A Quantitative Method for Characterizing of Structures’ Debris Release

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

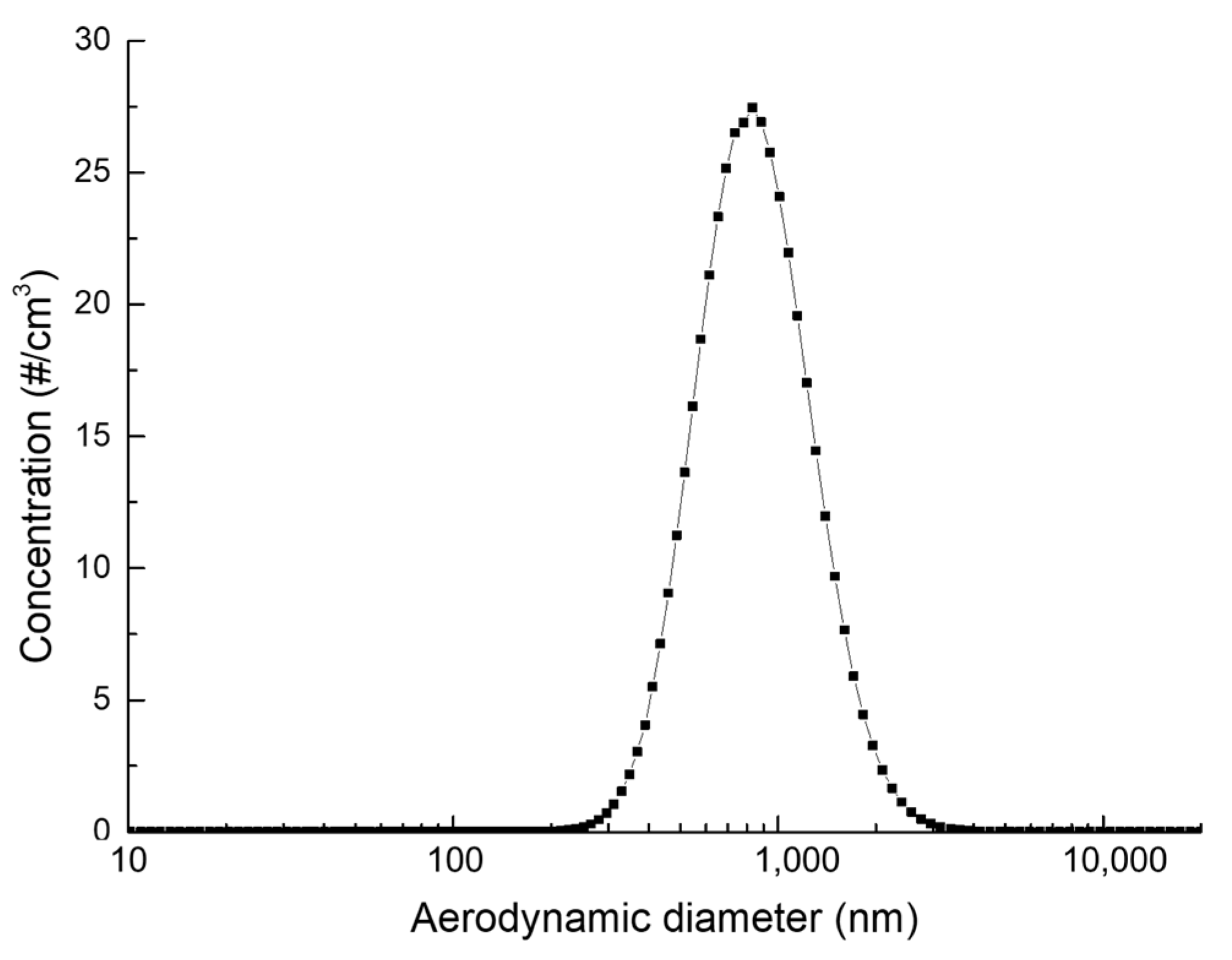

2.1.1. Known Aerosol and Validation of the Protocol

2.1.2. Unknown Aerosol

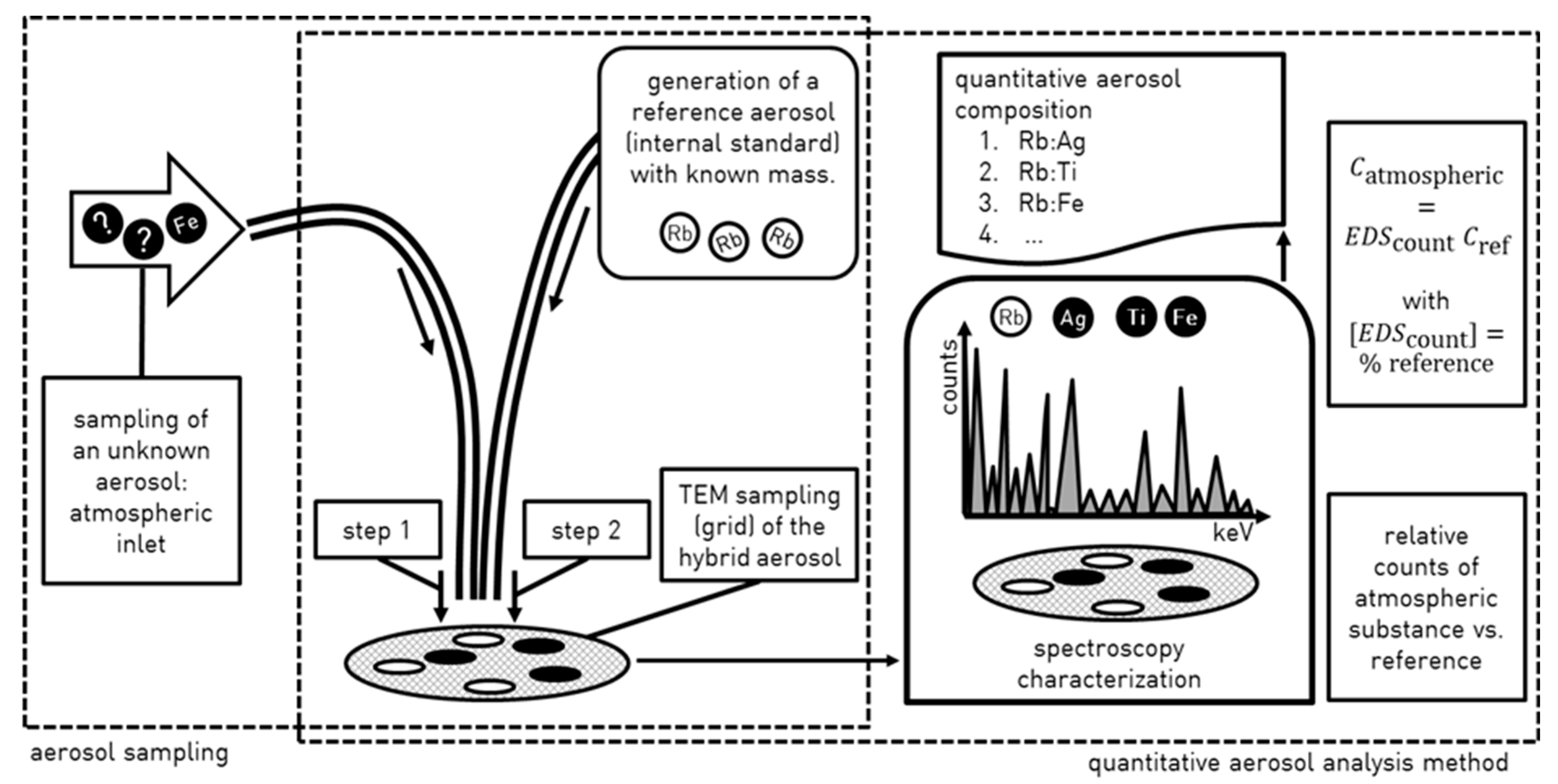

2.2. Methods

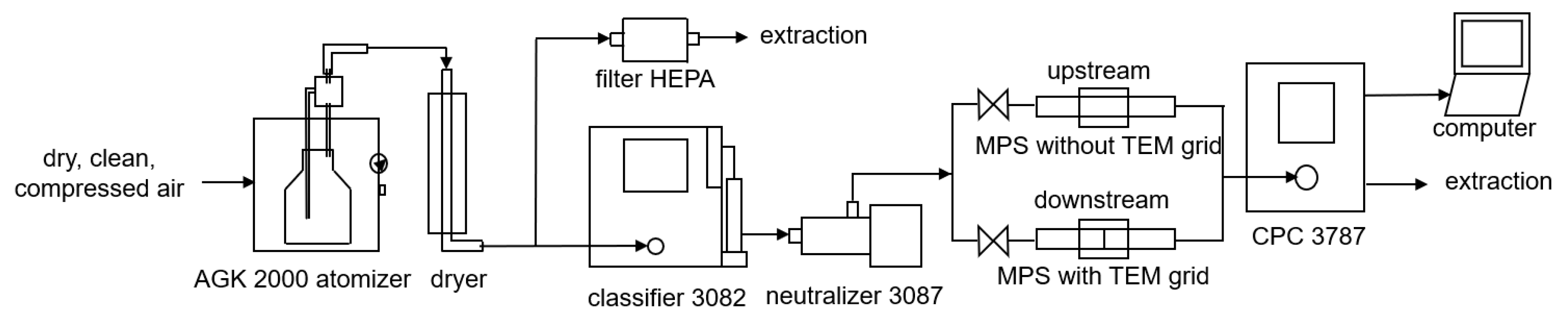

2.2.1. Experimental Set-Up

Set-Up for Step 1: Sampling of Unknown Aerosol

- a.

- Set-up for Step 1a: sampling of pseudo-unknown aerosol (salt particles)

- b.

- Set-up for Step 1b: sampling of a real-life aerosol (braking particles)

Set-Up for Step 2: Sampling of Reference Aerosol (Salt Particles)

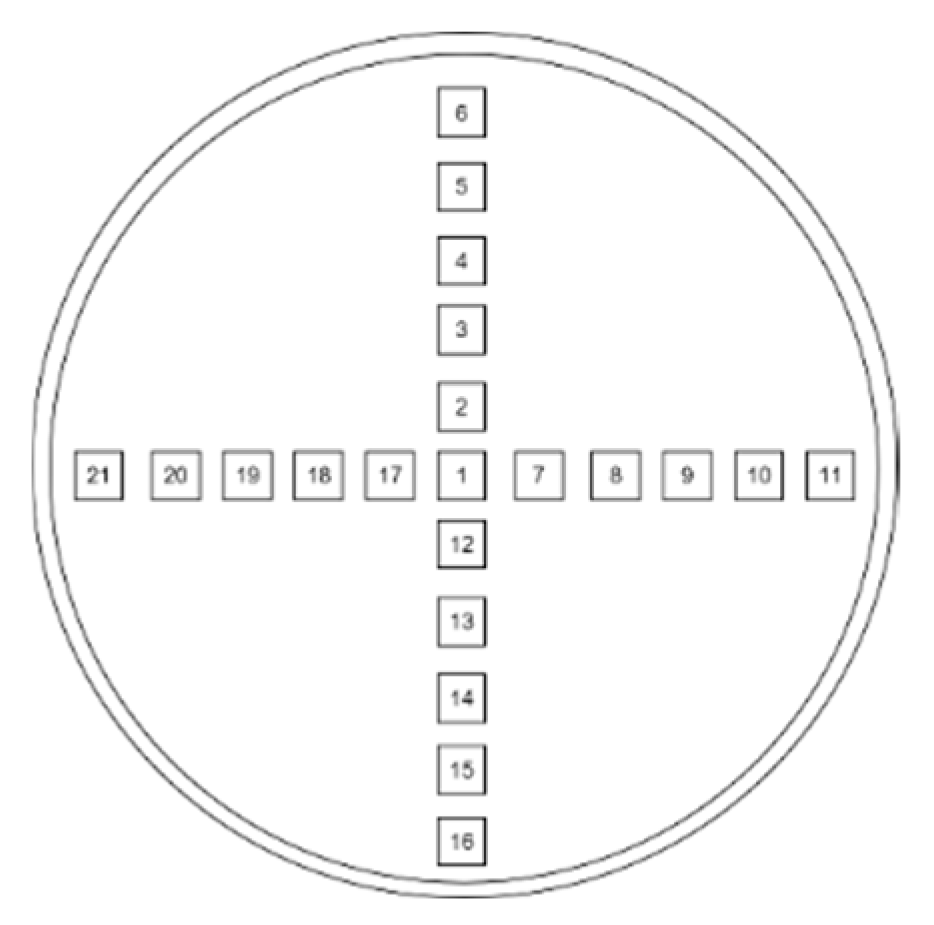

2.2.2. Microscopical Analysis of the Sampled Airborne Particles from Steps 1 and 2

2.3. Determination of the Theoretical Elemental Mass Ratio

2.3.1. Mass Ratio Between Elements Involved in Reference Salt Particles and Pseudo-Unknown Salt Particles

2.3.2. Mass Ratio Between Elements Involved in Reference Salt Particles and Braking Particles

3. Results and Discussions

3.1. Qualitative and Quantitative Analysis of Reference Particles

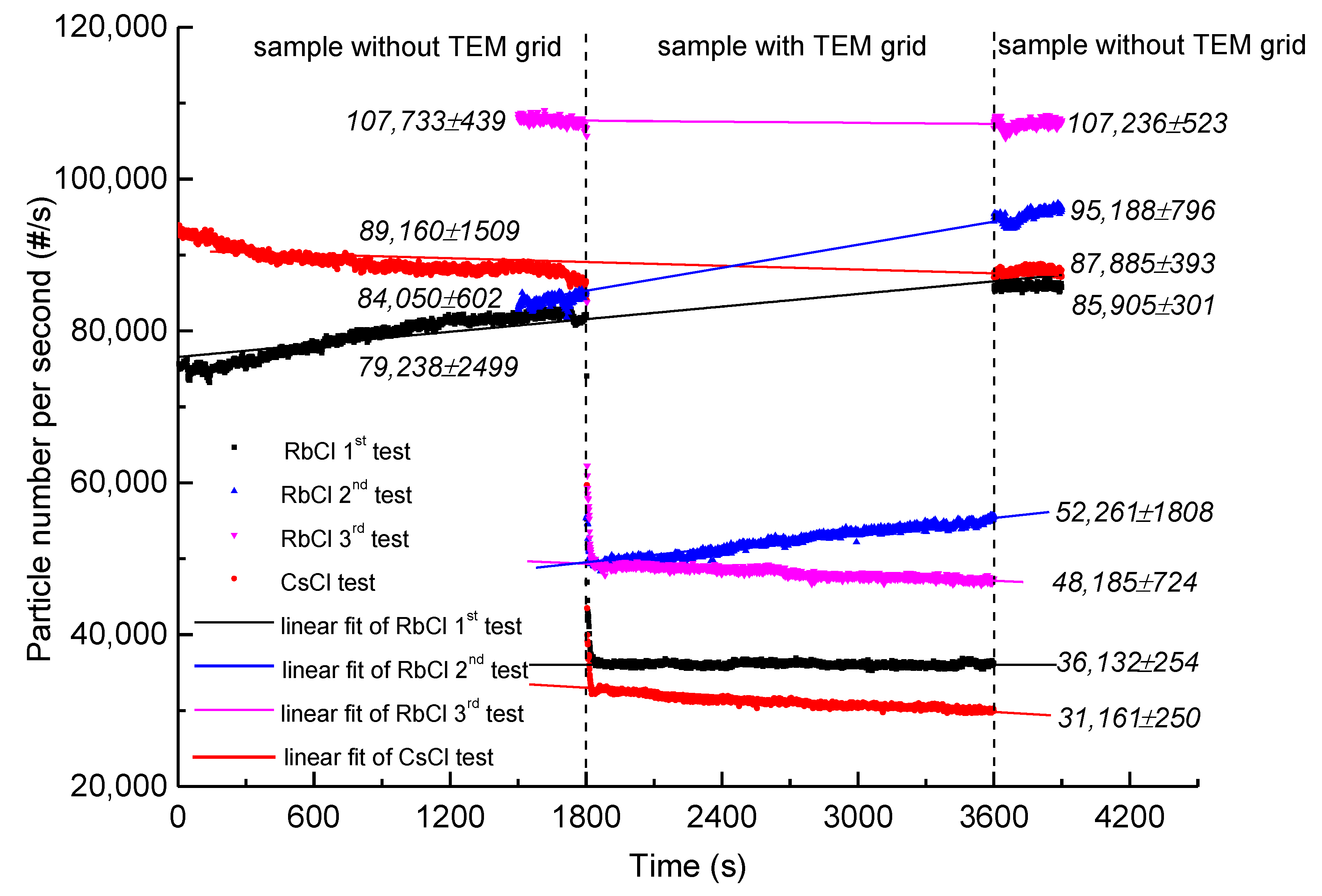

3.1.1. Reproducibility, Repeatability, and Stability of Reference Particle Deposition

Reproducibility and Repeatability of the Deposited Particle Number and Collection Efficiency

Variations in the Particle Number During Sampling

Stability of the Set-Up During Long-Term Depositions

3.1.2. TEM Analysis of Reference Particles

3.2. Elemental Mass Ratio Obtained by EDS

3.2.1. RbCl and CsCl Description of Particle Deposition

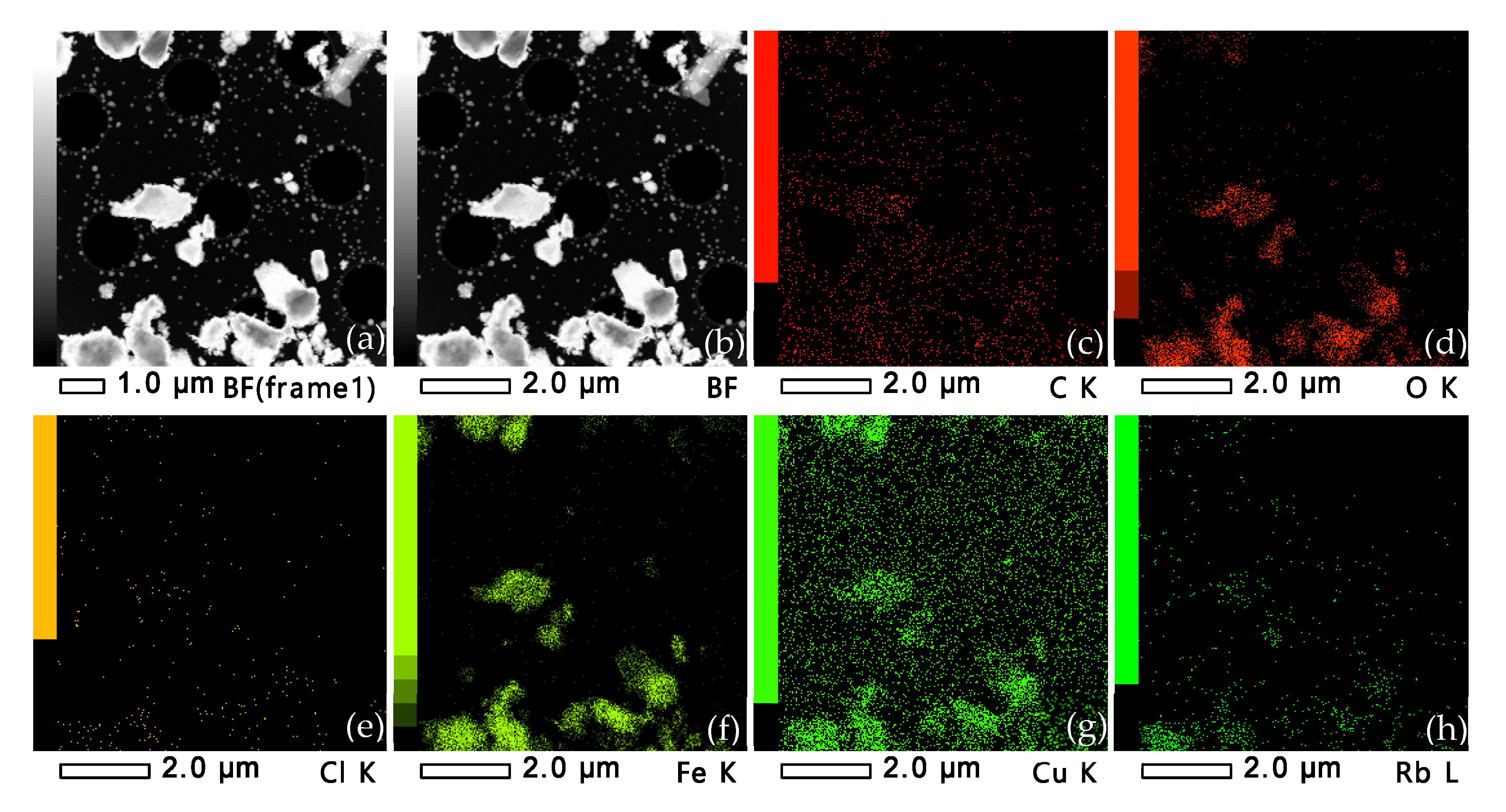

3.2.2. RbCl and Braking Partsicles Description of Particle Deposition

3.3. Comparison Between Experimental Mass Ratio and Theoretical Mass Ratio

3.3.1. Mass Ratio Between Elements Involved in RbCl Particles and Pseudo-Unknown Salt Particles

- RbCl and CsCl,

- RbCl and NaCl,

- RbCl and Ga(NO3)3

3.3.2. Mass Ratio Between Elements Involved in RbCl Particles and Braking Particles

4. Uncertainties and Expectations

4.1. Uncertainty Sources

4.1.1. Size and Shape of Reference Particles

4.1.2. Density and Purity of Reference Particles

4.1.3. Number of Reference Particles

4.1.4. Particle Distribution

4.1.5. Uncertainty of EDS Quantitative Analysis

4.1.6. Braking Particle Sampling

4.2. Requirements and Expectations

4.2.1. Aerosol Sampling

4.2.2. Reference Aerosol and Unknown Aerosol

4.2.3. EDS Quantitative Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bressot, C.; Manier, N.; Pagnoux, C.; Aguerre-Chariol, O.; Morgeneyer, M. Environmental release of engineered nanomaterials from commercial tiles under standardized abrasion conditions. J. Hazard. Mater. 2017, 322, 276–283. [Google Scholar] [CrossRef] [PubMed]

- Wahlström, J.; Olofsson, U. A field study of airborne particle emissions from automotive disc brakes. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 747–757. [Google Scholar] [CrossRef]

- Oliveira, M.L.; Izquierdo, M.; Querol, X.; Lieberman, R.N.; Saikia, B.K.; Silva, L.F. Nanoparticles from construction wastes: A problem to health and the environment. J. Clean. Prod. 2019, 219, 236–243. [Google Scholar] [CrossRef]

- Ding, Y.; Kuhlbusch, T.A.; Van Tongeren, M.; Jiménez, A.S.; Tuinman, I.; Chen, R.; Alvarez, I.L.; Mikolajczyk, U.; Nickel, C.; Meyer, J. Airborne engineered nanomaterials in the workplace—A review of release and worker exposure during nanomaterial production and handling processes. J. Hazard. Mater. 2017, 322, 17–28. [Google Scholar] [CrossRef]

- Dhananjayan, V.; Ravichandran, B.; Sen, S.; Panjakumar, K. Source, effect, and risk assessment of nanoparticles with special reference to occupational exposure. Nanoarchitectonics Biomed. 2019, 643–676. [Google Scholar] [CrossRef]

- Svendsen, C.; Walker, L.A.; Matzke, M.; Lahive, E.; Harrison, S.; Crossley, A.; Park, B.; Lofts, S.; Lynch, I.; Vázquez-Campos, S.; et al. Key principles and operational practices for improved nanotechnology environmental exposure assessment. Nat. Nanotechnol. 2020, 15, 731–742. [Google Scholar] [CrossRef]

- Bressot, C.; Shandilya, N.; Jayabalan, T.; Fayet, G.; Voetz, M.; Meunier, L.; Le Bihan, O.; Aguerre-Chariol, O.; Morgeneyer, M. Exposure assessment of Nanomaterials at production sites by a Short Time Sampling (STS) approach: Strategy and first results of measurement campaigns. Process Saf. Environ. Prot. 2018, 116, 324–332. [Google Scholar] [CrossRef]

- Schwaferts, C.; Niessner, R.; Elsner, M.; Ivleva, N.P. Methods for the analysis of submicrometer-and nanoplastic particles in the environment. TrAC Trends Anal. Chem. 2019, 112, 52–65. [Google Scholar] [CrossRef]

- Harvey, D. Analytical Chemistry, 2.0.; LibreTexts: Davis, CA, USA, 2010. [Google Scholar]

- Hossain, M.; Karmakar, D.; Begum, S.N.; Ali, S.Y.; Patra, P.K. Recent trends in the analysis of trace elements in the field of environmental research: A review. Microchem. J. 2021, 165, 106086. [Google Scholar] [CrossRef]

- Jin, M.; Yuan, H.; Liu, B.; Peng, J.; Xu, L.; Yang, D. Review of the distribution and detection methods of heavy metals in the environment. Anal. Methods 2020, 12, 5747–5766. [Google Scholar] [CrossRef]

- Yang, X.; Liu, S.; Shao, P.; He, J.; Liang, Y.; Zhang, B.; Liu, B.; Liu, Y.; Tang, G.; Ji, D. Effectively controlling hazardous airborne elements: Insights from continuous hourly observations during the seasons with the most unfavorable meteorological conditions after the implementation of the APPCAP. J. Hazard. Mater. 2020, 387, 121710. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.-M.; Wagner, J.; Ghosal, S.; Bedi, G.; Wall, S. SEM/EDS and optical microscopy analyses of microplastics in ocean trawl and fish guts. Sci. Total Environ. 2017, 603, 616–626. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Wang, Y.; Xiao, J.; Fan, H.; Chen, C. Preparation and characterization of magnetic nanomaterial and its application for removal of polycyclic aromatic hydrocarbons. J. Hazard. Mater. 2019, 371, 323–331. [Google Scholar] [CrossRef] [PubMed]

- Mathis, U.; Kaegi, R.; Mohr, M.; Zenobi, R. TEM analysis of volatile nanoparticles from particle trap equipped diesel and direct-injection spark-ignition vehicles. Atmos. Environ. 2004, 38, 4347–4355. [Google Scholar] [CrossRef]

- Maynard, A.D.; Ito, Y.; Arslan, I.; Zimmer, A.T.; Browning, N.; Nicholls, A. Examining elemental surface enrichment in ultrafine aerosol particles using analytical scanning transmission electron microscopy. Aerosol Sci. Technol. 2004, 38, 365–381. [Google Scholar] [CrossRef]

- Chen, Y.; Shah, N.; Huggins, F.E.; Huffman, G.P. Transmission electron microscopy investigation of ultrafine coal fly ash particles. Environ. Sci. Technol. 2005, 39, 1144–1151. [Google Scholar] [CrossRef]

- Ku, B.K.; Maynard, A.D. Comparing aerosol surface-area measurements of monodisperse ultrafine silver agglomerates by mobility analysis, transmission electron microscopy and diffusion charging. J. Aerosol Sci. 2005, 36, 1108–1124. [Google Scholar] [CrossRef]

- Methner, M.; Beaucham, C.; Crawford, C.; Hodson, L.; Geraci, C. Field application of the Nanoparticle Emission Assessment Technique (NEAT): Task-based air monitoring during the processing of engineered nanomaterials (ENM) at four facilities. J. Occup. Environ. Hyg. 2012, 9, 543–555. [Google Scholar] [CrossRef]

- Methner, M.; Hodson, L.; Dames, A.; Geraci, C. Nanoparticle emission assessment technique (NEAT) for the identification and measurement of potential inhalation exposure to engineered nanomaterials—Part B: Results from 12 field studies. J. Occup. Environ. Hyg. 2010, 7, 163–176. [Google Scholar] [CrossRef]

- Fierz, M.; Meier, D.; Steigmeier, P.; Burtscher, H. In Miniature nanoparticle sensors for exposure measurement and TEM sampling. J. Phys. Conf. Ser. 2015, 617, 012034. [Google Scholar] [CrossRef]

- Eom, H.-J.; Gupta, D.; Li, X.; Jung, H.-J.; Kim, H.; Ro, C.-U. Influence of collecting substrates on the characterization of hygroscopic properties of inorganic aerosol particles. Anal. Chem. 2014, 86, 2648–2656. [Google Scholar] [CrossRef] [PubMed]

- R’mili, B.; Le Bihan, O.L.; Dutouquet, C.; Aguerre-Charriol, O.; Frejafon, E. Particle sampling by TEM grid filtration. Aerosol Sci. Technol. 2013, 47, 767–775. [Google Scholar] [CrossRef]

- Ogura, I.; Hashimoto, N.; Kotake, M.; Sakurai, H.; Kishimoto, A.; Honda, K. Aerosol particle collection efficiency of holey carbon film-coated TEM grids. Aerosol Sci. Technol. 2014, 48, 758–767. [Google Scholar] [CrossRef]

- Morgeneyer, M.; Aguerre-Chariol, O.; Bressot, C. STEM imaging to characterize nanoparticle emissions and help to design nanosafer paints. Chem. Eng. Res. Des. 2018, 136, 663–674. [Google Scholar] [CrossRef]

- Bourrous, S.; Ribeyre, Q.; Lintis, L.; Yon, J.; Bau, S.; Thomas, D.; Vallières, C.; Ouf, F.-X. A semi-automatic analysis tool for the determination of primary particle size, overlap coefficient and specific surface area of nanoparticles aggregates. J. Aerosol Sci. 2018, 126, 122–132. [Google Scholar] [CrossRef]

- Fonseca, A.S.; Kuijpers, E.; Kling, K.I.; Levin, M.; Koivisto, A.J.; Nielsen, S.H.; Fransman, W.; Fedutik, Y.; Jensen, K.A.; Koponen, I.K. Particle release and control of worker exposure during laboratory-scale synthesis, handling and simulated spills of manufactured nanomaterials in fume hoods. J. Nanoparticle Res. 2018, 20, 48. [Google Scholar] [CrossRef]

- Xiang, M.; Morgeneyer, M.; Aguerre-Chariol, O.; Philippe, F.; Bressot, C. Airborne nanoparticle collection efficiency of a TEM grid-equipped sampling system. Aerosol Sci. Technol. 2021, 55, 526–538. [Google Scholar] [CrossRef]

- Xiang, M.; Aguerre-Chariol, O.; Morgeneyer, M.; Philippe, F.; Liu, Y.; Bressot, C. Uncertainty assessment for the airborne nanoparticle collection efficiency of a TEM grid-equipped sampling system by Monte-Carlo calculation. Adv. Powder Technol. 2021, 32, 1793–1801. [Google Scholar] [CrossRef]

- Philippe, F.; Xiang, M.; Morgeneyer, M.; Chen, Y.-M.; Charles, P.; Guingand, F.; Bressot, C. Emission rate assessment of airborne brake particles by characterization of the pad and disc surfaces from a pin-on-disc tribometer. Toxicol. Res. Appl. 2020, 4, 2397847320977782. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Z.; Zhang, Z.; Jiang, F.; Du, R. Enhancement of filtration efficiency by electrical charges on nebulized particles. Particuology 2018, 37, 81–90. [Google Scholar] [CrossRef]

- Givehchi, R.; Li, Q.; Tan, Z. The effect of electrostatic forces on filtration efficiency of granular filters. Powder Technol. 2015, 277, 135–140. [Google Scholar] [CrossRef]

- Williams, D.B.; Carter, C.B. Quantitative X-ray analysis. In Transmission Electron Microscopy; Springer: Berlin/Heidelberg, Germany, 2009; pp. 639–662. [Google Scholar]

- Xiang, M.; Morgeneyer, M.; Philippe, F.; Manokaran, M.; Bressot, C. Comparative review of efficiency analysis for airborne solid submicrometer particle sampling by nuclepore filters. Chem. Eng. Res. Des. 2020, 164, 338–351. [Google Scholar] [CrossRef]

- Spurny, K.; Gentry, J. Aerosol fractionization by graded nuclepore filters. A review. Powder Technol. 1979, 24, 129–142. [Google Scholar] [CrossRef]

- Sioutas, C. Experimental investigation of pressure drop with particle loading in nuclepore filters. Aerosol Sci. Technol. 1999, 30, 71–83. [Google Scholar] [CrossRef]

- Verma, P.C.; Alemani, M.; Gialanella, S.; Lutterotti, L.; Olofsson, U.; Straffelini, G. Wear debris from brake system materials: A multi-analytical characterization approach. Tribol. Int. 2016, 94, 249–259. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. 2015, 22, 2491–2504. [Google Scholar] [CrossRef]

- Wiedensohler, A. An approximation of the bipolar charge distribution for particles in the submicron size range. J. Aerosol Sci. 1988, 19, 387–389. [Google Scholar] [CrossRef]

- Coquelin, L.; Le Brusquet, L.; Fischer, N.; Gensdarmes, F.; Motzkus, C.; Macé, T.; Fleury, G. Uncertainty propagation using the Monte Carlo method in the measurement of airborne particle size distribution with a scanning mobility particle sizer. Meas. Sci. Technol. 2018, 29, 055801. [Google Scholar] [CrossRef]

| Grid Type | Pore Size, µm | Pore Pitch, µm | Porosity, % |

|---|---|---|---|

| 1.2/1.3 | 1.2 | 1.2 | 18.1 |

| 2/2 | 2 | 2 | 19.6 |

| 2/1 | 2 | 1 | 34.9 |

| Sampling Without TEM Grid (Stage 1) | Sampling with TEM Grid (Stage 2) | |

|---|---|---|

| RbCl 1st test | Y = 76,570 + 2.769x; r = 0.93293 | Y = 36,402 − 0.102x;/ |

| RbCl 2nd test | Y = 75,298 + 5.303x; r = 0.99534 | Y = 42,912 + 3.453x; r = −0.98166 |

| RbCl 3rd test | Y = 10,812 − 0.234x | Y = 51,576 − 1.254x |

| CsCl test | Y = 90,080 − 0.834x | Y = 35,075 − 1.454x |

| (a) | (b) | (c) | (d) | (e) | (f) | ||

|---|---|---|---|---|---|---|---|

| TEM grid | 1.2/1.3 | 1.2/1.3 | 1.2/1.3 | 1.2/1.3 | 2/1 | 1.2/1.3 | |

| 1st deposition | particle | RbCl | RbCl | CsCl | NaCl | SrCl2 | CsCl |

| salt concentration | 10 mmol/L | 10 mmol/L | 10 mmol/L | 20 mmol/L | 5 mmol/L | 20 mmol/L | |

| size from DMA | 60 nm | 60 nm | 60 nm | 100 nm | 100 nm | 60 nm | |

| time | 5 min | 5 min | 3 min | 40 s | 3 min | 9 h | |

| 2nd deposition | particle | CsCl | Ga(NO3)3 | / | / | / | / |

| salt concentration | 10 mmol/L | 10 mmol/L | |||||

| size from DMA | 60 nm | 60 nm | |||||

| time | 5 min | 5 min |

| Number of Square | % Mass of Rb | % Mass of Cs |

|---|---|---|

| 1 | 50 | 50 |

| 2 | 48 | 52 |

| 3 | 46 | 54 |

| 4 | 37 | 63 |

| 5 | 47 | 53 |

| 6 | 42 | 58 |

| 7 | 35 | 65 |

| 8 | 33 | 67 |

| 9 | 35 | 65 |

| 10 | 56 | 44 |

| 11 | 54 | 46 |

| 12 | 54 | 46 |

| 13 | 42 | 58 |

| 14 | 44 | 56 |

| 15 | 53 | 47 |

| 16 | 38 | 62 |

| 17 | 47 | 53 |

| 18 | 50 | 50 |

| 19 | 58 | 42 |

| 20 | 56 | 44 |

| 21 | 48 | 52 |

| Mean | 46 | 54 |

| SD | 7.59 | 7.59 |

| Number of Square | % Mass of Rb | % Mass of Fe |

|---|---|---|

| 1 | 10 | 90 |

| 2 | 7 | 93 |

| 3 | 7 | 93 |

| 4 | 3 | 97 |

| 5 | 3 | 97 |

| 6 | 13 | 87 |

| 7 | 10 | 90 |

| 8 | 9 | 91 |

| 9 | 4 | 96 |

| 10 | 3 | 97 |

| 11 | 9 | 91 |

| 12 | 3 | 97 |

| 13 | 5 | 95 |

| 14 | 1 | 99 |

| 15 | 14 | 86 |

| 16 | 5 | 95 |

| 17 | 17 | 83 |

| 18 | 10 | 90 |

| 19 | 9 | 91 |

| 20 | 10 | 90 |

| 21 | 9 | 91 |

| Mean | 8 | 92 |

| SD | 4.13 | 4.13 |

| Elements and Size | Rb:Cs | Rb:Na | Rb:Ga | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 nm | 100 nm | 60 nm | 100 nm | 60 nm | |||||||

| Theoretical mass ratio | 68/32 | 79/21 | 62/38 | 65/35 | 65/35 | 63/37 | 62/38 | 26/74 | 36/64 | 31/69 | 54/46 |

| Experimental mass ratio | 75/25 | 75/25 | 54/46 | 58/42 | 70/30 | 57/43 | 69/31 | 33/67 | 37/63 | 33/67 | 55/45 |

| Absolute deviation (%) | 7 | 4 | 8 | 7 | 5 | 6 | 7 | 7 | 1 | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, M.; Morgeneyer, M.; Aguerre-Chariol, O.; Lefebvre, C.; Philippe, F.; Meunier, L.; Bressot, C. A Quantitative Method for Characterizing of Structures’ Debris Release. Eng 2025, 6, 157. https://doi.org/10.3390/eng6070157

Xiang M, Morgeneyer M, Aguerre-Chariol O, Lefebvre C, Philippe F, Meunier L, Bressot C. A Quantitative Method for Characterizing of Structures’ Debris Release. Eng. 2025; 6(7):157. https://doi.org/10.3390/eng6070157

Chicago/Turabian StyleXiang, Maiqi, Martin Morgeneyer, Olivier Aguerre-Chariol, Caroline Lefebvre, Florian Philippe, Laurent Meunier, and Christophe Bressot. 2025. "A Quantitative Method for Characterizing of Structures’ Debris Release" Eng 6, no. 7: 157. https://doi.org/10.3390/eng6070157

APA StyleXiang, M., Morgeneyer, M., Aguerre-Chariol, O., Lefebvre, C., Philippe, F., Meunier, L., & Bressot, C. (2025). A Quantitative Method for Characterizing of Structures’ Debris Release. Eng, 6(7), 157. https://doi.org/10.3390/eng6070157