Loading Response of Segment Lining with Pea-Gravel Grouting Defects for TBM Tunnel in Transition Zones of Surrounding Rocks

Abstract

1. Introduction

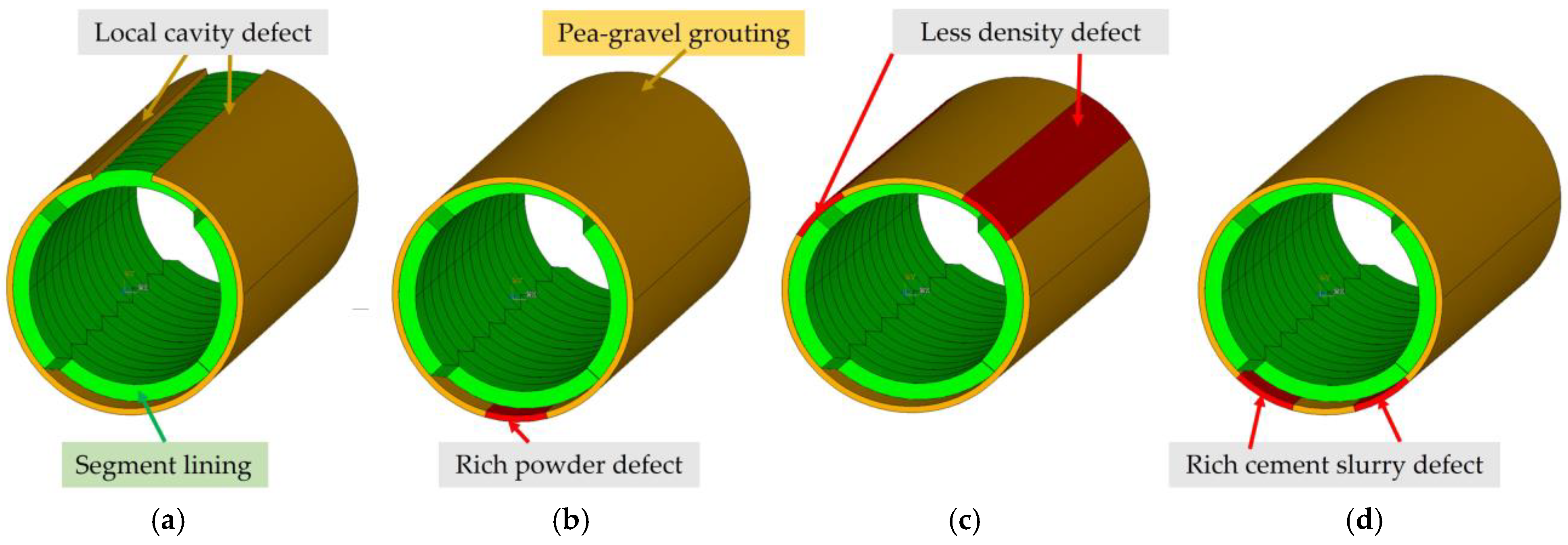

2. Numerical Models of TBM Tunnel Structures

2.1. FEM Numerical Models

2.2. Constitutive Relationships of Materials

2.3. Cases for Numerical Analysis

2.4. Verification of Numerical Models

3. Analytical Results and Discussion

3.1. Effect of Local Cavities on Pea-Gravel Grouting

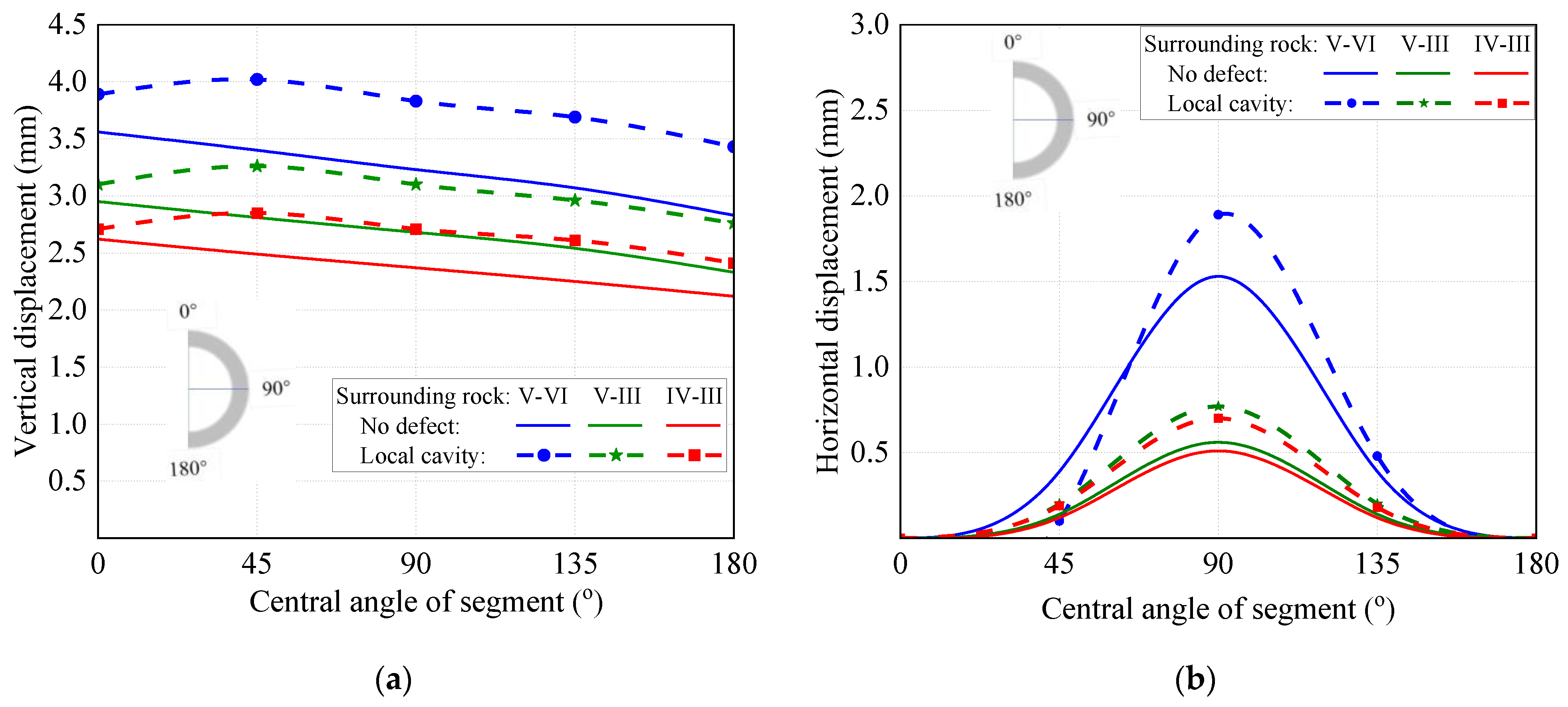

3.1.1. Displacement of Segment

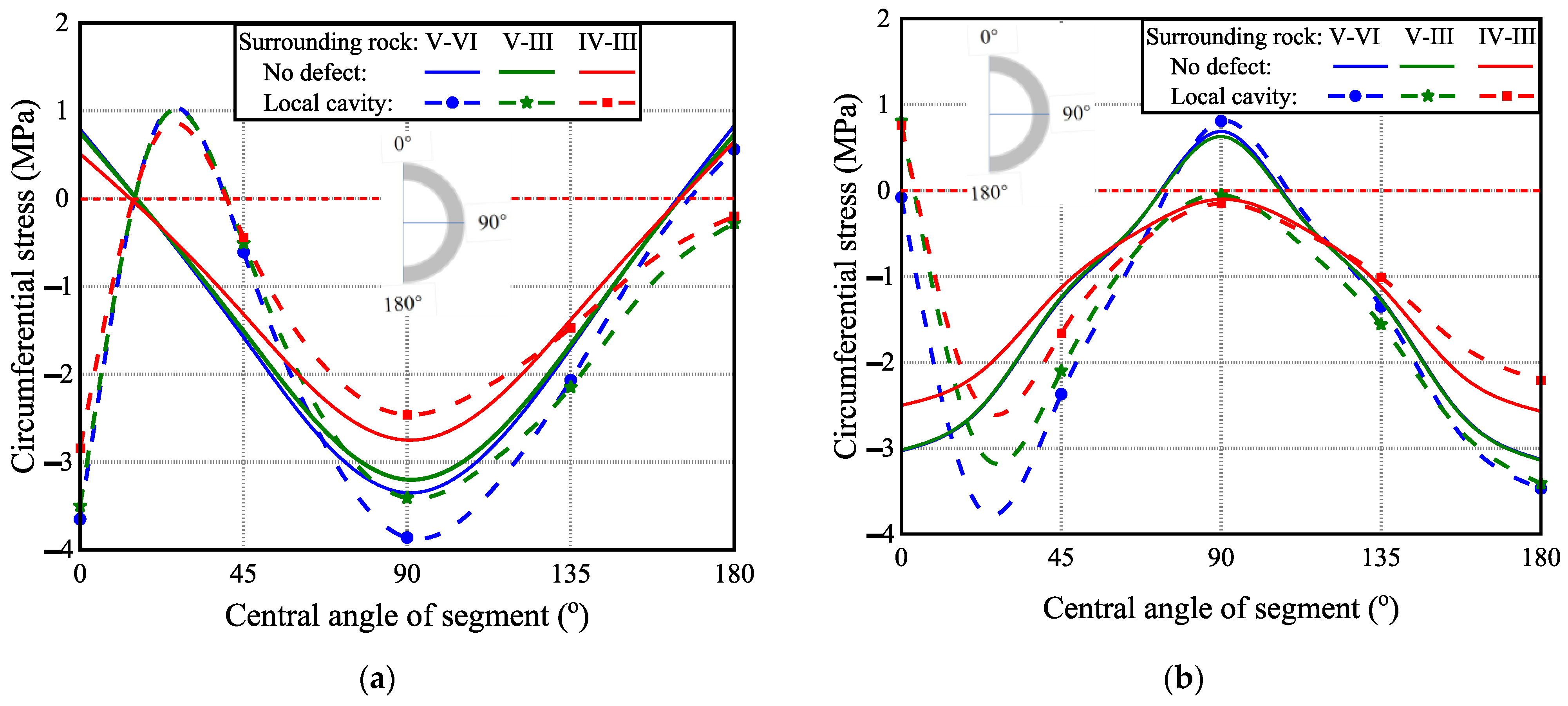

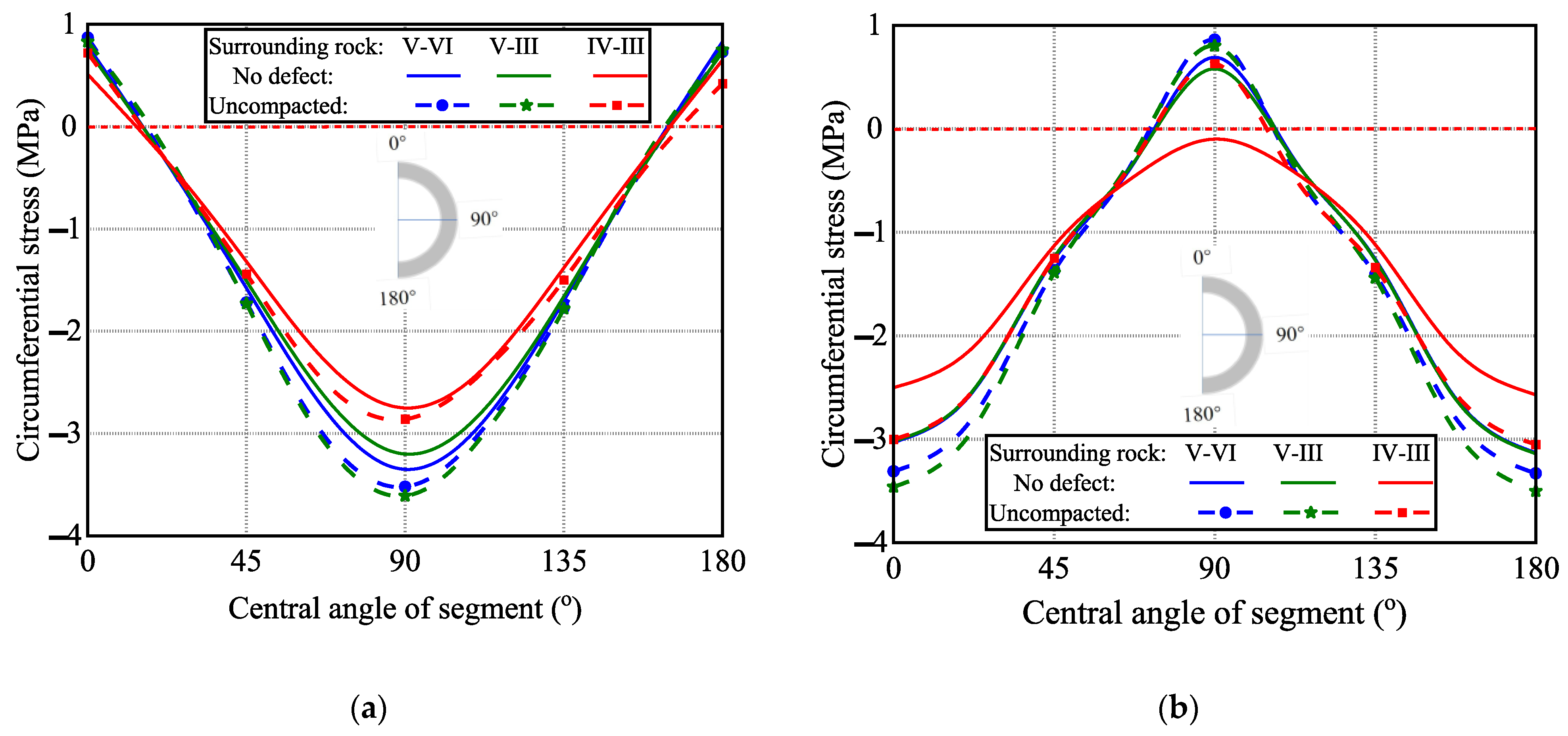

3.1.2. Circumferential Stress of Segment

3.2. Effect of Less Density on Pea-Gravel Grouting

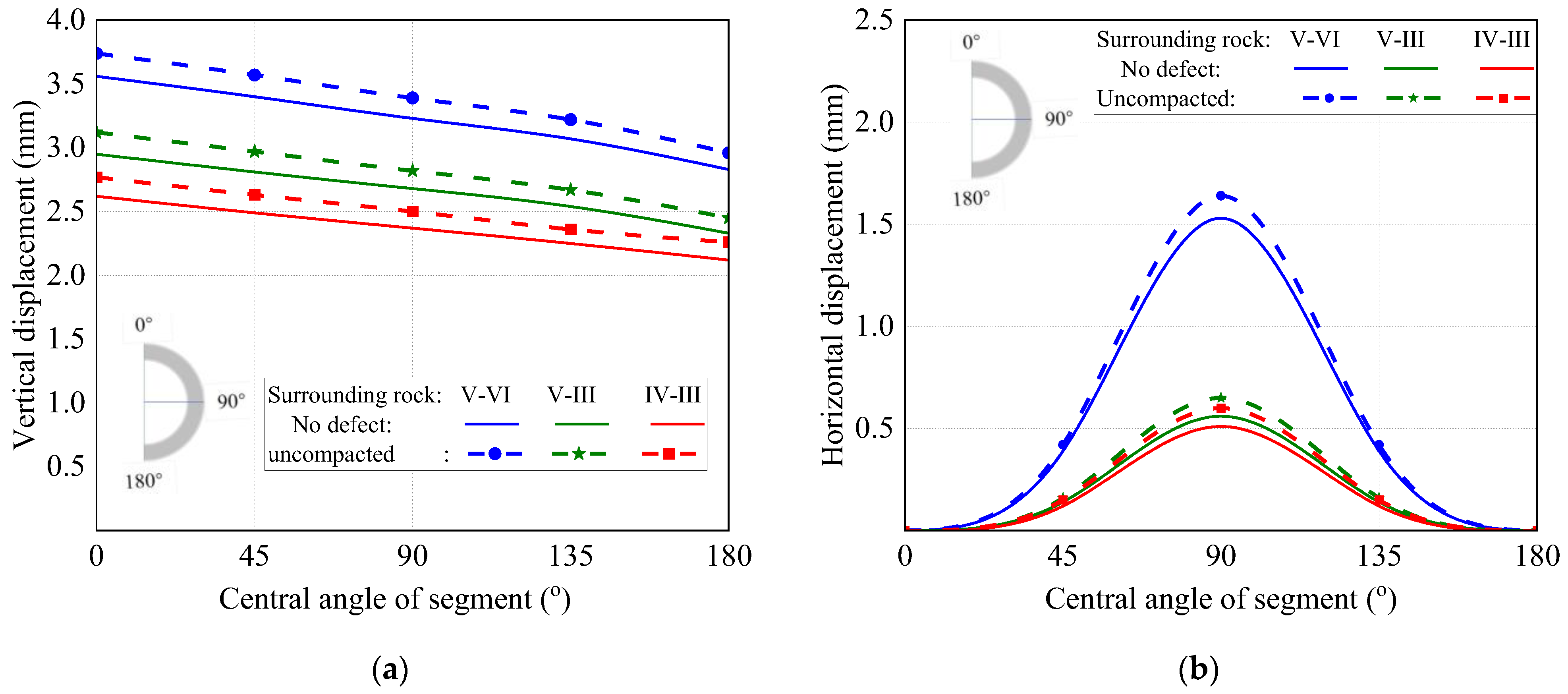

3.2.1. Displacement of Segment

3.2.2. Circumferential Stress of Segment

3.3. Effect of Rich Rock Powder on Pea-Gravel Grouting

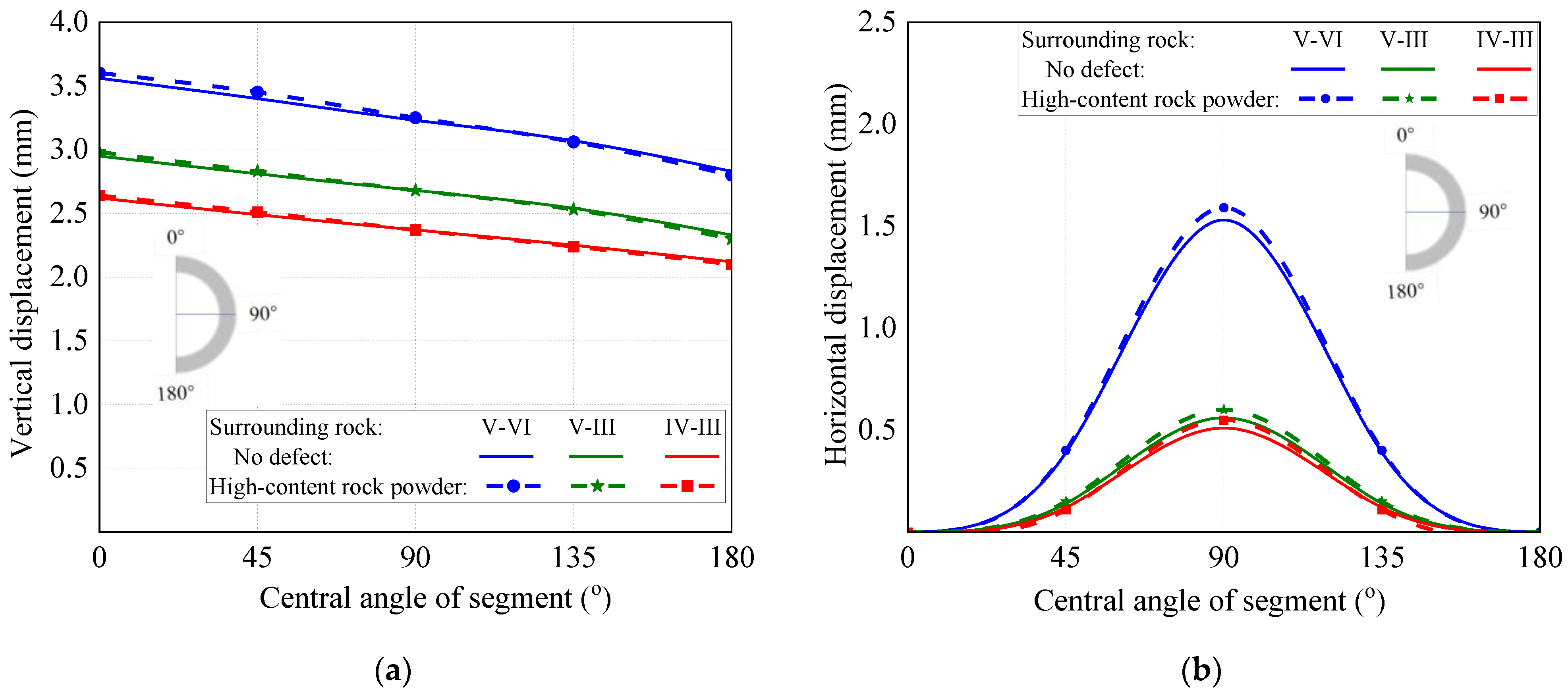

3.3.1. Displacement of Segment

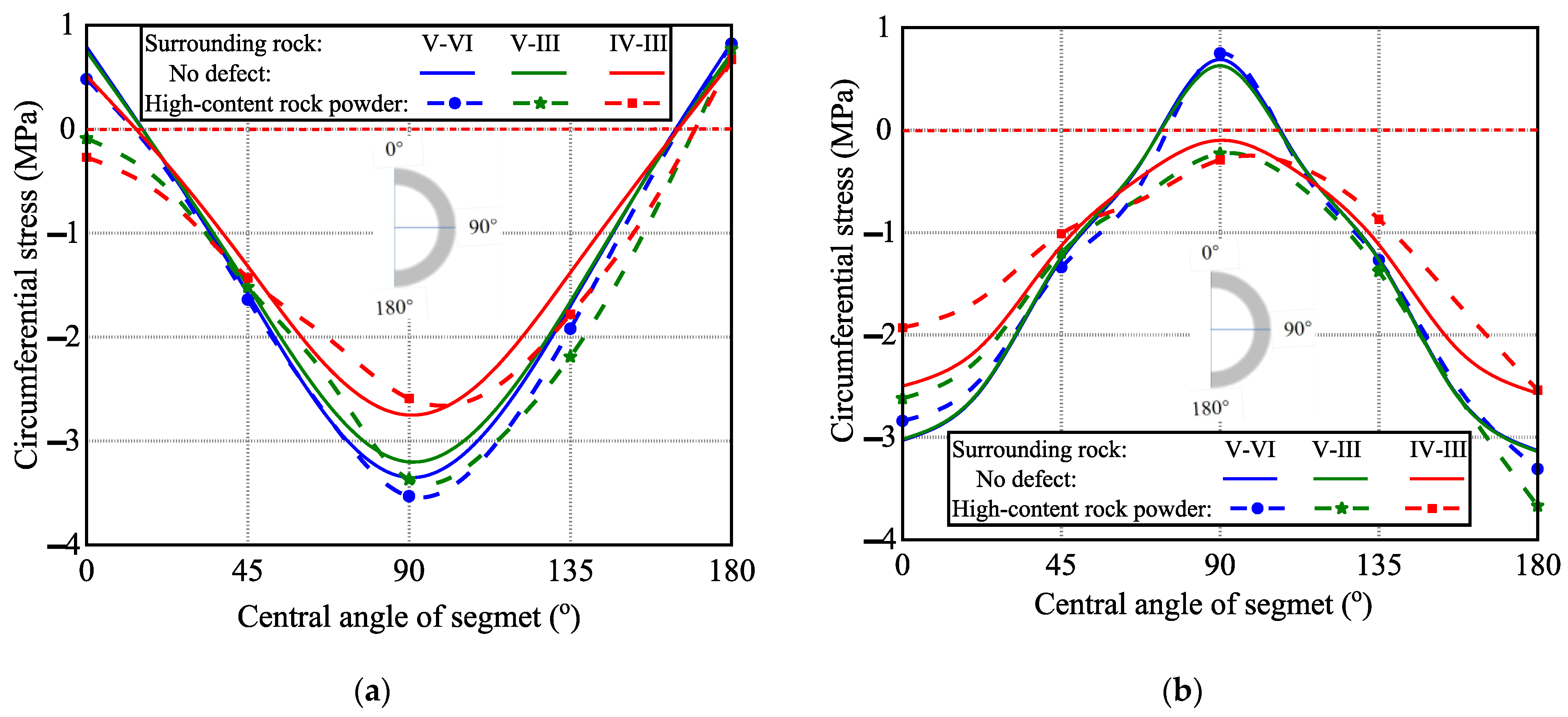

3.3.2. Circumferential Stress of Segment

3.4. Effect of Rich Cement Slurry on Pea-Gravel Grouting

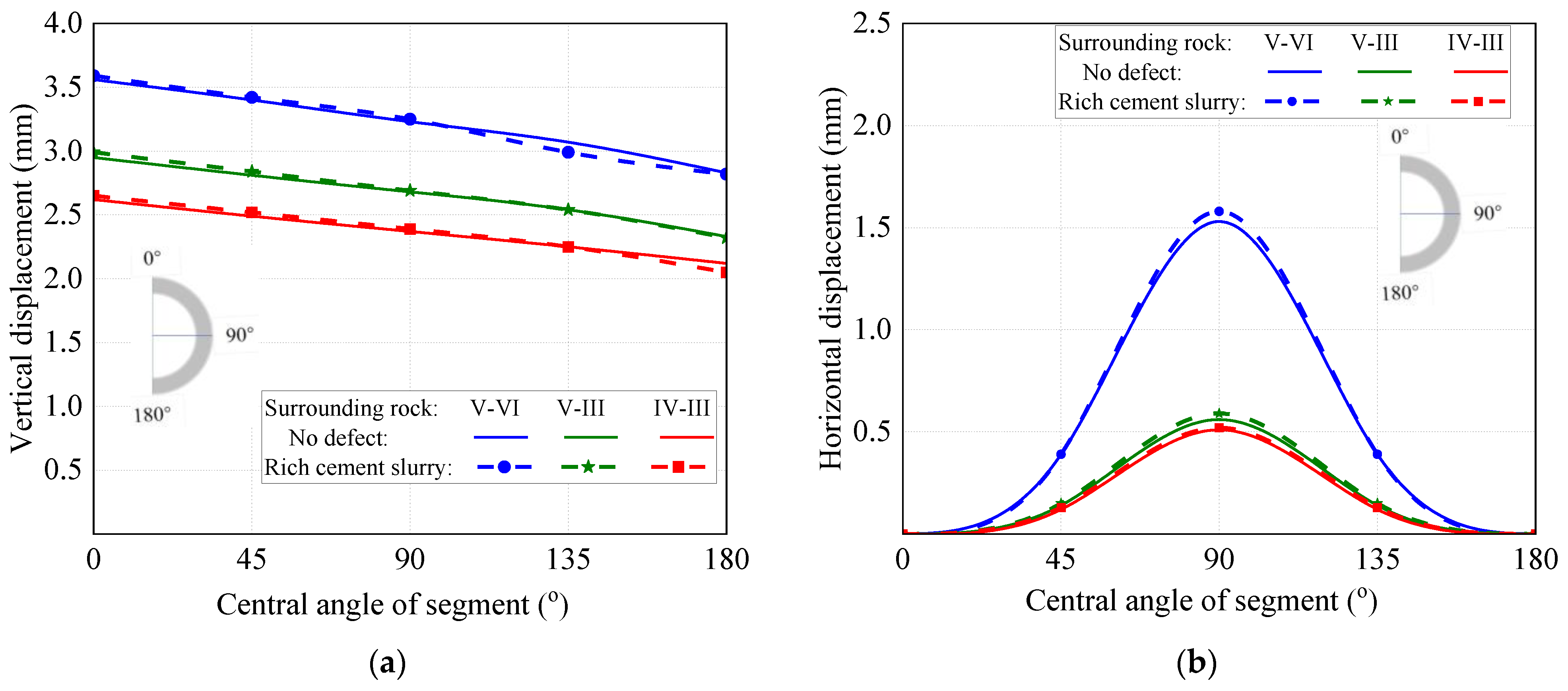

3.4.1. Displacement of Segment

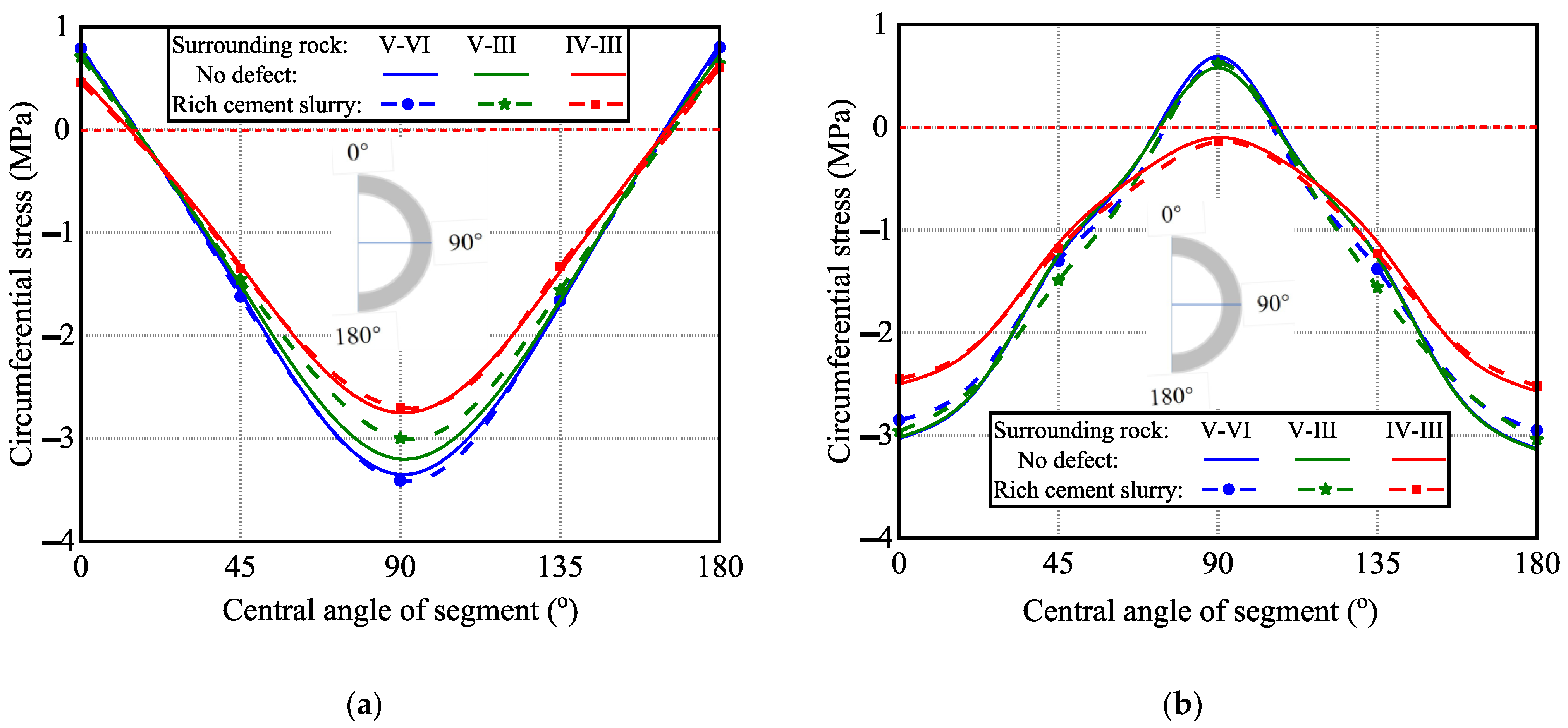

3.4.2. Circumferential Stress of Segment

3.5. General Discussion

4. Conclusions

- (1)

- The vertical and horizontal displacements of segment lining maintain similar regulation for the segment lining with or without pea-gravel grouting defects. The vertical displacement of segment lining decreases from top to bottom, and the horizontal displacement increases from top or bottom to the web. The local cavities have a comparatively large effect with an increase of 10.9–21.2% vertical displacement and 23.5–37.5 horizontal displacement. The other three types of defects have less influence on the displacement of segment lining.

- (2)

- The local cavities of pea-gravel grouting convert the tensile and compression of circumferential stress on the upper half ring of segment lining, leading to the greatest effect on the stress distribution. The other three types of pea-gravel grouting defects have a comparatively lower effect on the stress distribution except for on changing stress values. The defect effects on the loading response of segment lining become stronger with the weaker self-support of surrounding rocks in the order of IV–III, V–III and V–IV, which results in relatively larger effects on the maximum tensile stress of segment lining at V–IV surrounding rocks.

- (3)

- With the combinations of all four defects, the segment lining is safe in compression with a maximum of only 44.2% compressive strength of concrete. Depending on the better self-support of IV–III surrounding rocks, segment lining under the combination of all four defects is safe without worrying about cracking, because the maximum tensile stress is within the limit. Cracking is possible on the inner bottom surface of segment concrete with a combination of defects, including less density, rich rock powder and rich cement slurry in the transition zone of V–III surrounding rocks, due to the maximum tensile stress being very close to the limit. For the segment lining in the transition zone of V–IV surrounding rocks, the most possible cracking exists on the inner bottom surface and the outer surface of the web sides with the combination of three defects or all four defects, due to the maximum tensile stresses being basically over the limit.

- (4)

- The results of this study show that the inner surface of the top and bottom, and the outer surface of the web sides of segment lining face the risk of concrete cracking. This can be referenced to determine the key positions of quality inspection for pea-gravel grouting in TBM tunnel construction and operation.

- (5)

- This study was limited to a tunnel for non-pressurized water delivery with an inner diameter of 3.5 m, with more limitations observed in the modeling approaches for geometry simplifications, material properties, and loading cases to confine the wide application of the results. Therefore, further studies on TBM tunnels under other conditions for water delivery should be continuously conducted, and should be combined with experimental or real-world measurements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qu, S.; Huang, H.; Gao, Z. Planning on water diversion project for central area of Yunnan Province. Yangtze River 2013, 44, 80–83. [Google Scholar]

- Qi, Z.; He, F. Application of sliding-type open TBM stepping technology to Songhua River Water Diversion Project. Tunn. Constr. 2017, 37, 184–188. [Google Scholar]

- Lu, A.; Xiao, H.; Shen, X.; Fu, Y. Design and construction technology of slurry shield used in Shiziyang water conveyance tunnel. Mod. Tunn. Technol. 2020, 57, 226–231. [Google Scholar]

- Wang, L.; Lin, Q.; Zhao, J. Brief introductions on overall layout of the River Diversion Project from the Yangtze River to the Han River. Chin. Water Resour. 2022, 19, 36–39. [Google Scholar]

- GB/T 51438-2021; Standard for Design of Shield Tunnel Engineering. China Building Industry Press: Beijing, China, 2021.

- Dong, L.; Yang, Z.; Wang, Z.; Ding, Y.; Qi, W. Study on internal force of tunnel segment by considering the influence of joints. Adv. Mater. Sci. Eng. 2020, 3, 1–13. [Google Scholar] [CrossRef]

- Mo, J.; Tang, X.; Yan, Z. Load bearing and deformation characteristics of single-layer segment lining structure for water conveyance tunnels. Chin. J. Geotech. Eng. 2023, 45, 1365–1373. [Google Scholar]

- Zhao, X.; Han, K.; Ju, J.; Chen, X.; Chen, W.; Xiong, H. Numerical analysis of size effect on the deformation behavior and damage evolution mechanism of segmental tunnel lining rings. Int. J. Damage Mech. 2023, 32, 600–622. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B.; Wang, X.; He, Y.; Wang, H.; Zhao, S. Safety risk assessment of TBM tunnel construction based on fuzzy evidence reasoning. Processes 2022, 10, 2597. [Google Scholar] [CrossRef]

- Li, F.; Si, P.; He, Y.; Wang, H.; Zhang, Z. Case studies of the load-bearing performance of shield tunnel segment with misaligned defects. Sci. Rep. 2024, 14, 17370. [Google Scholar] [CrossRef] [PubMed]

- Si, P.; Li, C.; Wang, X.; He, Y.; Che, Q.; Zhao, S. A case study of systemic risk assessment for the operational safety of a long-distance water delivery tunnel. Processes 2025, 13, 1677. [Google Scholar] [CrossRef]

- Hu, M. Study on Mechanical Effect of Pea-gravel Backfill Grout Layer in TBM Tunnel Lining System. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2019. [Google Scholar]

- GB50446-2017; Code for Construction and Acceptance of Shield Tunnelling Method. China Building Industry Press: Beijing, China, 2017.

- Luo, J.; Peng, L. Pea-stone backfilling and quality control in TBM construction. Hunan Water Resour. Hydropower 2018, 63, 37–40. [Google Scholar]

- Han, W.; Wang, X. Study on the optimum grouting materials and their performance in the TBM tunnel collapse reinforcement project. IOP Confer. Ser. Earth Environ. Sci. 2020, 570, 052065. [Google Scholar]

- Liang, X.; Ying, K.; Ye, F.; Su, E.; Xia, T.; Han, X. Selection of backfill grouting materials and ratios for shield tunnel considering stratum suitability. Constr. Build. Mater. 2022, 314, 125431. [Google Scholar] [CrossRef]

- Jiang, B.; Wu, M.; Wu, S.; Zheng, A.; He, S. A review on development of industrial solid waste in tunnel grouting materials: Feasibility, performance, and prospects. Materials 2023, 16, 6848. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Guo, J.; Wang, Z. Lattice Boltzmann simulation for grout filling process during simultaneous backfill grouting of shield in tunnel construction. Euro. J. Environ. Civ. Eng. 2022, 26, 4039–4054. [Google Scholar] [CrossRef]

- Qin, N.; Ye, F.; He, B.; Liang, X.; Han, X.; Su, E. Model study on backfill grouting in shield tunnels based on fractal theory. Euro. J. Environ. Civ. Eng. 2022, 26, 5901–5911. [Google Scholar] [CrossRef]

- Su, S.; Cheng, B.; Sun, W.; Zhang, J. Preliminary design for pea-gravel grouting in TBM tunnelling. Chin. J. Rock. Mechan. Eng. 2001, 20, 208–211. [Google Scholar]

- Liu, L. Pea-gravel backfilling grouting technology of TBM construction. Water Resour. Hydropower Eng. 2012, 43, 63–66. [Google Scholar]

- Wu, S.; Zhao, H.; Xie, H.; Dong, Y.; Fang, L.; Wang, M.; Liu, Y. Distribution characteristics of pea gravel behind segment in shield tunnel boring Machine tunnels. Adv. Eng. Sci. 2023, 56, 150–160. [Google Scholar]

- Yang, F.; Jin, J.; Yang, F. Influence of backfill grouting property and compactness of TBM pea-gravel on supporting effect. Yellow River 2024, 46, 139–145. [Google Scholar]

- Zhang, J.; Huang, Q.; Wang, X.; Hu, C.; Zhang, S. The engineering influence of pea gravel annulus grouting layer with defects. Morden Tunn. Tech. 2021, 58, 163–172. [Google Scholar]

- Wang, M.; Hou, S.; Liu, Y.; Jin, F. Influence of backfill grouting compactness in TBM pea-gravel on supporting effect. Tunn. Constr. 2020, 40, 326–336. [Google Scholar]

- Zheng, R. Design and construction of pea-gravel grouting for No.1 tunnel in north route of Wanjiazhai Yellow River Diversion Project. Water Resour. Hydropower Eng. 2007, 38, 39–40. [Google Scholar]

- Fan, C. Analysis on key points to control engineering quality of tunnel constructed by TBM in Tao River Delivery Project and the countermeasure. Shanxi Hydrotech. 2008, 3, 64–65. [Google Scholar]

- Henzinger, M.R.; Pejic, D.; Schubert, W. Design improvements of segmental linings due to unfavorable bedding situations. Procedia Eng. 2017, 191, 729–734. [Google Scholar] [CrossRef]

- SL 279-2016; Specification for Design of Hydraulic Tunnel. China HydroPower Press: Beijing, China, 2016.

- SL 191-2008; Design Code for Hydraulic Concrete Structures. China HydroPower Press: Beijing, China, 2008.

- Shang, P.; Qu, F.; Wang, J.; Geng, Y.; Yan, T.; Zhao, S. A Simplified limit-state design and verification for prestressed concrete cylinder pipes under internal water pressure. Buildings 2023, 13, 2825. [Google Scholar] [CrossRef]

- Qu, F.; Zhang, D.; Wang, H.; Zheng, W.; Zhao, S. Full-scale test and bearing capacity evaluation of large diameter prestressed concrete cylinder pipe under internal water pressure. Buildings 2022, 12, 1791. [Google Scholar] [CrossRef]

- Sun, W.; Li, X.; Cheng, K.; Jia, W.; Liu, H. Analysis on the influence of large diameter intercity railway tunnel under passing the main canal of the middle route of South-to-North Water Diversion Project. J. North China Univ. Water Resou. Electr. Power (Nat. Sci. Ed.) 2020, 41, 46–52. [Google Scholar]

- Chen, Z.; Li, X.; Yang, Y.; Zhao, S.; Fu, Z. Experimental and numerical investigation of the effect of temperature patterns on behaviour of large scale silo. Eng. Fail. Anal. 2018, 91, 543–553. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Xue, G.; Yao, G.; Chen, Z.; Zhao, S. Mechanical performance of the prestressed concrete lining withstanding prestress of steel strands: Full-scale test and numerical simulation. Alex. Eng. J. 2025, 114, 621–635. [Google Scholar] [CrossRef]

- Li, F.; Si, P.; He, Y.; Wang, H.; Zhang, Z.; Zhao, S. Numerical analysis of the single-directionally misaligned segment behavior of hydraulic TBM tunnel. Buildings 2024, 14, 2198. [Google Scholar] [CrossRef]

- Zhao, S.; Cui, H.; He, Y.; Yang, Y.; Zhang, Z.; Yuan, L. Bearing performance of shield tunnel lining segments affected by softened base due to internal water leakage. J. Water Resour. Water Eng. 2024, 35, 201–206. [Google Scholar]

- He, Y.; Li, C.; Wang, X.; Che, Q.; Wang, L.; Zhao, S. Case study of the impacts of pea-gravel grouting defects on loading responses of TBM tunnel segment lining with different surrounding rocks. Result. Eng. 2025, 27, 105807. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, P.; Jin, X.; Wang, J.; Yang, Y. Tunnel structure analysis using the multi-scale modeling method. Tunn. Undergr. Space Technol. 2012, 28, 124–134. [Google Scholar] [CrossRef]

- Wang, X. ANSYS Engineering Structures Numerical Analysis; China Communications Press: Beijing, China, 2007. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures (2024 Ed.). China Building Industry Press: Beijing, China, 2024.

- SL 62-2014; Technical Specifications for Cement Grouting of Hydraulic Structures. China Hydropower Press: Beijing, China, 2014.

- GB 50218-94; Standard for Engineering Classification of Rock Masses. China Building Industry Press: Beijing, China, 1994.

- Wang, Y.; Li, X.; Cao, R.; Xu, Z.; Chen, B.; Zhang, X. Study on classification of surrounding rock suitable for TBM construction of hydraulic tunnel. J. Hydraul. Eng. 2023, 54, 880–888. [Google Scholar]

| Modulus of Elasticity (GPa) | Poisson’s Ratio μ | Density (kg/m3) | Axial Compression Strength (MPa) | Tensile Strength (MPa) | Shear Modulus (GPa) |

|---|---|---|---|---|---|

| 35 | 0.2 | 2500 | 32.4 | 2.64 | 13.8 |

| Pea-Gravel Grouting | Density (kg/m3) | Modulus of Elasticity (GPa) | Poisson’s Ratio μ | Cohesive Force c (MPa) | Internal Fraction Angle ϕ (°) |

|---|---|---|---|---|---|

| complete | 2000 | 3.25 | 0.26 | ||

| less density | 1486 | 0.65 | - | 0.016 | 17 |

| rich rock powder | 1757 | 1.80 | - | 2.0 | 30 |

| rich cement slurry | 1246 | 2.56 | - | 0.5 | 42 |

| Surrounding Rock Class | Internal Fraction Angle ϕ (°) | Cohesive Force c (MPa) | Deformation Modulus E0 (GPa) | Poisson’s Ratio μ | Density (kg/m3) | Elastic Resistance Coefficient k0 (MPa/cm) |

|---|---|---|---|---|---|---|

| III | 36 | 0.70 | 7.0 | 0.27 | 2450 | 8.0 |

| IV | 30 | 0.10 | 2.0 | 0.32 | 2150 | 2.0 |

| V | 20 | 0.08 | 0.5 | 0.40 | 1850 | 0.3 |

| Case | Defect | Class of Surrounding Rocks | ||

|---|---|---|---|---|

| V–IV | V–III | IV–III | ||

| 1~3 | — | √ | √ | √ |

| 4~6 | Local cavities | √ | √ | √ |

| 7~9 | Less density | √ | √ | √ |

| 10~12 | Rich rock powder | √ | √ | √ |

| 13~15 | Rich cement slurry | √ | √ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, Q.; Li, C.; Wang, X.; Zhang, Z.; He, Y.; Zhao, S. Loading Response of Segment Lining with Pea-Gravel Grouting Defects for TBM Tunnel in Transition Zones of Surrounding Rocks. Eng 2025, 6, 166. https://doi.org/10.3390/eng6070166

Che Q, Li C, Wang X, Zhang Z, He Y, Zhao S. Loading Response of Segment Lining with Pea-Gravel Grouting Defects for TBM Tunnel in Transition Zones of Surrounding Rocks. Eng. 2025; 6(7):166. https://doi.org/10.3390/eng6070166

Chicago/Turabian StyleChe, Qixing, Changyong Li, Xiangfeng Wang, Zhixiao Zhang, Yintao He, and Shunbo Zhao. 2025. "Loading Response of Segment Lining with Pea-Gravel Grouting Defects for TBM Tunnel in Transition Zones of Surrounding Rocks" Eng 6, no. 7: 166. https://doi.org/10.3390/eng6070166

APA StyleChe, Q., Li, C., Wang, X., Zhang, Z., He, Y., & Zhao, S. (2025). Loading Response of Segment Lining with Pea-Gravel Grouting Defects for TBM Tunnel in Transition Zones of Surrounding Rocks. Eng, 6(7), 166. https://doi.org/10.3390/eng6070166