Abstract

Tea polyphenols are a phenolic bioactive compound extracted from tea leaves and have been widely used as additives to prepare functional materials used in packaging, adsorption and energy fields. Nevertheless, tea polyphenols should be extracted first from the leaves before use, leading to energy consumption and the waste of tea. Therefore, completely and directly utilizing the tea leaf to fabricate novel composite materials is more attractive and meaningful. Herein, semi-transparent green-tea-based all-biomass light-management films with improved strength, a tunable haze (60–80%) and UV-shielding properties (24.23% for UVA and 4.45% for UVB) were directly manufactured from green tea by adding high-degree polymerization wood pulps to form entanglement networks. Additionally, the green-tea-based composite films can be produced on a large scale by adding green tea solution units to the existing continuous production process of pure cellulose films. Thus, a facile and feasible approach was proposed to realize the valorization of green tea by preparing green-tea-based all-biomass light-management films that have great prospects in flexible devices and energy-efficient buildings.

1. Introduction

Tea produced from the leaves of plants is widely consumed in the world due to its fascinating aroma and beneficial health effects [1,2]. As one of the three major functional beverages, tea can be classified into six types, named black tea, green tea, oolong tea, pu-erh tea, yellow tea and white tea [3,4]. It was reported that more than 5 million tons of tea has been consumed worldwide, and its consumption still continues to grow [4]. Moreover, China is the largest tea producing and consuming country, whose production was approximately 2.5 million tons in 2017. Green tea (GT) [5], a non-fermented tea, is the primary type of tea produced and consumed in China [3].

Generally, the chemical compositions of tea leaves are diverse, including polyphenols, saccharides and minerals [6]. The chemical composition varies greatly with the types, climate and region [7]. Tea polyphenols (TP), a kind of phenolic bioactive compounds extracted from tea leaf and account for 25–35% dry weight of green tea leaves, which are widely incorporated into drink and food products in formulations with green tea extracts (GTEs) [6,8,9].

Some studies indicated that tea polyphenols have many advantages, such as antioxidant and antimicrobial properties, due to copious hydroxyl groups, which could protect the cardiovascular system and are beneficial to human health [10,11,12,13,14]. Therefore, exploiting functional materials by using tea as resource and widening their application is important and meaningful.

Extensive attempts have been made to fabricate functional composites using tea as a resource, which show great potential in packaging [15], adsorption and energy fields [16]. By using green tea extracts as additives, poly (vinylalcohol) (PVA) [17], chitosan [18,19], polylactic acid (PLA)/nanocellulose [20], pectin-konjac glucomannan [21] and carrageenan/agar-based functional films [22] have been fabricated successfully using the solution casting method. Moreover, linear low-density polyethylene (LLDPE), thermoplastic starch and green tea blends can also be prepared via the conventional extrusion [23], while poly (vinyl alcohol)/ethyl cellulose/tea polyphenol composite nanofibrous films were achieved by blending electrospinning [24].

Additionally, spent tea leaf powder [25,26] and tea dust [27] can be employed as a filler to reinforce the polymer composites. Bio-char can be obtained from the tea-seed shells [28] and GT powder [29] by a simple calcination method, which can be used in lithium ion batteries and heavy metal ion removal fields. Nevertheless, most investigations were centered on the antioxidant and antimicrobial activities of tea polyphenols. Tea polyphenols should be extracted first from the leaves before use, which is laborious, energy consuming and a waste of the other components in green tea. Hence, completely and directly utilizing tea to fabricate novel composite materials is attractive and meaningful.

It is known that lignocellulosic biomass possesses “biomass recalcitrance”, and many pre-treatment methods have been developed to overcome this recalcitrance in the last few decades; however, extensive chemicals and energy are consumed in the pre-treatment process, leading to the disadvantages of high cost, environmental pollution and severe corrosion [30,31,32]. Fortunately, it has been found that many kinds of ionic liquids show the capacity to dissolve cellulose, lignin and even lignocellulose [33,34,35]. Moreover, increasing investigations have been successfully conducted to convert lignocellulose into functional material directly without pre-treatment.

Researchers reported that waste newspaper can be dissolved in 1-allyl-3-methyimidazolium chloride (AmimCl) to prepare cellulose-based aerogels without any pretreatment [36]. Similarly, by using AmimCl as a solvent, cellulose-based films can be fabricated directly from agricultural straw [37], corn husks [38] and waste corrugated paper [39] as shown in our previous work, which suggests great possibilities to replace or substitute petroleum-based plastics. AmimCl may possess toxicity to humans or the environment; however, it can be recycled and reused to decrease these side effects.

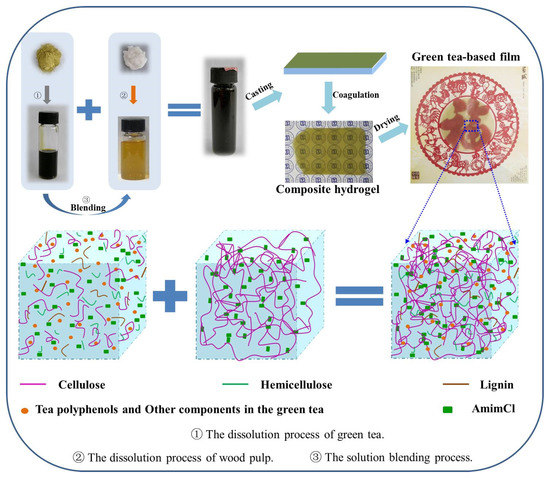

In this work, new green-tea-based functional materials were fabricated directly from green tea through a facile, economical and green strategy. As displayed in Figure 1, natural green tea powder was dissolved in AmimCl after shredding. Then, wood pulps with a high degree of polymerization (DP = 990) were incorporated into the green tea/AmimCl solutions, where enhanced entanglement networks formed in all-biomass materials, contributing to improving the mechanical strength of composite films.

Figure 1.

Schematic illustration of the fabrication process of green-tea-based all-biomass composite films.

There are no chemical pretreatments, component extractions or isolation in this process. After mixing, the all-biomass gels were obtained using the Sol-gel method. Finally, green-tea-based all-biomass light-management films were successfully achieved, where nearly all of the water-insoluble components in green tea were completely retained and utilized. Moreover, we conducted a series of characterizations to research the structures and properties of the composite films.

2. Materials and Methods

2.1. Materials and Chemicals

Green tea (GT) was bought from Rizhao city, Shandong Province, China and shredded into powder for further use. Wood pulps (WPs) with a degree of polymerization (DP) of 990 were prepared using the sulfate method, and the beating degree was 15 °SR. The DP of cellulose was obtained at 25 °C and characterized by Ubbelodhe viscometry with reference to the previous study [40]. The ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl) was kindly donated by Shandong Henglian New Materials Co., Ltd. (Weifang, China) and produced according to our previous work [41]. Deionized water was self-made in the laboratory.

2.2. Preparation of Green-Tea-Based Light-Management Films

The fabrication process of green-tea-based all-biomass films is illustrated in Figure 1. First, the purchased green tea was shredded into powder by the household wall breaker to improve the dissolution efficiency. Then, both AmimCl and shredded tea powder were mixed together and mechanically stirred for 4 h at 80 °C to obtain homogeneous tea/AmimCl solution, where the solid content of green tea was 4%. WPs and AmimCl were also blended together and mechanically stirred for 2 h to obtain a 4% cellulose/AmimCl solution.

After dissolution, the mixed green tea/WPs solutions with different proportions were obtained by blending the tea/AmimCl solution and WPs/AmimCl solution at 80 °C for 30 min, in which the total solid content was 4% and the proportions of WPs were 0%, 10%, 20%, 30%, 40% and 50%, respectively (Table S1). Finally, six kinds of tea/WPs/AmimCl solution mixtures were obtained. The mixed tea/WPs/AmimCl solution was cast on a flat plate to obtain a 1000 μm thickness of liquid film, and then the plate with the liquid film was soaked in deionized water to achieve the tea/WPs composite gels. The composite hydrogel was rinsed with deionized water thoroughly to remove the Cl- completely, and then 8% by volume of glycerol was added to the last coagulation bath.

Six kinds of semi-transparent green gels were achieved (named Gel-WPT0, Gel-WPT10, Gel-WPT20, Gel-WPT30, Gel-WPT40 and Gel-WPT50). After drying the tea/WPs hydrogel with Kessel paper dryer, the green-tea-based all-biomass composite films were fabricated, which are named WPT0, WPT10, WPT20, WPT30, WPT40 and WPT50. Additionally, raw cellulose gel (WPs-gel) and cellulose film (WPs-film) fabricated from wood pulps were also prepared for comparison.

2.3. Characterization

2.3.1. Polarized Optical Microscopy of Green Tea/AmimCl Solution

The solubility of green tea in AmimCl was probed by the PM6000 polarizing microscope (POM), which was purchased from Nanjing Jiangnan Yongxin Optical Co., Ltd. (Nanjing, China), where the solution was spread on a glass slide and covered by another glass slide.

2.3.2. Ultraviolet and Visible (UV-Vis) Spectra of the Green-Tea-Based All-Biomass Light-Management Films

The UV-Vis transmittance and haze plots ranging from 200 to 800 nm of the green-tea-based all-biomass light-management film were measured using an Ultraviolet spectrophotometer with ISR-2600Plus integrating sphere (UV 2600, Shimadzu, Kyoto, Japan), where GB/T 2410-2008 or the ASTM1003-13 standard method (Plastics) were used as the reference. The absorbance spectra of the composite film were also recorded.

2.3.3. The Surface Hydrophilicity of the Green-Tea-Based All-Biomass Light-Management Films

The surface hydrophilicity of the green-tea-based all-biomass light-management films was characterized by the OCA 50 machine (Dataphysics, Filderstadt, Germany). At least six spots were pictured for each film, and the average value was finally output.

2.3.4. Wide-Angle X-ray Diffraction (WAXD) of the WPs, GT, WPs-Film and Green-Tea-Based All-Biomass Light-Management Films

The X-ray diffractograms (XRD) of all-biomass light-management films and their raw materials were recorded in reflection mode by employing an X-ray diffractometer (D8 AD-VANCE, Bruker, Ettlingen, Germany) in which the scanning speed was set at 8°/min, and the 2θ span was set from 5° to 80°.

2.3.5. Fourier-Transform Infrared (FTIR) Spectra of the WPs, GT, WPs-Film and Green-Tea-Based All-Biomass Light-Management Films

Fourier-transform infrared spectrometer in the attenuated total reflectance mode (ATR-FTIR ALPHA, Bruker, Ettlingen, Germany) was employed to investigate the constituents and chemical structures of the samples, where the resolution of the detector was 4 cm−1 and 32 scans were conducted. Ethanol was used to wash the Germanium (Ge) crystal between samples, and the software OPUS was applied to calculate the results.

2.3.6. Mechanical Tests of the Green-Tea-Based All-Biomass Composite Films

TA.XT Plus C texture Analyzer (StableMicroSystem, Godalming, UK) with a 5 kN load cell was adopted to analyze the mechanical properties of the green-tea-based all-biomass light-management films, where the drawing speed was 4.8 mm min−1, and the gauge length was set at 2.5 cm. The films were cut to 6.0 cm in length and 1.0 cm in width, and five to seven strips were tested for each sample. Finally, the optimized value was output.

2.3.7. Thermogravimetric Analysis (TGA) of the WPs, GT, WPs-Film and Green-Tea-Based All-Biomass Light-Management Films

The thermogravimetric analyzer (TA Q50, Woodland, CA, USA) in nitrogen atmosphere was applied to measure the thermal decomposition behavior of all-biomass light-management films and their raw materials, where the heating rate was at 10 °C/min and the temperature was set from 50 to 800 °C. About 5–6 mg of samples were cut into pieces and placed into the crucible pot for testing.

2.3.8. Morphology of Green-Tea-Based All-Biomass Light-Management Films

Scanning electron micrographs (SEM) were recorded using a COXEM EM-30 Plus to see the morphology of green-tea-based all-biomass light-management films, where a platinum coating is necessary for all samples before the test. Moreover, the samples were quenched in liquid nitrogen to achieve the cross-sectional images.

3. Results and Discussion

3.1. Dissolution of Green Tea in AmimCL

Ionic liquids harboring many merits have gained extensive attraction and been widely used in various manufacturing and synthetic processes in the last decade [39,41,42]. We found that ionic liquids can dissolve cellulose efficiently. Most importantly, some of them show great potential to dissolve wood chips, and AmimCl was the most powerful ionic liquid as proven by the high-throughput screening test [34,43,44]. In our recent works, lignocellulose, such as waste corrugated cartons and bamboo-based disposal paper cups, have been employed as raw materials to prepare the regenerated cellulose-based films successfully by using AmimCl as the solvent [39,45,46].

Therefore, AmimCl was also chosen to dissolve green tea to prepare functional green-tea-based all-biomass light-management films in this work. First, the green tea was pulverized into a powder before dissolution, and this is also described in the Experimental Section. Then, a homogenous and stable solution of 4% green tea was achieved after 4 h at 80 °C by mechanical stirring (Figure S1a).

Generally, green tea contains many different components, including tea polyphenols, proteins, cellulose and other polysaccharides, which interact intensively with each other, limiting the complete dissolution of the green tea. Hence, there were still some un-dissolved particles in the mixed tea/cellulose/AmimCl solution, which was proven by microscope (Figure S1b). Furthermore, the green tea may be dissolved deeply in AmimCl by raising the heating temperature; however, this will consume more time and energy [37].

3.2. Optical Properties and UV-Vis Spectra of the Green-Tea-Based Light-Management Films

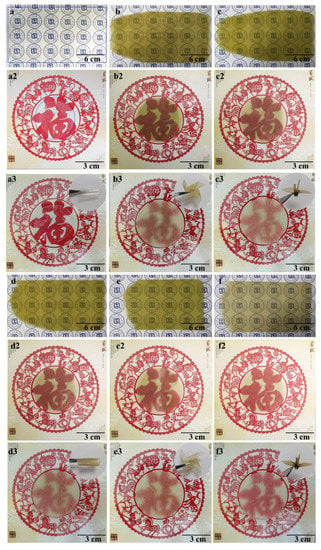

The transparency of films is important to their application, and digital pictures were first recorded to evaluate the transparency of the regenerated films. Semi-transparent yellow-green green-tea-based composite gels and films can be prepared from the raw green tea/wood pulps/AmimCl mixed solutions (Figure 2), and the texture of them was homogeneous. Nevertheless, during the drying process, the pure hydrogel prepared directly from green tea is quite fragile and easily collapsed into small pieces (Figure S2).

Figure 2.

Optical photographs of patterns covered with composite hydrogels ((a), WPs-gel; (b), Gel-WPT10; (c), Gel-WPT20; (d), Gel-WPT30; (e), Gel-WPT40; (f), Gel-WPT50), films without distance and films with 10 mm distance ((a2,a3), WPs-film; (b2,b3), WPT10; (c2,c3), WPT20; (d2,d3), WPT30; (e2,e3), WPT40; and (f2,f3), WPT50).

The reasons behind this are the following. On one hand, the content and degree of polymerization of cellulose in green tea are extremely low, thereby, limiting the formation of the entanglement networks (Figure 1). On the other hand, the high contents of tea polyphenols, proteins and inorganic compounds limit the formation and even serve as defects. Hence, cellulose with a high degree of polymerization (wood pulps), which can form enough entanglement networks in the composites, is introduced into the green tea/AmimCl solution in this work.

The formability and mechanical properties is improved with the addition of wood pulps. The WPs-gel and WPs-film were colorless; however, the green-tea-based composite hydrogels and films were all in yellow-green color, because tea polyphenols or pigments are confined in them.

As presented, the Gel-WPT50 and WPT50 displayed the lightest colors among the composite materials and were assigned to the highest content of WPs. Moreover, the transparency of the all-biomass composite gels and films was also improved by increasing the content of wood pulps (Figure 2(a–f,a2–f2)). Additionally, the Chinese character “fu” was clearly visible when covered with the WPs-film with no distance and with a 10 mm distance (Figure 2(a2,a3)). In contrast, the Chinese character “fu” was vague to the naked eyes when it was covered by the green-tea-based composite films with a 10 mm distance, thereby, demonstrating light scattering, which is related to the haze (Figure 2(b3–f3)).

The above phenomena indicate that the pure WPs-film is in ultralow haze, while the green-tea-based composite films are in high haze. The haze of the composites can be controlled by the mass ratio of green tea and WPs. Green-tea-based composite films are flexible enough to be rolled and can even be folded into windmill or paper crane shapes (the inset pictures of Figure 2(a3–f3)). In short, the green-tea-based composite films showed good transparency, although some impurities were still retained. Most importantly, the transparent composite films were accompanied with a tunable haze capacity and high flexibility, showing potential possibilities to complement or replace non-degradable plastics.

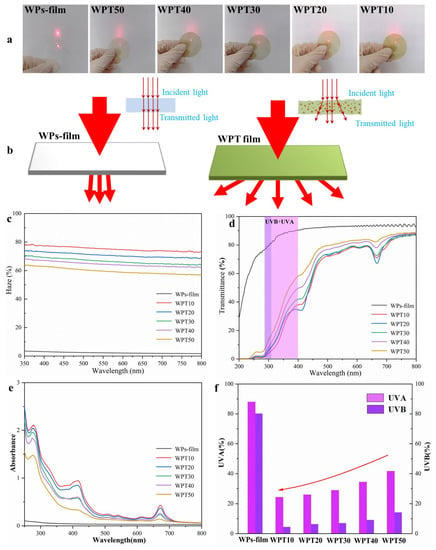

As demonstrated in Figure 3a, a red laser was used to irradiate the all-biomass composite films to further assess their light-scattering behavior. For the WPs-film, the light spot is concentrated in the middle, and no significant light scattering could be seen. In contrast, the area of the light spot for the composite films was enlarged by increasing the addition of green tea, meaning that the light scattering was elevated significantly by the composite films.

Figure 3.

(a) The light scattering effect of the regenerated films; (b) the schematic comparison between the WPs-film and the green-tea-based composite film; (c) haze; (d) the transmittance; (e) absorbance; and (f) UVA and UVB of the regenerated films.

Generally, the optical properties of the films are affected by their structure and morphology [47]. The light scattering of the composite films was enhanced by their interior defects and rough surface due to some organic and inorganic insoluble particles in the composite films, while the WPs-film possessed a relatively flawless structure, leading to low haze but high transparency (Figure 3b). To conclude, the regenerated films demonstrated different haze levels, and their haze varied significantly with their composition.

UV-Vis spectra were recorded to quantitatively evaluate the optical properties of the composite films, and the results of their haze and transparency are shown in Figure 3c,d. Compared to the WPs-film, whose transmittance and haze were about 93% and 3%, the composite films demonstrated a relatively higher haze but lower transmittance. Nevertheless, the transmittance of the green-tea-based all-biomass composite films was still high in the visible light region although the green tea showed a minor absorption peak at approximately 670 nm (Table S2 and Figure 3e).

Moreover, the transmittance increased, and the haze declined by increasing mass ratio of WPs. For example, the transmittance and haze of WPT10 film were around 78% and 74%, while the transmittance of WPT50 increased to 83%, and the haze of WPT50 reduced to 60%, respectively. Thus, these all-biomass composite films with high transparency and tunable haze can be applied in building privacy protection, optoelectronic devices or antiglare and antireflective coating by varying the content of components. UV radiation, categorized into UVB (290–315 nm) and UVA (315–400 nm), accelerates outdoor material aging and poses significant threats to humans [48,49].

The all-biomass composites displayed better UV-blocking capacity compared with the raw cellulose film (WPs-film) because the cellulose lacked absorption peaks at 200–400 nm, while the tea polyphenols, lignin, pigments and other anti-UV radiation substances included in the green tea showed distinct absorption peaks at approximately 280, 410 and 670 nm. The averaged values of TUVA and TUVB of composite films calculated according to GB/T 18830-2009 increased with increasing the content of wood pulps (Figure 3f).

The TUVA and TUVB of WPs-film were 87.94% and 80.12%, while the TUVA and TUVB of WPT10 film reduced by 72.45% and 94.45% to 24.23% and 4.45%, respectively. Hence, the green-tea-based all-biomass composite films showed good UV-blocking capacity, displaying superiority to be used in outdoor material fields. It should be noticed that the mechanical properties of the composite films may be influenced by the intensive UV radiation due to absorption.

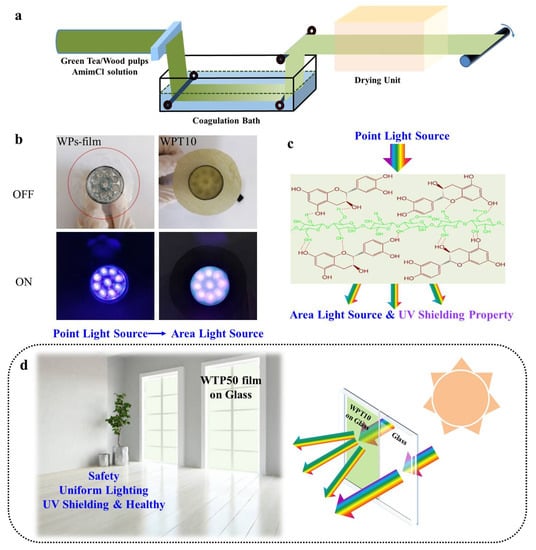

It is known that light-management films with high transparency and haze are extensively used in electrical and optical devices [47]. Nevertheless, most light-management films are prepared from the petroleum-based plastics, leading to significant pollution to our planet [47]. Herein, the renewable and biodegradable green-tea-based all-biomass composite films with good transparency, tunable haze and high UV-shielding capacity show great prospects in light management fields. The green-tea-based composite films are capable of mass production by adding green tea/AmimCl solution units to the existing continuous production process of pure cellulose films (Figure 4a).

Figure 4.

(a) A scheme of continuous production line of the green-tea-based all-biomass light-management films. (b) Application of the WPs-film and green-tea-based all-biomass composite films on a LED display device. (c) The UV-shielding mechanism of the green-tea-based all-biomass composite films. (d) The schematic scene of the green-tea-based all-biomass composite films attached to the glass door for the energy-saving buildings.

Most importantly, the optical performance of the green-tea-based composite films can be controlled by the content of WPs, which can meet the requirements in different fields. For example, the green tea/WPs composite films can be employed as coatings on the LED screen to modulate the light. As presented in Figure 4b, the little bulbs in the LED device are clearly seen for the naked LED or LED covered with native cellulose film (WPs-film). However, it is difficult to see the little bulbs clearly for the LED device coated with the WPT10 film, due to the intensive light diffusion effects.

When the light is on, the point light source can be automatically transitioned to an area light source by the WPT10 film, while the light from the LED device covered with WPs-film is harsh and strong, leading to glare. Thus, without sacrificing the light brightness or remodeling LED’s structures, achieving the uniform illumination via altering the light propagation path can be realized by these light-management films prepared directly from green tea.

Additionally, the composite films displayed good UV-shielding capacity, and the mechanism is illustrated in the Figure 4c, where nearly all UV light can be removed by the composite film due to the existence of anti-ultraviolet substances, including tea polyphenols and epicatechin (EC), one of components in tea polyphenols used for the model. It is worth noticing that these light-management films can be coated on the glass window or door to manipulate sunlight for the energy-saving buildings. Compared to the naked glass with a low haze, the glass coated with WPT10 film produces a gentle, uniform and large areal lighting, and then a comfortable, safe and energy-saving living surroundings are constructed (Figure 4d).

These green-tea-based composite films show good mechanical properties and thermal stability, which will be discussed in the following part. Moreover, these all-biomass light-management films can be decayed completely in nature at the end of their service and feature low carbon footprint, which is compatible with the sustainable development. In summary, these green-tea-based all-biomass light-management films will play an important role in smart buildings to realize carbon neutrality.

3.3. Morphology and Structure of the Green-Tea-Based Composite Films

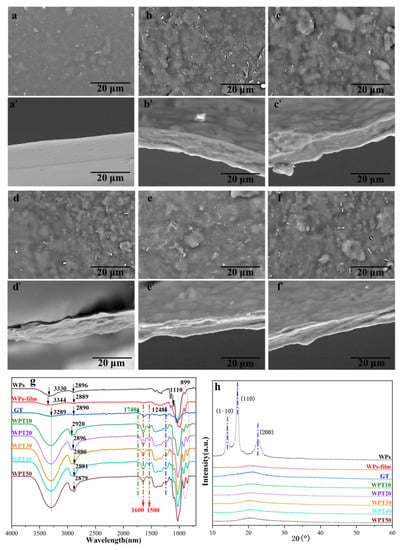

The structures are significant to the properties and application of composite films. The morphology of the regenerated films was assessed by scanning electron microscopy. Figure 5 and Figure S3 displayed the surface and cross section images of WPs-film and the composite films. As can be seen, the composite films possess relatively dense and homogenous microstructures from the surface to the inner.

Figure 5.

SEM micrographs of the regenerated films: (a–f) the surface and (a’–f’) the cross section of WPs-film, WPT10, WPT20, WPT30, WPT40 and WPT50; (g) FTIR; and (h) XRD profiles of WPs, WPs-film, GT, WPT10, WPT20, WPT30, WPT40 and WPT50.

However, compared to those of pure WPs-film (Figure 5a,a’), both the surface and cross section of the all-biomass composite films are rough and the composite films exhibit a laminated structure, due to the complex components embedded in the composite films, leading to the high haze of the composite films. Moreover, the surface of the composite film becomes smoother and the cross-sectional structure becomes denser by increasing the content of WPs. Therefore, the structure and properties of composite films are influenced by the mass ratio of green tea and WPs.

The green-tea-based composite films were prepared after the regeneration and drying processes. As displayed in Figure 5g, different from the FTIR spectra of the raw wood pulps and WPs-film, the raw green tea and green-tea-based all-biomass composite films demonstrated distinct peaks at approximately 1740 cm−1 (C=O stretching), 1600 and 1500 cm−1 (aromatic ring stretching) and a tiny peak at 1245 cm−1 (C-O stretching of lignin), which are the characteristic peaks of hemicellulose, tea polyphenols and lignin [39,40,50,51].

Most components, including tea polyphenols, lignin and hemicellulose, deriving from green tea are confined in the regenerated all-biomass films, and only some water-soluble pigments and inorganic substances were removed after the preparation process. Generally, cellulose crystalline structure and hydrogen bonds change greatly after the dissolution and regeneration. Hence, the wood pulps show peaks at 3330 cm−1 and 2896 cm−1, assigned to the O-H stretching and C-H stretching bands, respectively.

These two peaks shift to 3344 and 2889 cm−1 for the regenerated films (WPs-film) [48]. Moreover, the peak at 1110 cm−1 vanishes, and the peak at 899 cm−1 is enhanced for the WPs-film, also indicating the changes of structures [48]. Compared to the profile of WPs-film, the green-tea-based all-biomass composite films still possess a peak at 1110 cm−1. Additionally, the C-H stretching band and O-H stretching band demonstrate different trends in changes, which may be attributed to the incomplete dissolution of cellulose in green tea.

X-ray diffraction was also conducted to analyze the crystalline phases in the raw materials and the regenerated films. As displayed in Figure 5h, wood pulps demonstrated prominent peaks at approximately 2θ = 15.1° (1–10), 16.8° (110) and 22.8° (200), corresponding to the crystal planes of cellulose I [48,52]. Compared with the spectrum of WPs, the green tea (GT) only displays a broad peak at around 21°, due to the low content of cellulose in the green tea. Generally, cellulose transformed from I to II after regeneration and drying processes, and thus the WPs-film showed a broad peak ranging from 15° to 25°, which is the overlapped peak of two peaks at 21.9° (200) and 20.1° (110) of cellulose II and the amorphous peak at 17.3° [48,52].

However, compared with WPs and WPs-film, the crystal changes of cellulose I to II are not clear for GT and the all-biomass composite films, attributed to the high content of nonstructural substances in the green tea. Additionally, compared with the raw materials, the peak intensity of the regenerated films is decreased dramatically, consequence of the low crystallinity index of the regenerated films, which is a common phenomenon for the regenerated cellulose materials. No significant differences were observed in the XRD patterns of all-biomass composite films, indicating that increasing the content of WPs showed no influence on the crystallinity of the films.

3.4. Mechanical Properties, Hydrophilicity and Thermal Degradation of the Green-Tea-Based Composite Films

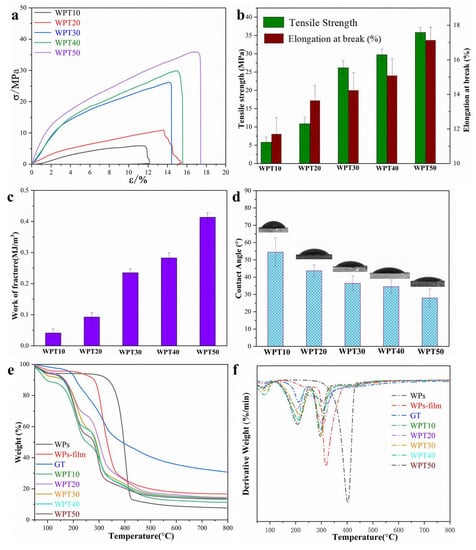

Mechanical properties of polymer films are significant to their application, and Figure 6a–c and Table S3 displayed the mechanical properties of green-tea-based all-biomass composite films. The pure green tea films are too fragile to be achieved during the regeneration and drying process. By contrast, the regenerated green-tea-based films show relatively good mechanical properties, due to the formation of a controllable entanglement networks in the green-tea-based composites.

Figure 6.

(a) Stress-strain profiles; (b) tensile strength and elongation at break; (c) work of fracture; (d) water contact angle of WPT10, WPT20, WPT30, WPT40 and WPT50; (e) TG; and (f) DTG of WPs, GT, WPs-film, WPT10, WPT20, WPT30, WPT40 and WPT50.

It can be seen that even the mass ratio of green tea/WP was 90/10, the obtained green-tea-based film was strong enough to form an intact composite film, and the corresponding tensile strength, elongation at break are about 6 MPa and 11%, respectively. Both the tensile strength and elongation at break of the composite films are increased by increasing content of WPs and they reach their maximum of 36 MPa and 17% in this work, where the mass content of the WPs with respect to total solids is 50 wt% (green tea/WPs, 50/50).

As we know, the tensile strength of the polyethylene self-sealing bag films, which are widely popular in household and laboratory is approximately 9–12 MPa, suggesting that the green-tea-based all-biomass composite films have great potential to replace the petroleum-based plastics. Generally, the tensile elongation of pure cellulose films is just around 2–6%, limiting their applications. Fortunately, the tensile elongation could be elevated by incorporating plasticizers.

The tensile elongation of the green-tea-based all-biomass composite films ranged from 10–20% in this work, due to the addition of glycerol, which was a common plasticizer [15,52,53]. Additionally, the toughness, expressed as a work of fracture is approximately 40 kJ/m3 for WPT10 and is improved by 900% to 400 kJ/m3 for WPT50, ascribed to the more content of the high degree of polymerization of WPs in WPT50 (Figure 6c). In short, the composite films possess great possibility to substitute or supplement the non-degradable petroleum-based plastics and their mechanical properties can be optimized via increasing the content of high-DP wood pulps.

Cellulose is hydrophilic due to extensive hydrogen bonds and materials fabricated from cellulose always possess low the water contact angles (WCAs). As exhibited in Figure 6d, the composite films are all hydrophilic and the WCAs for WPT10, WPT20, WPT30, WPT40 and WPT50 are approximately 54.5°, 43.7°, 36.4°, 34.5° and 28.0°, respectively. WPT10 with the highest content of green tea displays the largest WCAs, because most of the hydrophobic lignin or other impurities are kept in the composite film WPT10. In fact, hydrophobicity is important to their application. Thus, the hydrophobicity of composite films could be adjusted by their components to meet various applications in this work.

Thermal stability is also the key factor for the application of composite films, and the thermogram curves (TG) and differential thermogram (DTG) curves of the composite films are recorded and presented in Figure 6e,f and Figure S4. Generally, the tiny mass loss at temperature below 120 °C was caused by the evaporation of moisture [48,52]. It can be noticed that high-quality WPs display the highest onset decomposition temperature (Tonset, 290 °C) and temperature of maximum weight loss rates (Tmax, 400 °C) because WPs possess the highest degree of crystallinity and polymerization [48].

Different from that of WPs, the green tea (GT) showed a broad band ranging from 105 to 400 °C and two distinct peaks at around 210 and 320 °C due to the complex compositions in green tea. Similar to most pure cellulose film, the WPs-film began to decompose above 200 °C, attributed to deconstruction of the cellulose chains. Moreover, the Tmax of WPs-film is around 320 °C, far less than that of its raw material WPs, attributed to the low degree of crystallinity, which was consistent with our previous study [48].

Different from the WPs-film, the all-biomass composite films start to degrade at about 150 °C, assigned to the decomposition of impurities in GT. Furthermore, the composites possess two prominent Tmax at around 200 and 300 °C, respectively, corresponding with those of the raw material GT. However, these two Tmax peaks of green-tea-based all-biomass composite films are trimmed when compared to those of GT, suggesting that some impurities in green tea are removed in the coagulation and washing process.

The intensity of Tmax peak at 200 °C is weakened, while that of the Tmax peak at 300 °C was enhanced when increasing the content of WPs, which may be attributed to high stability of high-DP wood pulps (Figure S4). The thermal performances of green-tea-based all-biomass light-management films are clearly different from those of the pure cellulose films, due to the complex composition of green-tea-based all-biomass composite films.

4. Conclusions

Green tea can be directly and completely fabricated into semi-transparent all-biomass composite films with tunable haze, improved strength and UV-shielding properties through adding high-DP wood pulps (WPs) to form entanglement networks using the ionic liquid AmimCl solvent method in this work. We found that certain organic or inorganic impurities, including tea polyphenols, were maintained in the regenerated films, resulting in a tunable haze (60–80%) and good UV-shielding properties, where the UVA and UVB values can reach 24.23% and 4.45%, respectively. Moreover, adding high-DP WPs can also improve the mechanical properties of the regenerated films.

Particularly, the composite film WPT50 demonstrated the best mechanical properties and the work of force, elongation at break and tensile strength of WPT50 were about 400 kJ/m3, 17% and 36 MPa, indicating that the green-tea-based composite films demonstrated great potential to replace or supplement the non-degradable petroleum-based materials in light-management fields, such as flexible photoelectric devices and energy-efficient building fields. A facile and feasible approach to realize the valorization of green tea by preparing green-tea-based all-biomass light-management films was proposed in this work, and this is significant to sustainable development and a low-carbon society.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/polysaccharides3040045/s1, Figure S1: Digital picture (a) and POM micrograph (b) of green tea/AmimCl solution mixtures at 80 °C after 4 h; Figure S2: Optical photographs of hydrogels (a, Gel-WTP0) and film (b, WTP0) prepared directly from green tea; Figure S3: (a–f) The surfacial SEM micrographs of WPs-film, WPT10, WPT20, WPT30, WPT40 and WPT50; Figure S4: Differential thermogram curves (DTG) of WPs-film, WPT10, WPT20, WPT30, WPT40 and WPT50; Table S1: The mass content of WPs in the green tea-based all-biomass light management composite films. Table S2: Light transmission values of WPs-film, WPT0, WPT10, WPT20, WPT30, WPT40 and WPT50; Table S3: The thicknesses and mechanical properties of WPT10, WPT20, WPT30, WPT40 and WPT50.

Author Contributions

Conceptualization, G.X.; methodology, J.P. and X.J.; software, J.P. and X.X.; validation, C.L. and Z.W.; formal analysis, G.X.; investigation, C.C.; resources, Z.X.; data curation, J.P.; writing—original draft preparation, J.P. and X.J.; writing—review and editing, G.X.; visualization, J.Z.; supervision, J.Z.; project administration, J.Z.; funding acquisition, G.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Pilot Project for Integrating Science, Education and Industry, Qilu University of Technology, Shandong Academy of Sciences (No. 2022PX056); Opening Found of CAS Key Laboratory of Engineering Plastics, Institute of Chemistry, Chinese Academy of Sciences (CAS) and National Key Research and Development Plan (No. 2020YFC1910301).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the author.

Conflicts of Interest

The authors report no declarations of interest.

References

- Liu, Z.; Zhang, R.; Yang, C.; Hu, B.; Luo, X.; Li, Y.; Dong, C. Research on moisture content detection method during green tea processing based on machine vision and near-infrared spectroscopy technology. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 271, 120921. [Google Scholar] [CrossRef] [PubMed]

- Rana, A.; Rana, S.; Kapoor, S.; Joshi, R.; Thakur, A.; Padwad, Y.; Kumar, S. Unravelling the comparative metabolite fingerprints and therapeutic effects of diverse teas. Food Biosci. 2022, 48, 101795. [Google Scholar] [CrossRef]

- Wang, J.-Q.; Fu, Y.-Q.; Chen, J.-X.; Wang, F.; Feng, Z.-H.; Yin, J.-F.; Zeng, L.; Xu, Y.-Q. Effects of baking treatment on the sensory quality and physicochemical properties of green tea with different processing methods. Food Chem. 2022, 380, 132217. [Google Scholar] [CrossRef]

- Deka, H.; Barman, T.; Sarmah, P.P.; Devi, A.; Tamuly, P.; Karak, T. Impact of processing method on selected trace elements content of green tea: Does CTC green tea infusion possess risk towards human health? Food Chem. X 2021, 12, 100173. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wu, X.; Wang, Y.; Zhang, S.; Dong, S.; Zhou, W. Short- and medium-chain chlorinated paraffins in green tea from 11 Chinese provinces and their migration from packaging. J. Hazard. Mater. 2022, 427, 128192. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Hou, X.; Han, M.; Qiu, S.; Li, Y.; Qin, S.; Chen, X. Discrimination and polyphenol compositions of green teas with seasonal variations based on UPLC-QTOF/MS combined with chemometrics. J. Food Compos. Anal. 2021, 105, 104267. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, J.; Li, M.; Chen, Y.; Cui, Q.; Lu, C.; Wang, Y.; Li, L.; Xu, Z.; Zhong, Y.; et al. Rapid identification of the green tea geographical origin and processing month based on near-infrared hyperspectral imaging combined with chemometrics. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 267, 120537. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, W.; Jia, T.; Liu, Y.; Yao, S. Ionic liquid@β-cyclodextrin-gelatin composite membrane for effective separation of tea polyphenols from green tea. Food Chem. 2020, 333, 127534. [Google Scholar] [CrossRef]

- Fallah, S.; Musa-Veloso, K.; Cao, J.; Venditti, C.; Lee, H.Y.; Hamamji, S.; Hu, J.; Appelhans, K.; Frankos, V. Liver biomarkers in adults: Evaluation of associations with reported green tea consumption and use of green tea supplements in U.S. NHANES. Regul. Toxicol. Pharmacol. 2021, 129, 105087. [Google Scholar] [CrossRef]

- Ruchika; Sehgal, A. An update on disease preventing potential of green tea in comparison with some tisanes. S. Afr. J. Bot. 2021, 144, 92–96. [Google Scholar] [CrossRef]

- Sabaghi, M.; Maghsoudlou, Y.; Kashiri, M.; Shakeri, A. Evaluation of release mechanism of catechin from chitosan-polyvinyl alcohol film by exposure to gamma irradiation. Carbohydr. Polym. 2019, 230, 115589. [Google Scholar] [CrossRef] [PubMed]

- Nanri, A.; Yamamoto, S.; Konishi, M.; Ohmagari, N.; Mizoue, T. Green tea consumption and SARS-CoV-2 infection among staff of a referral hospital in Japan. Clin. Nutr. Open Sci. 2022, 42, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Sabaghi, M.; Hoseyni, S.Z.; Tavasoli, S.; Mozafari, M.; Katouzian, I. Strategies of confining green tea catechin compounds in nano-biopolymeric matrices: A review. Colloids Surf. B Biointerfaces 2021, 204, 111781. [Google Scholar] [CrossRef]

- Casado, F.; Teruel, J.A.; Casado, S.; Ortiz, A.; Rodríguez-López, J.N.; Aranda, F.J. Location and Effects of an Antitumoral Catechin on the Structural Properties of Phosphatidylethanolamine Membranes. Molecules 2016, 21, 829. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Ji, X.; Xu, Z.; Ji, X. Transparent cellulose-based bio-hybrid films with enhanced anti-ultraviolet, antioxidant and antibacterial performance. Carbohydr. Polym. 2022, 298, 120118. [Google Scholar] [CrossRef]

- Jamróz, E.; Kulawik, P.; Kopel, P.; Balková, R.; Hynek, D.; Bytesnikova, Z.; Gagic, M.; Milosavljevic, V.; Adam, V. Intelligent and active composite films based on furcellaran: Structural characterization, antioxidant and antimicrobial activities. Food Packag. Shelf Life 2019, 22, 100405. [Google Scholar] [CrossRef]

- Wen, H.; Hsu, Y.-I.; Asoh, T.-A.; Uyama, H. Antioxidant activity and physical properties of pH-sensitive biocomposite using poly(vinyl alcohol) incorporated with green tea extract. Polym. Degrad. Stab. 2020, 178, 109215. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, W. Antioxidant and antibacterial chitosan film with tea polyphenols-mediated green synthesis silver nanoparticle via a novel one-pot method. Int. J. Biol. Macromol. 2019, 155, 1252–1261. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Li, Y. Development of tea extracts and chitosan composite films for active packaging materials. Int. J. Biol. Macromol. 2013, 59, 282–289. [Google Scholar] [CrossRef]

- Vilarinho, F.; Stanzione, M.; Buonocore, G.; Barbosa-Pereira, L.; Sendón, R.; Vaz, M.; Silva, A.S. Green tea extract and nanocellulose embedded into polylactic acid film: Properties and efficiency on retarding the lipid oxidation of a model fatty food. Food Packag. Shelf Life 2020, 27, 100609. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, H.; Jiao, C.; Jiang, Y.; Liu, R.; Xiao, D.; Lu, J.; Zhang, Z.; Shen, G.; Li, S. Investigation of the structural and physical properties, antioxidant and antimicrobial activity of pectin-konjac glucomannan composite edible films incorporated with tea polyphenol. Food Hydrocoll. 2019, 94, 128–135. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Carrageenan/agar-based functional film integrated with zinc sulfide nanoparticles and Pickering emulsion of tea tree essential oil for active packaging applications. Int. J. Biol. Macromol. 2021, 193, 2038–2046. [Google Scholar] [CrossRef] [PubMed]

- Panrong, T.; Karbowiak, T.; Harnkarnsujarit, N. Thermoplastic starch and green tea blends with LLDPE films for active packaging of meat and oil-based products. Food Packag. Shelf Life 2019, 21, 100331. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, Y.; Cao, X.; Liu, Q.; Wang, H.; Kong, B. Preparation and functional properties of poly(vinyl alcohol)/ethyl cellulose/tea polyphenol electrospun nanofibrous films for active packaging material. Food Control 2021, 130, 108331. [Google Scholar] [CrossRef]

- Duan, J.; Reddy, K.O.; Ashok, B.; Cai, J.; Zhang, L.; Rajulu, A.V. Effects of spent tea leaf powder on the properties and functions of cellulose green composite films. J. Environ. Chem. Eng. 2015, 4, 440–448. [Google Scholar] [CrossRef]

- Xia, G.; Reddy, K.O.; Maheswari, C.U.; Jayaramudu, J.; Zhang, J.; Zhang, J.; Rajulu, A.V. Preparation and Properties of Biodegradable Spent Tea Leaf Powder/Poly(Propylene Carbonate) Composite Films. Int. J. Polym. Anal. Charact. 2015, 20, 377–387. [Google Scholar] [CrossRef]

- Theja, K.K.; Bharathiraja, G.; Murugan, V.S.; Muniappan, A. Evaluation of mechanical properties of tea dust filler reinforced polymer composite. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Nie, S.; Li, R.; Xin, Y.; Tan, Y.; Miao, C.; Xiang, Y.; Xiao, W. Enhanced cycling performance of Sn nanoparticles embedded into the pyrolytic biochar from tea-seed shells as composite anode materials for lithium ions batteries. Solid State Ionics 2021, 368, 115703. [Google Scholar] [CrossRef]

- Jayaramudu, T.; Varaprasad, K.; Kim, H.C.; Kafy, A.; Kim, J.W.; Kim, J. Calcinated tea and cellulose composite films and its dielectric and lead adsorption properties. Carbohydr. Polym. 2017, 171, 183–192. [Google Scholar] [CrossRef]

- Woiciechowski, A.L.; Neto, C.J.D.; de Souza Vandenberghe, L.P.; de Carvalho Neto, D.P.; Sydney, A.C.N.; Letti, L.A.J.; Karp, S.G.; Torres, L.A.Z.; Soccol, C.R. Lignocellulosic biomass: Acid and alkaline pretreatments and their effects on biomass recalcitrance—Conventional processing and recent advances. Bioresour. Technol. 2020, 304, 122848. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Chen, Z.; Wan, C. Reducing biomass recalcitrance via mild sodium carbonate pretreatment. Bioresour. Technol. 2016, 209, 386–390. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Fakayode, O.A.; Yagoub, A.E.A.; Ji, Q.; Zhou, C. Lignin fractionation from lignocellulosic biomass using deep eutectic solvents and its valorization. Renew. Sustain. Energy Rev. 2021, 156, 111986. [Google Scholar] [CrossRef]

- Fort, D.A.; Remsing, R.C.; Swatloski, R.P.; Moyna, P.; Moyna, G.; Rogers, R.D. Can ionic liquids dissolve wood? Processing and analysis of lignocellulosic materials with 1-n-butyl-3-methylimidazolium chloride. Green Chem. 2006, 9, 63–69. [Google Scholar] [CrossRef]

- Zavrel, M.; Bross, D.; Funke, M.; Büchs, J.; Spiess, A.C. High-throughput screening for ionic liquids dissolving (ligno-)cellulose. Bioresour. Technol. 2009, 100, 2580–2587. [Google Scholar] [CrossRef] [PubMed]

- Im, J.; Lee, S.; Jo, I.; Kang, J.W.; Kim, K.-S. Structural characteristics and thermal properties of regenerated cellulose, hemicellulose and lignin after being dissolved in ionic liquids. J. Ind. Eng. Chem. 2021, 107, 365–375. [Google Scholar] [CrossRef]

- Jin, C.; Han, S.; Li, J.; Sun, Q. Fabrication of cellulose-based aerogels from waste newspaper without any pretreatment and their use for absorbents. Carbohydr. Polym. 2015, 123, 150–156. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Zhang, J.; Mi, Q.; Jia, F.; Wu, J.; Yu, J.; Zhang, J. Direct and complete utilization of agricultural straw to fabricate all-biomass films with high-strength, high-haze and UV-shielding properties. Carbohydr. Polym. 2019, 223, 115057. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, N.; Wan, J.; Xia, G.; Yu, J.; He, J.; Zhang, J. Directly Converting Agricultural Straw into All-Biomass Nanocomposite Films Reinforced with Additional In Situ-Retained Cellulose Nanocrystals. ACS Sustain. Chem. Eng. 2017, 5, 5127–5133. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Ji, X.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Cellulose-Based Films with Ultraviolet Shielding Performance Prepared Directly from Waste Corrugated Pulp. Polymers 2021, 13, 3359. [Google Scholar] [CrossRef]

- Xia, G.; Wan, J.; Zhang, J.; Zhang, X.; Xu, L.; Wu, J.; He, J.; Zhang, J. Cellulose-based films prepared directly from waste newspapers via an ionic liquid. Carbohydr. Polym. 2016, 151, 223–229. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-Methylimidazolium Chloride Room Temperature Ionic Liquid: A New and Powerful Nonderivatizing Solvent for Cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef] [PubMed]

- Sun, N.; Rahman, M.; Qin, Y.; Maxim, M.L.; Rodríguez, H.; Rogers, R.D. Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem. 2009, 11, 646–655. [Google Scholar] [CrossRef]

- Sun, N.; Jiang, X.; Maxim, M.L.; Metlen, A.; Rogers, R.D. Use of Polyoxometalate catalysts in ionic liquids to enhance the dissolution and delignification of woody biomass. ChemSusChem 2010, 4, 65–73. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Q.; Ji, X.; Peng, J.; Nawaz, H.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J. Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers 2022, 14, 1070. [Google Scholar] [CrossRef]

- Jia, P.; Ji, X.; Zheng, B.; Wang, C.; Hao, W.; Han, W.; Zhang, J.; Xia, G.; Ji, X.; Zhang, J. Eco-Friendly and Complete Recycling of Waste Bamboo-Based Disposable Paper Cups for Value-Added Transparent Cellulose-Based Films and Paper Plastic Composites. Polymers 2022, 14, 1589. [Google Scholar] [CrossRef]

- Song, Y.; Xu, Y.; Li, D.; Chen, S.; Xu, F. Sustainable and Superhydrophobic Lignocellulose-Based Transparent Films with Efficient Light Management and Self-Cleaning. ACS Appl. Mater. Interfaces 2021, 13, 49340–49347. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Zhang, J.; Wang, J.; You, J.; Wang, Y.; Nawaz, H. Transparent cellulose/aramid nanofibers films with improved mechanical and ultraviolet shielding performance from waste cotton textiles by in-situ fabrication. Carbohydr. Polym. 2021, 273, 118569. [Google Scholar] [CrossRef]

- Jhappan, C.; Noonan, F.P.; Merlino, G. Ultraviolet radiation and cutaneous malignant melanoma. Oncogene 2003, 22, 3099–3112. [Google Scholar] [CrossRef]

- Ye, J.; Wang, S.; Lan, W.; Qin, W.; Liu, Y. Preparation and properties of polylactic acid-tea polyphenol-chitosan composite membranes. Int. J. Biol. Macromol. 2018, 117, 632–639. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, L.; Cai, J.; Dong, Q.; Din, Z.-U.; Hu, Z.-Z.; Wang, G.-Z.; Ding, W.-P.; He, J.-R.; Cheng, S.-Y. Starch/tea polyphenols nanofibrous films for food packaging application: From facile construction to enhance mechanical, antioxidant and hydrophobic properties. Food Chem. 2021, 360, 129922. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Han, W.; Xu, Z.; Zhang, J.; Kong, F.; Zhang, J.; Zhang, X.; Jia, F. Complete recycling and valorization of waste textiles for value-added transparent films via an ionic liquid. J. Environ. Chem. Eng. 2021, 9, 106182. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, Q.; Wang, L.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers 2021, 13, 4209. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).