Flexible Visible Spectral Sensing for Chilling Injuries in Mango Storage

Abstract

1. Introduction

2. Materials and Methods

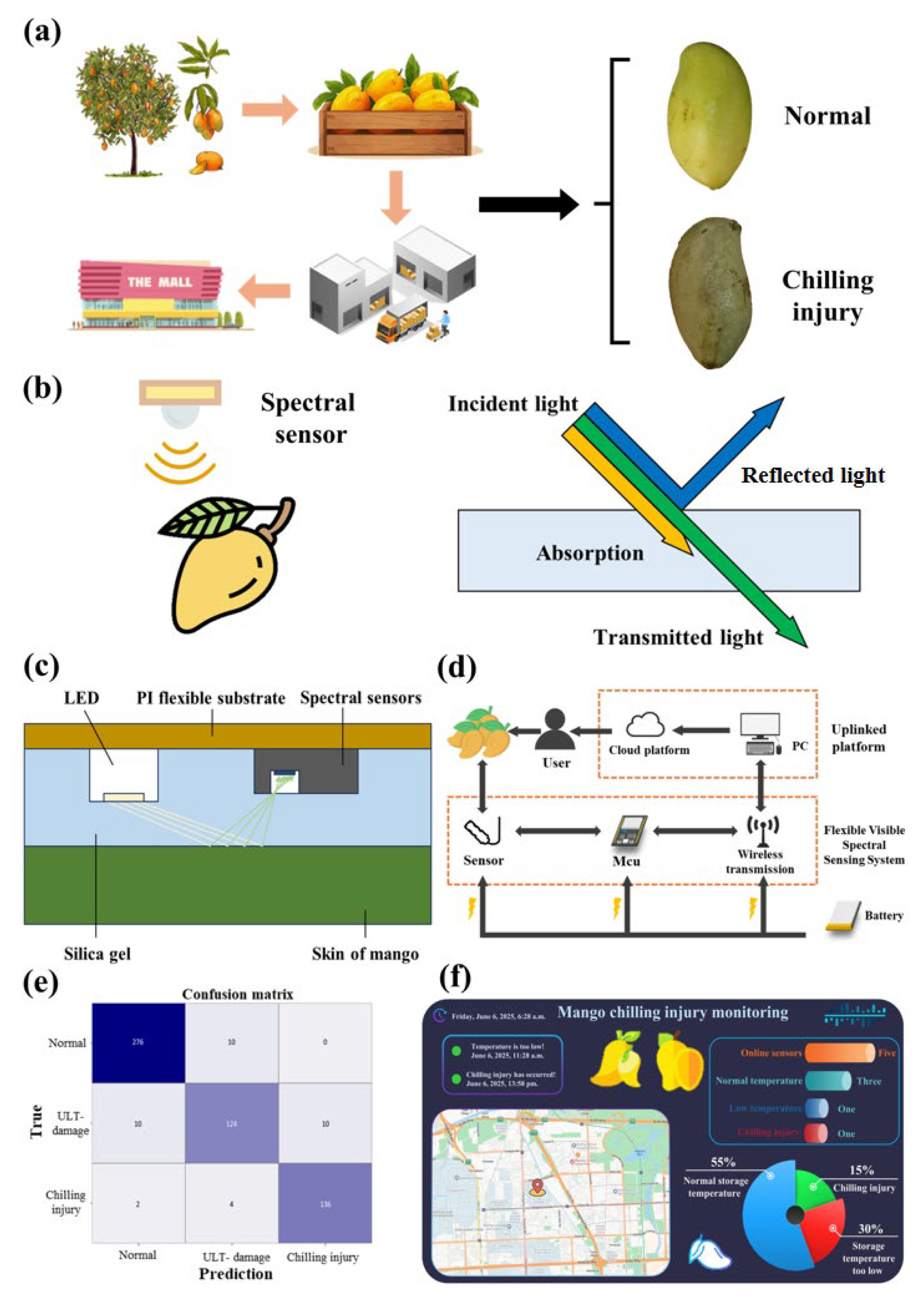

2.1. System Architecture

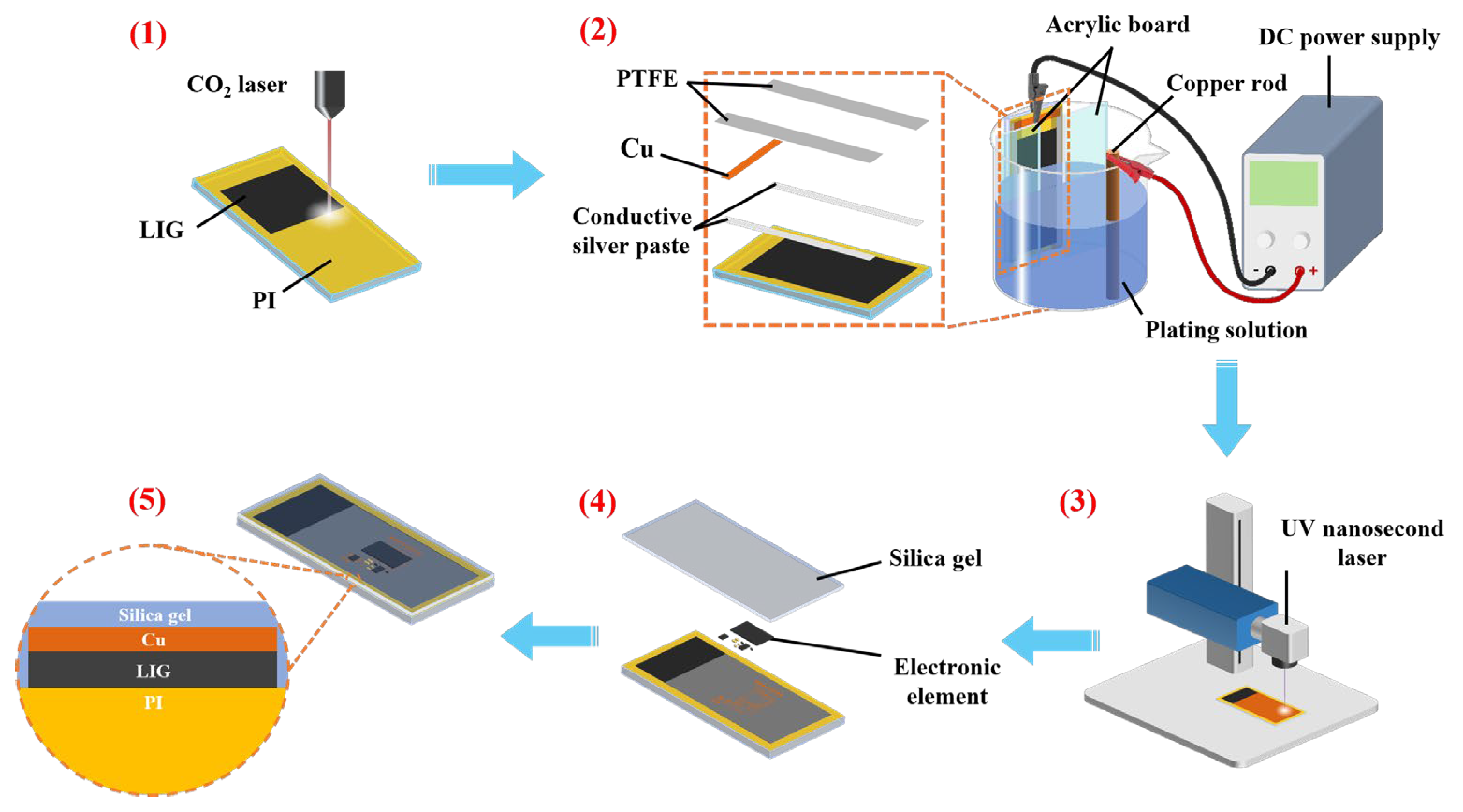

2.2. FVSS (Flexible Visible Light Spectroscopy System) Implementation

2.3. Chilling Injury Model

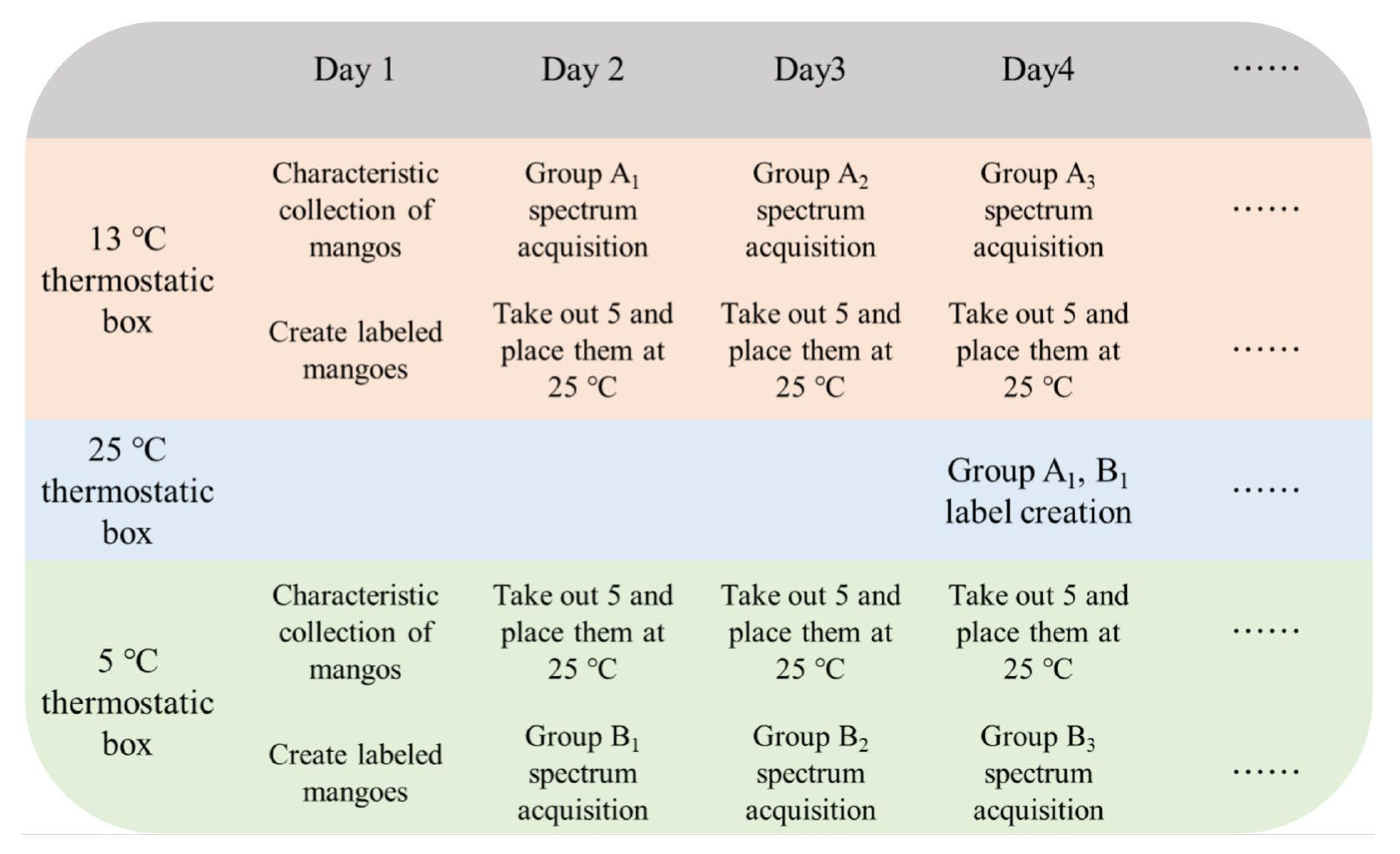

2.4. Experimental Scheme

- (1)

- Spectral characteristics acquisition

- (2)

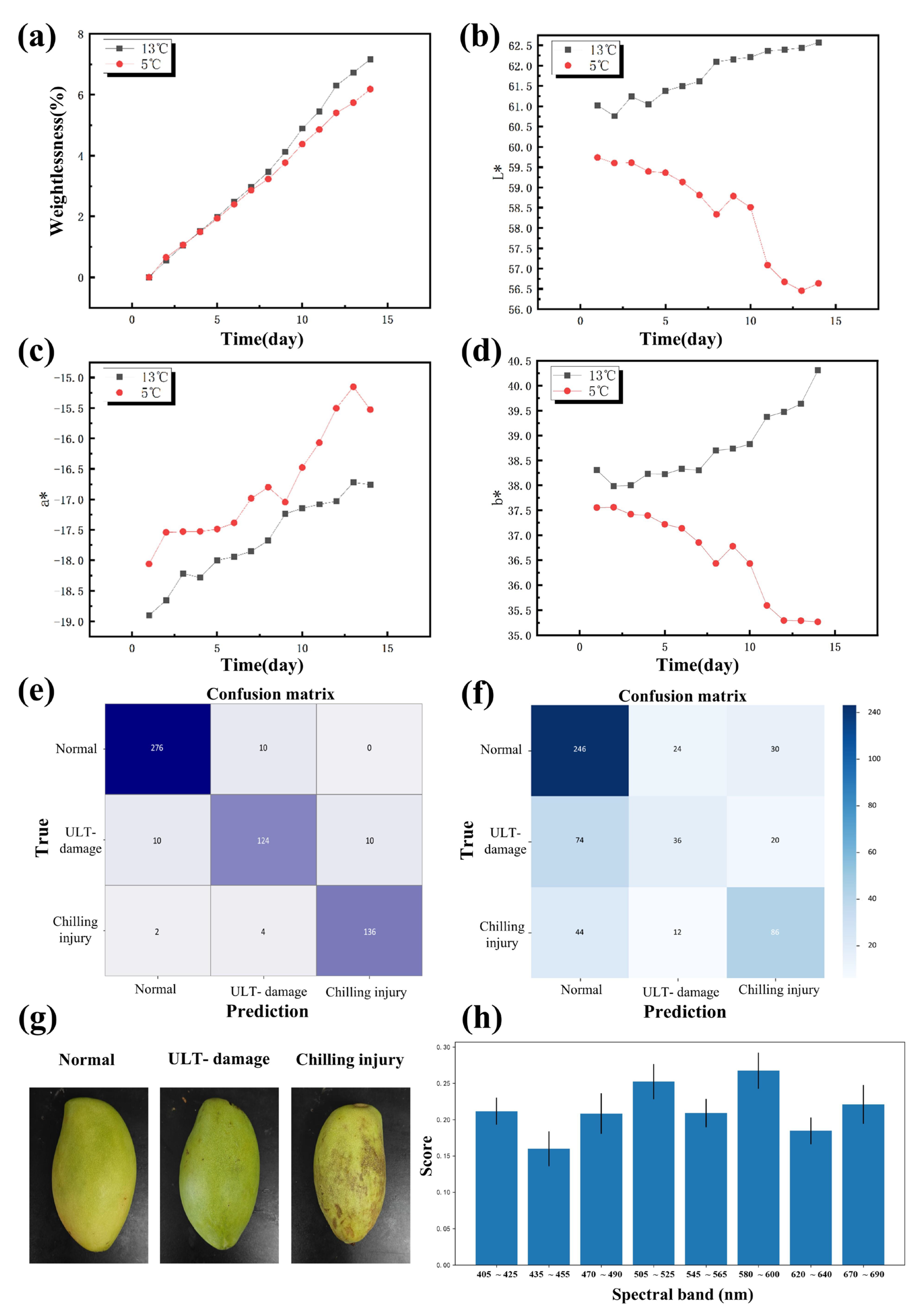

- Physical and chemical indicesThe physical and chemical indices measured during the experiment were color difference and weight loss rate.

- (a)

- Color differenceSignificant changes in color difference also occur during mango chilling injury and ripening and can be used as training data for judging and predicting chilling injury. While measuring the reflected spectrum data, a CR-400 color difference meter (Konica Minolta in Japan) was used to measure the a*, b*, and L* values at three points on the mango skin. The measurement results were taken as the average of three measurements.

- (b)

- Weight loss rateThe weight loss rate of mangoes was measured using a JA5003 high-precision electronic scale (Shanghai Jingke, China). The weight of the same mango on the current day and the previous day was recorded. The weight loss rate formula is as follows:σ = (G0 − G)/G0 × 100%σ represents the weight loss rate of mangoes, G0 is the weight of mangoes on the previous day, and G is the weight of mangoes on the current day.

- (3)

- Model evaluation

- (4)

- Flexible sensing system performance

3. Results and Discussion

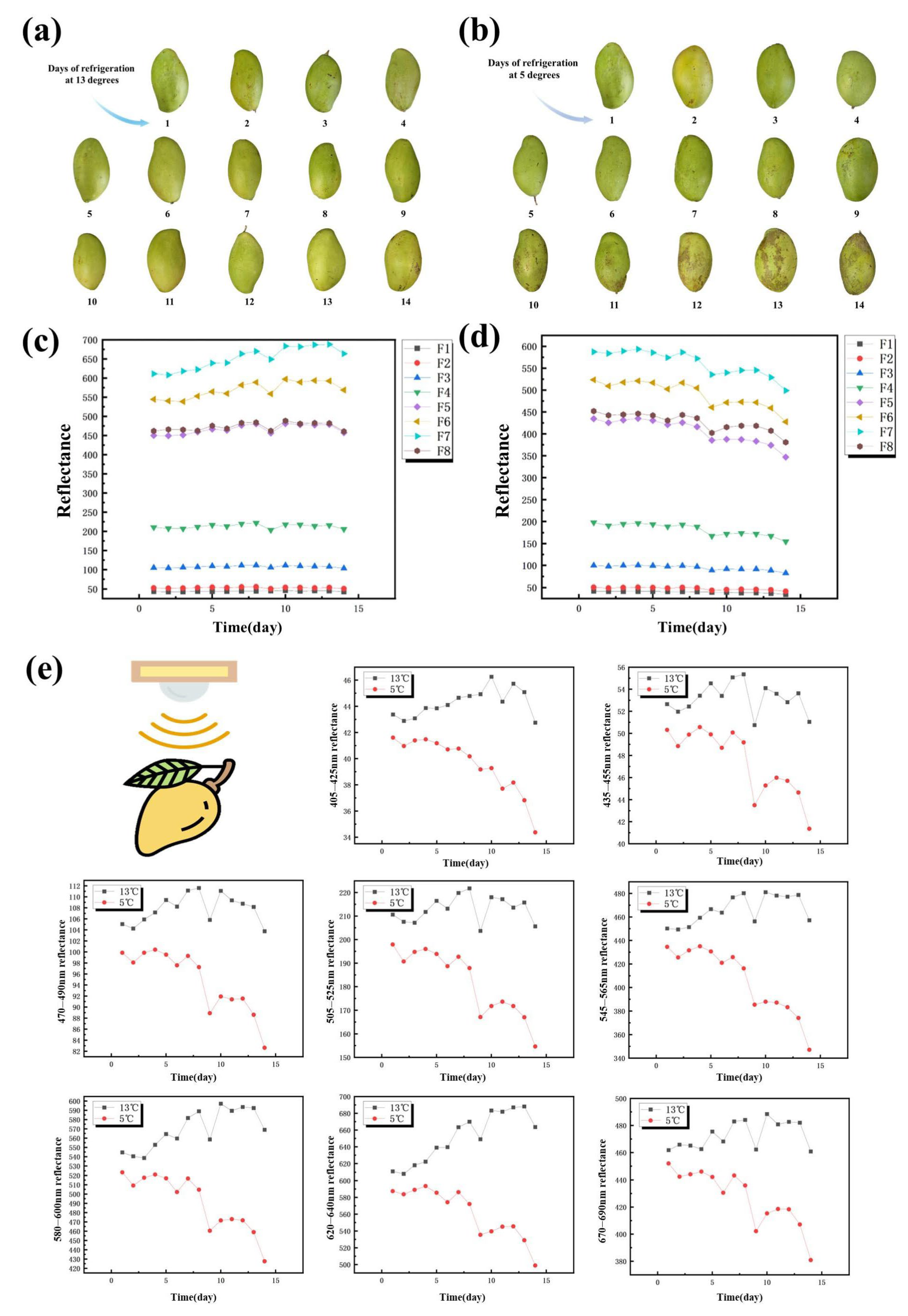

3.1. Spectral Characteristics Analysis

3.2. Physical and Chemical Indices Analysis

3.3. Model Evaluation

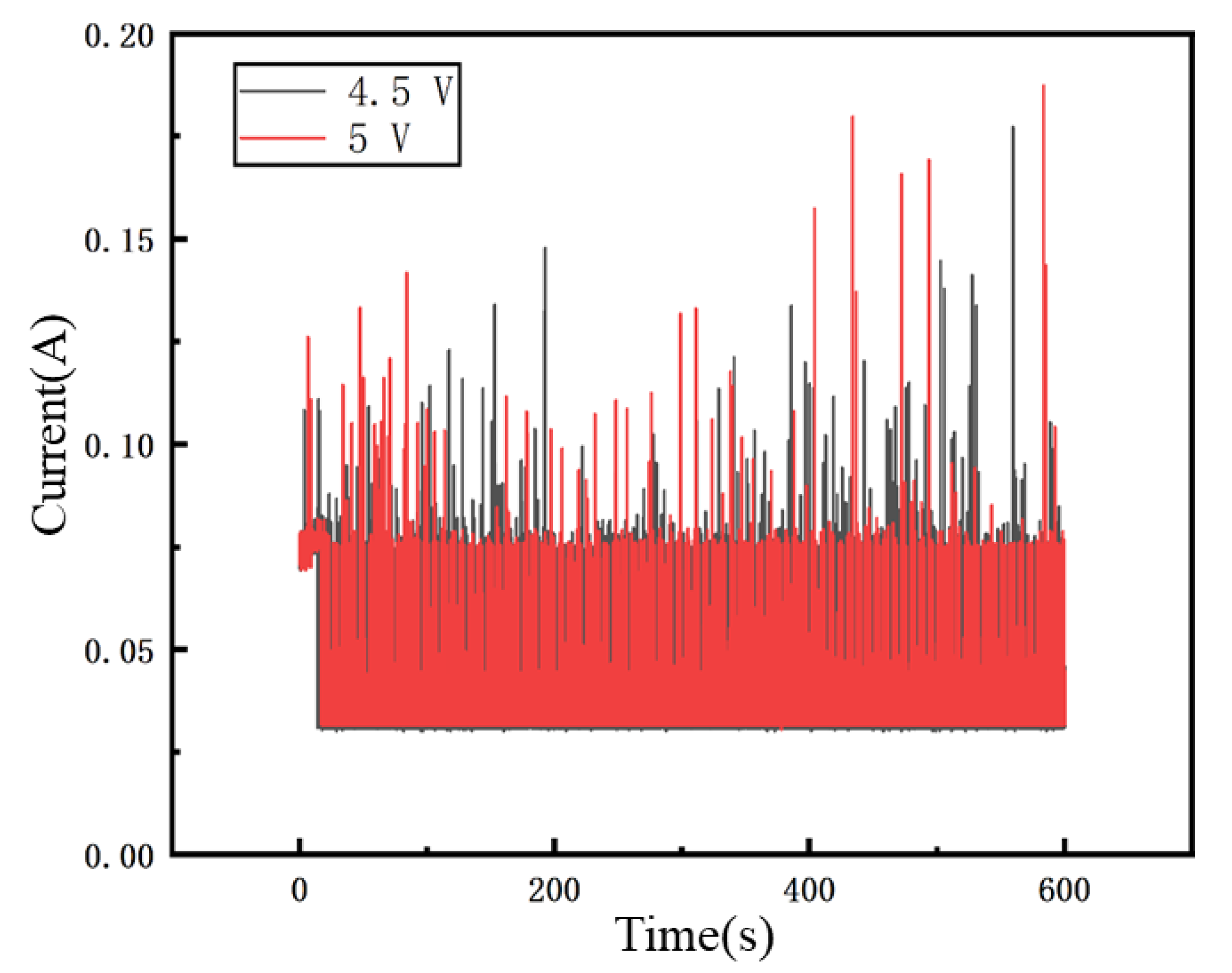

3.4. Flexible Sensing System Performance

- (1)

- Power consumption

- (2)

- Signal transmission

- (3)

- Ambient light interference

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tharanathan, R.N.; Yashoda, H.M.; Prabha, T.N. Mango (Mangifera indica L.), “The king of fruits”—An overview. Food Rev. Int. 2006, 22, 95–123. [Google Scholar] [CrossRef]

- Xu, P.; Huber, D.J.; Gong, D.; Yun, Z.; Pan, Y.; Jiang, Y.; Zhang, Z. Amelioration of chilling injury in ‘Guifei’mango fruit by melatonin is associated with regulation of lipid metabolic enzymes and remodeling of lipidome. Postharvest Biol. Technol. 2023, 198, 112233. [Google Scholar] [CrossRef]

- Evans, E.A.; Ballen, F.H.; Siddiq, M. Mango production, global trade, consumption trends, and postharvest processing and nutrition. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; Wiley: Hoboken, NJ, USA, 2017; pp. 1–16. [Google Scholar]

- Kiran, P.R.; Aradwad, P.; Arunkumar, T.V.; Parray, R.A. Enhancing mango quality control: A novel approach to spongy tissue inspection through image clustering and machine learning models via X-ray imaging. J. Food Process Eng. 2024, 47, e14664. [Google Scholar] [CrossRef]

- Ding, F.; Zuo, C.; García-Martín, J.F.; Ge, Y.; Tu, K.; Peng, J.; Xiao, H.; Lan, W.; Pan, L. Non-invasive prediction of mango quality using near-infrared spectroscopy: Assessment on spectral interferences of different packaging materials. J. Food Eng. 2023, 357, 111653. [Google Scholar] [CrossRef]

- Kiran, P.R.; Yeasin, M.; Aradwad, P.; Arunkumar, T.V.; Parray, R.A. Advancing mango quality assurance: Non-destructive detection of spongy tissue using visible near-infrared spectroscopy and machine learning classification. Future Postharvest Food 2024, 1, 237–251. [Google Scholar] [CrossRef]

- Wendel, A.; Underwood, J.; Walsh, K. Maturity estimation of mangoes using hyperspectral imaging from a ground based mobile platform. Comput. Electron. Agric. 2018, 155, 298–313. [Google Scholar] [CrossRef]

- Li, Q.; Hu, Z.; Zhang, F.; Song, D.; Liang, Y.; Yu, Y. Multispectral remote sensing monitoring of soil particle-size distribution in arid and semi-arid mining areas in the middle and upper reaches of the Yellow River Basin: A case study of Wuhai City, Inner Mongolia Autonomous Region. Remote Sens. 2023, 15, 2137. [Google Scholar] [CrossRef]

- Wang, M.; Luo, D.; Liu, M.; Zhang, R.; Wu, Z.; Xiao, X. Flexible wearable optical wireless sensing system for fruit monitoring. J. Sci. Adv. Mater. Devices 2023, 8, 100555. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, R.; Wu, Z.; Xiao, X. Flexible wireless in situ optical sensing system for banana ripening monitoring. J. Food Process Eng. 2023, 46, e14474. [Google Scholar] [CrossRef]

- Xia, J.; Wang, X.; Zhang, J.; Kong, C.; Huang, W.; Zhang, X. Flexible dual-mechanism pressure sensor based on Ag nanowire electrodes for nondestructive grading and quality monitoring of fruits. ACS Appl. Nano Mater. 2022, 5, 10652–10662. [Google Scholar] [CrossRef]

- Song, C.; Wang, D.; Bai, H.; Sun, W. Apple disease recognition based on small-scale data sets. Appl. Eng. Agric. 2021, 37, 481–490. [Google Scholar] [CrossRef]

- Sarkar, S.; Basak, J.K.; Moon, B.E.; Kim, H.T. A comparative study of PLSR and SVM-R with various preprocessing techniques for the quantitative determination of soluble solids content of hardy kiwi fruit by a portable Vis/NIR spectrometer. Foods 2020, 9, 1078. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Kim, J.H.; Kim, J.Y.; Oh, S.E. Egg freshness prediction model using real-time cold chain storage condition based on transfer learning. Foods 2022, 11, 3082. [Google Scholar] [CrossRef] [PubMed]

- Wan, Z.; Chen, X.; Song, D.; Wu, Z.; Zhang, R.; Wang, M.; Xiao, X. Battery-free flexible wireless temperature sensing for food storage. FlatChem 2024, 47, 100709. [Google Scholar] [CrossRef]

- Al-Fahdawi, S.; Al-Waisy, A.S.; Zeebaree, D.Q.; Qahwaji, R.; Natiq, H.; Mohammed, M.A.; Nedoma, J.; Martinek, R.; Deveci, M. Fundus-deepnet: Multi-label deep learning classification system for enhanced detection of multiple ocular diseases through data fusion of fundus images. Inf. Fusion 2024, 102, 102059. [Google Scholar] [CrossRef]

- Tavassoli-Kafrani, E.; Gamage, M.V.; Dumée, L.F.; Kong, L.; Zhao, S. Edible films and coatings for shelf life extension of mango: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 2432–2459. [Google Scholar] [CrossRef]

- Pu, Y.; Sun, D. Vis–NIR hyperspectral imaging in visualizing moisture distribution of mango slices during microwave-vacuum drying. Food Chem. 2015, 188, 271–278. [Google Scholar] [CrossRef]

- Kiran, P.R.; Jadhav, P.; Avinash, G.; Aradwad, P.; TV, A.; Bhardwaj, R.; Parray, R.A. Detection and classification of spongy tissue disorder in mango fruit during ripening by using visible-near infrared spectroscopy and multivariate analysis. J. Near Infrared Spectrosc. 2024, 32, 140–151. [Google Scholar] [CrossRef]

- Liu, B.; Xin, Q.; Zhang, M.; Chen, J.; Lu, Q.; Zhou, X.; Li, X.; Zhang, W.; Feng, W.; Pei, H. Research progress on mango post-harvest ripening physiology and the regulatory technologies. Foods 2022, 12, 173. [Google Scholar] [CrossRef]

- Kumar, A.; Bhuj, B.D.; Singh, C.P. Fruit drops in mango: A review. Ann. Rom. Soc. Cell Biol. 2021, 25, 925–946. [Google Scholar]

- Yi, F.; Wang, J.; Xiang, Y.; Yun, Z.; Pan, Y.; Jiang, Y.; Zhang, Z. Physiological and quality changes in fresh-cut mango fruit as influenced by cold plasma. Postharvest Biol. Technol. 2022, 194, 112105. [Google Scholar] [CrossRef]

- Zhang, S.; Jiao, W.; Ni, C.; Hao, G.; Huang, M.; Bi, X. Effect of ultrasound on the activity and structure of polyphenol oxidase purified from mango (Mangifera indica cv. “Xiaotainong”). LWT 2024, 203, 116412. [Google Scholar] [CrossRef]

- Peichl, M.; Thober, S.; Samaniego, L.; Hansjürgens, B.; Marx, A. Machine-learning methods to assess the effects of a non-linear damage spectrum taking into account soil moisture on winter wheat yields in Germany. Hydrol. Earth Syst. Sci. 2021, 25, 6523–6545. [Google Scholar] [CrossRef]

- Algamili, A.S.; Khir, M.H.M.; Dennis, J.O.; Ahmed, A.Y.; Alabsi, S.S.; Ba Hashwan, S.S.; Junaid, M.M. A review of actuation and sensing mechanisms in MEMS-based sensor devices. Nanoscale Res. Lett. 2021, 16, 16. [Google Scholar] [CrossRef]

- Swain, A.; Abdellatif, E.; Mousa, A.; Pong, P.W. Sensor technologies for transmission and distribution systems: A review of the latest developments. Energies 2022, 15, 7339. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, C.; Yang, H.; Jiang, H.; Li, L.; Yang, G. Non-destructive and in-site estimation of apple quality and maturity by hyperspectral imaging. Comput. Electron. Agric. 2022, 195, 106843. [Google Scholar] [CrossRef]

| Algorithm | Accuracy | F1 Score | ||

|---|---|---|---|---|

| Normal | ULT-Damage | Chilling Injury | ||

| RF | 77.6% | 0.85 | 0.61 | 0.79 |

| MLP | 87.1% | 0.9 | 0.76 | 0.90 |

| XGBoost | 78.7% | 0.87 | 0.64 | 0.78 |

| SVM | 95.5% | 0.97 | 0.93 | 0.96 |

| Algorithm | Accuracy | F1 Score | ||

|---|---|---|---|---|

| Normal | ULT-Damage | Chilling Injury | ||

| RF | 64.0% | 0.75 | 0.39 | 0.60 |

| MLP | 60.5% | 0.74 | 0.03 | 0.51 |

| XGBoost | 64.3% | 0.74 | 0.36 | 0.62 |

| SVM | 55.2% | 0.70 | 0.10 | 0.48 |

| Outdoors | Indoors | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Communication distance (m) | 20 | 40 | 60 | 80 | 1 | 5 | 10 | 15 | 20 |

| PLR | 0 | 0 | 0 | 0.2% | 0 | 0 | 0 | 0 | 0.3% |

| Waveband (nm) | 405–425 | 435–455 | 470–490 | 505–525 | 545–565 | 580–600 | 620–640 | 670–690 | |

|---|---|---|---|---|---|---|---|---|---|

| Reflectance Value | Dark box | 41.3 | 49.8 | 100 | 193.1 | 427.3 | 518.6 | 588.5 | 445.2 |

| Lab | 41.8 | 50.3 | 101.2 | 195.5 | 433.1 | 523.7 | 595.6 | 452.3 | |

| Category | Accuracy | Recall | F1 Score |

|---|---|---|---|

| Normal | 0.76 | 1.00 | 0.87 |

| ULT-damage | 0.97 | 0.69 | 0.81 |

| Chilling injury | 0.99 | 0.98 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Wan, Z.; Yang, Z.; Chen, X.; Zhang, R.; Yin, M.; Xiao, X. Flexible Visible Spectral Sensing for Chilling Injuries in Mango Storage. Eng 2025, 6, 158. https://doi.org/10.3390/eng6070158

Ma L, Wan Z, Yang Z, Chen X, Zhang R, Yin M, Xiao X. Flexible Visible Spectral Sensing for Chilling Injuries in Mango Storage. Eng. 2025; 6(7):158. https://doi.org/10.3390/eng6070158

Chicago/Turabian StyleMa, Longgang, Zhengzhong Wan, Zhencan Yang, Xunjun Chen, Ruihua Zhang, Maoyuan Yin, and Xinqing Xiao. 2025. "Flexible Visible Spectral Sensing for Chilling Injuries in Mango Storage" Eng 6, no. 7: 158. https://doi.org/10.3390/eng6070158

APA StyleMa, L., Wan, Z., Yang, Z., Chen, X., Zhang, R., Yin, M., & Xiao, X. (2025). Flexible Visible Spectral Sensing for Chilling Injuries in Mango Storage. Eng, 6(7), 158. https://doi.org/10.3390/eng6070158