Abstract

Technological advances are prompting mining companies to explore new options to enhance the efficiency of activities such as drilling, blasting, ventilation, and the loading and hauling of ore and waste. The emergence of digital environments, such as the Metaverse, allows companies in mining and other industrial sectors to simulate or predict scenarios in real time, generate ideas, and propose solutions before implementing them in the real world. There are various risks associated with the Metaverse and virtual worlds; however, there is insufficient information about the potential threats that could impact the Mining Metaverse. This investigation aims to establish a preliminary model for the efficient integration of the Metaverse into the mining industry. It highlights its potential by referencing previously adopted technologies such as virtual reality (VR), augmented reality (AR), and the Internet of Things (IoT) in mining and other sectors. It also seeks to identify and explain the risks associated with using a Mining Metaverse, considering constraints that will be valuable not only to the Australian mining industry but also on a global scale.

1. Introduction

The advent of Industry 5.0 has redefined how machines and new technologies enhance company productivity [1]. This transformation has led to digital and virtual environments where users can engage in various activities, from interacting with others via avatars to performing remote medical surgeries. The main purpose of Industry 5.0 is the collaboration between technology and humans. While Industry 4.0 focused on developing technology programmed to substitute humans, Industry 5.0 emphasises human participation, blending ethics, creativity, and decision-making with technology [2]. At this stage, industries are increasingly enhancing efficiency and improving the adaptability of machinery across various manufacturing and production fields. Repsol, a Spanish multinational energy and petrochemical company, has started applying automation to its industrial processes. They are developing Artificial Intelligence (AI) to simulate potential scenarios and upgrade production processes. Repsol has recently implemented a “cobot”, an autonomous robot that can be controlled and managed remotely. The term “cobot” is a blend of “robot” and “collaboration”, and it refers to tools designed to assist humans in their tasks [2]. Furthermore, in Bundesgartenschau, a biennial federal horticulture expo in Germany, technology capable of collaborating with humans in carpentry tasks has been introduced and discussed [2,3].

During the Mining 4.0 era, the introduction of artificial neural networks (ANNs) brought notable advantages to the industry. These networks enhanced the ability to predict equipment maintenance needs, thereby preventing damage and failure [4,5]. Additionally, based on previously collected data, ANNs improved safety on mine sites by effectively predicting the formation of toxic gases in underground operations [6]. This technology has also been adapted to rock blasting design in mines with complex geotechnical parameters, significantly improving drilling and blasting performance [7].

Virtual reality (VR) has emerged as a valuable tool for virtual simulations and emergency training [7]. The Internet of Things (IoT) and smart sensors have enabled the exploration and study of hazardous and inaccessible areas where human inspection is not feasible. These advancements have significantly improved safety conditions, increased productivity, and reduced energy consumption in mining operations [8].

As digital and virtual resources continue to evolve, there is potential to enhance existing applications and operations in mining [9,10]. The Metaverse, an immersive environment, where users interact in real time within a boundless virtual universe, is a key development not yet applied or notably investigated in mining [11,12]. Some technological and social media companies have established Metaverses to enhance social interactions, facilitate community creation, enable shopping, and support video game development [11,13,14].

Currently, virtual reality (VR), augmented reality (AR), and immersive software are utilised as collaborative tools alongside humans. Digital technologies have evolved since the First Industrial Revolution [15,16] and are also integrated into various mining operations (Table 1), from ensuring occupational safety to planning mining cycles [17].

Table 1.

Digital maturity in the mining industry.

Industry 5.0 emerged as a transition from tasks performed automatically by robots to a collaboration between technology and humans to solve tasks and achieve results. In this technological revolution, the Metaverse is presented as an advanced technology that offers immersive digital worlds based on virtual reality (VR), augmented reality (AR), and digital twin technologies, significantly impacting the companies that adopt it. In the mining industry, the Metaverse is a tool that enables achieving Industry 5.0 goals by optimising risk control plans and decision-making processes, streamlining communication methods between departments, and simulating scenarios for prevention, planning, and scheduling [12,14,18].

Meta, formerly known as Facebook, developed a virtual social platform where users can create avatars to interact with each other. Meta allows these avatars to engage in a virtual world, much like real-life interactions, including attending concerts, visiting movie theatres, learning new subjects, buying books, or playing sports [19,20]. On the other hand, gaming companies have created Metaverses, such as Roblox, Minecraft, and Grand Theft Auto, among others. Users can build virtual worlds using simple blocks on these platforms, from miniature house replicas to entire metropolises. These interfaces also enable other users to join and explore these digital environments. Recent studies suggest that these immersive environments hold potential as educational tools [19,21].

Renown companies are increasingly adopting Industry 5.0 technologies. A notable example is Renault, which, in 2022, transformed its supply chain management by integrating digital twins into its factories. This technology provided a comprehensive view of the production process, enabling precise predictive maintenance, real-time monitoring of warehouse inventory, and minimising downtime caused by emergencies or unplanned outages. By 2025, Renault expects to save approximately 330 million US dollars due to Industry 5.0 innovations. Further, they aim to reduce vehicle delivery times by 60% and cut their carbon footprint by 50% in the following years [22,23]. General Motors (GM) is integrating the Metaverse into its processes to create digital twins, aiming to harmonise operations between robots and human operators. GM also uses the Metaverse to simulate and assess operator performance, primarily focusing on protecting the biomechanics of their workforce [22,24]. Integrating machines within industrial companies and the emergence of Industry 5.0 promotes collaboration between intelligent robots and humans. It has transformed conventional approaches to managing processes, supply chains, and real-time scenario evaluation and supervision [9,18,25,26]. Technologies popularised during Industry 4.0, such as virtual and augmented reality, IoT, and Artificial Intelligence, remain essential for reducing processing costs, preventing incidents and accidents, and minimising carbon footprints [27,28,29,30,31,32,33,34,35].

Despite the emerging potential, there is still very limited information on how these models apply specifically to mining classifications in terms of daily production and the possible risks involved. This indicates a significant gap in the literature and research that needs to be investigated. For the above reasons, this unprecedented research aims to investigate and answer the following questions:

- Have current technologies such as virtual reality (VR), augmented reality (AR), and the Internet of Things (IoT) improved the mining industry?

- What mining classifications, based on daily production as a parameter for mine size, might adopt the Metaverse?

- How can an integration model be structured to measure the efficiency of applying the Metaverse in the mining industry?

- How would communication between the Metaverse and stakeholders vary according to the mining classifications?

Addressing these questions will support the design, preliminary establishment and development of a new model that can serve as a reference for the industry with the aim of guiding mining companies in the integration of new technologies. This model will include the application of the Metaverse in small-, medium-, and large-scale mining operations, its use at each stage of mining activity from planning to mineral delivery, the potential advantages and challenges of integrating the Metaverse into various mining activities, and the identification of risks associated with technological integration, along with proposed solutions.

2. Materials and Methods

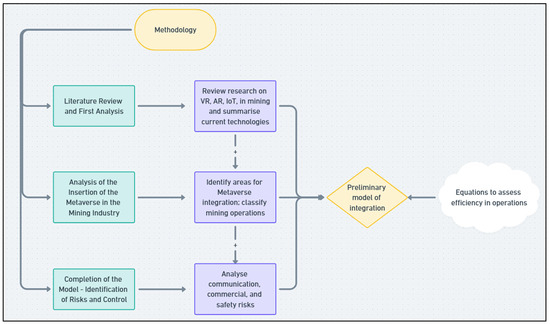

The methodology employed in this study is subdivided into three primary stages: Literature Review and First Analysis; Analysis of the Insertion of the Metaverse in the Mining Industry; and Establishment of the Preliminary Model—Case Study: Identification of Risks and Control. The three stages are further broken down into subtopics. The first analysis discusses the scientific production related to integrating the Metaverse and other similar technologies in the mining and other industries. Control variables and commercial and safety risks are identified in the second stage. Furthermore, separate integration evaluations are made based on the mine size (big, medium, and small). In the third and final stage, the establishment of a preliminary model is discussed, and a simplified case study is presented, followed by the identification of practical risks. Figure 1 shows a flowchart of the methodology and how it leads to developing the preliminary model for Metaverse integration.

Figure 1.

Methodology guide for the preliminary model of metaverse integration in mining.

2.1. Literature Review and First Analysis

To understand how the Metaverse could benefit the industry, it was first necessary to review previous research and experiences with similar technologies in other fields and conceive adaptations to the mining sector. This literature survey is focused on applying virtual reality, augmented reality, and IoT in mining while exploring the potential of combining these tools, for the first time, to implement the Metaverse in the industry. It identifies and incorporates insights from other industry sectors already using the Metaverse to determine risks associated with previous technologies applied during Industry 4.0 (Section 3.1, Section 3.2, and Section 3.3).

The literature review was conducted in the first stage of this research, identifying and incorporating insights from other industry sectors already using the Metaverse to determine risks associated with previous technologies applied during Industry 4.0.

The research involved searching scientific databases such as ScienceDirect, Web of Science, Scopus, and Google Scholar for white and grey literature. Books, articles, and research reports were considered to select appropriate sources. In addition, the criteria for selecting relevant studies included the terms virtual reality (VR), augmented reality (AR), and IoT technologies applied and/or integrated and/or used in the mining industry and/or other industries, as well as Metaverse technology, applied and/or integrated and/or used in the mining industry and/or other industries. The deliverable for this first stage was a summary of the technologies currently applied in the mining industry.

2.2. Analysis of the Insertion of the Metaverse in the Mining Industry

Mining operations were reviewed individually to identify if the Metaverse has already been applied in them and, otherwise, where and how it could be integrated to enhance safety conditions, communication, and operational efficiency. Additionally, mining operations were classified into small-, medium-, and large-scale enterprises; thus, each class was evaluated to determine the feasibility of applying this technology in alignment with Industry 5.0 (Section 3.5).

Each state in Australia uses different criteria to classify a mine site, which may depend on environmental regulations, the type of ore being mined, or the size of the mining concession. For the proposed insertion model, mine site classification will only be based on daily production capacity, measured in metric tonnes. The purpose of the general specification, as shown in Table 2, is to establish a preliminary universal model that can be adapted to any mine site worldwide.

Table 2.

Mining classification according to daily production.

The deliverables for this stage were charts and tables outlining when and how the Metaverse could be implemented based on general site conditions, forming the first part of the proposed preliminary model.

2.3. Establishment of the Preliminary Model—Case Study: Identification of Risks and Control

The interaction between mining classifications (small, medium and large scale) and Metaverse integration was analysed to provide a better view of how communications will be performed when using the Metaverse in different operations or activities within the mining industry. This was achieved by considering who the people responsible for each activity were and what the main activities were to complete each mining process.

Additionally, part of the model evaluated the commercial and safety risks associated with integrating the Metaverse into the mining industry. This methodology helped pinpoint significant challenges and weaknesses that must be addressed before the technology can be implemented in the industry. The deliverable for this final stage was the preliminary model (Section 3.6), followed by a simplified case study to showcase the impact of implementing the Metaverse in mining operations (Section 3.7). The example is not based on an existing data set but uses arbitrary numbers to perform simple calculations. Nevertheless, the demonstration of the case study supports our goal to specify hazards, risks, and controls identified to prevent unsafe conditions when using the Metaverse within a mining company (Section 3.8).

A limitation identified is the method used to quantify the integration of the Metaverse in terms of efficiency. For this reason, as an alternative addition to this preliminary model, the Cobb–Douglas and KLEMS equations proposed by Manrique et al. [36], Ogujiuba and Stiegler [37], and Sancho and Serrano [38] are discussed later in this work. KLEMS is a productivity framework with five inputs: capital, labour, energy, materials, and services. It is engineered in such a way as to analyse the input and how efficiently it contributes to the output. Cobb–Douglas analysis works as a production function that relates inputs (commonly capital and labour) to outputs, thus ascertaining productivity and returns to scale.

Together, they facilitate analysing variations in operational efficiency introduced in sectors such as mining due to changes in input, output and productivity increases.

3. Results and Discussions

Technologies like virtual and augmented reality, IoT, and Artificial Intelligence, which emerged during Industry 4.0 and Industry 5.0, have already been incorporated into various industrial sectors, including mining [1,11,17,39,40,41,42,43]. However, there is a noticeable lack of information on how the Metaverse can be utilised within the mining industry. Currently, the mining sector faces ongoing challenges related to communication, operational safety, environmental impact, and resource optimisation [44,45,46,47,48], all of which could be improved by adopting Industry 5.0 technologies like the Metaverse.

This section highlights the experiences companies are gaining through the Metaverse and its potential to improve real-time operations. These improvements include making work areas safer, enhancing communication and collaboration across departments, and creating immersive digital environments for training or mining simulations.

Table 3 outlines the stakeholders who will benefit directly and indirectly from developing a model for integrating the Metaverse into the mining industry based on the proposals by Stothard et al. [12,14], Wang [49], Gupta et al. [50].

Table 3.

Groups benefiting from the integration of the Metaverse in the mining industry.

3.1. Scientific Production Related to the Integration in the Mining Industry—Metaverse

Currently, scientific production related to the integration of the Metaverse as technology in mining operations is limited. As the Metaverse is a new technology still in its early stages in other industries, any studies regarding its application in the mining industry remain largely theoretical. The most relevant studies on this integration are discussed below.

Liu et al. [18] addressed how the Metaverse may be used to improve operational effectiveness and safety in the mining sector through a proposed conceptual framework called MetaMining. The authors pointed out advantages in the use of Metaverse technology such as increased levels of communication, remote decision-making, and collaborative planning that will allow users to map out and solve mining operational issues. The authors also mentioned some challenges relating to high computational resources and cybersecurity ramifications.

Similarly, Stothard et al. [12] deliberated on the importance of developing industry standards for the sustainable growth of software applications related to the Metaverse. The author noted that industry involvement in both the Mining Metaverse and the Metaverse would be economically stimulating and environmentally sustainable, as Metaverse technologies have yet to be introduced experimentally into the mining industry. In addition, Stothard et al. [14] developed a typology of the Metaverse that was founded in consensus opinion for Standards Australia IT-031 Modelling and Simulation Committee and ISO/IEC JTC 1/SC 24 Committee. The authors collectively note the need for partnerships between governments, businesses, and technology to assist in developing standards for the Metaverse but do not state that this is singularly or entirely due to the associated risks, including cybercrime and the security and protection associated with data.

3.2. Scientific Production Related to the Integration in the Mining Industry—Other Technologies

In another work, Stothard et al. [17] investigated the role that virtual worlds play in the mining industry. They described a taxonomy for selecting computer-based technologies that aid a user in determining the best tools for specific mining operational tasks. Their contribution included a diagram (Figure 2), which illustrates the technology that supports the user based on the risk factors involved, particularly for high-risk situations associated with active headings where there are both safety and financial risks. They concluded with the overarching message that continual safety challenges in mining warrant the employment of advanced technologies.

Figure 2.

User support technology based on the risk factors involved [6].

Further to this application, Stothard [13] ran an experimental program in 2008 at the Argenton Mines Rescue Station, examining the integration of virtual reality (VR) technology to train inexperienced workers. That study described the installation, supervision, and final implementation of a VR-based system to train workers to identify hazardous environments in mining operations. Strzałkowski et al. [27] analysed the recent implementations of VR in the mining sector, demonstrating its benefits compared to older technologies. Their analysis showed the application of VR, three-dimensional (3D) scanning, and software simulation to increase efficiency in underground mining. They also discussed a scenario where the VR model increased the visibility of light and heavy equipment and how VR provided a vantage point to view subsidence and karst formations. However, VR has not yet reached full technological maturity, although the potential for increasing productivity is considerable [27,51,52]. Similarly, Molaei et al. [31] provided an overview of the application of the Internet of Things (IoT) in mining, concluding that it has automation potential for increasing safety and productivity. They referenced a mining company in South America that positioned IoT as a predictor of material quality before processing, which led to cost reductions and efficiency improvements. IoT sensors monitored geotechnical data in real time and optimised mining processes [31,53,54].

From the specifications above, various technologies are available and currently applied in the mining industry. Table 4 below outlines computer-based technologies and their functions in the mining sector.

Table 4.

Computer-based technologies and current applications in the mining industry.

3.3. Scientific Production Related to the Integration in Other Industries—Metaverse

Nleya and Velempini [22] investigated the environmental benefits resulting from the implementation of the Metaverse in a bottling company. They observed a 9% reduction in energy usage over three months, after Helllenic, Coca-Cola’s leading bottling company in Europe, implemented digital twins in the Metaverse. Hellenic operates 55 sites across Europe, with each site producing approximately 90,000 bottles per hour. As with most production sites, the operators needed better control of processes to maintain a safer environment for their employees and the surrounding ecosystem [22,83,84].

Guo et al. [85] studied the preliminary incorporation of the Metaverse in the automotive industry, with the BMW Group exemplified by designing the first digital factory in collaboration with NVIDIA Omniverse. In this Metaverse, BMW Group can monitor its vehicle manufacturing, from design to feature insertion, contributing to a 30% increase in operational efficiency [86].

Moreover, Kim and Oh [87] assessed the possibilities and barriers of the Metaverse for the automotive and mobility industry and its opportunity to optimise the manufacturing process. They identified high potential for this new technology to be adapted to platforms such as vehicles or mobility services, as well as the challenge of increasing bandwidth and network availability to manage real-time experiences.

In the healthcare field, the study conducted by Bansal et al. [88] shows the various uses of the Metaverse, including Epazz Slims technology, which allows for virtual appointments with medical professionals providing live interaction. Additionally, augmented reality (AR) increases patient experience and recreates physical sensation and general movement. In the medical space, practitioners can complete clinical examinations utilising full senses. Epazz reported strong performance in 2021, with revenue increasing by more than 35% and EBITDA rising by 1168% compared to the previous year. There is also the adoption of the Metaverse into medical training to help demonstrate surgical specifics, educate patients on pregnancy stages, and reduce preoperative anxiety [88,89,90,91].

3.4. Control Variables and Commercial/Safety Risks Identified

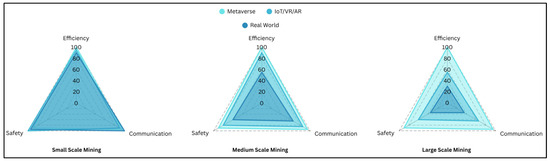

The control variables used to define the preliminary model are efficiency, safety, and communication (Figure 3). The three diagrams represent an equal number of different scales of mining operations (small, medium, large mining). Efficiency, communication and safety are critical to consider when introducing new technologies. Most importantly, the integration must support the production process, enhancing efficiency. Additionally, three key areas must be considered—the real world, the Metaverse, and IoT/VR/AR—each corresponding to the variables at the corners of the diagrams.

Figure 3.

Control variables for selecting the appropriate technology for mining operation purposes.

The following observations can be made from Figure 3:

- The three diagrams (Figure 3) have been used to illustrate three distinct zones, each defined by specific conditions. These zones help analyse the potential integration of different technologies within various stages of mining operations.

- Currently, scientific databases lack information regarding the quantitative distribution of key variables such as efficiency, communication, and safety when implementing computer-based technologies (virtual reality, augmented reality, IoT, metaverse) within industries. However, sufficient evidence has been provided by Flores et al. and Humphreys [92,93], who highlighted the significant role that computer-based technologies play in the mining industry and their positive impact on operational efficiency, safety, the environment, and stakeholders.

- For medium- and large-scale mining, in the real-world area, which represents a scenario without the utilisation of advanced technologies, communication and safety will have very low values. As a result, the production process at the mine site will not be efficient. The area corresponding to the real world can be adapted to all mining classifications. However, as seen in the diagrams, communication, safety, and efficiency will vary depending on the mine size being analysed.

- Each mining classification will have different values for the decision variables, significantly influenced by the situation or the analysis stage.

- For this preliminary model, the behaviour of the values is assumed to be linear, which does not completely reflect the reality, as there may be secondary parameters that need to be investigated and quantified to apply appropriate constraints to the diagram. As a first step, the ideal scenario for companies implementing technologies such as virtual reality, augmented reality, IoT, or the Metaverse is to achieve a balance between efficiency, communication, and safety.

3.5. Evaluations Based on Mine Size

The diagrams in Figure 3 identify up to three zones for small-, medium-, and large-scale mining operations, which are discussed in detail hereinafter.

3.5.1. Large-Scale Mining Evaluation

In large-scale operations, there are three areas identified:

- Real World: Technologies that do not include the use of the Metaverse, IoT, VR, or AR are still practical tools for large-scale mining. However, the absence of such technologies limits the operational efficiency, situational awareness, and safety response capabilities. For instance, without IoT-enabled sensors and devices, communication often relies on human observation and radio reports, which are prone to error and delay. Furthermore, the Metaverse, in the context of digital twins and collaborative 3D environments, allows engineers, geologists, and operators to jointly interpret geological models, plan operations, and simulate scenarios quickly and efficiently. Additionally, the diagram considers the current state of some large-scale mine sites. Some of these may operate without advanced computer-based technologies but maintain control over communication and safety. However, traditional methods are generally less efficient than more advanced technologies.

- IoT/VR/AR: The analysis for this area is like the ‘real-world’ zone but focuses on the degree to which efficiency, communication, and safety can be controlled through these technologies. The impact will depend on the specific technologies used and the stages of the mining process in which they are implemented. IoT, VR, and AR can bring about substantial improvements, but their success relies on strategic and appropriate integration within the operation.

- Metaverse: In this zone, a balance between efficiency, communication, and safety can be achieved. This balance represents the ideal scenario for companies implementing new computer-based technologies. By integrating the Metaverse, companies can enhance communication and safety measures while also optimising operational efficiency. This holistic approach maximises the benefits of these advanced technologies, making them essential for future operations.

3.5.2. Medium-Scale Mining Evaluation

The control applied to medium-scale operations identifies two primary zones:

- Real World: Like large-scale operations, traditional technologies can be helpful, but there are limitations, particularly concerning efficiency and safety improvements. The absence of advanced communication tools can lead to operational inefficiencies and potential safety risks.

- IoT/VR/AR: The analysis mirrors that of large-scale mining. Implementing IoT, VR, and AR can improve operational processes, but the extent of their impact depends on how well these technologies are integrated into specific mining stages. For medium-scale operations, the focus is often on cost-effective solutions that still provide significant gains in safety and efficiency.

3.5.3. Small-Scale Mining Evaluation

The control applied to small-scale mining identifies a single zone:

- Real World: Traditional approaches are more prevalent in small-scale mining. Due to the limited scale of operations, there is often less emphasis on adopting high-tech solutions, which can significantly restrict the ability to improve efficiency, communication, and safety. However, even in small-scale operations, there is a tendency to find a balance between these control variables, focusing on affordable solutions that can still deliver improvements without requiring extensive technological investments.

3.6. Establishment of a Preliminary Model

Figure 3 is used as the foundation for preparing Table 5, Table 6, Table 7, Table 8, Table 9 and Table 10. This structure is further supported by the evidence provided by Flores et al. and Humphreys [92,93], who highlighted the significant role that computer-based technologies play in the mining industry and their positive impact on operational efficiency, safety, environmental performance, and stakeholder engagement. Mining activities are structured based on the order defined by Bullock [94], and each will be analysed according to mining classification and the control variables for selecting the appropriate technology. The evaluation of each activity will focus on improving safety and addressing communication needs to enhance the efficiency of the mining production process.

Table 5.

Integration criteria in the exploration phase.

Table 6.

Integration criteria in the transportation phase.

Table 7.

Integration criteria in the closure planning phase.

Table 8.

Integration criteria in the planning and feasibility phase.

Table 9.

Integration criteria in the construction and mine development phase.

Table 10.

Integration criteria in the mine and plant operation phase.

As shown in Table 5, Table 6 and Table 7, the same model applies to small-, medium-, and large-scale mining due to the critical need to enhance safety and communication during the exploration, transportation, and closure planning phases. For medium-scale mining, it is important to implement technologies to visualise the mine’s growth and operational evolution. In contrast, large-scale mining requires an advanced communication system to improve efficiency during these stages further. Scientific studies have confirmed that implementing technologies to streamline and facilitate communication during the exploration and closure planning phases can foster stakeholder agreements, prevent misunderstandings, and enable continuous improvement in operational activities [95,96].

Table 8, Table 9 and Table 10 present a model demonstrating where the Metaverse should be applied in medium- and large-scale mining. Specifically, this technology is critical during the planning and feasibility, construction and mine development, and mine and plant operation phases, where seamless communication across different areas is essential. Effective integration helps supervise the supply chain from extraction to market, manage mine expansions, and ensure environmental control from the beginning to the closure of the project. Scientific studies also support integrating advanced technologies to enhance strategic planning and project execution [94,97,98]. As shown in the model, small-scale mining is not typically classified as a sector where computer-based technologies are applied during mining stages. However, given the current environmental challenges, integrating technology into the closure planning and operations phases can significantly improve control over environmental parameters, supporting remediation efforts and managing gas emissions [99,100].

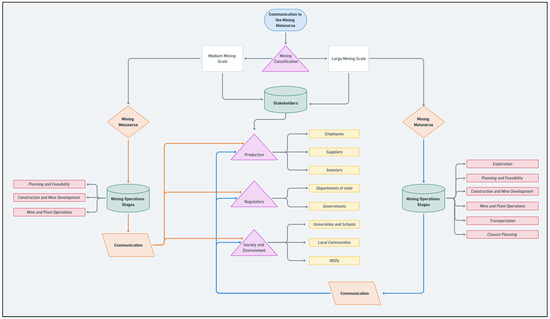

Figure 4 shows communication channels through the Mining Metaverse, indicating how they change according to mining classification (medium/large scale) and throughout various stages of operation. These communication approaches are customised for diverse stakeholder groups, including employees, suppliers, investors, government bodies, local community organisations, and non-governmental organisations (NGOs).

Figure 4.

Flowchart of medium and large mining scale communication structure.

The Metaverse is embedded into mining operations at different stages. In medium-scale mining projects, communications predominantly support three significant mining stages: planning and feasibility, construction, mine development, and mine and plant operations. On the other hand, communication in large-scale mining projects spans the broadest range of stages, from exploration to transportation to closure planning, including the stages mentioned above. Every mining stage initiates communication pathways with abidance to three main stakeholder domains: production, regulators, and society and environment. At the same time, the stakeholder domains work together and engage with specific stakeholder groups (such as investors, departments of state under production, or local communities and NGOs under society and environment). This structure was developed based on the analysis performed in Table 5, Table 6, Table 7, Table 8, Table 9 and Table 10, which detail the communication requirements and stakeholder interactions at various mining stages. Mapping these relationships gives an idea of how the communication moves dynamically through the Metaverse to support decision-making, safety, and efficiency throughout the mining life cycle.

To prepare the model for future research, integration efficiency can be quantified using the statistical model described below. Variables may vary depending on the specific mining stage being evaluated. This evaluation aims to compare scenarios with and without integrating new technology, ultimately refining Figure 3 by applying the formulations proposed by Manrique et al. [36], Ogujiuba and Stiegler [37], and Sancho and Serrano [38] (Equations (1)–(11)), so that accurate constraints can be incorporated to produce a precise diagram (Equation (1)):

where

- Q is the production;

- A is the technological process;

- K is the labour force;

- L is the capital;

- α and β are parameters of the equation.

The above factors will be evaluated based on their changes over time. To resolve Equation (1) generally it can be transformed to its logarithmic form (Equation (2)):

In this equation, α and β values are greater than zero and less than 1 and for that reason the following constraints are developed (Equations (3) and (4)):

KLEMS is a well-known model to measure labour productivity from multiple perspectives. The variables taken into consideration for this model are work hours, capital, energy, and services. The advantage of using the KLEMS model in this research is the experience that other investigators had when studying the economic growth and productivity of industrial companies or countries. The equation of the KLEMS model is expressed as follows (Equation (5)):

The behaviour of the product applied is defined by the following expression (Equation (6)):

where

- K is the mean capital;

- L are the working hours;

- E is energy;

- M is materials;

- S is services;

- α, β, γ, ɛ, ϴ indicate the annual participation of the factors in the value of the product;

- A is the total productivity of the factors.

If A is isolated, then the following expression will be obtained (Equation (7)):

To measure productivity in a mining company, a combination of the Cobb–Douglas and KLEMS models will be developed [36,37,38]. One visible strength visible of this combination is that KLEMS considers materials (M) and services (S), which will be interpreted as mineral reserves in this analysis. As mineral reserves are constant during the studied period, then M will not be considered in the analysis. The resulting equation from the combination is detailed as follows (Equation (8)):

where

- K is the capital (total linear metres of production per month);

- L is labour productivity (man-hours/tonne);

- E is the diesel consumption (litters);

- Q is production (tonnes of hauled material);

- A is the technological process.

All these variables depend on time. Hence, the equation to find productivity according to the Cobb–Douglas and KLEMS model is expressed below (Equation (9)).

Finally, one new variable needs to be added to the model. For this case, D will be added to change from 0 to 1 when the Metaverse is applied and when it is not, respectively. The relation between the technological process A and variable D is expressed in the following equation (Equation (10)):

Dt will change from 0 to 1 when the Metaverse is not applied and when it is applied, respectively. According to this criterion, the functional equation of productivity including the Metaverse will be defined as (Equation (11))

Calculating these parameters will allow the user to answer the research question. Based on the results, it can be determined if using fleet management systems will increment production efficiency in the mining industry.

3.7. Simplified Case Study

These models incorporate parameters such as capital (measured as total linear metres of production per month), labour productivity (man-hours per tonne), and energy consumption (litres of diesel). The production output (tonnes of hauled material) is the dependent variable. Efficiency changes are assessed using monthly operational data, allowing for short-term monitoring and long-term trend analysis. Medium-term impacts are not considered in this example.

To illustrate how the productivity model can be applied to a practical problem, below is an example of a hypothetical case applying the integrated Cobb–Douglas and KLEMS model. It aims to predict labour productivity in various operational and technological conditions, considering

- -

- Elasticities of capital, α = 0.3;

- -

- Labour, β = 0.2;

- -

- Energy, γ = 0.1.

The value of these coefficients will depend on how reliable they are in representing mining production. Together, they also reflect conditions that can limit mining operations. By using Equation (11), the following variables can be defined:

- -

- K is capital, measured as the total linear metres of production per month. In the first scenario (without the use of the metaverse), the value is 200 metres drilled per month. In the second scenario (with the metaverse), it is expected that the number of metres drilled will increase due to the introduction of new technology. For this reason, the value in this case will be 250.

- -

- L is labour productivity, measured by the number of man-hours. In this example, the value can be kept the same for both scenarios, although in real situations it could vary as it does not behave in a fixed way.

- -

- E represents energy, measured by the amount of fuel (in litres) or power used for a specific activity or group of activities over a certain period. Like labour productivity, this variable will not behave consistently in real life, but for this example, the same value will be used in both cases.

Case 1: Without Metaverse (Dt = 0), K = 200:

Case 2: With Metaverse (Dt = 1), K = 250, expected increased capital:

These cases demonstrate that, given an application of the Metaverse and an increase in capital development, labour productivity increases from 21.38 to 24.04, accounting for an increase of around 12.4%. This is consistent with the argument that digital and best-in-class operating inputs can transform mining productivity.

The proposed preliminary model excludes other variables directly related to production, such as the number of tonnes hauled, truck cycles per shift, and haul–dump time. Including these factors in the future would provide a more refined and realistic measure of productivity. Also, when applying this model, all equipment and machinery involved in production should be included in the analysis. Proper recording and storage of energy-related data is essential to maintaining accurate tracking. Since this example of the preliminary model evaluates two scenarios, it is crucial to log all data before and after integrating new technologies to obtain accurate values and a more meaningful analysis of results. In some cases, mines may not maintain such records, which creates a limitation due to insufficient data samples.

3.8. Identification of Risks and Control

A summary of the commercial and safety hazards associated with integrating the Metaverse into the mining sector is provided below, considering aspects identified solely found in literature sources and adapted to the context of the mining industry.

- Commercial Risk:High Startup Investment: Creating a Metaverse platform and connecting it with the current mining infrastructure can require a substantial investment. Hardware (such as VR headsets and sensors), software development, and staff training are all included in the costs. There is also a danger that the intended return on investment (ROI) may not be realised if the technology fails to deliver the promised benefits [101,102].Scalability and relationship: Ensuring that Metaverse solutions work with existing mining systems might be difficult. Customisation may be required, resulting in extra charges. The technology’s capacity to expand across multiple mining operations, particularly in distant or hostile settings, remains questionable. This might prevent widespread adoption [49,103].Uncertain Market Acceptance: The success of incorporating Metaverse technology is determined by how well it is received by stakeholders such as miners, managers, and investors. Resistance to change or concerns about its feasibility may hinder acceptance. If the technology fails to acquire momentum, businesses may suffer financial losses and missed potential for optimisation [49,50].Data Safety and Privacy Concerns: The Metaverse is based on data collection and integration across several platforms. The handling of sensitive data (such as mine layouts, equipment performance, and worker details) presents data security risks. Data breaches may pose business risks to mining organisations, resulting in intellectual property loss, operational interruptions, or reputational harm [104,105,106,107].

- Safety Risk:Virtual–Physical Interface Errors: The Metaverse refers to real-time interactions between virtual surroundings and physical mining activities. Failures in this interface might result in safety risks, such as erroneous remote operation of equipment or inadequate monitoring of hazardous locations. Technical faults, software problems, or network failures may create hazardous situations for workers who rely on real-time data for their safety [108].Employee Over-dependence on Technology: Workers may grow excessively dependent on the Metaverse’s automated or aided technologies. This dependency may impair situational awareness, posing a safety risk if the device malfunctions or gives erroneous information. There may also be difficulties in managing emergencies if staff are not properly trained to switch to manual processes when necessary [109,110].VR-Related Health and Safety Concerns: Prolonged usage of VR technology may result in health issues such as eye strain, motion sickness, or disorientation. In the mining industry, this might lead to lower worker efficiency and an increased risk of accidents. Workers utilising VR equipment in dangerous places may require regular breaks to reduce health concerns, which might impede production and require additional safety measures [108,110].

To prevent threats, it is critical to establish comprehensive cybersecurity measures such as strong data encryption, regular security audits, and real-time monitoring [106,107]. Transparent data management processes and user privacy policies can create stakeholder confidence. Comprehensive training programmes should be implemented to teach employees how to utilise the Metaverse platform successfully and securely, including handling system malfunctions and crises. Balancing technology use with situational awareness will assist in avoiding over-reliance on automated systems [104,108,109]. Furthermore, pilot testing before full-scale adoption enables businesses to detect and fix issues early on, while continual monitoring and feedback loops maintain the system’s reliability, safety, and financial viability [49,50].

Technological innovation and its positive impacts are important aspects to consider, along with market acceptance, when implementing a new technology. Therefore, technology acceptance models have been applied to analyse how users might respond to adopting a new technology. One recent study evaluated the perceptions of mining employees in Australia regarding the potential integration of the Metaverse into the mining industry. The authors concluded that the target population uses the Metaverse to perform their tasks enthusiastically. The participants came from various countries, providing a broad perspective on user behaviour [93]. For this reason, the authors intend to combine these outcomes to develop a new investigation to analyse further and quantify the benefits of integrating the Metaverse into the mining industry.

4. Conclusions and Future Work

Current technologies such as virtual reality (VR), augmented reality (AR), and the Internet of Things (IoT) have already begun to reshape mining operations by enabling remote monitoring, predictive maintenance, immersive training environments, and real-time visualisation of complex processes. These technologies lay the groundwork for broader Metaverse applications, reinforcing the sector’s digital transformation. Drawing from the experiences of other industry sectors, mining could facilitate sustainable development by fostering collaboration between society, academia, and industry. Additionally, supply chain management and the key variables analysed in this investigation, efficiency and communication, will likely improve.

Mining operations are classified in this study by daily production as small, medium, and large. Given their higher capacity for technological investment and operational complexity, medium- to large-scale operations are most likely to adopt the Metaverse. In these classifications, the Metaverse can simulate mine layouts, train personnel in safety protocols, and integrate data from IoT systems into immersive dashboards for faster decision-making.

Communication between the Metaverse and stakeholders also varies based on mine size. In large-scale mining operations, communication is often complex and involves multiple departments and external partners; here, the Metaverse can serve as a centralised platform for integrated planning, scenario simulation, and risk forecasting. In smaller operations, communication needs are typically more direct and limited in scope, so the Metaverse might focus on simpler applications such as real-time monitoring or training modules, ensuring that technology adoption aligns with operational scale and capacity.

This investigation enhances operations under the harsh conditions typically found at mine sites of any scale. By providing engineers, investors, and managers with real-time information on the current state of operations, it will be possible to make quick decisions, improve planning, and anticipate emergencies and hazardous conditions. As a result, the overall mining cycle will become more efficient.

A preliminary integration model is proposed around control variables like efficiency, communication, and safety under the umbrella of mining classifications to measure the efficiency of applying the Metaverse in mining or not. This draft model draws on the Cobb–Douglas and KLEMS models to incorporate quantitative metrics with qualitative assessments. Benchmarking these outcomes before and after Metaverse implementation provides a clear picture of performance change.

Nevertheless, this preliminary model does not come without limitations. It is still largely theoretical, mainly based on other industries’ extrapolation rather than tested mining-specific data. Further, Table 5, Table 6, Table 7, Table 8, Table 9 and Table 10 show that small-scale operations are mostly excluded from using VR/AR/IoT and Metaverse technologies. Thus, the model offers limited integration pathways for the Metaverse in small-scale projects. These limitations give way to future work, including improvements like adaptability to stakeholder dynamics, better communication structure, and versatility in mine sizes, geographies, and technological maturity levels.

In conclusion, while integrating the Metaverse into the mining industry presents significant opportunities for enhanced efficiency, communication, and safety, it also brings a range of commercial and safety risks that must be carefully managed. The commercial challenges are high initial investments, data security concerns, and potential system failures. Safety risks pose significant concerns, such as over-reliance on technology, VR-related health issues, and integration with autonomous systems. However, mining companies can effectively address these risks by implementing robust cybersecurity measures, comprehensive training programs, and continuous monitoring. Successful integration will depend on striking the right balance between innovation, safety, and cost management, ensuring that the benefits of the Metaverse are realised without compromising worker safety or operational stability.

Finally, the scope is to motivate those in the mining industry to continue researching the Metaverse and other technologies to improve mining operations. This initiative encourages collaboration among employees and stakeholders while also supporting sustainable development.

Author Contributions

Conceptualization, J.R. and A.M.A.Q.; methodology, J.R.; validation, J.R., P.S., G.B. and A.M.A.Q.; formal analysis, G.B.; investigation, J.R.; writing—original draft preparation, J.R.; writing—review and editing, J.R. and G.B.; visualisation, A.M.A.Q.; supervision, G.B.; project administration, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data sets employed in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Martínez-Gutiérrez, A.; Díez-González, J.; Perez, H.; Araújo, M. Towards industry 5.0 through Metaverse. Robot. Comput.-Integr. Manuf. 2024, 89, 102764. [Google Scholar] [CrossRef]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Zhou, M.; Jiang, K.; Shi, H.; Yu, Y.; Hao, N. Application of lightweight convolutional neural network for damage detection of conveyor belt. Appl. Sci. 2021, 11, 7282. [Google Scholar] [CrossRef]

- Senjoba, L.; Sasaki, J.; Kosugi, Y.; Toriya, H.; Hisada, M.; Kawamura, Y. One-dimensional convolutional neural network for drill bit failure detection in rotary percussion drilling. Mining 2021, 1, 297–314. [Google Scholar] [CrossRef]

- Meng, X.; Chang, H.; Wang, X. Methane concentration prediction method based on deep learning and classical time series analysis. Energies 2022, 15, 2262. [Google Scholar] [CrossRef]

- Zhironkin, S.; Ezdina, N. Review of transition from mining 4.0 to mining 5.0 innovative technologies. Appl. Sci. 2023, 13, 4917. [Google Scholar] [CrossRef]

- Motlagh, N.H.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of Things (IoT) and the energy sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Silamu, W.; Li, Q.; Ge, S.; Wang, F.Y. Smart mining with autonomous driving in Industry 5.0: Architectures, platforms, operating systems, foundation models, and applications. IEEE Trans. Intell. Veh. 2024, 9, 4383–4393. [Google Scholar] [CrossRef]

- Stothard, P. Developing an Enhanced VR Simulation Capability for the Coal Mining Industry; UNSW School of Mining Engineering: Kensington, NSW, Australia, 2008. [Google Scholar]

- Doherty, P. Definitions. In Unlocking the Metaverse; John Wiley & Sons: Hoboken, NJ, USA, 2023; pp. 1–13. [Google Scholar]

- Stothard, P. Mining Metaverse—A future collaborative tool for best practice mining. Min. Technol. 2023, 132, 165–178. [Google Scholar] [CrossRef]

- Wang, Y.; Su, Z.; Zhang, N.; Xing, R.; Liu, D.; Luan, T.H.; Shen, X. A survey on Metaverse: Fundamentals, security, and privacy. IEEE Commun. Surv. Tutor. 2022, 25, 319–352. [Google Scholar] [CrossRef]

- Stothard, P.; Ryan, P.; Kurata, T.; Stapleton, D. Towards a mining metaverse. Min. Technol. 2024, 133, 142–161. [Google Scholar] [CrossRef]

- Humphreys, D. The mining industry after the boom. Miner. Econ. 2019, 32, 145–151. [Google Scholar] [CrossRef]

- Humphreys, D. Mining productivity and the fourth industrial revolution. Miner. Econ. 2020, 33, 115–125. [Google Scholar] [CrossRef]

- Stothard, P.; Squelch, A.; van Wyk, E.; Schofield, D.; Fowle, K.; Caris, C.; Kizil, M.S.; Schmid, M. Taxonomy of interactive computer-based visualisation systems and content for the mining industry: Part One. First Int. Future Min. Conf. Exhib. 2008, 10, 201–210. [Google Scholar] [CrossRef]

- Liu, K.; Chen, L.; Li, L.; Ren, H.; Wang, F.Y. MetaMining: Mining in the Metaverse. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 3858–3867. [Google Scholar] [CrossRef]

- Rospigliosi, P.A. Metaverse or Simulacra? Roblox, Minecraft, Meta and the turn to virtual reality for education, socialisation, and work. Interact. Learn. Environ. 2022, 30, 1–3. [Google Scholar] [CrossRef]

- Costa-Sánchez, C. Facebook, crisis reputacional y huida hacia el metaverso. Anu. ThinkEPI 2022, 16, 1–6. [Google Scholar] [CrossRef]

- Meier, C.; Saorín, J.L.; de León, A.B.; Cobos, A.G. Using the Roblox video game engine for creating virtual tours and learning about the sculptural heritage. Int. J. Emerg. Technol. Learn. (iJET) 2020, 15, 268–280. [Google Scholar] [CrossRef]

- Nleya, S.M.; Velempini, M. Industrial Metaverse: A comprehensive review, environmental impact, and challenges. Appl. Sci. 2024, 14, 5736. [Google Scholar] [CrossRef]

- Ooi, K.-B.; Tan, G.W.-H.; Al-Emran, M.; Al-Sharafi, M.A.; Arpaci, I.; Zaidan, A.A.; Lee, V.-H.; Wong, L.-W.; Deveci, M.; Iranmanesh, M. The Metaverse in engineering management: Overview, opportunities, challenges, and future research agenda. IEEE Trans. Eng. Manag. 2023, 71, 13882–13889. [Google Scholar] [CrossRef]

- Triantafyllou, M.; Al-Bazi, A.; Ahmad, M.A. Digital twins: Revolutionizing automotive supply chains. In Proceedings of the International Conference on Logistics Operations Management, Marrakesh, Morocco, 2–4 May 2024. [Google Scholar]

- Chen, L.; Xie, J.; Zhang, X.; Deng, J.; Ge, S.; Wang, F.Y. Mining 5.0: Concept and framework for intelligent mining systems in CPSS. IEEE Trans. Intell. Veh. 2023, 8, 3533–3536. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Netto, M.; Stapleton, L.; Wan, Z.; Wang, F.Y. Smart decentralized autonomous organizations and operations for smart societies: Human–autonomous organizations for Industry 5.0 and Society 5.0. IEEE Intell. Syst. 2023, 38, 70–74. [Google Scholar] [CrossRef]

- Strzałkowski, P.; Bęś, P.; Szóstak, M.; Napiórkowski, M. Application of virtual reality (VR) technology in mining and civil engineering. Sustainability 2024, 16, 2239. [Google Scholar] [CrossRef]

- Zhang, S.X. Augmented reality on longwall face for unmanned mining. Appl. Mech. Mater. 2011, 40, 388–391. [Google Scholar] [CrossRef]

- Qin, X.; Fu, M.; Shen, B. Coal mine gas wireless monitoring system based on WSNs. In Proceedings of the 2011 Second International Conference on Digital Manufacturing & Automation, Zhangjiajie, China, 5–7 August 2011. [Google Scholar]

- Liu, Z.; Li, C.; Ding, Q.; Wu, D. A coal mine personnel global positioning system based on wireless sensor networks. In Proceedings of the 2010 8th World Congress on Intelligent Control and Automation, Jinan, China, 7–9 July 2010. [Google Scholar]

- Molaei, F.; Rahimi, E.; Siavoshi, H.; Afrouz, S.G.; Tenorio, V. A comprehensive review on Internet of Things (IoT) and its implications in the mining industry. Am. J. Eng. Appl. Sci. 2020, 13, 499–515. [Google Scholar] [CrossRef]

- Chen, Y.; Meng, F.; Guo, H. Design of detection system for mine oxygen concentration based on Internet of Things. Electron. Des. Eng. 2012, 20, 65–66, 70. [Google Scholar]

- Kim, H.; Choi, Y. Performance comparison of user interface devices for controlling mining software in virtual reality environments. Appl. Sci. 2019, 9, 2584. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, X. The Tailings Dam Monitoring and Pre-Alarm System (TDMPAS) and its applications in mines. In Proceedings of the 2012 SME Annual Meeting and Exhibit, Seattle, WA, USA, 19–22 February 2012. [Google Scholar]

- Tripathy, D. Virtual reality and its applications in mining industry. J. Mines Met. Fuels 2014, 62, 7. [Google Scholar]

- Manrique Maraví, J.E.; Yapias Cajahuanca, E.A.; Rojas García, R.; Torres Oliva, O.R. Análisis de la relación entre la implementación de un sistema de despacho y la productividad laboral de las operaciones en la minería subterránea: Un estudio de caso para la mina Vazante en Brasil. Master’s Thesis, Maestría en Gestión Minera, Escuela de Postgrado GĚRENS, Lima, Peru, 28 June 2022. [Google Scholar]

- Ogujiuba, K.; Stiegler, N. Efficiency of capital-labor in Nigeria’s mining sector: A Cobb-Douglas framework. J. Econ. Behav. Stud. 2014, 6, 760–770. [Google Scholar] [CrossRef]

- Econometría de Económicas. 2005. Available online: https://www.uv.es/~sancho/panel (accessed on 20 December 2024).

- Stothard, P.M.; Otto, D.; Laurence, D.C.; Galvin, J.M. E-minesafe safety and training simulator: The integration of knowledge and skills to achieve safe human responses. In The UMRC Research Report RR10/01; University of New South Wales: Sydney, Australia, 2001. [Google Scholar]

- Schofield, D.; Denby, B.; Hollands, R. Mine safety in the twenty-first century: The application of computer graphics and virtual reality. In Mine Health and Safety Management; Society for Mining, Metallurgy, and Exploration (SME): Englewood, CO, USA, 2001; pp. 153–174. [Google Scholar]

- Squelch, A. Virtual reality for mine safety training in South Africa. J. S. Afr. Inst. Min. Metall. 2001, 101, 209–216. [Google Scholar]

- Mallett, L.; Unger, R. Virtual reality in mine training. In Proceedings of the 2007 SME Annual Meeting and Exhibit, Denver, CO, USA, 25–28 February 2007. [Google Scholar]

- Van Wyk, E.; De Villiers, R. Virtual reality training applications for the mining industry. In Proceedings of the 6th International Conference on Computer Graphics, Pretoria, South Africa, 4–6 February 2009. [Google Scholar]

- Li, Y.; Li, Z.; Teng, S.; Zhang, Y.; Zhou, Y.; Zhu, Y.; Cao, D.; Tian, B.; Ai, Y.; Xuanyuan, Z.; et al. AutoMine: An unmanned mine dataset. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, LA, USA, 18–24 June 2022. [Google Scholar]

- Chen, L.; Zhan, W.; Tian, W.; He, Y.; Zou, Q. Deep integration: A multi-label architecture for road scene recognition. IEEE Trans. Image Process. 2019, 28, 4883–4898. [Google Scholar] [CrossRef]

- Li, Y.; Teng, S.; Li, L.; Xuanyuan, Z.; Chen, L. Foundation models for mining 5.0: Challenges, frameworks, and opportunities. In Proceedings of the 2023 IEEE 3rd International Conference on Digital Twins and Parallel Intelligence (DTPI), Orlando, FL, USA, 7–9 November 2023. [Google Scholar]

- Ge, S.; Wang, F.-Y.; Yang, J.; Ding, Z.; Wang, X.; Li, Y.; Teng, S.; Liu, Z.; Ai, Y.; Chen, L. Making standards for smart mining operations: Intelligent vehicles for autonomous mining transportation. IEEE Trans. Intell. Veh. 2022, 7, 413–416. [Google Scholar] [CrossRef]

- Tian, F.; Zhou, R.; Li, Z.; Li, L.; Gao, Y.; Cao, D.; Chen, L. Trajectory planning for autonomous mining trucks considering terrain constraints. IEEE Trans. Intell. Veh. 2021, 6, 772–786. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhang, X.; Zhou, L.; Liu, Y.; Liu, X. A survey on the Metaverse: The state-of-the-art, technologies, applications, and challenges. IEEE Internet Things J. 2023, 10, 14671–14688. [Google Scholar] [CrossRef]

- Gupta, R.; Rathore, B.; Biswas, B.; Jaiswal, M.; Singh, R.K. Are we ready for Metaverse adoption in the service industry? Theoretically exploring the barriers to successful adoption. J. Retail. Consum. Serv. 2024, 79, 103882. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, H.; Zhou, W. Development of a 3D GIS and its application to karst areas. Environ. Geol. 2008, 54, 1037–1045. [Google Scholar] [CrossRef]

- Foster, P.; Burton, A. Modelling potential sightline improvements to underground mining vehicles using virtual reality. Min. Technol. 2006, 115, 85–90. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, X.; Li, Z. The internet of things (IOT) and cloud computing (CC) based tailings dam monitoring and pre-alarm system in mines. Saf. Sci. 2012, 50, 811–815. [Google Scholar] [CrossRef]

- Saroufim, C.E. Internet of Things and Anomaly Detection for the Iron Ore Mining Industry. Master’s Thesis, Science in Operations Research, Massachusetts Institute of Technology, Cambridge, MA, USA, 2016. [Google Scholar]

- Hernández-Sampieri, R.; Mendoza, C. El proceso de la investigación cualitativa. In Metodología de la Investigación: Las Rutas Cuantitativa, Cualitativa y Mixta, 6th ed.; McGraw-Hill: Ciudad de México, Mexico, 2020; pp. 355–531. [Google Scholar]

- Kizil, M. Virtual reality applications in the Australian minerals industry. In Proceedings of the 31st International Symposium on Application of Computers and Operations Research in the Minerals Industries, Cape Town, South Africa, 14–16 May 2003. [Google Scholar]

- Kizil, M.; Hancock, M.; Edmunds, O. Virtual reality as a training tool. In Proceedings of the AusIMM Youth Congress, Brisbane, Australia, 2–6 May 2001. [Google Scholar]

- Singh, D.R.; Mishra, A.K. Review of IT enabled technologies in Indian mining industry for improved productivity & safety. In Proceedings of the 2016 3rd International Conference on Recent Advances in Information Technology (RAIT), Dhanbad, India, 3–5 March 2016. [Google Scholar]

- Akbulut, N.; Anani, A. Application of virtual reality in the mining industry—Where are we now? In Proceedings of the SME Annual Conference and Expo, Denver, CO, USA, 26 February–1 March 2023. [Google Scholar]

- Ivina, O.; Belova, A.; Klimchuk, A.; Akhmetgalym, T. Dynamic Construction of Underground Mining Operations with Visualization in Virtual Reality. E3S Web Conf. 2020, 174, 01055. [Google Scholar] [CrossRef]

- Moreby, R.; Whitmore, J.; Dunn, P. Integration of strategic ventilation and heat management planning with 3D virtual reality simulation of underground mines. In Proceedings of the 11th US/North American Mine Ventilation Symposium, University Park, PA, USA, 5–7 June 2006. [Google Scholar]

- Bellanca, J.L.; Orr, T.J.; Helfrich, W.J.; Macdonald, B.; Navoyski, J.; Demich, B. Developing a Virtual Reality Environment for Mining Research. Min. Metall. Explor. 2019, 36, 597–606. [Google Scholar] [CrossRef] [PubMed]

- Siew, C.Y.; Ong, S.-K.; Nee, A.Y. A practical augmented reality-assisted maintenance system framework for adaptive user support. Robot. Comput.-Integr. Manuf. 2019, 59, 115–129. [Google Scholar] [CrossRef]

- Erkoyuncu, J.A.; del Amo, I.F.; Dalle Mura, M.; Roy, R.; Dini, G. Improving efficiency of industrial maintenance with context aware adaptive authoring in augmented reality. CIRP Ann. 2017, 66, 465–468. [Google Scholar] [CrossRef]

- Vanneste, P.; Huang, Y.; Park, J.Y.; Cornillie, F.; Decloedt, B.; Van den Noortgate, W. Cognitive support for assembly operations by means of augmented reality: An exploratory study. Int. J. Hum.-Comput. Stud. 2020, 143, 102480. [Google Scholar] [CrossRef]

- Lai, Z.-H.; Tao, W.; Leu, M.C.; Yin, Z. Smart augmented reality instructional system for mechanical assembly towards worker-centered intelligent manufacturing. J. Manuf. Syst. 2020, 55, 69–81. [Google Scholar] [CrossRef]

- Valencia Quiceno, J.D.; Kecojevic, V.; McBrayer, A.; Bogunovic, D. Augmented Reality System for Training of Heavy Equipment Operators in Surface Mining. Min. Metall. Explor. 2024, 41, 2217–2229. [Google Scholar] [CrossRef]

- Zhu, L.-F.; Wang, X.-F.; Zhang, B. Modeling and visualizing borehole information on virtual globes using KML. Comput. Geosci. 2014, 62, 62–70. [Google Scholar] [CrossRef]

- Huang, B.; Lin, H. GeoVR: A web-based tool for virtual reality presentation from 2D GIS data. Comput. Geosci. 1999, 25, 1167–1175. [Google Scholar] [CrossRef]

- Lee, S.; Suh, J.; Park, H.-D. BoreholeAR: A mobile tablet application for effective borehole database visualization using an augmented reality technology. Comput. Geosci. 2015, 76, 41–49. [Google Scholar] [CrossRef]

- Mathiesen, D.; Myers, T.; Atkinson, I.; Trevathan, J. Geological Visualisation with Augmented Reality. In Proceedings of the 2012 15th International Conference on Network-Based Information Systems, Melbourne, Australia, 26–28 September 2012. [Google Scholar]

- González, C.; Navarro, F.; Rojas, C.; González, M.; Pardo, S.; Comte, D.; Carrizo, D.; Díaz, M.; Salvo, J. An immersive 3D geological and mining data visualization environment. In Proceedings of the 6th International Conference on Innovations in Mine Operations (MININ), Santiago, Chile, 21–23 August 2016. [Google Scholar]

- Erarslan, K. Augmented Reality Applications on Quarries and Mines. J. Sci. Rep.-B 2021, 3, 13–24. [Google Scholar]

- Zhou, C.; Damiano, N.; Whisner, B.; Reyes, M. Industrial Internet of Things (IIoT) applications in underground coal mines. Min. Eng. 2017, 69, 50. [Google Scholar] [CrossRef]

- Anastasova, Y. Internet of Things in the Mining Industry-Security Technologies in Their Application. Sustain. Extr. Process. Raw Mater. 2020, 1, 7–10. [Google Scholar] [CrossRef]

- Aguirre-Jofré, H.; Eyre, M.; Valerio, S.; Vogt, D. Low-cost internet of things (IoT) for monitoring and optimising mining small-scale trucks and surface mining shovels. Autom. Constr. 2021, 131, 103918. [Google Scholar] [CrossRef]

- Laskier, R. Modernizing the mining industry with the Internet of Things. In Internet of Things and Data Analytics Handbook; John Wiley & Sons: Campbell, CA, USA, 2017; pp. 521–543. [Google Scholar]

- Theissen, M.; Kern, L.; Hartmann, T.; Clausen, E. Use-case-oriented evaluation of wireless communication technologies for advanced underground mining operations. Sensors 2023, 23, 3537. [Google Scholar] [CrossRef] [PubMed]

- Young, A.; Rogers, P. A Review of Digital Transformation in Mining. Min. Metall. Explor. 2019, 36, 683–699. [Google Scholar] [CrossRef]

- Codoceo-Contreras, L.; Rybak, N.; Hassall, M. Exploring the impacts of automation in the mining industry: A systematic review using natural language processing. Min. Technol. 2024, 133, 191–213. [Google Scholar] [CrossRef]

- Jang, H.; Topal, E. Transformation of the Australian mining industry and future prospects. Min. Technol. 2020, 129, 120–134. [Google Scholar] [CrossRef]

- Salam, A. Internet of Things for Sustainable Mining. In Internet of Things for Sustainable Community Development: Wireless Communications, Sensing, and Systems; Springer International Publishing: Cham, Switzerland, 2019; pp. 243–271. [Google Scholar]

- Microsoft Touts Industrial Metaverse as Innovation, Sustainability Tool. Available online: https://www.sdxcentral.com/articles/news/microsoft-touts-industrial-metaverse-as-innovation-sustainability-tool/2022/10/ (accessed on 11 December 2024).

- Kshetri, N.; Dwivedi, Y.K. Pollution-reducing and pollution-generating effects of the Metaverse. Int. J. Inf. Manag. 2023, 69, 102620. [Google Scholar] [CrossRef]

- Guo, J.; Leng, J.; Zhao, J.L.; Zhou, X.; Yuan, Y.; Lu, Y.; Mourtzis, D.; Qi, Q.; Huang, S.; Song, X.; et al. Industrial Metaverse towards Industry 5.0: Connotation, architecture, enablers, and challenges. J. Manuf. Syst. 2024, 76, 25–42. [Google Scholar] [CrossRef]

- Kshetri, N. Organizational impacts of the industrial metaverse. In Proceedings of the 32nd European Conference of the International Telecommunications Society (ITS): “Realising the Digital Decade in the European Union—Easier Said Than Done?”, Madrid, Spain, 19–20 June 2023. [Google Scholar]

- Kim, J.Y.; Oh, J.M. Opportunities and Challenges of Metaverse for Automotive and Mobility Industries. In Proceedings of the 2022 13th International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 19–21 October 2022. [Google Scholar]

- Bansal, G.; Rajgopal, K.; Chamola, V.; Xiong, Z.; Niyato, D. Healthcare in Metaverse: A survey on current Metaverse applications in healthcare. IEEE Access 2022, 10, 119914–119946. [Google Scholar] [CrossRef]

- Epazz Deskflex Metaverse Solution Takes Telemedicine. Available online: https://martechseries.com/predictive-ai/augmented-reality/epazz-deskflex-metaverse-solution-takes-telemedicine-in-augmented-reality-environment-for-accurate-patient-assessment-and-diagnosis/ (accessed on 8 January 2025).

- Sridhar, A.; Shiliang, Z.; Woodson, R.; Kwan, L. Non-pharmacological anxiety reduction with immersive virtual reality for first-trimester dilation and curettage: A pilot study. Eur. J. Contracept. Reprod. Health Care 2020, 25, 480–483. [Google Scholar] [CrossRef] [PubMed]

- Noben, L.; Goossens, S.M.T.A.; Truijens, S.E.M.; van Berckel, M.M.G.; Perquin, C.W.; Slooter, G.D.; van Rooijen, S.J. A virtual reality video to improve information provision and reduce anxiety before cesarean delivery: Randomized controlled trial. JMIR Ment. Health 2019, 6, e15872. [Google Scholar] [CrossRef]

- Flores-Castañeda, R.O.; Olaya-Cotera, S.; López-Porras, M.; Tarmeño-Juscamaita, E.; Iparraguirre-Villanueva, O. Technological Advances and Trends in the Mining Industry: A Systematic Review. Miner. Econ. 2024; accepted. [Google Scholar]

- Acosta, A.; Stothard, P.; Berrios, M.; Rodriguez, J. Evaluation of the Technology Acceptance Model of Digital Twins Supported by Artificial Intelligence in the Mining Metaverse: A PLS-SEM Analysis. Min. Technol. 2025; accepted. [Google Scholar]

- Bullock, R.L. Mineral Property Feasibility Studies. In SME Mining Engineering Handbook, 3rd ed.; Darling, P., Ed.; SME: Englewood, CO, USA, 2011; Volume 1, pp. 227–261. [Google Scholar]

- Stothard, P.; Squelch, A.; Stone, R.; Van Wyk, E. Towards sustainable mixed reality simulation for the mining industry. Min. Technol. 2019, 128, 246–254. [Google Scholar] [CrossRef]

- “Digital Revolution 4.0” in the Raw Materials and Mining Industry. In Digital Transformation and Industry 4.0. Available online: https://www.philippine-resources.com/articles/2022/6/digital-revolution-4-0-in-the-raw-materials-and-mining-industry (accessed on 11 February 2025).

- Optimizing Mining Feasibility Studies: The $100 Billion Opportunity. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/optimizing-mining-feasibility-studies-the-100-billion-opportunity (accessed on 2 January 2025).

- Dai, F.; Olorunfemi, A.; Peng, W.; Cao, D.; Luo, X. Can mixed reality enhance safety communication on construction sites? An industry perspective. Saf. Sci. 2021, 133, 105009. [Google Scholar] [CrossRef]

- Zvarivadza, T. Artisanal and small-scale mining as a challenge and possible contributor to sustainable development. Resour. Policy 2018, 56, 49–58. [Google Scholar] [CrossRef]

- Keane, S.; Bernaudat, L.; Davis, K.J.; Stylo, M.; Mutemeri, N.; Singo, P.; Twala, P.; Mutemeri, I.; Nakafeero, A.; Dossou Etui, I. Mercury and artisanal and small-scale gold mining: Review of global use estimates and considerations for promoting mercury-free alternatives. Ambio 2023, 52, 833–852. [Google Scholar] [CrossRef]

- Nanda, P.; Patnaik, S. Metaverse innovation for start-up creation. In Global Trends in Technology Startup Project Development and Management: From Innovation to Startup Creation; Springer: Cham, Switzerland, 2023; pp. 185–206. [Google Scholar]

- Cheng, S. Metaverse and investing. In Metaverse: Concept, Content and Context; Springer: Cham, Switzerland, 2023; pp. 187–205. [Google Scholar]

- Reveron, D.E. Evaluating Network Scalability of Metaverse-Applicable Use Cases. Master’s Thesis, Science in Engineering and Management, Massachusetts Institute of Technology, Cambridge, MA, USA, 10 May 2024. [Google Scholar]

- Canbay, Y.; Utku, A.; Canbay, P. Privacy concerns and measures in Metaverse: A review. In Proceedings of the 2022 15th International Conference on Information Security and Cryptography (ISCTURKEY), Ankara, Turkey, 17–18 December 2022. [Google Scholar]

- Di Pietro, R.; Cresci, S. Metaverse: Security and privacy issues. In Proceedings of the 2021 Third IEEE International Conference on Trust, Privacy and Security in Intelligent Systems and Applications (TPS-ISA), Virtual Event, 13–15 December 2021. [Google Scholar]

- Huang, Y.; Li, Y.J.; Cai, Z. Security and privacy in Metaverse: A comprehensive survey. Big Data Min. Anal. 2023, 6, 234–247. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, J.; Gan, W.; Qi, Z. Metaverse security and privacy: An overview. In Proceedings of the 2022 IEEE International Conference on Big Data (Big Data), Osaka, Japan, 17–20 December 2022. [Google Scholar]

- Khanna, P.; Karim, R.; Kumari, J. Issues and challenges in implementing the Metaverse in the industrial contexts from a human-system interaction perspective. In Proceedings of the International Congress and Workshop on Industrial AI, Berlin, Germany, 13–15 June 2023. [Google Scholar]

- Zamfir, M.; Marinescu, I.A.; Iordache, D.; Barbu, M.; Cîrnu, C.E. Exploring ethical considerations in Metaverse from the education perspective. Int. Conf. Virtual Learn. 2023, 18, 91–100. [Google Scholar]

- Yasuda, A. Metaverse ethics: Exploring the social implications of the Metaverse. AI Ethics 2024, 5, 1639–1650. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).