Abstract

This research aims to define an operational plan for the sustainability of small-scale artisanal gold mining (ASGM) in Northeast Antioquia, Colombia. A qualitative approach with a descriptive scope was used, for which a documentary or bibliographical review technique was made. Accordingly, articles, theses, books and institutional documents were reviewed as any contribution to the research topic. Likewise, this documentation contributed to defining aspects for elaborating the operational plan. Based on the reviewed sources, the need was found to propose an operational plan for this area to contribute to sustainability. Based on the sustainability analysis of ASGM in the zone, three common factors could be identified within the various positions proposed: the environmental, economic, and socio-cultural dimensions. With these, different needs were recognised in the area of study that still need action. An operational plan was devised to address these challenges and support the sector’s long-term sustainability.

1. Introduction

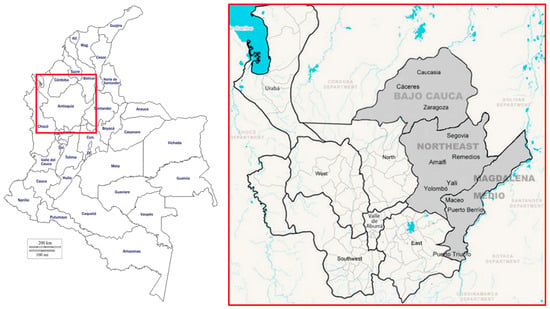

In previous research [1], the principles of a sustainable society were exposed, including those designed for industries such as mining to join these objectives [2,3,4,5]. Based on these principles, it has been possible to analyse the current small-scale artisanal gold mining situation in Northeast Antioquia, Colombia (Figure 1). According to official data [1], this region accounts for more than 65% of national gold production

Figure 1.

Location of the Northeast Antioquia area (adapted from [1], area in red zoomed).

Likewise, it was stated that in this area, it is possible to work to achieve the sustainable development of small-scale artisanal gold mining projects. This situation was evidenced in the reduction of systematic increases in the concentration of substances in the earth’s crust and the decrease in the concentration of substances produced by mining activity. In this research, all achievements were accomplished without talking about sustainability, having an operational plan or a roadmap that dictates the steps to be followed by this industry.

Therefore, it is necessary to continue working to change specific persistent needs in all areas of sustainability. For example, although mercury use has been reduced in the environmental dimension, ASGM still uses it excessively in the area of study [1]. This aspect prevents progress in other critical aspects of sustainability, such as eliminating structural barriers that affect people’s health.

In the same way, in the economic field, some work has also been done for sustainability through changes in processes such as the Whole Ore Amalgamation (WOA); as its name states, this method consists of putting the whole ore into contact with mercury with no previous concentration into smaller mass [6]) and the introduction of gold concentration equipment that maximises the benefits of mining work. However, the complete amalgamation of the mineral persists, a process that prevents further progress in the sustainability of this sector [7,8,9].

Lastly, socio-cultural needs also significantly impact achieving the principles of a sustainable society and industry [6,7,8,9,10,11]. As noted, it is possible to generate more added value if enough time is dedicated to concentrating the ore extracted from the mine, just like in Canada, where this process has become part of their culture. Thus, in the same way that concentration equipment and retorts have been entering the culture [12,13], work can continue to change the complete method for one without using mercury [14].

This research aims to design an operational plan based on the previous research results [1] that serves as a guide to contribute to the sustainability of ASGM in Northeast Antioquia as an operative answer to the identified needs. This research aims to answer the following questions: Can an operative plan be designed to move ASGM towards sustainability? How can it be designed? The results of the previous research will provide added value because they will help diagnose the ASGM situation in Northeast Antioquia. Therefore, they are going to the baseline for an operative plan.

2. Materials and Methods

The methodology used is a qualitative approach with a descriptive scope [15]. The technique used was the documentary or bibliographical review [16] to develop the specific objectives. A literature review from different sources and institutions was performed, and the documentation analysis reviewed contributed to exposing the needs of the ASGM in Northeast Antioquia.

2.1. Identifying Needs

Table 1 summarises the steps proposed to make the information analysis necessary to assess the situation described before.

Table 1.

Needs identified in previous studies by category.

2.2. Contrasting the Needs with the Planning Theory and Objectives

The main objective of the operational plan methodology is to propose basic principles for the sustainability of artisanal gold mining in Northeast Antioquia for those interested in applying them to their project. Thus, based on the exposed needs and opportunities, specific objectives are proposed that outline the goals to be achieved to contribute to the sustainability of this industry.

2.2.1. Design Strategies

A fundamental aspect to consider when preparing an operational plan is the strategy of the seven questions posed by the MMSD (Mining, Minerals and Sustainable Development) project [17]. These are used not only to assess the sustainability of mining activity according to the identified need), but also to plan a project.

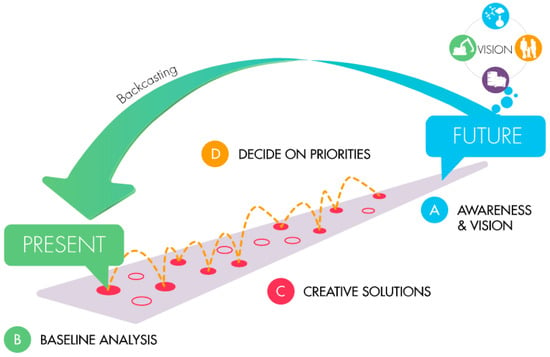

Another important concept to remember is backcasting, which was developed by Natural Step. The main idea of this concept is that, first, you should think about the future: where do you want to go? And what will that future look like? For example, for Natural Step the vision of the future is based on the four principles of a sustainable society. Second, after you have the vision, you go back to the present to design a process to achieve this vision [17].

Precisely, for the design of this process, four steps are recommended, known as the ABCD process [16]:

- (a)

- Recognition or awareness: consists of recognising or accepting the current situation. For example, Natural Step recognised that it was necessary to understand how to define sustainability. From there, the company used science-based definitions of sustainability to craft its vision: What will success look like in the future?

- (b)

- Evaluation: this step consists of evaluating the objectives or principles proposed to achieve the vision under current conditions. After defining it, Natural Step defines the four principles to assess how the activities of a company can go against the principles of sustainability.

- (c)

- Adequate vision: After comparing the current situation and the vision, solutions can be proposed to get where you want. In this sense, having a sustainable product is what Natural Step aims to achieve through creative solutions, for example.

- (d)

- Action plan: consists of designing an action plan to know what should be done and when to do things.

Figure 2 depicts the backcasting concept scheme [18].

Figure 2.

The backcasting scheme proposed by Natural Step. (Image licensed by CC BY-NC-SA 4.0).

2.2.2. Principles, Objectives and Goals

The objectives will be classified into basic principles that should be taken into account by any project, whether it is in progress or one that is to be undertaken from the beginning. Tables 2–4 (see Section 3) show the different needs, opportunities and objectives according to the identified principles. In this, seven principles can be determined that represent the sustainability approach for small-scale artisanal gold mining in Northeast Antioquia:

- Resource quality and production potential

- Staff health and safety

- Transformation of contracting processes

- Environmental responsibility

- Planning and projection

- Formation of bonds

- Circular economy

With these objectives and principles, it is possible to propose a guide of activities and actions that make it easier for any small-scale artisanal gold mining project in Northeast Antioquia to apply contributions to sustainability. However, as mentioned above, it is necessary to introduce the seven sustainability questions. With all this in mind, two things must be evaluated: first, if the identified principles align with the proposed mining sustainability concepts, and second, if all the activities fit within the seven steps presented by the MMSD [19] to plan the sustainability of mining activity.

Once the activities and their field of evaluation are defined, the stage of the mining cycle to be applied must be specified. This will allow the miner to find order within the guide and facilitate planning as the project advances and the risks decrease. Thus, for example, if the purchase of mineral transformation equipment is proposed, it will not be purchased during the exploration stage because the magnitude and composition of the deposit are hardly known. So, depending on its nature, gravity concentrators, flotation equipment, or direct cyanidation could be used. Buying equipment without first knowing the composition could lead to an incorrect investment.

On the other hand, for the approach of principles and objectives, the sustainability report of Continental Gold [20] was taken into account since it is an example of how environmental, economic and socio-cultural sustainability can be approached for mining operations.

2.3. Operational Plan

The operational plan will consist of a matrix of work or activities divided into three different matrices, each with a sustainability component: environmental, economic and socio-cultural. Each matrix comprises three columns: the first includes the sustainability evaluation categories (seven questions), the second defines the stage of the mining cycle in which it will be applied, and the third consists of the activities to be carried out.

This operational plan is also based on different authors and institutions. First, the Spanish Agency for International Development Cooperation [21] developed an example of a sustainability plan to expand an aqueduct system. In this document, this institution proposed the preparation of two matrices: one comprised of the project execution times and the other of the activities that will contribute to sustainability. Both matrices served as a starting point for designing the current operational plan.

Secondly, Eggert’s approach [22], based on the three dimensions (environmental, economic and socio-cultural), builds three matrices with three areas of action, from which one contributes to ASGM in the area of study.

3. Results

3.1. Needs and Opportunities

It should be noted that although particular needs were identified due to this type of activity in Northeast Antioquia, many also represent an investment opportunity in small-scale artisanal gold mining projects. Table 2 summarises the primary needs of ASGM at Northeast Antioquia.

Table 2.

The primary needs of small-scale artisanal gold mining are in northeastern Antioquia.

Similarly, Table 3 shows a count of requirements that may represent an investment opportunity.

Table 3.

The needs that mean an investment opportunity.

3.2. Principles, Objectives and Goals

Table 4 summarises the sustainability principles and objectives.

Table 4.

Sustainability principles and objectives.

3.3. Operational Plan

As stated at the beginning, the operational plan has as its starting point the three areas of sustainability proposed by Eggert [21]. In this sense, Table 5, Table 6 and Table 7 show the work plan from economic, environmental and socio-cultural sustainability and represent the matrix of action or activities.

Table 5.

Economic sustainability.

Table 6.

Environmental sustainability.

Table 7.

Socio-cultural sustainability.

4. Conclusions

Identifying needs helped to find the areas that still need action to move towards sustainability in ASGM in Northeast Antioquia. When compared with the steps proposed by theory and projects implemented in the field by different researchers, it was possible to determine that an operative plan can be designed for this type of activity.

During the development of this research, it was possible to observe the backcasting implementation as follows:

- Step A: It was applied when the mercury contamination problem was identified or recognised, as well as issues such as child labour or lack of gold-added-value in Northeast Antioquia.

- Step B: This was followed by contrasting the needs and different sustainability principles identified.

- Step C: It was applied when proposing the ideal scenarios for ASGM in Northeast Antioquia, such as using equipment that allows gold to be transformed without mercury.

- Step D: Plan preparation through the action or activities matrix and the schedule matrix to answer the following questions: What should be done? When to do things?

Likewise, it was possible to observe how the seven questions of the MMSD were used to evaluate the activities proposed in the operational plan and as part of the matrices to guide and plan those activities to be implemented. In this way, the MMSD proposal can be used to confirm that mining can be included in sustainability and as a starting point for designing plans that contribute to it. Identifying the mineral composition with the proper selection of the gold beneficiation circuit will reduce the potential for pollution and will help improve the economy of projects and the population. Moreover, implementing cyanide elimination methods will reduce the concentration of substances produced by society, thus contributing to environmental and social sustainability. In addition, knowing the inventory of the project (through exploration), progress will be made in the assurance of resources, which will have economic benefits for miners.

In summary, clear tools are given on how to design the plan. Nevertheless, several factors could represent limitations for this project, such as public order difficulties, the willingness of miners and the government itself, and funding. Finally, evaluation indicators must be designed to assess its effectiveness.

Author Contributions

Conceptualization, L.E.M.M. and O.J.R.B.; methodology, L.E.M.M. and O.J.R.B.; investigation, all authors; resources, O.J.R.B. and J.M.M.-A.; writing—original draft preparation, L.E.M.M.; writing—review and editing, O.J.R.B. and J.M.M.-A.; supervision O.J.R.B. and J.M.M.-A.; project administration, O.J.R.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Restrepo Baena, O.J.; Martínez Mendoza, L.E. Sustainability of the Artisanal and Small-Scale Gold Mining in Northeast Antioquia-Colombia. Sustainability 2021, 13, 9345. [Google Scholar] [CrossRef]

- De Haan, J.; Dales, K.; Mcquilken, J. Mapping Artisanal and Small-Scale Mining to the Sustainable Goals; University of Delaware: Newark, DE, USA, 2020. [Google Scholar]

- Giovannoni, E.; Fabietti, G. What Is Sustainability? A Review of the Concept and Its Applications. In Integrated Reporting: Concepts and Cases that Redefine Corporate Accountability; Busco, C., Frigo, M., Riccaboni, A., Quattrone, P., Eds.; Springer International Publishing: Cham, Switzerland, 2013; pp. 21–40. [Google Scholar] [CrossRef]

- Lopez, I. On sustainable development and sustainability: Conceptualisation and critique. Manchegan J. Soc. Sci. 2015, 20, 111–128. [Google Scholar] [CrossRef][Green Version]

- Veiga, M. Antioquia, Colombia: The World’s Most Polluted Place by Mercury: Impressions from Two Field Trips; University of British Columbia: Vancouver, BC, Canada, 2010. [Google Scholar]

- United Nations Environment Program—UNEP. Reducing Mercury Use in Artisanal and Small-Scale Gold Mining; UNEP: Nairobi, Kenya, 2012; Available online: https://www.unido.org/sites/default/files/files/2017-11/ASGM_English%20%281%29.pdf (accessed on 13 May 2025).

- Bernal-Guzman, L.J. Gold mining in Northeast Antioquia: A territorial dispute for development. Manag. Environ. 2018, 21, 74–85. [Google Scholar]

- Garcia, O.; Molina, J. Introduction of cleaner technologies in artisanal mining and gold extraction in northeast Antioqueño and Bajo Cauca Antioqueño, Colombia. In Patrimonio geominero, geología y minería ambiental: Libro de actas del Primer Congreso sobre Patrimonio Geominero, Geología y Minería Ambiental de Bolívia y los Andes; SOBPAGYM: Manresa, Spain, 2011; Available online: https://www.yumpu.com/es/document/read/14509279/introduction-of-cleaner-technologies-in-mining (accessed on 13 May 2025).

- García, O.; Veiga, M.; Cordy, P.; Suescún, O.; Molina, J.; Roeser, M. Artisanal gold mining in Antioquia, Colombia: A successful case of mercury reduction. J. Clean. Prod. 2015, 90, 244–252. [Google Scholar] [CrossRef]

- Telmer, K.; Veiga, M. World Emissions of Mercury from Artisanal and Small Scale Gold Mining. In Mercury Fate and Transport in the Global Atmosphere; Pirrone, N., Robert, M., Eds.; Springer: Dordrecht, The Netherlands; Berlin/Heidelberg, Germany; London, UK; New York, NY, USA, 2009; pp. 131–172. Available online: https://link.springer.com/content/pdf/bfm%3A978-0-387-93958-2%2F1.pdf (accessed on 13 May 2025).

- Trefny Center. Mercury and Gold—Amy Martin—EDS. [Video]. Vimeo. 1 November 2018. Available online: https://vimeo.com/298472887/ea1d73d5e0 (accessed on 13 May 2025).

- Richard, M.; Moher, P.; Rossin, R.; Telmer, K. Using Retorts to Reduce Mercury Use, Emissions and Exposures in Artisanal and Small Scale Gold Mining: A Practical Guide; Artisanal Gold Council: Victoria, BC, Canada, 2014; Available online: https://www.unep.org/globalmercurypartnership/resources/guidance/retort-guide-using-retorts-reduce-mercury-use-emissions-and-exposures-artisanal (accessed on 13 May 2025).

- Perea, C.; Restrepo, O. Incorporación de tecnologías limpias en unidades mineras ubicadas en el departamento de Antioquia. In Proceedings of the XIV Congreso Internacional de Ingeniería Metalúrgica, Materiales y Medio Ambiente CONIMETM, Huacho, Peru, 10–13 November 2015. [Google Scholar] [CrossRef]

- Pantoja, F.H.; Pantoja, S.D. Problems and challenges of artisanal and small-scale gold mining in Colombia. Rev. Fac. Cienc. Económicas 2016, 24, 147–160. [Google Scholar] [CrossRef]

- Hernández, R.; Fernández, C.; Baptista, M. Investigation Methodology, 6th ed.; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Bernal, C. Metodología de la investigación, 3rd ed.; Pearson: London, UK, 2010. [Google Scholar]

- MMSD. Seven Questions to Sustainability: How to Assess the Contribution of Mining and Minerals Activities; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2002; Available online: https://www.iisd.org/system/files/publications/mmsd_sevenquestions.pdf (accessed on 13 May 2025).

- Mining Notes by Dirk Van Zyl. Lecture 3—Tools for Incorporating Sustainable Development [Video]. Youtube. 3 February 2012. Available online: https://www.youtube.com/watch?v=JgFflz0_L2U (accessed on 13 May 2025).

- Available online: https://www.thenaturalstep.de/wp-content/uploads/TNS-backcasting-from-sustainability-principles-.pdf (accessed on 13 May 2025).

- Zijin Mining Group Co., Ltd. 2019 Environmental, Social and Governance Report. Available online: https://www.zijinmining.com/upload/file/2020/07/31/cc2b38ac1fd94cc889e9036d7543db33.pdf (accessed on 13 May 2025).

- Agencia Española de Cooperación Internacional para el Desarrollo (AECID). Plan de Sostenibilidad. Ejemplo Práctico; Ministerio de Asuntos Exteriores y Cooperación de España: Madrid, Spain, 2015. Available online: https://www.aecid.es/documents/20120/90536/Anexo%20el%20Salvador%20Corregido%20NOVIEMBRE_interactivo.pdf/661dde25-6c24-f783-e6be-7d2b523cb61d?t=1661328276552 (accessed on 13 May 2025).

- Eggert, R. What Sustainability and Sustainable Development Mean for Mining. In Sustainable Management of Mining Operations; Botin, J.A., Ed.; Society for Mining: Littleton, CO, USA, 2009; pp. 19–32. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).