Optimization of Focused Ion Beam Patterning Parameters for Direct Integration of Plasmonic Nanostructures on Silicon Photodiodes †

Abstract

1. Introduction

Plasmonic Enhancement Optical Sensors

2. Methods

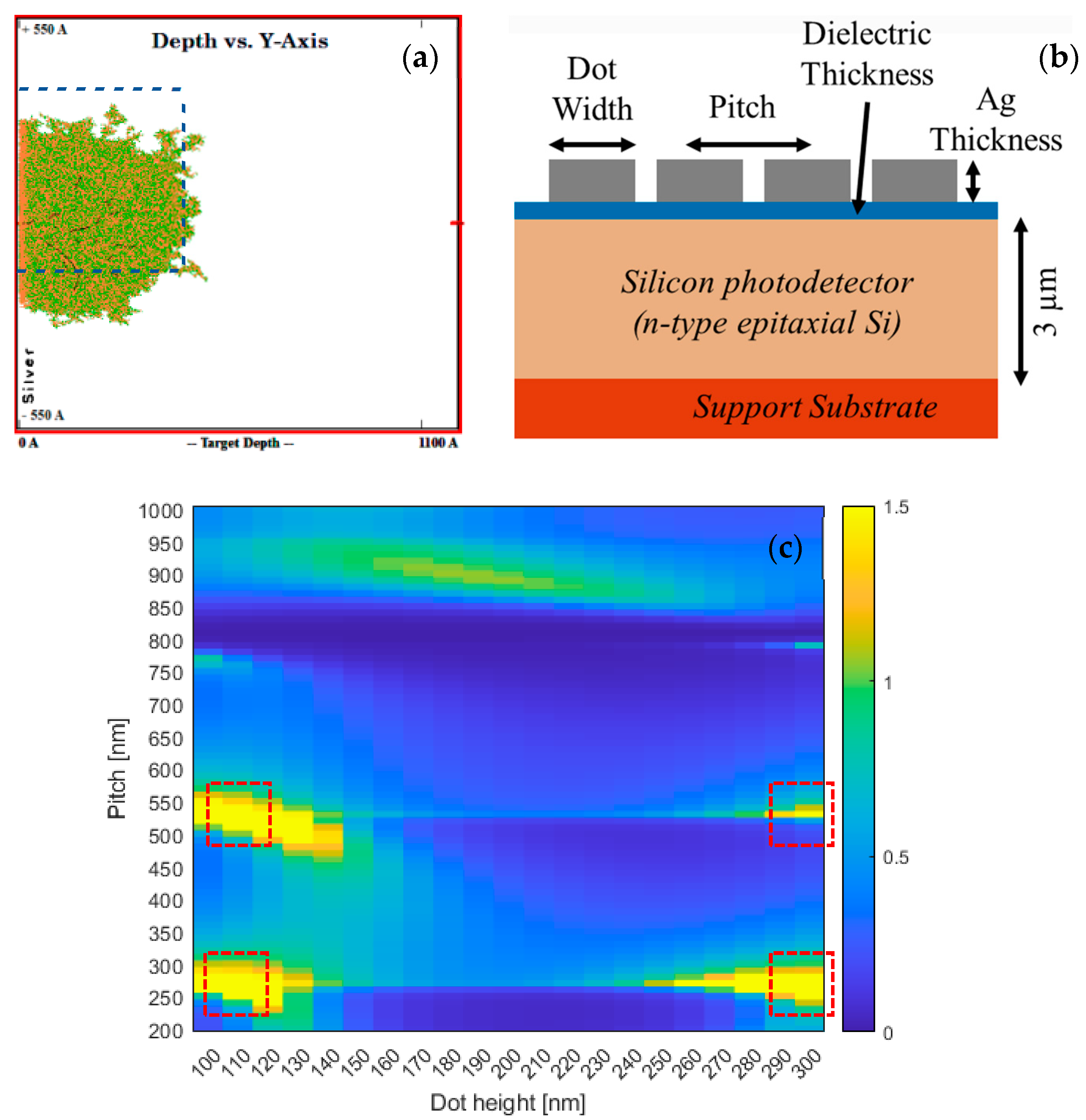

2.1. Montecarlo Simulations

2.2. Finite-Difference Time-Domain Simulations

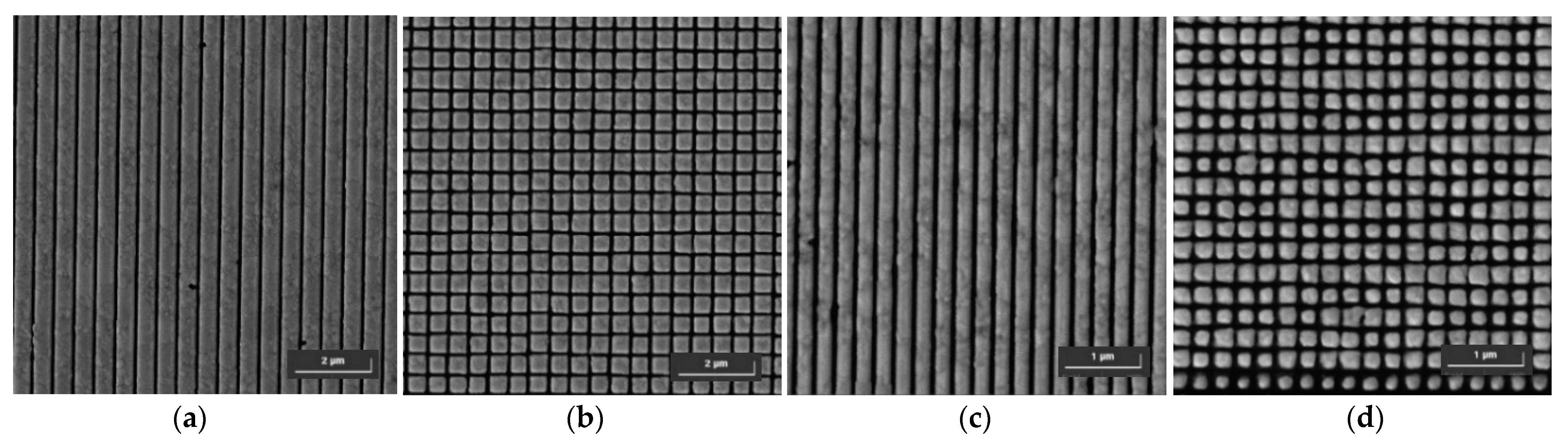

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Konstantatos, G.; Sargent, E.H. Nanostructured materials for photon detection. Nat. Nanotechnol. 2010, 5, 391–400. [Google Scholar] [CrossRef]

- Soci, C.; Zhang, A.; Bao, X.Y.; Kim, H.; Lo, Y.; Wang, D. Nanowire photodetectors. J. Nanosci. Nanotechnol. 2010, 10, 1430–1449. [Google Scholar] [CrossRef] [PubMed]

- Schuller, J.A.; Barnard, E.; Cai, W.; Jun, Y.C.; White, J.S.; Brongersma, M.L. Plasmonics for extreme light concentration and manipulation. Nat. Mater. 2010, 9, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, B.; Espinoza-Gonzales, R. Plasmon-enhanced optical absorption with graded bandgap in diamond-like carbon (DLC) films. J. Mater. Sci. 2017, 52, 218. [Google Scholar] [CrossRef]

- Gola, A.; Acerbi, F.; Capasso, M.; Marcante, M.; Mazzi, A.; Paternoster, G.; Piemonte, C.; Regazzoni, V.; Zorzi, N. NUV-Sensitive Silicon Photomultiplier Technologies Developed at Fondazione Bruno Kessler. Sensors 2019, 19, 308. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.-S.; Ahn, S.-H.; Jang, D.-Y. Review: Developments in micro/nanoscale fabrication by focused ion beams. Vacuum 2012, 86, 1014–1035. [Google Scholar] [CrossRef]

- Wilhelmi, O.; Reyntjens, S.; Mitterbauer, C.; Roussel, L.; Stokes, D.J.; Hubert, D.H.W. Rapid Prototyping of Nanostructured Materials with a Focused Ion Beam. Jpn. J. Appl. Phys. 2008, 47, 5010–5014. [Google Scholar] [CrossRef]

- Rubanov, S.; Munroe, P. The application of FIB milling for specimen preparation from crystalline germanium. Micron 2004, 35, 549–556. [Google Scholar] [CrossRef]

- Schoendorfer, C.; Lugstein, A.; Bischoff, L.; Hyun, Y.; Pongratz, P.; Bertagnolli, E. FIB induced growth of antimony nanowires. Microelectron. Eng. 2007, 84, 1440–1442. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Wang, X.; Zhang, M.; Li, J.; Shi, Z.; Li, H.; Zhou, Z.; Ji, H.; Niu, X.; et al. Ion-Beam-Directed Self-Ordering of Ga Nanodroplets on GaAs Surfaces. Nanoscale Res. Lett. 2016, 11, 38. [Google Scholar] [CrossRef]

- Kawano, Y.; Fuse, T.; Toyokawa, S.; Uchida, T.; Ishibashi, K. Terahertz photon-assisted tunneling in carbon nanotube quantum dots. J. Appl. Phys. 2008, 103, 034307. [Google Scholar] [CrossRef]

- Komiyama, S. Single-Photon Detectors in the Terahertz Range. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 54–66. [Google Scholar] [CrossRef]

- Pan, Z.W.; Dai, Z.R.; Wang, Z.L. Nanobelts of Semiconducting Oxides. Angew. Chem. Int. Ed. Engl. 1996, 291, 1947–1949. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Takai, I.; Matsubara, H.; Soga, M.; Ohta, M.; Ogawa, M.; Yamashita, T. Single-Photon Avalanche Diode with Enhanced NIR-Sensitivity for Automotive LIDAR Systems. Sensors 2016, 16, 459. [Google Scholar] [CrossRef] [PubMed]

- Niu, C.; Huang, T.; Hu, J. Plasmonic Nanograting Structures for Sensor Applications, Texas Symposium on Wireless and Microwave Circuits and Systems. In Proceedings of the Texas Symposium on Wireless and Microwave Circuits and Systems, Waco, TX, USA, 3–4 April 2014. [Google Scholar]

- Andersen, S.K.H.; Bogdanov, S.; Makarova, O.; Xuan, Y.; Shalaginov, M.Y.; Boltasseva, A.; Bozhevolnyi, S.I.; Shalaev, V.M. Hybrid Plasmonic Bullseye Antennas for Efficient Photon Collection. ACS Photon. 2018, 5, 692–698. [Google Scholar] [CrossRef]

- Caldwell, J.D.; Glembocki, O.; Bezares, F.J.; Bassim, N.D.; Rendell, R.W.; Feygelson, M.; Ukaegbu, M.; Kasica, R.; Shirey, L.; Hosten, C. Plasmonic Nanopillar Arrays for Large-Area, High-Enhancement Surface-Enhanced Raman Scattering Sensors. ACS Nano 2011, 5, 4046–4055. [Google Scholar] [CrossRef]

- Selvakumar, N.; Barshilia, H. Review of physical vapor deposited (PVD) spectrally selective coatings for mid- and high-temperature solar thermal applications. Sol. Energy Mater. Sol. Cells 2012, 98, 1–23. [Google Scholar] [CrossRef]

- Stanley Middleman, B.; Hochberg, A.K. Process Engineering Analysis in Semiconductor Device Fabrication; Mcgraw-Hill College: New York, NY, USA, 1993. [Google Scholar]

- Newman, T.H. High resolution patterning system with a single bore objective lens. J. Vac. Sci. Technol. B: Microelectron. Nanometer Struct. 1987, 5, 88. [Google Scholar] [CrossRef]

- Orloff, J.; Utlaut, M.; Swanson, L. High Resolution Focused Ion Beams: FIB and its Applications. In High Resolution Focused Ion Beams: FIB and Its Applications; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Ziegler, J.F.; Biersack, J.P.; Ziegler, J.F. The Stopping and Range of Ions in Matter. In Treatise on Heavy-Ion Science; Bromley, D.A., Ed.; Springer: Boston, MA, USA, 1960. [Google Scholar]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Lumerical: High-Performance Photonic Simulation Software. Available online: www.lumerical.com (accessed on 22 September 2021).

- Maradudin, A.A.; Simonsen, I.; Polanco, J.; Fitzgerald, R.M. Rayleigh and Wood anomalies in the diffraction of light from a perfectly conducting reflection grating. J. Opt. 2016, 18, 024004. [Google Scholar] [CrossRef]

- Davis, G.L. Gold in semiconductor technology. Gold Bull. 1974, 7, 90–96. [Google Scholar] [CrossRef][Green Version]

| p-535,h-110 | p-535,h-300 | p-260,h-110 | p-260,h-300 | |

|---|---|---|---|---|

| Metal thickness (nm) | 110 | 300 | 100 | 300 |

| Periodicity (nm) | 535 | 535 | 260 | 260 |

| Reference | FIB 1D | FIB 2D |

| p-535,h-110 | p-535,h-110 | |

| 21 pA | 41 pA | 25 pA |

| p-260,h-110 | p-260,h-110 | |

| 10 pA | 37 pA |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scattolo, E.; Cian, A.; Giubertoni, D.; Paternoster, G.; Petti, L.; Lugli, P. Optimization of Focused Ion Beam Patterning Parameters for Direct Integration of Plasmonic Nanostructures on Silicon Photodiodes. Eng. Proc. 2021, 10, 2. https://doi.org/10.3390/ecsa-8-11259

Scattolo E, Cian A, Giubertoni D, Paternoster G, Petti L, Lugli P. Optimization of Focused Ion Beam Patterning Parameters for Direct Integration of Plasmonic Nanostructures on Silicon Photodiodes. Engineering Proceedings. 2021; 10(1):2. https://doi.org/10.3390/ecsa-8-11259

Chicago/Turabian StyleScattolo, Elia, Alessandro Cian, Damiano Giubertoni, Giovanni Paternoster, Luisa Petti, and Paolo Lugli. 2021. "Optimization of Focused Ion Beam Patterning Parameters for Direct Integration of Plasmonic Nanostructures on Silicon Photodiodes" Engineering Proceedings 10, no. 1: 2. https://doi.org/10.3390/ecsa-8-11259

APA StyleScattolo, E., Cian, A., Giubertoni, D., Paternoster, G., Petti, L., & Lugli, P. (2021). Optimization of Focused Ion Beam Patterning Parameters for Direct Integration of Plasmonic Nanostructures on Silicon Photodiodes. Engineering Proceedings, 10(1), 2. https://doi.org/10.3390/ecsa-8-11259