Sealing Technologies for the Manufacturing of Bipolar Plates via Active and Passive Hydroforming †

Abstract

:1. Introduction

1.1. Motivation

1.2. State of the Art

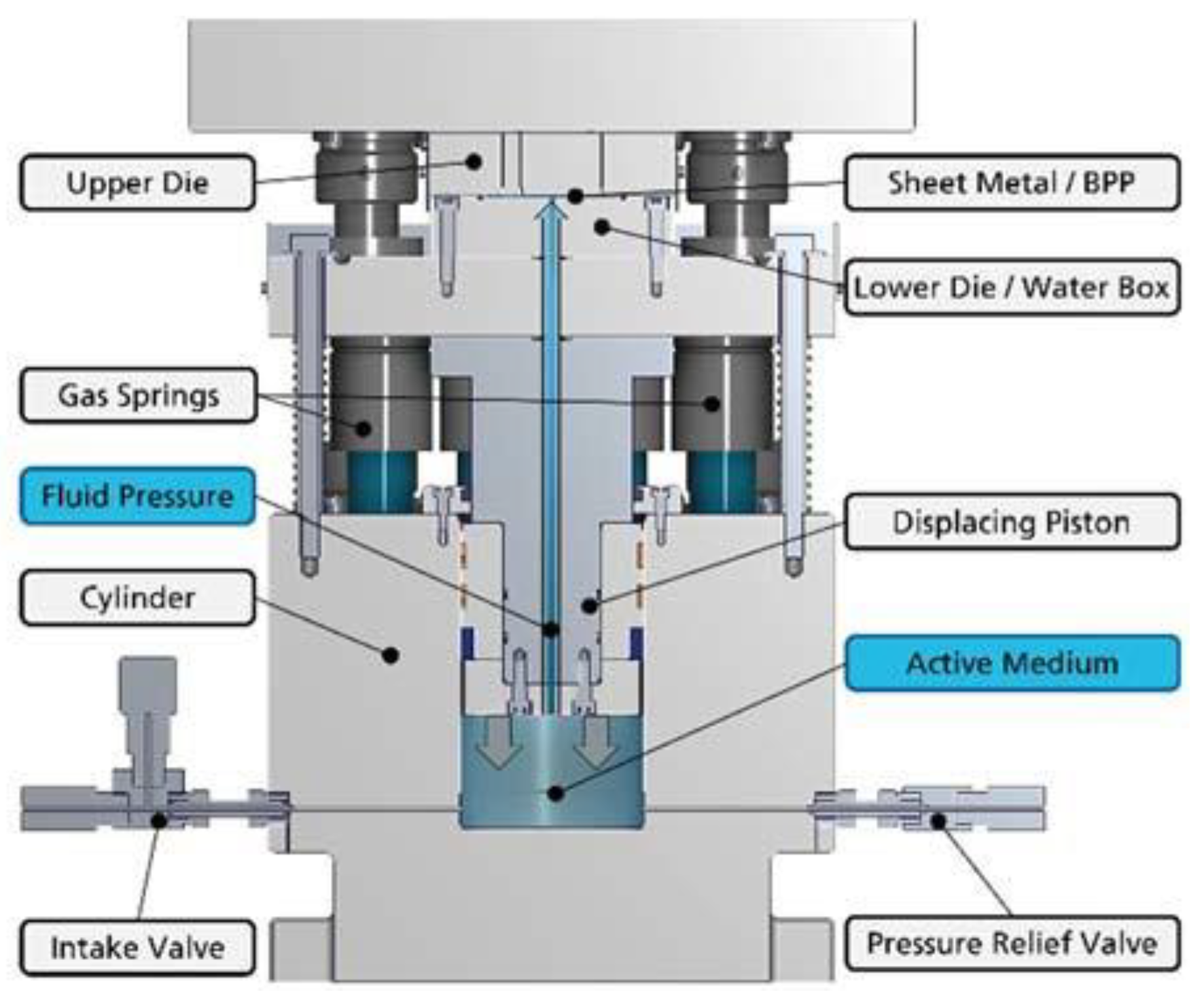

1.2.1. Active Hydroforming

1.2.2. Passive Hydroforming

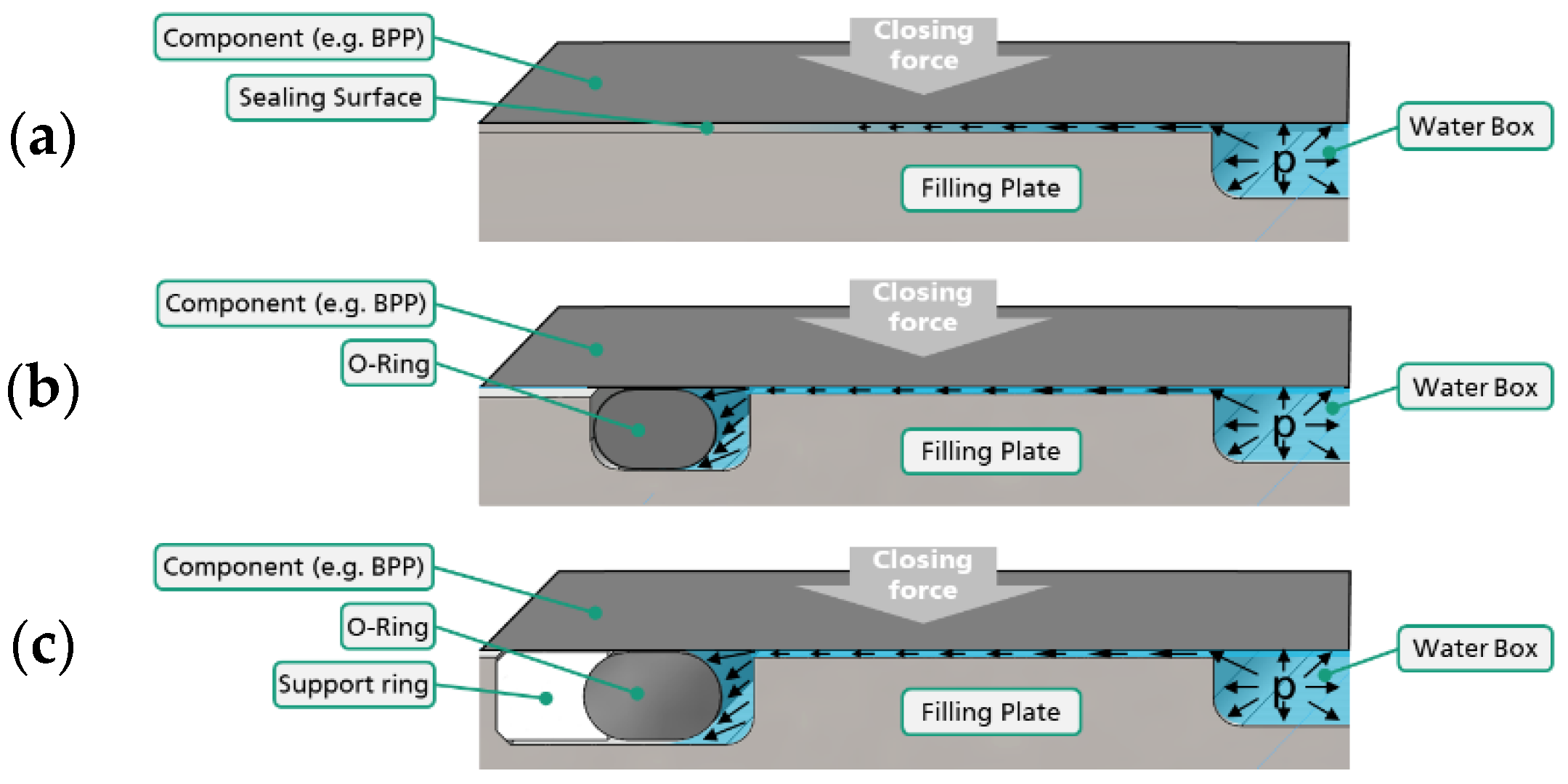

1.2.3. Sealing Systems for the Hydroforming of Sheet Metal Components

1.3. Aims and Approach

2. Materials and Methods

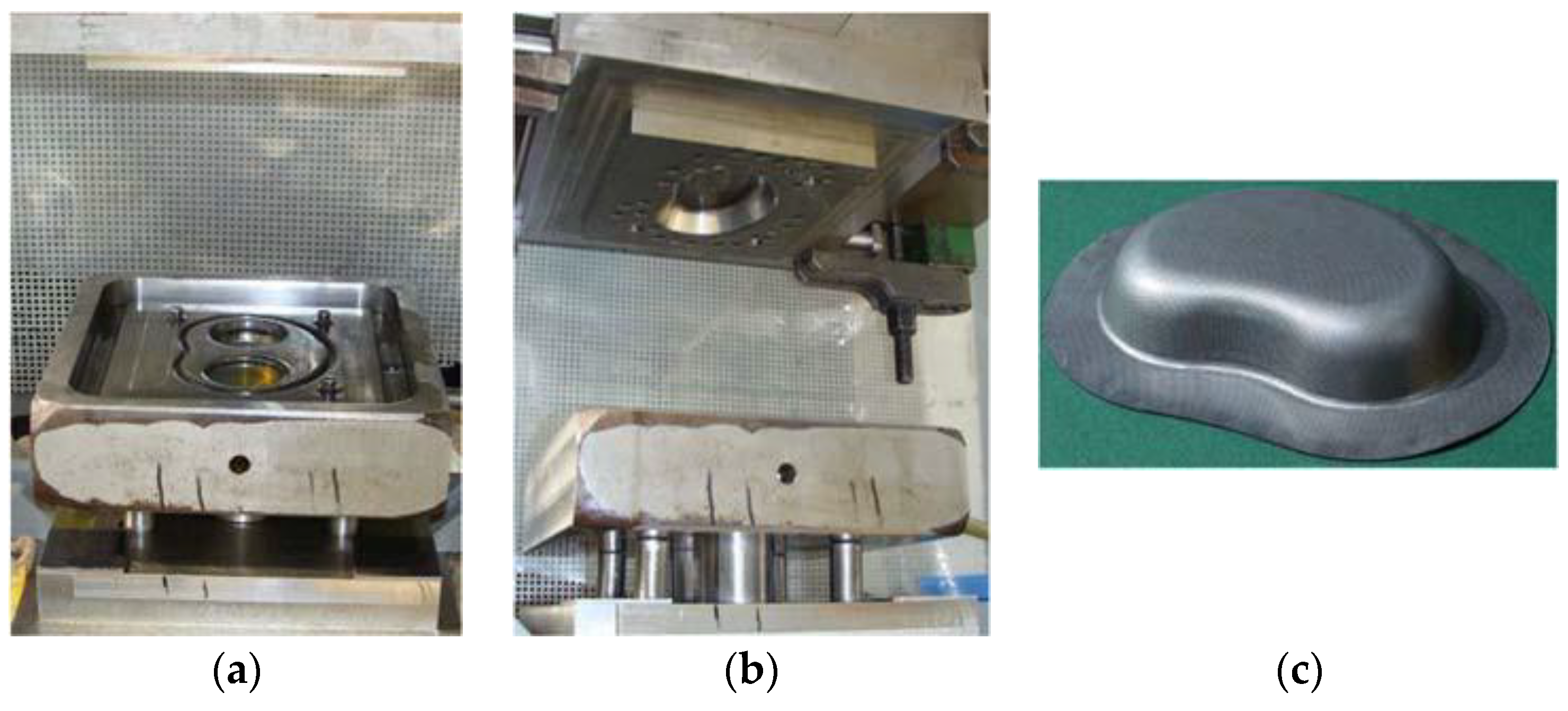

2.1. Development of the Passive Hydroforming for Bipolar Plate

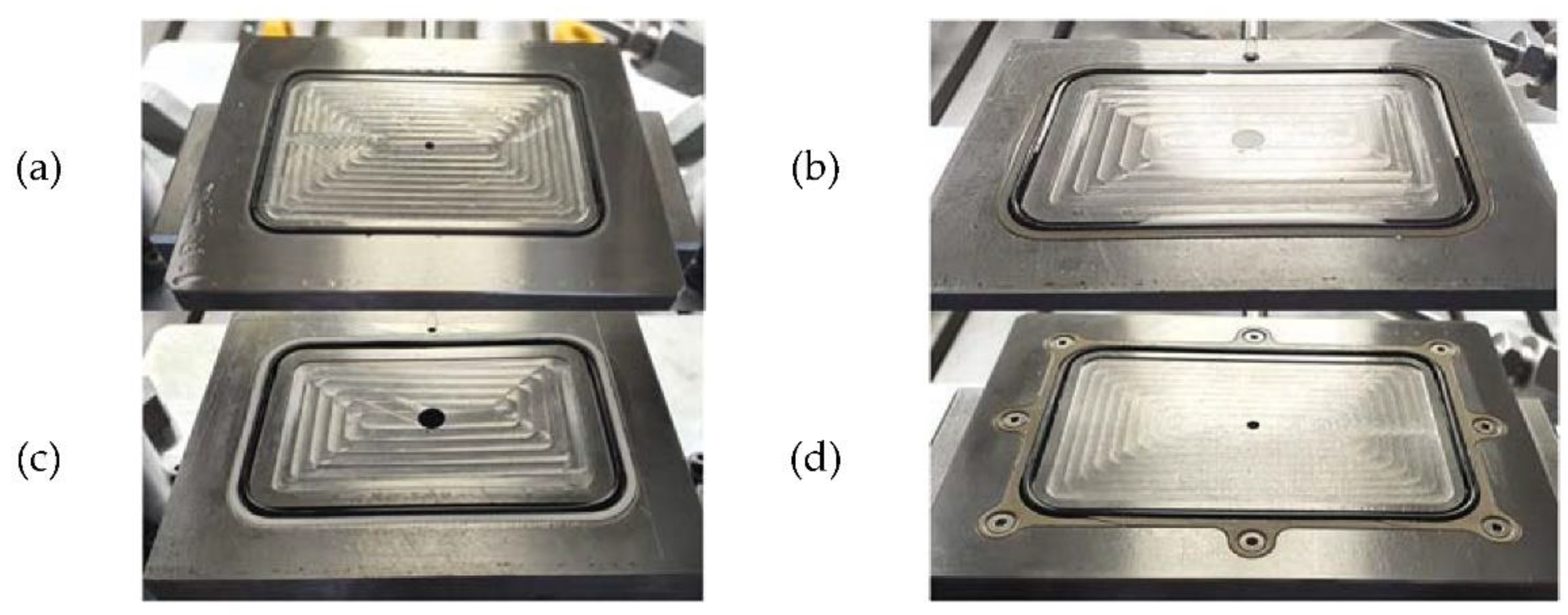

2.2. Development of Sealing Systems

3. Results

3.1. Comparison of Active and Passive Hydroforming

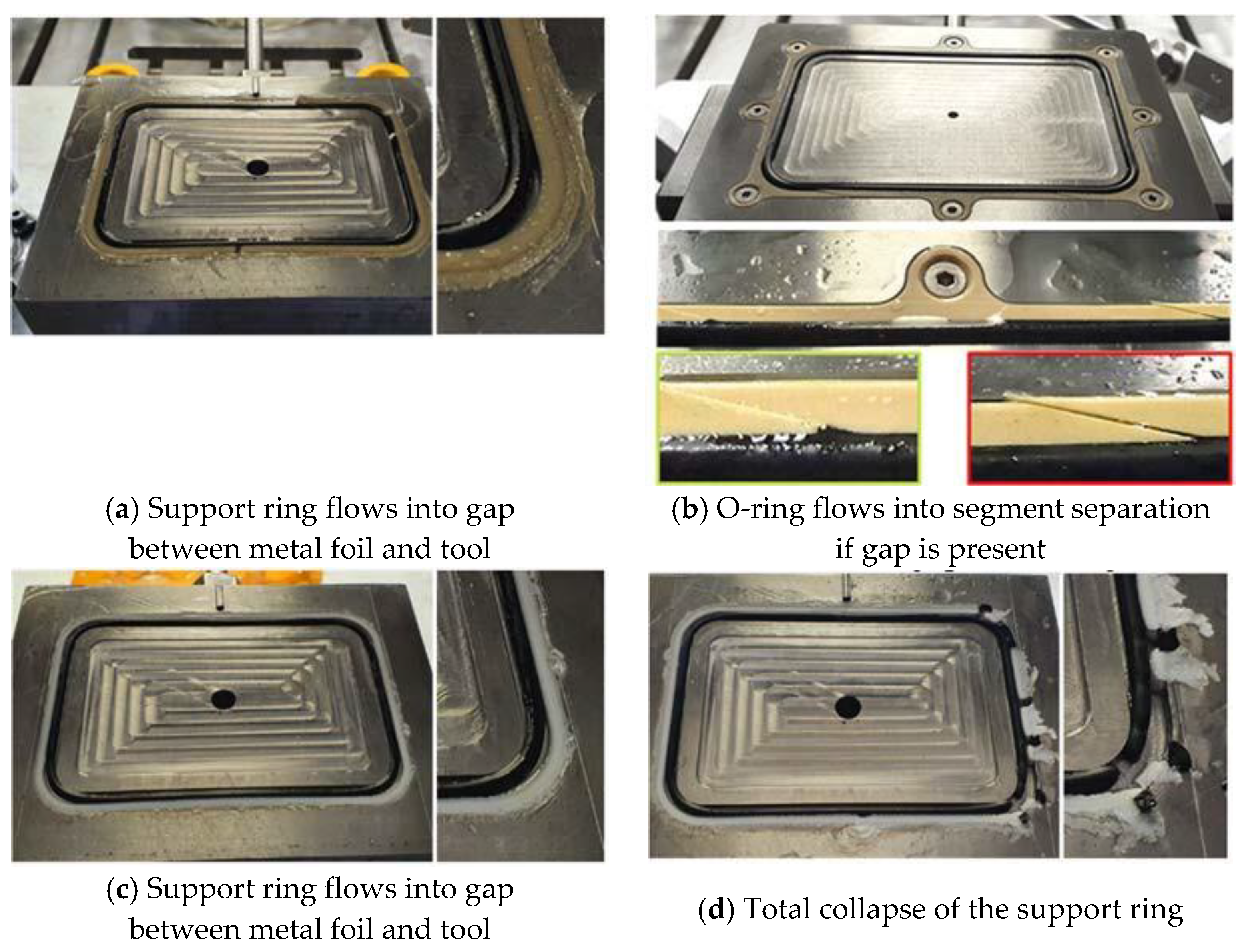

3.2. Sealing Systems for the Hydroforming of Sheet-Metal Components

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Uchtmann, H. Schuler Pressen GmbH: “Großserienfertigung von metallischen Bipolarplatten für Brennstoffzellen” in 40. In Kolloquium Blechverarbeitung; EFB: Hannover, Germany, 2022; ISBN 978-3-86776-586-2. [Google Scholar]

- Fraunhofer ISE-Eine Wasserstoff-Roadmap für Deutschland. 2020, p. 10. Available online: https://de.statista.com/statistik/daten/studie/1195138/umfrage/prognosen-zur-nachfrage-nach-wasserstoff-in-deutschlandund-in-der-eu/ (accessed on 6 January 2022).

- Siegert, K.; Lösch, B. Hydroblechumformung. In Hydroforming von Rohren, Strangpressprofilen und Blechen, Band 1; Siegert, K., Ed.; Springer: Berlin/Heidelberg, Germany, 1999; p. 263. ISBN 3-88355-284-4. [Google Scholar]

- Porstmann, S.; Wannemacher, T.; Drossel, W.-G. A comprehensive comparison of state-of-the-art manufacturing methods for fuel cell bipolar plates including anticipated future industry trends. J. Manuf. Process. 2020, 60, 366–383. [Google Scholar] [CrossRef]

- Gräbener Maschinentechnik GmbH & Co. KG. Von der Individuellen Einzelanlage bis hin zur Skalierbaren Fertigungslinie. Available online: https://www.graebener.com/de/fertigungsanlagen (accessed on 17 October 2021).

- Kapp, D. Hydroformwerkzeug. European Patent EP2221125B1, 28 September 2011. [Google Scholar]

- Budai, A.F.; Achimas, G.; Neugebauer, R.; Pröhl, M. Method and Tool Design for Passive Sheet Metal Hydroforming on Conventional Single Action Presses. J. Manuf. Sci. Eng. 2013, 135, 021014. [Google Scholar] [CrossRef]

- von Finkenstein, E.; Gartzke, A.; Homberg, W.; Kleiner, M.; Kollek, R.; Szücs, E.; Weidner, T. Entwicklung von Verfahren und Werkzeugsystemen zur Hydroumformung höherfester Stahlbleche; Forschungsvereinigung StahlAnwendung e.V.: Düsseldorf, Germany, 1999; ISBN 3-930621-99-1. [Google Scholar]

- Krei, M. Stand der Dichtungstechnik für IHU-Werkzeuge. In Hydroforming von Rohren, Strangpressprofilen und Blechen, Band 1; Siegert, K., Ed.; Springer: Berlin/Heidelberg, Germany, 1999; p. 461. ISBN 3-88355-284-4. [Google Scholar]

- Zhang, S.H.; Wang, Z.R.; Xu, Y.; Wang, Z.T.; Zhou, L.X. Recent developments in sheet hydroforming technology. J. Mater. Process. Technol. 2004, 151, 237–241. [Google Scholar] [CrossRef]

- Siegert, K. Blechumformung—Verfahren, Werkzeuge und Maschinen, VDI Buch; Springer: Berlin/Heidelberg, Germany, 2015; p. 86. ISBN 978-3-540-68418-3. [Google Scholar]

- Celeghini, M. Wirkmedienbasierte Blechumformung: Grundlagenuntersuchungen zum Einfluss von Werkstoff und Bauteilgeometrie. Ph.D. Thesis, Technische Fakultät der Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2004. [Google Scholar]

- Hein, P. Innenhochdruck-Umformen von Blechpaaren: Modellierung, Prozessauslegung und Prozessführung. Ph.D. Thesis, Universität Erlangen-Nürnberg, Erlangen, Germany, 1999. [Google Scholar]

- Hung, J.-C.; Lin, C.-C. Fabrication of micro-flow channels for metallic bipolar plates by a high-pressure hydroforming apparatus. J. Power Sources 2012, 206, 179–184. [Google Scholar] [CrossRef]

- Bridgman, P.W. The Physics of High Pressure; Bell: London, UK, 1931. [Google Scholar]

- Vovk, A. Verfahrensentwicklung zur Fertigung Qualitätsgerechter Bauteile mit dem Hydro-Impuls-Umformen von Blechen. Ph.D. Thesis, Otto-von-Guericke Universität Magdeburg, Magdeburg, Germany, 2008. [Google Scholar]

- hmetoglu, M.; Hua, J.; Kulukuru, S.; Altan, T. Hydroforming of sheet metal using a viscous pressure medium. J. Mater. Process. Technol. 2004, 146, 97–107. [Google Scholar] [CrossRef]

- Blankl, A. Untersuchungen zur Erhöhung der Prozessrobustheit bei der Innenhochdruck-Umformung von Flächigen Halbzeugen mit Vorbzw. Nachgeschalteten Laserstrahlfügeoperationen. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2008. [Google Scholar]

- Celeghini, M. Verfahren zur Wirkmedienbasierten Umformung von Blech-Werkstücken und Wirkmedium zur Verwendung bei Diesem Verfahren. Patent DE19959769C2, 31 July 2003. [Google Scholar]

- Celeghini, M. Method for the pressure medium based forming of sheet metal workpieces and use of pressure medium in this method. European patent EP1270106A1, 2 January 2003. [Google Scholar]

- Vahl, M. Beitrag zur Gezielten Beeinflussung des Werkstoffflusses Beim Innenhochdruck-Umformen von Blechen. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2004. [Google Scholar]

- Neugebauer, R.; Schieck, F. Hydro Forming at Elevated Temperatures. In Proceedings of the 4th International Conference on tube Hydroforming (TUBEHYDRO 2009), Kaohsiung, Taiwan, 6–9 September 2009. [Google Scholar]

- Porstmann, S.; Polster, S.; Reuther, F.; Melzer, S.; Nagel, M.; Psyk, V.; Dix, M. Zielgrößen und Spannungsfelder beim Vergleich von Herstellungsverfahren für metallische Bipolarplatten. In Proceedings of the FC³ Fuel Cell Conference, Chemnitz, Germany, 31 May 2022/1 June 2022; Available online: https://nbn-resolving.org/urn:nbn:de:bsz:ch1-qucosa2-764559 (accessed on 27 June 2022).

- Eplast Material Informations. Available online: https://www.esun3d.com/epla-st-product/ (accessed on 27 June 2022).

| Key Figures | 2030 (Scenario A) | 2030 (Scenario B) | 2050 (Scenario A) | 2050 (Scenario B) |

|---|---|---|---|---|

| Hydrogen demand (in TWh), Germany | 4 | 20 | 250 | 800 |

| Hydrogen demand (in TWh), EU | 30 | 140 | 800 | 2250 |

| Electrolysis capacity (in GW), Germany | 1 | 5 | 50 | 80 |

| Electrolysis capacity (in GW), EU | 7 | 35 | 341 | 511 |

| Cycle Times of the Single Processes | Total Cycle Time | |||||

|---|---|---|---|---|---|---|

| Coil Feed | Closing of the Press | Buildup of the Clamping Force | Hydroforming Process | Opening of the Press | ||

| Active hydroforming | 1 s | 1 s | 2 s | 3 s | 1 s | 8 s |

| Passive hydroforming | 1 s | 2 s | 1 s | 4 s | ||

| Parameter | Active Hydroforming | Passive Hydroforming |

|---|---|---|

| Part | Fraunhofer Bipolar plate V1 | Vitesco Bipolar plate |

| Size of the pressurized area (length × width) | 97,650 mm2 530.2 mm × 188.2 mm | 8840 mm2 95 mm × 95 mm |

| Material | 1.4404 with 0.1 mm sheet thickness | |

| Forming press | Schuler SHP 50.000 | Dunkes HS3-1500/Retrofit by AP&T |

| Sealing technology | combination of O-ring and support ring | |

| Process parameter closing force forming pressure | 20,000 kN 200 MPa | 2000 kN 200 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albert, A.; Anders, A.; Psyk, V.; Kräusel, V.; Dix, M. Sealing Technologies for the Manufacturing of Bipolar Plates via Active and Passive Hydroforming. Eng. Proc. 2022, 26, 11. https://doi.org/10.3390/engproc2022026011

Albert A, Anders A, Psyk V, Kräusel V, Dix M. Sealing Technologies for the Manufacturing of Bipolar Plates via Active and Passive Hydroforming. Engineering Proceedings. 2022; 26(1):11. https://doi.org/10.3390/engproc2022026011

Chicago/Turabian StyleAlbert, André, Andreas Anders, Verena Psyk, Verena Kräusel, and Martin Dix. 2022. "Sealing Technologies for the Manufacturing of Bipolar Plates via Active and Passive Hydroforming" Engineering Proceedings 26, no. 1: 11. https://doi.org/10.3390/engproc2022026011

APA StyleAlbert, A., Anders, A., Psyk, V., Kräusel, V., & Dix, M. (2022). Sealing Technologies for the Manufacturing of Bipolar Plates via Active and Passive Hydroforming. Engineering Proceedings, 26(1), 11. https://doi.org/10.3390/engproc2022026011