Abstract

This paper is devoted to determining the influence of some risk elements on the asphalted surfaces of bridge ramps, in order to detect possible damages or potential collapses of the embankment. The main factors will be characterized by (a) movements of floating reinforced concrete (r.c.) slab over the embankment connected to the border of the bridge; (b) longitudinal cracks on the asphalt produced by small sliding deformations; (c) emerging vegetation from the slope of the ramps. The authors propose a set of possible techniques to determine level of risk indicators, illustrating a set of case studies related to several asphalt roads approaching r.c. bridges.

1. Introduction

As is well known, road pavements, from a constructive point of view, are divided into three main types:

- Flexible;

- Rigid;

- Semi-rigid.

The first type consists of multiple overlapping layers (base, binder, and wearing course), each made of mixtures of mineral aggregates and bitumen of increasing quality in the surface layers. The load distribution pattern changes from layer to layer, as the strength of each layer is different. The stratigraphy varies from the least flexible but most resistant material (on the surface) to the most flexible and least resistant material in the bottom layer, on which the load is distributed over a larger area.

Rigid pavements are generally made of Portland Cement Concrete (PCC) slabs characterized by a high modulus of elasticity, resting on a foundation layer of cement-treated base. The latter in turn rests on a foundation layer of granular mix.

Semi-rigid pavements are a middle ground between the two. They differ from flexible pavements in that, between the bituminous base layer and the foundation, a layer of hydraulically bound mixed material is applied with a discrete flexural rigidity in order to significantly decrease the deformability of the pavement.

Regardless of the type, pavements serve four main functions: (i) to provide a smooth riding surface with low roughness, essential for driving comfort conditions for users [1]; (ii) to ensure adequate tire–road friction conditions, which are essential for safe driving, especially in wet conditions [2]; (iii) to protect the subgrade, which must have sufficient structural capacity in terms of strength and thickness to reduce the loads on the subgrade that could compromise its bearing capacity [3]; (iv) to ensure waterproofing, preventing water from penetrating into the underlying layers. The saturation of the underlying layers would lead to a loss of load-bearing capacity with the consequent failure of the pavement [4,5].

The service life of a road structure, defined during the design phase, identifies the time period during which the infrastructure maintains its functionality. However, (i) vehicular traffic, especially heavy vehicles, (ii) moisture, (iii) subgrade quality, and (iv) construction quality are factors that influence its performance. Specifically, the magnitude of the vehicular load, its configuration, and the number of repetitions of heavy vehicle loads are determining factors in the wear of the superstructure [6]. Moisture can significantly reduce the strength of natural granular materials, particularly the subgrade [7,8]. Rainfall infiltration and groundwater affect the degradation of the subgrade of the bridge ramps from a hydro-mechanical perspective, reducing the shear strength of the embankment by seepage and consequent deformations. Water penetration into the road structure, through cracks and holes in the surface, compromises the strength of granular materials and causes the loss of cohesion and pavement failure [9]. A weak or uneven subgrade leads to deformation and the differential deterioration of the pavement. An accurate assessment at the design stage is therefore essential. It is clear that the correct execution of the work is of fundamental importance. In fact, errors during laying, insufficient compaction, the use of poor materials, or incorrect thicknesses drastically reduce the life of the pavement.

The scheduling and timing of maintenance is crucial in this respect, as it significantly extends the service life of the road and reduces overall costs. Delaying work leads to an exponential increase in repair costs and serious economic losses in the medium term.

Bridge ramps and associated structures, like floating r.c. slabs (approach slabs), are critical components of transport infrastructure [10]. Their soundness is necessary to ensure safety and longevity. Their deterioration can manifest in the form of asphalt surface cracking, concrete slabs deteriorating, and vegetation intrusion, all of which can degrade structural performance. Other failure damages can be found in Ref. [11].

This paper provides an overview of current research into the detection of such deterioration, with a focus on

- Asphalt overlaid in ramps cracks;

- Floating r.c. slabs (approach slabs);

- Vegetation in the vicinity of ramps.

This paper is organized as follows. Section 2 presents the main defects and types of deterioration in road pavement bridge ramps. Section 3 provides a literature review concerning the three factors listed above, which contribute to the deterioration of bridge abutments. Finally, Section 4 presents the conclusions of the study.

2. Defects and Deterioration of Road Pavements

Road pavement defects or deteriorations are the explicit demonstration of its changed condition. As far as general road pavement distress classification is concerned, the reader should refer to ASTM D6433-24 [12]. There are multiple causes including performance deficiencies of the used materials, possible errors during design or construction phases, environmental and climatic factors, and heavy traffic conditions not properly considered during design. A first broad classification of the distresses is made according to the affected layer, based on which the deteriorations are distinguished into functional and structural. The former affect the surface layers, while the latter involve the load-bearing layers of the structure [13].

Functional defects are typical of the surface layer and concern the reduction in the pavement’s functional characteristics, such as the friction and roughness of the driving surface, to the detriment of traffic safety. Structural defects, on the other hand, affect the load-bearing layers of the superstructure. They are due to a deterioration of the bearing properties and cause serious consequences if not addressed in time.

2.1. Functional Defects

Functional defects are distinguished on the basis of the performance characteristic whose functionality is impaired, such as

- Grip;

- Roughness.

Within the framework of road infrastructure safety, the phenomenon of tire–road grip plays a crucial role. It occurs during motion through the area of mutual contact (contact patch) and must always be ensured, even in the presence of rainwater.

Grip characteristics depend on vehicle speed, tire type and wear, environmental conditions, and the road surface. In particular, the latter contributes in terms of micro and macro texture. Macro texture is related to the pavement’s asperities and is caused by the protrusions of the aggregate particles, even if coated with bitumen. Micro texture is linked to the roughness of the surface of the aggregate particles.

Deteriorations that undermine grip manifest as surface damage to the pavement. Among the most common are

- Polishing of aggregates;

- Bleeding of bitumen (bleedings);

- Disintegration and raveling of aggregates (stripping or erosion by weathering agents).

The smoothness of the driving surface strongly influences driving safety and ride comfort. A lack of smoothness causes increased stresses on the structural parts of vehicles and leads to variability in the dynamic loads transmitted by vehicles to the pavement superstructure, resulting in a reduction in the forces that generate grip and the fatigue resistance of pavements.

Deteriorations related to smoothness manifest as pavement deformations. The most common are

- Depressions and bulges;

- Rutting over extensive areas;

- Surface irregularities of the driving lane;

- Edge cracking;

- Block cracking;

- Joint cracking.

2.2. Structural Defects

Structural defects are deteriorations that affect the layers of the superstructure and lead to a decline in bearing capacity and noise characteristics. For the purpose of this study, only the former will be briefly addressed.

The behavior of a structure subjected to a load, whether static or dynamic, depends on its stiffness, that is, the resistance it offers to deformation. The stiffness of a structure is evaluated through bearing capacity measurements, using point load tests, either static or dynamic.

Deteriorations related to bearing capacity manifest as cracks and failures in the pavement and can be classified as

- Longitudinal cracking;

- Branching, transverse, and longitudinal cracking, spiderweb or crocodile skin cracking;

- Settlements;

- Potholes.

2.3. Overview of Defects

This section concludes with a summary of the main defects and deteriorations of road pavements, grouped by type of degradation: smoothness (S) and bearing capacity (B). In Table 1, a representative image, a brief description, and an assessment of the possible causes are provided for each type.

Table 1.

Summary of the main smoothness and bearing capacity defects and deteriorations of pavements.

Understanding the main causes and mechanisms underlying pavement deterioration is fundamental for establishing and developing effective design, monitoring, and maintenance strategies. In particular, regarding maintenance, the adoption of advanced monitoring techniques, such as the use of sensors to monitor pavement condition or the latest automatic crack detection technologies, can certainly improve the management and durability of road infrastructure [4]. Specifically to bridge ramps, the main defects can be attributed to

- (A)

- The slope of the embankment;

- (B)

- The movement of the r.c. floating slab;

- (C)

- The growth of vegetation in the adjacence of the ramp

3. Analysis Technologies of Defects on Bridge Ramps

3.1. Cracks in Asphalt Overlays on Ramps

Traditionally, pavement damage mapping was performed visually, either directly from a moving vehicle or by capturing digital video of the pavement. However, these methods have proven to be costly and not always sufficiently reliable and repeatable. In the past decade, Saarenketo et al. [14] conducted an analysis combining traditional techniques, such as the Falling Weight Deflectometer (FWD), profilometer, and visual assessments, with three techniques based on electromagnetic wavelengths longer than visible light: (i) Ground Penetrating Radar (GPR), (ii) thermal imaging camera, and (iii) laser scanner. The advantage of the latter two techniques is the detection of cracks within the pavement that cannot be seen with the naked eye. Additionally, the first two ((i) and (ii)) can also be useful for detecting moisture in the asphalt, which is often the main cause of damage. The disadvantage is that, due to the relatively complex nature of these technologies, they have struggled to become routine investigation tools for most road agencies.

Manual crack detection is extremely time-consuming and costly. Therefore, in recent years, to improve efficiency and accuracy in road maintenance while reducing the need for manual inspections, the scientific community has increasingly focused on deep learning approaches and image processing techniques.

Models developed using deep learning innovations can identify and categories cracks in asphalt overlays. Using an improved YOLO-based model, CR-YOLO, in conjunction with a modified PSPNet model, bridge surface fractures were precisely detected and segmented [15]. When detecting cracks from many automobiles, Convolutional Autoencoders (CAEs) have >90% accuracy and minimize false-negative rates to less than 1% [16]. In images with poor contrast, the Hilbert–Huang Transform (HHT) can identify microcracks by showing a 15% amplitude reduction in damaged areas [17] as in Table 2.

Table 2.

Crack detection performance.

Computational image processing methods like adaptive thresholding and edge detection have been used in a bid to detect cracks in asphalt roads.

Yao et al. [18] presented a method that integrated deep convolutional neural networks and adaptive thresholding, and the method attained a classification rate of 94.4%.

CNNs are a type of neural network widely used for computer vision tasks, such as image recognition. In [19], the authors developed an automatic system using convolutional neural networks (CNNs) to analyze pavement images and automatically identify the presence of cracks. In the study, a CNN is implemented with a structured prediction approach, which takes into account the spatial relationships between cracks, namely, the shape and arrangement of cracks within the overall image context. To train the neural network, the study uses a dataset of pavement images with cracks of varying severity. The results obtained from the CNN model indicated that the system has a good ability to accurately detect cracks. In fact, the model demonstrated high precision, with a significant reduction in errors compared to manual or semi-automatic methods. Furthermore, compared to these methods, it has the advantage of being faster and enabling real-time monitoring.

Maeda et al. [20] also proposed a method for detecting road damage using CNNs on images captured with a smartphone mounted on a car. In this way, they created a dataset of approximately 9053 images of road damage containing 15,435 instances of surface damage. Furthermore, each image was annotated with bounding boxes indicating the position and type of damage. The proposed detection method enabled the classification of different types of damage with high accuracy.

Although some countries, such as Japan, have developed economical and easily accessible smartphone-based methods for the automatic monitoring of road conditions, other countries still struggle to find efficient solutions. In this regard, Ref. [21] evaluated the use of transfer learning to adapt the Japanese model to other countries. The study contributes to the literature by (i) providing a large-scale, heterogeneous dataset of road damages, consisting of 26,620 images collected across multiple countries using smartphones, and (ii) presenting generalized models capable of detecting and classifying road damages in international contexts.

Naddaf-Sh et al. [22] analyzed visual data related to pavement deterioration in real time. The researchers used a database of road crack images, composed of a diverse sample of crack types, such as longitudinal cracks, transverse cracks, and “alligator” cracks, photographed using mobile devices. Finally, they trained a family of efficient and scalable models optimized for detecting cracks in the road surface.

In [23], the authors, leveraging recent advances in deep learning for computer vision, proposed a new neural network architecture called Feature Pyramid and Hierarchical Boosting Network (FPHBN). The proposed network integrates contextual information at lower-level features in a pyramidal manner and balances the contribution of easy and hard samples to the loss function through a nested hierarchical reweighting of samples during training. Additionally, they proposed a new evaluation metric for crack detection, called AIU (Average Intersection over Union).

The method was evaluated on five different road crack datasets and compared with the most advanced existing methods for crack detection, edge detection, and semantic segmentation. The results demonstrated that the proposed method has excellent generalization capability and delivers superior accuracy, outperforming the methods it was compared against.

Finally, accelerated aging tests demonstrated that epoxy microcapsule-filled self-healing asphalt reduces the recurrence of cracks by 40% [24].

3.2. Floating R.C. Approach Slabs

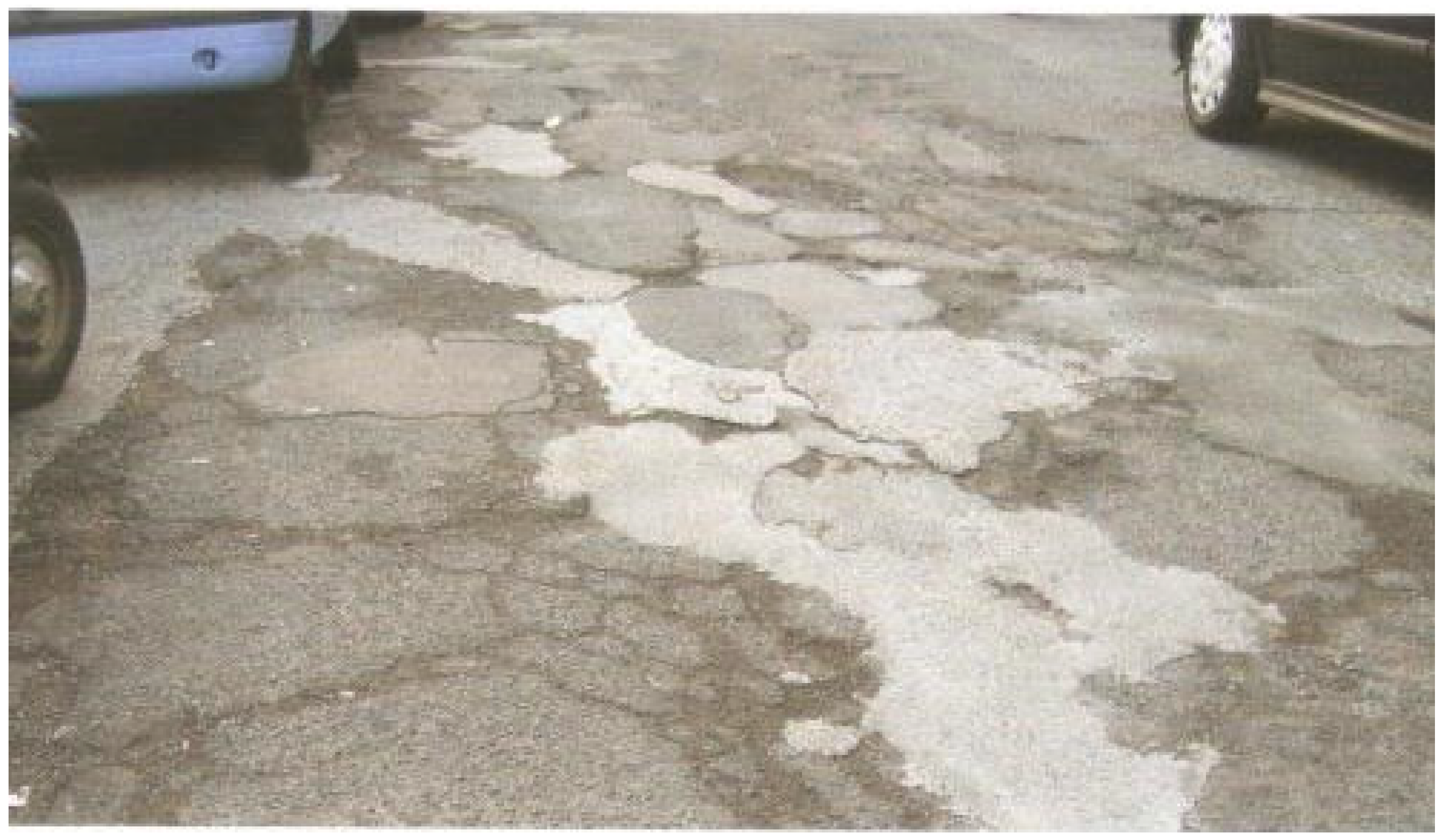

Approach slabs are susceptible to voids, settlement, and other subsurface intrusions. Ultra-High Frequency (UHF)-band Ground Penetrating Radar (GPR) has been applied for the detection of such defects. Yamaguchi et al. [25] demonstrated that UHF-band GPR could successfully detect delamination and voids beneath R.C. bridge slabs by applying signal processing techniques. An example of the effects given by degradation of the embankment under the floating R.C. approach slab is in Figure 1: the Badilone 1 Bridge on the northern part of the highway of Olbia, with the vibrations produced by traffic causing perimetral cracks on the asphalt surface and out-of-plane deformations on the road joints.

Figure 1.

Badilone 1 Bridge (Olbia, Italy): (a) perimetral cracks of floating RC approach slab; (b) out-of-plane deformations of road joint.

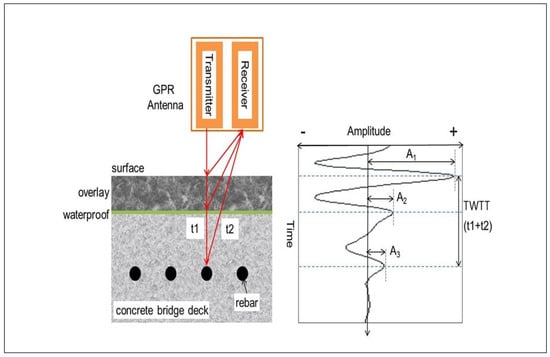

Air-coupled GPR systems (Figure 2) also offer a non-contact method for the assessment of bridge decks with asphalt overlays. A case study on a field test on a Korean highway employed this technology to examine the deterioration depth of a concrete bridge deck and mapped out zones with serious chloride-induced deterioration [26].

Figure 2.

Illustration of GPR scanning on a concrete bridge deck and a possible path of EM waves in asphalt-covered concrete bridge decks.

To prevent resonances caused by traffic-induced vibrations, new floating bridges, like the Nordhordland Bridge in Norway (Figure 3), also satisfy 3 mm of deflection to dead loads and natural frequencies of 10–24 Hz [27] as in Table 3.

Figure 3.

Norway’s Nordhordland Bridge.

Table 3.

Deflection standards for floating RC slabs [27].

In the real-time UAV deflection tracking system, deep learning architectures, such as the CNN network (CD-YOLOv8), can achieve a maximum accuracy of >93%, surpassing the traditional modal analysis-based approach (Figure 4) [27].

Figure 4.

The CNNs on images captured with a smartphone [20].

The significance of hybrid PCA-GMM model-based vulnerability assessment (83.3% accuracy) was highlighted by the Francis Scott Key Bridge collapse in 2024, which revealed that 68 US bridges exceeded AASHTO’s ship collision risk criteria [28].

3.3. Vegetation in the Adjacence of Ramps

Vegetation around bridge ramps may result in moisture retention and root intrusion, weakening the structure further. There are a few research papers exclusively on vegetation detection, but the fusion of vegetation indices of remote sensing data with structure evaluation can detect hazards. This data may be used in conjunction with GPR and visual inspection to improve the identification of regions where vegetation is a causative element in structural problems. According to Ref. [29], vegetation root penetration and water retention compromise structural strength. The Villanova Bridge (Figure 5) and the Seulo-Gadoni Bridge (Figure 6) represent emblematic case studies of low-traffic roads in which the lack of maintenance of vegetation along the ramps created problems to the serviceability stage.

Figure 5.

A general view of the upstream elevation of the Villanova Bridge. The image was captured by a quadcopter drone (photo by Elizalde (2024) from [29]).

Figure 6.

The collapsed upper ramp (a) and the cracked lower ramp (b) of the Seulo-Gadoni Bridge (image by the authors, 2025).

Possible mitigation strategies can be summarized as follows, when direct periodical inspection is difficult due to the large size of the road network with respect to human resources.

- Integrated Vegetation Management (IVM): Native species (e.g., switchgrass) reduce invasive biomass by 30% and maintenance costs by USD 4200/acre annually [30].

- LiDAR drones map root systems, enabling targeted herbicide application.

- Corrosion Monitoring: Electrochemical sensors embedded in concrete detect pH drops (<11) and chloride ingress, preventing rebar corrosion [31].

3.4. Integrated Approaches and Future Directions

Combining multiple technologies offers a comprehensive assessment of bridge ramps and adjacent structures. The most important are predictive analytics and material advancements.

Predictive analytics:

- GPR and AI Integration: Merging GPR data with AI models can improve the detection of subsurface anomalies;

- UAV-Based Inspections: Utilizing Unmanned Aerial Vehicles (UAVs) equipped with high-resolution cameras enables efficient visual inspections, especially in hard-to-reach areas;

- Edge Computing: Deploying AI models on edge devices allows for real-time damage detection and assessment in the field;

- The LSTM-driven Health Index (HI) predicts RC slab deterioration with >93% accuracy, enabling initiative-taking maintenance [32];

- Vehicle–Bridge Interaction (VBI) systems use vehicle-mounted sensors to monitor bridge frequencies, reducing reliance on fixed infrastructure [31].

With regard to material advancements, Carbon Fiber-Reinforced Polymers (CFRPs) retrofit corroded slabs, reducing CO2 emissions by 60% compared to steel [24].

4. Conclusions

For the safety of vehicles, bridge ramps and related components must be structurally sound. Damage or failure on bridge ramps, representing the connection between a relatively rigid background (the bridge) and the road embankment, is a crucial aspect of the integrity of the road line. The ability to identify and evaluate damage has been recently improved by the developments in NDE techniques, deep learning, and integrated inspection approaches, made available by recent major advances in electronics, telecommunications, and big data management.

The adoption of these technologies and further study will be essential for initiative-taking bridge infrastructure management and maintenance. Orienting the focus to the approaching ramps of bridge infrastructure can be profitable in terms of the prevention of collapses or damages in the road network. The best solutions should be characterized by the following aspects.

- -

- Quick and easy use: In most cases, the technicians managing the road network are not highly trained to manage and interpret the data.

- -

- Efficiency in transmission and conservation of data: The wireless data or the automatic measurements must be stored and retained for possible future uses.

- -

- Early warning factors: The data shall be accompanied by synthetic factors, in order to compare the measurements over time and prevent failures or large damages.

- -

- Finally, the experimental monitoring activity should be extended to the underground of the bridge ramps, to better determine the causes of damage and failures, including geotechnical measurements.

Author Contributions

All the authors contributed to the conceptualization, methodology, and data curation. Writing—original draft preparation, N.R. and F.M.; writing—review and editing, N.R. and M.L.P.; supervision, M.C. and M.S.; funding acquisition, M.C. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by (1) the Ministry of University Research through project PRIN 2022 PNRR Rock-Resilience; (2) the project e.INS–Ecosystem of Innovation for Next Generation Sardinia funded by the Italian Ministry of University and Research (MIUR) under the Next-Generation EU Programme (National Recovery and Resilience Plan–PNRR, M4C2, INVESTMENT 1.5–DD 1056 of 23 June 2022, ECS00000038)- SPOKE 8–CUP F53C22000430001; (3) the Metropolitan City of Cagliari, through the Collaboration Agreement “Creation of an innovative monitoring of the road infrastructures and their artworks of relevance to the Metropolitan City of Cagliari”, signed on 1 June 2021, following the commitment of expenditure n.58 of 31 December 2020 by the Road Department.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

The authors would like to thank student Muhammed Ziad Bacha for the collection of some data.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Robbins, M.M.; Tran, N.H. A synthesis report: Value of pavement smoothness and ride quality to roadway users and the impact of pavement roughness on vehicle operating costs. Natl. Cent. Asph. Technol. (NCAT) Auburn Univ. 2016, 16-03. [Google Scholar]

- Dorozhko, Y.; Batrakova, A.; Tymoshevskyi, V.; Zakharova, E. ENSURING ADHESION BETWEEN THE ASPHALTCONCRETE ROAD SURFACE AND RIGID BASE AT THE ROADBED DESIGN STAGE. East. -Eur. J. Enterp. Technol. 2021, 111, 84. [Google Scholar]

- Schaefer, V.R.; White, D.J.; Ceylan, H.R.; Stevens, L.J. Design Guide for Improved Quality of Roadway Subgrades and Subbase, Digital Repository, Institute for Transportations, Iowa State University, 2008- n.9. Available online: https://www.intrans.iastate.edu/wp-content/uploads/sites/10/2019/01/Design-Guide-for-Improved-Quality-of-Roadway-Subgrades-and-Subbas.pdf (accessed on 25 June 2025).

- Adlinge, S.S.; Gupta, A.K. Pavement deterioration and its causes. Int. J. Innov. Res. Dev. 2013, 2, 437–450. [Google Scholar]

- Zhou, Y.; Peng, Z.; Wang, J.; Wei, J.; Liu, H.; Wang, D.; Li, J. A review on adhesion behavior of chip seal pavement and aggregate. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 441–466. [Google Scholar] [CrossRef]

- Sybilski, D.; Bańkowski, W.; Sudyka, J.; Krysiński, L. Reasons of premature cracking pavement deterioration—A case study. In 7th RILEM International Conference on Cracking in Pavements: Mechanisms, Modeling, Testing, Detection and Prevention Case Histories 2012; Springer: Dordrecht, The Netherlands, 2012; pp. 1029–1038. [Google Scholar]

- Ikechukwu, A.F.; Hassan, M.M. Assessing the extent of pavement deterioration caused by subgrade volumetric movement through moisture infiltration. Int. J. Pavement Res. Technol. 2022, 15, 676–692. [Google Scholar] [CrossRef]

- Bhuyan, H.; Scheuermann, A.; Bodin, D.; Becker, R. Use of time domain reflectometry to estimate moisture and density of unbound road materials: Laboratory calibration and field investigation. Transp. Res. Rec. J. Transp. Res. Board 2017, 2655, 71–81. [Google Scholar] [CrossRef]

- Yan, G.; Bore, T.; Schlaeger, S.; Scheuermann, A.; Li, L. Dynamic effects in soil water retention curves: An experimental exploration by full-scale soil column tests using spatial time-domain reflectometry and tensiometers. Acta Geotech. 2024, 19, 7517–7543. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, Y.; Liu, J.; Lan, S.; Yang, J. Causes and statistical characteristics of bridge failures: A review. J. Traffic Transp. Eng. 2022, 9, 388–406. [Google Scholar] [CrossRef]

- Li, P.; Yang, C.; Xu, F.; Li, J.; Jin, D. Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study. Buildings 2024, 14, 2466. [Google Scholar] [CrossRef]

- ASTM D6433-24; Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys. Nov 15, 2024. Available online: https://store.astm.org/d6433-24.html (accessed on 25 June 2025).

- Ragnoli, A.; De Blasiis, M.R.; Di Benedetto, A. Pavement distress detection methods: A review. Infrastructures 2018, 3, 58. [Google Scholar] [CrossRef]

- Saarenketo, T.; Matintupa, A.; Varin, P. The Use of Ground Penetrating Radar, Thermal Camera and Laser Scanner Technology in Asphalt Crack Detection and Diagnostics. In 7th RILEM International Conference on Cracking in Pavements; Scarpas, A., Kringos, N., Al-Qadi, I., Loizos, A., Eds.; RILEM Bookseries; Volume 4; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Zhang, J.; Qian, S.; Tan, C. Automated bridge surface crack detection and segmentation using computer vision-based deep learning model. Eng. Appl. Artif. Intell. 2022, 115, 105225. [Google Scholar] [CrossRef]

- Lee, K.; Jeong, S.; Sim, S.; Shin, D.H. Damage-Detection Approach for Bridges with Multi-Vehicle Loads Using Convolutional Autoencoder. Sensors 2022, 22, 1839. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Mokrani, B.; Alaluf, D.; Yu, J.; Preumont, A. Damage detection in active suspension bridges: An experimental investigation. Sensors 2018, 18, 3002. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.; Liu, Y.; Li, X.; You, Z.; Feng, Y.; Lu, W. A detection method for pavement cracks combining object detection and attention mechanism. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22179–22189. [Google Scholar] [CrossRef]

- Fan, Z.; Wu, Y.; Lu, J.; Li, W. Automatic pavement crack detection based on structured prediction with the convolutional neural network. arXiv 2018, arXiv:1802.02208. [Google Scholar]

- Maeda, H.; Sekimoto, Y.; Seto, T.; Kashiyama, T.; Omata, H. Road damage detection using deep neural networks with images captured through a smartphone. arXiv 2018, arXiv:1801.09454. [Google Scholar]

- Arya, D.; Maeda, H.; Ghosh, S.K.; Toshniwal, D.; Mraz, A.; Kashiyama, T.; Sekimoto, Y. Transfer learning-based road damage detection for multiple countries. arXiv 2020, arXiv:2008.13101. [Google Scholar]

- Naddaf-Sh, S.; Naddaf-Sh, M.M.; Kashani, A.R.; Zargarzadeh, H. An Efficient and Scalable Deep Learning Approach for Road Damage Detection. In Proceedings of the 2020 IEEE International Conference on Big Data (Big Data), Atlanta, GA, USA, 10–13 December 2020; pp. 5602–5608, IEEE. Available online: https://arxiv.org/abs/2011.09577 (accessed on 25 June 2025).

- Yang, F.; Zhang, L.; Yu, S.; Prokhorov, D.; Mei, X.; Ling, H. Feature pyramid and hierarchical boosting network for pavement crack detection. IEEE Trans. Intell. Transp. Syst. 2019, 21, 1525–1535. [Google Scholar] [CrossRef]

- Klym, A.; Blikharskyy, Y.; Gunka, V.; Poliak, O.; Selejdak, J.; Blikharskyy, Z. An Overview of the Main Types of Damage and the Retrofitting of Reinforced Concrete Bridges. Sustainability 2025, 17, 2506. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Mizutani, T.; Tarumi, M.; Su, D. Sensitive damage detection of reinforced concrete bridge slab by “Time-Variant deconvolution” of SHF-Band radar signal. IEEE Trans. Geosci. Remote. Sens. 2018, 57, 1478–1488. [Google Scholar] [CrossRef]

- Rhee, J.; Choi, J.; Kee, S. Evaluation of the Depth of Deteriorations in Concrete Bridge Decks with Asphalt Overlays Using Air-Coupled GPR: A Case Study from a Pilot Bridge on Korean Expressway. Int. J. Concr. Struct. Mater. 2019, 13, 23. [Google Scholar] [CrossRef]

- Wang, C.; Cui, M.; Cheng, Z.; Moan, T. A review on design and analysis of floating bridges: Numerical simulations, model tests and field measurements. Ocean Eng. 2024, 306, 118065. [Google Scholar] [CrossRef]

- Dadoulis, G.; Manolis, G.D.; Katakalos, K.; Dragos, K.; Smarsly, K. Damage detection in lightweight bridges with traveling masses using machine learning. Eng. Struct. 2024, 322, 119216. [Google Scholar] [CrossRef]

- Rodríguez Elizalde, R. Comprehensive technical inspection of a medieval bridge (Ponte de Vilanova, in Allariz) using microtechnological tools. Eng 2024, 5, 3259–3283. [Google Scholar] [CrossRef]

- Available online: https://infrastructurereportcard.org/cat-item/bridges-infrastructure/ (accessed on 21 May 2025).

- Fiandaca, D.; Di Matteo, A.; Patella, B.; Moukri, N.; Inguanta, R.; Llort, D.; Mulone, A.; Mulone, A.; Alsamahi, S.; Pirrotta, A. An integrated approach for structural health monitoring and damage detection of bridges: An experimental assessment. Appl. Sci. 2022, 12, 13018. [Google Scholar] [CrossRef]

- Jeon, C.H.; Kwon, T.H.; Kim, J.; Jung, K.S.; Park, K.T. Quantitative Evaluation of Reinforced Concrete Slab Bridges Using a Novel Health Index and LSTM-Based Deterioration Models. Appl. Sci. 2024, 14, 10530. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).