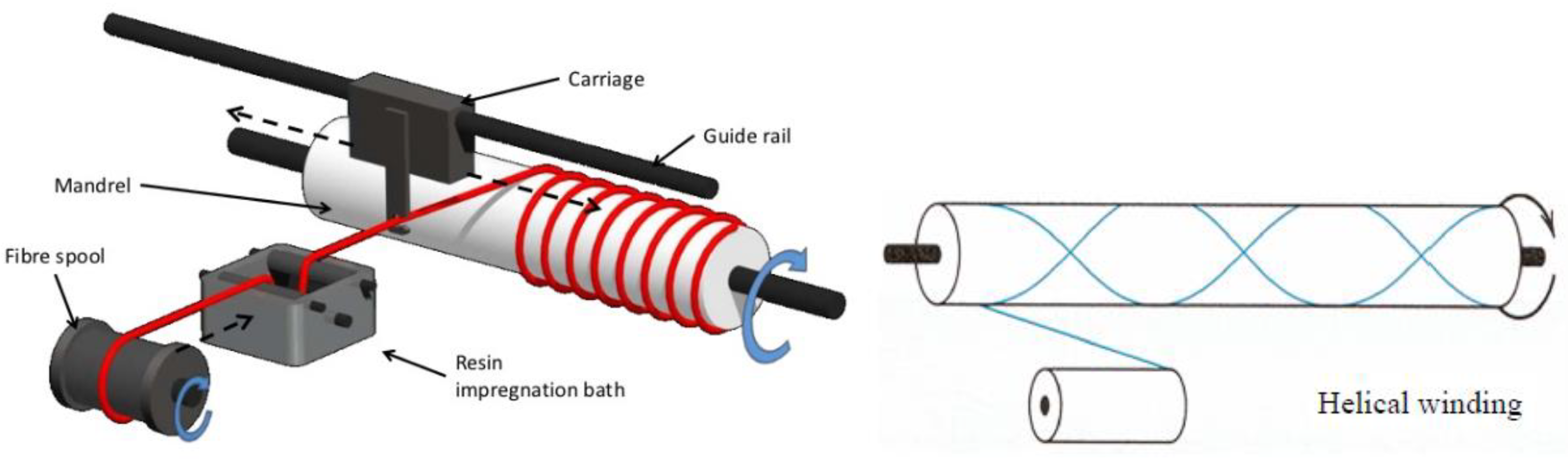

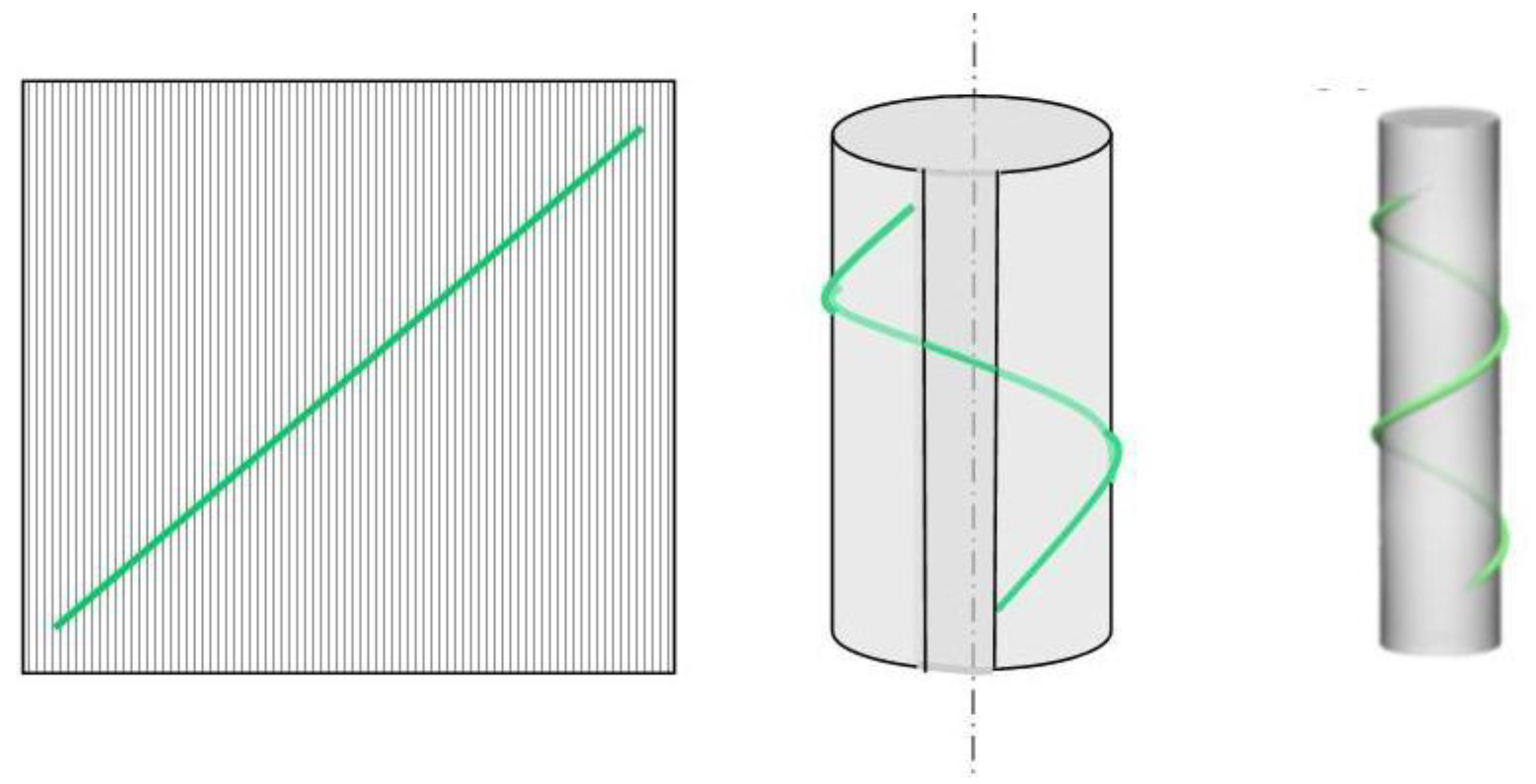

2.1. Geodesic Path Principle

The starting point in identifying the optimum winding angle is the use of certain mathematical tools, such as the geodesic path principle, which is one of the main principles employed in filament winding. A line segment (the shortest distance between two points) wrapped onto a right-angle cylinder is a geodesic arc, i.e., the shortest path around a cylinder (see

Figure 3). This is true no matter how tightly the cylinder is rolled (decreasing the radius

r). The profile of a geodesic arc on a right circular cylinder is a function of arcsine, i.e., sin

−1, which is a part of a circular helix. This definition is useful in filament winding, since the fibres will follow the shortest path on the mandrel surfaces between any given two points. Logically, the geodesic arc is a stable path, as the fibres would have to stretch to deviate from the set path. On a cylinder, the geodesic arc is a helical path with a constant winding angle,

α. This means that in order to wind the end points of a cylinder, the geodesic path cannot be followed completely. A change in the winding direction is required to generate a complete layer, where this deviation from the geodesic path ensures that the fibres stay in place through friction [

7].

When the geodesic principle is utilised, any point on the geodesic arc of an axisymmetric mandrel satisfies [

8]:

where

r is the radius of the cylinder and

α is the winding angle, which represents the orientation of the fibre with respect to the axial direction of the cylinder. When helical winding is used, as in the current study, the winding angle varies between 5° and 85°. Depending on this angle, the mandrel might rotate several times before the fibres have traversed the whole circumference of the mandrel and start laying adjacent to the previous winding. This provides a pattern of alternating positive and negative winding angles, with each layer forming a two-ply layup of [

α/−

α].

2.2. Material and Boundary Conditions

The various mechanical properties of the utilised glass fibre composite material in the current study are summarised in

Table 1. These properties were measured through mechanical testing at Swansea University during the course of the current project. As would be expected, the Young’s modulus in the X direction (longitudinal) is higher than that in the Y and Z directions (transverse). This also applies to the other mechanical properties such as the shear modulus, tensile strength, and Poisson’s ratio, as shown in the table.

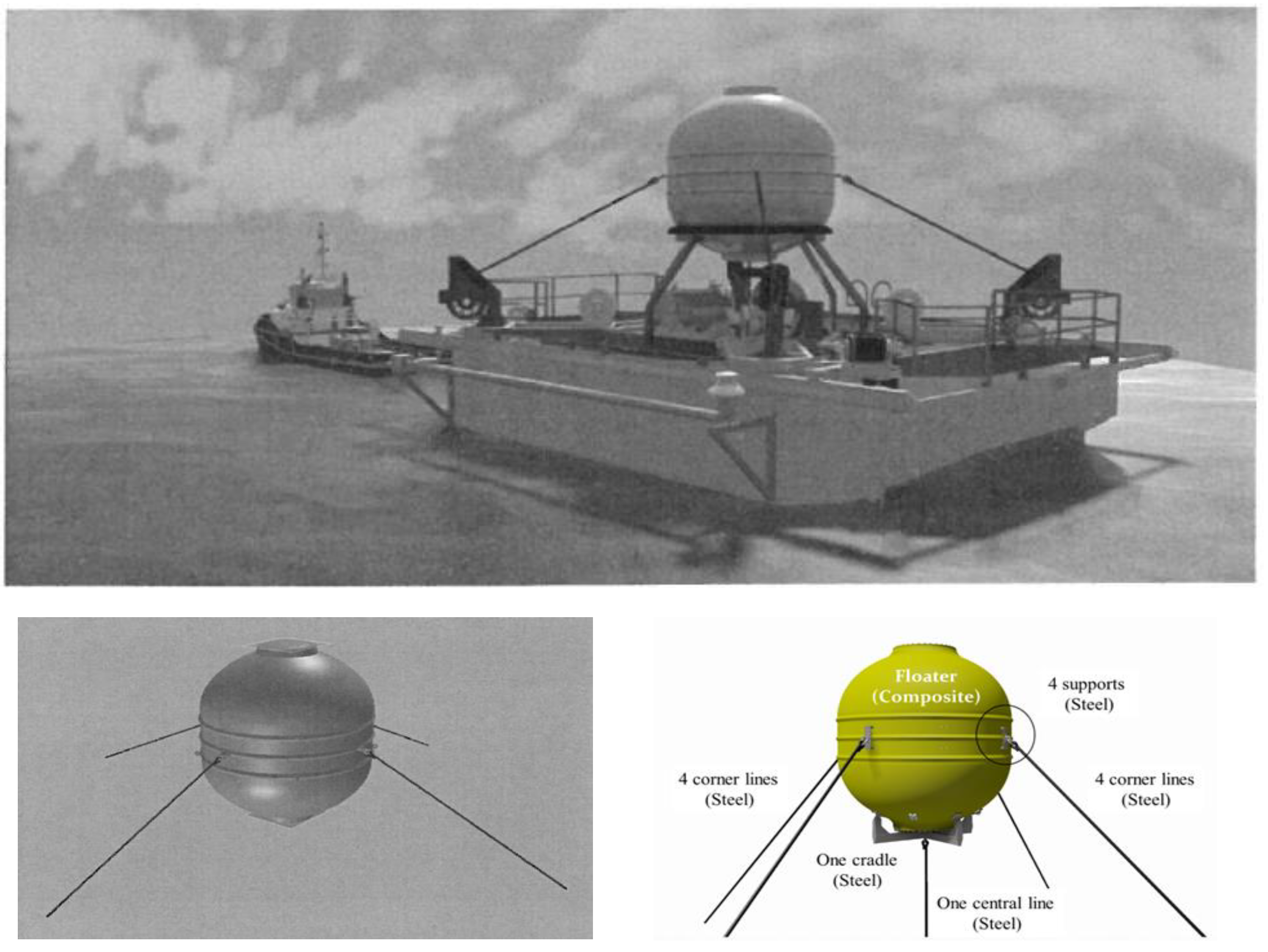

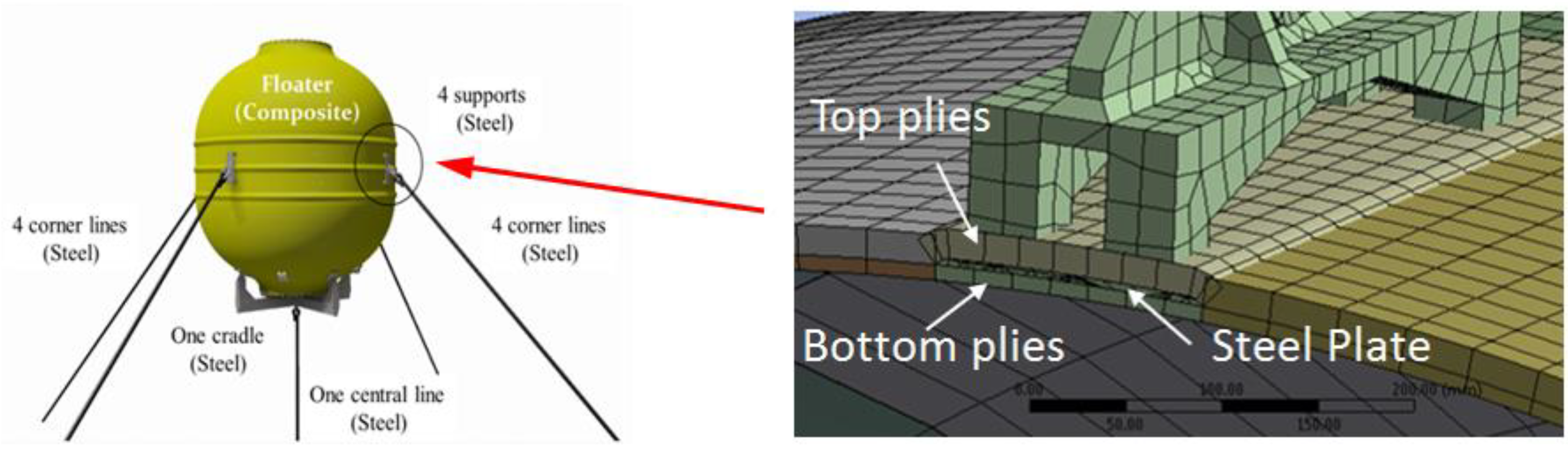

A sub-structure modelling technique was utilised to allow the analysis of the (float) model and the solid (anchoring system) model to assess the stress levels in the laminate that was built utilising the filament winding approach. The plate of the support, which is connected to a stainless steel cable, was embedded between the plies of the top and bottom shells. The contact boundary condition of the plate with the top and bottom shells was assumed to be frictionless in order to reduce the number of uncertain parameters, as well as to minimise the modelling time and cost. The “ribs” that surround the float were assumed to be circumferential around the body of the float system. The cables utilised in the model were assumed to be made of stainless steel, with fixed supports assumed at the end of the cables. In order to simplify the analysis of the geometry, one quarter of the float was modelled by applying symmetric axis boundary conditions. These conditions assume that as long as the float is symmetric along the three employed axes, one-quarter is sufficient to simplify the problem, as well as to generalise the solution. This makes the analysis significantly more efficient and applicable to the whole geometry.

2.3. Multi-Level Optimisation Strategy

One of the major aims of the current study is to determine the optimum thickness of the filament-wound composite top and bottom shells that support the stainless steel plate, as shown in

Figure 4. Moreover, the sequence for the filament winding angle orientations of the plies is also required to ensure that the highest possible strength of the structure is attained. This requires the optimum combined solution for the thickness and filament winding angle orientations that provide the highest supportive strength to the float system.

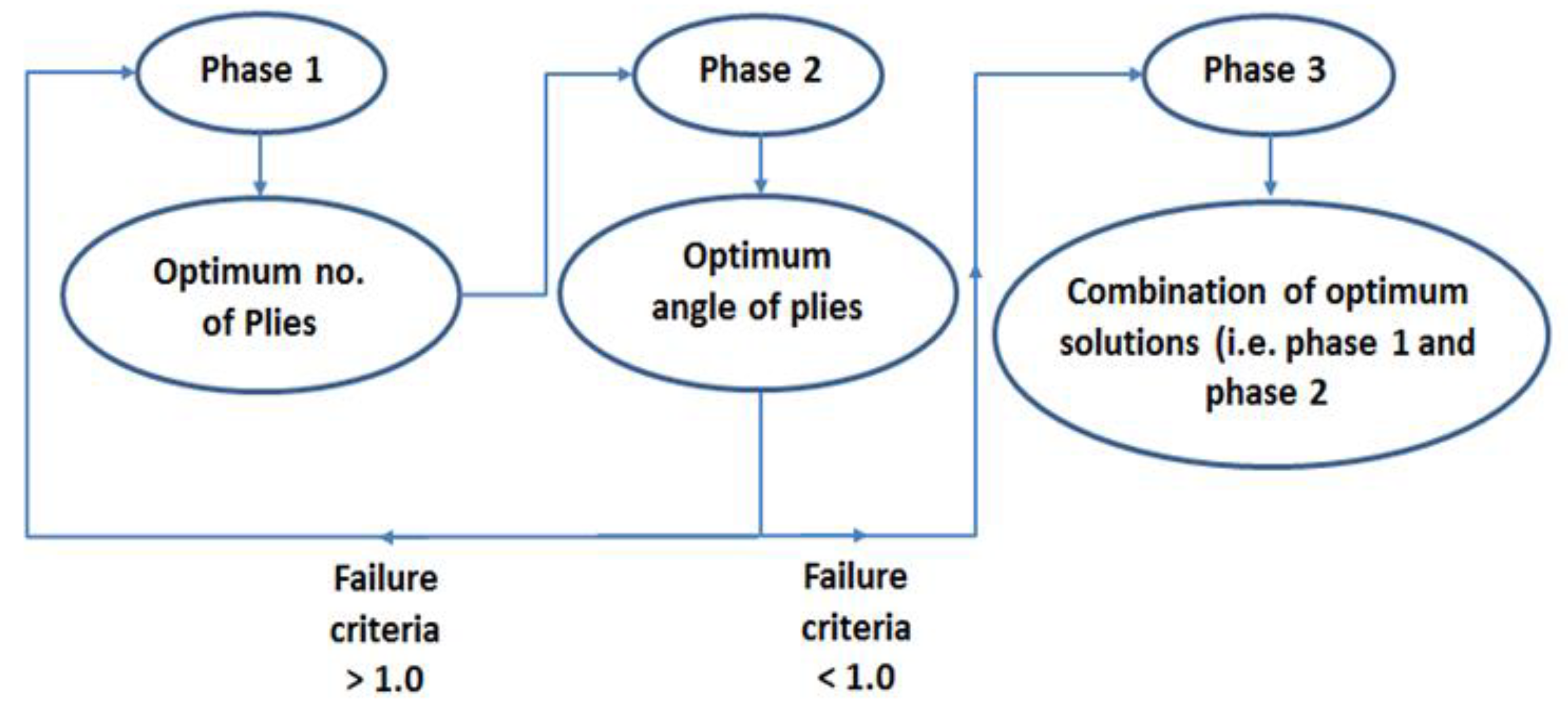

Thus, the design variables of the system consist of the stacking sequence in terms of angle orientations, as well as the number of plies in the top and bottom shells used to support the structure. The optimisation process of the float system can be divided into three successive phases that involve the thickness of the top and bottom shells, as well as the stacking sequence of the plies, as shown in the flow diagram of

Figure 5.

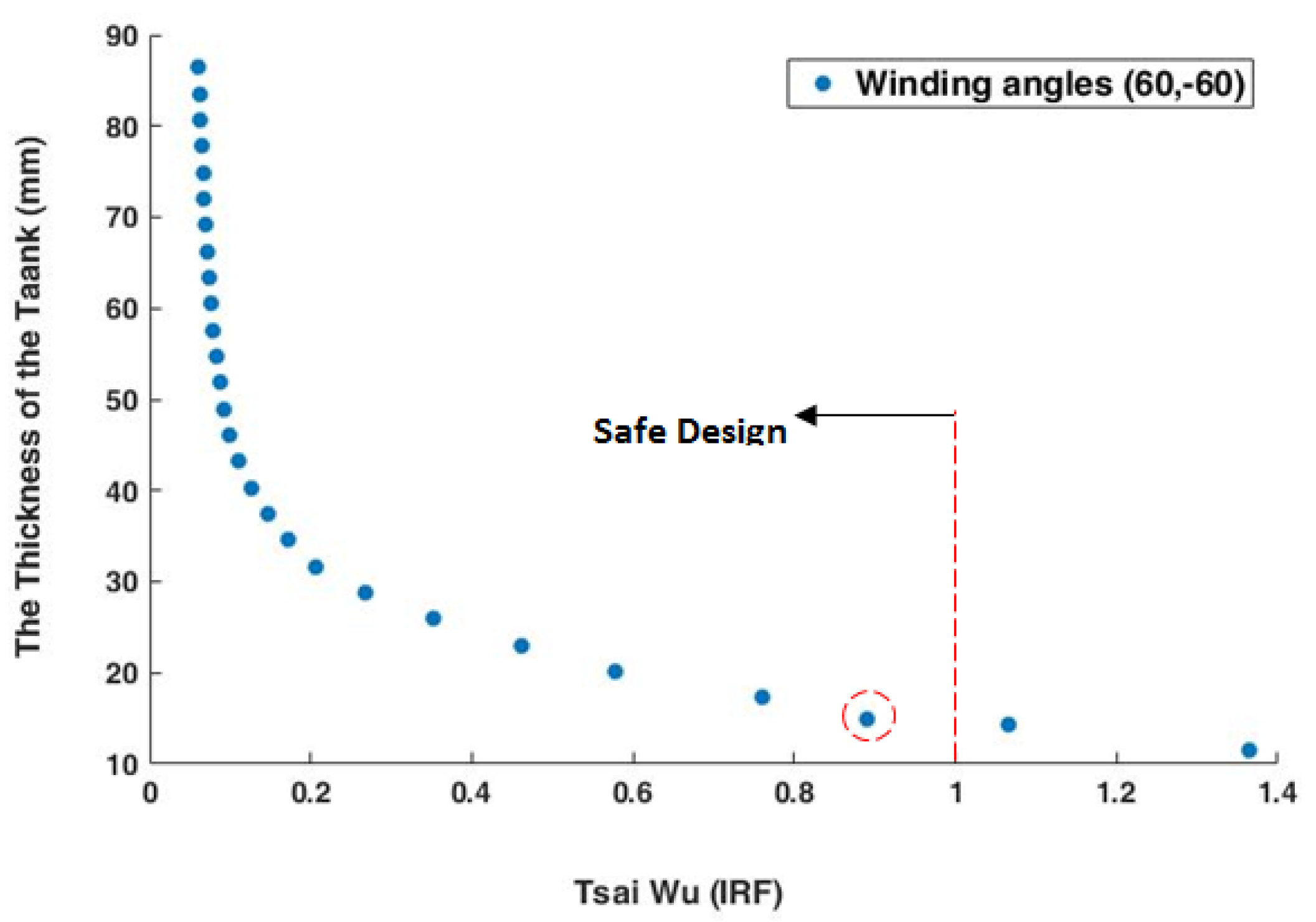

In this analysis, the Tsai–Wu failure theory is applied to the composite material structures to estimate the remaining life of the material under various loading conditions [

9]. The Tsai–Wu failure criterion with a high safety limit is widely applied to composite materials. This approach allows the sensitivity of each shell to be investigated and for the inverse reverse factor (

IRF) to be studied, which is given by [

9,

10]:

where the ultimate applied load is the maximum allowable load imposed on the structure, whereas the ultimate strength is the maximum load that the material can withstand prior to fracture. If the value of

IRF is below 1, then the applied load is below the ultimate strength of the material, which indicates that the structure is safe. Whereas when the value of

IRF is above 1, the applied load is beyond the material’s strength, which means that the structure is unsafe, i.e., failure is likely. The various phases for the analysis are:

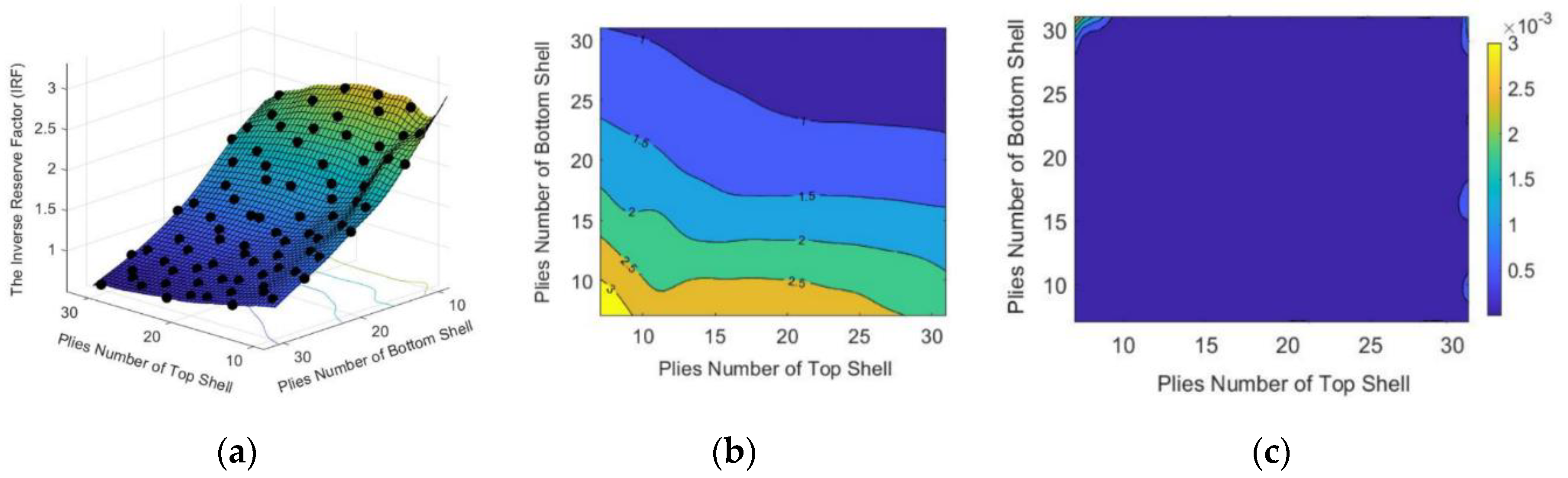

- Phase 1.

The minimum number of plies for the top and bottom shells

This phase starts by assuming that the fibre orientation for all plies is 90°. This assumption will provide the best option to hold the stainless steel supports in place. This stems from the fact that when the stainless steel cables are under tension, they will try to pull the stainless steel support that resides within the plies. This action will result in pure tension in the uni-directional orientation of the fibres, which are assumed to be 90° filament-wound. This will provide a coherent and strong design for the float, with the minimum number of plies used to start the process and simplify the solution. The Tsai–Wu failure criterion is employed at this stage and solutions with IRF < 1.0 are considered for the next phase.

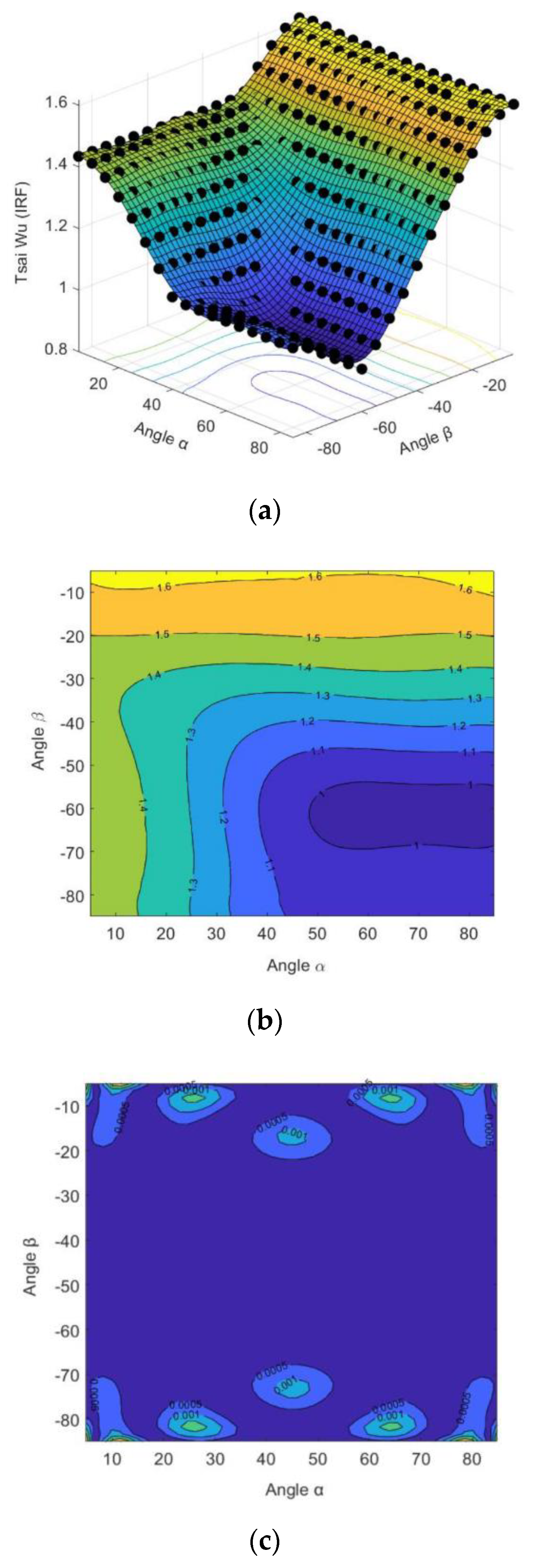

- Phase 2.

The optimum stacking sequence, i.e., fibre orientations

At this stage, the thickness of the top and bottom plies is kept constant while varying the stacking sequence of the fibres during filament winding. The angles start with [5°/85°] and [−5°/−85°] stacking sequences, which means that the optimum solution is within this range of angles. The reason for this selection is that angles between 0° and ±5° result in “planar” winding rather than “helical” winding, which are best suited to support the heads, domes, or caps and are beyond the scope of the current study. Additionally, angles above 85° are closer to “hoop” winding, which is been explored in the current study, since the “helical” design is the major focus of the present investigation, as recommended by Marine Power Systems (MPS). The Tsai–Wu criterion is again employed and fibre orientations with IRF < 1.0 are considered for the final stage of the optimisation process.

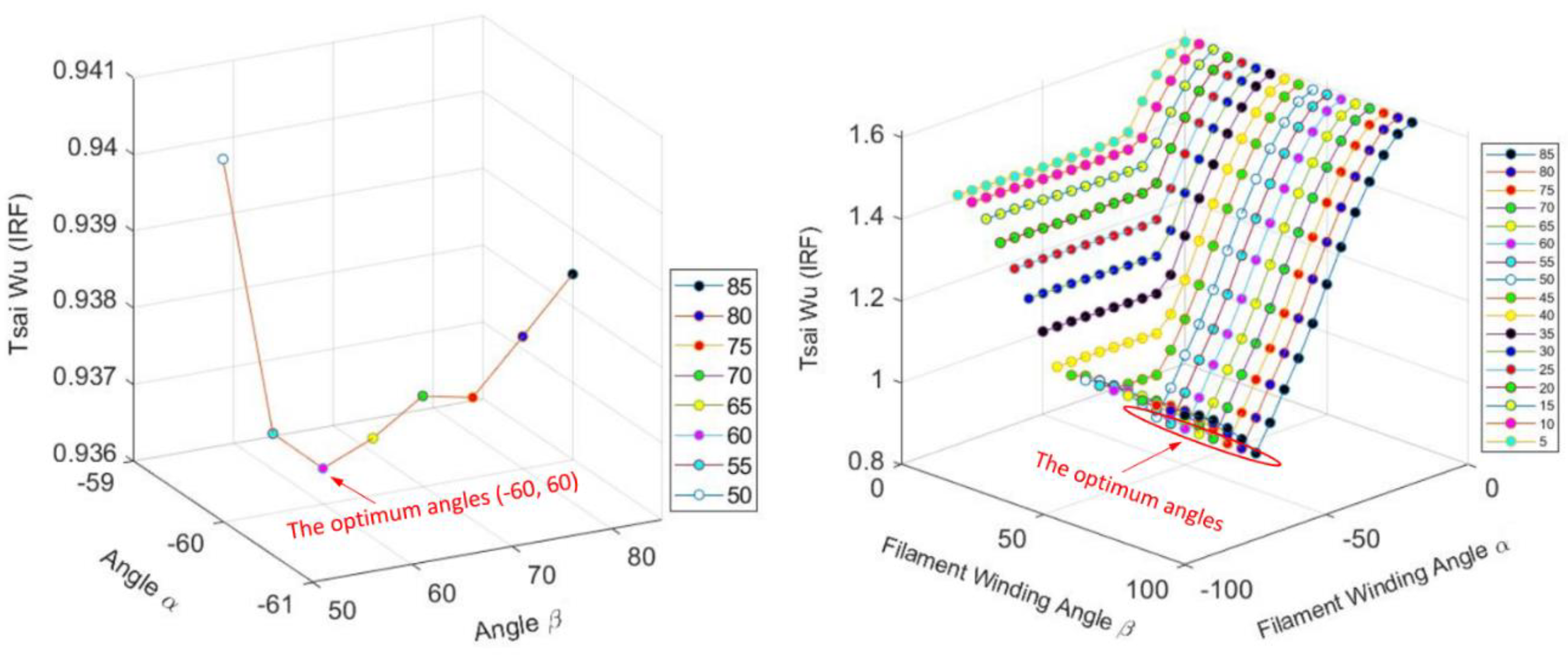

- Phase 3.

The optimum combination of plies vs. stacking sequence

In this phase, a 3D surface response is created in order to evaluate the combined effects of the stacking sequence and the ply thickness. The optimum solutions for phases 1 and 2 with the minimum IRF values are combined at this stage. Again, the Tsai–Wu failure criterion is employed to find the minimum combined IRF value of the stacking sequence alongside the ply thickness, which ensures the highest level of safety in the structure.

2.4. Uncertainty and Robust Design Procedure

The probability distribution of the possible solutions was obtained from the fact that there are 16 possible angles in the (+) direction and 16 possible angles in the (-) direction, given that the angles are within the range of 5° to 85° (with 5° increments). This gives a total 256 combined possible solutions for the stacking angles (16

2 = 256 solutions). The reason for the 5° increments is that in real-world situations, filament winding processes are restricted to winding the fibres at angles of 0°, 5°, 10°, 15°, 20°,…….., 90°. These input values of the stacking sequence were manually input into the innovative model that was developed at Swansea University. Through this, ANSYS Workbench was linked via MATLAB utilising the developed and in-house written code. The code automatically operates ANSYS, runs the model, retrieves the results, and continues to obtain the remaining sets of results. This reduces the effort, time, and number of trials used to choose the optimum design parameters for any given design. The framework for robust design proposed and employed by the authors has recently been published elsewhere, although for carbon fibre composite materials bonded via aluminium joints [

11]. For the optimum and robust design, the blind kriging approach [

12], a typical meta-model process, was utilised in the analysis. This approach provided outstanding results with a minimal amount of variation. This facilitated the construction of the response surfaces for each stage in the analysis, from which the optimum and robust design parameters were determined. The strategy used to optimise the uncertain parameters and the robust design starts by assuming that a certain number of plies are oriented at 90° to provide the maximum possible strength while optimising the number of plies, which is the first phase. This reduces the risk of failure of the glass fibre material. The optimum number of plies will then be taken into the second phase to obtain the best angle combinations of the filament-wound fibres. At this stage, the number of plies is kept unchanged while optimising the fibre orientation so that the likelihood of failure is eliminated. The third phase optimises the number of plies and the fibre orientations in order to obtain the best performance, i.e., maximum strength and no failure. This exercise provides a procedure that can be applied to any engineering application that involves more than a single variable through the employment of 3D response surfaces that are able to define the safest operational region.

2.5. Meta-Model Design Optimisation

In industrial practice, the optimisation of complex engineering problems is becoming increasingly popular utilising meta-model based approaches. This is due to the fact such methods reduce the burden of computationally expensive simulations. The meta-model-based optimisation relies on building a surrogate model, i.e., a meta-model, based on a reduced number of simulations, after which the model is used for optimisation purposes [

13]. An approximate relationship is developed by the meta-model between the design variables and the output variable, e.g.,

, where

y is the output variable and

are the input variables. This process can provide an optimised solution more quickly when the surrogate model is utilised and is less expensive to execute compared to the corresponding deterministic simulations. The “response surface” is commonly used to present the results, with a linear model being the simplest form, where the functional relationship

is approximated by a linear function of the design variables. On the other hand, higher order response surfaces (e.g., polynomial models) can be employed, in which the response surface is a polynomial function of the design variables. The linear or polynomial response functions are developed by minimising the sum of the squared distances from the response surface for given set of data points, i.e., the ordinary least squares approach. In this respect, the surrogate modelling approach assumes that all errors obtained from the ordinary least squared approach are normally distributed with a defined mean and variance. This assumption is often only approximate in real-world problems.

The most widely used meta-model approach is known as the “kriging” or the “Gaussian interpolation” method. The surrogate model is assumed to be capable of approximating the deterministic noise-free data and is used for high level optimisation, design space exploration, sensitivity analyses, visualization, and prototyping [

14]. The additional advantage of using the kriging approach compared to the conventional least squares method is that the model goes through each data point. This allows the model to describe the uncertainty of the interpolation outside the given range of data points [

15]. The kriging method is favourable compared to other techniques due to the fact that it is able to approximate complex response functions with less restrictive assumptions on the distribution of residual errors [

16].

2.6. The Ordinary Kriging Model

The kriging approach is normally pre-fixed with various names, depending on the form of the function utilised in the regression analysis. In this context, the simple kriging method assumes a constant function, i.e.,

f(

x) = 0. However, the ordinary kriging method assumes aconstant function,

f(

x) = 0. For more complex processes, the trend functions can be linear or quadratic, with the universal kriging model utilising a multi-variate polynomial of the form:

where

b1(

x),

b2(

x), …,

bp(

x), are the basis functions (i.e., the basis polynomials) and

αi = (

α1,

α2, …,

αp) denote the coefficients. In this approach, the regression function reproduces the general trend in the data (i.e., the largest variance), after which a Gaussian process is used to interpolate the residuals.

2.7. The Blind Kriging Model

In contrast, the blind kriging approach assumes a trend function

f(

x) that is unknown and difficult to determine for a given problem. This offers the possibility of identifying the most reasonable interactions within the data points [

12]. This method determines the most efficient functions or features that capture the most observed variance in the sample. In an ideal scenario, the data is represented fully by a chosen trend function. The main idea is to choose new features in addition to the existing features that can be included in the kriging regression function to improve the results. The linear model that incorporates a whole set of candidate functions is:

where

t is the number of candidate functions. The first term in this equation is the kriging regression function, where the values of the coefficient are determined independently relative to

βi = (

β1,

β2, …,

βt). The second term involves the parameters that are estimated based on the relevance of the candidate features. The estimation of the parameters, i.e., the least-squared solution, is a straightforward approach that can help to rank the features.

2.8. The Co-Kriging Model

The co-kriging approach is considered a special case of the multi-output or multi-task Gaussian process. This method exploits the correlation between coarse and fine model data to improve the predictive capability and accuracy [

17]. The co-kriging model can be interpreted as the sequential construction of two kriging models—the first Kriging model is related to the coarse data and the second Kriging model is related to the residuals of the coarse data. In other words, this model employs a small set of short-term characteristics in order to predict the long-term characteristics. This, in turn, reduces the time and cost associated with generating such long-term characteristics and can provide predictions both within and outside the assumed range of characteristics.

In the current study, the ordinary, blind, and co-kriging approaches were employed in order to determine the optimum regions of the bond strength in the current case study. The study aims to validate existing data, as well as provide information on the optimum and robust design parameters. In essence, these models attempt to find the surrogate model that simulates the problem using less strict assumptions about the residual errors [

18].