1. Introduction

Biodiesel, a renewable and sustainable alternative to conventional petroleum-based fuels, has gained increasing attention in recent years, particularly as a substitute for traditional diesel fuel. These advancements in biodiesel technology are driven by global efforts to reduce dependency on fossil fuels and mitigate environmental impacts. Although the military is typically exempt from such mandates, the global defense community is increasingly pursuing similar sustainability goals. By doing so, militaries can align with governmental policies and leverage technological advancements for strategic and tactical advantages. In particular, there is a strong desire from the military for edge sustainment, where fuel is produced at the point of need, reducing the need for long supply lines. Additionally, since the military is a significant global consumer of diesel fuel, transitioning to a more sustainable alternative could have a substantial environmental impact.

This review initially presents a high-level overview of biodiesel trends, including discussions on advances in feedstocks and processing techniques. This review then focuses specifically on the various advances that align with the unique needs of the military maritime and ground vehicle communities, the two major military consumers of diesel fuel. These advances are critically analyzed to understand the advantages and technical challenges of militaries shifting to biodiesel.

2. Background of Biodiesel

2.1. History

Biodiesel’s origins trace back to the late 19th century when Rudolf Diesel designed his engine to run on vegetable oils. In 1895, he demonstrated its potential by running an engine on peanut oil at the Munich Exhibition. However, World War I and the petroleum industry’s rise shifted focus away from these fuels [

1,

2]. Interest in biodiesel resurfaced during the 1970s oil crisis and with growing environmental concerns [

3].

By the 1980s, researchers revisited vegetable oils and animal fats as diesel substitutes, leading to renewed testing of Diesel’s original ideas [

4]. The EU’s policies in the mid-1990s and its 2003 biofuel directive further boosted research, development, and global interest in biodiesel [

5]. In the early 21st century, commercial biodiesel production flourished, with advancements in transesterification processes and a variety of feedstocks explored. Despite these advances, biodiesel has typically been blended with conventional diesel to meet performance standards. Recent research has focused on enhancing biodiesel’s properties, engine compatibility, and sustainability, positioning it as a crucial component of future energy strategies [

6,

7].

2.2. Importance of Biodiesel for Sustainability

As the transportation sector moves towards ambitious sustainability goals, it becomes increasingly evident that the approach must involve various solutions. While electric vehicles will encompass a large portion of the transportation market, the weight and cost of the batteries limit their usage [

8]. Moreover, there are numerous markets where a complete overhaul of the vehicles will require several decades, including shipping, agriculture, and commercial trucking. Indeed, a multifaceted strategy encompassing various pathways is essential to effectively mitigate greenhouse gas emissions and diminish reliance on fossil fuels [

9].

Biodiesel is a cornerstone of this eclectic approach, offering a drop-in solution that integrates seamlessly into existing infrastructure without necessitating extensive vehicle modifications. This technical advantage is particularly significant in sectors where retrofitting vehicles or overhauling infrastructure would be prohibitively costly or logistically challenging [

10]. By serving as a direct substitute for conventional diesel fuel, biodiesel facilitates a smoother transition to renewable energy sources, thereby reducing carbon emissions across a broad spectrum of transportation applications [

11].

Biodiesel’s compatibility with existing diesel engines and distribution networks makes it a versatile option for addressing these varied needs. Moreover, its capacity to utilize diverse feedstocks, ranging from soybean oil to recycled cooking oil, enhances its adaptability and resilience within the broader energy landscape [

12]. Therefore, by embracing biodiesel alongside other sustainable fuel options, stakeholders can effectively navigate the technical complexities of the future transportation sector while advancing towards collective sustainability objectives.

2.3. Importance of Biodiesel for the Military

The military currently has two large consumers of diesel fuel—ships and ground vehicles. These two types of vehicles will likely rely on biodiesel in the future, especially as the global market shifts away from traditional diesel. As the world prioritizes sustainability and reduces reliance on fossil fuels, conventional diesel supplies may diminish, making biodiesel a strategic alternative. By adopting biodiesel, militaries can secure a renewable, domestically producible fuel source that reduces dependence on finite petroleum resources, ensuring operational resilience in the face of potential diesel scarcity [

13].

Switching to biodiesel also aligns military institutions with governmental sustainability policies, promoting carbon emission reductions. Although militaries are often exempt from strict regulations, adopting renewable energy signals support for broader environmental goals, enhancing reputation and fostering collaboration with civilian agencies [

14].

Military biodiesel requirements differ from commercial needs due to unique operational challenges. Biodiesel must perform reliably across diverse climates, have a long shelf life for remote storage, and balance low volatility with high combustion efficiency for safety in combat. Its inherent flexibility and local production capability provide strategic advantages, reducing reliance on foreign oil and mitigating supply chain vulnerabilities. Biodiesel’s diverse feedstock options, such as agricultural residues and algae, enhance energy security and operational autonomy by diversifying fuel supply chains [

15].

3. Methodology

3.1. Structure of Review

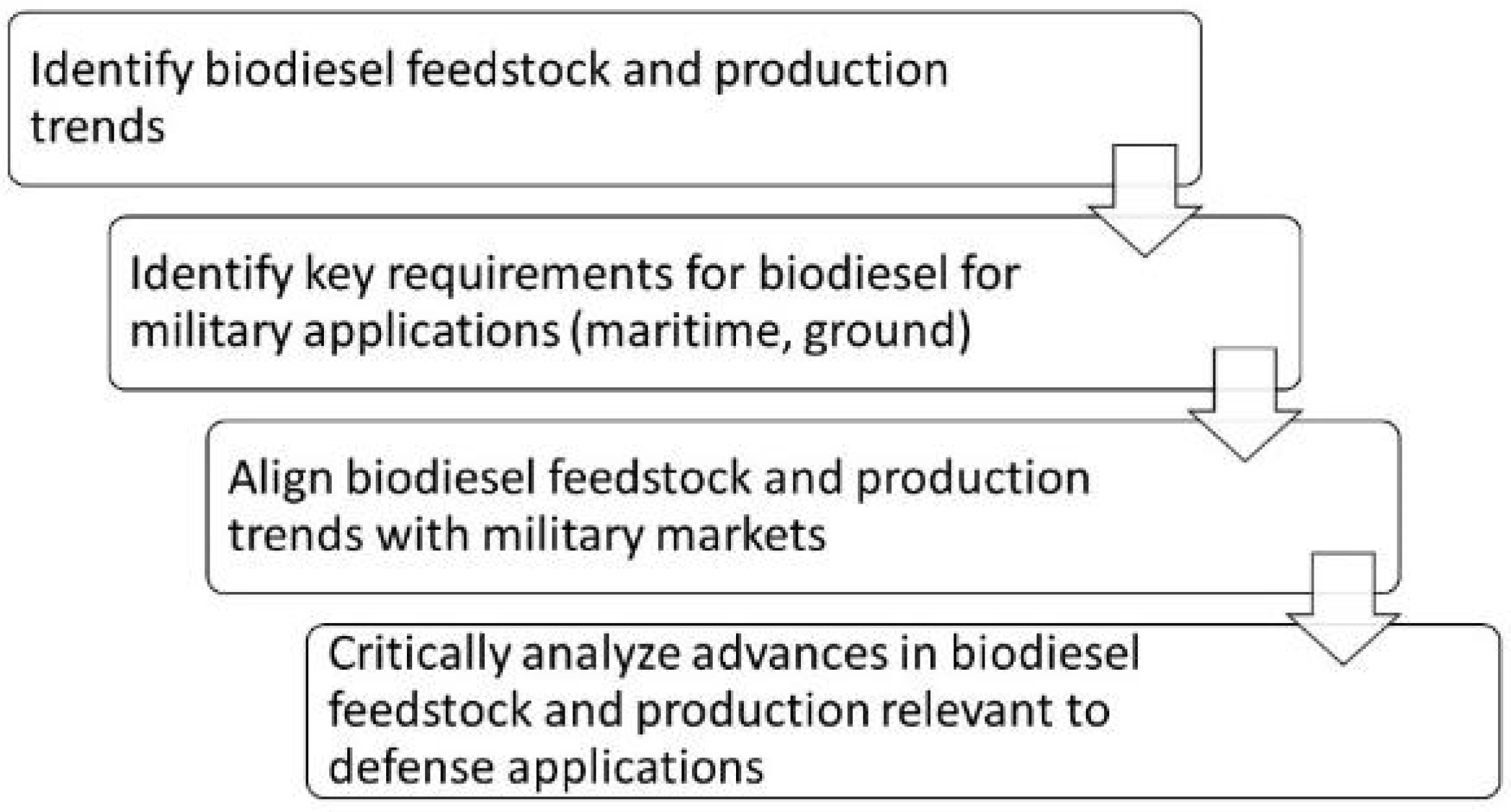

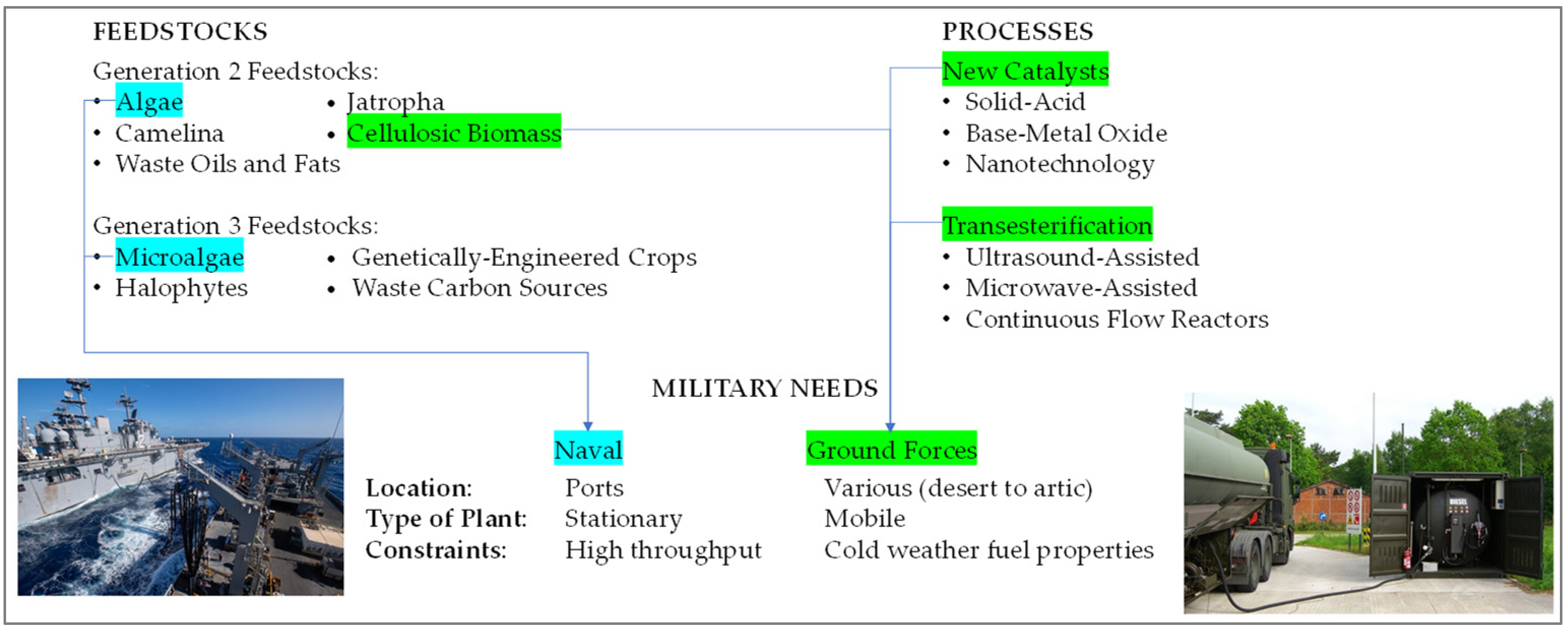

Figure 1 presents the structure for this review. This review uses a methodology common in technology road mapping for analyzing future technologies. First, biodiesel feedstock and production advances are identified at a high level, and major research trends are discussed. This step allows for a comprehensive understanding of the current landscape, facilitating informed decision making regarding biodiesel utilization in military contexts. By staying abreast of emerging trends, the analysis ensures that this review remains relevant and up to date, capturing the latest advancements in biodiesel technology.

Subsequently, essential requirements specific to biodiesel for maritime and ground military applications are identified and analyzed. Understanding the unique needs and constraints of military operations enabled the alignment of biodiesel feedstock and production trends with the demands of military markets. This targeted approach ensures that the study focuses on advancements with the potential to directly benefit military operations, optimizing resource allocation and maximizing the impact of biodiesel integration. By tailoring the analysis to meet military requirements, this review study identifies opportunities to enhance operational efficiency, reduce environmental footprint, and improve energy security, thereby highlighting the strategic advantages of biodiesel adoption in defense applications.

3.2. Comparison to Other Reviews on Biodiesels

Given the importance of biodiesel for future sustainability goals, there are a number of review articles related to the topic. Generally, these reviews fall into one of three categories. First, many reviews analyze biodiesel advances at a high level, highlighting global trends and progress. Such reviews are inherently helpful in understanding the broad scope of research advancements in the field. For example, a review by Mathew et al. discussed the advances in fifteen different feedstocks, highlighting advances in crops, waste, microorganisms, and insect oil [

16]. Similarly, a review by Sales et al. looked over a broad range of different feedstocks with a focus on the geographic dispersion and the research trends related to each type of feedstock through data scraping from 4586 databases [

17].

Second, other studies focus on a specific feedstock or development process associated with biodiesel. In particular, reviews tend to be focused on the development of biodiesel from waste oils and algae, which are two attractive feedstocks for the future of sustainability [

17]. These articles generally focus on the supply aspect of biodiesel.

Third, many of the review articles focus on biodiesel for specific applications and markets, such as for maritime operations [

18] and agriculture [

19]. These articles are typically limited to specific geographic regions where the demand for diesel fuel, whether conventional or from biodiesel, will remain due to a lack of alternative options. These articles focus on the demand side of biodiesel.

This review article differs from the other review articles by narrowing this research down to the defense community, focusing on advances pertinent to military needs. This review does include aspects similar to the three aforementioned review types. It includes a high-level review of different feedstock and production options and then focuses on both the supply and demand of biodiesel specific to military applications.

4. Biodiesel Feedstock Sources

Feedstock refers to the raw materials or resources used in the production of biodiesel, serving as the foundation for the conversion process into a usable fuel. The chemical characteristic of a feedstock that makes it viable for use as biodiesel is a high content of fatty acids, specifically triglycerides. Triglycerides are esters composed of three fatty acid molecules linked to a glycerol molecule. The high fatty acid content supports the biodiesel production process.

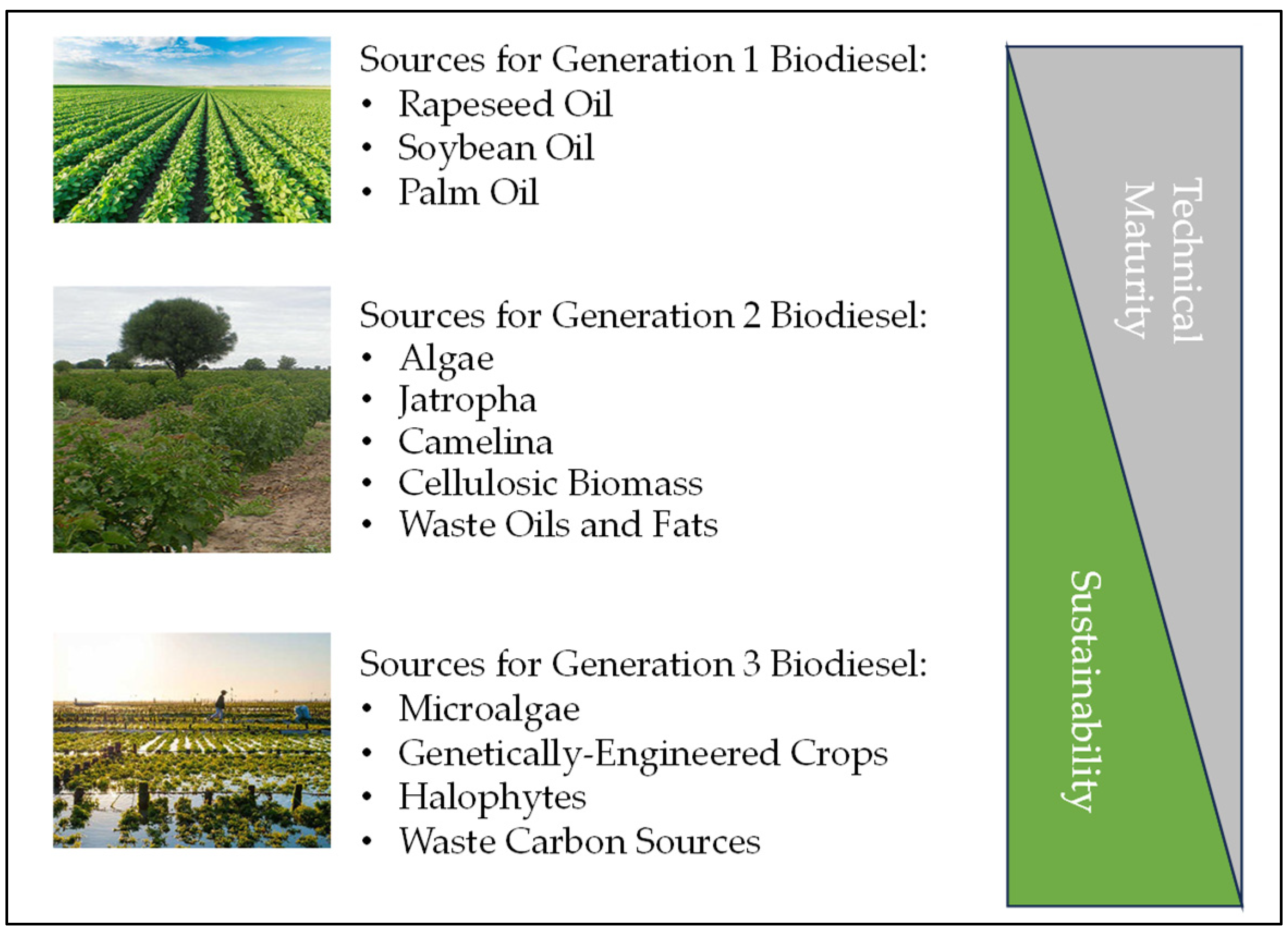

As shown in

Figure 2, biodiesel feedstocks are broken down into three generations. Generation 1 feedstocks are currently available on a large scale. Generation 2 feedstocks are available on significantly smaller scales and significant research is underway for scaling up production. Generation 3 feedstock has low technical maturity; though feasible as a future biodiesel feedstock, Generation 3 feedstocks require significant research and development [

20]. Note that while some studies will classify waste carbon sources and genetically engineered crops as Generation 4 biodiesels, this review follows most studies’ trends and groups them with Generation 3.

4.1. First-Generation Feedstocks

Historically, the earliest biodiesel feedstocks were derived from natural oils and fats, primarily animal fats and plant oils, which have been used for centuries as fuel sources. The first commercial-scale biodiesel production facilities were established in Europe in the 1980s, primarily using rapeseed oil (canola oil) as the primary feedstock [

21]. Throughout the 1990s and early 2000s, biodiesel production expanded globally, with various feedstocks being utilized based on regional agricultural resources and economic factors [

22]. In the United States, soybean oil emerged as the dominant feedstock due to the country’s large soybean production capacity. In Europe, rapeseed oil remained a primary feedstock, while palm oil gained prominence in Southeast Asia due to its high oil yield and lower production costs.

Biodiesels derived from these feedstocks are commonly referred to as being first generation. First-generation feedstocks are well established. In 2021, almost 14 billion gallons of biodiesel, primarily from first-generation feedstocks, accounted for approximately 3 percent of the global diesel demand [

23]. The biodiesel is blended with conventional diesel, with the most common blends being B5 and B20, which are 5 and 20 percent biodiesel, respectively [

24].

4.2. Second-Generation Feedstocks

However, concerns about land-use change, deforestation, and food-versus-fuel competition have prompted the exploration of alternative feedstock sources that offer lower environmental impacts and do not compete with food production. As a result, there is increased research on second-generation biodiesels that are derived from non-food feedstocks.

One such feedstock is jatropha, a resilient shrub known for its drought tolerance, which produces seeds with high oil content. Jatropha can thrive on marginal lands unsuitable for food crops, thus reducing competition for arable land [

25]. However, challenges such as yield variability and the toxicity of the seeds have limited the widespread adoption of jatropha-based biodiesel production. Numerous countries have considered jatropha, including China, Malaysia, India, and Indonesia [

26]. The climates in south and southeast Asia favor the growth of jatropha, allowing it to grow with limited resources [

27].

Another second-generation feedstock is camelina, an oilseed crop. It can be grown in rotation with conventional crops or on marginal lands, providing oil suitable for biodiesel production [

28]. Camelina cultivation may also offer benefits for soil health and sustainable crop rotation practices, making it an environmentally friendly feedstock choice [

29]. Numerous countries are looking at camelina as a possible feedstock for biodiesel, including the United States and Canada, whose climates support the growth of camelina in regions currently not used for agriculture [

30].

Grouped in with second-generation feedstock is cellulosic biomass, including agricultural and forestry residues, which present an abundant and renewable feedstock source for biodiesel production [

31]. Advanced technologies enable the conversion of cellulose, hemicellulose, and lignin into sugars, which can then be fermented into biodiesel. This feedstock offers the advantage of utilizing non-food biomass resources without competing with food production [

32].

Second-generation feedstocks also include waste oils and fats from various sources, such as food processing industries and restaurants, which contain the fatty acids necessary for conversion into biodiesel. This process is not new, and it has been common for individuals to run diesel vehicles off used oil from fast-food restaurants that had been filtered [

33]. However, such a system has not been implemented economically at scale. If implemented, this feedstock provides environmental benefits by diverting waste from landfills and reducing greenhouse gas emissions associated with waste disposal. However, challenges related to collection, processing, and quality control must be addressed to ensure the viability of waste-based biodiesel production [

34].

4.3. Third-Generation Feedstocks

While non-food feedstocks do not compete for food supplies, they still require significant water and land to cultivate the necessary crops, reducing the overall sustainability of the crop. As such, there is a move for third-generation feedstocks, which tend to use waste products or products that will not compete with resources required by the agricultural community.

One of the most researched third-generation feedstock is algae. Algae-based biodiesel, which is sometimes classified as a second- or fourth-generation feedstock, is derived from microalgae. Algae possess high oil content and can be cultivated on non-arable land using wastewater or brackish water, minimizing competition with food crops [

35]. This feedstock has the potential for carbon neutrality if produced sustainably, making it an attractive option for environmentally conscious biodiesel production. Microalgae represent a significant avenue for third-generation biodiesel production [

36]. Advanced cultivation techniques, such as photobioreactors and closed-loop systems, optimize growth conditions and oil yields [

37]. With the potential to produce significantly higher oil yields per hectare compared to traditional oilseed crops, microalgae offer highly efficient and sustainable feedstock options for biodiesel production.

An alternative to algae for biodiesel is halophytes, a salt-tolerant plant capable of growing in saline environments. Halophytes offer advantages over algae as a biodiesel feedstock due to their ability to thrive in saline environments, requiring less competition for freshwater resources and potentially yielding high lipid content [

38]. Additionally, halophytes can contribute to soil reclamation in coastal and degraded areas, while their cultivation may pose lower risks of contamination compared to algae [

39].

More broadly, the category of genetically engineered crops for biodiesel feedstock is classified as a third-generation biodiesel. Scientists are modifying the metabolic pathways of plants to enhance oil production traits, aiming to increase oil content and improve overall production efficiency [

40]. Crops such as camelina, soybean, and canola are being studied for their potential to serve as biodiesel feedstocks with improved characteristics [

41].

Taking a completely different pathway, another third-generation biodiesel approach focuses on utilizing waste carbon sources, such as industrial emissions or captured carbon dioxide, as feedstock for microbial fermentation processes. Microorganisms can convert waste carbon into lipids, which can then be converted into biodiesel through biochemical processes [

42]. These innovative approaches offer opportunities to further enhance the sustainability and efficiency of biodiesel production, contributing to the development of a more environmentally friendly and economically viable biofuel industry. However, of the various feedstock options, this approach is the least mature and requires the most technical advances to be a viable alternative [

43].

5. Biodiesel Production Techniques

5.1. Traditional Biodiesel Production Processes

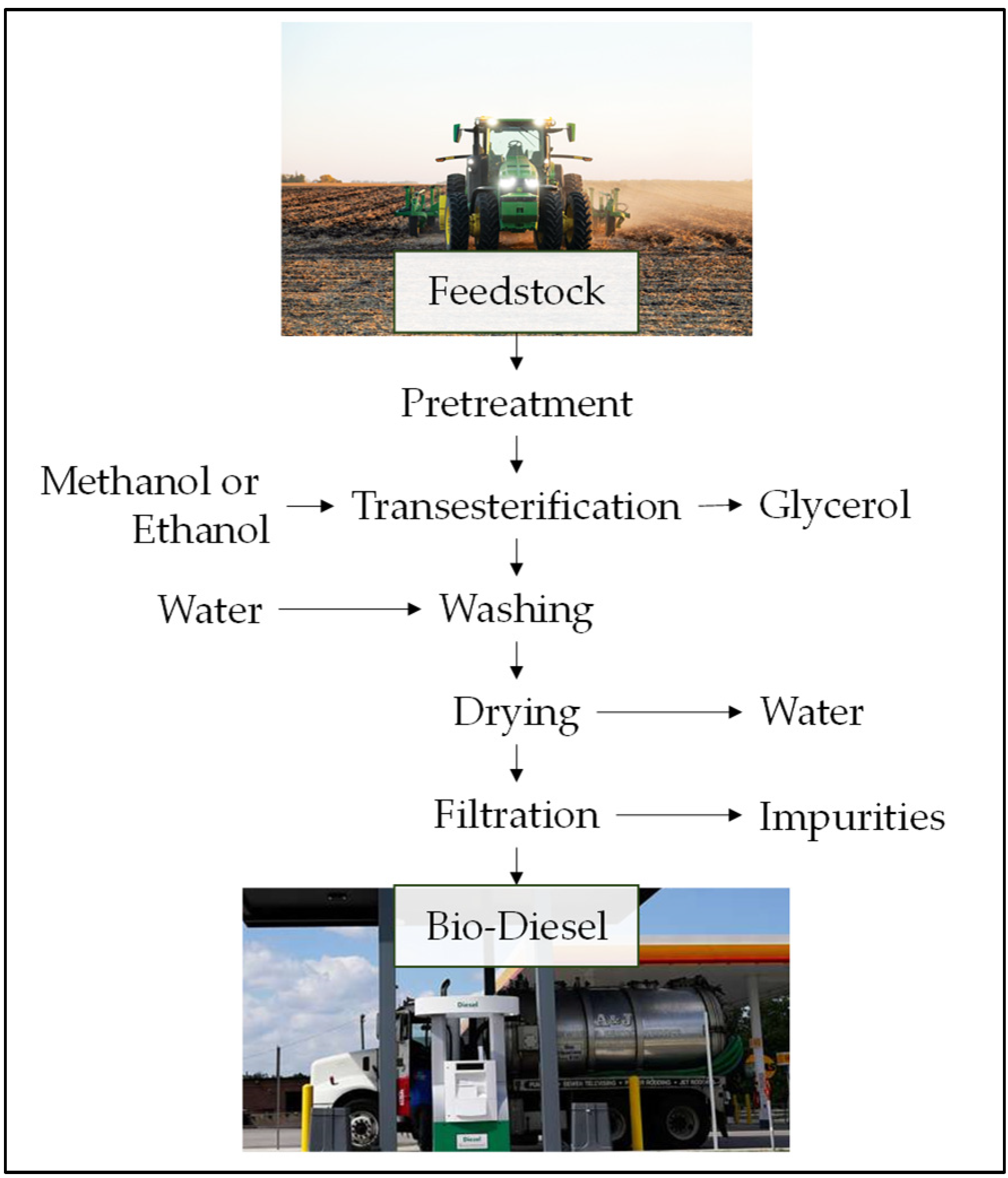

The process for producing biodiesel consists of two primary steps, as shown in

Figure 3. First, the carbon-based material used for producing the biodiesel is cultivated and collected. Once collected, this carbon-based material, termed feedstock, undergoes a series of processes to transform into biodiesel.

The first is a process called transesterification. This chemical reaction converts triglycerides, which are found in oils and fats, into fatty acid methyl esters (FAMEs), the primary component of biodiesel. The process begins by mixing the feedstock oil with an alcohol, commonly methanol or ethanol, and a catalyst, often sodium hydroxide or potassium hydroxide. The catalyst helps to speed up the reaction. During transesterification, the alcohol replaces the glycerol backbone of the triglyceride, forming esters and glycerol as byproducts. The esters are then separated from the glycerol and washed to remove any remaining impurities, resulting in the production of biodiesel.

After the transesterification reaction, the biodiesel undergoes a purification process to remove any remaining impurities, such as excess alcohol, catalyst, and soap. This purification step typically involves washing the biodiesel with water and then allowing it to settle to separate out any impurities. The next step involves drying the biodiesel to remove any remaining water, ensuring its stability and quality. After that, the biodiesel is run through a mechanical filter to remove any impurities.

5.2. New Catalysts to Support Transesterification

Recent advancements in biodiesel production have focused on developing novel catalysts for transesterification reactions, aiming to improve reaction efficiency, reduce costs, and enhance sustainability. One promising research avenue involves utilizing heterogeneous catalysts, characterized by their solid-state nature and distinct catalytic sites. Among these catalysts, solid acids, such as sulfonated carbon materials and zeolites, have garnered significant attention due to their strong acidity and high surface area [

44]. These features facilitate the activation of triglycerides and alcohol molecules, promoting the transesterification process. Additionally, the heterogeneous nature of these catalysts allows for easy separation from the reaction mixture and subsequent reuse, contributing to process sustainability and cost-effectiveness.

In parallel, base-metal oxides have emerged as another class of heterogeneous catalysts for transesterification. Materials such as calcium oxide and magnesium oxide exhibit basic properties, which facilitate the deprotonation of alcohol molecules and the subsequent formation of alkoxide intermediates crucial for biodiesel synthesis [

45]. The abundance and low cost of these metal oxides further enhance their appeal as catalysts for large-scale biodiesel production. Additionally, their robust nature ensures stability under the harsh reaction conditions typical of transesterification processes, contributing to process reliability and longevity.

Furthermore, advancements in nanotechnology have facilitated the development of supported metal nanoparticles as highly efficient catalysts for biodiesel production. Metal nanoparticles deposited on porous supports, such as activated carbon, silica, and alumina, offer high surface areas and well-defined catalytic sites, enabling precise control over reaction kinetics and selectivity [

46]. The use of supported metal nanoparticles allows for the optimization of catalytic performance while minimizing catalyst loading, thereby reducing costs and improving process economics. Overall, the exploration of new catalysts for transesterification represents a pivotal aspect of ongoing research in biodiesel production, with the potential to revolutionize the efficiency, economics, and environmental footprint of biofuel technologies.

5.3. Advances in Transesterification of Biodiesel Production

Each individual step in the process outlined in

Figure 3 can be optimized to be more efficient and sustainable. In particular, there is significant research on making the transesterification process more efficient.

One notable approach is ultrasound-assisted transesterification, which involves the application of high-frequency sound waves to the reaction mixture. Ultrasound waves induce cavitation, creating microbubbles in the reaction mixture that enhance mass transfer and accelerate chemical reactions [

47]. This results in shorter reaction times and higher yields of biodiesel. Additionally, ultrasound-assisted transesterification can be conducted at lower temperatures and without the need for catalysts in some cases, reducing energy consumption and environmental impact.

Microwave irradiation is another promising technique for process intensification in biodiesel production. By exposing the reaction mixture to microwave radiation, rapid and uniform heating can be achieved, leading to faster reaction rates and higher yields of biodiesel [

48]. Microwave-assisted transesterification offers several advantages, including shorter reaction times, reduced energy consumption, and improved product quality. Furthermore, the use of microwave irradiation allows for the selective heating of specific reactants, minimizing side reactions and increasing the efficiency of the transesterification process.

Continuous flow reactors represent another advancement in process intensification for biodiesel production [

49]. Unlike traditional batch reactors, continuous flow reactors enable the continuous mixing of reactants and the constant removal of products, resulting in improved reaction kinetics and higher throughput. Continuous flow systems offer several benefits, including precise control over reaction parameters, reduced reaction times, and enhanced scalability. Additionally, continuous flow reactors can be integrated with other process intensification techniques, such as ultrasound or microwave irradiation, further enhancing their efficiency and productivity. Overall, process intensification techniques hold great promise for advancing biodiesel production, making it more sustainable, economically viable, and competitive with conventional fossil fuels.

6. Maritime Military Vehicles

Given the advances in biodiesel feedstocks and development processes, biodiesel technology is expected to advance significantly, with the goal of offsetting and eventually replacing conventional diesel fuels. This section discusses how the advances in biodiesel relate to the maritime military vehicle market.

6.1. Overview of Biodiesel in Military Maritime Applications

While many larger navy vessels, including aircraft carriers and some submarines, use nuclear power, the bulk of naval vessels are powered by diesel engines or gas turbines. This includes destroyers, littoral combat ships, cruisers, amphibious assault ships, some submarines, support ships, and coastal patrol ships. In 2006, the United States Navy reported that it used approximately 5 million barrels of oil for marine diesel. This accounted for 11 percent of that year’s total United States Department of Defense energy consumption [

50].

Although the military is typically exempt from international sustainability initiatives, it can leverage them to enhance combat readiness. The global maritime industry is shifting away from traditional diesel fuels to reduce greenhouse gas emissions, with the International Maritime Organization (IMO) adopting a 2018 strategy to cut emissions from shipping by at least 50 percent by 2050 compared to 2008 levels and eventually phase out fuels that increase net emissions [

51]. Central to the IMO’s plan is biodiesel, seen as the most economical and sustainable alternative for maritime vessels especially in the near-term [

18]. The IMO, supported by most countries and industries, aims to use biodiesel to achieve its sustainability goals.

The maritime community is also supporting other alternative energy initiatives, including battery-electric and hydrogen technologies. In particular, hydrogen produced through electrolysis powered by renewable energy is emerging as a likely long-term solution for large segments of the maritime industry. However, the use of hydrogen for military applications would be limited due to its volatility. In combat situations, the pressurized tanks of highly volatile hydrogen inherently pose a significant liability, especially compared to more stable biodiesel fuel.

In the military context, the global movement away from diesel towards biodiesel has the potential to reduce the fuel supply chains associated with large navies. Currently, diesel for naval applications is based on oil pumped in one country, refined in another country, and then transported to the port, resulting in several supply chain vulnerabilities. Further, it could allow countries to be less dependent on foreign countries for oil for the production of fuels, a critical vulnerability in the current supply chains.

An example of the military’s efforts to adopt biodiesel was in 2016, when the United States Navy launched the Great Green Fleet initiative, which aimed to demonstrate the viability of alternative fuels in naval operations. This initiative involved deploying the John C. Stennis Strike Group using a blend of traditional diesel and biodiesel derived from beef tallow. The alternative fuel was made of 10% beef tallow and 90% marine diesel. Using a drop-in alternative, no modifications to the engines were required. Despite showcasing the potential for integrating biodiesel, the high production costs at the time rendered widespread operational use economically unfeasible [

52]. Regardless, this initiative showcased critical areas for improvement in the biodiesel technology in the Navy.

6.2. Alignment with Feedstock Sources and Challenges

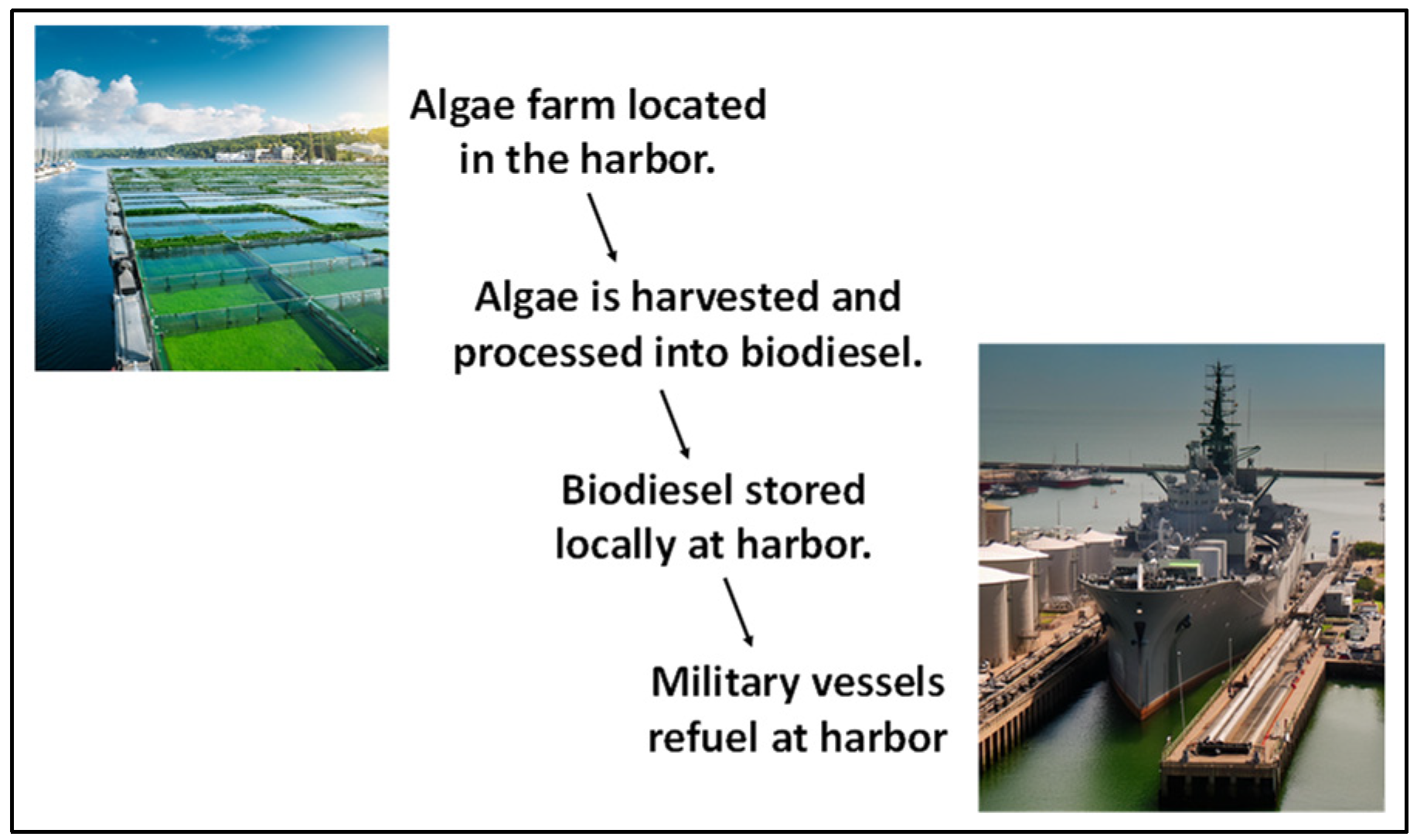

Maritime operations are on the water, where algae can readily grow. As such, the generation of biodiesel from algae for maritime sources makes natural sense. Indeed, one of the often-cited issues with algae-based biodiesel is the large amount of water required to grow the algae [

53]. Port cities have ready access to large areas of water that could be used for cultivating algae.

Figure 4 displays the high-level pathway for the lifecycle of these fuels from feedstock production to usage in a military vessel. By growing the algae feedstock, refining it into biodiesel locally, and distributing it all in the same area (i.e., the port), the process would have increased efficiency with a reduction in transportation needs. This approach also leverages the limited number of large port cities globally, which would need such facilities.

For algae to be viable as the feedstock to support the military maritime community, there must be significant advances in the development of algae-based biodiesel. First, the lipid content in the algae feedstock must be increased through genetic engineering or cultivation optimization. Second, the high cost associated with algae cultivation, harvesting, and processing inhibits large-scale commercialization. Addressing this challenge requires innovations in cultivation techniques, harvesting methods, and downstream processing technologies to reduce production costs. Further, the lack of standardized cultivation and processing protocols complicates scalability and quality control in algae-based biodiesel production. Streamlining protocols and establishing industry standards are essential steps towards overcoming this obstacle and realizing the full potential of algae as a viable feedstock for biodiesel production [

54].

Further, there are challenges with the use of biodiesel that would be unique for military applications. A key issue is fuel stability, since biodiesel made from algae can degrade faster than conventional fuels, which is problematic during long missions or storage. Additionally, algae biodiesel tends to have lower energy density, which could reduce range and operational efficiency for military vessels. The fuel must also meet strict safety standards, requiring low flammability while maintaining performance across varying conditions and temperatures, including extreme cold, which can lead to gelling and reduced fuel flow. Furthermore, scalability and consistent fuel quality remain challenges for large-scale military use.

6.3. Relevant Advances in Maritime Aligned Biodiesel Production Methods

A large number of studies have been conducted on improving the pathways for producing biodiesel from algae. These studies typically focus on different algae species and production techniques for increasing the biodiesel yield and ensuring that the fuel is of suitable quality. A subset of these studies also addresses the challenges associated with using algae-based biodiesel for military maritime operations. These studies are outlined in

Table 1 and discussed in this section.

Pugliese et al. conducted preliminary tests using cultures of

Selenastrum capricornutum in a lab-scale photobioreactor for biodiesel production [

55]. The resulting biodiesel’s fatty acid profile had a high concentration of oleic acid, which exceeded typical values for other microalgae. This high oleic acid content is advantageous, contributing to desirable fuel properties such as improved viscosity and lubricity. Using established equations, the researchers calculated the biodiesel’s technical characteristics and determined that it possesses good quality attributes, making it a promising fuel candidate.

Another study by Song et al. determined the fatty acid profiles, biodiesel properties, biomass concentration, and lipid productivity of ten algae species in China [

56]. They identified five species—

Selenastrum capricornutum,

Chlorella vulgaris,

Scenedesmus obliqnus,

Phaeodactylum tricornutum, and

Isochrysis sphacrica—as having good lipid content and favorable biodiesel properties. Their analysis found

Phaeodactylum tricornutum to be the most suitable strain for widespread biodiesel production due to its favorable fatty acid profiles, resulting in improved oxidative stability, cold-flow properties, and combustion efficiency, which are critical for military maritime applications.

Roriguez-Palacio et al. conducted a similar study but focused on algae species native to Mexico, including

Chlorella miniata,

Coelastrella sp.,

Desmodesmus quadricauda,

Neochloris oleoabundans, and

Verrucodesmus verrucosus [

57]. They found all five species viable for biodiesel production, with

Coelastrella sp. and

Verrucodesmus verrucosus having the best fatty acid profiles for biodiesel production, a key factor for fuel stability in military conditions.

Further studies have explored genetically modifying algae strains to optimize biodiesel production. Munoz et al. reviewed advances in microalgae genetic engineering to enhance lipid productivity, highlighting that the most common strategies modify metabolic pathways to increase lipid synthesis and carbon capture [

58]. While progress has been made, productivity remains too low for economic feasibility for the commercial sector; however, it is economically feasible for the military market, which is willing to pay more per gallon of fuel. Further, research advances have improved photosynthesis and carbon flux without hindering growth. Promising candidates for lipid production include

Nannochloropsis,

Schizochytrium, and

Tisochrysis, which show promise due to their high growth rates.

Additionally, there have been advances in processing algae for biodiesel production. Hasnain et al. investigated the enhancement of biodiesel production from algae using microwave irradiation to streamline transesterification and extraction processes [

59]. Addressing high oil extraction and conversion costs, the research optimized conditions using response surface methodology (RSM), finding a 67–88 percent increase in biodiesel yields for four algae species treated with microwave-assisted transesterification. The results indicated that this method was more efficient than conventional methods, reducing the need for extensive solvents, prolonged reaction times, and high temperatures and pressures. Among the algae species evaluated,

Ulothrix sp. emerged as the most promising feedstock for biodiesel production, highlighting the potential of microwave techniques for advancing biodiesel as a clean alternative fuel for military naval vessels.

Garg and Jain’s study examined the impact of process parameters on biodiesel yield from algal oil transesterification at low temperatures, utilizing both RSM and artificial neural networks (ANNs) [

60]. They compared the predictive capabilities of the two models, with ANNs showing superior accuracy. The research supports the use of ANNs for optimizing biodiesel production parameters at low temperatures, essential for cold-weather military operations. Although progress has been made, further work is needed to enhance the accuracy and reliability of ANN models for biodiesel production, ensuring the efficiency and feasibility of biodiesel as a sustainable fuel alternative for military maritime vessels.

6.4. Discussion of Algae-Based Biodiesel for Maritime Use

The usage of algae-based biodiesel for military naval vehicles is expected to remain limited even though there has been significant progress in improving fuel properties. As mentioned in the previous section, algae-based biodiesel has demonstrated advancements in areas such as oxidative stability, cold-flow properties, and combustion efficiency, all of which are critical for military maritime operations. However, the primary obstacle remains the ability to produce it at the scale needed for military use. Algae cultivation and biodiesel production require substantial resources, including water, land, and specific chemicals, which complicates efforts to meet the vast fuel demands of naval fleets.

Scaling up production to meet military needs presents a significant challenge. While port cities offer strategic advantages with access to water for algae cultivation, the infrastructure for large-scale operations is still lacking. Additionally, despite improvements in fuel qualities, algae-based biodiesel continues to face challenges such as lower energy density and fuel degradation over time, which could reduce operational efficiency during long missions. These issues, combined with the high costs associated with production, make it difficult to fully replace traditional fuels in military vessels.

Looking ahead, as the commercial market transitions to Generation 2 and Generation 3 biodiesels, production processes are expected to become more efficient, which could alleviate many of the logistical challenges. These transitions are not likely to occur in the near-term. However, given the long life-span of military ships, there is a high likelihood that many current ships will eventually be powered by biodiesel.

7. Military Ground Vehicles

While the military maritime community can benefit from algae-based biodiesel, the requirements for ground vehicles are different. Indeed, they must be able to operate over a broad range of environments, resulting in different feedstocks and processes being relevant for ground vehicles. This section discusses this market and the relevant advances in biodiesel technology.

7.1. Overview of Biodiesel in Military Ground Vehicle Applications

Over the past few years, military sectors have also engaged in efforts to curb carbon emissions and promote sustainability, recognizing the importance of reducing its environmental footprint while maintaining operational effectiveness. The United States Army put out its Climate Strategy in 2022, which outlines a series of milestones and policies to reduce carbon emissions for military vehicles, all of which currently run on diesel fuel. In particular, the United States Army has a number of initiatives, including the development of electric tactical vehicles [

14]. However, larger combat vehicles, which are the primary fuel consumer for the Army, are currently slated to remain as having diesel engines or gas turbines.

Biodiesel holds significant strategic importance for military operations, where fuel reliability, security, and operational efficiency are critical considerations. Military ground vehicles operate in diverse and often austere environments, where access to reliable fuel sources can directly impact mission success and troop safety. Biodiesel, characterized by its stability and compatibility with existing diesel engines, offers a viable alternative fuel option for military applications, ensuring continuity of operations while reducing dependence on conventional fossil fuels. The stability of biodiesel as a fuel source is particularly advantageous for military logistics, where fuel supply chains may face disruptions or vulnerabilities due to geopolitical instability or hostile environments. Unlike some alternative fuels prone to degradation or volatility, biodiesel provides a stable and reliable energy source that can be stored for extended periods without compromising performance or safety, enhancing the resilience of military fuel logistics and reducing supply chain risks in mission-critical scenarios.

Moreover, as the global market transitions away from oil-based diesel, the availability of traditional diesel will decrease, especially as commercial markets move towards fully electric or hydrogen fuel cell options [

61]. Given the power and range requirements of military vehicles, these alternatives are not feasible. Biodiesel’s compatibility with existing diesel engines, infrastructure, and logistics networks makes it a practical and accessible solution for military fleets [

62]. Additionally, biodiesel’s stability and ease of integration into existing fuel systems reduce the need for costly modifications or adaptations, enabling military forces to leverage renewable energy sources without compromising performance or mission objectives.

Further, by incorporating biodiesel into their fuel portfolios, military organizations can enhance energy security, reduce greenhouse gas emissions, and demonstrate leadership in sustainable defense practices, aligning with broader national security objectives and commitments to environmental stewardship [

63]. As such, biodiesel plays a vital role in enhancing the resilience, sustainability, and effectiveness of military operations, safeguarding critical fuel supplies, and supporting mission success in complex and dynamic operational environments.

The United States military has explored the use of biodiesel both in forward locations and domestically on their bases. A 2010 study by Arden Consulting recommended the use of biodiesel from cellulosic biomass in Afghanistan, which would reduce the logistics footprint associated with shipping diesel fuel from the United States while also boosting the local economy [

64]. Another study by the US Army Engineer Research and Development Center recommended using cellulosic biomass grown domestically on military bases to reduce the amount of diesel fuel purchased by the military and support domestic sustainability initiatives [

65]. While neither study has been implemented, they both found tactical, economical, and sustainable benefits with the use of biodiesel.

7.2. Alignment with Feedstock Sources

Military operations must take place over a range of environments, with the exact environments being dictated by the global socio-political status. Further, as other sectors transition away from fossil fuel-based diesel, the supply of diesel may diminish, resulting in a reliance on biodiesel. This likely reliance on biodiesel necessitates a diverse set of feedstocks to maintain a robust and secure supply channel. Historically, when countries have lacked access to the fuels or the raw materials to produce the fuel, as seen by Germany in World War II, their military operations become severely hindered.

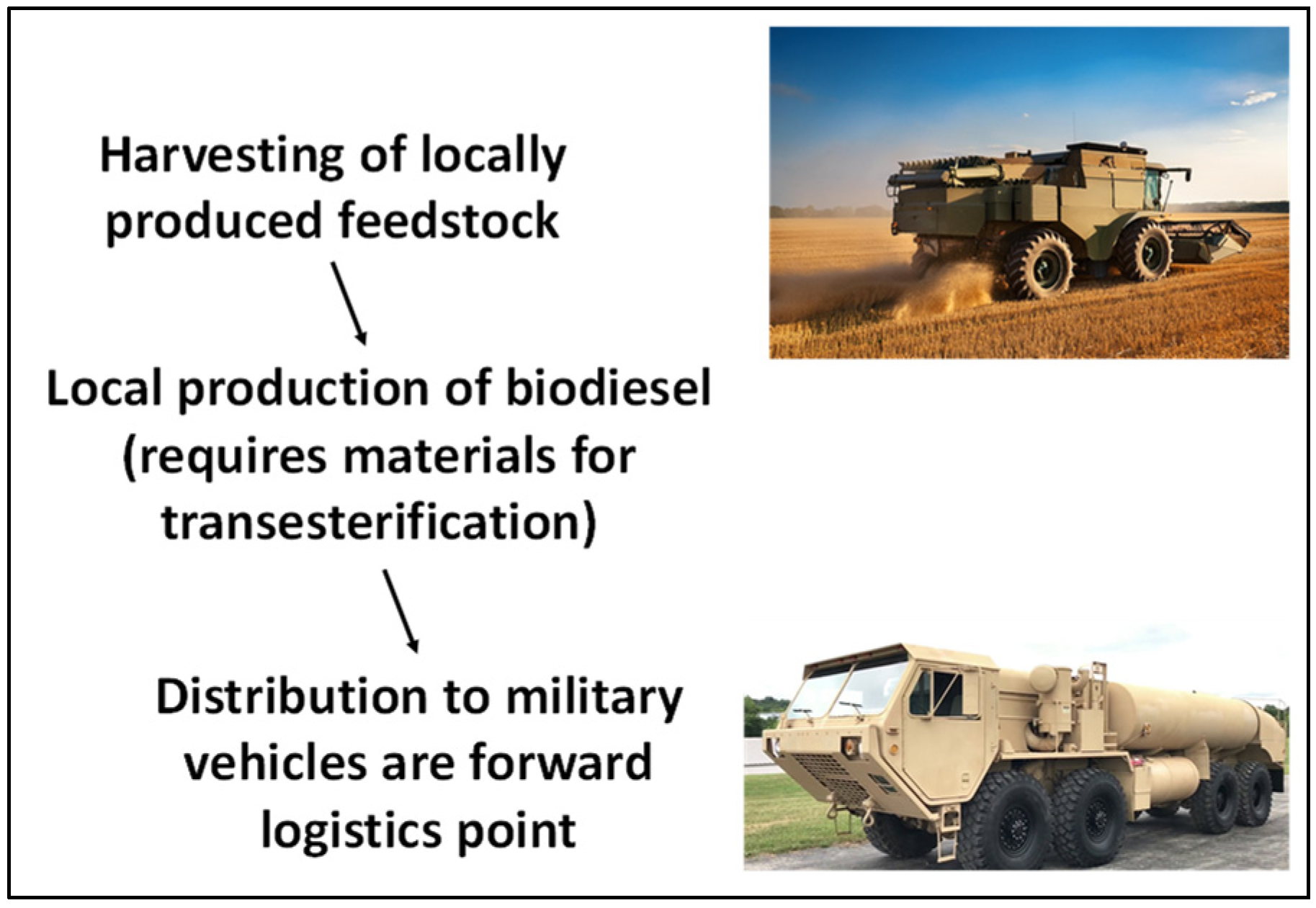

Figure 5 provides a high-level pathway for the production of biodiesel at the tactical edge for military vehicles.

By diversifying feedstocks for biodiesel production, militaries can mitigate such risks, ensuring operational continuity even in the face of disruptions to traditional fuel supplies. This flexibility allows for adaptation to changing geopolitical dynamics, market fluctuations, and environmental concerns, reducing dependence on a single resource or region for energy needs. Additionally, embracing diverse feedstocks promotes innovation and resilience within the military sector, fostering the development of alternative energy sources and technologies that enhance strategic autonomy and readiness. Through strategic investment in biodiesel derived from various feedstocks such as algae, waste oils, and crops, the military can bolster its energy security and readiness while simultaneously advancing sustainability objectives.

Further, the production of biodiesel, especially from diverse feedstock, allows for fuel production to be performed at the “edge”, as opposed to relying on long supply channels that may span across continents. For example, during the Global War on Terror, the JP-8 required for all American tactical vehicles was shipped from the United States to Pakistan, where it was then moved overland in tankers to different bases in Afghanistan. With biodiesel, using local feedstocks, a mobile refinery could produce the biodiesel at a forward operating base.

7.3. Relevant Advances in Ground Vehicle Aligned Biodisel Production Methods

The military desire to produce biodiesel at the edge differs from the main consumer sector, which is focusing on large-scale central production from targeted feedstocks. Regardless, there are significant advances for small-scale, localized production from diverse feedstocks, especially for agricultural and emergency-response needs. A summary of these advances is given in

Table 2 and discussed in this section.

Advances in mobile biodiesel production have been notable. For instance, Oliviera et al. developed a mobile biodiesel unit for small farms in Brazil capable of processing 100 L per hour [

66]. Mounted on a truck with a continuous flow reactor, decanter, and distillation unit, it converts farm oil into biodiesel on-site, reducing costs for small producers. This mobile system could also serve military applications. Ten Kate et al. evaluated a mobile biodiesel refinery in Indonesia using rubber seeds with a 40–50 percent oil yield [

67]. They found the units efficient but more costly than centralized production, although military applications could offset this cost through reduced transportation expenses. The Vermont Biofuel Initiative examined small-batch biodiesel facilities using oilseed feedstocks like soybean, sunflower, canola, and camelina, along with methane from livestock, awarding contracts to successful local facilities [

68]. These local facilities were using advanced processing techniques including microwave irradiation to improve the efficiency of the conversion process. In Ethiopia, Benti et al. studied local biodiesel production using castor and jatropha feedstocks, finding dual benefits for the economy and reduced distribution costs, with technology available both globally and domestically [

69].

For military applications, it would be useful to be able to source the biodiesel from a diverse array of feedstocks as opposed to depending on a single one. Indeed, many of the catalysts and conversion technologies are specifically tailored to the chemical composition of specific feedstocks. However, research is underway to develop processes that can work for an array of feedstocks, especially as it pertains to converting organic waste into biodiesel. Li et al. and Surendra et al. both studied an approach that added an intermediate step of cultivating larvae from soldier flies that feed on the organic waste [

70,

71]. They found that this approach is feasible, producing biodiesel similar in properties to that produced from more common feedstocks. Such an approach would work for a broad range of feedstocks. Another approach was studied by Karmee et al., who cultivated high-lipid fungi from organic waste, finding this approach to be suitable for large-scale biodiesel production [

72]. Arumugamurthy attempted a different approach that used spent yeast from a brewery as a catalyst in the transesterification process [

73]. The study found that this approach worked well when ultrasonic waves were used to enhance the chemical reaction.

While these studies focused primarily on the refining, they still required methanol for transesterification, which results in still needing a reliable supply channel. A study by Brunschwig et al. attempted to work around this through the use of bioethanol. The process for producing bioethanol is well established, although, as their study noted, bioethanol typically has purity issues, including the presence of water [

74]. However, they noted that many of these issues are reduced for small-level production facilities. They found that ethyl esters produced from transesterification were a suitable replacement for methyl esters currently produced from the process. Another study by Nakagawa looked at the production of biomethanol from forage grasses, trees, and crop residues [

75]. Their study discussed the production of biomethanol using a new approach based on the gasification of biomass by partial oxidation. Depending on the feedstock, the process was between 36 and 55 percent efficient. This biomethanol could then potentially be used in place of methanol for the transesterification process.

7.4. Discussion of Biodiesel for Ground Vehicle Use

The integration of biodiesel for military ground vehicles has made significant strides, though challenges remain. Advances in production methods have enhanced compatibility with existing diesel engines, allowing military fleets to adopt biodiesel with minimal adjustments. This aligns well with the U.S. Army’s Climate Strategy, which aims to reduce carbon emissions while maintaining the operational efficiency of vehicles. Biodiesel’s improved fuel properties, including better energy density and stability in extreme conditions, make it increasingly viable for tactical vehicles.

One of the primary hurdles in scaling biodiesel for military applications is the production levels, especially for larger vehicles which have high power draws. Although mobile biodiesel refineries that convert local feedstocks into fuel on-site have shown potential, these systems are not yet as efficient as centralized production methods. Moreover, producing biodiesel in the field requires access to specific chemicals like methanol, complicating supply logistics in operational theaters. The transesterification process requires approximately a 1:1 volume ratio of methanol to biodiesel produced, hence negating the logistics savings from local production of biodiesel or requiring a local source of methanol [

76].

Another challenge lies in the scalability of biodiesel production to meet military demands. Research into processing biodiesel from a broader range of feedstocks, such as organic waste, is progressing and could provide more flexibility in fuel sourcing. However, ensuring consistent quality and performance in the fuel remains difficult, especially given the rigorous performance standards required for military vehicles. While biodiesel offers a practical solution for certain military applications, further innovations are needed to overcome the logistical and technical limitations before it can fully replace traditional fuels across military ground operations.

8. Conclusions

The global transportation sector is shifting towards renewable energy sources to curb climate change and mitigate pollution. A key component of this transition is biodiesel, which is crucial for markets like maritime shipping to reach carbon neutrality. Consequently, there is extensive research focused on improving biodiesel through the development of different feedstocks and production methods.

The defense community, a large consumer of diesel fuel, relies heavily on diesel for ground vehicles and marine diesel for naval vessels. Given the long lifecycle of military vehicles, advancements in biodiesel are increasingly relevant to the defense sector. Future military vehicles will need to use biodiesel as oil-based diesel is phased out. Biodiesel has the potential to decrease supply chains and increase military flexibility by enabling on-site production.

Figure 6 provides a mapping for the advances in biodiesel research to the needs of the defense naval and ground forces community.

For naval applications, advances in algae as a feedstock allow biodiesel production to occur near port areas where ships refuel. Although algae-based biodiesel faces challenges such as high water requirements and costs, local production and distribution can enhance efficiency and reduce transportation needs. Genetic engineering and cultivation techniques are essential for increasing lipid content and reducing costs, while standardized protocols are needed for effective scaling. Certain algae species, like Phaeodactylum tricornutum and Ulothrix sp., show promise for high biodiesel yields. Innovative processing methods, such as microwave-assisted transesterification and artificial neural networks for optimization, could improve the economic feasibility of algae-based biodiesel for military applications.

For military ground vehicles, biofuels offer the opportunity to sustain operations at the edge by producing biodiesel locally, thus reducing the need for long supply chains. Despite ongoing efforts to develop mobile biodiesel production facilities, challenges remain in producing biodiesel from diverse feedstocks and reducing reliance on methanol for transesterification.

In conclusion, the advancements in biodiesel production from various feedstocks and innovative processing techniques hold significant potential for both civilian and military applications. These developments not only support sustainability goals but can also enhance a military’s operational flexibility and efficiency, making biodiesel a vital component of future energy strategies.

Author Contributions

Conceptualization, V.M. and E.L.; methodology, V.M.; background research, V.M. and E.L.; writing—original draft preparation, V.M.; writing—review and editing, E.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

DURC Statement

Current research is limited to the advances in biodiesel for marine and ground vehicle applications, which is beneficial for both the military and civilian sectors and does not pose a threat to public health or national security. Authors acknowledge the dual-use potential of the research involving the maritime shipping industry, emergency disaster relief, and operating ground vehicles in austere environments. The authors confirm that all necessary precautions have been taken to prevent potential misuse. As an ethical responsibility, authors strictly adhere to relevant national and international laws about DURC. Authors advocate for responsible deployment, ethical considerations, regulatory compliance, and transparent reporting to mitigate misuse risks and foster beneficial outcomes.

References

- Knothe, G. History of vegetable oil-based diesel fuels. In The Biodiesel Handbook; Knothe, G., Krahl, J., Gerpen, J., Eds.; AOCS Press: Urbana, IL, USA, 2010; pp. 5–19. [Google Scholar]

- Segovia-Hernández, J.G.; Sanchez-Ramirez, E.; Alcocer-Garcia, H.; Romero-Garcia, A.G.; Quiroz-Ramirez, J.J. Biofuels: Historical Development and Their Role in Today’s Society. In Sustainable Production of Biofuels Using Intensified Processes; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–7. [Google Scholar]

- Balasubramanian, N.; Steward, K.F. Biodiesel: History of an innovation to keep the world moving. Substantia 2019, 3, 57–71. [Google Scholar]

- Shahid, E.M.; Jamal, Y. A review of biodiesel as vehicular fuel. Renew. Sustain. Energy Rev. 2008, 12, 2484–2494. [Google Scholar] [CrossRef]

- Balat, M. An overview of biofuels and policies in the European Union. Energy Sources Part B 2007, 2, 167–181. [Google Scholar] [CrossRef]

- Johnston, M.; Holloway, T. A global comparison of national biodiesel production potentials. Environ. Sci. Technol. 2007, 41, 7967–7973. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Karimi, K.; Sárvári Horváth, I.; Kumar, R. Recent trends in biodiesel production. Biofuel Res. J. 2015, 2, 258–267. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A review on electric vehicles: Technologies and challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Senecal, K.; Leach, F. Racing Towards Zero: The Untold Story of Driving Green; SAE International: Warrendale, PL, USA, 2021. [Google Scholar]

- Nizami, A.S.; Mohanakrishna, G.; Mishra, U.; Pant, D. Trends and sustainability criteria for liquid biofuels. In Biofuels; CRC Press: Boca Raton, FL, USA, 2016; pp. 77–114. [Google Scholar]

- Kaushik, S.; Sati, V.; Kanojia, N.; Mehra, K.S.; Malkani, H.; Pant, H.; Gupta, H.; Singh, A.P.; Kumar, A.; Paul, A.R.; et al. Biodiesel a substitution for conventional diesel fuel: A comprehensive review. Adv. Mech. Eng. Sel. Proc. CAMSE 2020, 2021, 113–122. [Google Scholar]

- Gülşen, E.; Olivetti, E.; Freire, F.; Dias, L.; Kirchain, R. Impact of feedstock diversification on the cost-effectiveness of biodiesel. Appl. Energy 2014, 126, 281–296. [Google Scholar] [CrossRef]

- National Research Council. Renewable Fuel Standard: Potential Economic and Environmental Effects of U.S. Biofuel Policy; The National Academies Press: Washington, DC, USA, 2012. [Google Scholar] [CrossRef]

- U.S. Department of the Army. Army Climate Strategy; U.S. Department of the Army: Washington, DC, USA, 2022; Available online: https://www.army.mil/e2/downloads/rv7/about/2022_army_climate_strategy.pdf (accessed on 9 July 2024).

- Kumbhar, V.; Pandey, A.K.; Varghese, A.; Wanjari, S. Application of Biodiesel for 12-Cylinder, Supercharged Military Combat Vehicle. Int. J. Ambient. Energy 2022, 43, 1959–1965. [Google Scholar] [CrossRef]

- Mathew, G.M.; Raina, D.; Narisetty, V.; Kumar, V.; Saran, S.; Pugazhendi, A.; Sindhu, R.; Pandey, A.; Binod, P. Recent advances in biodiesel production: Challenges and solutions. Sci. Total Environ. 2021, 794, 148751. [Google Scholar] [CrossRef]

- Sales, M.B.; Borges, P.T.; Ribeiro Filho, M.N.; Miranda da Silva, L.R.; Castro, A.P.; Sanders Lopes, A.A.; Chaves de Lima, R.K.; de Sousa Rios, M.A.; Santos, J.C.S.d. Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis. Bioengineering 2022, 9, 539. [Google Scholar] [CrossRef] [PubMed]

- Noor, C.W.M.; Noor, M.M.; Mamat, R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Awasthi, P.; Shrivastava, S.; Kharkwal, A.C.; Varma, A. Biofuel from Agricultural Waste: A Review. Int. J. Curr. Microbiol. Appl. Sci. 2015, 4, 470–477. [Google Scholar]

- Zhang, Y.; Zhong, Y.; Lu, S.; Zhang, Z.; Tan, D. A Comprehensive Review of the Properties, Performance, Combustion, and Emissions of the Diesel Engine Fueled with Different Generations of Biodiesel. Processes 2022, 10, 1178. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, H.; Lin, L. Biodiesel: An alternative to conventional fuel. Energy Procedia 2012, 16, 1874–1885. [Google Scholar] [CrossRef]

- Shahid, E.M.; Jamal, Y. Production of biodiesel: A technical review. Renew. Sustain. Energy Rev. 2011, 15, 4732–4745. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Biofuels Explained. Available online: https://www.eia.gov/energyexplained/biofuels/data-and-statistics.php (accessed on 2 May 2024).

- Randazzo, M.L.; Sodré, J.R. Exhaust emissions from a diesel powered vehicle fuelled by soybean biodiesel blends (B3–B20) with ethanol as an additive (B20E2–B20E5). Fuel 2011, 90, 98–103. [Google Scholar] [CrossRef]

- Parawira, W. Biodiesel production from Jatropha curcas: A review. Sci. Res. Essays 2010, 5, 1796–1808. [Google Scholar]

- Yang, C.-Y.; Fang, Z.; Li, B.; Long, Y.-F. Review and prospects of Jatropha biodiesel industry in China. Renew. Sustain. Energy Review 2012, 16, 2178–2190. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Prospects of biodiesel from Jatropha in India: A review. Renew. Sustain. Energy Review 2010, 14, 763–771. [Google Scholar] [CrossRef]

- Özçelik, A.E.; Aydoğan, H.; Acaroğlu, M. Determining the performance, emission and combustion properties of camelina biodiesel blends. Energy Convers. Manag. 2015, 96, 47–57. [Google Scholar] [CrossRef]

- Stamenković, O.S.; Gautam, K.; Singla-Pareek, S.L.; Dhankher, O.P.; Djalović, I.G.; Kostić, M.D.; Mitrović, P.M.; Pareek, A.; Veljković, V.B. Biodiesel production from camelina oil: Present status and future perspectives. Food Energy Secur. 2023, 12, e340. [Google Scholar] [CrossRef]

- Mohammed, Y.A.; Chen, C.; Afshar, R.K. Nutrient requirements of camelina for biodiesel feedstock in central Montana. Agron. J. 2017, 109, 309–316. [Google Scholar] [CrossRef]

- Siqueira, J.G.W.; Rodrigues, C.; Vandenberghe, L.P.S.; Woiciechowski, A.L.; Soccol, C.R. Current advances in on-site cellulase production and application on lignocellulosic biomass conversion to biofuels: A review. Biomass Bioenergy 2020, 132, 105419. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, B.; Korstad, J. Utilization of lignocellulosic biomass by oleaginous yeast and bacteria for production of biodiesel and renewable diesel. Renew. Sustain. Energy Rev. 2017, 73, 654–671. [Google Scholar] [CrossRef]

- Huynh, L.-H.; Kasim, N.S.; Ju, Y.-H. Biodiesel production from waste oils. In Biofuels; Academic Press: Cambridge, MA, USA, 2011; pp. 375–396. [Google Scholar]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Trends in biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Powar, R.S.; Yadav, A.S.; Ramakrishna, C.S.; Patel, S.; Mohan, M.; Sakharwade, S.G.; Choubey, M.; Ansu, A.K.; Sharma, A. Algae: A potential feedstock for third generation biofuel. Mater. Today Proc. 2022, 63, A27–A33. [Google Scholar] [CrossRef]

- Jacob, A.; Ashok, B.; Alagumalai, A.; Chyuan, O.H.; Le, P.T.K. Critical review on third generation micro algae biodiesel production and its feasibility as future bioenergy for IC engine applications. Energy Convers. Manag. 2021, 228, 113655. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, Z.; Heidarrezaei, M.; Ong, H.C.; Koloor, S.S.R.; Petrů, M.; Lau, W.J.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass: Challenges and future directions. Chemosphere 2021, 285, 131535. [Google Scholar] [CrossRef]

- Joshi, A.; Kanthaliya, B.; Arora, J. Halophytes: The nonconventional crops as source of biofuel production. In Handbook of Halophytes: From Molecules to Ecosystems Towards Biosaline Agriculture; Zaman, M., Qadir, M., Khan, M.A., Eds.; Springer Nature: Cham, Switzerland, 2020; pp. 1–28. [Google Scholar]

- Behera, S.S.; Ramachandran, S. Potential uses of halophytes for biofuel production: Opportunities and challenges. In Sustainable Biofuels; Sharma, B.K., Khan, S.K., Mohanty, S.K., Eds.; 2021; pp. 425–448. [Google Scholar]

- Qi, W.; Lu, H.; Zhang, Y.; Cheng, J.; Huang, B.; Lu, X.; Sheteiwy, M.S.A.; Kuang, S.; Shao, H. Oil crop genetic modification for producing added value lipids. Crit. Rev. Biotechnol. 2020, 40, 777–786. [Google Scholar] [CrossRef]

- Lin, C.-Y. The influences of promising feedstock variability on advanced biofuel production: A review. J. Mar. Sci. Technol. 2022, 29, 714–730. [Google Scholar] [CrossRef]

- Ramirez, A.; Sarathy, S.M.; Gascon, J. CO2 derived E-fuels: Research trends, misconceptions, and future directions. Trends Chem. 2020, 2, 785–795. [Google Scholar] [CrossRef]

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Liu, Q. A critical review of technologies, costs, and projects for production of carbon-neutral liquid e-fuels from hydrogen and captured CO2. Energy Adv. 2022, 1, 580–605. [Google Scholar] [CrossRef]

- Mukhtar, A.; Saqib, S.; Lin, H.; Shah, M.U.H.; Ullah, S.; Younas, M.; Rezakazemi, M.; Ibrahim, M.; Mahmood, A.; Asif, S.; et al. Current status and challenges in heterogeneous catalysis for biodiesel production. Renew. Sustain. Energy Rev. 2022, 157, 112012. [Google Scholar] [CrossRef]

- Mulyatun, M.; Prameswari, J.; Istadi, I.; Widayat, W. Production of non-food feedstock based biodiesel using acid-base bifunctional heterogeneous catalysts: A review. Fuel 2022, 314, 122749. [Google Scholar] [CrossRef]

- Pandya, H.N.; Parikh, S.P.; Shah, M. Comprehensive review on application of various nanoparticles for the production of biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 1945–1958. [Google Scholar] [CrossRef]

- Ponnappan, V.S.; Munuswamy, D.B.; Nagappan, B.; Devarajan, Y. Investigation on the effect of ultrasound irradiation on biodiesel properties and transesterification parameters. Environ. Sci. Pollut. Res. 2021, 28, 64769–64777. [Google Scholar] [CrossRef]

- Mohamad Aziz, N.A.; Yunus, R.; Kania, D.; Abd Hamid, H. Prospects and challenges of microwave-combined technology for biodiesel and biolubricant production through a transesterification: A review. Molecules 2021, 26, 788. [Google Scholar] [CrossRef]

- Carlucci, C. An overview on the production of biodiesel enabled by continuous flow methodologies. Catalysts 2022, 12, 717. [Google Scholar] [CrossRef]

- Fonte, S. A Cost Estimation Analysis of U.S. Navy Ship Fuel-Savings Techniques and Technologies. Master’s Thesis, Naval Postgraduate School, Monterey, CA, USA, September 2009. [Google Scholar]

- IMO Action to Reduce Greenhouse Gas Emissions from International Shipping. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Reducing-greenhouse-gas-emissions-from-ships.aspx (accessed on 13 March 2023).

- John, C. Stennis Strike Group Public Affairs. The Great Green Fleet Explained; U.S. Navy: Washington, DC, USA, 2016; Available online: https://www.navy.mil/Press-Office/News-Stories/Article/2259656/the-great-green-fleet-explained/ (accessed on 15 October 2023).

- Quinn, J.C.; Davis, R. The Potentials and Challenges of Algae-Based Biofuels: A Review of the Techno-Economic, Life Cycle, and Resource Assessment Modeling. Bioresour. Technol. 2015, 184, 444–452. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Karthigadevi, G.; Praveenkumar, R.; Aniskumar, M.; Jayakumar, M.; Gurunathan, B. Potentials and Challenges in Biodiesel Production from Algae—Technological Outlook. In Biofuels and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 183–203. [Google Scholar]

- Pugliese, A.; Biondi, L.; Bartocci, P.; Fantozzi, F. Selenastrum capricornutum a new strain of algae for biodiesel production. Fermentation 2020, 6, 46. [Google Scholar] [CrossRef]

- Song, M.; Pei, H.; Hu, W.; Ma, G. Evaluation of the potential of 10 microalgal strains for biodiesel production. Bioresour. Technol. 2013, 141, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Palacio, M.C.; Cabrera-Cruz, R.B.E.; Rolón-Aguilar, J.C.; Tobías-Jaramillo, R.; Martínez-Hernández, M.; Lozano-Ramírez, C. The cultivation of five microalgae species and their potential for biodiesel production. Energy Sustain. Soc. 2022, 12, 10. [Google Scholar] [CrossRef]

- Muñoz, C.F.; Südfeld, C.; Naduthodi, M.I.; Weusthuis, R.A.; Barbosa, M.J.; Wijffels, R.H.; D’Adamo, S. Genetic engineering of microalgae for enhanced lipid production. Biotechnol. Adv. 2021, 52, 107836. [Google Scholar] [CrossRef] [PubMed]

- Hasnain, M.; Abideen, Z.; Naz, S.; Roessner, U.; Munir, N. Biodiesel production from new algal sources using response surface methodology and microwave application. Biomass Convers. Biorefinery 2023, 13, 6213–6228. [Google Scholar] [CrossRef]

- Garg, A.; Jain, S. Process parameter optimization of biodiesel production from algal oil by response surface methodology and artificial neural networks. Fuel 2020, 277, 118254. [Google Scholar] [CrossRef]

- Shafiei, E.; Davidsdottir, B.; Leaver, J.; Stefansson, H.; Asgeirsson, E.I.; Keith, D.R. Analysis of supply-push strategies governing the transition to biofuel vehicles in a market-oriented renewable energy system. Energy 2016, 94, 409–421. [Google Scholar] [CrossRef]

- Uyumaz, A.; Solmaz, H.; Yılmaz, E.; Yamık, H.; Polat, S. Experimental examination of the effects of military aviation fuel JP-8 and biodiesel fuel blends on the engine performance, exhaust emissions and combustion in a direct injection engine. Fuel Process. Technol. 2014, 128, 158–165. [Google Scholar] [CrossRef]

- Pandey, A.K.; Nandgaonkar, M.R. Comparison and Evaluation of Performance, Combustion and Emissions of Diesel, Jatropha and Karanja Oil Methyl Ester Biodiesel in a Military 780 hp CIDI Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010; No. 2010-01-2138. [Google Scholar]

- Arden, W.; Fox, J. Producing and Using Biodiesel in Afghanistan. 2010. Available online: https://arden-consulting.com/wp-content/uploads/2017/03/Producing-and-Using-Biodiesel-in-Afghanistan-June-10-2010.pdf (accessed on 15 October 2024).

- Myers, N.R.; Howard, H.R.; Gebhart, D.L.; Josefik, N.M.; Sharīf, M. Onsite Army Biofuel Production: Opportunities, Thresholds, and Considerations. 2013. Available online: https://apps.dtic.mil/sti/citations/ADA593918 (accessed on 15 October 2024).

- Oliveira, L.S.; Brasil, A.N.; Nunes, D.L. Design and operation of a mobile biodiesel production unit. In Chemical, Biological and Environmental Engineering; World Scientific: Singapore, 2010; pp. 29–32. [Google Scholar]

- ten Kate, J.; Teunter, R.; Kusumastuti, R.D.; van Donk, D.P. Biodiesel production using mobile processing units: A case in Indonesia. Agric. Syst. 2017, 152, 121–130. [Google Scholar] [CrossRef]

- Sawyer, S.; Kahler, E. Vermont Biofuels Initiative: Local Production for Local Use to Supply a Portion of Vermont’s Energy Needs; Vermont Sustainable Jobs Fund: Montpelier, VT, USA, 2009. [Google Scholar] [CrossRef]

- Benti, N.E.; Aneseyee, A.B.; Geffe, C.A.; Woldegiyorgis, T.A.; Gurmesa, G.S.; Bibiso, M.; Asfaw, A.A.; Milki, A.W.; Mekonnen, Y.S. Biodiesel production in Ethiopia: Current status and future prospects. Sci. Afr. 2023, 19, e01531. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, L.; Cai, H.; Garza, E.; Yu, Z.; Zhou, S. From organic waste to biodiesel: Black soldier fly, Hermetia illucens, makes it feasible. Fuel 2011, 90, 1545–1548. [Google Scholar] [CrossRef]

- Surendra, K.C.; Olivier, R.; Tomberlin, J.K.; Jha, R.; Khanal, S.K. Bioconversion of organic wastes into biodiesel and animal feed via insect farming. Renew. Energy 2016, 98, 197–202. [Google Scholar] [CrossRef]

- Karmee, S.K.; Linardi, D.; Lee, J.; Lin, C.S.K. Conversion of lipid from food waste to biodiesel. Waste Manag. 2015, 41, 169–173. [Google Scholar] [CrossRef] [PubMed]

- Arumugamurthy, S.S.; Sivanandi, P.; Pandian, S.; Choksi, H.; Subramanian, D. Conversion of a low value industrial waste into biodiesel using a catalyst derived from brewery waste: An activation and deactivation kinetic study. Waste Manag. 2019, 100, 318–326. [Google Scholar] [CrossRef] [PubMed]

- Brunschwig, C.; Moussavou, W.; Blin, J. Use of bioethanol for biodiesel production. Prog. Energy Combust. Sci. 2012, 38, 283–301. [Google Scholar] [CrossRef]

- Nakagawa, H.; Harada, T.; Ichinose, T.; Takeno, K.; Matsumoto, S.; Kobayashi, M.; Sakai, M. Biomethanol production and CO2 emission reduction from forage grasses, trees, and crop residues. Jpn. Agric. Res. Q. JARQ 2007, 41, 173–180. [Google Scholar] [CrossRef]

- Noriega, M.A.; Narváez, P.C. Scale-Up and Cost Analysis of Biodiesel Production Using Liquid-Liquid Film Reactors: Reduction in the Methanol Consumption and Investment Cost. Energy 2020, 211, 118724. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).