Analysis of the Influence of Underlying Karst Caves on the Stability of Pipe Jacking Construction Based on the Finite Element Method

Abstract

1. Introduction

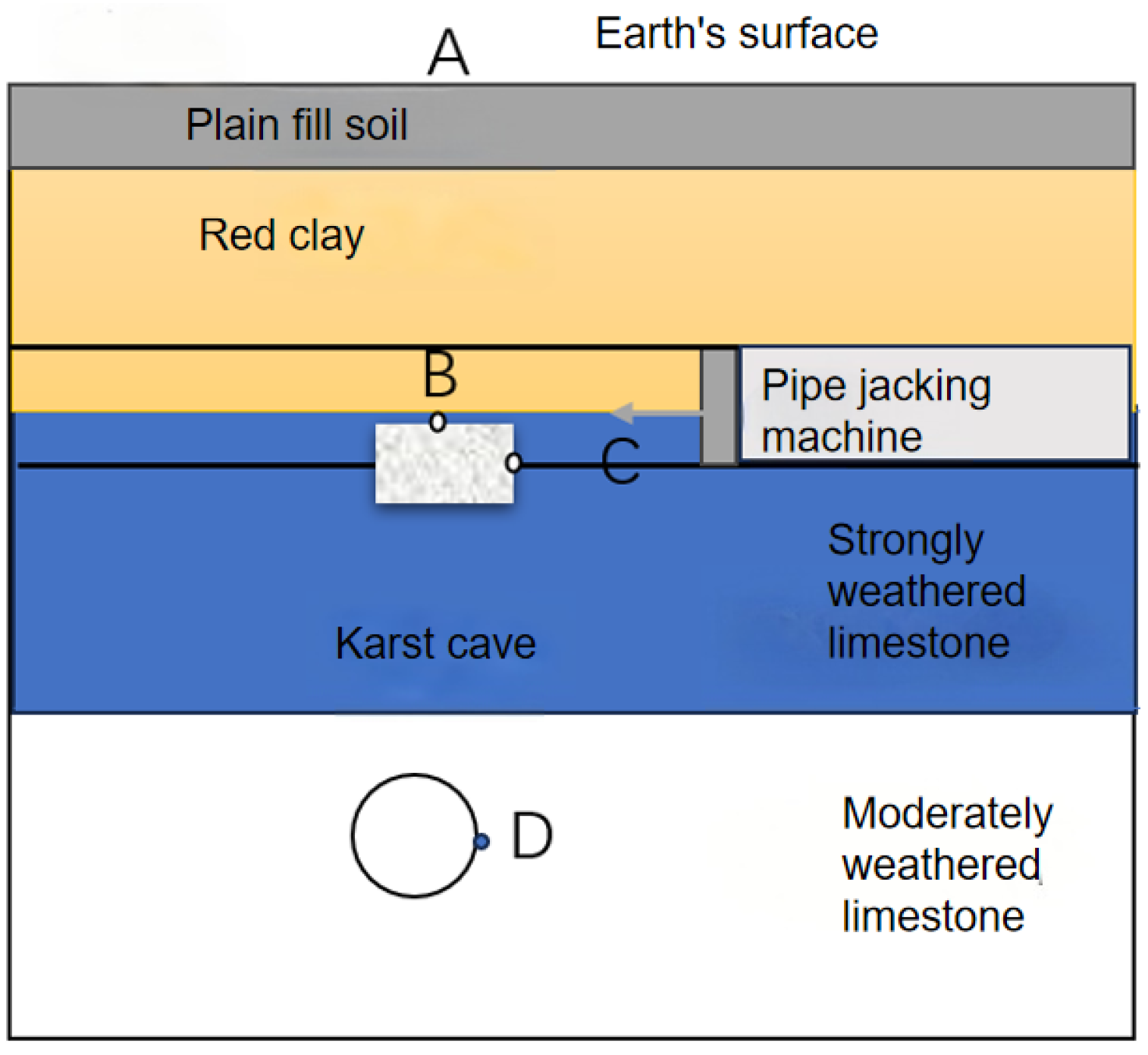

2. Project Overview

3. Numerical Simulation Studies

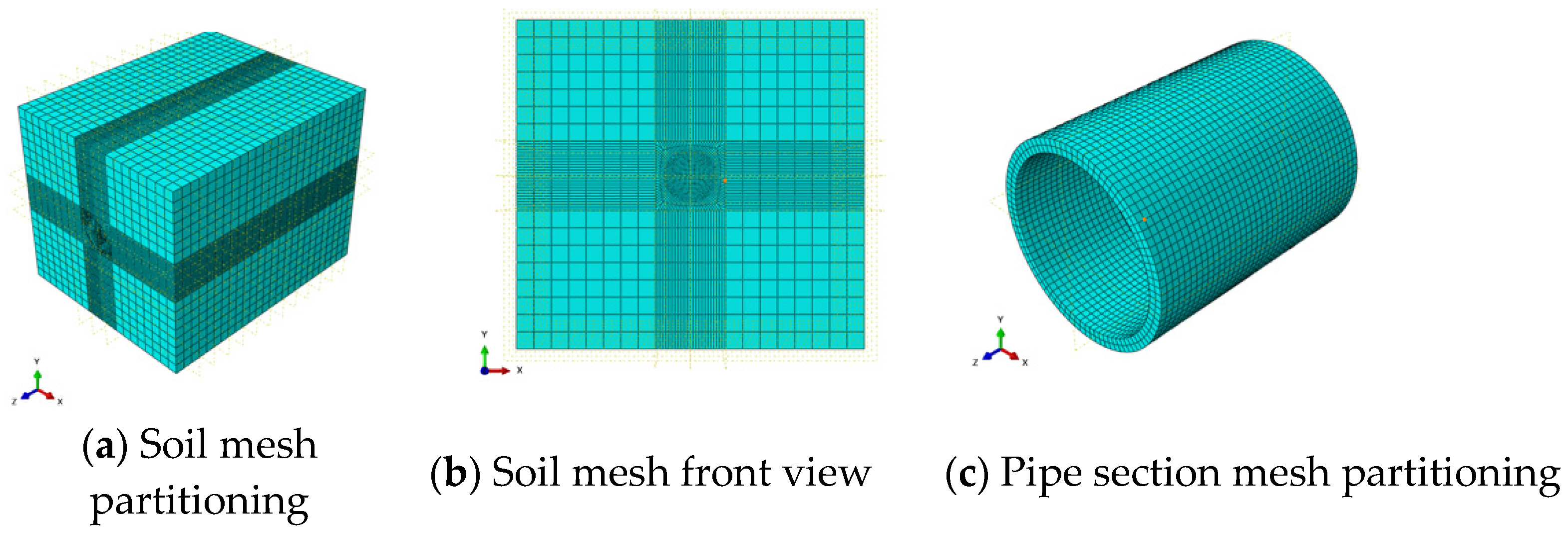

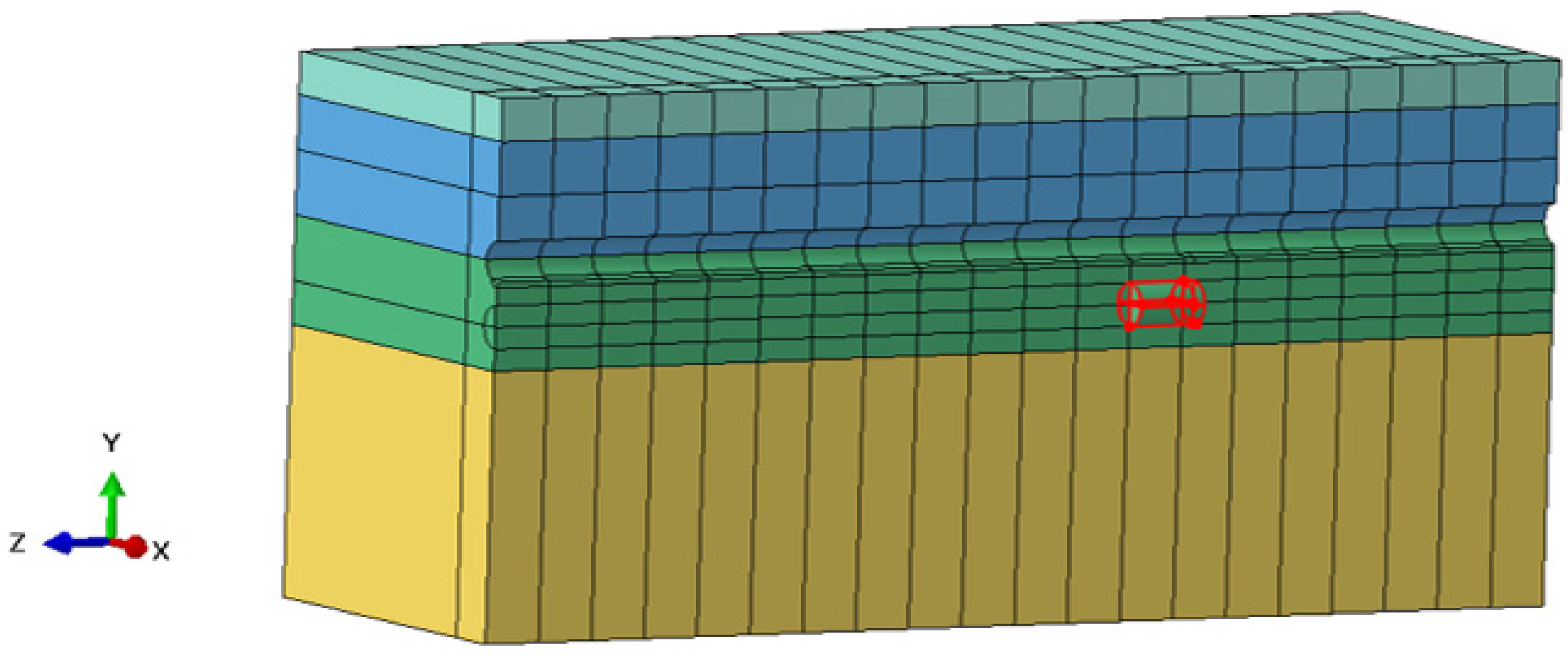

3.1. Model Development and Material Parameters

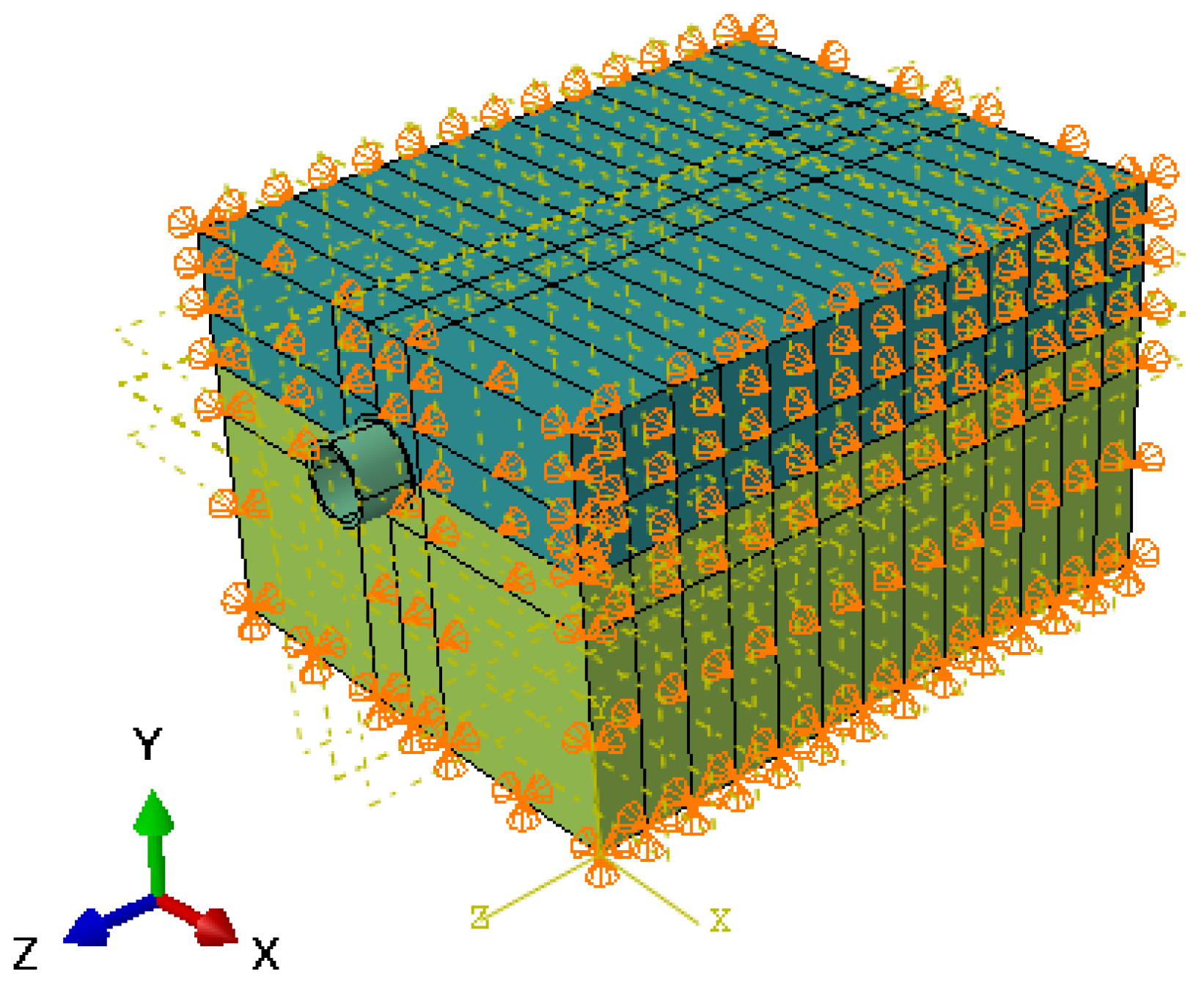

3.2. Boundary Conditions

4. Simulation Results and Analysis

4.1. Analysis of Surrounding Rock Displacement Response

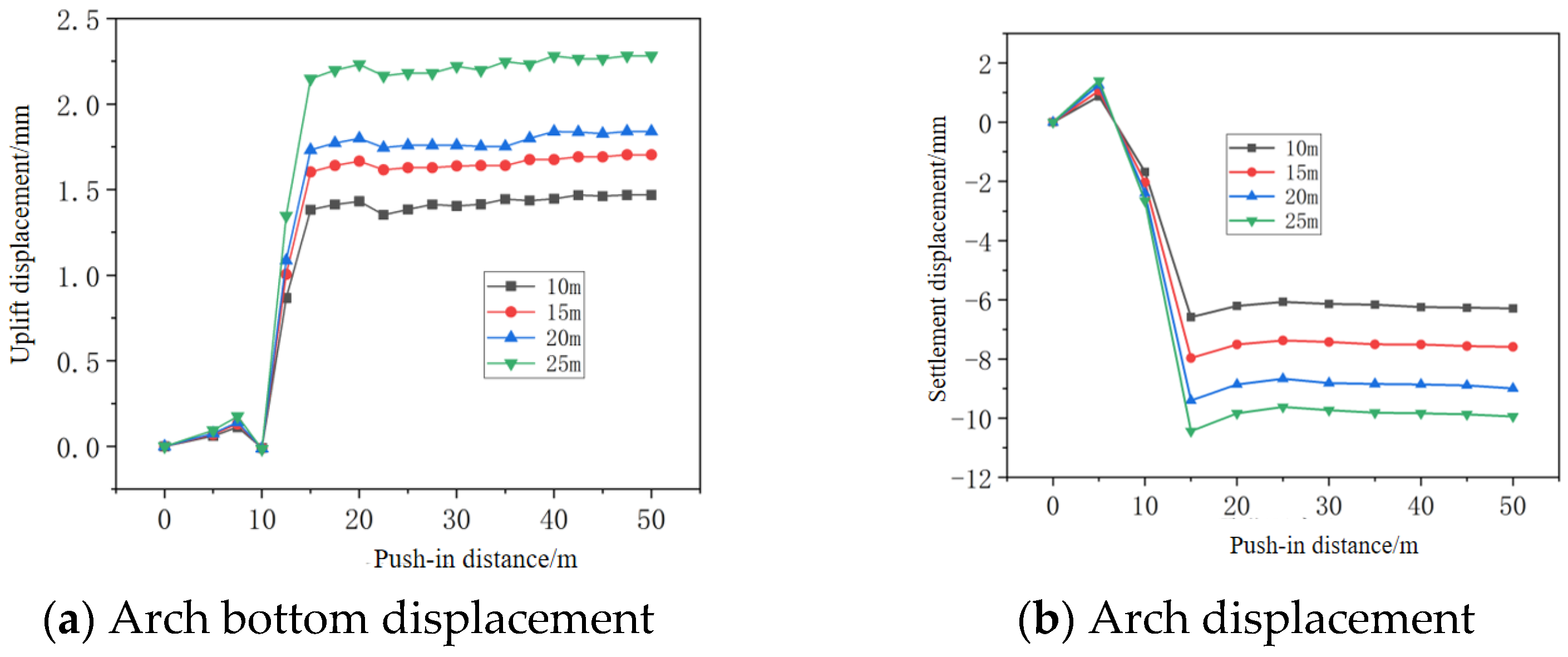

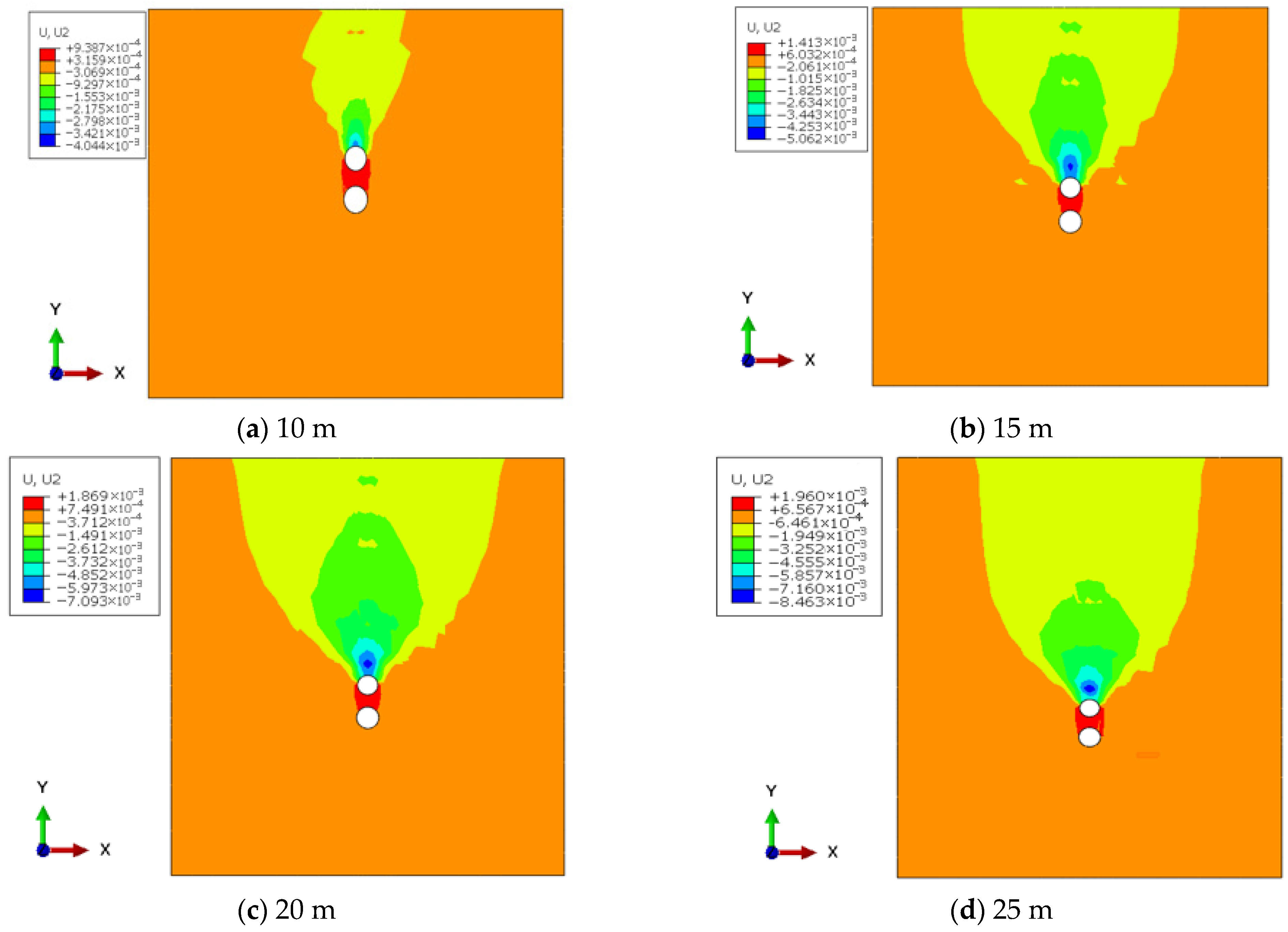

4.1.1. Influence of Tunnel Burial Depth on Surrounding Rock Displacement

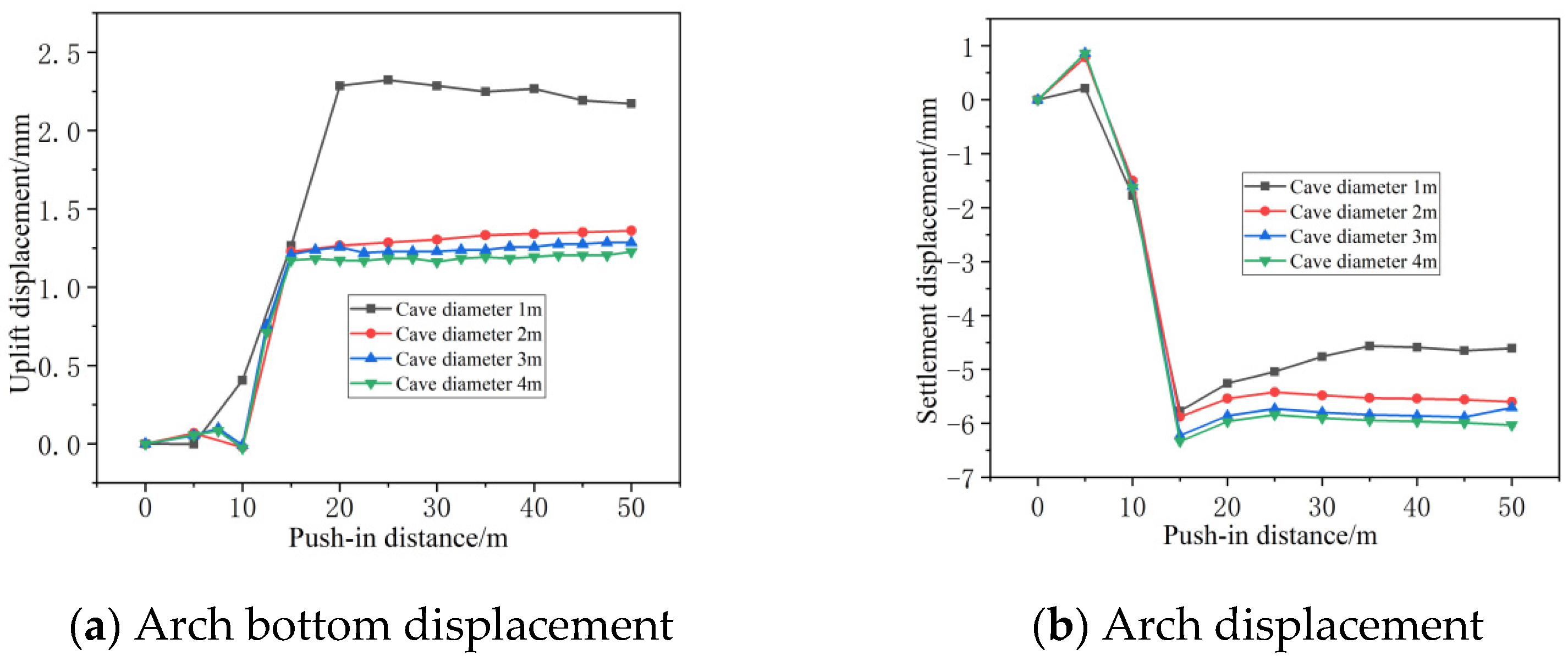

4.1.2. Effect of Karst Cavity Size on Tunnel-Surrounding Rock Displacement

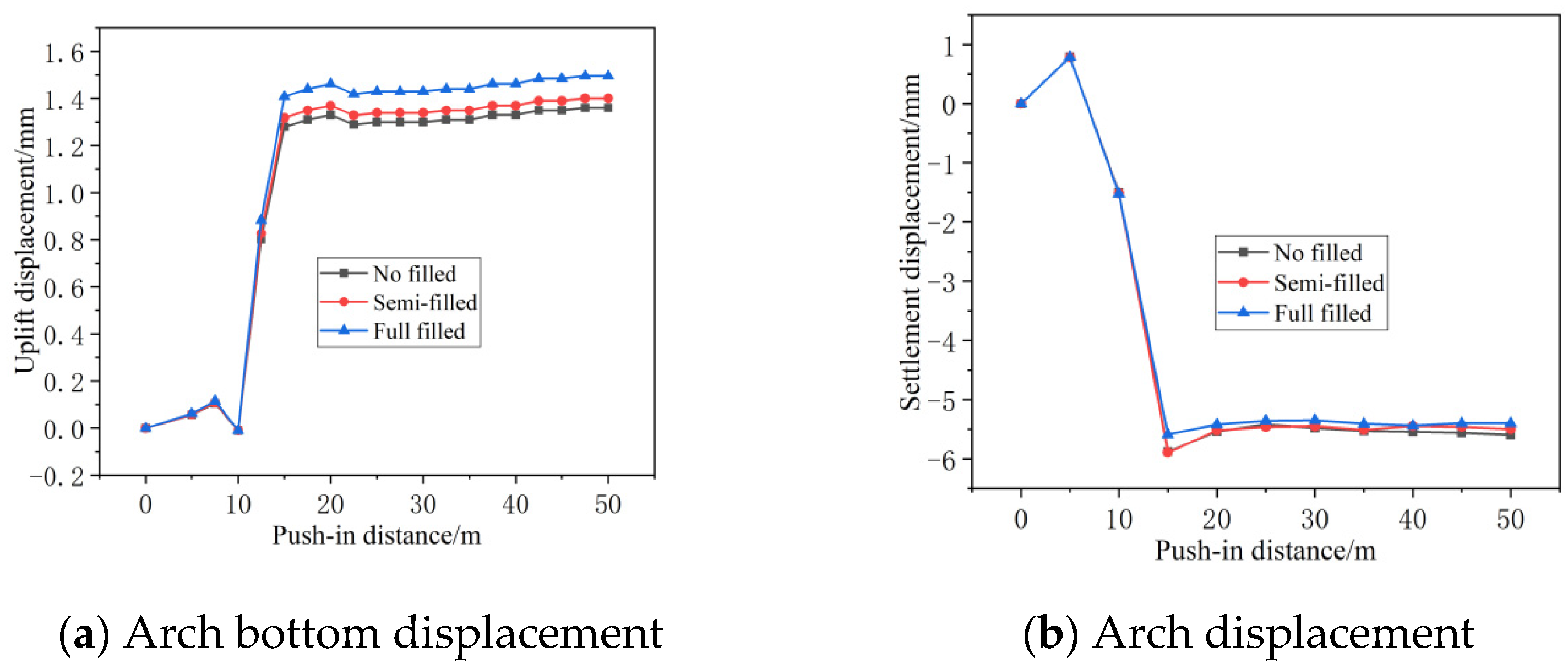

4.1.3. Influence of Backfill Condition on Tunnel Surrounding Rock Displacement

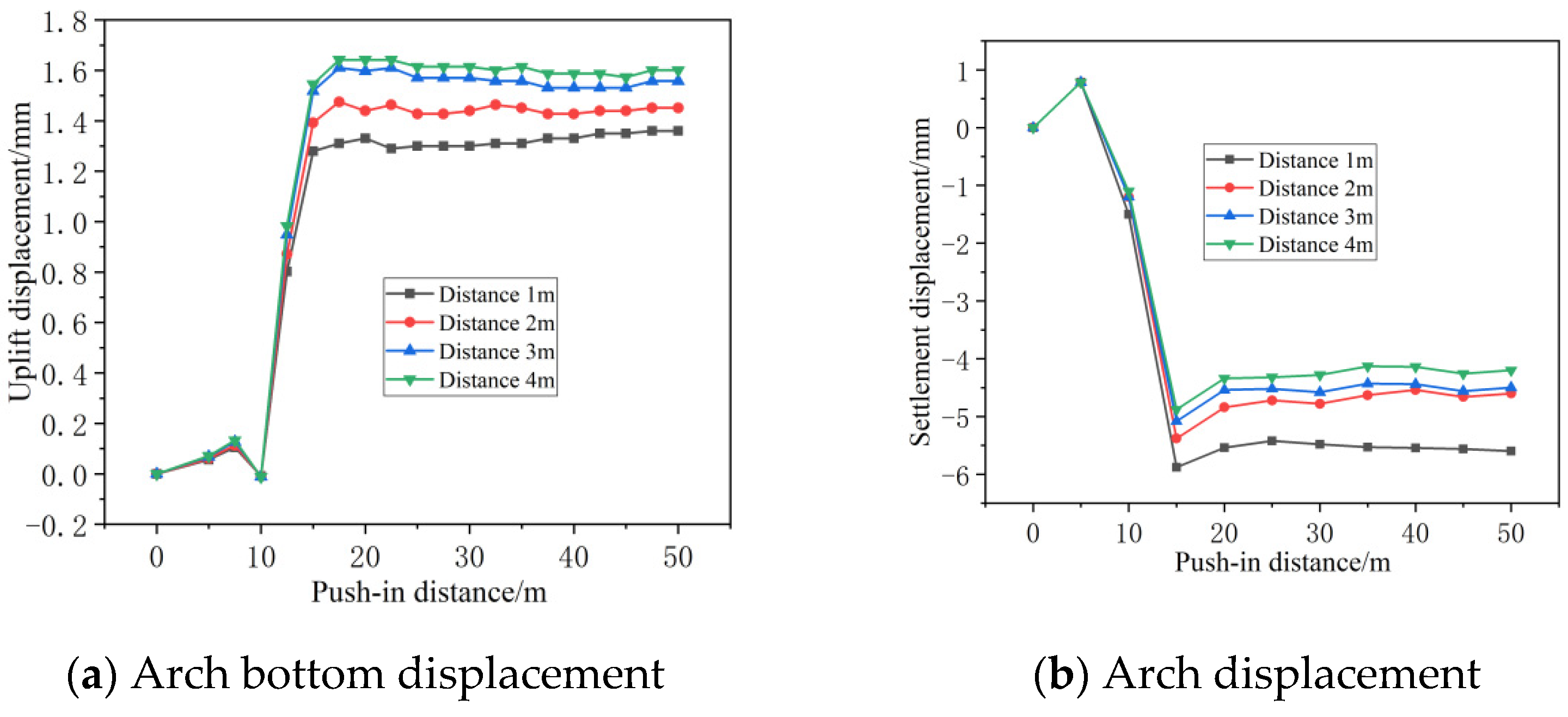

4.1.4. Influence of Spacing Between Karst Cavities and Tunnels on Surrounding Rock Displacement

4.2. Analysis of Surrounding Rock Stress Response

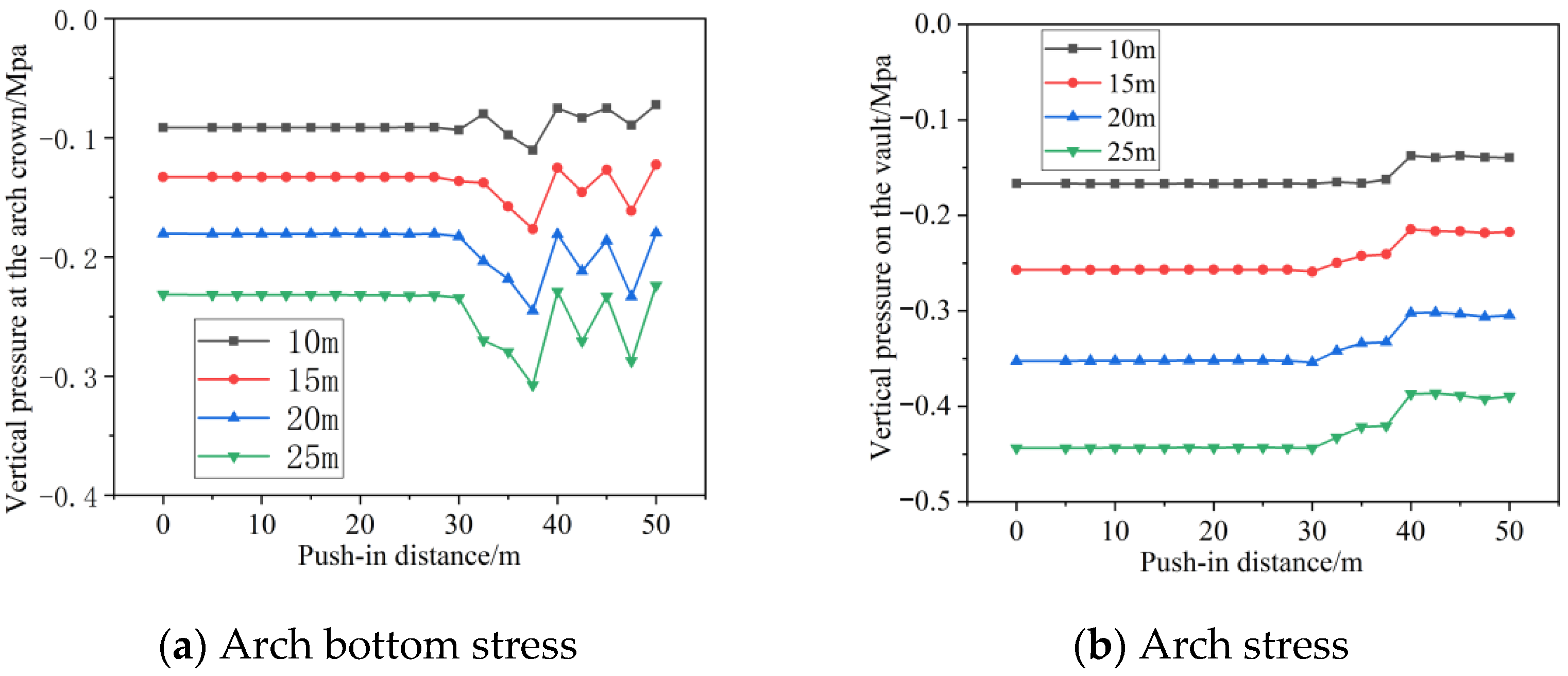

4.2.1. Effect of Tunnel Burial Depth on Surrounding Rock Stress

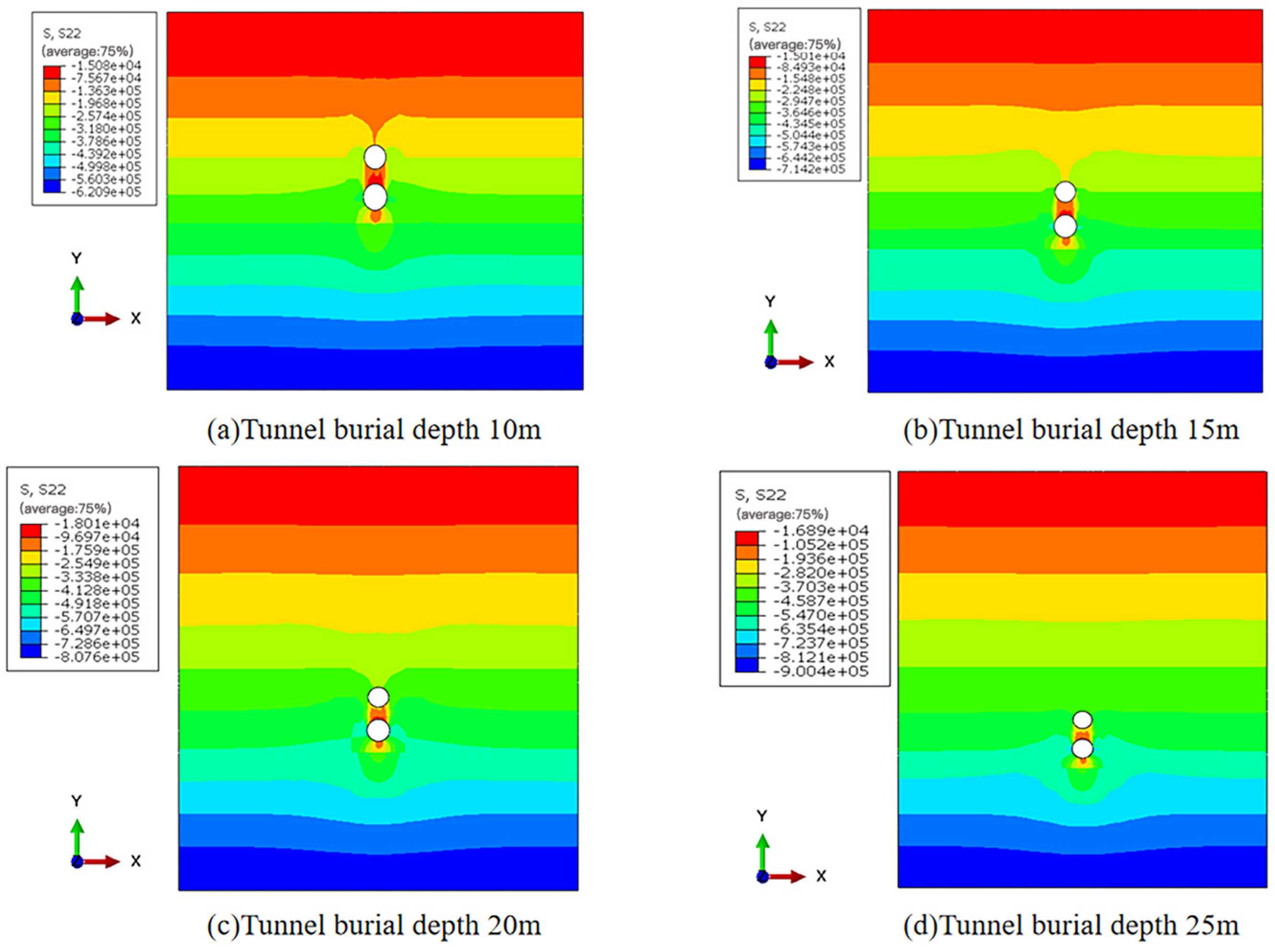

4.2.2. Influence of Cave Size on Tunnel Rock Mass Stress

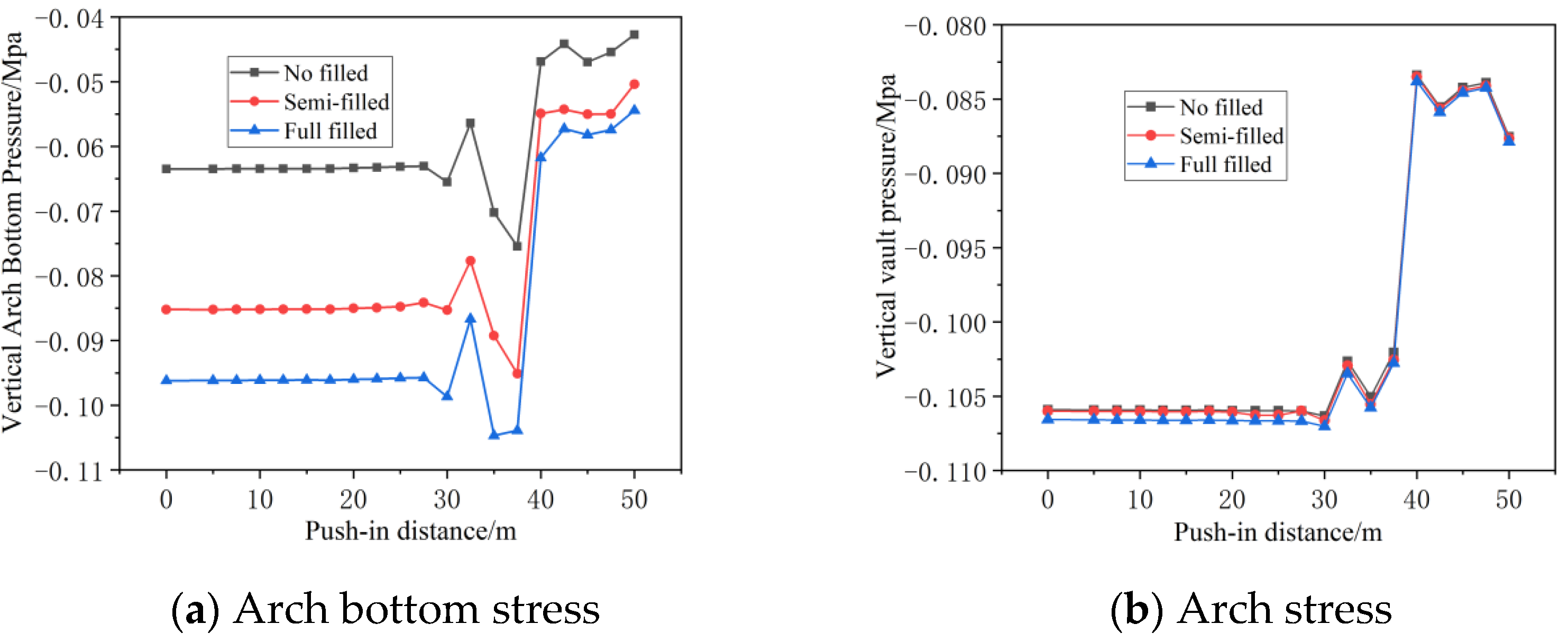

4.2.3. Influence of Backfill Condition on Tunnel-Surrounding Rock Stress

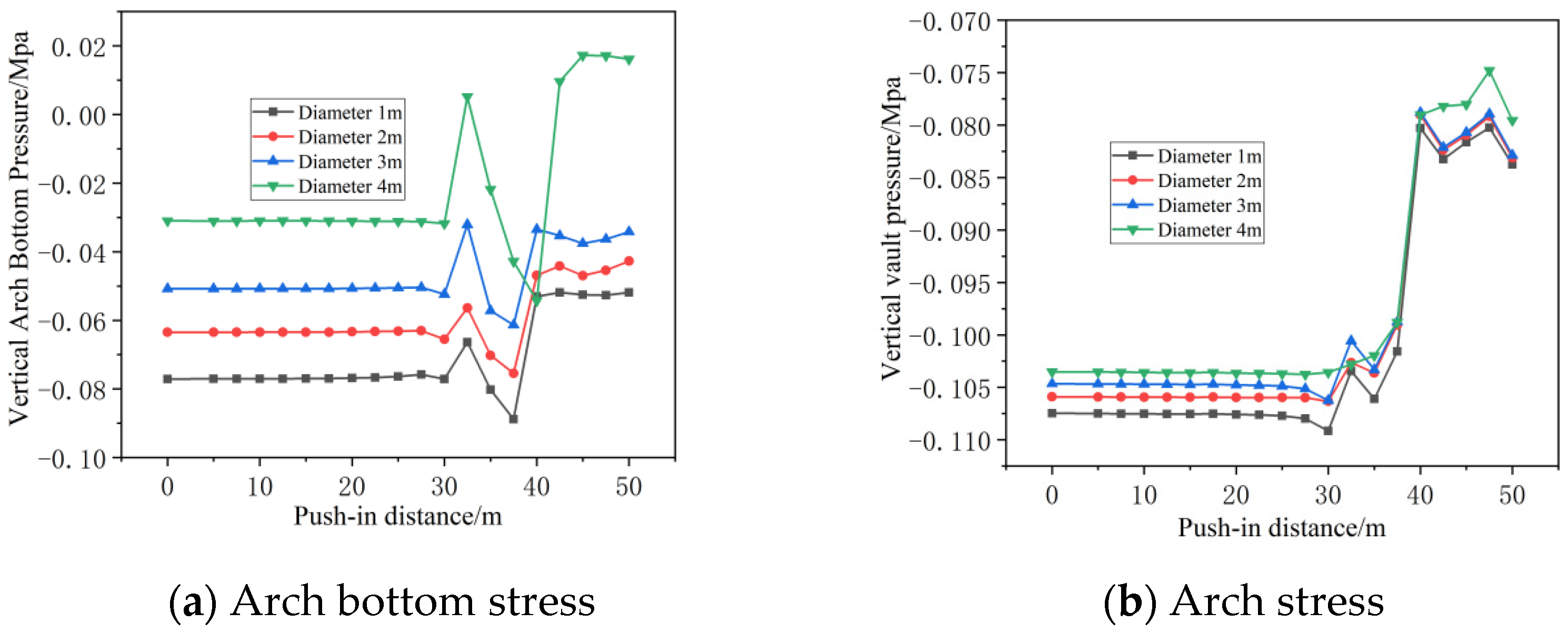

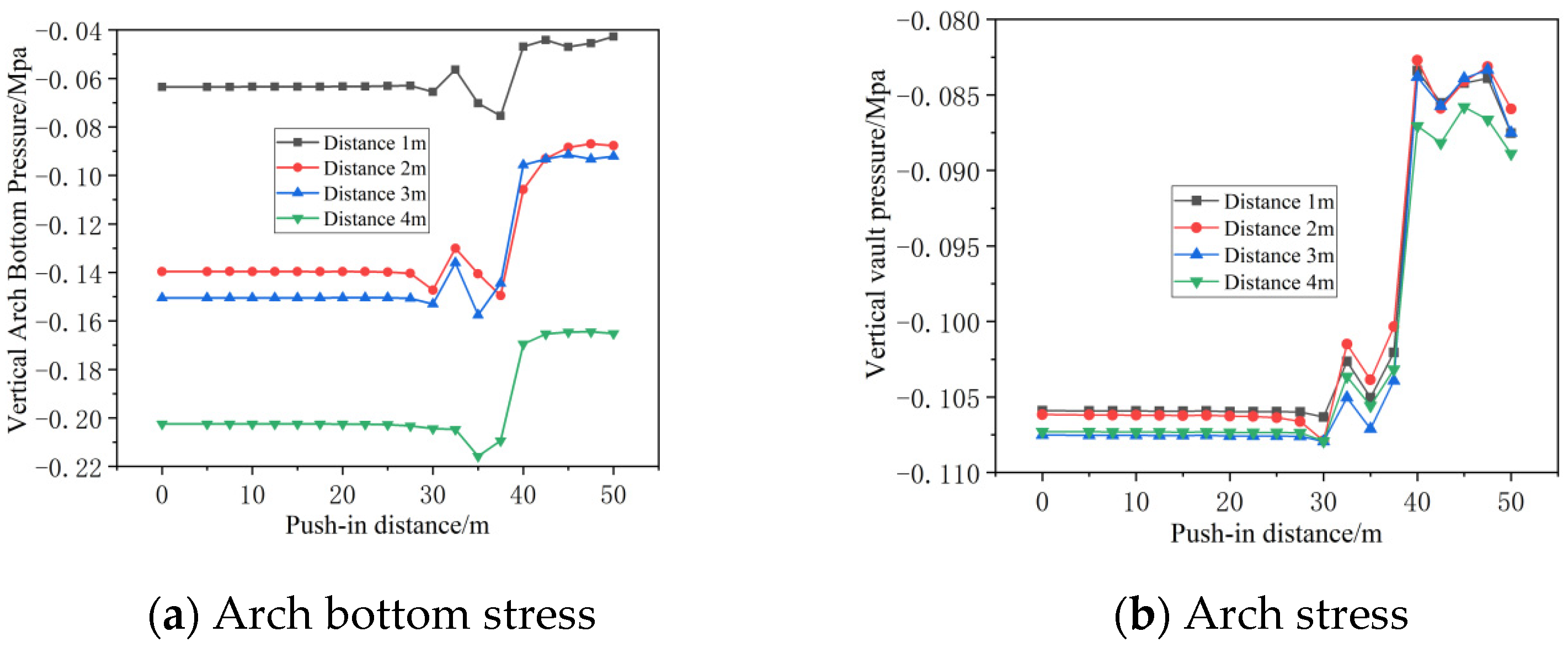

4.2.4. Effect of Spacing Between Karst Cavities and Tunnels on Surrounding Rock Stress

4.3. Pipe Section Displacement Response Analysis

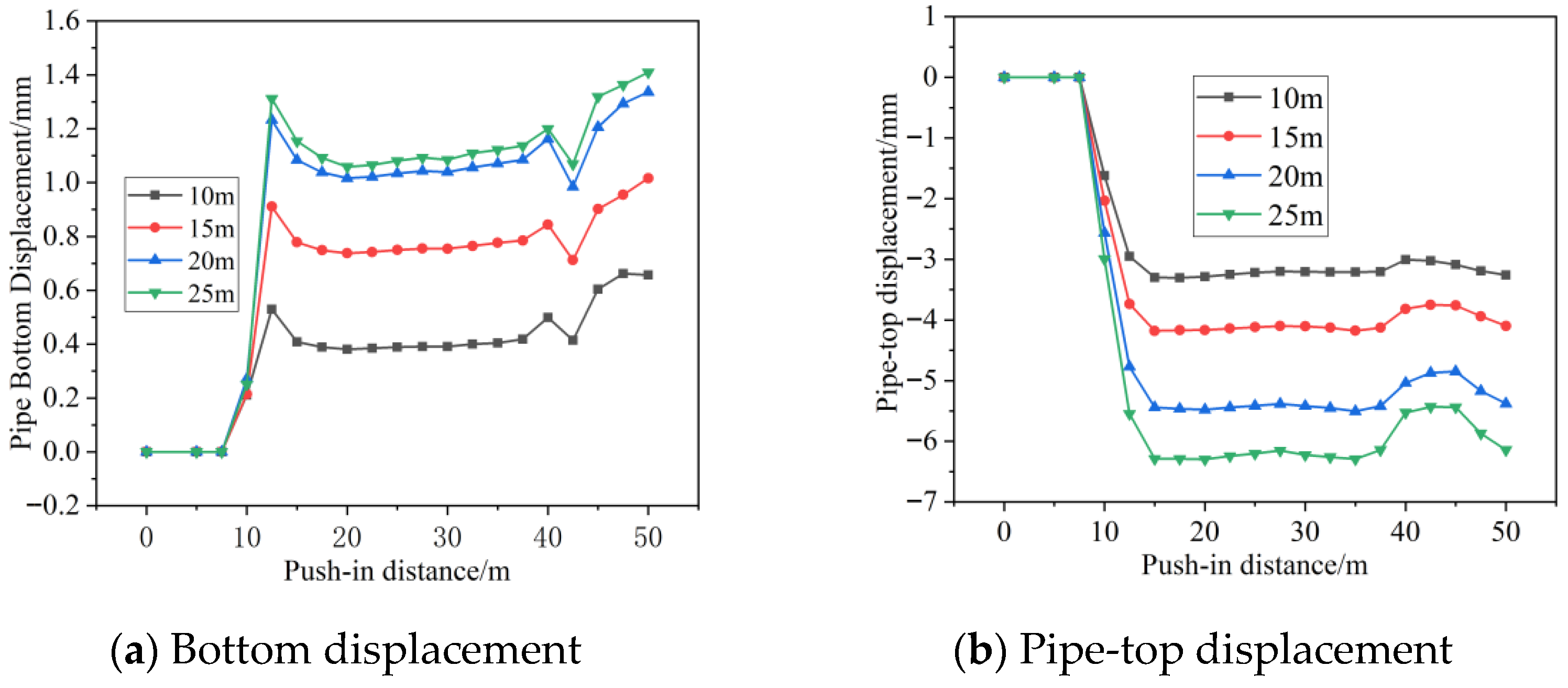

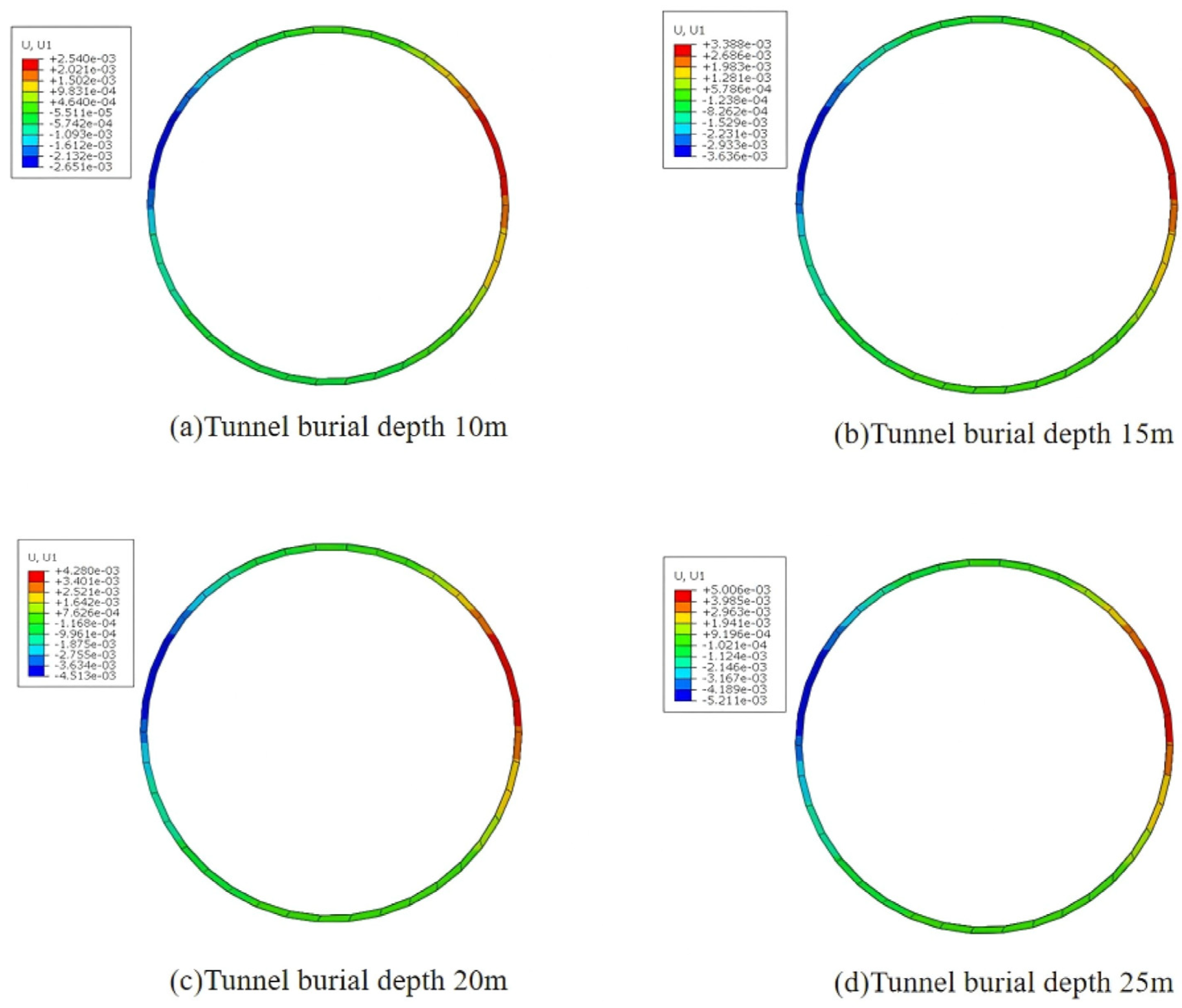

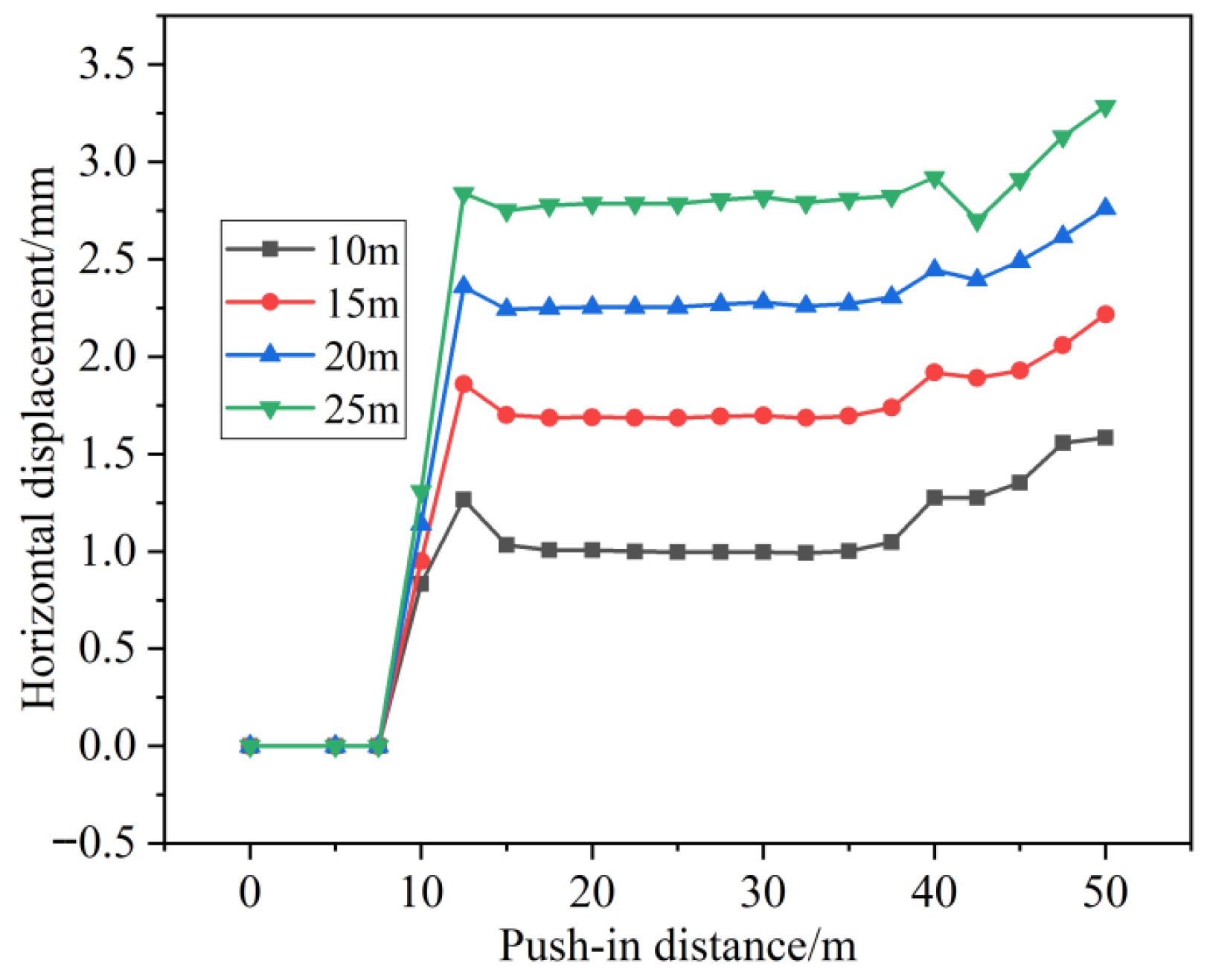

4.3.1. Effect of Tunnel Burial Depth on Segment Displacement

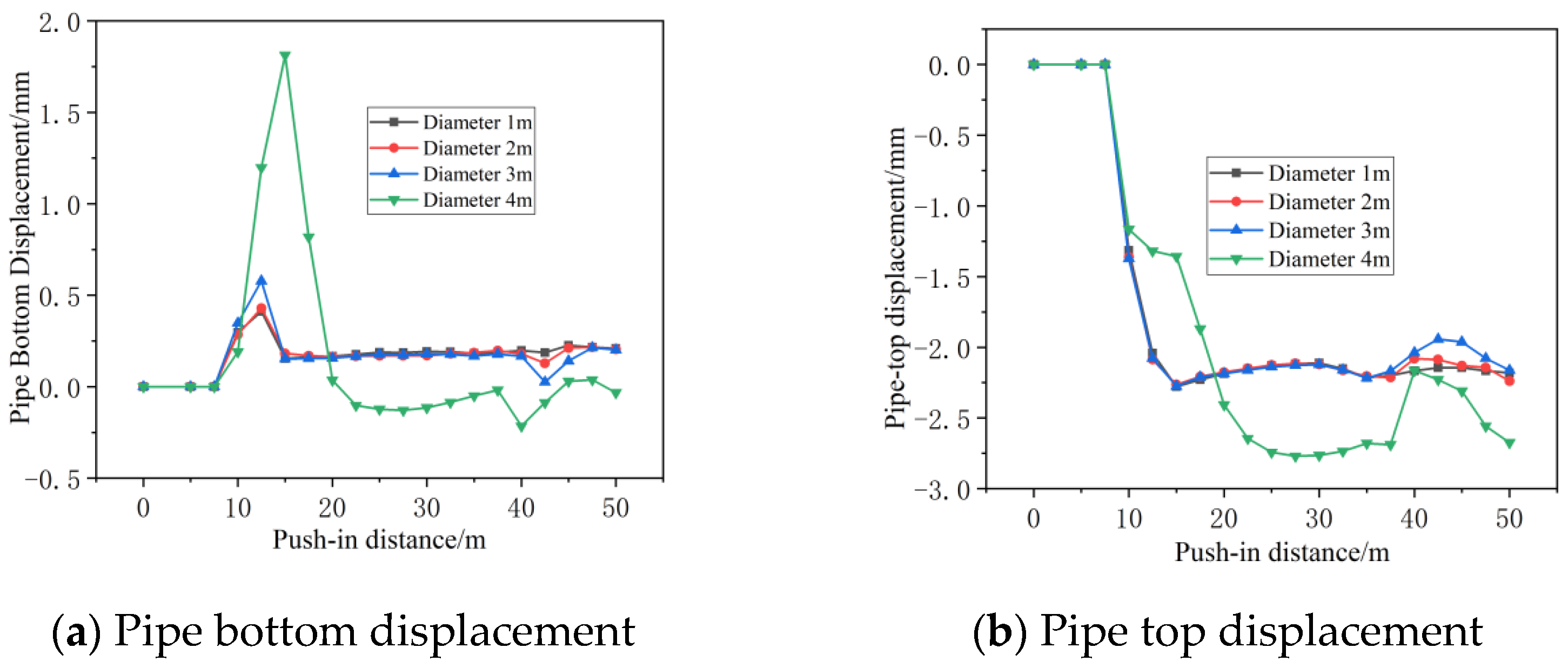

4.3.2. Effect of Cave Size on Segment Displacement

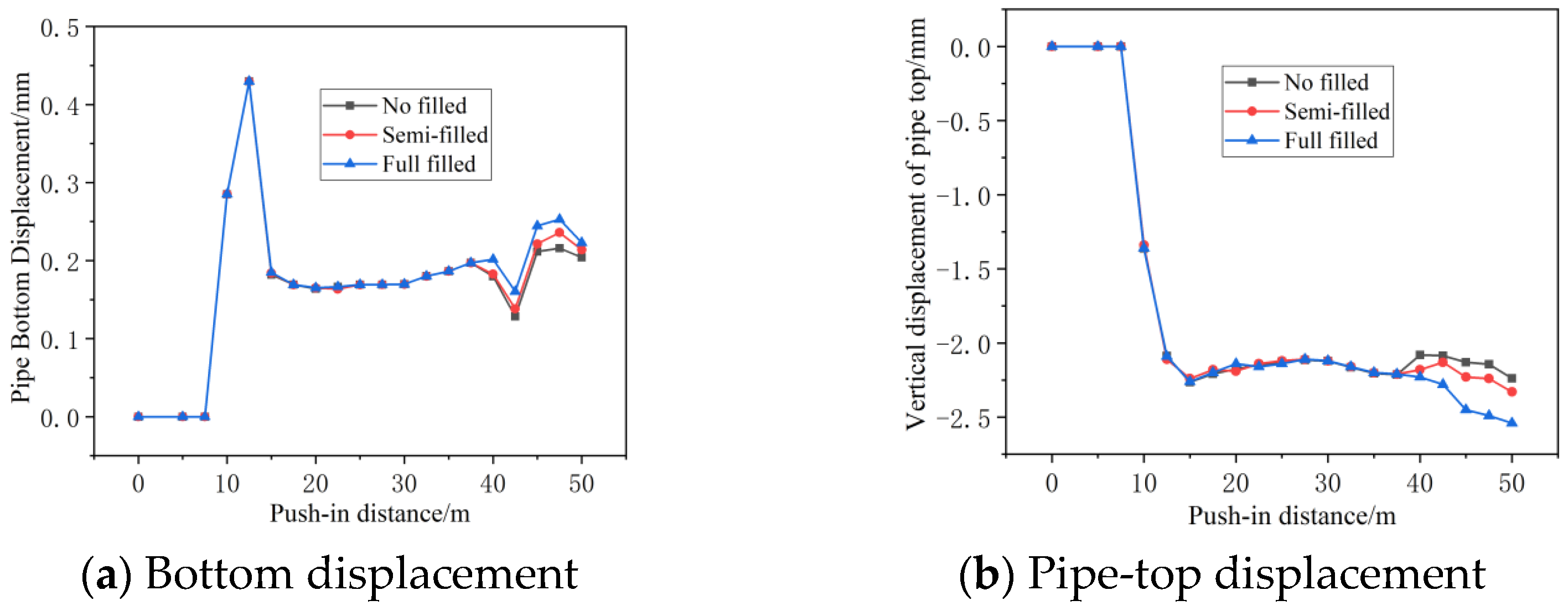

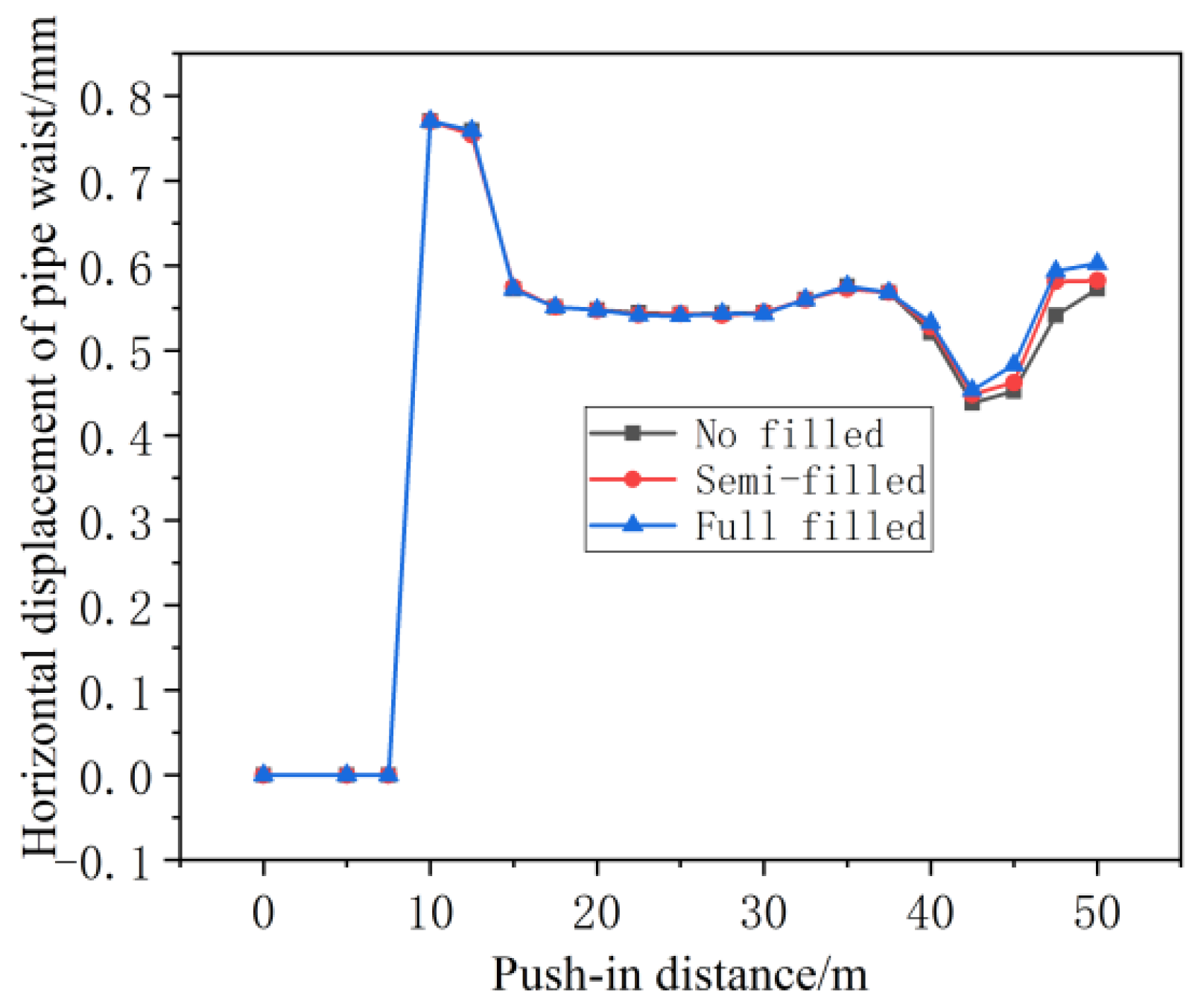

4.3.3. Effect of Grout Filling Condition on Segment Displacement

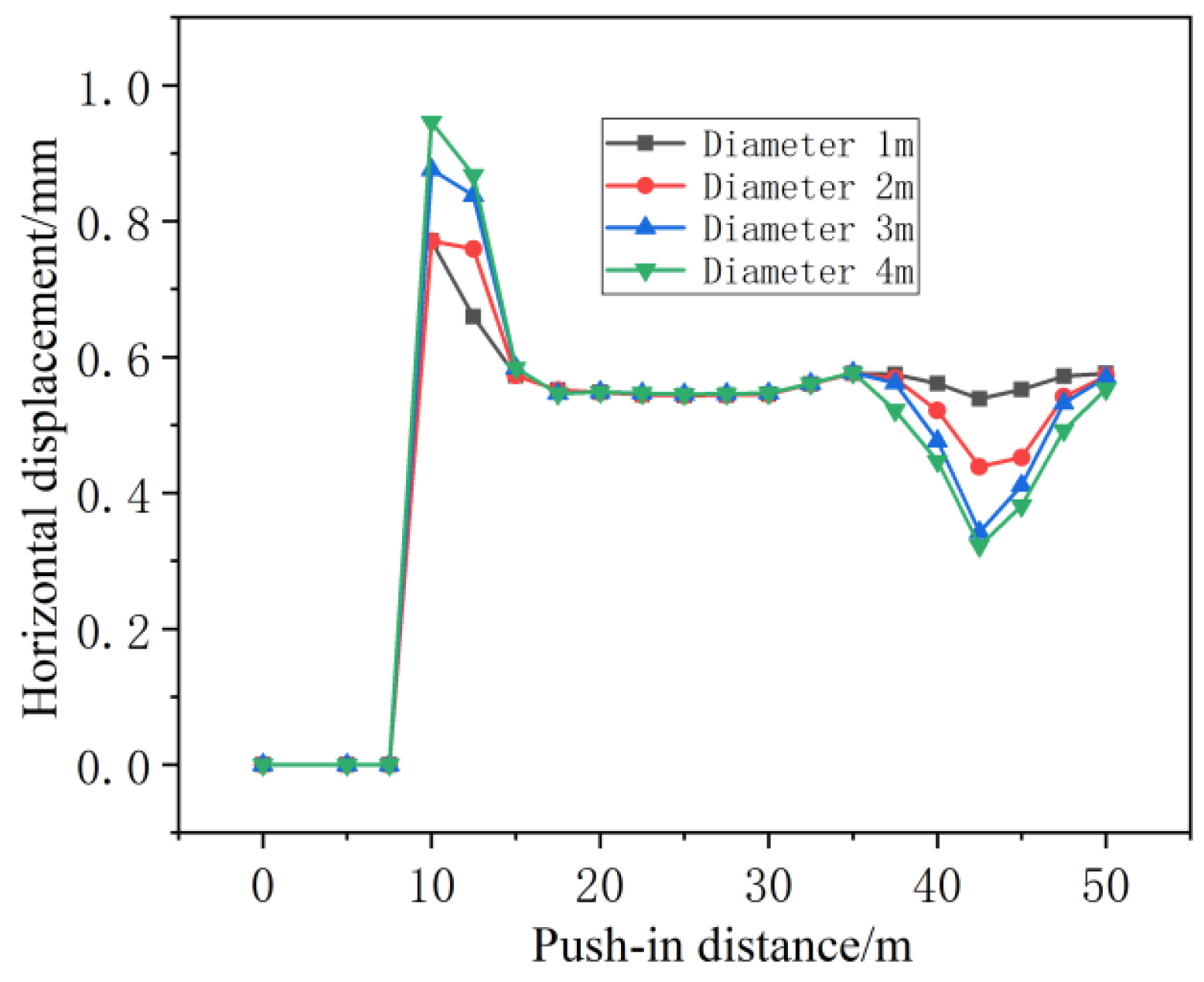

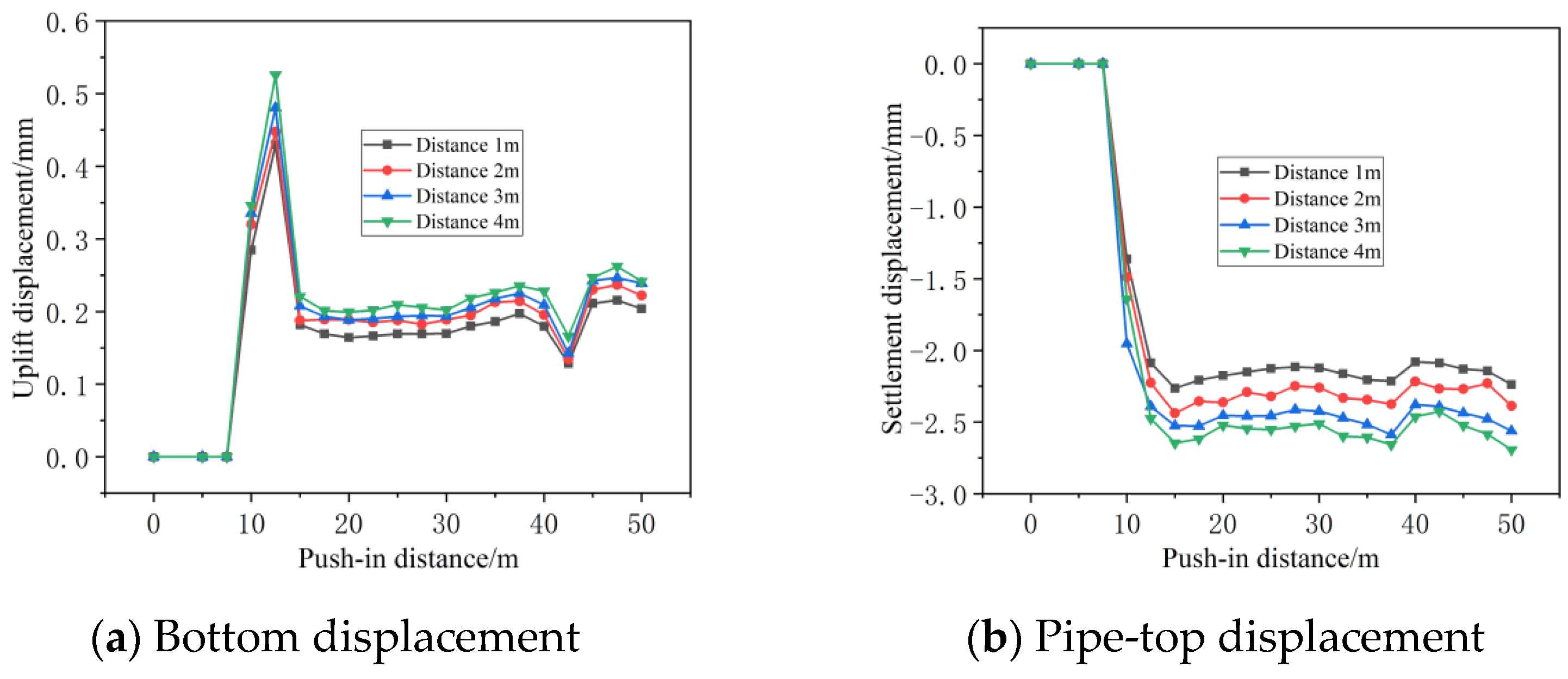

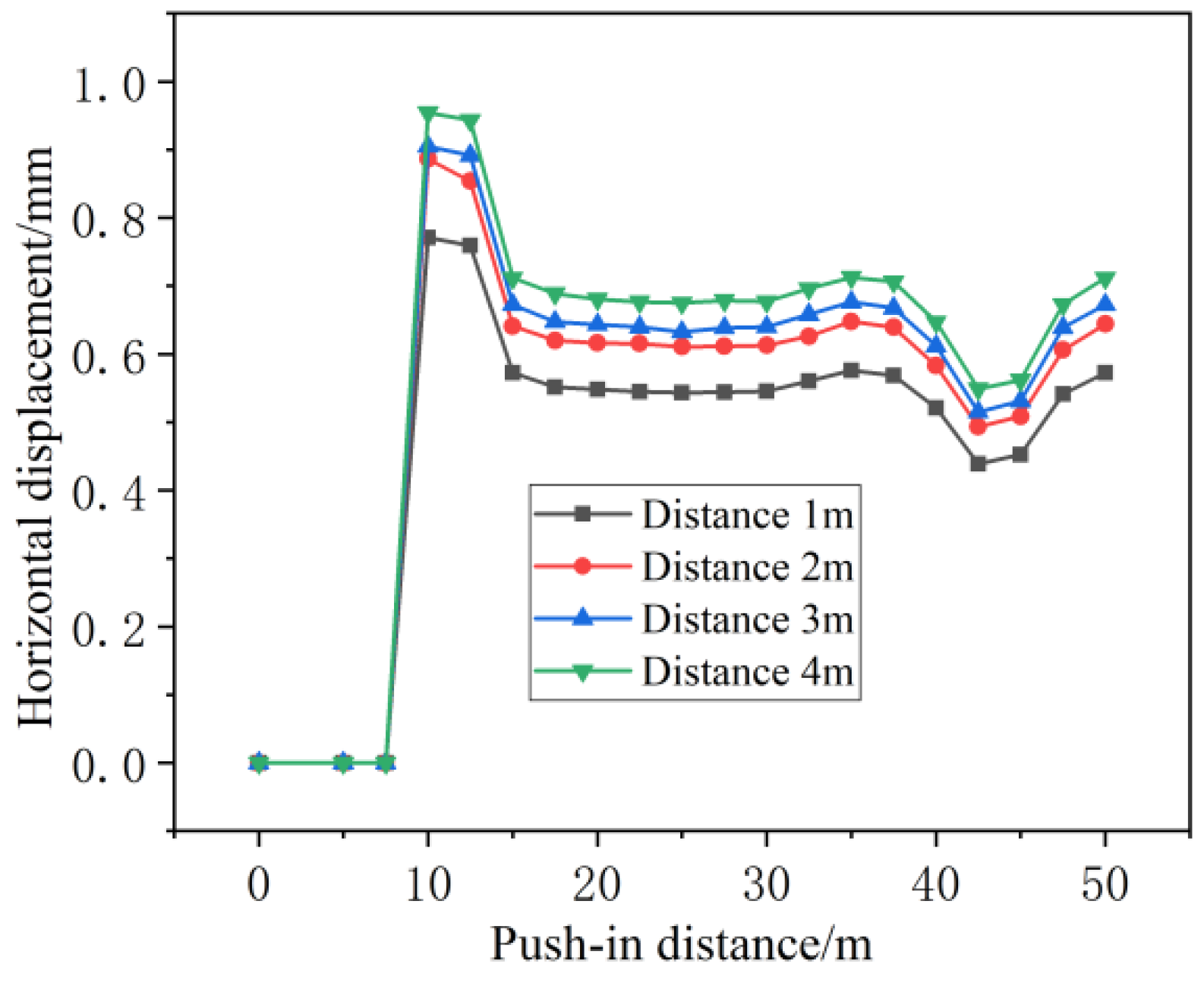

4.3.4. Effect of Spacing Between Karst Cavities and Tunnels on Segment Displacement

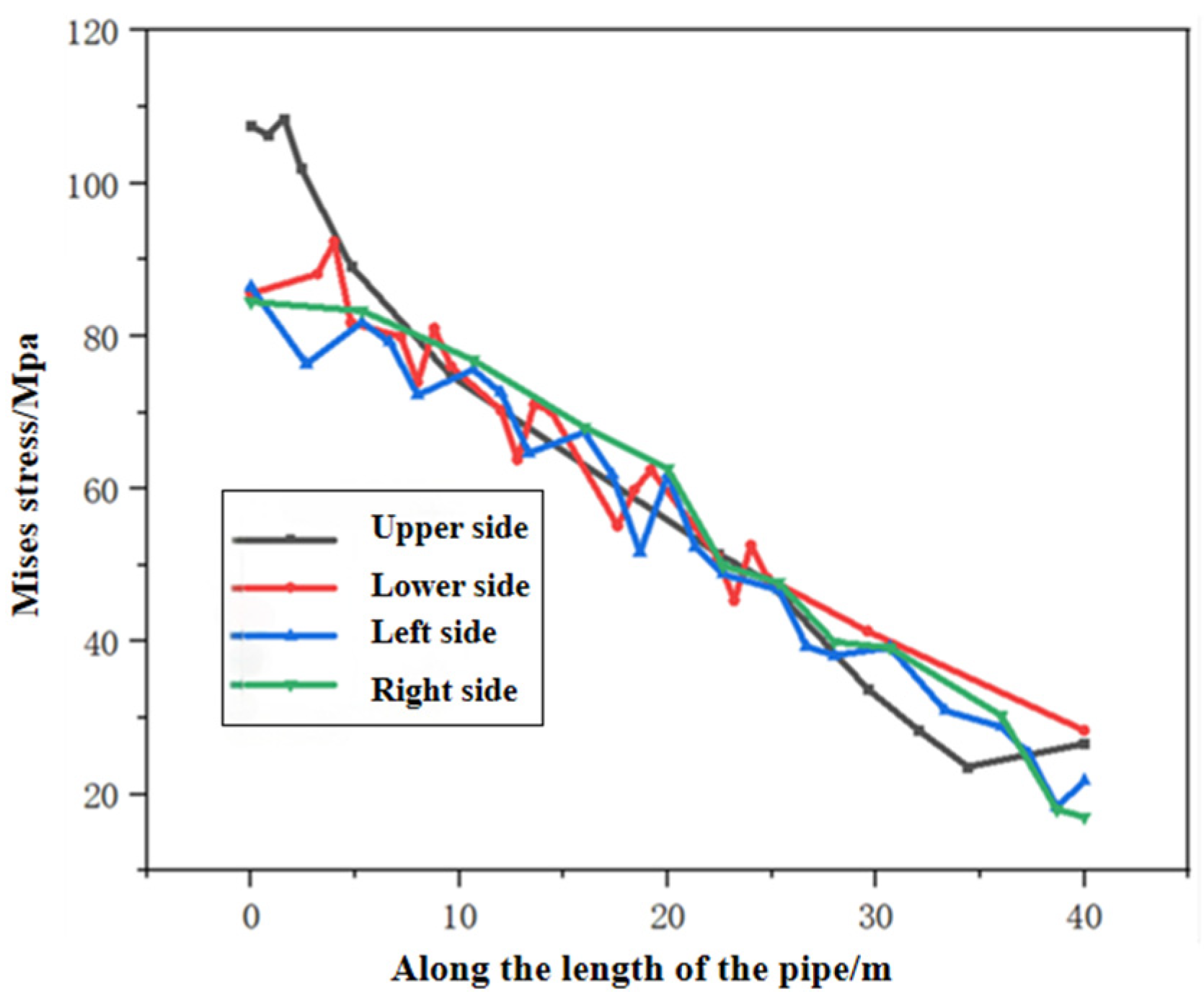

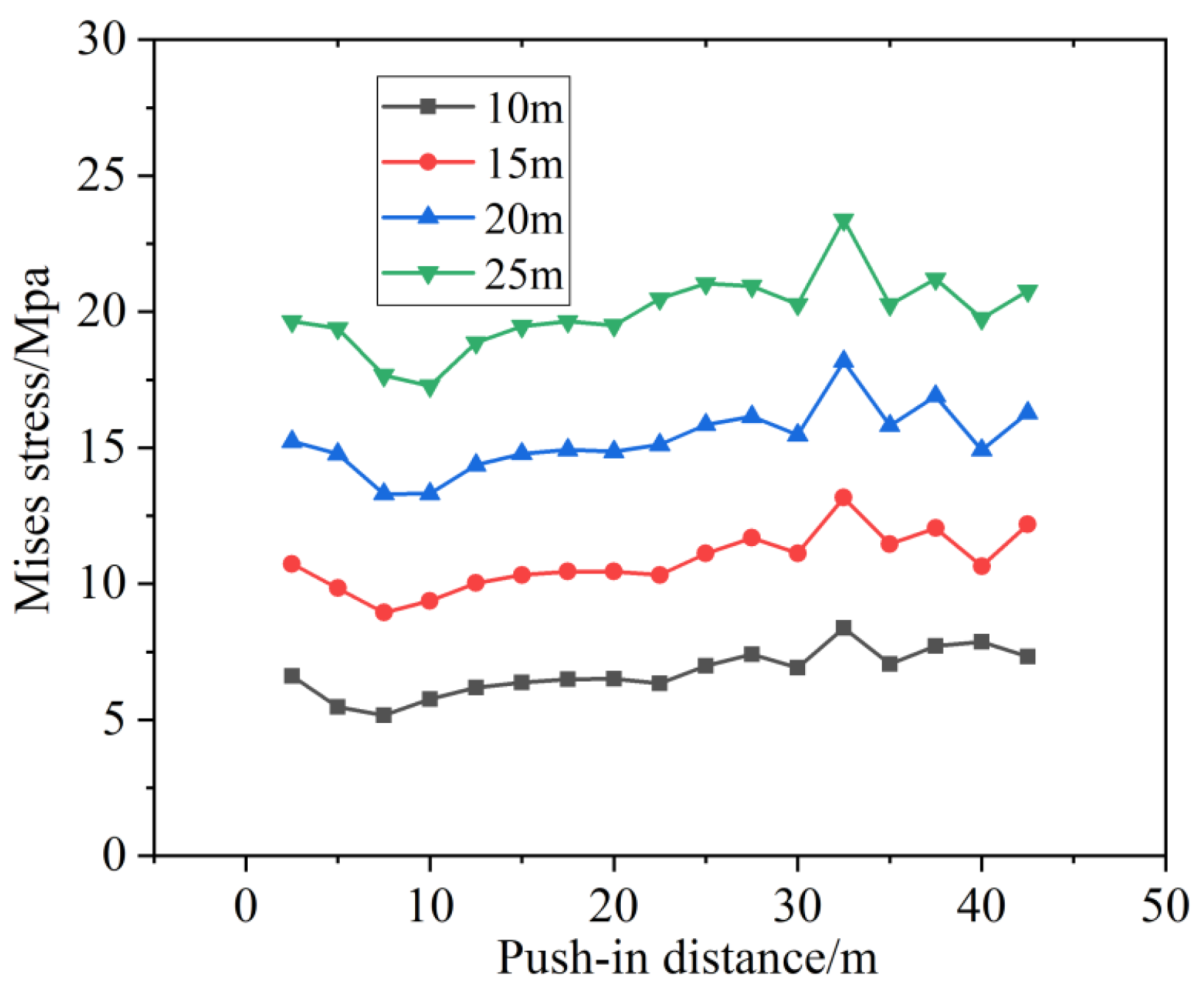

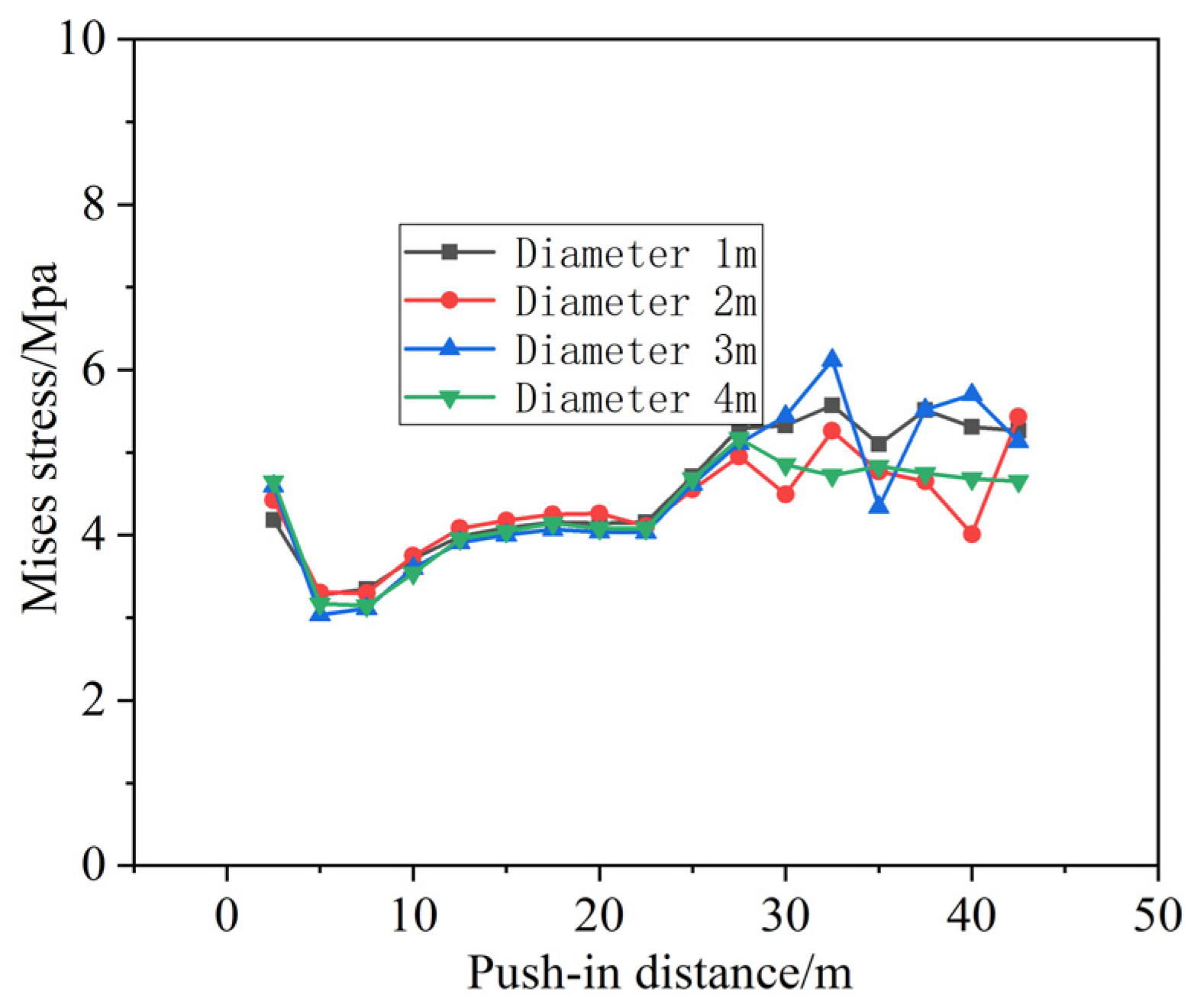

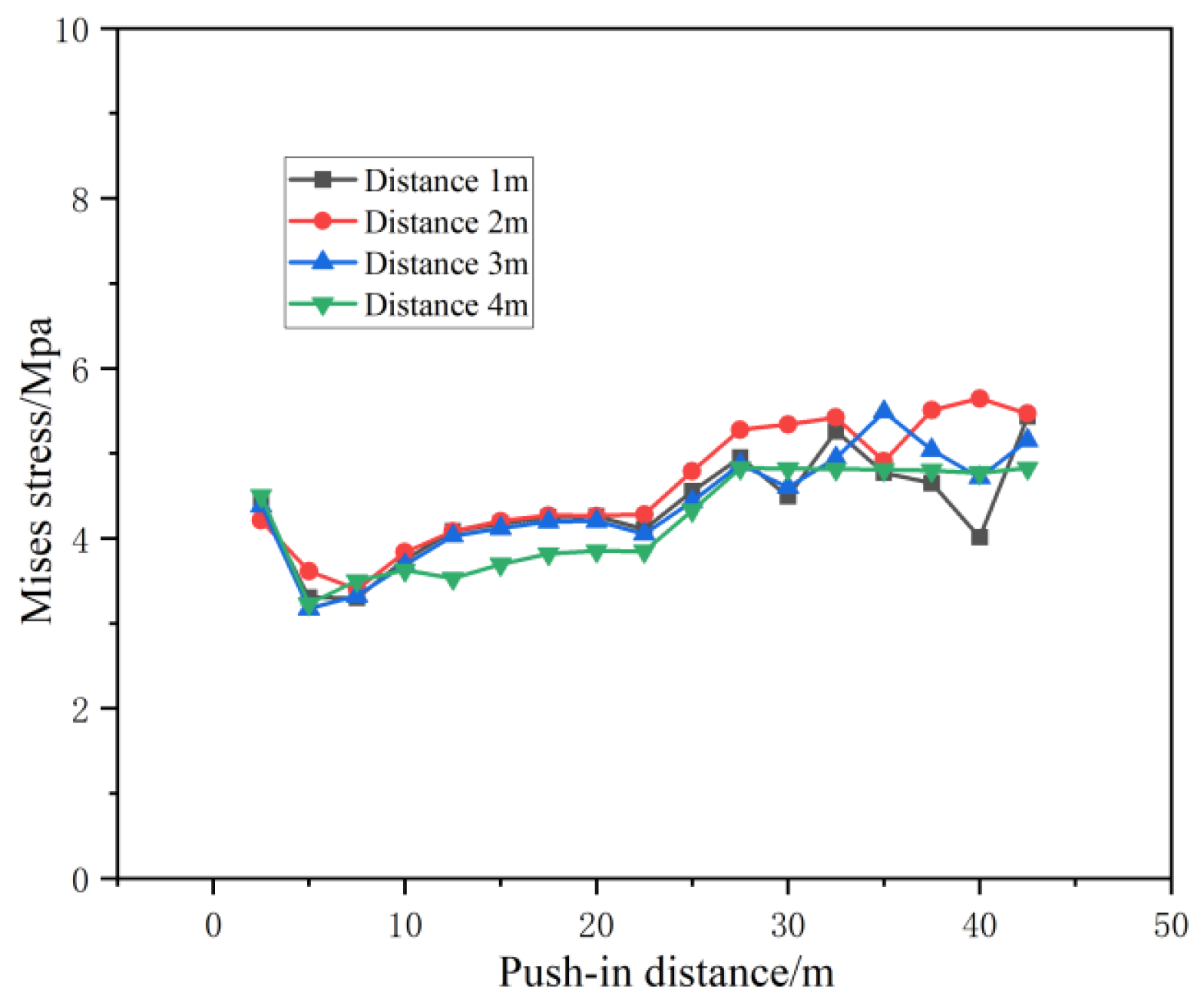

4.4. Stress Response Analysis of Pipe Sections

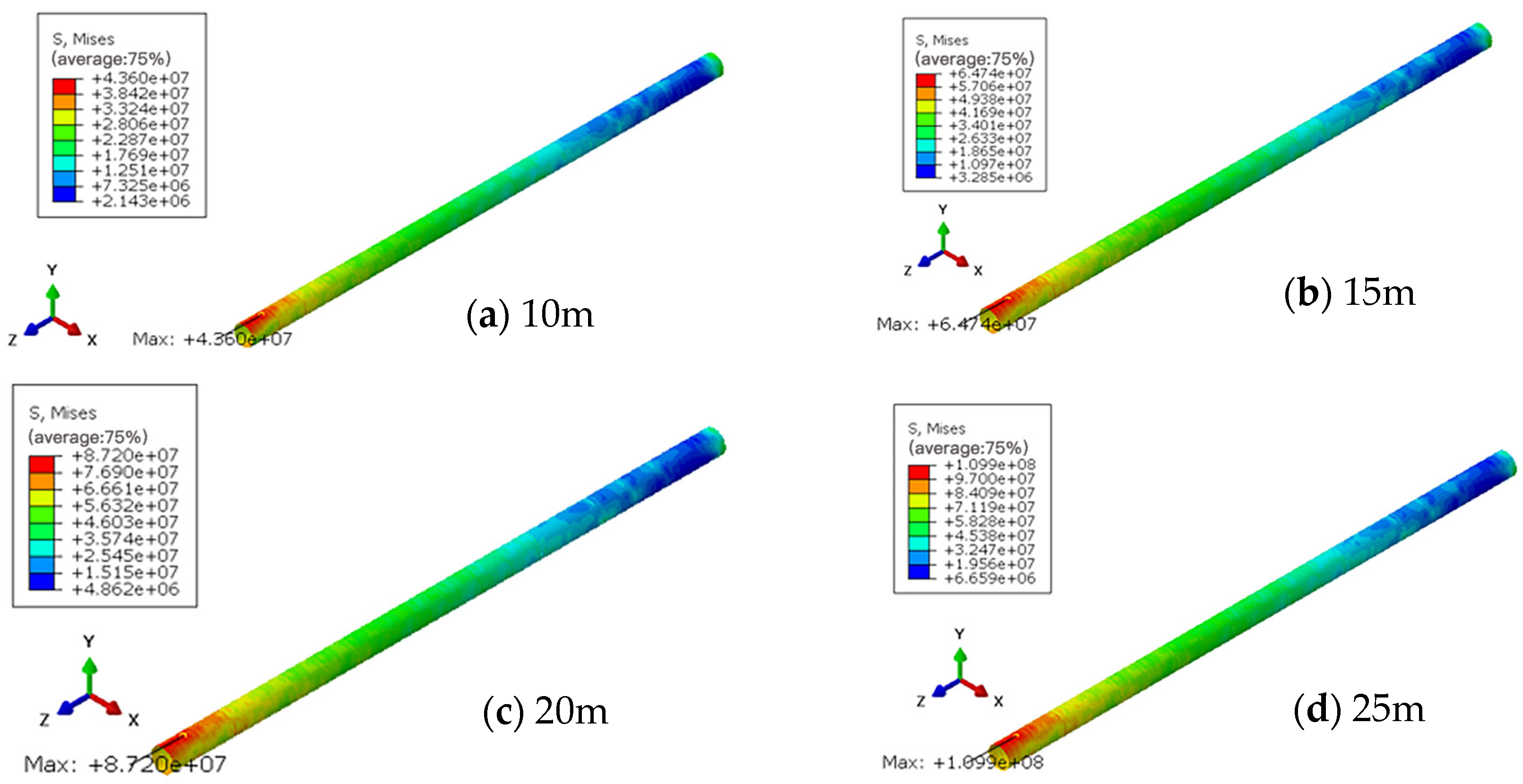

4.4.1. Effect of Tunnel Burial Depth on Segment Stress

4.4.2. Effect of Cave Size on Segment Stress

4.4.3. Effect of Filling Conditions on Segment Stress

4.4.4. Effect of Spacing Between Karst Cavities and Tunnels on Segment Stress

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sterling, R.L. Developments and research directions in pipe jacking and microtunneling. Undergr. Space 2020, 5, 1–19. [Google Scholar] [CrossRef]

- Sha, F.; Zhang, M.; Dong, Y.; Wang, Q.; Ni, L. A review on the key factors influencing the stability of shield tunneling. KSCE J. Civ. Eng. 2025, 29, 100266. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, X.; Liu, X.; Hao, J.; Wang, B. Numerical analysis of influence of karst caves beside the tunnel on stability of its surrounding rock mass. J. Chongqing Jianzhu Univ. 2003, 25, 6–11. [Google Scholar]

- Zhao, M.; Liu, X.; Hao, J.; Wang, B. Numerical analysis of influence of karst caves in top of tunnel on stability of surrounding rock masses. Rock Soil Mech. 2003, 24, 445–449. [Google Scholar]

- Zhao, M.; Hao, J.; Liu, X.; Wang, B. Model testing research on influence of karst cave size on stability of surrounding rock masses during tunnel construction. Chin. J. Rock Mech. Eng. 2004, 23, 213–217. [Google Scholar]

- Zhao, M.; Xu, R.; Xu, X. Deformation modeling of surrounding-rock during full-face excavation of tunnel in karst regions. J. Tongji Univ. 2004, 32, 710–715. [Google Scholar]

- Zheng, Y.; He, S.; Yu, Y.; Zheng, J.; Zhu, Y.; Liu, T. Characteristics, challenges and countermeasures of giant karst cave: A case study of Yujingshan tunnel in high-speed railway. Tunn. Undergr. Space Technol. 2021, 114, 103988. [Google Scholar] [CrossRef]

- Cheng, W.C.; Cui, Q.L.; Shen, J.S.L.; Arulrajah, A.; Yuan, D.-J. Fractal prediction of grouting volume for treating karst caverns along a shield tunneling alignment. Appl. Sci. 2017, 7, 652. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, A.; Pan, Y.; Shen, S.L. Measurement and prediction of tunnelling-induced ground settlement in karst region by using expanding deep learning method. Measurement 2021, 183, 109700. [Google Scholar] [CrossRef]

- Tang, Z.Z.; Fan, H.J.; Yi, X.; Zou, L. Numerical analysis of influence of cavity distribution sites on the stability of the tunnel. Highw. Eng. 2013, 38, 198–201. [Google Scholar]

- Li, J.; Chen, Q.; Huang, X.; Zou, G.; Deng, J. Pretreatment for Tunnel Karst Cave during Excavation: A Case Study of Guangxi, China. Adv. Civ. Eng. 2021, 2021, 9013815. [Google Scholar] [CrossRef]

- Yang, X.L.; Huang, F. Collapse mechanism of shallow tunnel based on nonlinear Hoek-Brown failure criterion. Tunn. Undergr. Space Technol. 2011, 26, 686–691. [Google Scholar] [CrossRef]

- Li, Z.Q.; Nie, L.; Xue, Y.; Li, W.; Fan, K. Model testing on the processe, characteristics, and mechanism of water inrush induced by karst caves ahead and alongside a tunnel. Rock Mech. Rock Eng. 2025, 58, 5363–5380. [Google Scholar] [CrossRef]

- Cheng, W.C.; Ni, C.; Huang, H.W.; Shen, J.S. The use of tunnelling parameters and spoil characteristics to assess soil types: A case study from alluvial deposits at a pipejacking project site. Bull. Eng. Geol. Environ. 2019, 78, 2933–2942. [Google Scholar] [CrossRef]

- Su, X.; Lai, J.; Ma, E.; Xu, J.; Qiu, J.; Wang, W. Failure mechanism analysis and treatment of tunnels built in karst fissure strata: A case study. Eng. Fail. Anal. 2025, 167, 109048. [Google Scholar] [CrossRef]

- Liu, D.; Liu, M.; Sun, H.; Liu, R.; Lu, X. Detection and comprehensive treatment for giant karst caves under the tunnel floor: A case study in Guangxi, China. Environ. Earth Sci. 2024, 83, 650. [Google Scholar] [CrossRef]

- Coli, M.; Castellucci, P. Karst and tunnelling: A reverse impact case history. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 062050. [Google Scholar] [CrossRef]

- Peng, P.; Peng, F.; Sun, Z.; Zhang, D. Grouting for tunnel stability control and inadequate grouting section recognition: A case study of countermeasure of giant karst cave. Appl. Sci. 2022, 12, 11895. [Google Scholar] [CrossRef]

- Tan, D.M.; Qi, T.Y.; Mo, Y.C. Numerical analysis and research on surrounding rock stability of lateral karst cave tunnels. Chin. J. Rock Mech. Eng. 2009, 28, 3497–3503. [Google Scholar]

- Wang, Z.; Tang, L.; Jiang, X.Z.; Hou, W.M.; Xu, H.Y.; Ji, X.F. Model test on stability of large cross-section highway tunnel adjacent to caverns. Tunn. Constr. 2019, 39, 16–24. [Google Scholar]

- Liu, D.Y.; Xie, B.; Li, Z.; Sun, X.H. Numerical analysis on influence of concealed karst caverns upon stability of metro shield tunnel. Tunn. Constr. 2020, 40, 151–160. [Google Scholar]

- Huang, F.; Zhao, L.; Ling, T.; Yang, X. Rock mass collapse mechanism of concealed karst cave beneath deep tunnel. Int. J. Rock Mech. Min. Sci. 2017, 91, 133–138. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, Q.; Wan, W.; Wang, W.; Chen, B. Fluid-solid coupling analysis of rock pillar stability for concealed karst cave ahead of a roadway based on catastrophic theory. Int. J. Min. Sci. Technol. 2014, 24, 737–745. [Google Scholar] [CrossRef]

- Wang, Z.G.; Liu, M.; Yu, Y.T.; Xu, S.; Xu, C.J.; Zheng, F.Q.; Huang, W.H.; Wu, Z.L.; Wan, J.X. Analysis of influence of tunnel through karst cave on deformationand internal force of lining structure. Hydropower Water Resour. 2024, 55, 435–446. [Google Scholar]

- Li, K.; Duan, Z.; Guo, D.P.; Zeng, B.; Wang, Q. Study on influence of different azimuth angles of concealed karst caveon the stress characteristics of tunnel lining tructure. Mod. Tunn. Technol. 2023, 60, 74–85. [Google Scholar]

- Hou, Y.; Zhang, D.; Luo, J.; Yang, Y.; Yang, Z. Damage mechanisms of cave stratum in water-rich karst areas induced by tunneling. Sci. China Technol. Sci. 2025, 68, 1620702. [Google Scholar] [CrossRef]

- Shabanimaschcool, M.; Bhasin, R. Three Dimensional Numerical Modelling of a Large Cavity Formed in an Underground Complex in a Hydropower Plant in the Himalayas. In Proceedings of the Paper presented at the 14th ISRM Congress, Foz do Iguaçu, Brazil, 16–18 September 2019. [Google Scholar]

- Guo, S.L.; Yan, C.H.; Yu, L.C.; Yan, C.; Li, H.; Xu, Y. Characteristics of shallow buried karst and its safety distance to tunnel in Wuxi city, Jiangsu province. J. Nanjing Univ. (Nat. Sci.) 2023, 59, 890–899. [Google Scholar]

- Huang, F.; Wang, D.; Feng, Y.; Zhang, M. Prediction of the Collapse Region Induced by a Concealed Karst Cave above a Deep Highway Tunnel. Adv. Civ. Eng. 2020, 8825262, 14. [Google Scholar] [CrossRef]

- Chen, K.; Ren, S.; Li, Z.; Chen, Z.; Yu, B.; Zhang, H. Investigation on the seepage-stress field evolution mechanism and failure process of karst tunnels in water-rich areas. Environ. Earth Sci. 2024, 83, 1–19. [Google Scholar] [CrossRef]

- Dong, B.; Yang, T.; Ju, B.; Qu, Z.; Yi, C. Analysis of the influence of karst cave parameters on surface settlement in TBM tunnelling. Bull. Pol. Acad. Sci.-Tech. Sci. 2024, 72, e150110. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, X.G.; Yang, S.; Chen, Y. Research on the impact of karst cave relative angle on tunnel surrounding rock deformation. Sci. Technol. Innov. 2025, 6, 161–164. [Google Scholar]

- Eric, A.C.D.; Özgür, A.; Haluk, T. Levent Stability charts for the collapse of residual soil in Karst. Geotech. Geoenviron. Eng. 2009, 135, 925–931. [Google Scholar]

- Gao, Z.C.; Cao, M.Q. Study on the influence of karst cavity location on the stability of surrounding rock at the portal of a cross-pressure tunnel. West. China Commun. Sci. Technol. 2024, 12, 137–140. [Google Scholar]

- Augarde, C.E.; Lyamin, A.V.; Sloan, S.W. Prediction of undrained sinkhole collapse. Geotech. Geoenviron. Eng. 2003, 129, 197–205. [Google Scholar] [CrossRef]

- Li, J.; Guo, D.; Wang, Y.; Qiu, Y.; Deng, F.; Chen, X.; Chen, H. Analysis of additional stress on the surrounding rock during a Large Diameter Shield Passing Through the Areas with Karst Strongly Developed. In Application and Development of Data Simulation and Mechanical Analysis in Civil Engineering ICCE 2024; Feng, G., Zhang, B., Wang, X.Y., Zhao, J., Almerich-Chulia, A., Eds.; Sustainable Civil Infrastructures; Springer: Cham, Switzerland, 2025. [Google Scholar]

- Mu, X.Y.; Li, C.L.; Zhang, F. Deformation characteristics for shallow karst sections during tunnel-entering construction. Transp. Sci. Technol. 2024, 6, 121–125. [Google Scholar]

- Mou, X.Y.; Zhang, F.; Li, C.L. Investigating the factors influencing the mechanical behavior of tunnel lining Structures in karst Regions. J. Transp. Eng. 2024, 24, 56–62+81. [Google Scholar]

- Phoon, K.K.; Shuku, T.; Ching, J. (Eds.) Uncertainty, Modeling, and Decision Making in Geotechnics; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Yang, Z.P.; Hou, S.M.; Zhang, Y.M.; Gao, Y.H.; Liu, X.R. Energy evolution and constitutive model for damage of degraded limestone undercoupling effects of hydrodynamic-stress-chemical corrosion. Chin. Ournal Geotech. Eng. 2025, 47, 759–768. [Google Scholar]

- Gao, H.Y.; Zhang, M. Statistical regularity of physical and mechanical indexes of secondary red clay in Chenggong district, Kunming. Coal Geol. Explor. 2021, 49, 174–181. [Google Scholar]

- Li, B.Q.; Atkinson, B.K. Stress corrosion cracking of quartz: A note on the influence of chemical environment. Tectonophysics 1981, 77, 1–11. [Google Scholar] [CrossRef]

- Saber, M.; Dez Vareh, G.; Bazzaz Zadeh, R. Corrosion prediction using the weight loss model in sewer pipes. Constr. Build. Mater. 2019, 199, 40–49. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, G.; Zhao, T.T.; Zhang, W.Y.; Hu, F.; Zhou, W. FDEM simulation for granular materials based on exact scaling and coarse granulation. Chin. J. Geotech. Eng. 2024, 46, 2371–2379. [Google Scholar]

| Name | Severe /kN·m−3 | Internal Friction Angle/(°) | Cohesion /kPa | Poisson Ratio | Modulus of Elasticity /MPa | Thickness (m) |

|---|---|---|---|---|---|---|

| Plain fill | 18.6 | 8.5 | 19 | 0.4 | 19.2 | 2 |

| Red clay | 18.3 | 11.5 | 40 | 0.3 | 20.7 | 5.5 |

| Strongly weathered limestone | 24 | 20 | 150 | 0.3 | 8000 | 5 |

| Moderately weathered limestone | 27.1 | 30 | 300 | 0.25 | 10,000 | 12.5 |

| Equivalent circle zone | 11 | - | - | 0.2 | 5 | - |

| Pipe section | 78.5 | - | - | 0.25 | 210,000 | - |

| Unit Type | Precision | Analysis Time | Contact Analysis |

|---|---|---|---|

| C3D8 | Poor | Short | Applicable |

| C3D8R | Accurate | Short | Applicable |

| C3D20 | Accurate | Long | Not applicable |

| C3D20R | Accurate | Long | Not applicable |

| Name | Bulk Density/(kN·m−3) | Modulus of Elasticity/MPa | Poisson Ratio |

|---|---|---|---|

| Soft plastic clay | 15 | 20 | 0.30 |

| Mud | 11 | 60 | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Xie, J.; Liu, K.; Xu, Z.; Zhan, H.; Zhang, H. Analysis of the Influence of Underlying Karst Caves on the Stability of Pipe Jacking Construction Based on the Finite Element Method. Eng 2025, 6, 334. https://doi.org/10.3390/eng6120334

Wang D, Xie J, Liu K, Xu Z, Zhan H, Zhang H. Analysis of the Influence of Underlying Karst Caves on the Stability of Pipe Jacking Construction Based on the Finite Element Method. Eng. 2025; 6(12):334. https://doi.org/10.3390/eng6120334

Chicago/Turabian StyleWang, Duozhi, Jianbin Xie, Kewen Liu, Zan Xu, He Zhan, and Haonan Zhang. 2025. "Analysis of the Influence of Underlying Karst Caves on the Stability of Pipe Jacking Construction Based on the Finite Element Method" Eng 6, no. 12: 334. https://doi.org/10.3390/eng6120334

APA StyleWang, D., Xie, J., Liu, K., Xu, Z., Zhan, H., & Zhang, H. (2025). Analysis of the Influence of Underlying Karst Caves on the Stability of Pipe Jacking Construction Based on the Finite Element Method. Eng, 6(12), 334. https://doi.org/10.3390/eng6120334