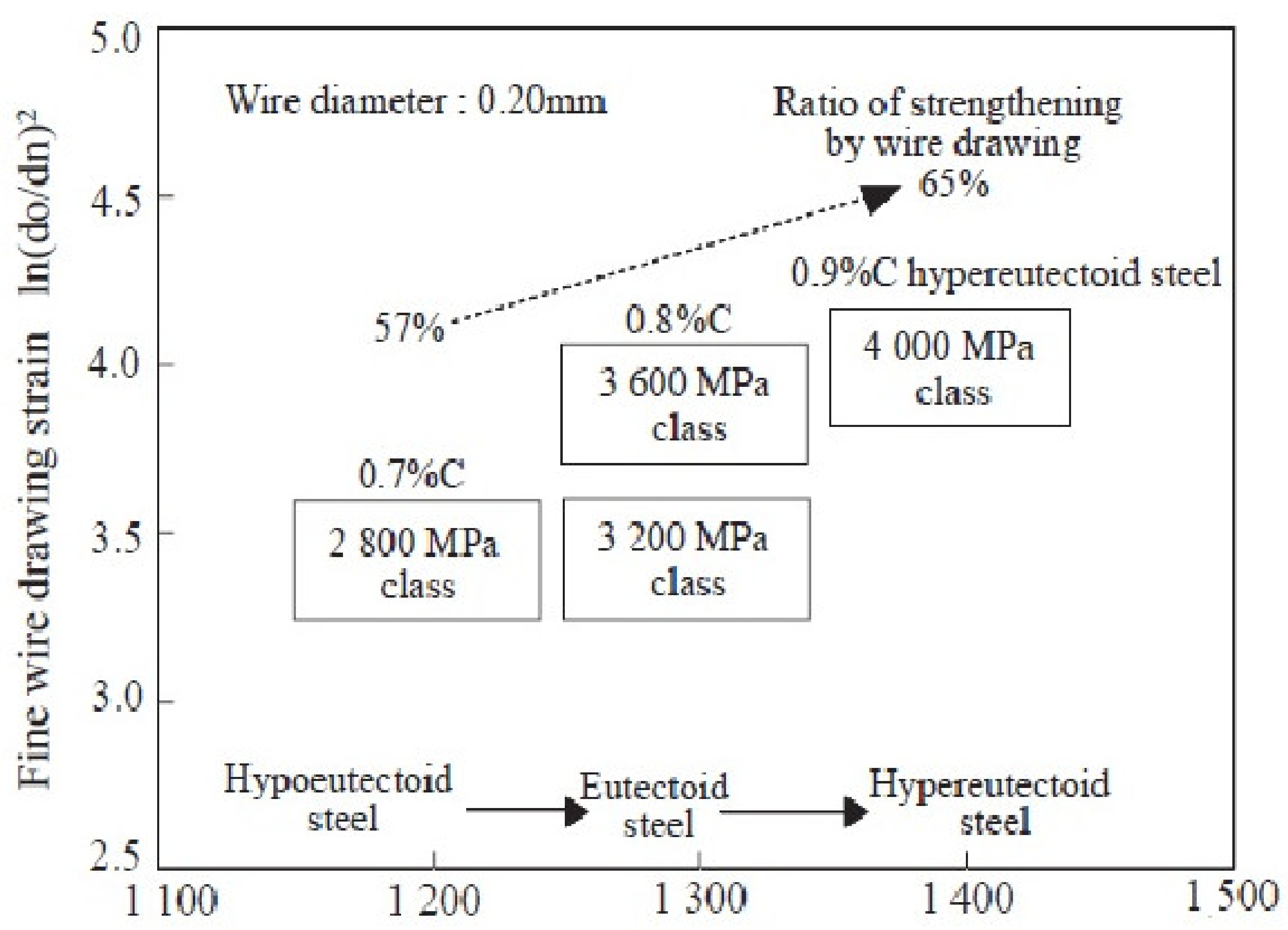

- Tarui, T.; Takahashi, T.; Tashiro, H.; Nishida, S. Metallurgical design of ultra high strength steel wires for bridge cable and tire cord. In Metallurgy Processing and Applications of Metal Wires; Paris, H.G., Kim, D.K., Eds.; TMS: Warrendale, PA, USA, 1996; pp. 87–96. [Google Scholar]

- Minamida, T.; Hiraga, N.; Shibata, T. R&D Kobe Steel Engineering Reports. 2000, p. 32. Available online: https://www.kobelco.co.jp/technology-review/pdf/50_3/031-035.pdf (accessed on 20 August 2021).

- Tashiro, H.; Tarui, T. Nippon Steel Technical Report. 2003, p. 87. Available online: https://www.nipponsteel.com/en/tech/report/nsc/pdf/n8818.pdf (accessed on 20 August 2021).

- Kirihara, K. Production technology of wire rod for high tensile strength steel cord. Kobelco Technol. Rev. 2011, 30, 62–65. [Google Scholar]

- Kanao, M. Improvement of the technology to get fine pearlite structure in wire. News Ferr. Metall. Abroad 2004, 1, 61–62. [Google Scholar]

- Dailoh, V.; Hamada, T. Microstructures of heavily deformed high steel wires. J. Iron Steel Inst. Jpn. 2003, 2, 105–110. [Google Scholar]

- Tashiro, H.; Tarui, T. State of the Art for High Tensile Strength Steel Cord: Technical Report. Nippon. Steel Tech. Rep. 2003, 88, 77–80. Available online: http://nsc.co.jp (accessed on 30 June 2021).

- Kharitonov, V.A.; Stolyarov, A.Y. Development of a competitive technology to make wire for metal cord. Metallurgist 2013, 57, 320–325. [Google Scholar] [CrossRef]

- Parusov, V.; Derevyanchenko, I.V.; Sychkov, A.B.; Nesterenko, A.M.; Zhigarev, M.A. Ensuring high quality indices for the wire rod used to make metal cord. Metallurgist 2005, 49, 439–448. [Google Scholar] [CrossRef]

- KOBELCO. Available online: https://www.kobelco.co.jp/english/ (accessed on 1 August 2021).

- Nippon Steel Corporation. Available online: https://www.nipponsteel.com/ (accessed on 1 August 2021).

- JFE Steel Corporation. Available online: https://www.jfe-steel.co.jp/en/ (accessed on 1 August 2021).

- Thyssenkrupp. Engineering. Tomorrow. Together. Available online: https://www.thyssenkrupp-steel.com/en/? (accessed on 1 August 2021).

- Wang, L.; Xi, Z.; Li, C. Modification of type B inclusions by calcium treatment in high-carbon hard-wire steel. Metals 2021, 11, 676. [Google Scholar] [CrossRef]

- Dey, I.; Chandra, S.; Saha, R.; Ghosh, S. Effect of Nb micro-alloying on microstructure and properties of thermo-mechanically processed high carbon pearlitic steel. Mater. Charact. 2018, 140, 45–54. [Google Scholar] [CrossRef]

- Han, K.; Edmonds, D.V.; Smith, G.D.W. Optimization of mechanical properties of high-carbon pearlitic steels with Si and V additions. Met. Mater. Trans. A 2001, 32, 1313–1324. [Google Scholar] [CrossRef]

- Han, K.; Smith, G.; Edmonds, D. Developments in ultra-high-carbon steels for wire rod production achieved through microalloying additions. Mater. Des. 1993, 14, 79–82. [Google Scholar] [CrossRef]

- Tarui, T.; Maruyama, N. Microstructure Control and Strengthening of High-Carbon Steel Wires Nippon Steel Technical Report No. 91. January 2005. Available online: https://www.nipponsteel.com/en/tech/report/nsc/pdf/n9112.pdf (accessed on 18 July 2021).

- Jiang, Y.; Lei, J.; Zhang, J.; Xiong, R.; Zou, F.; Xue, Z. Effect of carbon content on ti inclusion precipitated in tire cord steel. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 283–286. [Google Scholar] [CrossRef][Green Version]

- Lei, J.; Xue, Z. Study on tin precipitation during solidification for hypereutectoid tire cord steel. Metal. Int. 2012, 17, 10–15. [Google Scholar]

- Vereshchagin, M.N.; Bobarikin, Y.L.; Savenok, A.N.; Vedeneev, A.V.; Tseluev, M.Y.; Ignatenko, O.I. Influence of the drawing rate on the temperature and stress-strain state of high-carbon wire. Steel Transl. 2007, 37, 1036–1041. [Google Scholar] [CrossRef]

- Kazama, H.; Ishimoto, K. Super High Tensile Steel Wire for Rubber Product Reinforcement, Steel Cord Using for Steel Wire and Radial Tire Using This Steel Cord. U.S. Patent 5888321, 15 May 1996. [Google Scholar]

- Person, L.E. Drawing wire with a smaller die angle. Wire Ind. 2004, 71, 437–441. [Google Scholar]

- Mamoru, N.; Takeshi, K. Suppression of delamination in hyper-eutectoid steel wires by multi-skin pass drawing. Tetsu to Hagane 2004, 90, 588–592. [Google Scholar]

- Hollinger, S.; Depraetere, E.; Giroux, O. Wear mechanism of tungsten carbide dies during wet drawing of steel tire cords. Wear 2003, 255, 1291–1299. [Google Scholar] [CrossRef]

- Matsuyama, K. Method for Manufacturing Brass-Plated Steel Wire and Apparatus for Drawing Brass Plated Steel Wire. U.S. Patent 20100294013A, 26 January 2009. [Google Scholar]

- Demidov, A.V.; Muraveiko, I.A. The experience of modernization of mills of wet wire drawing for the metal wire cord. Foundry Prod. Metall. 2019, 4, 97–102. [Google Scholar] [CrossRef]

- Haddi, A.; Imad, A.; Vega, G. Analysis of temperature and speed effects on the drawing stress for improving the wire drawing process. Mater. Des. 2011, 32, 4310–4315. [Google Scholar] [CrossRef]

- Fetisov, V.P. Change of deformational aging rate of brass plated wire under high reductions. Steel Transl. 1998, 11, 55–57. [Google Scholar]

- Zelin, M. Microstructure evolution in pearlitic steels during wire drawing. Acta Mater. 2002, 50, 4431–4447. [Google Scholar] [CrossRef]

- Kemp, I.P.; Pollard, G.; Bramley, A.N. Static strain aging in high carbon steel wire. Mater. Sci. Technol. 1990, 6, 331–337. [Google Scholar] [CrossRef]

- Lee, S.-K.; Lee, S.-B.; Kim, B.-M. Process design of multi-stag wet drawing for improving the drawing speed for 0.72 wt% steel wire. J. Mater. Process. Technol. 2010, 210, 776–783. [Google Scholar] [CrossRef]

- Process for Heat Treating a Carbon Steel Wire. U.S. Patent 4830684.122113, 18 November 1987.

- Process for Producing Patented Steel Wire. U.S. Patent 5749981.767467, 16 December 1996.

- High Flexibility Steel Wire and Method of Treating Same. U.S. Patent 3574000.675522, 17 February 1969.

- High Flexibility Steel Wire and Method of Treating Same. U.S. Patent 3584494.826229, 20 May 1969.

- Heat Treatment of Steel Wire. U.S. Patent 6228188.08/278910, 22 July 1994.

- Process for Manufacturing Pearlitic Steel and Product Made Thereby. U.S. Patent 4759806.948077, 31 December 1986.

- Tyl, T.W. Thermodynamic wire transformation process in the manufacture of steel tire cord. Wire J. Int. 2008, 7, 80–86. [Google Scholar]

- Tyl, T.W. Steel patenting technology in the manufacture of steel tire cord. Wire J. Int. 2008, 10, 80–87. [Google Scholar]

- Kruzel, R.; Suliga, M. The impact of the heat treatment parameters on patenting line on mechanical-technological properties of steel cord wires. Mater. Sci. 2016. Available online: https://www.semanticscholar.org/paper/The-impact-of-the-heat-treatment-parameters-on-line-Kruzel-Suliga/29650620f2e28463c4b1a3133a021d9d2f738657#citing-papers (accessed on 18 July 2021).

- Buytaert, G.; Coornaert, F.; DeKeyser, W. Characterization of the steel tire cord—Rubber interface. Rubber Chem. Technol. 2009, 82, 430–441. [Google Scholar] [CrossRef]

- Khrol, O.N. Influence of the quality of compounds on the adhesion properties of metal cord. Foundry Prod. Metall. 2020, 2, 36–41. [Google Scholar] [CrossRef]

- Su, Y.-Y.; Shemenski, R.M. Investigation the parameters for torsion ductility of bead wire. Mater. Des. 2010, 31, 1423–1430. [Google Scholar] [CrossRef]

- Zhou, L.; Fang, F.; Wang, L.; Hu, X.; Xie, Z.; Jiang, J. Torsion performance of pearlitic steel wires: Effects of morphology and crystallinity of cementite. Mater. Sci. Eng. A 2018, 743, 425–435. [Google Scholar] [CrossRef]

- Sychkov, A.B.; Stolyarov, A.Y.; Kamalova, G.Y.; Efimova, Y.Y.; Gulin, A.E.; Selivanov, V.N. Peculiarities of structure formation in thin wire. Vestn. Nosov Magnitogorsk State Tech. Univ. 2017, 15, 75–84. (In Russian) [Google Scholar] [CrossRef]

- Parusov, V.; Starov, R.V.; Derevyanchenko, I.V.; Sychkov, A.B.; Kucherenko, O.L. A decade of quality steel production: Developing a production technology for steel used in metal-cord manufacture. Steel Transl. 2010, 40, 82–87. [Google Scholar] [CrossRef]

- Qiao, L.; Wang, Z.; Wang, Y.; Zhu, J. Mechanical performance-based optimum design of high carbon pearlitic steel by particle swarm optimization. Steel Res. Int. 2020, 92, 2000252. [Google Scholar] [CrossRef]

- Shmurak, I.I. Improvement of metal cord for tyres. Int. Polym. Sci. Technol. 2006, 33, 1–4. [Google Scholar] [CrossRef]

- Valiev, R.; Islamgaliev, R.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zechetbauer, M.J.; Zhu, Y. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Langdon, T.G. Processing by severe plastic deformation: Historical development and current input. Mater. Sci. Forum 2011, 667–669, 9–14. [Google Scholar]

- Segal, V. Review: Modes and processes of severe plastic deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polyakova, M.; Stolyarov, A. Automobile Tires’ High-Carbon Steel Wire. Encyclopedia 2021, 1, 859-870. https://doi.org/10.3390/encyclopedia1030066

Polyakova M, Stolyarov A. Automobile Tires’ High-Carbon Steel Wire. Encyclopedia. 2021; 1(3):859-870. https://doi.org/10.3390/encyclopedia1030066

Chicago/Turabian StylePolyakova, Marina, and Alexey Stolyarov. 2021. "Automobile Tires’ High-Carbon Steel Wire" Encyclopedia 1, no. 3: 859-870. https://doi.org/10.3390/encyclopedia1030066

APA StylePolyakova, M., & Stolyarov, A. (2021). Automobile Tires’ High-Carbon Steel Wire. Encyclopedia, 1(3), 859-870. https://doi.org/10.3390/encyclopedia1030066