1. Introduction

Today, the electric vehicle represents an alternative to combustion engine cars in the pursuit of a cleaner environment. The electric vehicle industry mainly uses electric batteries to propel EVs; however, the problems associated with the scarcity of lithium, the main component of electric vehicle batteries, due to its increasing demand in the electric vehicle industry [

1,

2], the associated problems with recycling the battery components [

3,

4], and the limited access to critical metals needed for the manufacturing of lithium batteries [

5,

6], has forced manufacturers to search for an alternative propelling system, hydrogen propulsion [

7]. Nevertheless, fuel cell vehicles are subjected to evaluation due to the need for life cycle verification [

8,

9], and their implementation depends on the results of comparative analysis with electric vehicles powered by lithium batteries [

10], combustion engines [

11], or biofuels [

12].

The development of hydrogen fuel cell electric vehicles (HFCEVs) is ongoing in the hopes of implementing this kind of transportation in modern society [

13]. The low specific power of fuel cells is the main problem that arises when using hydrogen cells in electric vehicles [

14,

15]. Consequently, fuel cells cannot power electric vehicles in periods of high power demand because of the dynamics of hydrogen cell operation, which uses batteries to power the vehicle [

16,

17]. Battery vehicles are more capable, but the high current supply leads to a high discharge rate, which affects the driving range [

18,

19,

20,

21].

A hydrogen system is lighter than the batteries needed to propel a vehicle; however, the acceleration capacity decreases. To reduce this effect, we can use supercapacitors, which operate like batteries but with a much higher charge and discharge capacity, weighing much less than a battery bank and playing the role of a power boost [

22,

23,

24].

In this work, we simulate the performance of electric vehicles equipped with a hybrid system made up of a fuel cell and a supercapacitor, determining the gain in the driving range compared to that achieved with a single-fuel cell system.

2. Fuel Cell Electric Vehicle (FCEV)

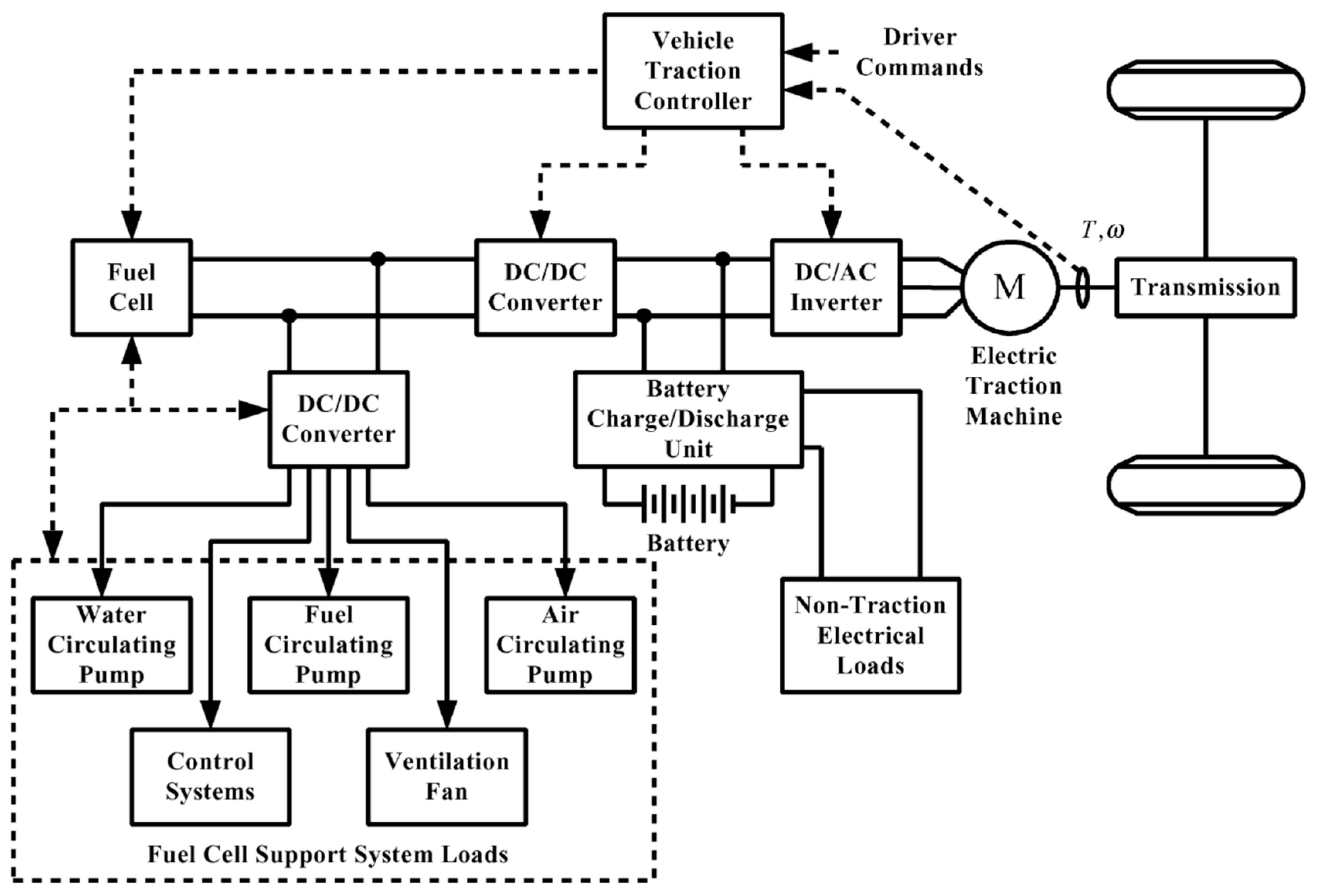

The basic structure of a fuel cell power system in an electric vehicle consists of a series of parallel fuel cell groupings to generate the required voltage and current to supply power to the electric motor.

Figure 1 shows the schematic layout of a fuel cell power system in an electric vehicle.

The global voltage of the fuel cell system is determined using the following equation:

Ns is the number of serial fuel cells,

Vr is the reversible voltage of the fuel cell, and Δ

V is the voltage drop [

25]. The sub-indexes

act,

ohm, and

conc account for the activation process of chemical species [

26,

27,

28], ohmic losses due to ionic and contact resistance [

29], and concentration effects caused by mass transportation [

30,

31].

The total current generated by a group of fuel cells,

IFC, depends on the hydrogen flow according to the following process:

Np is the number of parallel cells in the fuel cell system; e− is the electron electric charge; and , , and are the density, molecular weight, and hydrogen flow, respectively.

Combining Equations (1) and (2), we obtain the fuel cell power,

PFC:

Considering that the reversible fuel cell voltage and the voltage drop, Δ

V, are constant:

where the constant

is:

5. Performance Simulation

To run the simulation, we design a prototype representing the main characteristics of a different electric vehicle model selection. We replace the batteries of the prototype with a hybrid fuel cell and supercapacitor unit. The simulation run applies to three scenarios, high, medium, and low energy demanding routes, corresponding to the three types of driving according to the drivers’ attitude, aggressive, moderate, and conservative mode. An acceleration of 2.75 m/s2, 1.75 m/s2, and 1.25 m/s2 characterizes the three driving modes, respectively.

The driving conditions for running the simulation correspond to the different processes included in urban routes: acceleration, deceleration, constant speed, and braking. These processes occur with a non-defined sequence in a daily urban route; therefore, to simplify the calculation, we grouped all segments corresponding to the same process independently of the time they occur. Nevertheless, since the driving conditions in which the process takes place are not the same; for instance, for different initial and final speeds or variations in the slope of the route, we divided every process into segments that share the same driving conditions.

Table 1,

Table 2 and

Table 3 show the result of this classification.

The simulation considers that the acceleration is not constant in all cases since the driver may accelerate the electric vehicle differently during a segment; therefore, we divided each acceleration process into three, 30% of the time accelerating in conservative mode (ECO mode), 60% in moderate acceleration (NORMAL mode), and 10% in aggressive acceleration (SPORT mode).

The simulation also calculates the charge consumption, in Ah/km, and the hydrogen flow required for every segment. The calculation method is the same as the one applied to electric vehicles equipped with batteries.

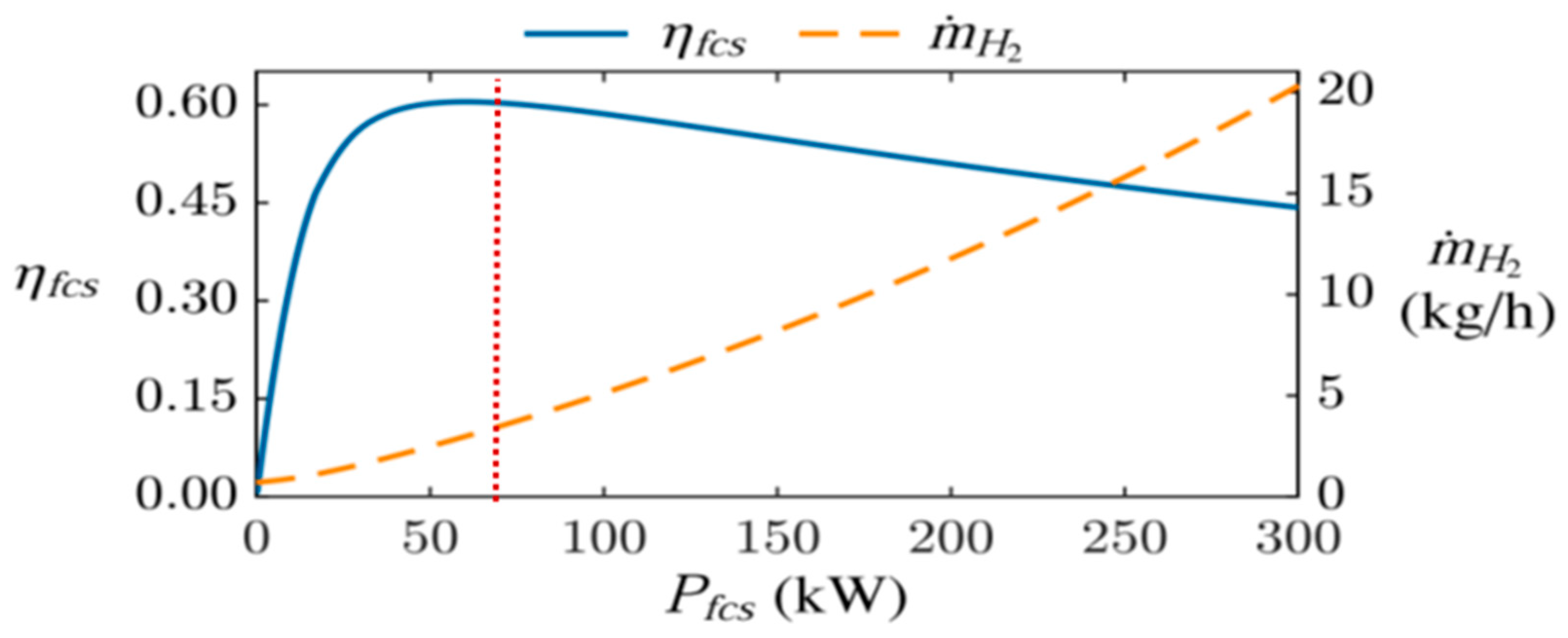

Today, we find few commercial electric vehicles equipped with fuel cells; therefore, to obtain a valid result from the simulation process, we take the Hyundai NEXO as a reference, with a reported hydrogen consumption rate of 0.95 kg/100 km [

46]. We use previous results as a reference for the process efficiency [

47], adapting the results to a lighter and less powerful electric vehicle (

Figure 2).

Figure 2 extends the analysis of the fuel cell power up to 300 kW, which corresponds to a heavy truck; however, in our case we establish the limit in 70.15 kW, corresponding to a light vehicle (red dotted line).

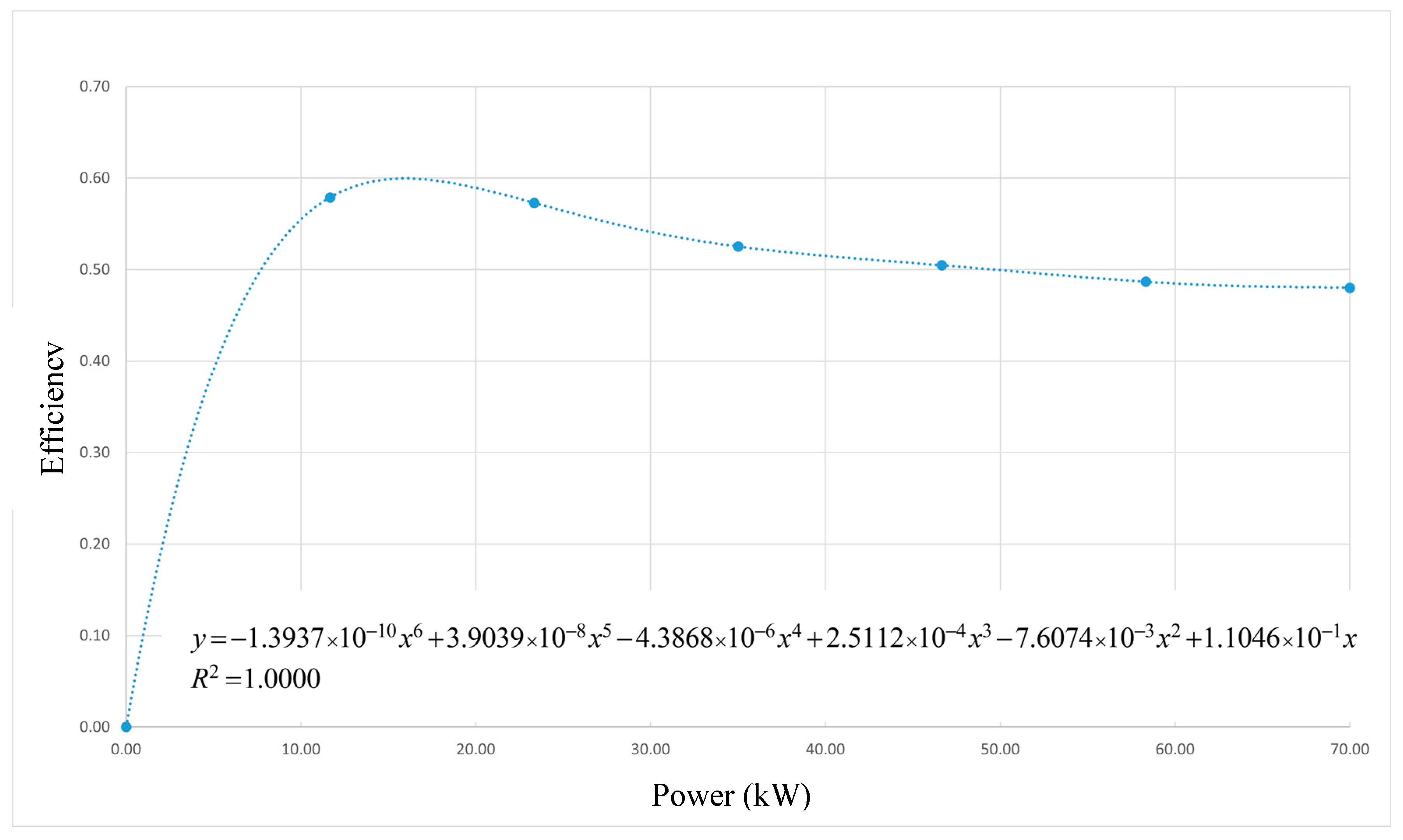

If we adapt the efficiency curve in

Figure 2 to the prototype tested in our case, we obtain (

Figure 3):

The algorithm inserted in

Figure 3 shows the polynomial function that fits the calculated efficiency of the simulated fuel cell. We notice the perfect fitting between theoretical calculation and correlation fit.

The efficiency allows the technician or user to determine the fuel consumption through the required energy for every segment.

Technical Data

The simulation runs on specific technical data for the fuel cell/supercapacitor hybrid system.

Table 4 shows the main parameters of the power battery for the electric vehicle.

The vehicle mass corresponds to the curb weight without a powertrain, battery, or fuel cell/supercapacitor hybrid system. The efficiencies, discharge, and regenerative braking correspond to the battery discharge (wheel to battery) and charge (battery to wheel) efficiency, which currently depend on temperature and driving mode; however, in our case, we consider these parameters constant for the simulation run. The selected efficiencies correspond to the Nissan LEAF model. A. Boretti [

48] reports wheel-to-battery and battery-to-wheel efficiencies for the Nissan LEAF within the range of 30–79% and 55.3–89.6%. We adopted representative values within the intervals based on statistical studies [

49,

50]. Nevertheless, since a battery and a supercapacitor do not have identical performance, the charge/discharge cycling

efficiency values are different; therefore, we use specific coefficients for each system at the simulation run.

According to the above statement, the parameter values used for the simulation in the case of supercapacitor are shown in

Table 5.

In absence of enough technical data for the Hyundai NEXO, the prototype used for evaluation in the present study, we based our analysis on data taken from the Technical Data Sheet of Toyota MIRAI [

51] and the webpage for Hyundai NEXO [

46], which are electric vehicles of similar characteristics to the Hyundai NEXO.

Previous work [

52] evaluated the supercapacitors’ efficiency during the regenerative process, reporting values between 80% and 98%. We decided to apply intermediate data within the mentioned interval to operate under similar conditions in the case of the battery propelling system.

We calculate the hydrogen storage mass tank using the technical data provided for the Hyundai NEXO [

53] and apply the data from the Toyota MIRAI technical characteristics, resulting in the values reported in

Table 4 [

54].

The supercapacitor used for the simulation run is the model XLM-69R0137A-R” from EATON [

55] since it supplies maximum power compatibility to the required value in the simulation.

6. Energy Evaluation

To calculate the energy consumption by the electric vehicle in every step of the route, we apply the dynamic equations to the driving conditions and the driving mode according to the drivers’ attitude. The calculation procedure comes from previous work from one of the authors [

56,

57,

58,

59,

60,

61].

Mechanic required power,

Pmech, derives from the dynamic driving conditions, and it is expressed by the following:

where

vav is the average value of the vehicle speed, and

FT represents the total mechanical force, which is obtained from:

The mass m accounts for the vehicle and power system mass, battery, or hybrid system. The parameter a represents the vehicle acceleration, and α is the slope of the route. Cx accounts for the aerodynamic coefficient of the vehicle, A is the front surface that opposes to the wind force, ρ is the air density, μ is the rolling friction coefficient, and g is the gravity acceleration.

Because the electric motor does not operate at full efficiency mode,

where

Pel and

ηel are the power and efficiency of the electric motor.

The battery capacity,

Cbat, depends on the required energy to cover the expected driving range.

where

i is the number of segments included in the driving range.

Combining Equations (6)–(9) results in the following:

Considering the acceleration process develops uniformly,

The analysis of statistical data shows that there is a relation between the capacity and the mass of an electric vehicle battery,

mEV [

62]:

Because the vehicle mass,

m, depends on the battery mass,

mbat,

Combining Equations (11)–(13) results in the following:

Equation (14) is a recurrent function that forces the application of an iteration process to determine the correct battery capacity value.

Using the fuel cell and supercapacitor, we must adapt the vehicle to the hybrid system. Following the same procedure as in the battery electric vehicle, we determine the required amount of hydrogen from the following:

where

represents the mass of hydrogen in moles,

Wel is the electric work,

QH2 is the hydrogen combustion heat, and

η is the combustion process efficiency.

Using the relation between mass and number of moles:

where

is the hydrogen molecular weight.

Equation (17) provides the relation between the electric power and the hydrogen mass flow.

The capacity of the supercapacitor,

CSC, is determined from the following classical expression:

PSC is the power delivered by the supercapacitor, and Vo and Vf are the voltages of the supercapacitor at the fully charged and discharged state.

Equation (18) is only valid if Vf ≥ Vmin, where Vmin is the minimum value of the supercapacitor voltage.

7. Energy Prediction Results

The prediction technique looks to improve the management of the electric vehicle power supply system, a methodology previously used with accurate results [

63]. One of the main goals of this process is to optimize the performance of the electric vehicle power system to enable it to be applied in a field other than economics [

64].

The prediction process includes the energy consumption calculation and power supply capacity. Additionally, we calculate the mass of the power source and electric vehicle to obtain the global weight. The prediction technique runs for the three defined scenarios, high, medium, and low demanding energy conditions, and for the three driving modes, aggressive (SPORT), moderate (NORMAL), and conservative (ECO), corresponding to high, medium, and low acceleration, respectively.

The first group of prediction tests focus on the electric vehicle equipped with a battery.

Table 6 shows the results of the tests.

The comparative analysis of the predictive technique results for the three driving modes shows an increase in all the parameter values as we move from ECO to SPORT mode, which is in close agreement with what we expected.

Table 7 shows the increasing ratio.

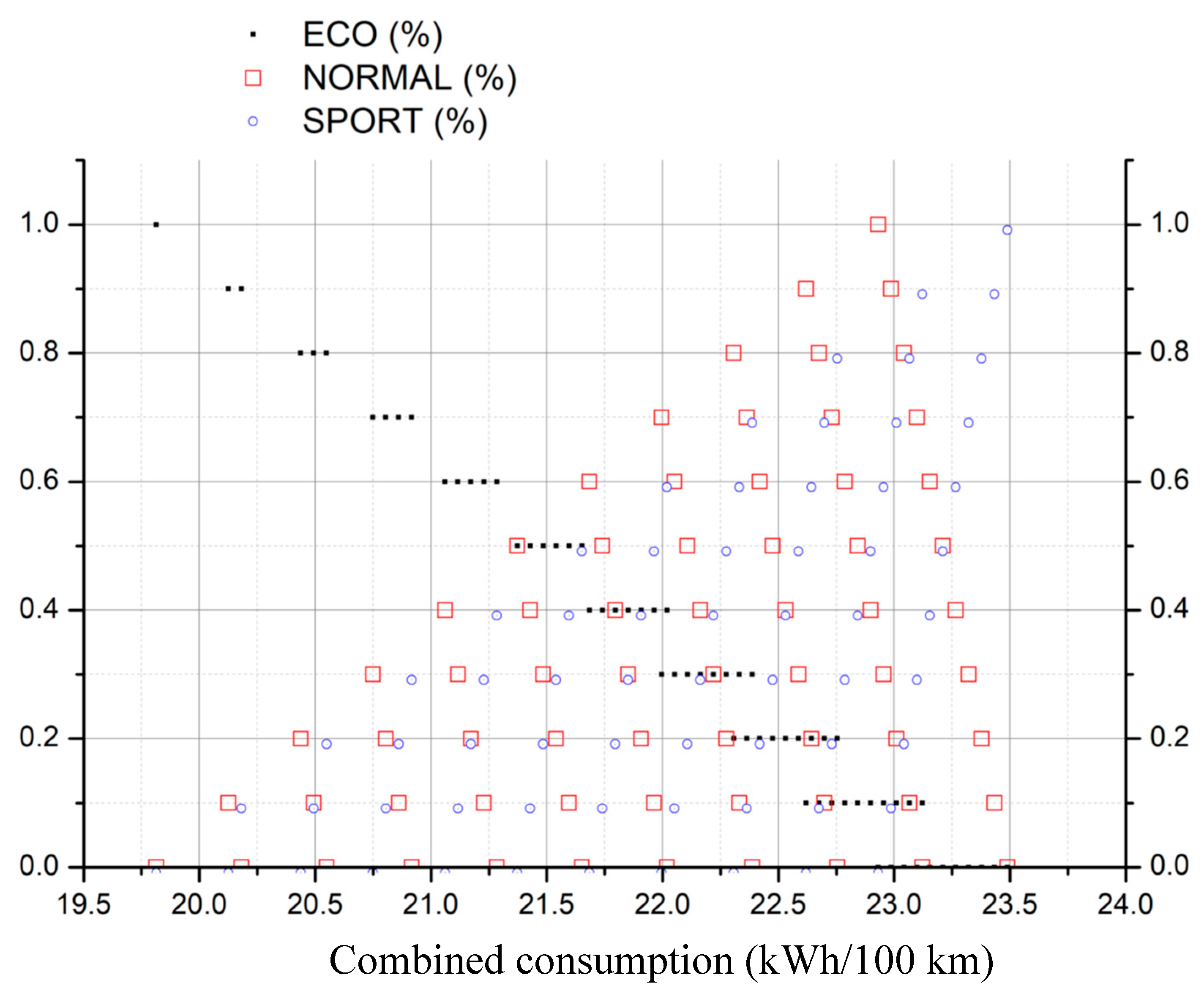

To calculate the energy consumption, we consider that each acceleration process combines the three driving modes, ECO, NORMAL, and SPORT, at different proportions. The fraction in which each driving mode contributes may change; therefore, we selected all combinations provided the sum of the fractions equals one.

The car must meet the driving range requirement, so we used the highest battery capacity of the proposed scenarios, corresponding to the fastest acceleration. Analogously, the heaviest battery is selected to cover all cases and all accelerations.

We observe the SPORT and NORMAL mode have similar values with a slight difference of 3.2%. However, from ECO to NORMAL mode, the increase reaches 21.4% and 25.4% from ECO to SPORT; therefore, we may conclude that the ECO mode represents the most significant energy saving.

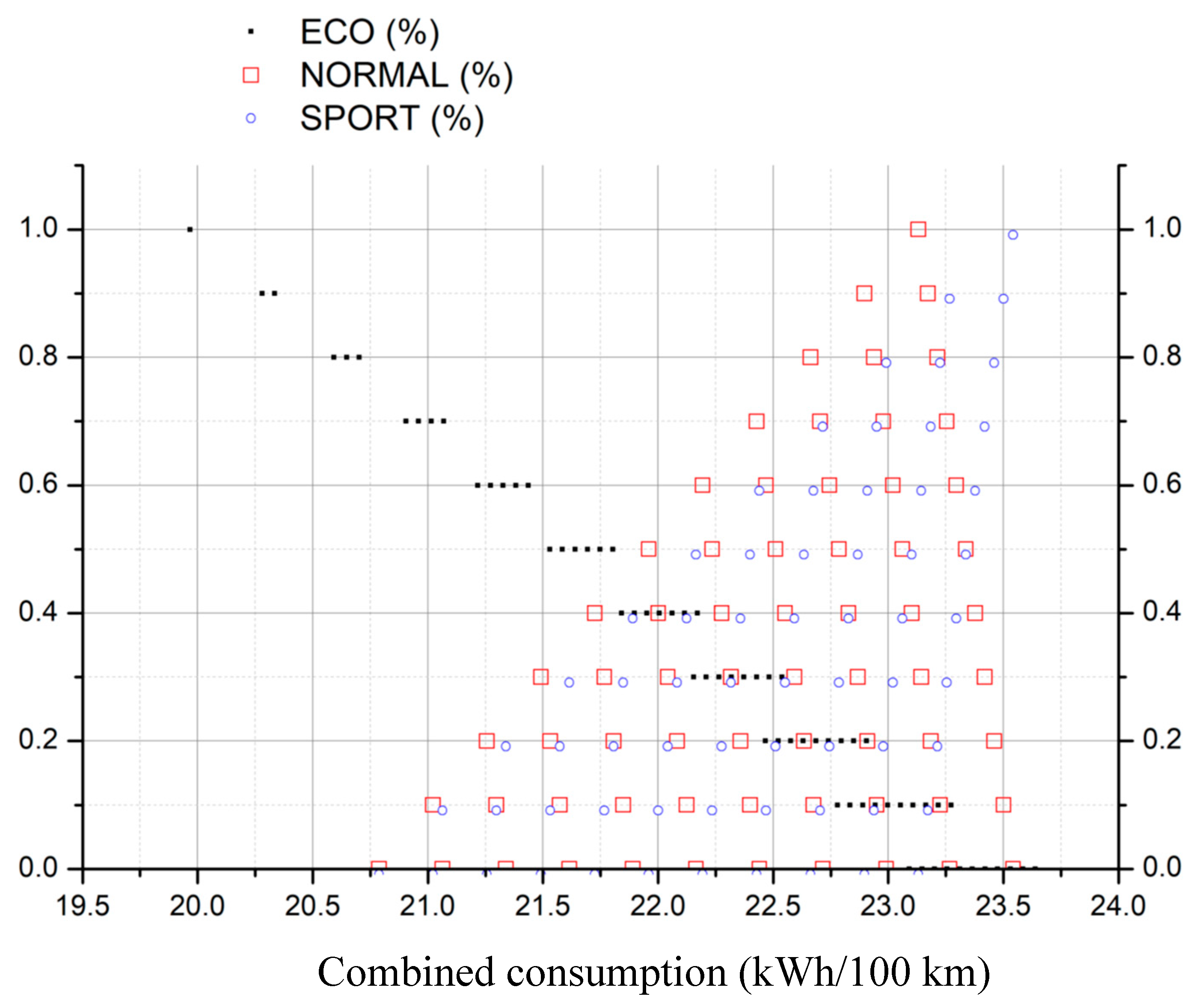

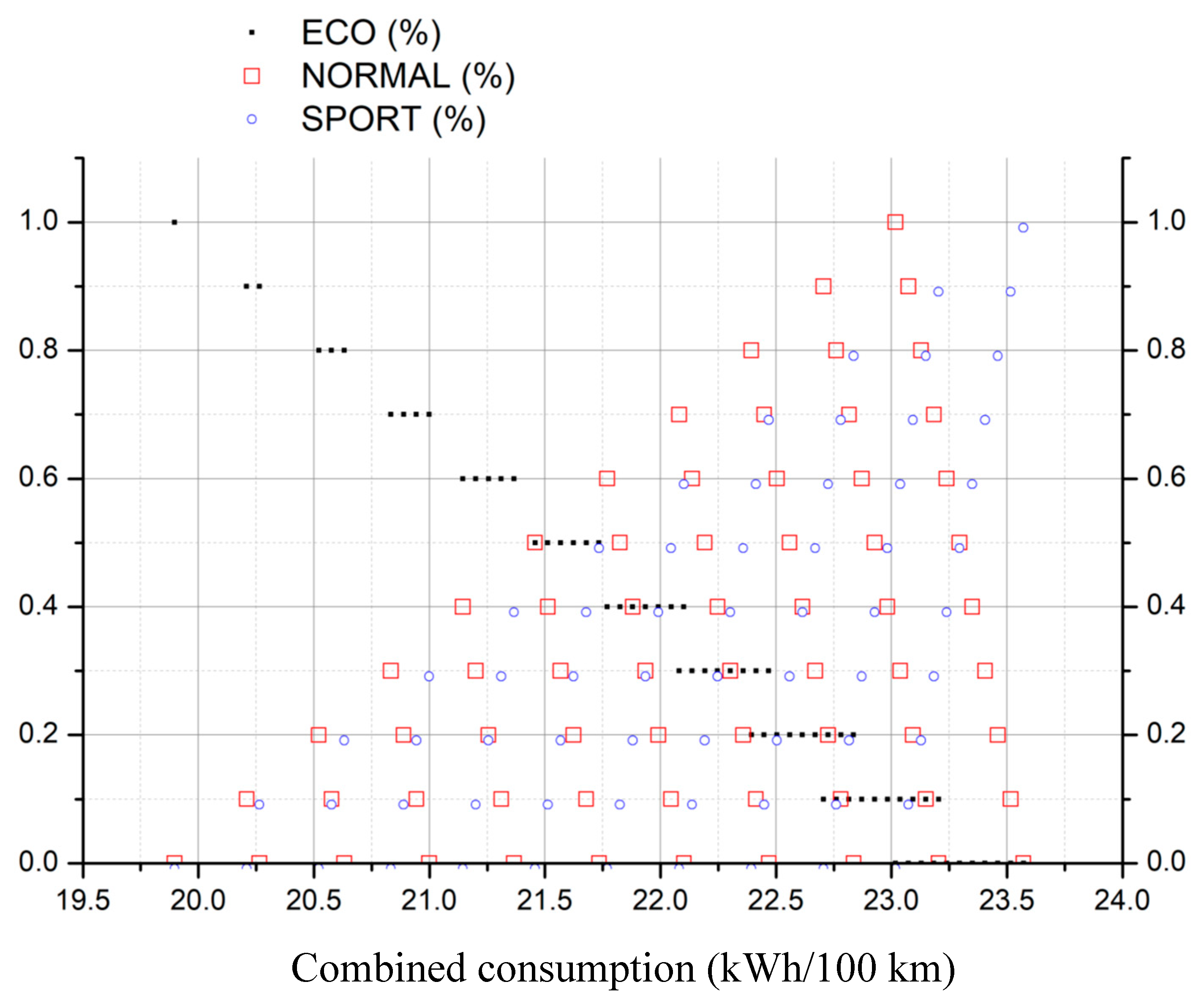

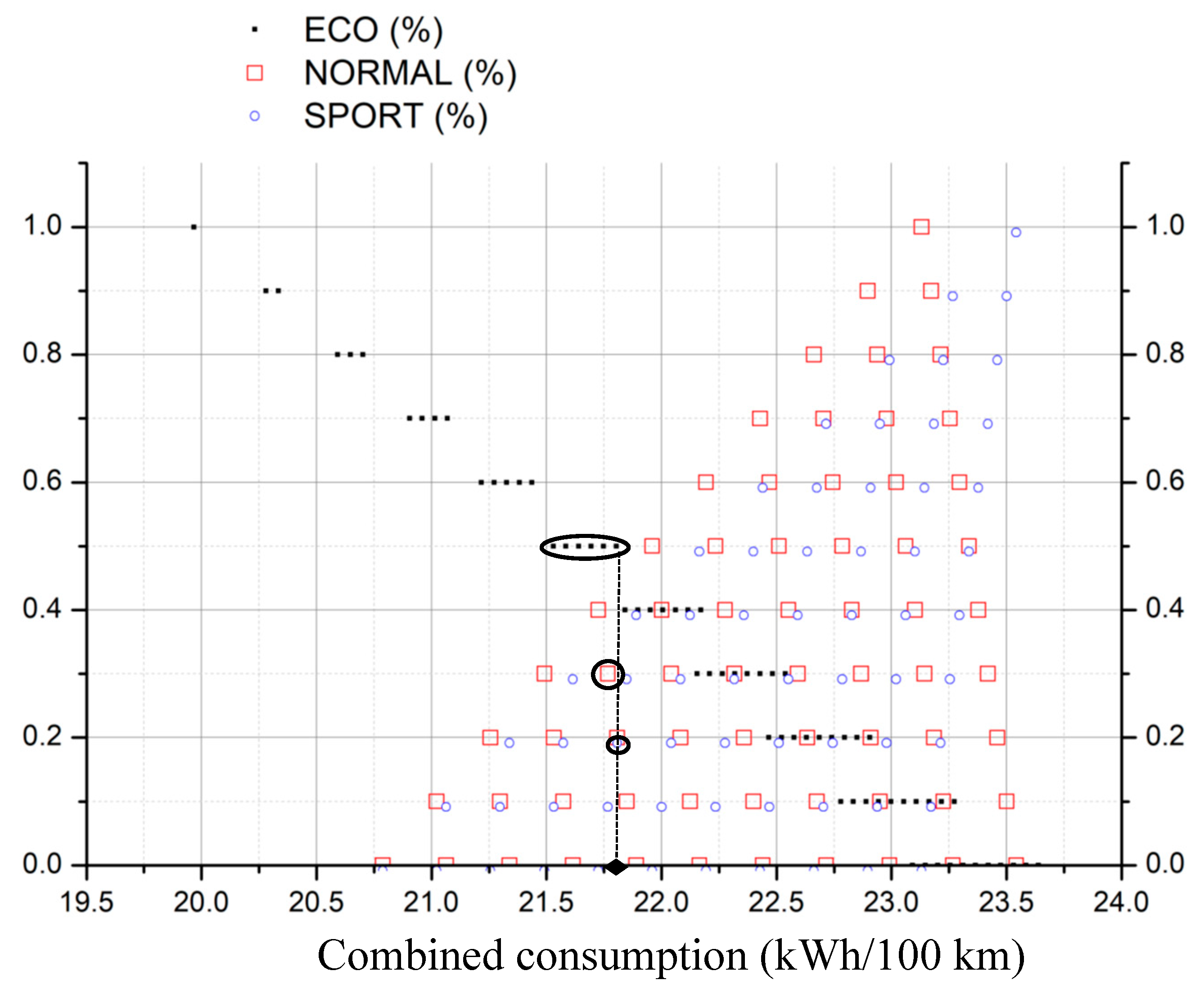

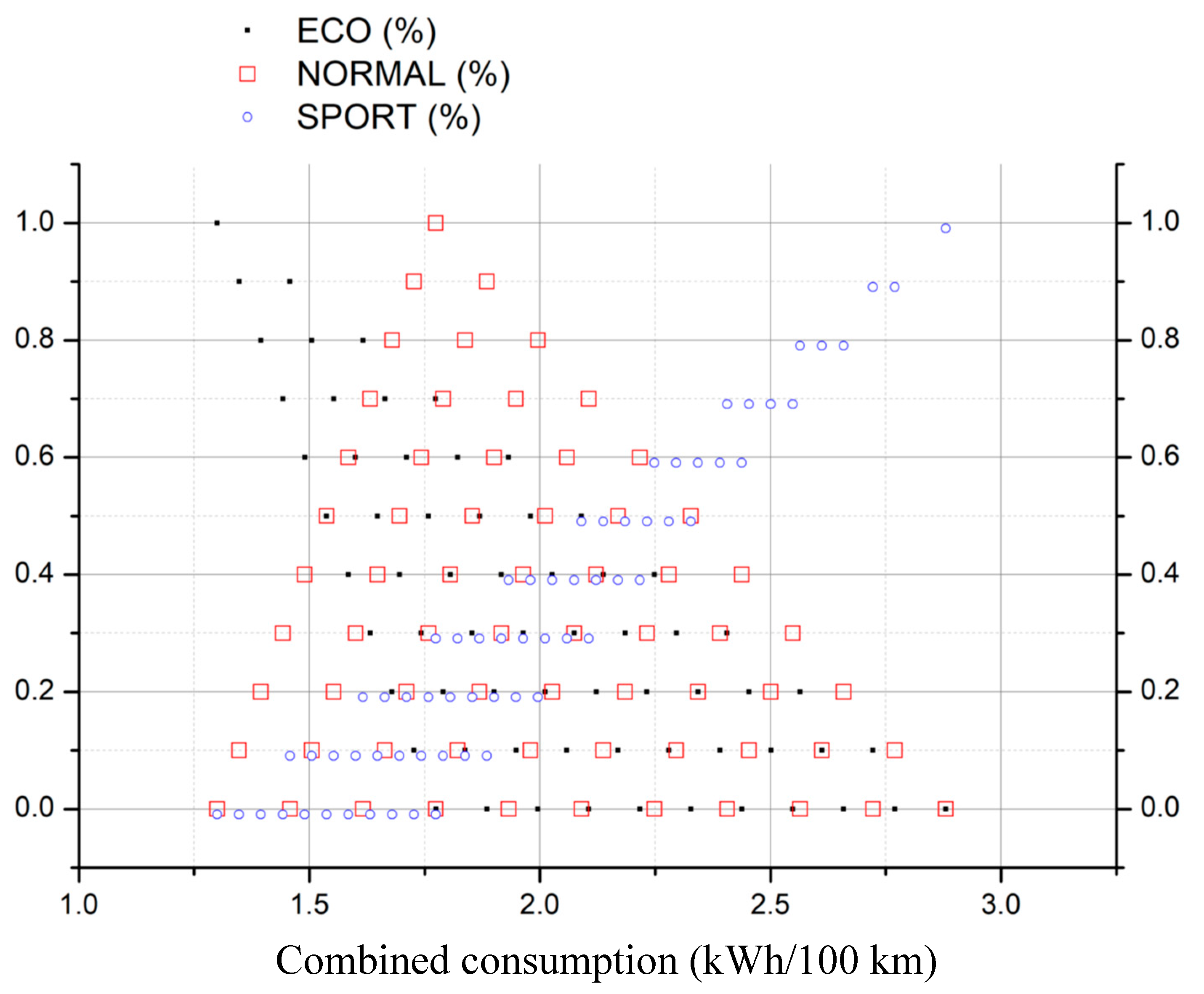

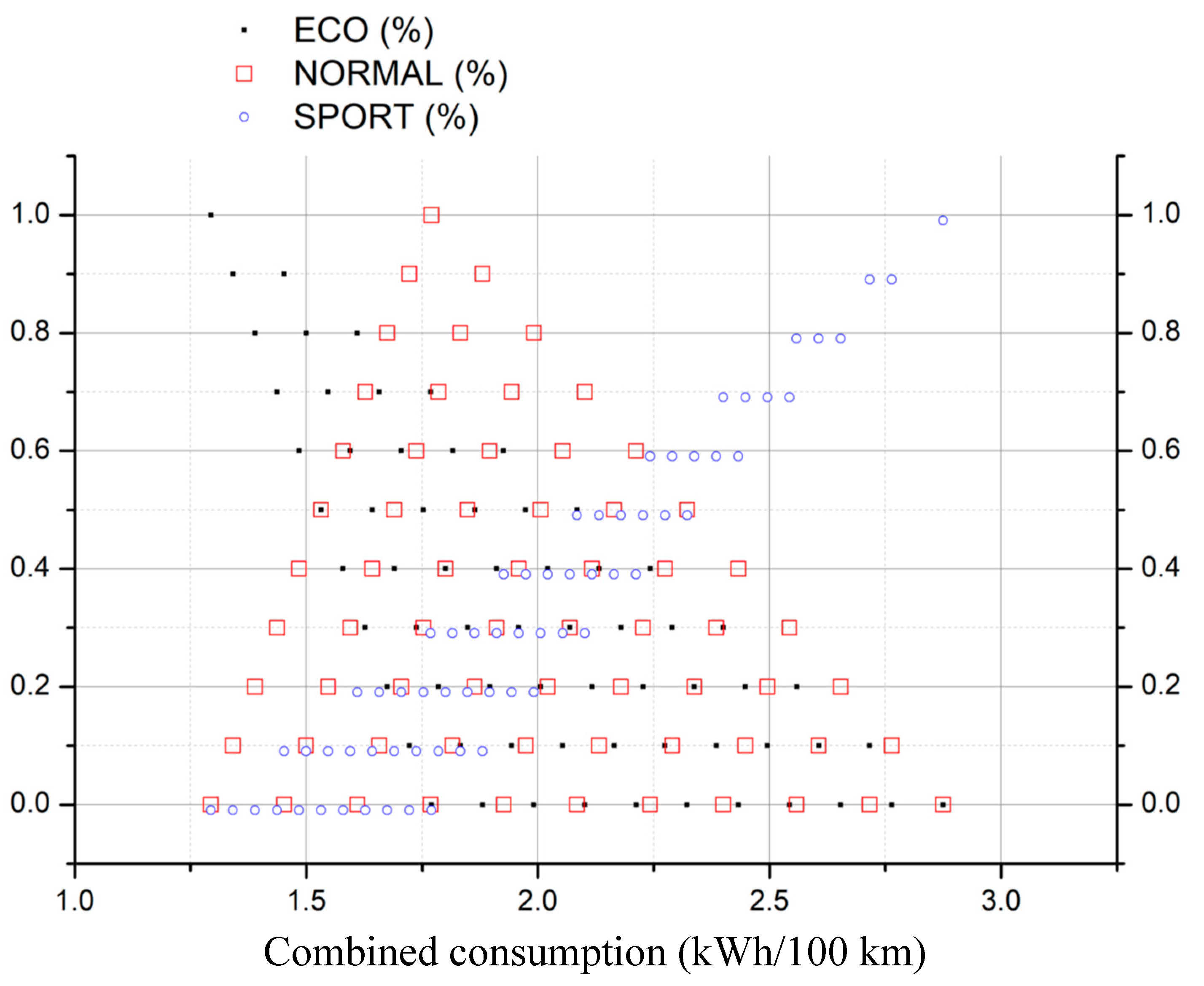

Figure 4,

Figure 5 and

Figure 6 show the results for the calculation for the three driving mode, and driving conditions.

To determine the combined consumption using

Figure 4,

Figure 5 and

Figure 6, the user should operate in the following way:

Chose the energy demand rate type and select the corresponding figure;

Select the fraction of conservative (ECO), moderate (NORMAL) and aggressive (SPORT) driving mode for the acceleration;

Search for the selected values in the figure;

Draw a vertical line downwards, joining all points of selected values until reaching the X-axis;

The intersecting point corresponds to the searched value.

To automatize the process, we developed a control routine based on the algorithms that produce the results in

Figure 4,

Figure 5 and

Figure 6.

Figure 7 shows the flowchart of the control routine.

Step 1

Control routine:

Demanding energy rate? ECO/NORMAL/SPORT

User:

NORMAL

Step 2

Control routine:

Fraction of ECO/NORMAL/SPORT acceleration?

User:

0.5/0.3/0.2

Control routine searches should be performed and selected points should be marked (black circles in

Figure 8), then a right vertical line joining the circles should be drawn (dotted black line in

Figure 8). The intersecting point at the X-axis determines the combined consumption (black rhombus).

The second group of simulations deals with the electric vehicle equipped with the hybrid fuel cell and supercapacitor system.

Table 8 shows the results of the simulation.

The analysis of results in

Table 8 shows that for every type of driving, ECO, NORMAL, or SPORT mode, the energy consumption rate, hydrogen consumption, and energy use do not depend very much on the power demand level, with a maximum difference of 0.7% for the ECO mode. The difference is almost the same for the NORMAL and SPORT mode, with values of 0.6% for both cases.

Comparing the obtained values for the three types of driving, ECO, NORMAL, and SPORT, we notice there is an increase in all reference parameters, energy consumption rate, hydrogen consumption, and energy demand, as the driving conditions are more demanding, with the highest values for the SPORT mode. The percentage increase applies to all parameters and remains constant, independent of the energy demand level. The obtained raise, on average, is 10.7% for the evolution from ECO to NORMAL, and 8.9% for the change from NORMAL to SPORT.

In a similar way to the development of the battery electric vehicle, the comparative analysis of the simulation results for the three driving modes in the hybrid system electric vehicle shows an increase in all the parameter values as we move from ECO to SPORT mode, in close agreement with what we expected.

Table 9 shows the increasing ratio.

The data in italics correspond to the battery electric vehicle. We notice that the increasing rate reduces in all driving conditions concerning the battery electric vehicle, except for the NORMAL to SPORT case, which means that the acceleration effects are of lower importance in the case of a hybrid system due to the supercapacitor, which supports the acceleration processes. These results confirm the benefits of using a supercapacitor instead of a battery for acceleration.

Comparing data from

Table 6 and

Table 8, we realize there is significant reduction in the energy and energy consumption rate for all driving modes.

Table 10 shows the values of the comparative analysis.

We observe that the reduction in energy consumption is 37%, on average, when using a hybrid fuel cell and supercapacitor system. This reduction is due to a higher performance of the hybrid system in the acceleration processes, where the supercapacitor supplies power to the electric vehicle.

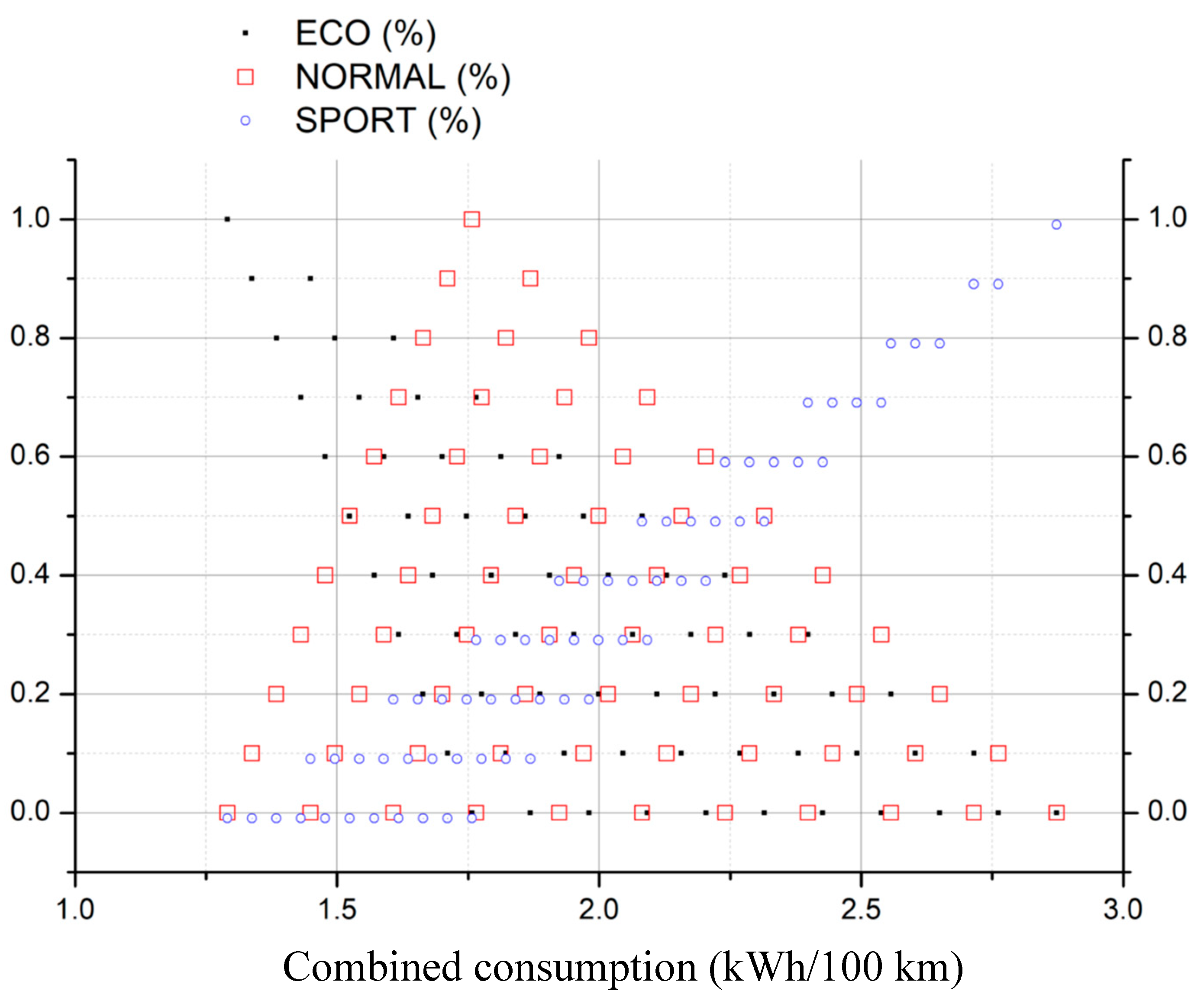

Repeating the process of energy calculation for the hybrid fuel cell and supercapacitor system, using the developed algorithms, we obtain the energy consumption for the three driving modes and driving conditions (

Figure 9,

Figure 10 and

Figure 11).

The results from

Figure 9,

Figure 10 and

Figure 11 show that the combined consumption increases as the driving mode evolves from ECO to SPORT, which is in close agreement with the energy demanding condition, since the acceleration and average speed for SPORT mode are the highest and the lowest for ECO mode.

The results also show that the energy requirements are reduced as the fraction of ECO and NORMAL mode raises when compared to SPORT mode. The reduction also occurs if the ECO mode fraction increases related to the NORMAL mode.

Comparing the results obtained from the prediction process for the two tested power systems, battery and hybrid system, fuel cell, and supercapacitor, we can summarize that the average reduction when using the hybrid system is 37% in the power system capacity and 27.1% in the vehicle weight.