Abstract

In this work, the thermochemical properties of municipal solid waste (MSW) are studied using the torrefaction process as the main method for investigation. Torrefaction experiments were carried out using an electric laboratory furnace, at temperatures of 200, 250, and 300 °C. The residence time was set to 90 min. Proximate and ultimate analysis were performed on the torrefied MSW samples and compared with the properties of the raw MSW samples. In addition, the thermal properties of the obtained torrefied MSW samples were evaluated by thermogravimetric analysis (TGA) and derivative thermogravimetric analysis (DTG). The following could be stated: the obtained results showed that mass and energy yields (MY and EY, respectively) decrease with increasing when torrefaction temperature, while the heating values (HHV) increased under the same conditions (from 24.3 to 25.1 MJ/kg). Elemental analysis showed an increase in carbon content (C), from 45.7 ± 0.9 to 52.8 ± 1.05 wt.%, and decrease in oxygen content (O), from 45.6 ± 0.9 to 39.5 ± 0.8 wt.%, when torrefaction temperature is increased, which is consistent with the general definition of the torrefaction process. In addition, enhancement factors (EFs) and fuel ratios (FRs) were calculated, which ranged from 1.00 to 1.02 and 0.16 to 0.23, respectively. Some anomalies were observed during the thermal analysis, which are assumed to be related to the composition of the selected MSW. This study therefore shows that torrefaction pretreatment can improve the physicochemical properties of raw MSW to a level comparable to coal, and could contribute to a better understanding of the conversion of MSW into a valuable, solid biofuel.

1. Introduction

The current global economic crisis and the resulting high energy prices of fossil fuels, such as electricity, natural gas, or coal, and subsequent emerging environmental issues have plunged the recent efforts toward exploring new alternative energy sources. In order to satisfy energy demands stated in the European Green Deal [1], the European Union (EU) adopted the target to achieve at least a 32% share of renewable energy sources (RES) by 2030 [2]. Much attention has already been given to wind, solar, hydro, and geothermal energy sources [3,4], but recently, bioenergy has stepped forward. Currently, biomass presents almost 60% of RES in the EU, mainly in the cooling and heating sectors (75%). According to the general definition, biomass is described as organic material that can be derived from trees, plants, agricultural, or urban wastes [5]. Apart from being carbon neutral, biomass is the only RES that is practically always available, and can be used in some thermochemical (pyrolysis, combustion, etc.), chemical (hydrolysis), and biochemical (fermentation, anaerobic digestion) conversion routes [6,7,8] to obtain numerous products, such as bio-oil [9] or syngas [10]. However, some disadvantages, such as high moisture content, high oxygen content, low bulk density, and poor grindability and so forth, are limiting the use of biomass as a fuel [11]. Moreover, these problems affect the handling, transportation, storage, conversion, and costs of raw biomass [12]. To overcome the above challenges, a suitable pretreatment method is required, and several approaches have already been proposed, e.g., the torrefaction process [13].

Torrefaction is a thermochemical conversion process in the presence of minimal oxygen atmosphere and at a temperature range of 200 to 300 °C for 30–60 min and atmospheric pressure [10]. Torrefaction is of great interest in today’s world as it can improve the properties of raw biomass to a level that rivals that of coal [14,15]. These include reducing its moisture content, increasing heating value (HHV), carbon content, and even improving grindability [16,17]. In addition, torrefied biomass is hydrophobic [18].

Currently, the properties of torrefied biomass have already been extensively studied worldwide, with most studies focusing on lignocellulosic and non-lignocellulosic biomass, e.g., herbaceous biomass [19], coffee grounds [20], wood [21], or even sewage sludge [22]. Cahyanti et al. [15], for example, used agricultural and wood wastes (barely straw, cumin stalks, and forestry wood wastes) from Estonia to investigate the influence of torrefaction operating parameters on physicochemical properties, chemical composition, ash melting behavior, and hydrophobicity. The torrefaction process was carried at three different temperatures (i.e., 225, 275, and 300 °C) and at two different residence times (i.e., 30 and 60 min) under nitrogen atmosphere (10 L/min). Something similar was investigated by Mei et al. [23]. Barley straw and vine shoot were subjected to the torrefaction process at moderate temperature and under air atmosphere conditions to evaluate the influence of the biomass composition and pretreatment temperature. In addition, the efficiency of the anaerobic digestion in terms of biogas and methane production was studied. Zhang et al. [24], investigated the effect of superheat steam (SHS) torrefaction (i.e., a type of torrefaction that uses superheat steam as the heat source to torrefy biomass) on improving the properties of waste from walnut oil production. The properties of the torrefied biomass were investigated in terms of proximate and ultimate analysis.

Nowadays, developing countries, with good living conditions, are experiencing rapid population growth and urbanization, leading to a drastic increase in the production of municipal solid waste (MSW) [25,26,27]. The term “municipal solid waste” refers to biomass waste generated by human activities, including plastics, kitchen waste, paper, wood, rubber, textiles, glass metals, or any other complex components from commercial, industrial, or residential sectors [28,29]. The amount of solid waste is linearly related to a country’s GDP, while its composition is influenced by socio-economic background and seasonal conditions [30]. The current global annual MSW production is approximately 1.9 billion tons and it is estimated that this number will rise to 3.4 billion tons per year by 2050 [31]. Raw MSW is characterized as a heterogeneous material, with a high moisture content, low calorific value, and a tough fibrous structure. MSW can cause many serious problems, including greenhouse gas emissions (GHG), energy instability, and even environmental and public health problems [32]. It has been stated in the work of Triyono [33] that MSW could be used for energy purposes, due to its calorific value (HHV) which is about 23 MJ/kg (dry basis) and is similar to that of sub-bituminous coal. Low awareness of waste recycling, problems with separate collection, and lack of funding have made it difficult to apply the technology to the treatment of MSW [30]. Recently, thermochemical technologies, such as incineration, pyrolysis and gasification have been mentioned as possible ways to treat MSW, although all face some technical problems such as high moisture content, irregular size and shape, or mixing of plastics with organic waste. The torrefaction process is an innovative technology that could be used to convert raw MSW into a high quality solid fuel [34].

The main objective of this work is to study the effects of torrefaction on the thermochemical properties of MSW from the Republic of Slovenia. The torrefaction temperature is investigated, together with the proximate and ultimate analysis. In addition, the thermal behavior is discussed. According to the Slovenian Statistical Biro (SURS) more than 12.3 million tons of MSW was collected in the Republic of Slovenia in year 2022, which is about 30% more than year 2021 [35]. To date, no study on the torrefaction process of MSW from the Republic of Slovenia has been published, therefore, it is believed that these results will be of interest for the utilization of MSW for the energy conversion or production processes.

2. Materials and Methods

2.1. Materials

In this study, municipal solid waste (MSW) was investigated. The initial selected MSW was in the heterogeneous form. Before being used in the torrefaction experiment, the MSW was homogenized, sieved to similar sizes (up to 1 cm) and dried at 105 ± 2 °C for 24 h until mass stabilization. Table 1 presents the properties of the raw MSW sample used in this study.

Table 1.

Properties of MSW (raw).

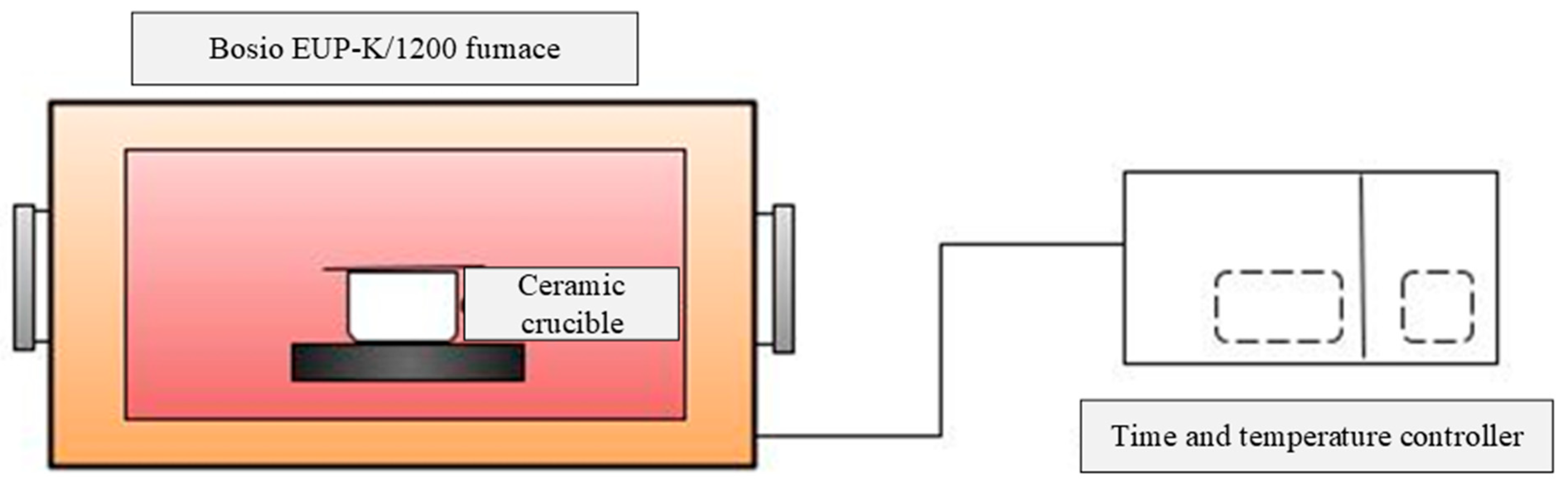

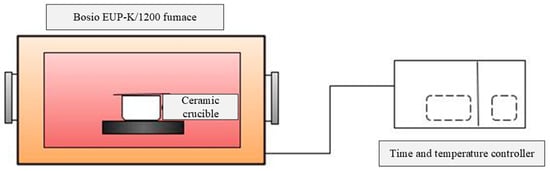

2.2. Torrefaction Experimental Setup and Procedure

The schematic diagram of the torrefaction process is shown on Figure 1. A detailed description of the experimental procedure is given in our previous works [12,36]. The torrefaction process was performed in an electric laboratory furnace, Bosio type EUP-K 6/1200. About around 50 g of the sample was used each time. Torrefaction was then carried out at 200, 250, and 300 °C and with a residence time of 90 min. A semi-inert atmosphere was ensured [12,36]. After torrefaction, the MSW samples were removed from the furnace, respectively, cooled down, and stored in hermetically sealed containers before being prepared for further analysis. Before each further analysis, the samples were dried again at 105 ± 2 °C for 1 h to constant weight was reached to reduce the moisture content. Each experimental run was repeated three times to ensure repeatability of the measurements. The average values are used in the discussion.

Figure 1.

Experimental set-up of the torrefaction process.

2.3. Torrefaction Product Analysis

2.3.1. Elemental Analysis

The contents of the elements C, H, N, and S were determined with the elemental analyzer from Perkin Elmer CHNS/O 2400 (Billerica, MA, USA) according to the international standards UNI EN 15104:2011 (“Solid biofuels—Determination of total content of carbon, hydrogen, and nitrogen—Instrumental methods”) and UNI EN 15289:2011 (“Solid biofuels—Determination of total content of sulfur and chlorine”), respectively, while the content of O was calculated by the difference, as shown in equation below (Equation (1)).

O (%) = 100% − C (%) − H (%) − N (%) − S (%) − Ash (%)

2.3.2. Proximate Analysis

The moisture content (MC), volatile matter (VM), ash content (Ash), and fixed carbon (FC) content were determined according to the ASTM D7582:2015 (“Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis”) standard.

2.3.3. Heating Value

The heating value (HHV) was measured in an IKA C6000 adiabatic bomb calorimeter (Isoperibol; Staufen, Germany) according to the UNI EN 14918:2019 (“Solid biofuels—Determination of calorific value”) and ASTM DIN 51,900 ISO 1928 standards (“Determining the gross calorific value of solid and liquid fuels”).

2.3.4. Thermogravimetric Analysis

Thermogravimetric analysis (TGA) was performed with the Mettler Toledo TGA/DSC 3+ STAR System (Greifensee, Switzerland) thermogravimetric analyzer. Thermal conversion was performed under nitrogen atmosphere (25 °C, 20 mL/min). All experiments were performed in an alumina crucible and up to 40 mg of the sample was used in each experiment, respectively. The samples were heated from 25 to 800 °C at a constant heating rate, 10 °C/min. In addition, derivative thermogravimetric (DTG) curves were examined. Three identical experiments were performed with each MSW sample to check reproducibility. The results show that the absolute differences between the three identical experiments are less than 5%.

3. Results and Discussion

3.1. Mass and Energy Yield

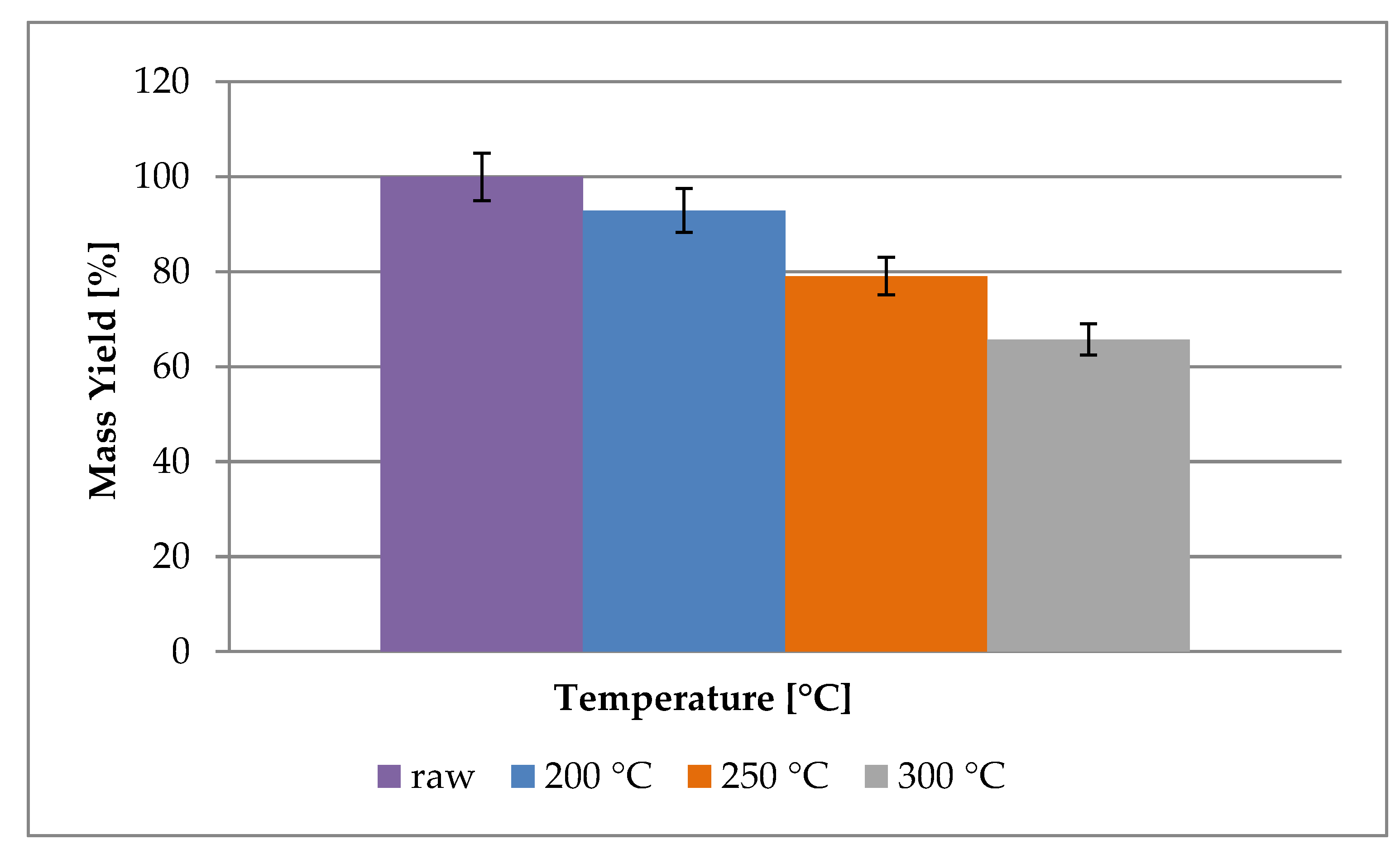

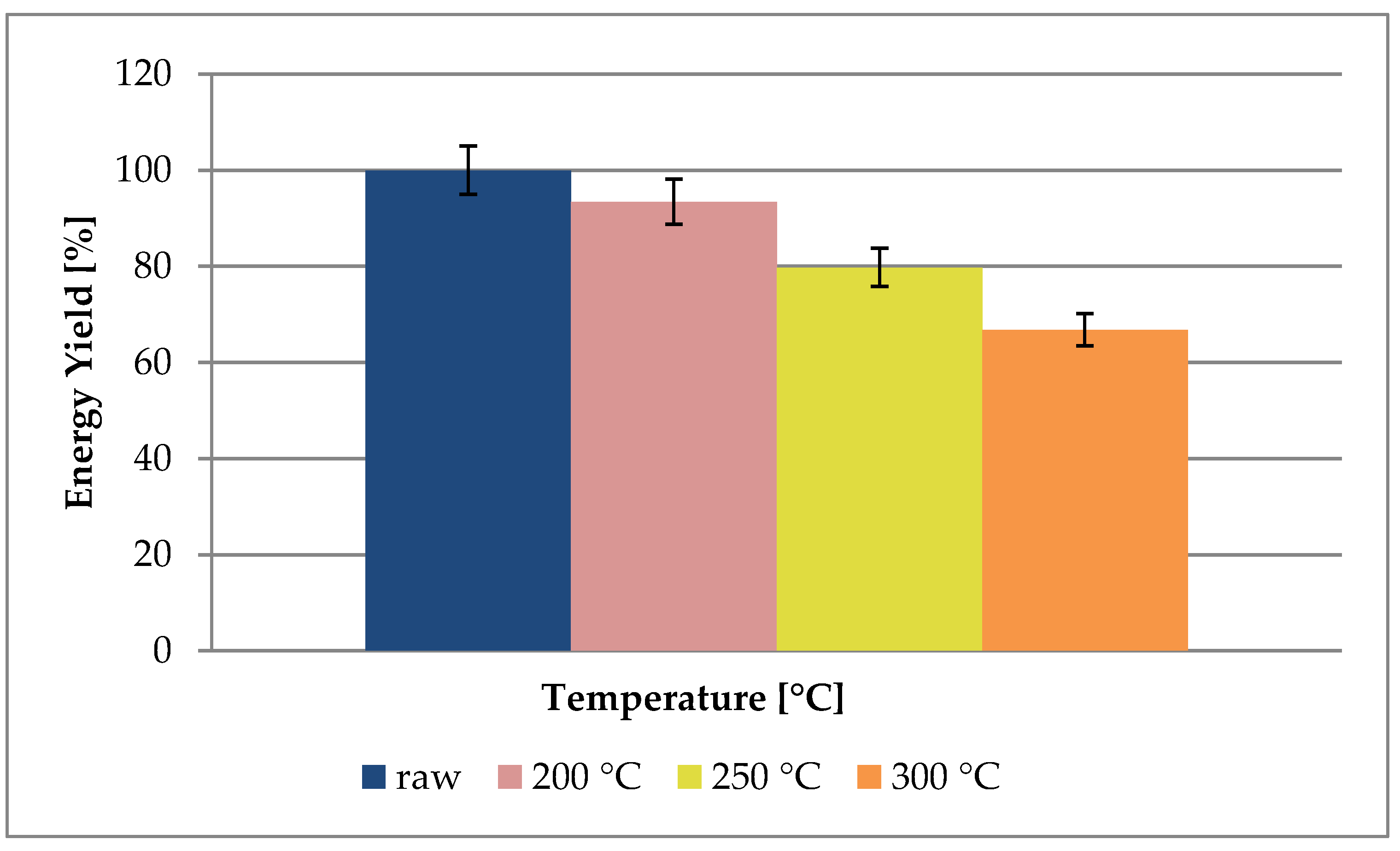

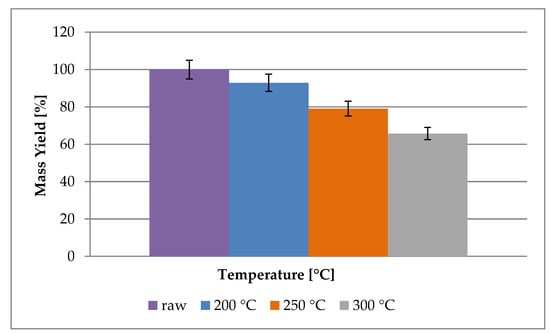

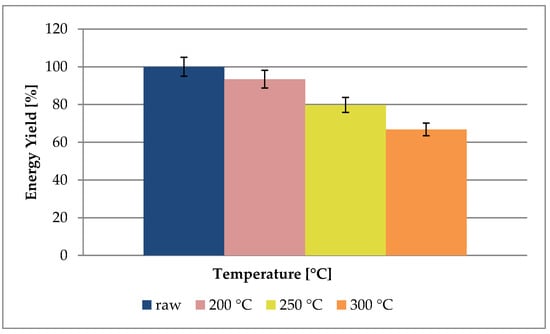

As noted in the work of Doddapaneni et al. [37] mass and energy yields are two most important parameters for evaluating the performance of the torrefaction process. In this work, mass (MY) and energy yields (EY) of the selected MSW samples were calculated using the following Equations (2) and (3). In addition, the enhancement factors (EF) are calculated (Equation (4)). Furthermore, Figure 2 and Figure 3 also show the mass and energy yields obtained at different torrefaction conditions. Torrefaction process took place at three temperatures, i.e., 200 °C, 250 °C, and 300 °C, respectively, and at a residence time of 90 min.

Figure 2.

Mass yield (wt.%) during the torrefaction process of MSW.

Figure 3.

Energy yield (%) during the torrefaction process of MSW.

As expected, MY decreased with an increasing torrefaction temperature. For example, the average MY for MSW sample torrefied at 200 °C was 92.9 ± 1.8 wt.%, but when the temperature increased from 200 to 250 °C, MY decreased to 79.1 ± 1.6 wt.%. A similar observation was made when the torrefaction temperature increased to 300 °C—the obtained MY decreased to 65.8 ± 1.3 wt.%. It is believed that such a decrease is also the result of the loss of volatile compounds during the torrefaction process [12]. Moreover, the average energy yields (EY) were 93.5 ± 1.9%, 79.8 ± 1.6%, and 66.8 ± 1.3% for each studied torrefaction temperature, respectively. The calculated EY values corresponded to the same findings as MY. As the torrefaction temperature increased, EY decreased. The same results were also confirmed in a considerable number of studies, such as in the work of Wilk and Magdziarz [38] or Bach et al. [39]. In both studies, it was stated that torrefaction temperature has a big impact on the physicochemical properties of the torrefied material. Moreover, regarding the temperature, a significant influence was also made by the torrefaction (residence) time, the biomass composition, or the particle size. In the study by Zhu et al. [40] three specific types of MSW (i.e., paper, wood, and PVC) were torrefied at 300 °C for 30 min and then both MY and EY were calculated and compared to the raw biomass samples. A decrease in both parameters was observed and confirmed. In another study, Iroba et al. [41], studied different temperature profiles of MSW (woody construction demolition waste and grass clippings) during microwave-assisted torrefaction. Similar results as stated previously were observed. Rago et al. [42], also noticed a decrease in MY of studied biomass and plastic, derived from municipal solid wastes (i.e., mango branches, waste newspaper, and low-density polyethylene). Municipal solid wastes were torrefied at 300 °C for 30 min and later proximate and ultimate analyses, HHVs, fuel ratio, and combustibility index were studied. Samad et al. [43], also confirmed that MY and EY are reduced with an increasing torrefaction temperature. In their work, MSW from Malaysia was studied. The main objective of their work was to study the effects of torrefaction temperatures ranging from 240 to 330 °C with a residence time of 30 min on two types of MSW, food waste and wood waste. The torrefied MSWs were characterized in terms of elemental and proximate analysis and HHV.

3.2. Ultimate and Proximate Analysis

Table 2 shows the results of the elemental and proximate analysis after the torrefaction process. The discussion uses the average values, while the results for each experimental run are presented in the Supplementary Materials (Table S1). The elemental and proximate analysis of the dry samples were performed as described in our previous papers [12,36,44]. A significant improvement in carbon content of the MSW was observed when the torrefaction temperature was increased for 90 min, from 45.7 ± 0.9 wt.% in the raw sample to 52.9 ± 1.0 wt.% when torrefied at 300 °C. At the same time, a noticeable decrease in the contents of hydrogen, oxygen, and sulfur was observed when increasing the torrefaction temperature for 90 min. For instance, the hydrogen contents varied between 8.1 ± 0.2 wt.% (raw sample) and 6.6 ± 0.1 wt.% (torrefied at 300 °C), the oxygen contents were in the range of 47.9 ± 0.9 wt.% (raw sample) and 39.5 ± 0.8 wt.% (torrefied at 300 °C), and the sulfur contents were between 0.03 ± 0 (raw sample) and 0.21 ± 0.0 wt.% (torrefied at 300 °C). The contents of nitrogen increased with when the temperature increased. The values were in the range from 0.78 ± 0.0 (raw sample) to 0.85 ± 0.0 wt.% (torrefied at 300 °C). The decrease in oxygen content and increase in carbon content may be a result of releasing the water vapor and the formation of CO and CO2 during the torrefaction process. The residence time has less influence on carbon, hydrogen, and oxygen contents of torrefied biomass. Similar observations for other biomasses were found in the literature [44,45].

Table 2.

Elemental and proximate analysis of MSW after torrefaction.

For the calculation of MC, VM, FC and Ash, the following Equations were used (5)–(8) [46].

where: A is the sum of the crucible mass and sample mass; B is the sum of the crucible mass and sample mass after drying; and C is the sum of the empty crucible mass.

The ash content increased with an increase in torrefaction temperature because of the loss of organic matter during the torrefaction process. Additionally, a significant downward tendency was detected in the VM for the torrefied material when torrefaction temperatures increased, resulting in high FC content. MC decreased by 87%, from 44.3 ± 0.88 wt.% in a raw state to 38.7 ± 0.8 wt.% in a torrefied state at 300 °C. Similarly, VM was reduced from 45.9 ± 0.9 wt.% (raw sample) to 44.7 ± 0.9 wt.% (torrefied at 300 °C), whereas FC and ash contents were increased. FC contents increased firstly from 6.7 ± 0.1 wt.% (raw sample) to 7.34 ± 0.1 wt.% (torrefied at 200 °C), then to 8.33 ± 0.2 wt.% (torrefied at 250 °C), and finally to 10.05 ± 0.2 wt.% (torrefied at 300 °C). The ash contents were in the range of 3.12 ± 0.1 wt.% (raw sample) to 6.61 ± 0.13 wt.% (torrefied at 300 °C) for each torrefaction temperature, respectively. The values are in a comparable range to other biomass samples reported in the literature [47,48].

3.3. Energy Content

Another parameter closely related to EY was examined here—the heating value (HHV). The HHV measures the heat content based on the gross energy content of the combustible fuel. The average heating values of selected MSW, raw and torrefied, are also listed in Table 1 and Table 2. The average values are used in the discussion, while the results for each experimental run are presented in the Supplementary Materials (Table S1). In addition, the theoretical HHV was calculated based on Equation (S1) from the Supplementary Materials. The average heating value of raw MSW is 24.3 ± 5 MJ/kg. Previous reported values of raw MSW are in the range of 35.2 MJ/kg to 38.7 MJ/kg [49]. As expected, the heating value of MSW increased with an increasing torrefaction temperature. For instance, at 200 °C, the HHV was 24.6 ± 0.5 MJ/kg, at 250 °C it was 24.7 ± 0.5 MJ/kg, and at 300 °C it was 25.3 ± 0.5 MJ/kg. Doddapaneni et al. [37], stated that the loss of low heating value volatiles could be the main reason for increased energy content. Similar findings were also reported by Fu et al. [50].

In addition, the enhancement factor (EF) was calculated based on the Equation (3), and the following average values were obtained: 1.00 (raw sample), 1.01 (torrefied at 200 °C), 1.01 (torrefied at 250 °C), and 1.02 (torrefied at 300 °C). The enhancement factor reflects the change in HHV during the torrefaction process [44]. EF increased with the torrefaction temperature. This could be due to the release of moisture content, increase in carbon content and decline in oxygen content during torrefaction. The effect of temperature is generally superior to residence time, but they both have a substantial impact on the final torrefied product.

The atomic ratios of O/C and H/C were calculated as well. Those ratios indicate the fuel quality. For example, fuels that have lower ratios of O/C and H/C are classified as high-ranking [51]. In this work, the average O/C ratio decreased from 1.11 (raw sample), 1.03 (torrefied at 200 °C), 0.91 (torrefied at 250 °C), to 0.75 (torrefied at 300 °C), while the average H/C ratio decreased from 0.19 (raw sample), 0.18 (torrefied at 200 °C), 0.15 (torrefied at 250 °C), to 0.13 (torrefied at 300 °C). It can easily be observed that the atomic ratio decreases with an increasing torrefaction temperature. Dehydration takes place during torrefaction, resulting in the lowest atomic ratio under severe torrefaction conditions. The reason for this is the removal of light volatiles and water, composed of hydrogen and oxygen during torrefaction, which ultimately took the lead to retain more carbon content. Similar findings were reported in our previous work where the torrefaction of woody biomass materials was studied [12].

3.4. Fuel Ratio

Lastly, fuel ratios (FR) were calculated. For this, Equation (9) was used. Doddapaneni et al. [37], described the fuel ratio as an index that provides theoretical information about decomposition efficiency.

The average fuel ratio of raw MSW was found to be 0.15, whereas when MSW was torrefied at 200 °C, the fuel ratio was 0.16, at 250 °C it was 0.18, and at 300 °C it was 0.23. Fuel ratios increased when the torrefaction temperature increased. Hung et al. [52] observed that the fuel ratio of raw leucaena biomass was 0.2, but after microwave torrefaction it increased up to 3.7. Sarker et al. [53], reported similar findings—fuel ratios were between 0.4 and 0.8 for torrefied canola residue.

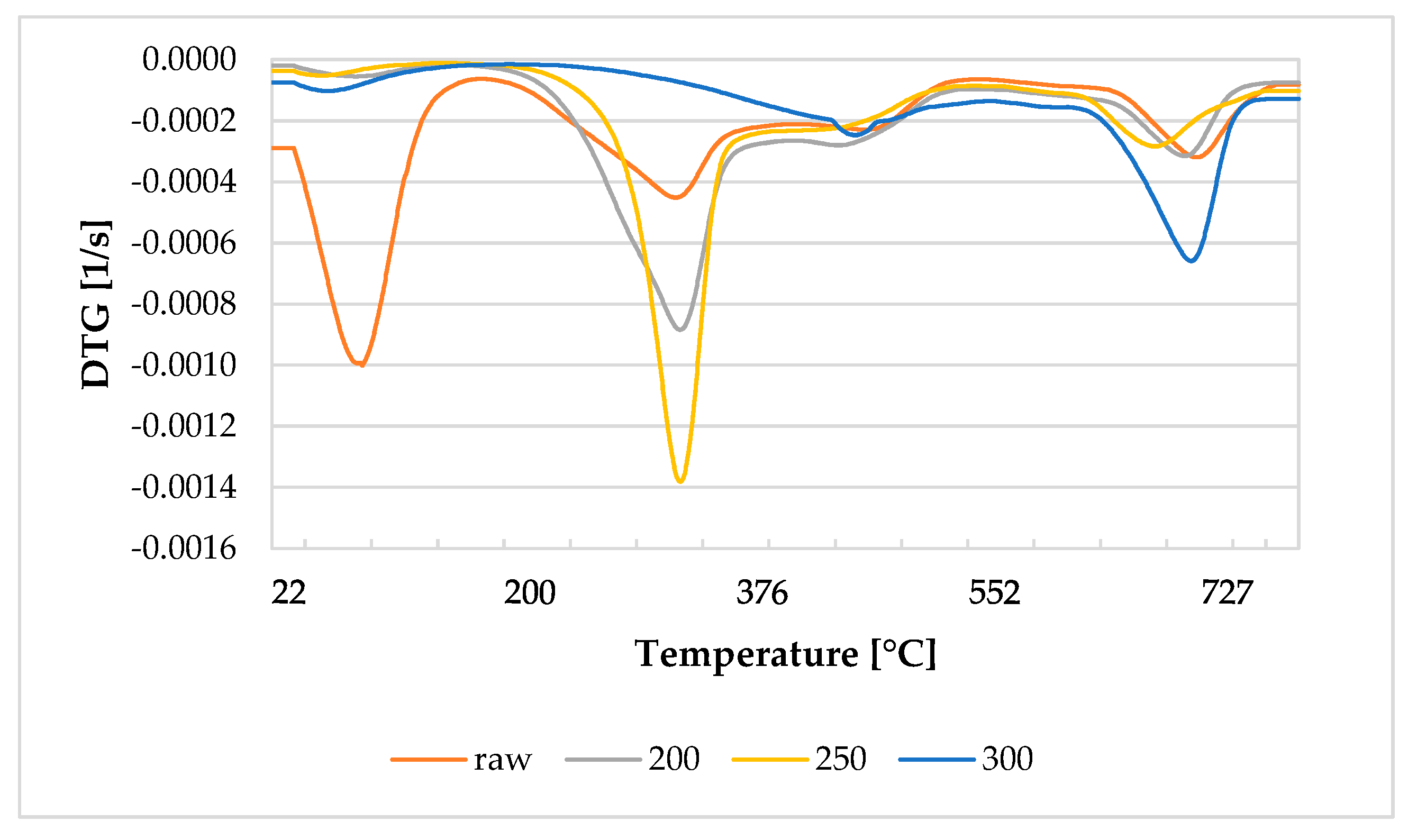

3.5. Thermal Behavior of Biomass

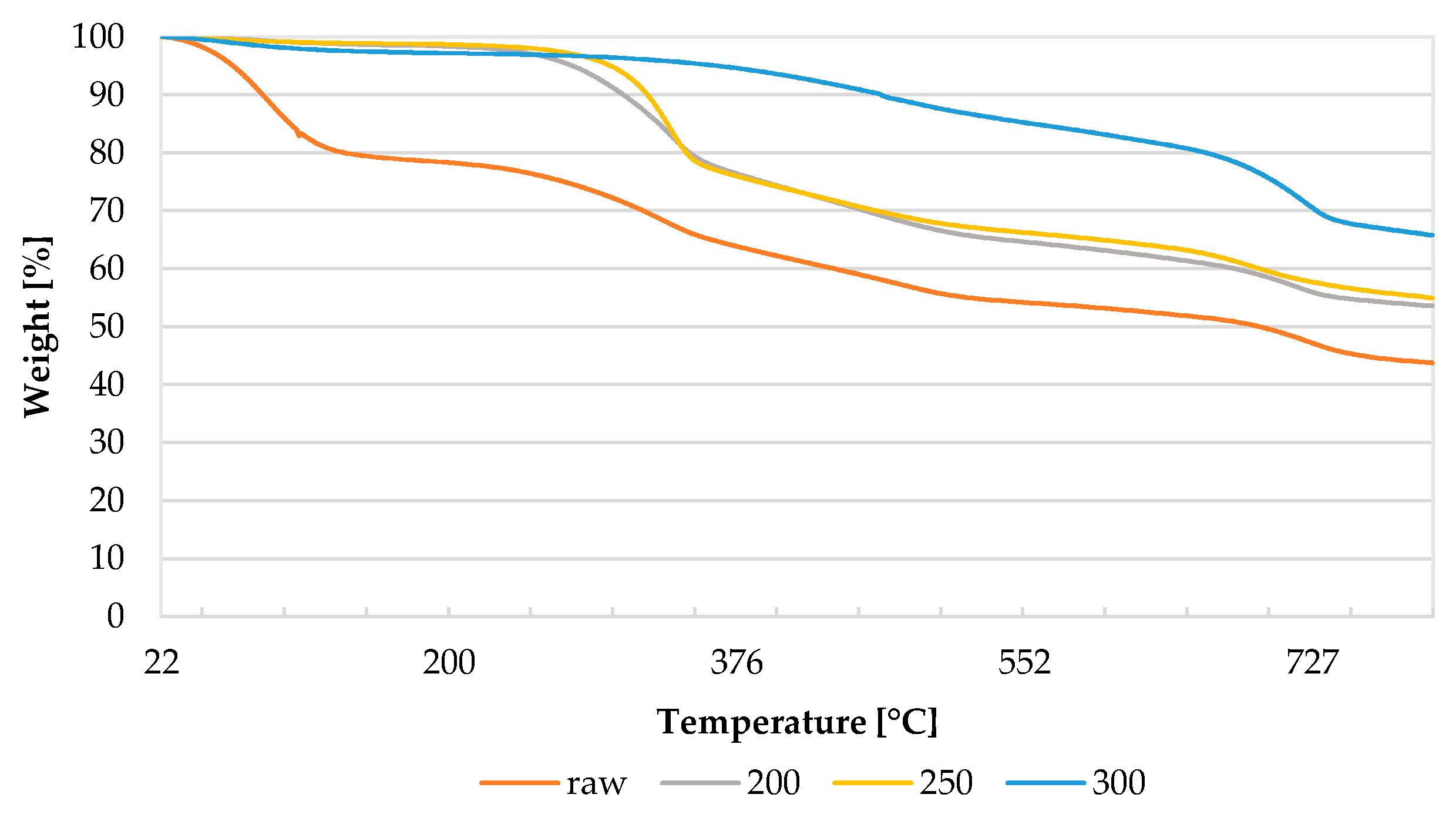

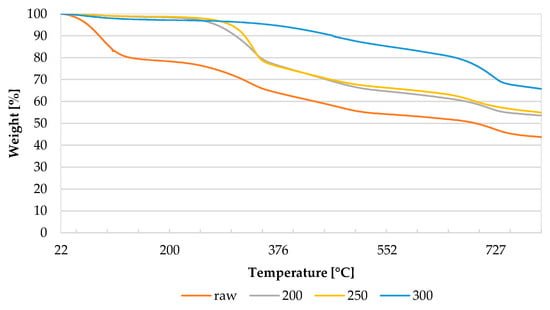

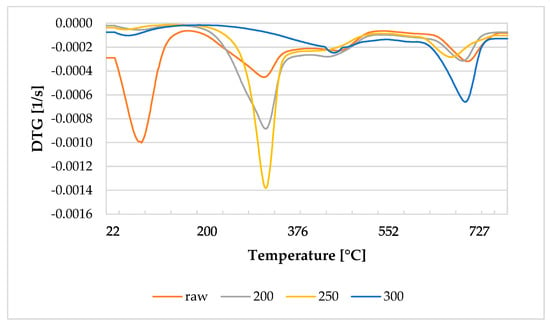

Figure 4 and Figure 5 show the TGA and DTG curves for raw and torrefied MSW samples, respectively. Figure 4 shows the percentage weight loss as a function of temperature, while Figure 5 shows the mass loss rate as a function of temperature. The TGA curves of the samples first looked similar, whereas the DTG profiles revealed more significant differences. In general, the decomposition process for all samples is divided into three phases, except for the sample torrefied at 300 °C, which showed some anomalies. The release of weakly bonded water molecules and hydrolysis was first observed at a stage called the evaporation or dehydration stage. A significant peak for the raw MSW samples was observed at around 90 °C, corresponding to the moisture evaporation phase. This phase lasted up to approximately 160 °C. For the samples torrefied at 200 °C and 250 °C, the decomposition peak was straggled. In the second stage, which takes place between 280 °C and 360 °C, the decomposition of lighter and heavier fractions of volatile substances takes place. The weight of raw samples decreased by approximately 25–30%, whereas in torrefied samples (200 and 250 °C), it decreased by approximately 40–45%. The last stage occurred at temperatures higher than 550 °C, and may be connected to the decomposition of complex organic components. The raw sample and the samples torrefied at 200 °C and 300 °C also showed a significant peak at around 650–700 °C, which could be related to the decomposition of some inorganic materials such as carbonates [36].

Figure 4.

TGA precent weight loss for raw and torrefied MSW samples.

Figure 5.

DTG weight loss rate for raw and torrefied MSW samples.

The thermal curves showed that torrefied materials have an initial decomposition temperature higher than raw material, since torrefaction reduces the thermal stability (except for the sample torrefied at 300 °C). Some anomalies occurred during the thermal analysis and it is believed this is connected to the composition of the selected MSW samples and their heterogeneity. Similar observations were found in the work of Abdulyekken et al. [25].

4. Conclusions

In this study, the physicochemical properties of municipal solid waste (MSW) from the Republic of Slovenia were investigated. The torrefaction of selected raw MSW was carried out at three different temperatures (200, 250, and 300 °C, respectively) and a residence time of 90 min. A semi-inert atmosphere was ensured. In the work, the torrefaction temperature was investigated for mass and energy yields, elemental and proximate contents, heating values, enhancement factors, and fuel ratios. Additionally, the thermal properties of selected MSW samples were studied. A thermogravimetric analysis was performed and the samples were heated at the constant heating rate, 10 °C/min, from 25 °C to 800 °C. The obtained results confirm the following statement: when the torrefaction temperature is increased, mass and energy yields decreased, HHV increased, carbon and nitrogen contents increased, while the oxygen, hydrogen, and sulphur contents also decreased. A similar statement could be made about moisture contents, volatile matter values, fixed carbon contents, and ash contents. When the torrefaction temperature increased, moisture and volatile matter contents decreased, whereas fixed carbon contents and ash contents increased. For the MSW samples used in this study: the average MY decreased to 65.75 wt.%. and the average EY decreased to 66.79% for each studied torrefaction temperature, respectively. The heating values increased from 24.3 to 25.1 MJ/kg. The carbon content increased from 43.2 ± 0.9 to 52.7 ± 1.0 wt.% and the oxygen content decreased from 47.9 ± 0.9 to 39.5 ± 0.8 wt.%. Under the same conditions, MC decreased from 44.3 ± 0.9 wt.% to 38.7 ± 0.8 wt.% VM content was reduced from 45.9 ± 0.9 wt.% to 44.3 ± 0.9 wt.%, whereas FC and ash content increased (from 6.7 ± 0.2 wt.% to 10.1 ± 0.5 wt.% and from 3.1 ± 0.0 wt.% to 6.9 ± 0.1 wt.%, respectively). Additionally, enhancement factors and fuel ratios were in the range from 1.00 to 1.02 and 0.15 to 0.23, respectively. Some anomalies occurred during the thermal analysis and it is believed that they are connected to the composition of selected MSW samples and their heterogeneity.

In conclusion, by using the torrefaction pretreatment, available domestic municipal waste from the Republic of Slovenia could be converted into a solid biofuel and therefore be used as an alternative to coal, but further investigation should be conducted, especially in the terms of investigation the thermal properties. In the future, our research will be expanded. Samples of municipal solid waste will be mixed with other biomasses and both physicochemical and thermal properties will be studied regard torrefaction temperature and time. The kinetics of pyrolysis of the samples will be evaluated in addition, and lastly, the emissions during the process will be determined.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/thermo3020017/s1. Figure S1: Elemental and Proximate analysis of MSW after torrefaction for each experimental run; Equation (S1): Equation for calculation the theoretical HHV values.

Author Contributions

Conceptualization, methodology, software, validation, investigation, formal analysis, writing—original draft: M.I.; methodology, validation, formal analysis, writing—review and editing, supervision: D.U.; supervision: D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| DTG | Derivative thermogravimetric analysis |

| EF | Enhancement factor |

| EU | European Union |

| EY | Energy yield |

| FC | Fixed carbon |

| FR | Fuel ratio |

| GHG | Greenhouse gas emissions |

| HHV | High heating value (MJ kg−1) |

| MC | Moisture content |

| MSW | Municipal solid waste |

| MY | Mass yield |

| RES | Renewable energy sources |

| SURS | Statistical Biro of Slovenia |

| VM | Volatile matter content |

| TGA | Thermogravimetric analysis |

| T | Temperature |

References

- European Commission European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 10 April 2023).

- Climate and Energy Framework. Available online: https://ec.europa.eu/clima/eu-action/climate-strategies-targets/2030-climate-energy-framework_en (accessed on 10 April 2023).

- Ang, T.Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A Comprehensive Study of Renewable Energy Sources: Classifications, Challenges and Suggestions. Energy Strateg. Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Bekirsky, N.; Hoicka, C.E.; Brisbois, M.C.; Ramirez Camargo, L. Many Actors amongst Multiple Renewables: A Systematic Review of Actor Involvement in Complementarity of Renewable Energy Sources. Renew. Sustain. Energy Rev. 2022, 161, 112368. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(Ethylene Terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef] [PubMed]

- Poudel, J.; Karki, S.; Oh, S.C. Valorization of Waste Wood as a Solid Fuel by Torrefaction. Energies 2018, 11, 1641. [Google Scholar] [CrossRef]

- Novian Cahyanti, M.; Rama Krishna, T.; Doddapaneni, C.; Kikas, T. Biomass Torrefaction: An Overview on Process Parameters, Economic and Environmental Aspects and Recent Advancements. Bioresour. Technol. 2020, 301, 122737. [Google Scholar] [CrossRef]

- Chen, F.; Chen, Z. Cost of Economic Growth: Air Pollution and Health Expenditure. Sci. Total Environ. 2021, 755, 142543. [Google Scholar] [CrossRef]

- Kumar, R.; Strezov, V.; Weldekidan, H.; He, J.; Singh, S.; Kan, T.; Dastjerdi, B. Lignocellulose Biomass Pyrolysis for Bio-Oil Production: A Review of Biomass Pre-Treatment Methods for Production of Drop-in Fuels. Renew. Sustain. Energy Rev. 2020, 123, 109763. [Google Scholar] [CrossRef]

- Das, P.; Chandramohan, V.P.; Mathimani, T.; Pugazhendhi, A. A Comprehensive Review on the Factors Affecting Thermochemical Conversion Efficiency of Algal Biomass to Energy. Sci. Total Environ. 2021, 766, 144213. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, E.; Ferreira, S. Biomass Waste for Energy Production. Energies 2022, 15, 5943. [Google Scholar] [CrossRef]

- Ivanovski, M.; Goricanec, D.; Krope, J.; Urbancl, D. Torrefaction Pretreatment of Lignocellulosic Biomass for Sustainable Solid Biofuel Production. Energy 2021, 240, 122483. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Bruno, M.; Blanco, I. Effectiveness of Thermodynamic Adaptative Equilibrium Models for Modeling the Pyrolysis Process. Sustain. Energy Technol. Assess. 2018, 27, 74–82. [Google Scholar] [CrossRef]

- Chen, D.; Cen, K.; Cao, X.; Li, Y.; Zhang, Y.; Ma, H. Restudy on Torrefaction of Corn Stalk from the Point of View of Deoxygenation and Decarbonization. J. Anal. Appl. Pyrolysis 2018, 135, 85–93. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Madissoo, M.; Pärn, L.; Virro, I.; Kikas, T. Torrefaction of Agricultural and Wood Waste: Comparative Analysis of Selected Fuel Characteristics. Energies 2021, 14, 2774. [Google Scholar] [CrossRef]

- Delgado, B.; López González, D.; Godbout, S.; Lagacé, R.; Giroir-Fendler, A.; Avalos Ramirez, A. A Study of Torrefied Cardboard Characterization and Applications: Composition, Oxidation Kinetics and Methane Adsorption. Sci. Total Environ. 2017, 593–594, 406–417. [Google Scholar] [CrossRef]

- Kota, K.B.; Shenbagaraj, S.; Sharma, P.K.; Sharma, A.K.; Ghodke, P.K.; Chen, W.H. Biomass Torrefaction: An Overview of Process and Technology Assessment Based on Global Readiness Level. Fuel 2022, 324, 124663. [Google Scholar] [CrossRef]

- Grams, J. Surface Analysis of Solid Products of Thermal Treatment of Lignocellulosic Biomass. J. Anal. Appl. Pyrolysis 2022, 161, 105429. [Google Scholar] [CrossRef]

- Xu, J.; Huang, M.; Hu, Z.; Zhang, W.; Li, Y.; Yang, Y.; Zhou, Y.; Zhou, S.; Ma, Z. Prediction and Modeling of the Basic Properties of Biomass after Torrefaction Pretreatment. J. Anal. Appl. Pyrolysis 2021, 159, 105287. [Google Scholar] [CrossRef]

- Chen, W.H.; Cheng, C.L.; Show, P.L.; Ong, H.C. Torrefaction Performance Prediction Approached by Torrefaction Severity Factor. Fuel 2019, 251, 126–135. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Nwabunwanne, N.; Vuyokazi, T.; Olagoke, A.; Mike, O.; Patrick, M.; Anthony, O. Improving the Solid Fuel Properties of Non-Lignocellulose and Lignocellulose Materials through Torrefaction. Materials 2021, 14, 2072. [Google Scholar] [CrossRef]

- Mei, Y.; Chen, Y.; Zhang, S.; Zheng, Y.; Li, W.; Chai, H.; Liu, K. Effect of Temperature Oscillation on Torrefaction and Pyrolysis of Elm. SSRN Electron. J. 2022, 271, 127055. [Google Scholar] [CrossRef]

- Zhang, D.; Han, P.; Zheng, H.; Yan, Z. Torrefaction of Walnut Oil Processing Wastes by Superheated Steam: Effects on Products Characteristics. Sci. Total Environ. 2022, 830, 154649. [Google Scholar] [CrossRef] [PubMed]

- Abdulyekeen, K.A.; Daud, W.M.A.W.; Patah, M.F.A.; Abnisa, F. Torrefaction of Organic Municipal Solid Waste to High Calorific Value Solid Fuel Using Batch Reactor with Helical Screw Induced Rotation. Bioresour. Technol. 2022, 363, 127974. [Google Scholar] [CrossRef] [PubMed]

- Johnson, T.R. Municipal Solid Waste Management. Routledge Handb. Environ. Policy China 2017, 8, 302–313. [Google Scholar] [CrossRef]

- Babasaheb, M.; Matsagar, K.C.-W.W. Biochar in Agriculture for Achieving Sustainable Development Goals; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Pulidori, E.; Gonzalez-Rivera, J.; Pelosi, C.; Ferrari, C.; Bernazzani, L.; Bramanti, E.; Tiné, M.R.; Duce, C. Thermochemical Evaluation of Different Waste Biomasses (Citrus Peels, Aromatic Herbs, and Poultry Feathers) towards Their Use for Energy Production. Thermo 2023, 3, 66–75. [Google Scholar] [CrossRef]

- Knapczyk, A.; Francik, S.; Jewiarz, M.; Zawiślak, A.; Francik, R. Thermal Treatment of Biomass: A Bibliometric Analysis—The Torrefaction Case. Energies 2021, 14, 162. [Google Scholar] [CrossRef]

- Mu’min, G.F.; Prawisudha, P.; Zaini, I.N.; Aziz, M.; Pasek, A.D. Municipal Solid Waste Processing and Separation Employing Wet Torrefaction for Alternative Fuel Production and Aluminum Reclamation. Waste Manag. 2017, 67, 106–120. [Google Scholar] [CrossRef] [PubMed]

- The World Bank. The Solid Waste Management. Available online: https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management (accessed on 10 April 2023).

- Zhu, X.; Li, S.; Zhang, Y.; Li, J.; Zhang, Z.; Sun, Y.; Zhou, S.; Li, N.; Yan, B.; Chen, G. Flue Gas Torrefaction of Municipal Solid Waste: Fuel Properties, Combustion Characterizations, and Nitrogen/Sulfur Emissions. Bioresour. Technol. 2022, 351, 126967. [Google Scholar] [CrossRef] [PubMed]

- Triyono, B.; Prawisudha, P.; Aziz, M.; Mardiyati; Pasek, A.D.; Yoshikawa, K. Utilization of Mixed Organic-Plastic Municipal Solid Waste as Renewable Solid Fuel Employing Wet Torrefaction. Waste Manag. 2019, 95, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Xing, Z.; Ping, Z.; Xiqiang, Z.; Zhanlong, S.; Wenlong, W.; Jing, S.; Yanpeng, M. Applicability of Municipal Solid Waste Incineration (MSWI) System Integrated with Pre-Drying or Torrefaction for Flue Gas Waste Heat Recovery. Energy 2021, 224, 120157. [Google Scholar] [CrossRef]

- Statistični urad Republike Slovenije. Mešani Komunalni Odpadki. Available online: https://www.stat.si/StatWeb/News/Index/10977 (accessed on 10 April 2023).

- Ivanovski, M.; Petrovic, A.; Ban, I.; Goricanec, D.; Urbancl, D. Determination of the Kinetics and Thermodynamic Parameters of Lignocellulosic Biomass Subjected to the Torrefaction Process. Materials 2021, 14, 7877. [Google Scholar] [CrossRef]

- Doddapaneni, T.R.K.C.; Pärn, L.; Kikas, T. Torrefaction of Pulp Industry Sludge to Enhance Its Fuel Characteristics. Energies 2022, 15, 6175. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Gajek, M.; Zajemska, M.; Jayaraman, K.; Gokalp, I. Combustion and Kinetic Parameters Estimation of Torrefied Pine, Acacia and Miscanthus Giganteus Using Experimental and Modelling Techniques. Bioresour. Technol. 2017, 243, 304–314. [Google Scholar] [CrossRef]

- Bach, Q.V.; Chen, W.H.; Chu, Y.S.; Skreiberg, Ø. Predictions of Biochar Yield and Elemental Composition during Torrefaction of Forest Residues. Bioresour. Technol. 2016, 215, 239–246. [Google Scholar] [CrossRef]

- Zhu, X.; Li, S.; Li, J.; Zhou, S.; Yan, B.; Sun, Y.; Chen, G. A Component Synergy of Flue Gas Torrefaction of Municipal Solid Waste. Fuel Process. Technol. 2022, 238, 107517. [Google Scholar] [CrossRef]

- Iroba, K.L.; Baik, O.D.; Tabil, L.G. Torrefaction of Biomass from Municipal Solid Waste Fractions I: Temperature Profiles, Moisture Content, Energy Consumption, Mass Yield, and Thermochemical Properties. Biomass Bioenergy 2017, 105, 320–330. [Google Scholar] [CrossRef]

- Rago, Y.P.; Collard, F.X.; Görgens, J.F.; Surroop, D.; Mohee, R. Torrefaction of Biomass and Plastic from Municipal Solid Waste Streams and Their Blends: Evaluation of Interactive Effects. Fuel 2020, 277, 118089. [Google Scholar] [CrossRef]

- Chang, S.S.; Sambeth, S.K.; Abdul Samad, N.A.F.; Saleh, S. Effect of Torrefaction on Thermal Degradation and Functional Group of Oil Palm Solid Waste. Mater. Today Proc. 2022, 57, 1248–1255. [Google Scholar] [CrossRef]

- Ivanovski, M.; Urbancl, D.; Petrovič, A.; Stergar, J.; Goričanec, D.; Simonič, M. Improving Lignocellulosic and Non-Lignocellulosic Biomass Characteristics through Torrefaction Process. Appl. Sci. 2022, 12, 2210. [Google Scholar] [CrossRef]

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemeš, J.J. Torrefied Biomass Fuels as a Renewable Alternative to Coal in Co-Firing for Power Generation. Energy 2020, 209, 118444. [Google Scholar] [CrossRef]

- Gajera, B.; Tyagi, U.; Sarma, A.K.; Jha, M.K. A Study of Impact of Torrefaction on Thermal Behavior of Wheat Straw and Groundnut Stalk Biomass from Punjab, India: Kinetic and Thermodynamic Approach. SSRN Electron. J. 2022, 12, 100073. [Google Scholar] [CrossRef]

- Demirbas, A. Potential Applications of Renewable Energy Sources, Biomass Combustion Problems in Boiler Power Systems and Combustion Related Environmental Issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal Solid Waste Management and Waste-to-Energy in the Context of a Circular Economy and Energy Recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Abdulyekeen, K.A.; Umar, A.A.; Patah, M.F.A.; Daud, W.M.A.W. Torrefaction of Biomass: Production of Enhanced Solid Biofuel from Municipal Solid Waste and Other Types of Biomass. Renew. Sustain. Energy Rev. 2021, 150, 111436. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Xu, W.; Chen, Z.; Evrendilek, F.; Sun, S. Torrefaction, Temperature, and Heating Rate Dependencies of Pyrolysis of Coffee Grounds: Its Performances, Bio-Oils, and Emissions. Bioresour. Technol. 2022, 345, 126346. [Google Scholar] [CrossRef]

- Oluoti, K.; Doddapaneni, T.R.K.C.; Richards, T. Investigating the Kinetics and Biofuel Properties of Alstonia Congensis and Ceiba Pentandra via Torrefaction. Energy 2018, 150, 134–141. [Google Scholar] [CrossRef]

- Huang, Y.F.; Cheng, P.H.; Chiueh, P.T.; Lo, S.L. Microwave Torrefaction of Leucaena to Produce Biochar with High Fuel Ratio and Energy Return on Investment. Energy Procedia 2017, 105, 35–40. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Meda, V. Enhancement of Fuel and Physicochemical Properties of Canola Residues via Microwave Torrefaction. Energy Rep. 2021, 7, 6338–6353. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).