The Structural Performance of Fiber-Reinforced Geopolymers: A Review

Abstract

1. Introduction

| Precursor | Source | Possible Cement Replacement % | Optimum Substitute % in the Literature | Lower Global Warming Potential | Per m3 Cost Reduction | Remarks | References |

|---|---|---|---|---|---|---|---|

| Fly ash (FA) | Coal power plant | 7% due to limited alkaline activator | 80–100% GPC (Geopolymer concret) 10–30% OPC | Environmental benefits 49.5%; human health 35% | 10.87–17.77% | Its alumina content and cement-like appearance make it a viable alternative material for geopolymers | [35,36,37,38,39] |

| GGBFS | Steel and iron industry | 6.5% replacement as per current slag production | 35–50% GPC 30–60% OPC | Energy consumption 49%; CO2 emission 39% | 10–15% | Enhanced strength and durability properties with more amorphous XRD patterns than the crystalline phases of fly ash | [40,41] |

| Metakaolin | Kaolinite rock | 1.4% replacement as per current production | 5–40% GPC 15–20% OPC | Energy demand 2.3%; CO2 emission 1.4% | 4.2% | Enhanced cohesive matrix and C-S-H gels; improved durability, thermal resistance, and mechanical properties | [35,42,43,44,45,46,47] |

| Silica fume (SF) | Silicon metal Ferrosilicon alloy | 2% replacement as per current production | 5–15% GPC 0–25% OPC | 47.61% for geopolymer with silica fume and without Na2SiO3 | 10.87–17.77% | SF improved mechanical durability due to fine spherical particles and amorphous silica causing binder—aggregate interfacial bonding and the pore size refinement of composites | [38,48,49,50,51] |

2. Structural Performance of Geopolymer

2.1. Role of Fibers in Performance Enhancement

2.2. Seismic Resistance of Fiber-Reinforced Geopolymers

3. Retrofitting/Rehabilitation of Structures Using Geopolymers

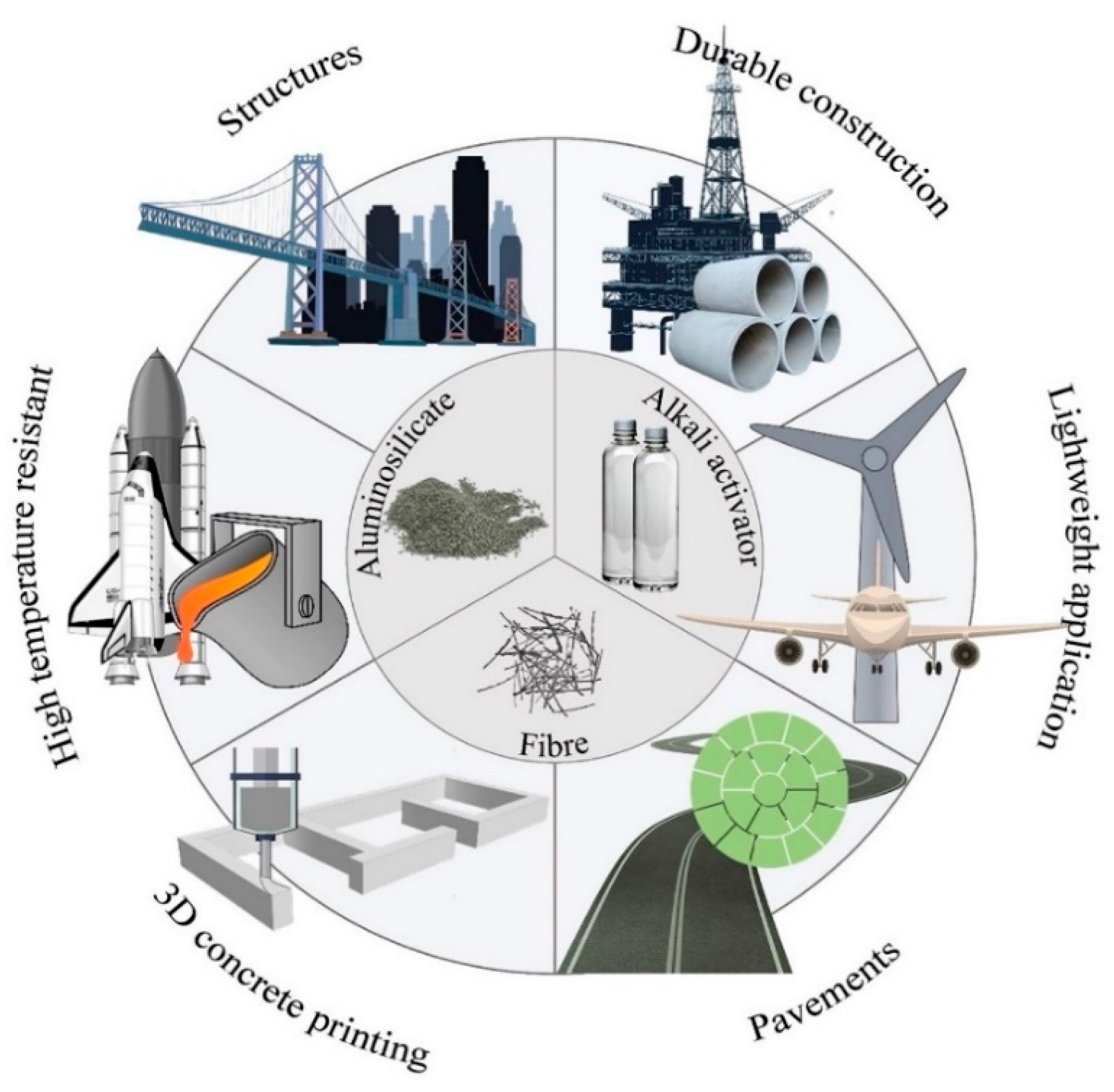

4. Geopolymer Applications

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, R.; Wang, J.; Bing, L.; Tong, D.; Ciais, P.; Davis, S.J.; Andrew, R.M.; Xi, F.; Liu, Z. Global CO2uptake by Cement from 1930 to 2019. Earth Syst. Sci. Data 2021, 13, 1791–1805. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Cecchin, D.; Carmo, D.F.; Silva, F.C.; Campos, C.M.O.; Shtrucka, T.G.; Marvila, M.T.; Monteiro, S.N. Analysis of the Compactness and Properties of the Hardened State of Mortars with Recycling of Construction and Demolition Waste (CDW). J. Mater. Res. Technol. 2020, 9, 5942–5952. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent Advances in Understanding the Role of Supplementary Cementitious Materials in Concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2017, 2018, 1641–1651. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, N.K.; Lee, H.K. Fresh and Hardened Properties of Alkali-Activated Fly Ash/Slag Pastes with Superplasticizers. Constr. Build. Mater. 2014, 50, 169–176. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The Effects of Nano Particles on Freeze and Thaw Resistance of Alkali-Activated Slag Concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. An Empathetic Added Sustainability Index (EASI) for Cementitious Based Construction Materials. J. Clean. Prod. 2019, 220, 475–482. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Pre-Packed Alkali Activated Cement-Free Mortars for Repair of Existing Masonry Buildings and Concrete Structures. Constr. Build. Mater. 2018, 173, 111–117. [Google Scholar] [CrossRef]

- Zinkaah, O.H.; Ashour, A. Load Capacity Predictions of Continuous Concrete Deep Beams Reinforced with GFRP Bars. Structures 2019, 19, 449–462. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of Engineering Properties of Normal and High Strength Fly Ash Based Geopolymer and Alkali-Activated Slag Concrete Compared to Ordinary Portland Cement Concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and Mechanical Properties of Alkali-Activated Fly Ash-Slag Concrete Cured at Ambient Temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Bai, T.; Song, Z.G.; Wu, Y.G.; Hu, X.D.; Bai, H. Influence of Steel Slag on the Mechanical Properties and Curing Time of Metakaolin Geopolymer. Ceram. Int. 2018, 44, 15706–15713. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of Water Addition, Plasticizer and Alkaline Solution Constitution on Fly Ash Based Geopolymer Concrete Performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix Design Development of Fly Ash and Ground Granulated Blast Furnace Slag Based Geopolymer Concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Ghazy, M.; Taman, M. Properties and Durability of Geopolymer Based Materials and It ’ s Utilizing as a Repair and Strengthening Materials: A Review. Int. Res. J. Eng. Technol. 2022, 9, 1272–1290. [Google Scholar]

- Krivenko, P.; Drochytka, R.; Gelevera, A.; Kavalerova, E. Mechanism of Preventing the Alkali-Aggregate Reaction in Alkali Activated Cement Concretes. Cem. Concr. Compos. 2014, 45, 157–165. [Google Scholar] [CrossRef]

- Yang, K.; Yang, C.; Magee, B.; Nanukuttan, S.; Ye, J. Establishment of a Preconditioning Regime for Air Permeability and Sorptivity of Alkali-Activated Slag Concrete. Cem. Concr. Compos. 2016, 73, 19–28. [Google Scholar] [CrossRef]

- Patil, S.; Joshi, D.; Mangla, D.; Savvidis, I. Recent Development in Geopolymer Concrete: A Review. Mater. Today Proc. 2023; in press. [Google Scholar]

- Nagar, P.A.; Gupta, N.; Kishore, K.; Parashar, A.K. Coupled Effect of B. Sphaericus Bacteria and Calcined Clay Mineral on OPC Concrete. Mater. Today Proc. 2021, 44, 113–117. [Google Scholar] [CrossRef]

- Das, S.K.; Mustakim, S.M.; Adesina, A.; Mishra, J.; Alomayri, T.S.; Assaedi, H.S.; Kaze, C.R. Fresh, Strength and Microstructure Properties of Geopolymer Concrete Incorporating Lime and Silica Fume as Replacement of Fly Ash. J. Build. Eng. 2020, 32, 101780. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.H.; Yehualaw, M.D. Rice Husk Ash in Concrete. Sustainability 2023, 15, 137. [Google Scholar] [CrossRef]

- Venkatesh, C.; Nerella, R.; Chand, M.S.R. Role of Red Mud as a Cementing Material in Concrete: A Comprehensive Study on Durability Behavior. Innov. Infrastruct. Solut. 2021, 6, 13. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Oliveira, L.B.; de Castro Xavier, G.; Vieira, C.M.F. Mechanical, Physical and Durability Properties of Activated Alkali Cement Based on Blast Furnace Slag as a Function of %Na2O. Case Stud. Constr. Mater. 2021, 15, e00723. [Google Scholar] [CrossRef]

- Guo, X.; Pan, X. Mechanical Properties and Mechanisms of Fiber Reinforced Fly Ash–Steel Slag Based Geopolymer Mortar. Constr. Build. Mater. 2018, 179, 633–641. [Google Scholar] [CrossRef]

- Longo, F.; Lassandro, P.; Moshiri, A.; Phatak, T.; Aiello, M.A.; Krakowiak, K.J. Lightweight Geopolymer-Based Mortars for the Structural and Energy Retrofit of Buildings. Energy Build. 2020, 225, 110352. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Structural Performance of Reinforced Geopolymer Concrete Members: A Review. Constr. Build. Mater. 2016, 120, 251–264. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fiber reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Farooq, M.; Bhutta, A.; Banthia, N. Tensile performance of eco-friendly ductile geopolymer composites (EDGC) incorporating different micro-fibers. Cem. Concr. Comp. 2019, 103, 183–192. [Google Scholar] [CrossRef]

- Kuder, K.G.; Nilufer Ozyurt, N.; Mu, E.B.; Shah, S.P. Rheology of fiber-reinforced cementitious materials. Cem. Concr. Res. 2007, 37, 191–199. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Ul Hassan, S.Z. Geopolymers and Fiber-reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef]

- Asil, M.B.; Ranjbar, M.M. Hybrid Effect of Carbon Nanotubes and Basalt Fibers on Mechanical, Durability, and Microstructure Properties of Lightweight Geopolymer Concretes. Constr. Build. Mater. 2022, 357, 129352. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of Availability of Source Materials for Geopolymer/Sustainable Concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ.—Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Tang, W.; Pignatta, G.; Sepasgozar, S.M.E. Life-Cycle Assessment of Fly Ash and Cenosphere-Based Geopolymer Material. Sustainability 2021, 13, 11167. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental Impact Assessment of Fly Ash and Silica Fume Based Geopolymer Concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Curpen, S.; Teutsch, N.; Kovler, K.; Spatari, S. Evaluating Life Cycle Environmental Impacts of Coal Fly Ash Utilization in Embankment versus Sand and Landfilling. J. Clean. Prod. 2023, 385, 135402. [Google Scholar] [CrossRef]

- Bhagath Singh, G.V.P.; Durga Prasad, V. Environmental Impact of Concrete Containing High Volume Fly Ash and Ground Granulated Blast Furnace Slag. J. Clean. Prod. 2024, 448, 141729. [Google Scholar] [CrossRef]

- Onn, C.C.; Mo, K.H.; Radwan, M.K.H.; Liew, W.H.; Ng, C.G.; Yusoff, S. Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability 2019, 11, 7194. [Google Scholar] [CrossRef]

- Miyan, N.; Omur, T.; Amed, B.; Özkan, H.; Aydın, R.; Kabay, N. Recycled Waste Concrete and Metakaolin Based Alkali-Activated Paste: Characterization, Optimization, and Life Cycle Assessment. Constr. Build. Mater. 2024, 416, 135233. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Kiliswa, M.W.; Awoyera, P.O.; Kolawole, J.T.; Babafemi, A.J. Engineering Performance of Metakaolin Based Concrete. Clean. Eng. Technol. 2022, 6, 100383. [Google Scholar] [CrossRef]

- Pelisser, F.; Silva, B.V.; Menger, M.H.; Frasson, B.J.; Keller, T.A.; Torii, A.J.; Lopez, R.H. Structural Analysis of Composite Metakaolin-Based Geopolymer Concrete. Rev. IBRACON Estrut. Mater. 2018, 11, 535–543. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Bahrami Jovein, H. Influence of Metakaolin as Supplementary Cementing Material on Strength and Durability of Concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Abdellatief, M.; AL-Tam, S.M.; Elemam, W.E.; Alanazi, H.; Elgendy, G.M.; Tahwia, A.M. Development of Ultra-High-Performance Concrete with Low Environmental Impact Integrated with Metakaolin and Industrial Wastes. Case Stud. Constr. Mater. 2023, 18, e01724. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based Geopolymer Concrete at Ambient and Elevated Temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Wu, X.; Shen, Y.; Hu, L. Performance of Geopolymer Concrete Activated by Sodium Silicate and Silica Fume Activator. Case Stud. Constr. Mater. 2022, 17, e01513. [Google Scholar] [CrossRef]

- Khater, H.M. Effect of Silica Fume on the Characterization of the Geopolymer Materials. Int. J. Adv. Struct. Eng. 2013, 5, 12. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in Rheology and Mechanical Properties of Ultra-High Performance Concrete with Silica Fume Content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of Silica Fume in Concrete: Review of Durability Properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Wong, L.S. Durability Performance of Geopolymer Concrete: A Review. Polymers 2022, 14, 868. [Google Scholar] [CrossRef] [PubMed]

- Payakaniti, P.; Pinitsoontorn, S.; Thongbai, P.; Amornkitbamrung, V.; Chindaprasirt, P. Electrical Conductivity and Compressive Strength of Carbon Fiber Reinforced Fly Ash Geopolymeric Composites. Constr. Build. Mater. 2017, 135, 164–176. [Google Scholar] [CrossRef]

- Rovnaník, P.; Šimonová, H.; Topolář, L.; Bayer, P.; Schmid, P.; Keršner, Z. Carbon Nanotube Reinforced Alka-li-Activated Slag Mortars. Constr. Build. Mater. 2016, 119, 223–229. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; Van Riessen, A. The Effect of Organic and Inorganic Fibres on the Mechanical and Thermal Properties of Aluminate Activated Geopolymers. Compos. B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- da Silva, A.C.R.; Almeida, B.M.; Lucas, M.M.; Cândido, V.S.; da Cruz, K.S.P.; Oliveira, M.S.; de Azevedo, A.R.G.; Monteiro, S.N. Fatigue Behavior of Steel Fiber Reinforced Geopolymer Concrete. Case Stud. Constr. Mater. 2022, 16, e00829. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Experimental Investigation on the Effect of Corrosion on the Bond Between Reinforcing Steel Bars and Fibre Reinforced Geopolymer Concrete. Structures 2018, 14, 251–261. [Google Scholar] [CrossRef]

- Faris, M.A.; Abdullah, M.M.A.B.; Muniandy, R.; Hashim, M.F.A.; Błoch, K.; Jeż, B.; Garus, S.; Palutkiewicz, P.; Mortar, N.A.M.; Ghazali, M.F. Comparison of Hook and Straight Steel Fibers Addition on Malaysian Fly Ash-based Geopolymer Concrete on the Slump, Density, Water Absorption and Mechanical Properties. Materials 2021, 14, 1310. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Tensile and Flexural Behaviour of Recycled Polyethylene Terephthalate (PET) Fibre Reinforced Geopolymer Composites. Constr. Build. Mater. 2020, 245, 118438. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of Cotton Fibre-Reinforced Geopolymer Composites. Compos. B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Fini, E.H. Polyethylene Terephthalate (PET) Waste Plastic as Natural Aggregate Replacement in Geopolymer Mortar Production. J. Clean. Prod. 2022, 375, 134083. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N. Sodium Hydroxide Effect on the Mechanical Properties of Flyash-Slag Based Geopolymer Concrete. Struct. Concr. 2021, 22, E368–E379. [Google Scholar] [CrossRef]

- Vijaya Prasad, B.; Anand, N.; Arumairaj, P.D.; Kumar, M.S.; Dhilip, T.; Srikanth, G. Studies on Mechanical Properties of High Calcium Fly Ash Based Sustainable Geopolymer Concrete. In Proceedings of the Second International Conference on Advances in Physical Sciences and Materials 2021(ICAPSM 2021), Virtual, 12–13 August 2021; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 2070. [Google Scholar]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of Fresh and Hardened Fly Ash/Slag Based Geopolymer Concrete: A Review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A State-of-the-Art Review on the Durability of Geopolymer Concrete for Sustainable Structures and Infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Tennakoon, C.; Shayan, A.; Sanjayan, J.G.; Xu, A. Chloride Ingress and Steel Corrosion in Geopolymer Concrete Based on Long Term Tests. Mater. Des. 2017, 116, 287–299. [Google Scholar] [CrossRef]

- Albegmprli, H.M.; Al-Qazzaz, Z.K.A.; Rejeb, S.K. Strength Performance of Alkali Activated Structural Lightweight Geopolymer Concrete Exposed to Acid. Ceram. Int. 2022, 48, 6867–6873. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.S.; Debbarma, S.; Rashid, R.S.M. Fire Resistance of Geopolymer Concrete: A Critical Review. Constr. Build. Mater. 2022, 324, 126722. [Google Scholar] [CrossRef]

- Shobeiri, V.; Bennett, B.; Xie, T.; Visintin, P. A Comprehensive Assessment of the Global Warming Potential of Geopolymer Concrete. J. Clean. Prod. 2021, 297, 126669. [Google Scholar] [CrossRef]

- Sun, Q.; Li, B.; Wang, H.; Wang, Y. Degradation Mechanism and Life Prediction of Tailings and Waste Rock Aggregate Geopolymer Concrete under Freeze-Thaw Corrosion. Mater. Res. Express 2022, 9, 015506. [Google Scholar] [CrossRef]

- Seneviratne, C.; Gunasekara, C.; Law, D.W.; Setunge, S.; Robert, D. Creep, Shrinkage and Permeation Characteristics of Geopolymer Aggregate Concrete: Long-Term Performance. Arch. Civ. Mech. Eng. 2020, 20, 140. [Google Scholar] [CrossRef]

- Dwibedy, S.; Panigrahi, S.K. Factors Affecting the Structural Performance of Geopolymer Concrete Beam Composites. Constr. Build. Mater. 2023, 409, 134129. [Google Scholar] [CrossRef]

- Bernal, S.A.; de Gutierrez, R.M.; Provis, J.L.; Rose, V. Effect of Silicate Modulus and Metakaolin Incorporation on the Carbonation of Alkali Silicate-Activated Slags. Cem. Concr. Res. 2010, 40, 898–907. [Google Scholar] [CrossRef]

- Li, F.; Fan, S.; Xiao, S.; Huo, J.; Yuan, Y.; Chen, Z. Flexural Performance and Damage of Reinforced Fly Ash and Slag-Based Geopolymer Concrete after Coupling Effect of Freeze-Thaw Cycles and Sustained Loading. Structures 2024, 64, 106537. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, B. Repair of Ordinary Portland Cement Concrete Using Alkali Activated Slag/Fly Ash: Freeze-Thaw Resistance and Pore Size Evolution of Adhesive Interface. Constr. Build. Mater. 2021, 300, 124334. [Google Scholar] [CrossRef]

- Junru, R.; Huiguo, C.; Ruixi, D.; Tao, S. Behavior of Combined Fly Ash/GBFS-Based Geopolymer Concrete after Exposed to Elevated Temperature. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 032056. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. High Tensile Strength Fly Ash Based Geopolymer Composite Using Copper Coated Micro Steel Fiber. Constr. Build. Mater. 2016, 112, 629–638. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Pordsari, A.J.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. A Comprehensive Study of the Polypropylene Fiber Reinforced Fly Ash Based Geopolymer. PLoS ONE 2016, 11, e0147546. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Sun, X. Experimental Investigation on the Elastic Modulus and Fracture Properties of Basalt Fiber–Reinforced Fly Ash Geopolymer Concrete. Constr. Build. Mater. 2022, 338, 127570. [Google Scholar] [CrossRef]

- Wang, F.; Ma, J.; Ding, Y.; Yu, J.; Yu, K. Engineered Geopolymer Composite (EGC) with Ultra-Low Fiber Content of 0.2%. Constr. Build. Mater. 2024, 411, 134626. [Google Scholar] [CrossRef]

- Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Characterizations of Flax Fabric Reinforced Nanoclay-Geopolymer Composites. Compos. B Eng. 2016, 95, 412–422. [Google Scholar] [CrossRef]

- Visintin, P.; Mohamed Ali, M.S.; Albitar, M.; Lucas, W. Shear Behaviour of Geopolymer Concrete Beams without Stirrups. Constr. Build. Mater. 2017, 148, 10–21. [Google Scholar] [CrossRef]

- Wu, C.; Hwang, H.J.; Shi, C.; Li, N.; Du, Y. Shear Tests on Reinforced Slag-Based Geopolymer Concrete Beams with Transverse Reinforcement. Eng. Struct. 2020, 219, 110966. [Google Scholar]

- Hassan, A.; Arif, M.; Shariq, M. Structural Performance of Ambient-Cured Reinforced Geopolymer Concrete Beams with Steel Fibres. Struct. Concr. 2021, 22, 457–475. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, T.Q. Shear Behaviour of Geopolymer-Concrete Beams Transversely Reinforced with Continuous Rectangular GFRP Composite Spirals. Compos. Struct. 2018, 187, 454–465. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Effect of Hybrid Fibers on Shear Behaviour of Geopolymer Concrete Beams Reinforced by Basalt Fiber Reinforced Polymer (BFRP) Bars without Stirrups. Compos. Struct. 2020, 243, 112236. [Google Scholar] [CrossRef]

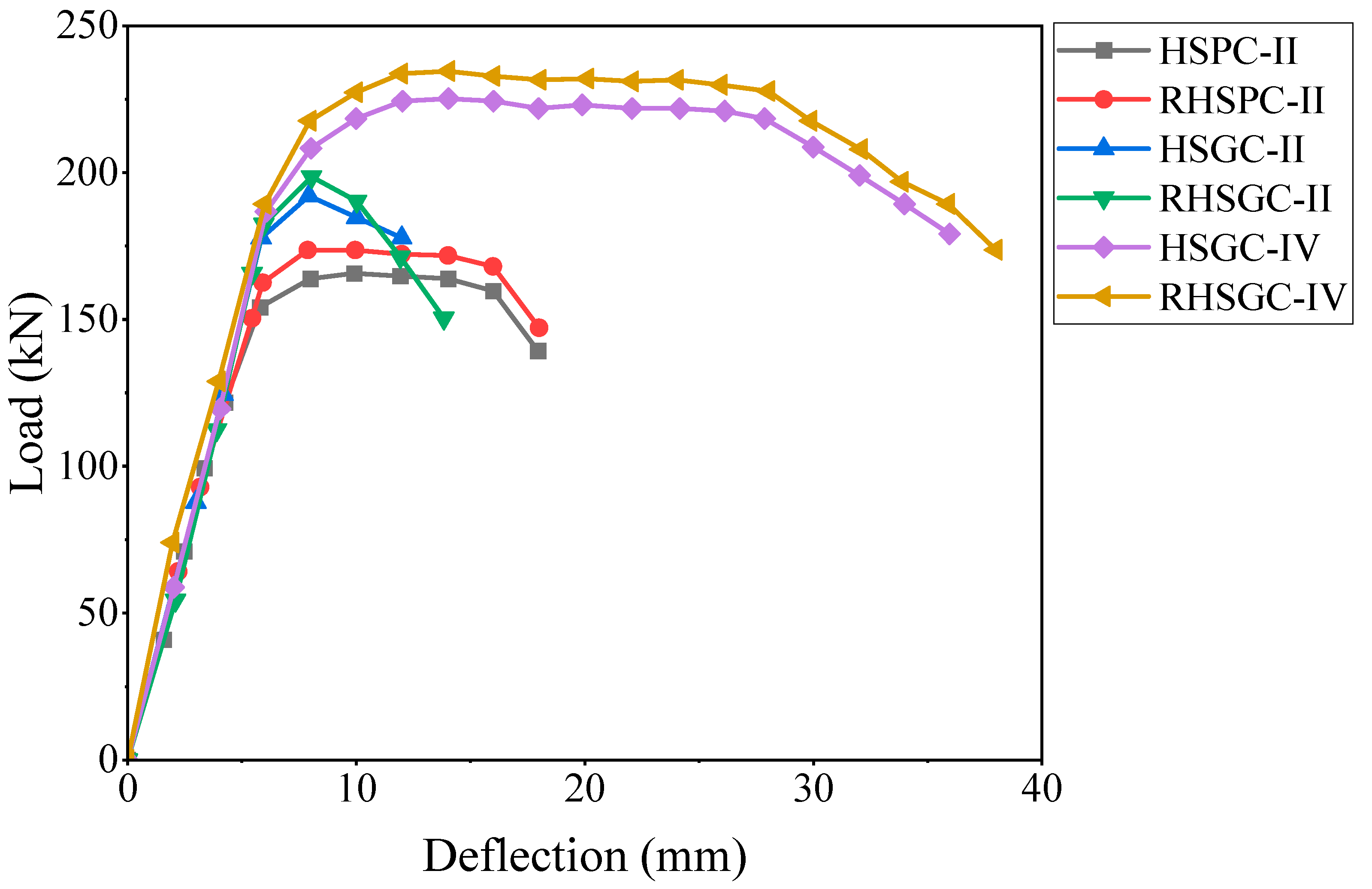

- Tran, T.T.; Pham, T.M.; Hao, H. Experimental and Analytical Investigation on Flexural Behaviour of Ambient Cured Geopolymer Concrete Beams Reinforced with Steel Fibers. Eng. Struct. 2019, 200, 109707. [Google Scholar] [CrossRef]

- Mo, K.H.; Yeoh, K.H.; Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z. Shear Behaviour and Mechanical Properties of Steel Fibre-Reinforced Cement-Based and Geopolymer Oil Palm Shell Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 148, 369–375. [Google Scholar] [CrossRef]

- Ardhira, P.J.; Ardra, R.; Santhosh, P.P.; Sathyan, D. A Review on Structural Performance of Geopolymer Beam and Geopolymer for Strengthening the Beam. Mater. Today Proc. 2022, 64, 74–78. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A Review of Properties and Behaviour of Reinforced Geopolymer Concrete Structural Elements- A Clean Technology Option for Sustainable Development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Nikmehr, B.; Kafle, B.; Al Zand, A.W.; Al-Ameri, R. The Effect of Hybrid Basalt Fibres on the Mechanical and Structural Characteristics of Geopolymer Concrete Containing Geopolymer-Coated Recycled Concrete Aggregates. Constr. Build. Mater. 2024, 450, 138649. [Google Scholar] [CrossRef]

- Zuaiter, M.; El-Hassan, H.; El-Maaddawy, T.; El-Ariss, B. Flexural and Shear Performance of Geopolymer Concrete Reinforced with Hybrid Glass Fibers. J. Build. Eng. 2023, 72, 106580. [Google Scholar] [CrossRef]

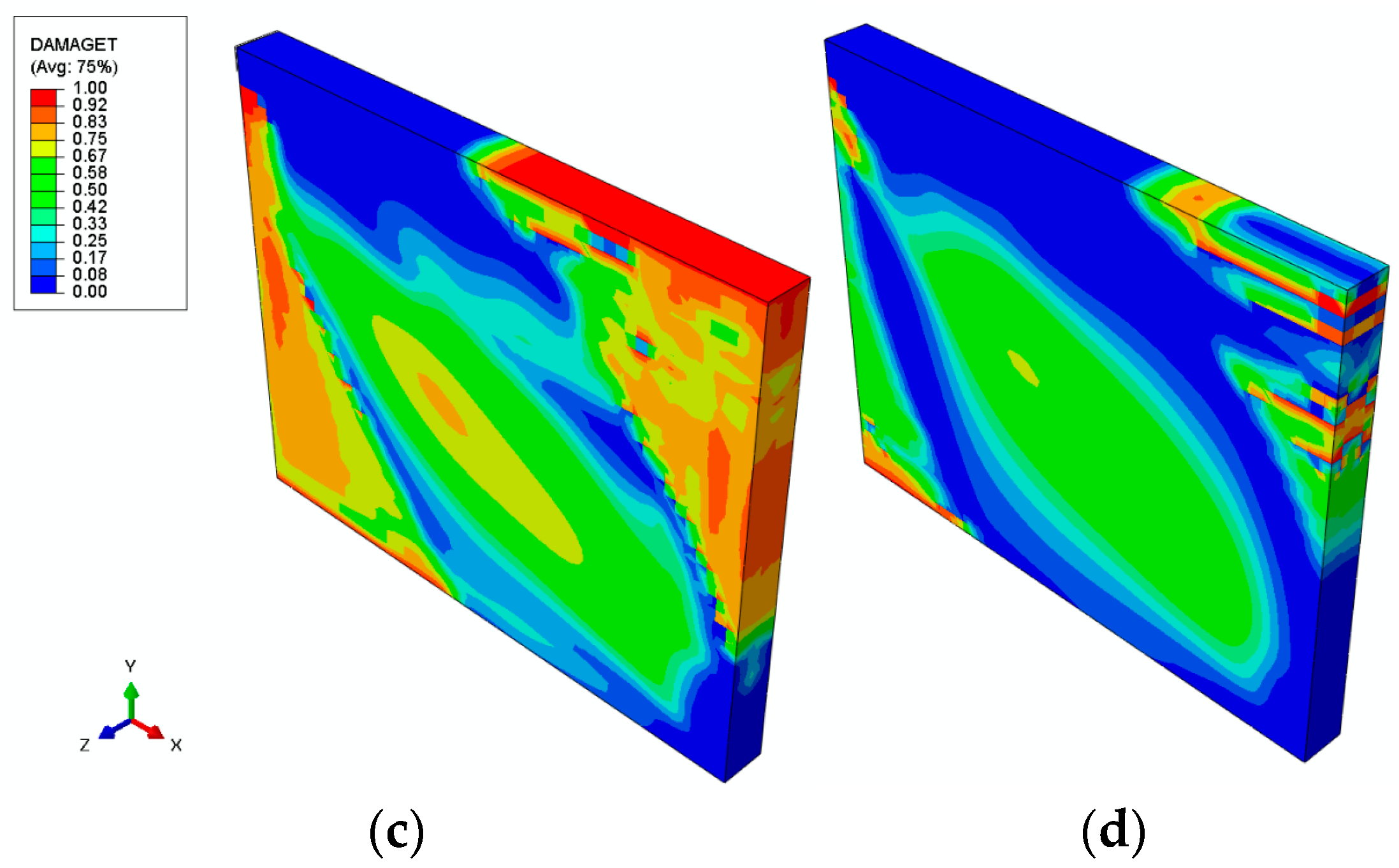

- Özbayrak, A.; Kucukgoncu, H.; Aslanbay, H.H.; Aslanbay, Y.G. Stress and Damage Distribution Analysis of Steel Reinforced Geopolymer Concrete Beams: Finite Element Method and Experimental Comparison under Varying Design Parameters. J. Build. Eng. 2025, 104, 112229. [Google Scholar] [CrossRef]

- Li, Z.; Chen, W.; Hao, H.; Xu, C.; Pham, T.M. Experimental and Analytical Study on Structural Performance of Reinforced Lightweight Geopolymer Composites Panels. Structures 2023, 51, 1219–1229. [Google Scholar] [CrossRef]

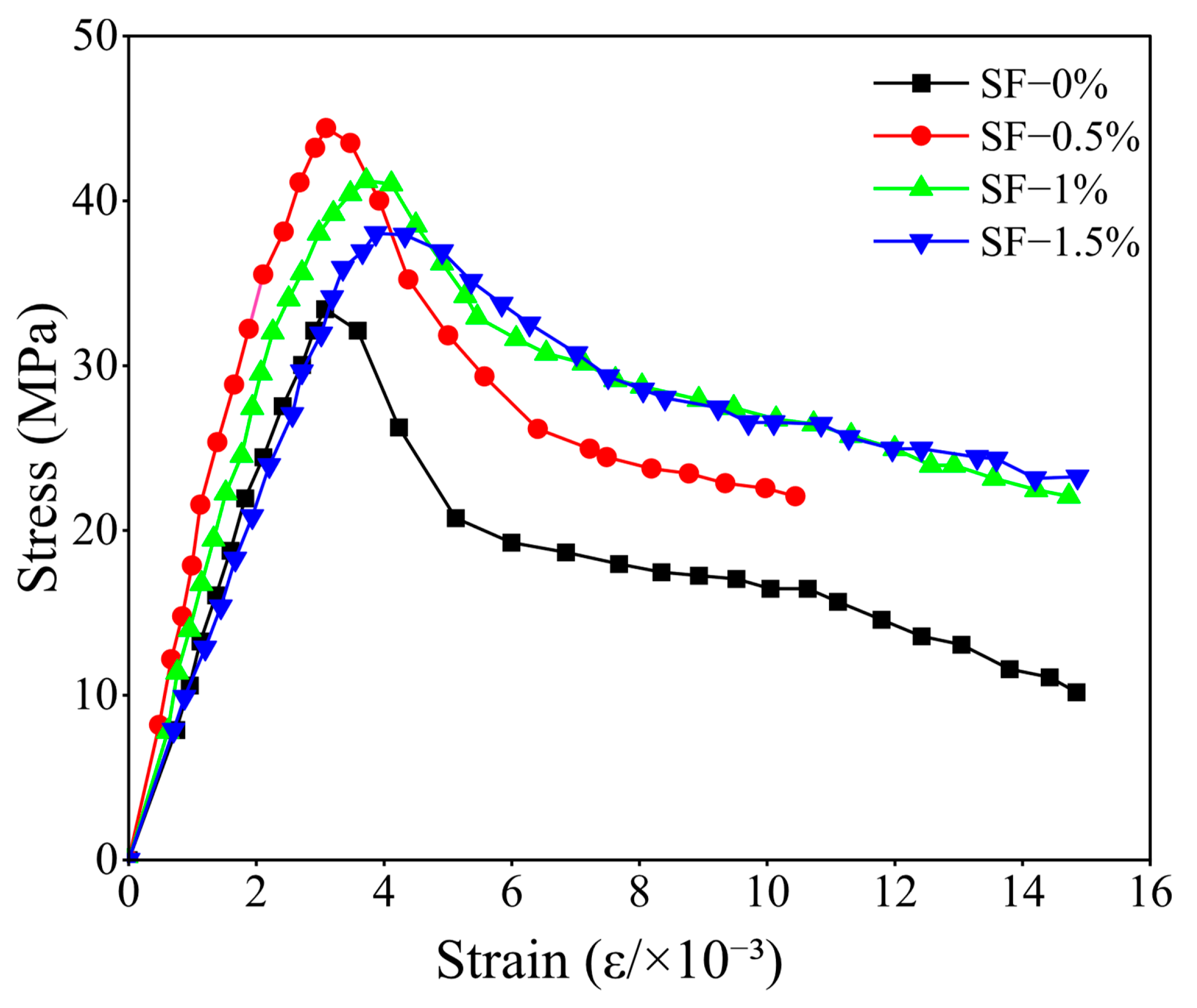

- Wen, Y.; Liu, X.; Sun, G.; Shen, W. Mechanical Properties and Stress-Strain Relationship of Steel Fiber Reinforced Geopolymer Recycled Concrete. Structures 2025, 75, 108697. [Google Scholar] [CrossRef]

- Huang, Y.; Tan, J.; Xuan, X.; Liu, L.; Xie, M.; Liu, H.; Yu, S.; Zheng, G. Study on Untreated and Alkali Treated Rice Straw Reinforced Geopolymer Composites. Mater. Chem. Phys. 2021, 262, 124304. [Google Scholar] [CrossRef]

- Malenab, R.A.J.; Ngo, J.P.S.; Promentilla, M.A.B. Chemical Treatment of Waste Abaca for Natural Fiber-Reinforced Geopolymer Composite. Materials 2017, 10, 579. [Google Scholar] [CrossRef]

- Jabbar, A.; Militký, J.; Wiener, J.; Usman Javaid, M.; Rwawiire, S. Tensile, Surface and Thermal Characterization of Jute Fibres after Novel Treatments. Indian J. Fibre Text. Res. 2016, 41, 249–254. [Google Scholar]

- Sanfilippo, C.; Fiore, V.; Calabrese, L.; Megna, B.; Valenza, A. Impact of Surface Treatment on the Strengthening of Geopolymer Composites Reinforced with Short Sisal Fibers. JOM 2024, 76, 4514–4525. [Google Scholar] [CrossRef]

- Benfratello, S.; Cirello, A.; Palizzolo, L.; Sanfilippo, C.; Valenza, A. Experimental Analysis and Numerical Modelling of the Mechanical Behavior of a Sisal-Fiber-Reinforced Geopolymer. Appl. Sci. 2024, 14, 5216. [Google Scholar] [CrossRef]

- Gu, H. Tensile Behaviours of the Coir Fibre and Related Composites after NaOH Treatment. Mater. Des. 2009, 30, 3931–3934. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on Fiber-Reinforced Concrete Using Industrial Hemp Fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

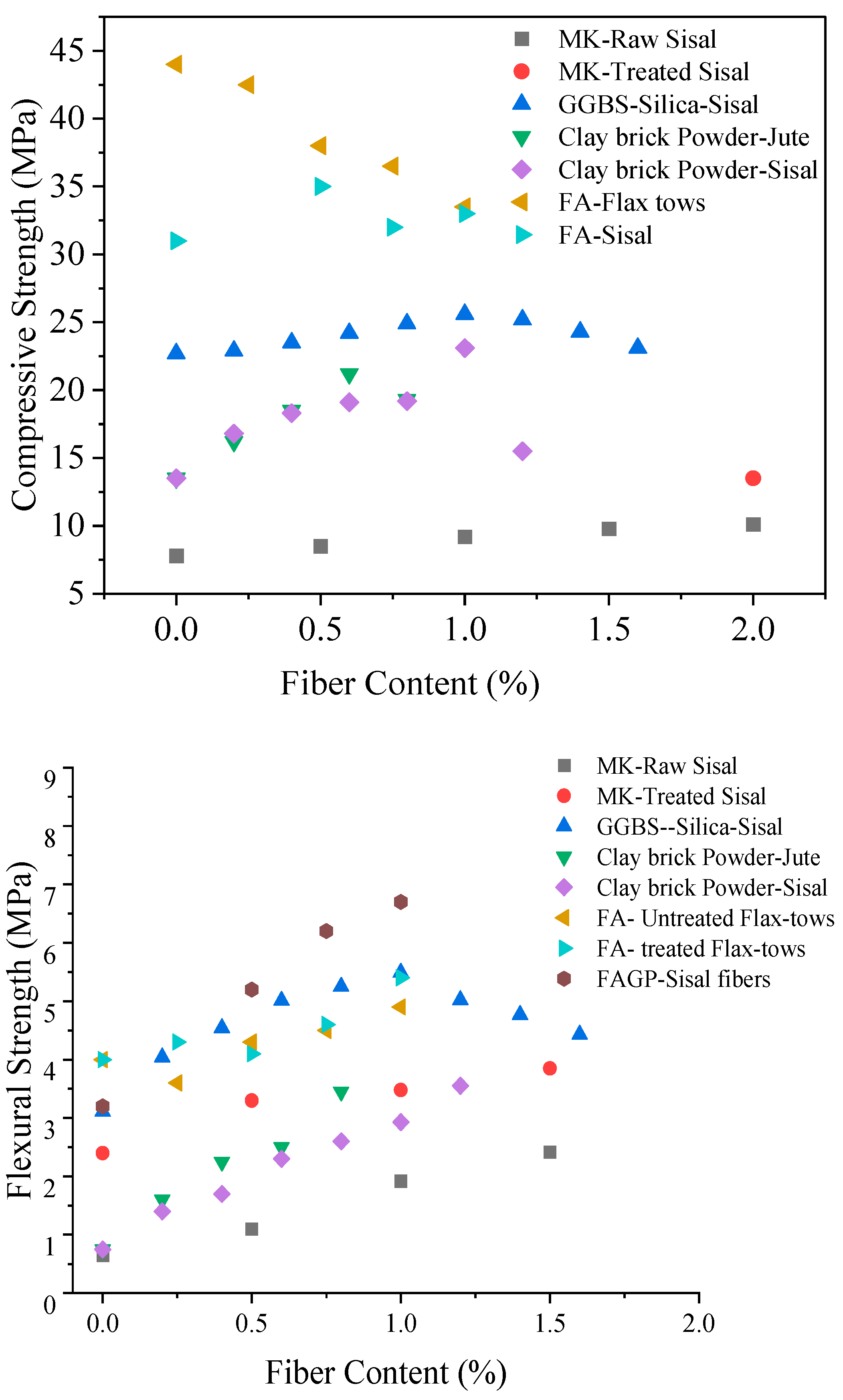

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B.S. A Comprehensive Review on the Use of Natural Fibers in Cement/Geopolymer Concrete: A Step towards Sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Meskhi, B.; Efremenko, I.; Shilov, A.A.; Vialikov, I.; Ananova, O.; Chernil’nik, A.; Elshaeva, D. Composition, Structure and Properties of Geopolymer Concrete Dispersedly Reinforced with Sisal Fiber. Buildings 2024, 14, 2810. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Optimization of a Reinforced Geopolymer Composite Using Natural Fibers and Construction Wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Kruglikov, A.; Mischinenko, V.; Yavna, V. Sustainable Geopolymer Composites Reinforced with Flax Tows. Ceram. Int. 2020, 46, 12870–12875. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural Fiber Reinforced High Calcium Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

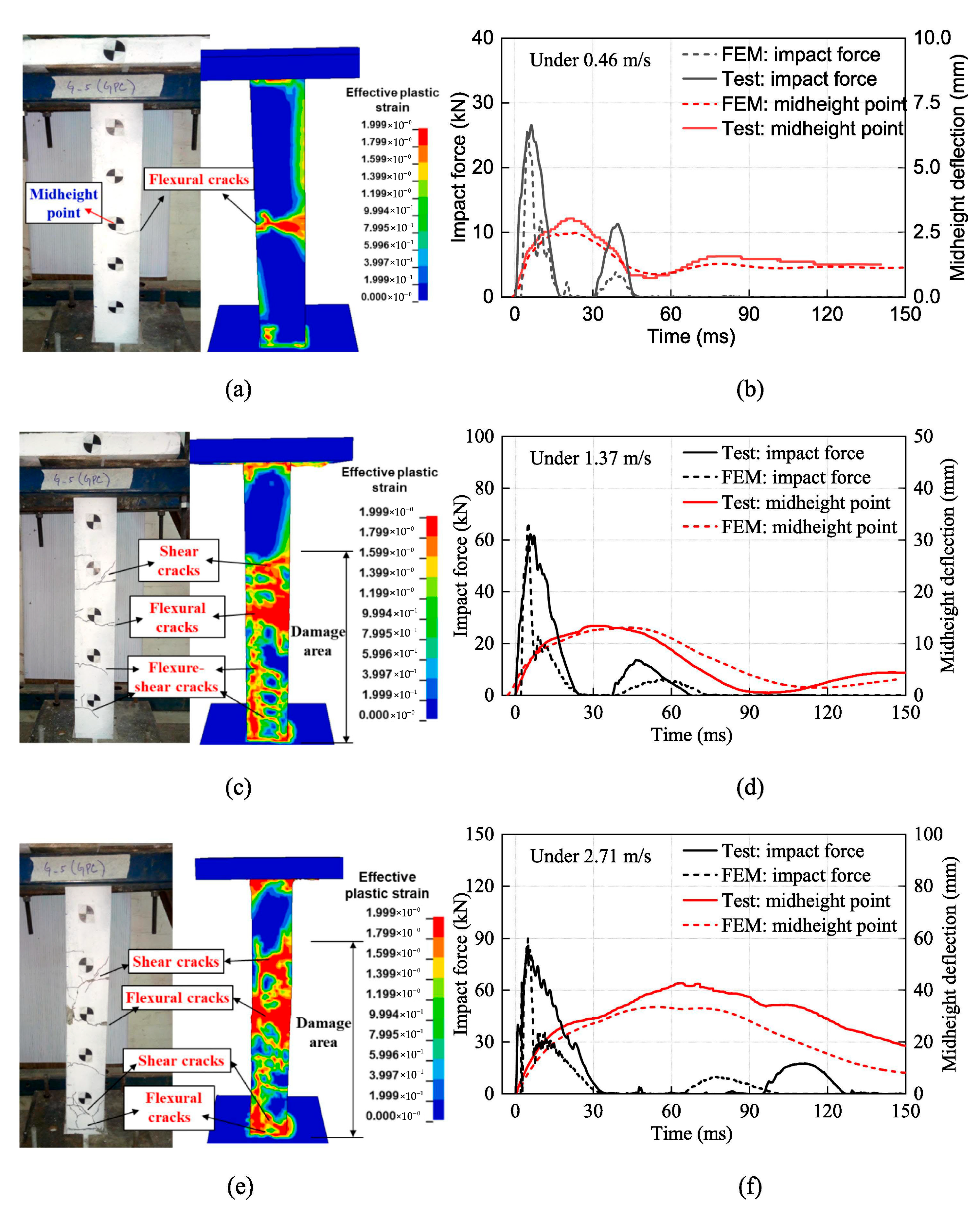

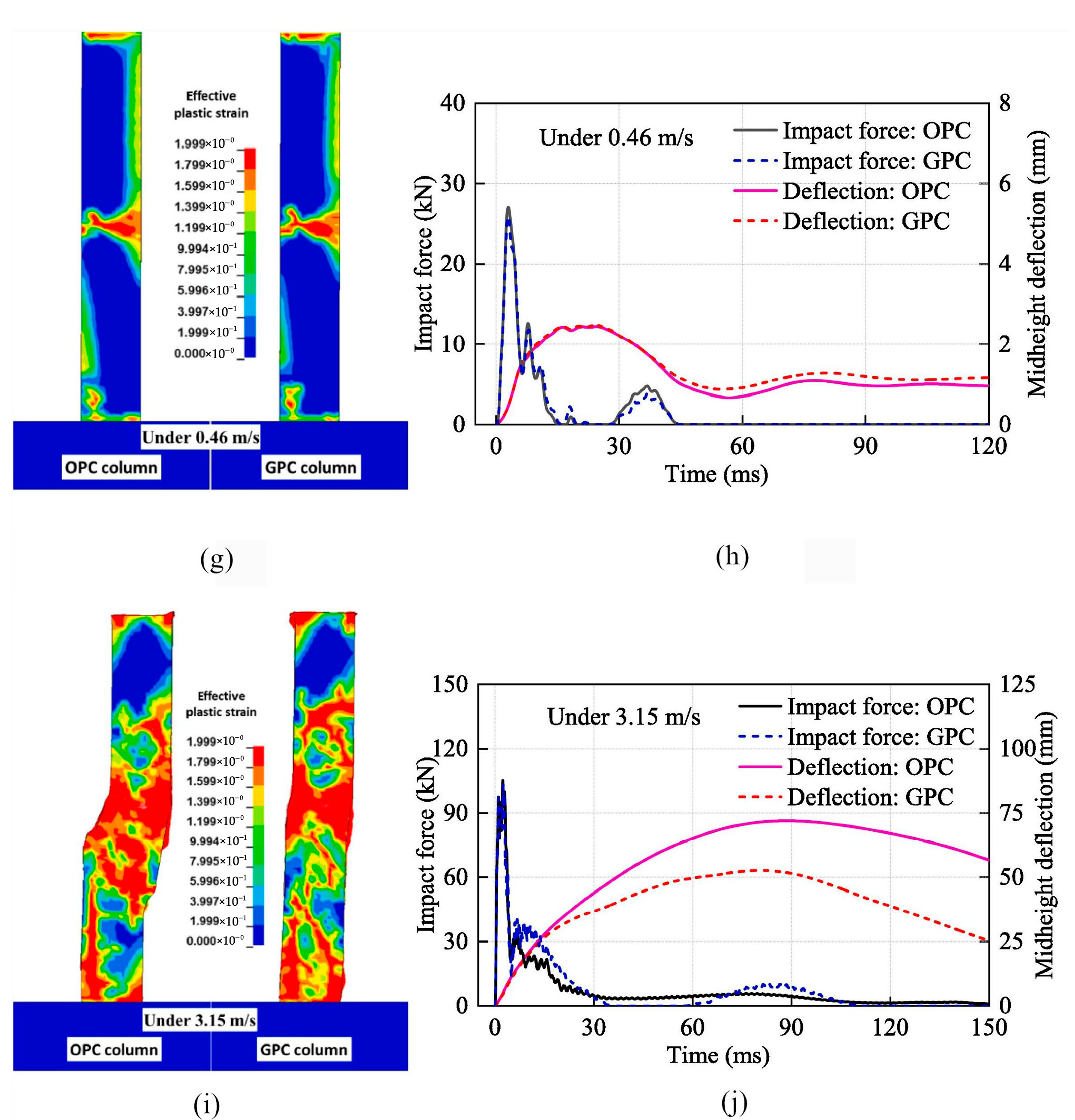

- Huang, Z.; Khan, M.Z.N.; Chen, W.; Hao, H.; Wu, Y.; Pham, T.M.; Elchalakani, M. Experimental and Numerical Study of the Performance of Geopolymer Concrete Columns Reinforced with BFRP Bars Subjected to Lateral Impact Loading. Constr. Build. Mater. 2022, 357, 129362. [Google Scholar] [CrossRef]

- Akduman, S.; Aktepe, R.; Aldemir, A.; Ozcelikci, E.; Yildirim, G.; Sahmaran, M.; Ashour, A. Structural Performance of Construction and Demolition Waste-Based Geopolymer Concrete Columns under Combined Axial and Lateral Cyclic Loading. Eng. Struct. 2023, 297, 116973. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, W.; Hao, H.; Siew, A.U.; Huang, T.; Ahmed, M.; Pham, T.M. Lateral Impact Performances of Geopolymer Concrete Columns Reinforced with Steel-BFRP Composite Bars. Constr. Build. Mater. 2024, 411, 134411. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Hao, H. Dynamic Tensile Properties of Geopolymer Concrete and Fibre Reinforced Geopolymer Concrete. Constr. Build. Mater. 2023, 393, 132159. [Google Scholar] [CrossRef]

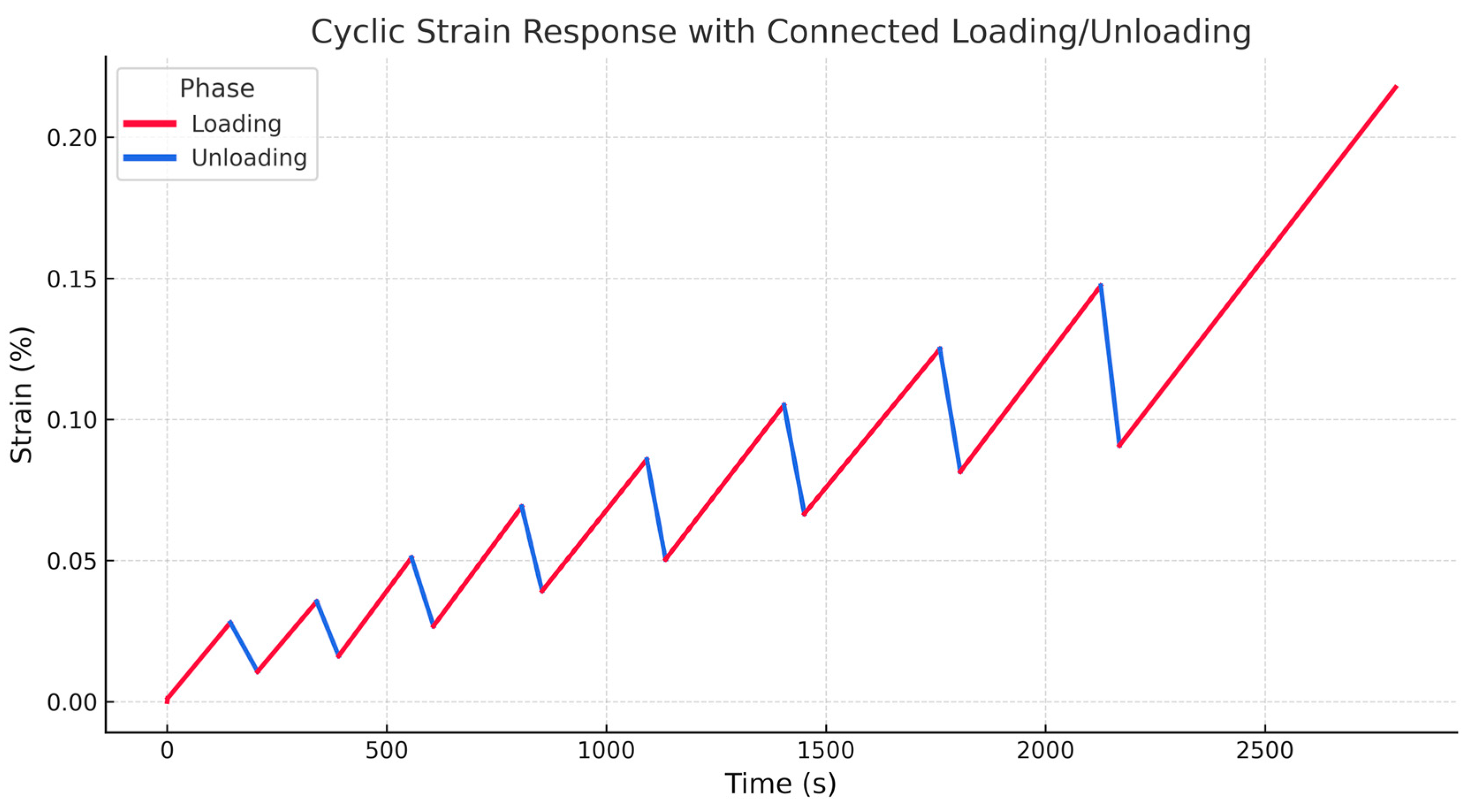

- Xu, W.; Niu, X.; Zhu, Y. Deformation Behavior and Damage Evaluation of Fly Ash-Slag Based Geopolymer Concrete under Cyclic Tension. J. Build. Eng. 2024, 86, 108664. [Google Scholar] [CrossRef]

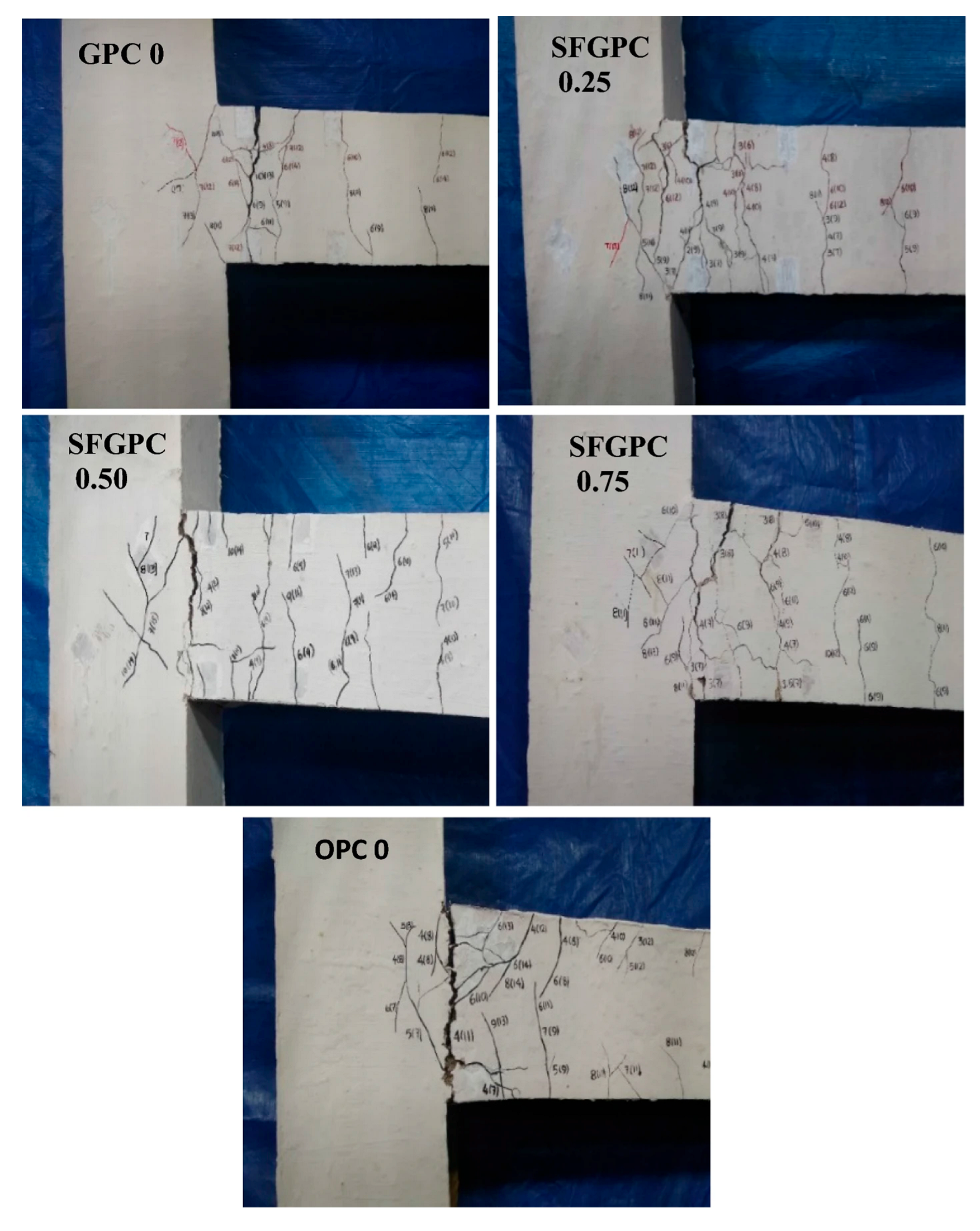

- Saranya, P.; Nagarajan, P.; Shashikala, A.P. Seismic Performance of Geopolymer Concrete Beam-Column Joints under Reverse Cyclic Loading. Innov. Infrastruct. Solut. 2021, 6, 92. [Google Scholar] [CrossRef]

- Li, Y.; Huang, L.; Qu, Y.; Liu, H.; Lv, B.; Li, S. Shaking Table Test on the Seismic Performance of Ternary Composite Geopolymer Recycled Concrete Frame. Structures 2024, 65, 106664. [Google Scholar] [CrossRef]

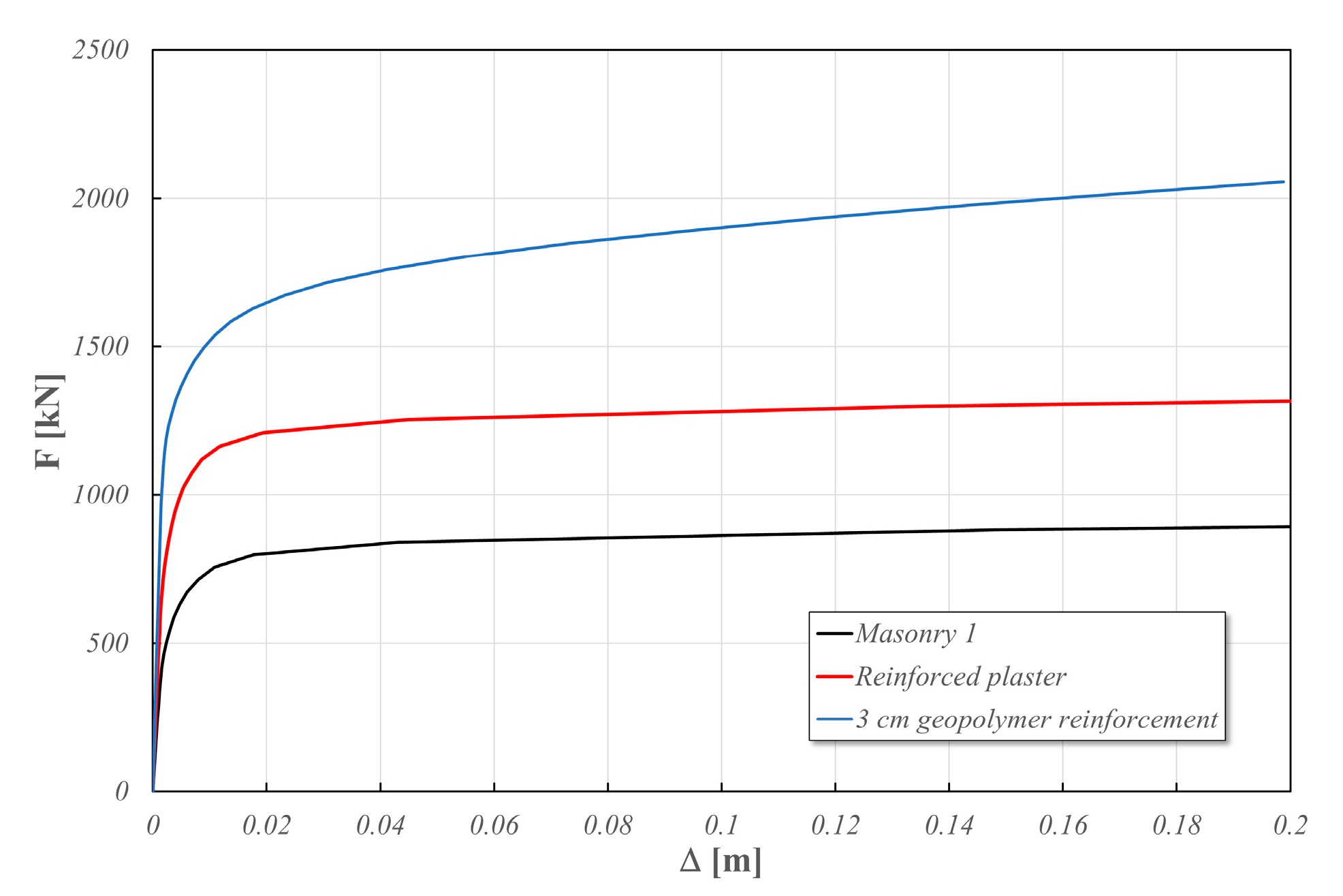

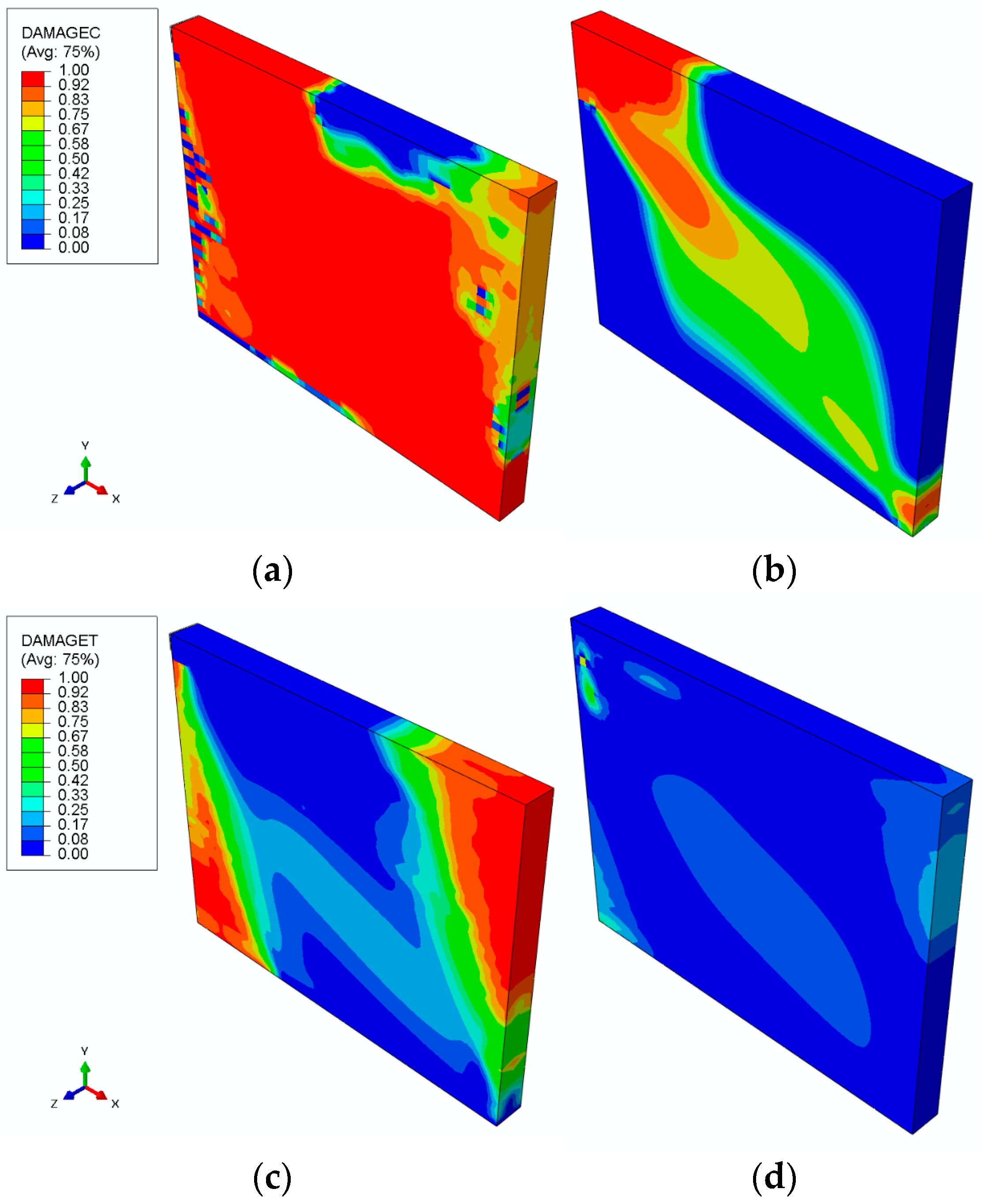

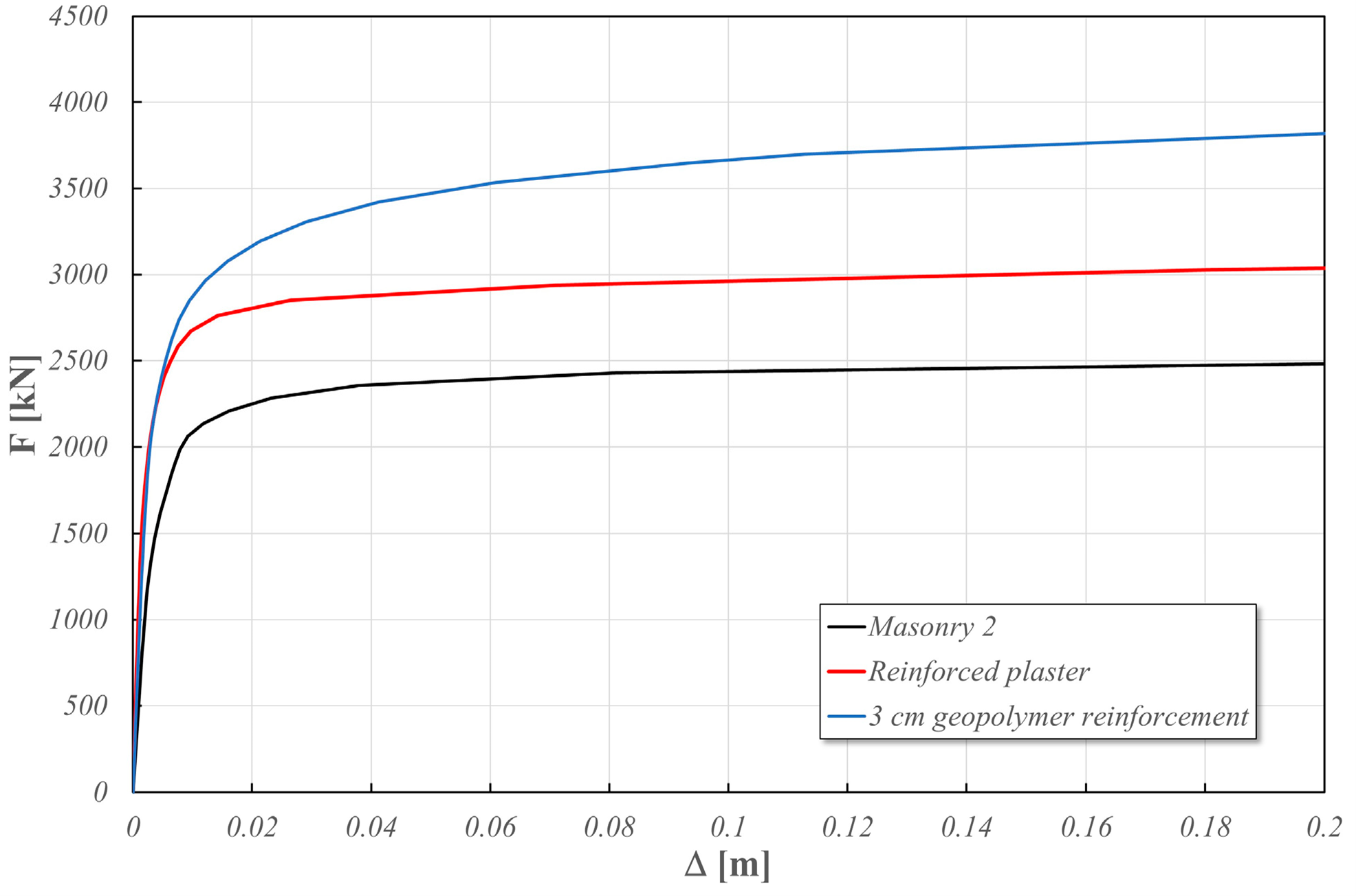

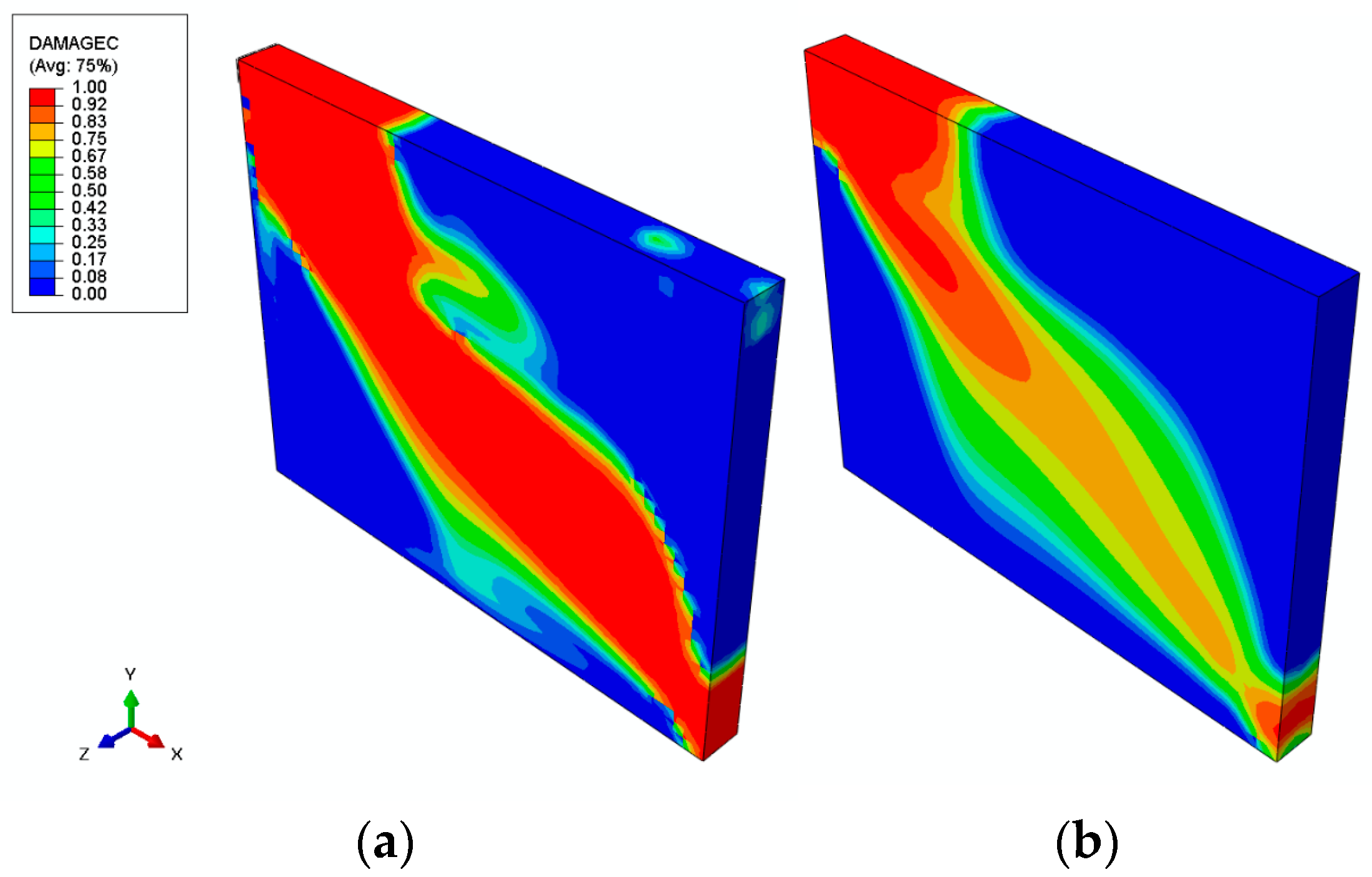

- Buyuktapu, M.; Murat Maras, M. Optimization of Production Parameters of Novel Hybrid Fiber-Reinforced Geopolymer Mortar: Application in Masonry Walls. Structures 2023, 53, 1300–1317. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, Y.; Wan, S.; Yang, C.; Zong, Z.; Qian, H.; Xu, X.; Elchalakani, M.; Cai, J. Experimental Studies on Behavior of One-Part Geopolymer Composite Slabs Subjected to Blast Loading. Structures 2024, 66, 106825. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Hao, H. Investigation on the Impact Resistance of Reinforced Geopolymer Concrete Slab. J. Clean. Prod. 2023, 406, 137144. [Google Scholar] [CrossRef]

- Srividya, T.; Kannan Rajkumar, P.R.; Sivasakthi, M.; Sujitha, A.; Jeyalakshmi, R. A State-of-the-Art on Development of Geopolymer Concrete and Its Field Applications. Case Stud. Constr. Mater. 2022, 16, e00812. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Liu, H.Y.; Kodur, V.; Li, M.Y.; Zhou, Y. Flexural Behavior of Concrete Slabs Strengthened with Textile Reinforced Geopolymer Mortar. Compos. Struct. 2022, 284, 115220. [Google Scholar] [CrossRef]

- Goonewardena, J.; Ghabraie, K.; Subhani, M. Flexural Performance of FRP-Reinforced Geopolymer Concrete Beam. J. Compos. Sci. 2020, 4, 187. [Google Scholar] [CrossRef]

- Hasan, M.A.; Sheehan, T.; Ashour, A.; Elkezza, O. Flexural Behaviour of Geopolymer Concrete T-Beams Reinforced with GFRP Bars. Structures 2023, 49, 345–364. [Google Scholar] [CrossRef]

- Taher, S.M.S.; Saadullah, S.T.; Haido, J.H.; Tayeh, B.A. Behavior of Geopolymer Concrete Deep Beams Containing Waste Aggregate of Glass and Limestone as a Partial Replacement of Natural Sand. Case Stud. Constr. Mater. 2021, 15, e00744. [Google Scholar] [CrossRef]

- Devika, C.P.; Nath, D.R. Study of Flexural Behavior of Hybrid Fibre Reinforced Geopolymer Concrete Beam. Int. J. Sci. Res. 2013, 4, 130–135. [Google Scholar]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P. Experimental Study on Fly Ash and Lead Smelter Slag-Based Geopolymer Concrete Columns. Constr. Build. Mater. 2017, 141, 104–112. [Google Scholar] [CrossRef]

- Danda, U.K.; Himath Kumar, Y.; Sarath Chandra Kumar, B. Experimental Study on Reinforced Geopolymer Concrete Columns Using GGBS. Mater. Today Proc. 2020, 33, 632–636. [Google Scholar] [CrossRef]

- Qu, Y.; Huang, L.; Li, Y.; Wei, L.; Liu, Y.; Li, S. Seismic Performance of Ternary Composite Geopolymer Recycled Concrete Columns: Experimental Study and Modeling. J. Build. Eng. 2024, 86, 108875. [Google Scholar] [CrossRef]

- Li, Y.; Huang, L.; Gao, C.; Qu, Y.; Luo, X.; Lv, B.; Chen, Z. Axial Compressive Behavior of Steel Reinforced GGBS-RFBP-FA Ternary Composite Geopolymer Recycled Fireclay Brick Aggregates Concrete Columns. Structures 2024, 60, 105913. [Google Scholar] [CrossRef]

- Abulencia, A.B.; Villoria, M.B.D.; Libre, R.G.D.; Quiatchon, P.R.J.; Dollente, I.J.R.; Guades, E.J.; Promentilla, M.A.B.; Garciano, L.E.O.; Ongpeng, J.M.C. Geopolymers as Sustainable Material for Strengthening and Restoring Unreinforced Masonry Structures: A Review. Buildings 2021, 11, 539. [Google Scholar]

- Al-Majidi, M.H.; Lampropoulos, A.P.; Cundy, A.B.; Tsioulou, O.T.; Al-Rekabi, S. A Novel Corrosion Resistant Repair Technique for Existing Reinforced Concrete (RC) Elements Using Polyvinyl Alcohol Fibre Reinforced Geopolymer Concrete (PVAFRGC). Constr. Build. Mater. 2018, 164, 603–619. [Google Scholar]

- Sudha, C.; Sambasivan, A.K.; Kannan, K.R.; Jegan, M. Investigation on the Performance of Reinforced Concrete Columns Jacketed by Conventional Concrete and Geopolymer Concrete. Eng. Sci. Technol. Int. J. 2022, 36, 101275. [Google Scholar] [CrossRef]

- Sánchez, M.; Faria, P.; Ferrara, L.; Horszczaruk, E.; Jonkers, H.M.; Kwiecień, A.; Mosa, J.; Peled, A.; Pereira, A.S.; Snoeck, D.; et al. External Treatments for the Preventive Repair of Existing Constructions: A Review. Constr. Build. Mater. 2018, 193, 435–452. [Google Scholar] [CrossRef]

- Huang, X.; Su, S.; Xu, Z.; Miao, Q.; Li, W.; Wang, L. Advanced Composite Materials for Structure Strengthening and Resilience Improvement. Buildings 2023, 13, 2406. [Google Scholar] [CrossRef]

- Guades, E.; Stang, H.; Fisher, G.; Schmidt, J. Hybrid Fibre-Reinforced Geopolymer (HFRG) Composites as an Emerging Material in Retrofitting Aging and Seismically-Deficient Concrete and Masonry Structures. In Proceedings of the 7th International Conference on Concrete Repair, Cluj-Napoca, Romania, 30 September–2 October 2019; EDP Sciences: Les Ulis, France, 2019; Volume 289. [Google Scholar]

- Xiong, G.; Guo, X.; Zhang, H. Preparation of Epoxy Resin-Geopolymer (ERG) for Repairing and the Microstructures of the New-to-Old Interface. Compos. B Eng. 2023, 259, 110731. [Google Scholar] [CrossRef]

- Tashan, J. Flexural Behavior Evaluation of Repaired High Strength Geopolymer Concrete. Compos. Struct. 2022, 300, 116144. [Google Scholar] [CrossRef]

- Qu, Y.; Huang, L.; Li, Y.; Ma, G.; Luo, X. Performance Recovery of a Repaired Earthquake-Damaged Ternary Composite Geopolymer Recycled Concrete Structure: Shake Table Tests. J. Build. Eng. 2024, 94, 110061. [Google Scholar] [CrossRef]

- Alexander, A.E.; Shashikala, A.P. Behavior of RC Beams Rehabilitated Using Carbon Textile Reinforced Geopolymer Mortar in Flexure. Structures 2024, 69, 107522. [Google Scholar] [CrossRef]

- Palizzolo, L.; Sanfilippo, C.; Ullah, S.; Benfratello, S. Strengthening of Masonry Structures by Sisal-Reinforced Geopolymers. Sustainability 2024, 16, 9181. [Google Scholar] [CrossRef]

- Stochino, F.; Majumder, A.; Frattolillo, A.; Valdes, M.; Martinelli, E. Jute Fiber Reinforcement for Masonry Walls: Integrating Structural Strength and Thermal Insulation in Sustainable Upgrades. J. Build. Eng. 2025, 104, 112210. [Google Scholar] [CrossRef]

- Salman, W.D.; Mansor, A.A. Fibrous Geopolymer Paste Composites for Near-Surface-Mounted Strengthening of Reinforced Concrete Beams in Flexure. Case Stud. Constr. Mater. 2021, 14, e00529. [Google Scholar] [CrossRef]

- Hadi, N.S.; Oleiwi, S.M.; Salman, W.D.; Ibrahim, A.M.; Mansor, A.A. Modified Geopolymer Paste Adhesive Bond Material for near Surface Mounted Strengthening Technique. In Proceedings of the 2nd International Conference on Civil and Environmental Engineering Technologies (ICCEET 2020), Najaf, Iraq, 10–11 June 2020; Institute of Physics Publishing: Bristol, UK, 2020; Volume 888. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Temporão, D.; Cidade, M.T. Experimental Assessment of Geopolymer Grouts for Stone Masonry Strengthening. Key Eng. Mater. 2019, 817, 507–513. [Google Scholar] [CrossRef]

- Sharkawi, A.; Taman, M.; Afefy, H.M.; Hegazy, Y. Efficiency of Geopolymer vs. High-Strength Grout as Repairing Material for Reinforced Cementitious Elements. Structures 2020, 27, 330–342. [Google Scholar] [CrossRef]

- Laskar, S.M.; Talukdar, S. Preparation and Tests for Workability, Compressive and Bond Strength of Ultra-Fine Slag Based Geopolymer as Concrete Repairing Agent. Constr. Build. Mater. 2017, 154, 176–190. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Yan, J.; Kodur, V.; Cao, L. Mechanical behavior of concrete beams shear strengthened with textile reinforced geopolymer mortar. Eng. Struct. 2019, 196, 109348. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Marini, A.; Passoni, C.; Pastore, T. Lightweight Cement-Free Alkali-Activated Slag Plaster for the Structural Retrofit and Energy Upgrading of Poor Quality Masonry Walls. Cem. Concr. Compos. 2019, 104, 103341. [Google Scholar] [CrossRef]

- Varma, D.A.; Sarker, P.K.; Madhavan, M.K.; Jayanarayanan, K. Experimental and Analytical Assessment of Strengthening of Concrete Cylinders Using Jute/Basalt Hybrid Textile Fiber Reinforced Mortar. Structures 2024, 70, 107807. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-Reinforced Geopolymer Composites: A Review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Commercial Production of Sewer Tubes with Betolar’s Geoprime® Solution Has Started in Belgium. Available online: https://www.betolar.com/releases/Commercial-production-of-sewer-tubes-with-Betolar’s-Geoprime®-solution-has-started-in-Belgium (accessed on 1 July 2025).

- Geopolymer 3D Printing _ Sustainable Construction. Available online: https://www.3dwasp.com/en/geopolymer-3d-printing/ (accessed on 1 July 2025).

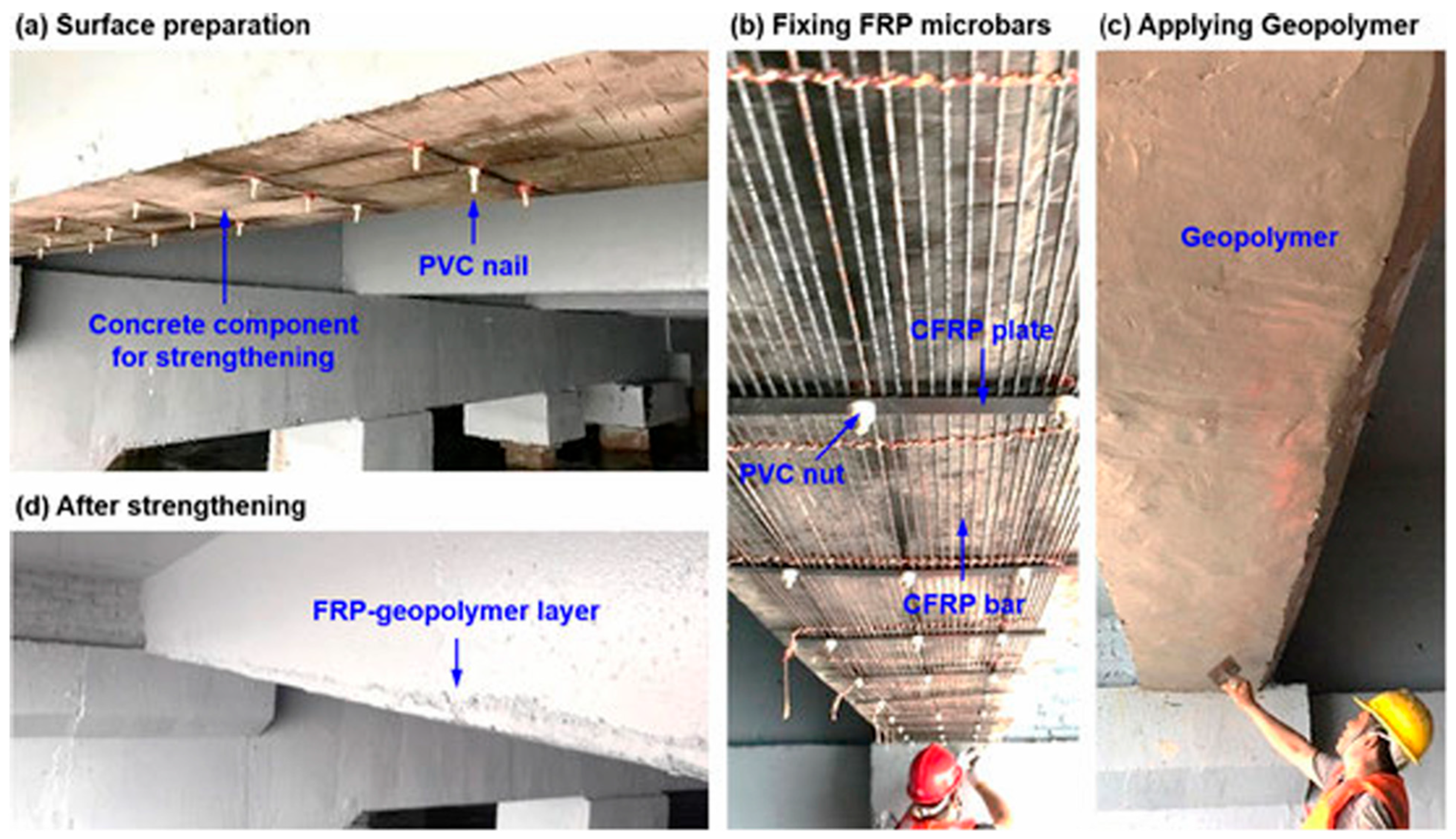

- Peng, K.D.; Huang, B.T.; Xu, L.Y.; Hu, R.L.; Dai, J.G. Flexural Strengthening of Reinforced Concrete Beams Using Geopolymer-Bonded Small-Diameter CFRP Bars. Eng. Struct. 2022, 256, 113992. [Google Scholar] [CrossRef]

- Wastewater, W. GeoSpray® Rehabilitates Heavily Damaged Culvert. Available online: https://www.cs-nri.com/case_study/geospray-rehabilitates-heavily-damaged-culvert/ (accessed on 1 July 2025).

| Properties | OPC | GPC | Remarks | References |

|---|---|---|---|---|

| Compressive strength | Lower | Higher | Higher compressive strength initially; however, this depends on the aluminosilicate source, activator type, reactivity of precursors curing time, duration, and temperature. | [62] |

| Tensile strength | Lower | Higher | Higher tensile strength than OPC-based concrete, depending on aluminosilicate sources, activator type, and curing condition. | [63] |

| Setting time | Slower | Faster | Setting time depends on the activator type and aluminosilicate source used in GPC; GPC setting time is faster than OPC. | [64] |

| Water absorption | Lower | Moderate | Water absorption in GPC is moderate due to internal matrix pores readily affecting its water absorption. | [64] |

| Durability | Lower | Higher | Silica and alumina in aluminosilicate source forms CASH (Calcium Alumina Silicate Hydrate) gel, and the dense packing of GPC matrix shows superior durability. | [65] |

| Chloride attack | Lower | Higher | Depends on the alumina silicate source, activator type, and curing condition. However, the chloride ingress rate in fly-ash-slag-based GPC and slag-based GPC is low; age factor also higher than OPC; and higher protection against corrosion than OPC. | [66] |

| Acid attack | Lower | Higher | Silica and alumina in pozzolanic sources; reactivity with alkaline activators of GPC shows better acid resistance. | [67] |

| Fire resistance | Lower | Higher | GPC maintains its microstructure at elevated temperatures up to 800 °C and performs better than OPC. GPC shows better insulating properties depending on various curing conditions, precursors, additives, and activators. | [68] |

| CO2 emissions | Higher | Lower | During the life cycle, GPC exhibits lower CO2 emissions and global warming potential than OPC. | [69] |

| Freeze–thaw effect | More affected | Less affected | GPC shows excellent chemical and physical properties in freeze and thaw cycles compared to OPC. | [70] |

| Shrinkage | Lower | Moderate | Shrinkage in GPC depends on curing conditions. | [71] |

| Porosity | Lower | Moderate | Due to dense packing of GPC matrix, GPC shows superior internal geopolymer structures than OPC. | [71] |

| Materials | Structural Member | Investigated Variables | Key Findings | References |

|---|---|---|---|---|

| FA, GGBS with steel wire mesh and poly vinyl alcohol (PVA) fibers | Slab | Blast loading, steel wire mesh, and fiber-reinforced geopolymer | Fiber-reinforced slabs improved blast resistance compared to steel-wire-mesh-reinforced composites. Moreover, one-part geopolymer concrete having PVA fibers on the top layer of the slab significantly improved energy dissipation capacity. | [116] |

| FA, GGBS, and steel wire mesh with poly vinyl alcohol (PVA) fibers | Slab | Static and dynamic loading; experimental and numerical modeling | ACI-318 and Eurocode 2 can predict the static slab -punching resistance of GPC slab, but not for dynamic punching shear capacity. The punching shear response is reliant on the peak impact load, while damage and flexural response are correlated on the duration of impact loading and impulse. | [117] |

| FA, GGBS, and basalt fiber reinforcement (BFRP) | Slab | Shear performance and FEM analysis; reinforcement ratio and comp strength | Diagonal tension or shear compression failure depends on the reinforcement ratio. Existing guidelines of RCC (reinforced cement concrete) can be adopted for predicting shear resistance; moreover, numerical models show compatibility with experimental results. | [118] |

| Textile-reinforced (TRGM) and polymer-modified (TRPM) | Slab | Static and numerical analysis; reinforcement ratio, layers, slab thickness | TRGM enhanced post-cracking stiffness and delayed progression and development of cracks, while flexural capacity increases with the number of layers; the numerical results found were in good agreement with experimental analysis. | [119] |

| Fly-ash-based and slag-based GPC | Beams | Compressive and flexural strength | Slag-based GP enhanced strength compared to normal concrete beams. Moreover, the cracking behavior, crack width, flexural cracks spacing, and number of cracks were observed to be similar to normal concrete beams. | [87,88] |

| FA- and slag-based GPC beams | Beams | Flexural behavior | Load carrying capacity and deflection in peak and service load stages were higher than conventional concrete. However, ductility factor was similar to conventional concrete. | [84] |

| CFRP and GFRP FA slag-based GP beams | Beams | Flexural behavior along with deflection | GFRP-reinforced GPC exhibits 2.5 times higher ultimate strength than CFRP sample. Both samples demonstrate a stiffness reduction of 40% in comparison with conventional RC beams. | [120] |

| FA-based GPC with GFRP bars | T-Beams | Reinforcement ratio and compressive strength | Increasing the bottom reinforcement ratio with GFRP bars improved load carrying capacity and reduction in deflection. | [121] |

| FA-based GPC with waste lime and glass powder as sand | Deep beams | Compressive and tensile strength with varying ratios | Incorporation of waste glass and lime caused degradation in compressive and tensile strength, and numerical analysis models based on loading capacity matched with experimental results. | [122] |

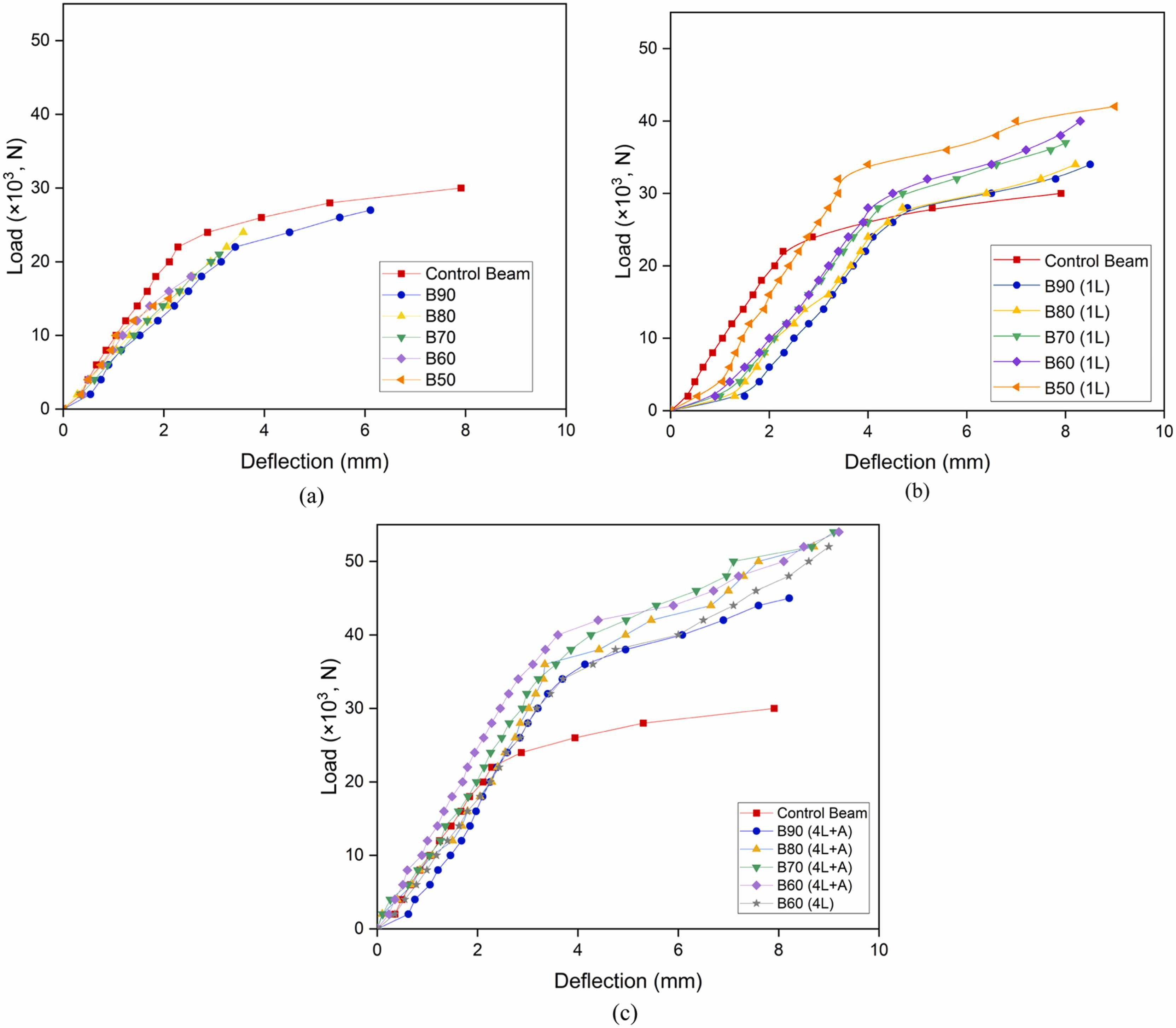

| FA with steel and polypropylene fibers | Beam | Flexural behavior with varying fibers | Strength capacity increased up to 30% in hybrid combinations of polypropylene and steel fibers. | [123] |

| FA-based GPC | Beams | Shear span ratio | The GPC properties of shear friction occurred within the range of shear friction properties of normal OPC-based concrete. | [82] |

| FAGLLSS-based GPC | Short and slender column | Loading position, ultimate, deflection, failure mode | The short column capacity decreased when the eccentricity of the load was decreased, displaying similar failure mode by crushing in the compressed face near the mid-height of column. | [124] |

| GGBS-based GPC | Column | Molarity activator stress–strain | Increasing the molarity of NaOH enhanced the load carrying capacity of columns, with deflection of columns decreased. | [125] |

| FA, GGBS, and recycled fireclay brick as aggregate | Column | Cyclic and seismic analysis, stirrup spacing | On cyclic loading, all samples showed similar flexural failure modes, failure drift ratio was 4.11%, and peak load observed was 288.87KN. Increasing RFBAC (recycled fireclay brick aggregates concrete) content decreased bearing capacity and lateral stiffness but enhanced seismic performance. | [126] |

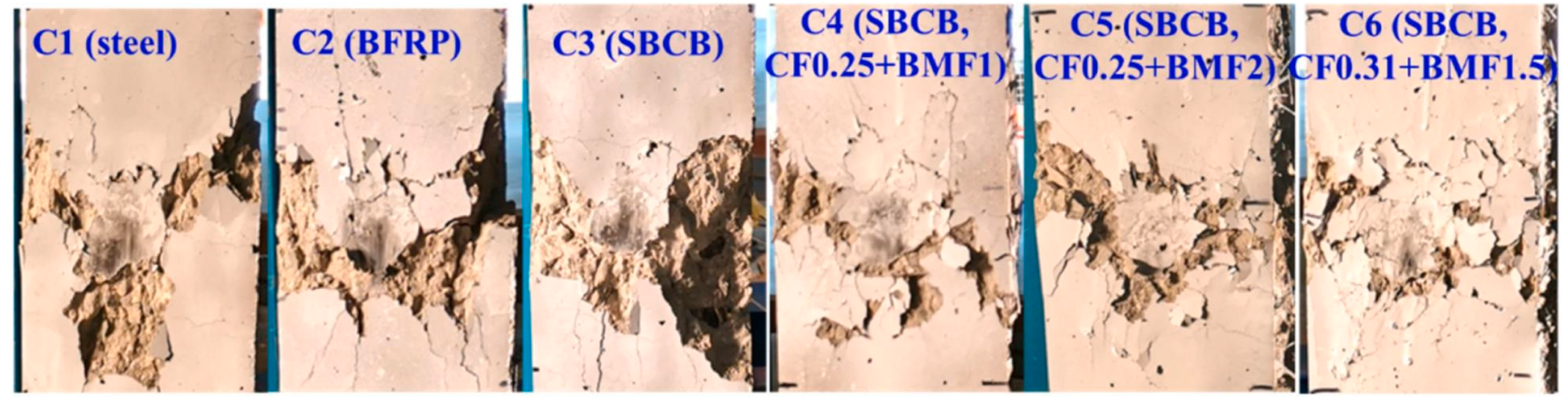

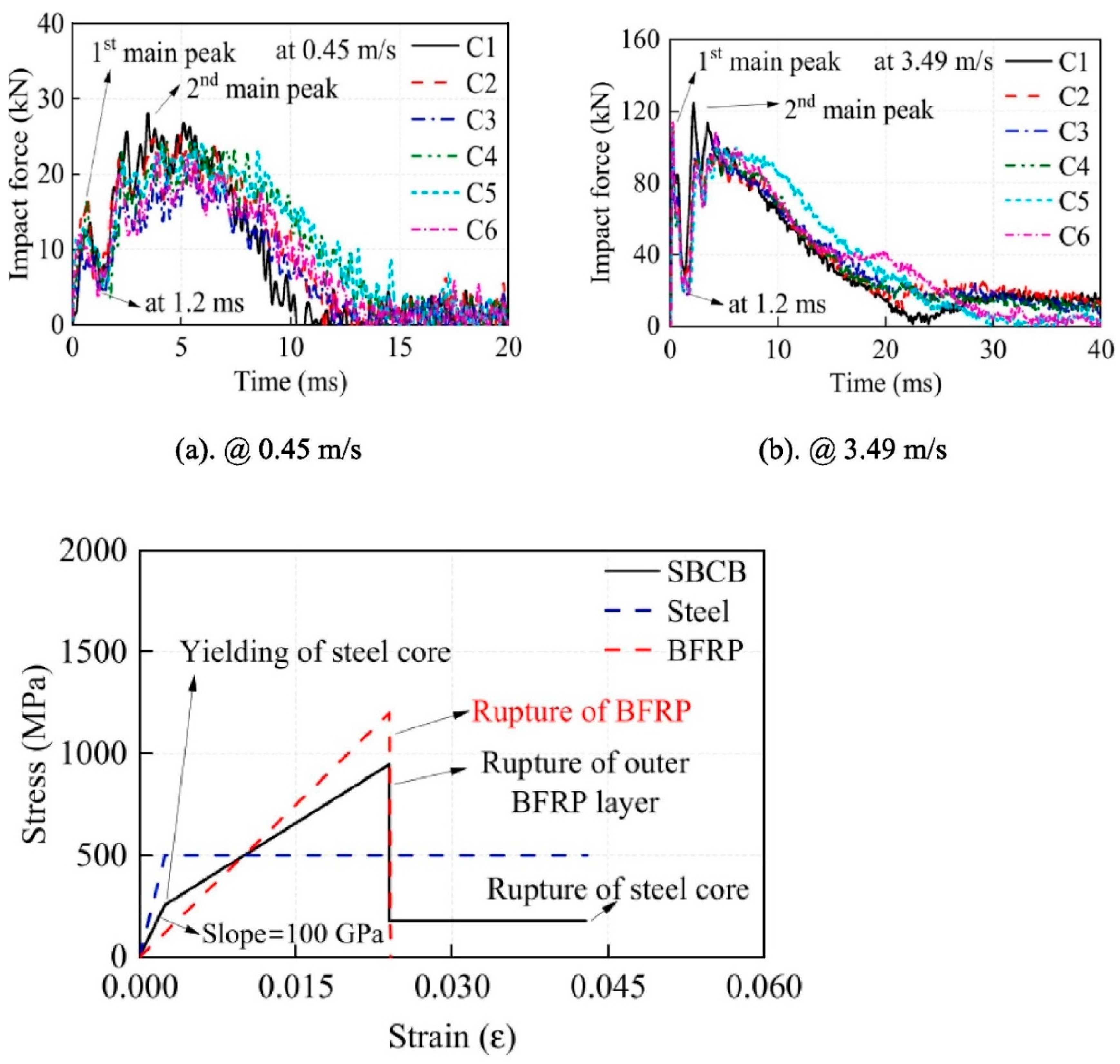

| FA/slag with carbon and basalt micro-fibers and steel fiber composite bars | Column | Fiber content SFCBs (Steel, carbon and basalt fiber); impact resistance | Similar failure mode observed independent of fiber content and reinforcement type. However, CFs and BMFs decreased mid-height deflection (7-42%) and cracking damage. Steel basalt composite bars are recommended for the replacement of steel bars for durable and sustainable structures. | [110] |

| FASLAG-based GPC | Column | Slenderness eccentricity | At ambient curing, FA-based/slag-based GPC columns show scaling issues in structural level in testing. | [90] |

| FA and GGBS with recycled brick and recycled aggregate | Column | Axial load-bearing capacity, ductility, reinforcement | Damage progression and failure mode were observed to be similar to OPC-based RCA (Recycled coarse aggregates ) concrete; ultimate bearing capacity decreased with an increase in RCA and enhanced with the increase in reinforcement ratio. | [127] |

| Source Materials | Investigated Variables | Key Findings | References |

|---|---|---|---|

| Naturally hydrated lime with FA (20-100%) and 12M NaOH | FA/NHL (Natural hydrated lime) ratios; mechanical and Rheological | FA-based grouts at 100% replacement of NHL exhibited higher compressive strength (8-23MPa), low water absorption, and chloride resistance, making them suitable for structural rehabilitation. Yield stress and consistency im-proved up to 50% NHL replacement. | [142] |

| Fly ash with steel, polypropylene, and glass fibers | Mechanical properties, ductility coefficient, and Flexural toughness | Flowability of hybrid fiber-based GP decreases with increasing fiber content and remains workable up to 2% fiber volume. Hybrid fiber (80% steel and 20% glass fibers or 70% steel fibers and 30% PP fibers) enhanced flexural toughness (10-181%) and increased flexural strength (7-18%) and ductility by 263% (PP + steel fibers) compared to monofiber geopolymer composites. It improved flexural toughness when compared with mechanical strength, as the repair material’s toughness is more important for structures subjected to dynamic loading. | [133] |

| Low-calcium FA, polypropylene fibers using styrene butadiene rubber, and epoxy resin | Slant shear, rebar pull-out, pull-off flexural corrosion | GPC mortar exhibits higher bond strength than a cementitious mix for both saturated and dry surface conditions. Epoxy resin performs better as an adhesive between geopolymer and cementitious mixes. PP fiber geopolymer mortar enhanced flexural performance in toughness, ultimate capacity, and crack control. A 2mm geopolymer repair coating is recommend for better corrosion resistance. | [143] |

| Ultra-fine-ground granulated blast furnace slag with FA (20-50%) | FA and slag molarities, plasticizer variation, and mechanical properties | Slag-based geopolymer with 30% fly ash ensured a homogenous matrix and improved bonding. UGGBFS as a repair material in structural retrofitting achieved 60% of its strength (28 days) in 24hrs. Improved bond strength with PCC (Plain cement concrete) surface and rebar, but workability decreases without fly ash, increasing the molarity (14M) of the alkaline activator. | [144] |

| Metakaolin (50%) and fly ash (50%) with and without textile-reinforced (TR) fibers | Comparison of TRG and TR-reinforced beams, and adhesive-type variation | Textile-reinforced geopolymer mortar (TRGM) enhanced shear capacity up to 47% and 106% with one and two TRG mortar layers in comparison with unstrengthened beams. Similarly, their effective strain matches with textile-reinforced mortar beams with similar wrappings. With enhanced properties in durability, TRGM is an optimal RC repair material. | [145] |

| Slag-based GP plaster with light-weight glass aggregates, air-entraining agents, and GFRP mesh | Seismic performance and energy efficiency | Alkali-activated geopolymer plaster with air-entraining agents and expanded glass aggregates exhibits 8 MPa compressive strength (28 days) and thermal conductivity of 0.35 W/mK at 700 kg/ m3. Moreover, using modified starch (MS), methylcellulose (MC), a shrinkage-reducing admixture (SRA), polypropylene fibers, and silane-based surface treatment enhanced adhesion, microcrack resistance, and detachment resistance, and low water absorption was observed. | [146] |

| Textile-reinforced geopolymer (TRM) mortar with jute and basalt fibers | Fiber variation %; textile layers | TRM with natural fibers are selected as a sustainable alternative to epoxy-based FRP systems. Enhanced load capacity and durability in various environmental conditions. Validation with finite element modeling emphasized the potential of TRM with natural fibers for structural retrofitting. | [147] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benfratello, S.; Palizzolo, L.; Sanfilippo, C.; Valenza, A.; Ullah, S. The Structural Performance of Fiber-Reinforced Geopolymers: A Review. Eng 2025, 6, 159. https://doi.org/10.3390/eng6070159

Benfratello S, Palizzolo L, Sanfilippo C, Valenza A, Ullah S. The Structural Performance of Fiber-Reinforced Geopolymers: A Review. Eng. 2025; 6(7):159. https://doi.org/10.3390/eng6070159

Chicago/Turabian StyleBenfratello, Salvatore, Luigi Palizzolo, Carmelo Sanfilippo, Antonino Valenza, and Sana Ullah. 2025. "The Structural Performance of Fiber-Reinforced Geopolymers: A Review" Eng 6, no. 7: 159. https://doi.org/10.3390/eng6070159

APA StyleBenfratello, S., Palizzolo, L., Sanfilippo, C., Valenza, A., & Ullah, S. (2025). The Structural Performance of Fiber-Reinforced Geopolymers: A Review. Eng, 6(7), 159. https://doi.org/10.3390/eng6070159