Optical Properties of a-SiC:H Thin Films Deposited by Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouadfel, A.M.; Keffous, A.; Kheloufi, A.; Cheriet, A.; Yaddaden, C.; Gabouze, N.; Kechouane, M.; Belkacem, Y.; Boukezzata, A.; Kaci, S.; et al. Silicon Carbide Thin Films with Different Processing Growth as an Alternative for Energetic Application. Opt. Mater. 2017, 65, 117–123. [Google Scholar] [CrossRef]

- Keffous, A.; Bourenane, K.; Kechouane, M.; Gabouze, N.; Kerdja, T. Morphological, Structural and Optical Properties of Thin SiC Layer Growth onto Silicon by Pulsed Laser Deposition. Vacuum 2007, 81, 632–635. [Google Scholar] [CrossRef]

- Myong, S.Y.; Kim, S.S.; Lim, K.S. In Situ Ultraviolet Treatment in an Ar Ambient upon p-Type Hydrogenated Amorphous Silicon–Carbide Windows of Hydrogenated Amorphous Silicon Based Solar Cells. Appl. Phys. Lett. 2004, 84, 5416–5418. [Google Scholar] [CrossRef]

- Collins, R.; Taylor, P.C.; Kondo, M.; Carius, R.; Biswas, R. Amorphous and Nanocrystalline Silicon Science and Technology; Cambridge University Press: Cambridge, UK, 2005; Volume 862. [Google Scholar]

- Chaussende, D.; Tabouret, V.; Crisci, A.; Morais, M.; Coindeau, S.; Berthomé, G.; Kollmuss, M.; Wellmann, P.; Jomard, F.; Pinault-Thaury, M.-A.; et al. Investigation of Amorphous-SiC Thin Film Deposition by RF Magnetron Sputtering for Optical Applications. Mater. Sci. Semicond. Process. 2024, 182, 108673. [Google Scholar] [CrossRef]

- Kumar, M. Studies of Structural and Optical Properties of Sputtered SiC Thin Films. Zast. Mater. 2024, 65, 343–349. [Google Scholar] [CrossRef]

- Daouahi, M.; Rekik, N. Effect of Substrate Temperature on (Micro/Nano)Structure of a-SiC:H Thin Films Deposited by Radio-Frequency Magnetron Sputtering. J. Phys. Chem. C 2012, 116, 21018–21026. [Google Scholar] [CrossRef]

- Swain, B.P.; Dusane, R.O. Effect of Substrate Temperature on HWCVD Deposited A-SiC:H Film. Mater. Lett. 2007, 61, 4731–4734. [Google Scholar] [CrossRef]

- Demichelis, F.; Crovini, G.; Pirri, C.F.; Tresso, E.; Giamello, E.; DellaMea, G. Hydrogen Evolution in Amorphous Silicon Carbide. Phys. B 1991, 170, 149–152. [Google Scholar] [CrossRef]

- Nussupov, K.; Beisenkhanov, N.; Bugybay, Z.; Sultanov, A. Study of Optical and Passivation Properties of Hydrogenated Silicon Carbide Thin Films Deposited by Reactive Magnetron Sputtering for C-Si Solar Cell Application. Thin Solid Film. 2023, 782, 140006. [Google Scholar] [CrossRef]

- Saito, N. Influence of Sputtering Pressure on the Properties of Hydrogenated Amorphous-Silicon Carbon Alloy Films Prepared by Magnetron Sputtering of Silicon in Methane-Argon Gas Mixtures. J. Appl. Phys. 1986, 59, 2498–2502. [Google Scholar] [CrossRef]

- Künle, M.; Kaltenbach, T.; Löper, P.; Hartel, A.; Janz, S.; Eibl, O.; Nickel, K.-G. Si-Rich a-SiC:H Thin Films: Structural and Optical Transformations during Thermal Annealing. Thin Solid Film. 2010, 519, 151–157. [Google Scholar] [CrossRef]

- Kwon, S.; Park, Y.; Ban, W.; Youn, C.; Lee, S.; Yang, J.; Jung, D.; Choi, T. Effect of Plasma Power on Properties of Hydrogenated Amorphous Silicon Carbide Hardmask Films Deposited by PECVD. Vacuum 2020, 174, 109187. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, P.; Zhang, R.; Han, G.; Weng, W. Structure and Properties of Hydrogenated Amorphous Silicon Carbide Thin Films Deposited by PECVD. J. Non Cryst. Solids 2008, 354, 1435–1439. [Google Scholar] [CrossRef]

- Kefif, K.; Bouizem, Y.; Belfedal, A.; Sib, J.D.; Benlakehal, D.; Chahed, L. Hydrogen Related Crystallization in Silicon Carbide Thin Films. Optik 2018, 154, 459–466. [Google Scholar] [CrossRef]

- Yunaz, I.A.; Hashizume, K.; Miyajima, S.; Yamada, A.; Konagai, M. Fabrication of Amorphous Silicon Carbide Films Using VHF-PECVD for Triple-Junction Thin-Film Solar Cell Applications. Sol. Energy Mater. Sol. Cells 2009, 93, 1056–1061. [Google Scholar] [CrossRef]

- Magafas, L.; Kalomiros, J.; Bandekas, D.; Tsirigotis, G. Optimization of the Electrical Properties of Al/a-SiC:H Schottky Diodes by Means of Thermal Annealing of a-SiC:H Thin Films. Microelectron. J. 2006, 37, 1352–1357. [Google Scholar] [CrossRef]

- Magafas, L.; Georgoulas, N.; Girginoudi, D.; Thanailakis, A. The Dependence of Electrical and Optical Properties of RF Sputtered Amorphous Silicon–Carbon Alloy Thin Films on Substrate Temperature and Hydrogen Flow Rate. Phys. Status Solidi (a) 1991, 126, 143–150. [Google Scholar] [CrossRef]

- Bullot, J.; Schmidt, M.P. Physics of Amorphous Silicon–Carbon Alloys. Phys. Status Solidi (b) 1987, 143, 345–418. [Google Scholar] [CrossRef]

- Vasin, A.V.; Kolesnik, S.P.; Konchits, A.A.; Kushnirenko, V.I.; Lysenko, V.S.; Nazarov, A.N.; Rusavsky, A.V.; Ashok, S. Effects of Hydrogen Bond Redistribution on Photoluminescence of A-SiC:H Films under Thermal Treatment. J. Appl. Phys. 2006, 99, 113520. [Google Scholar] [CrossRef]

- Calcagno, L.; Musumeci, P.; Roccaforte, F.; Bongiorno, C.; Foti, G. Crystallisation Mechanism of Amorphous Silicon Carbide. Appl. Surf. Sci. 2001, 184, 123–127. [Google Scholar] [CrossRef]

- Herlach, F. (Ed.) Strong and Ultrastrong Magnetic Fields and Their Applications; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1985. [Google Scholar] [CrossRef]

- Mott, N.; Davis, E. Electronic Processes in Non-Crystalline Materials, 2nd ed.; Clarendon Press: Oxford, UK, 1979. [Google Scholar]

- Tauc, J. Amorphous and Liquid Semiconductors; Springer: New York, NY, USA, 1974. [Google Scholar]

- Brik, M.G.; Srivastava, A.M.; Popov, A.I. A Few Common Misconceptions in the Interpretation of Experimental Spectroscopic Data. Opt. Mater. 2022, 127, 112276. [Google Scholar] [CrossRef]

- Anderson, D.A.; Spear, W.E. Electrical and Optical Properties of Amorphous Silicon Carbide, Silicon Nitride and Germanium Carbide Prepared by the Glow Discharge Technique. Philos. Mag. 1977, 35, 1–16. [Google Scholar] [CrossRef]

- Jubu, P.R.; Yam, F.K.; Igba, V.M.; Beh, K.P. Tauc-Plot Scale and Extrapolation Effect on Bandgap Estimation from UV–Vis–NIR Data—A Case Study of β-Ga2O3. J. Solid State Chem. 2020, 290, 121576. [Google Scholar] [CrossRef]

- Ghobadi, N. Band Gap Determination Using Absorption Spectrum Fitting Procedure. Int. Nano Lett. 2013, 3, 2. [Google Scholar] [CrossRef]

- Joannopoulos, J.D.; Lucovsky, G. (Eds.) The Physics of Hydrogenated Amorphous Silicon II: Electronic and Vibrational Properties; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Kalomiros, I. Study of Certain Properties of the Series of the Phyllomorphic Semiconductors mZnS:1ln2S3; Aristotle University of Thessaloniki: Thessaloniki, Greece, 1989. [Google Scholar]

- Magafas, L.; Bandekas, D.; Boglou, A.K.; Anagnostopoloulos, A.N. Electrical Properties of Annealed A-SiC:H Thin Films. J. Non Cryst. Solids 2007, 353, 1065–1069. [Google Scholar] [CrossRef]

- Mellassi, K.; El Idrissi, M.C.; Barhdadi, A.; Chouiyakh, A.; Rjeb, A. Study of Some Structural Properties of Hydrogenated Amorphous Silicon Thin Films Prepared by Radiofrequency Cathodic Sputtering; IC/2001/103; ICTP Preprint: Trieste, Italy, 2001. [Google Scholar]

- Kasap, S.; Capper, P. Springer Handbook of Electronic and Photonic Materials; Springer: London, UK, 2006. [Google Scholar]

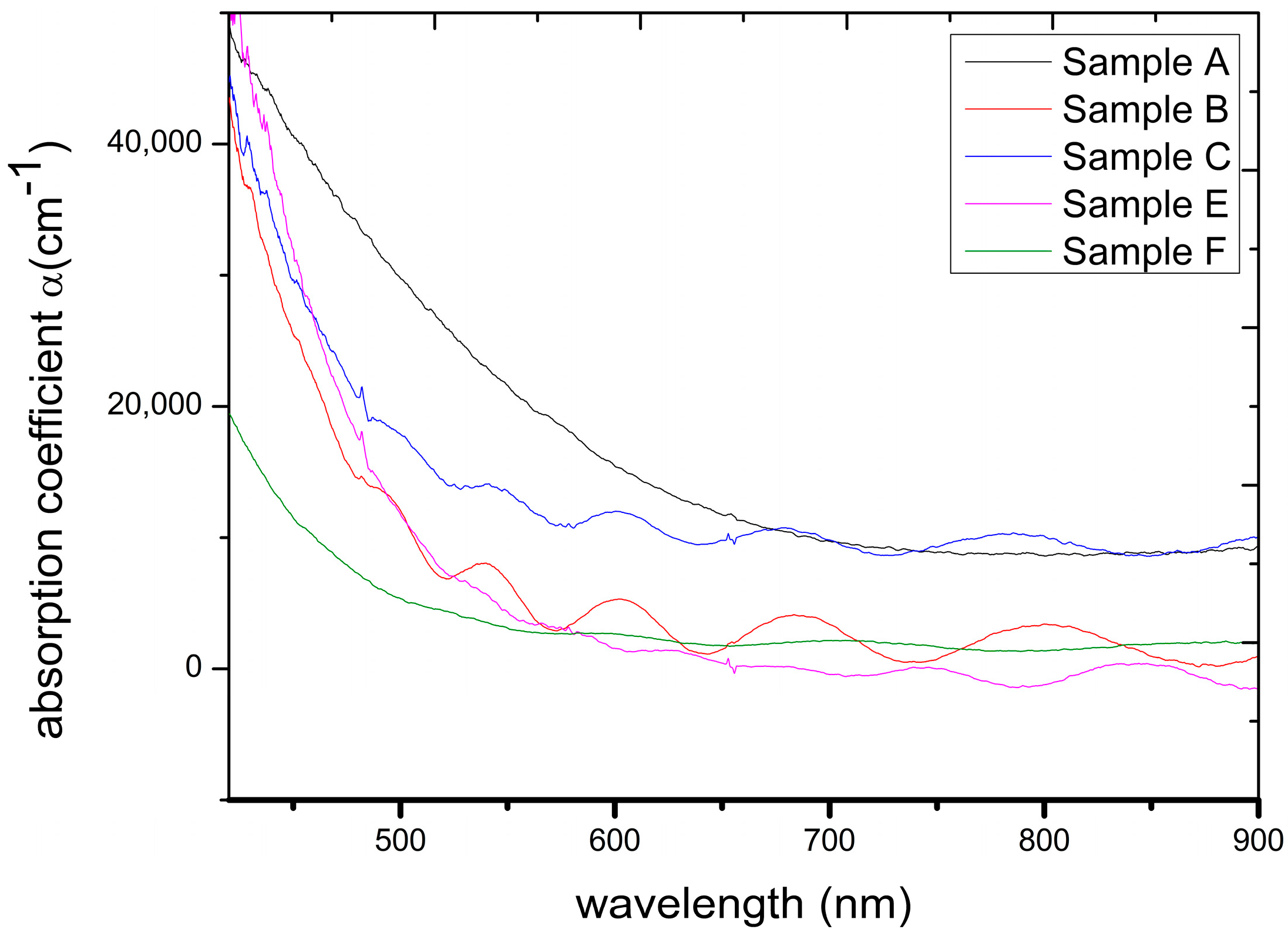

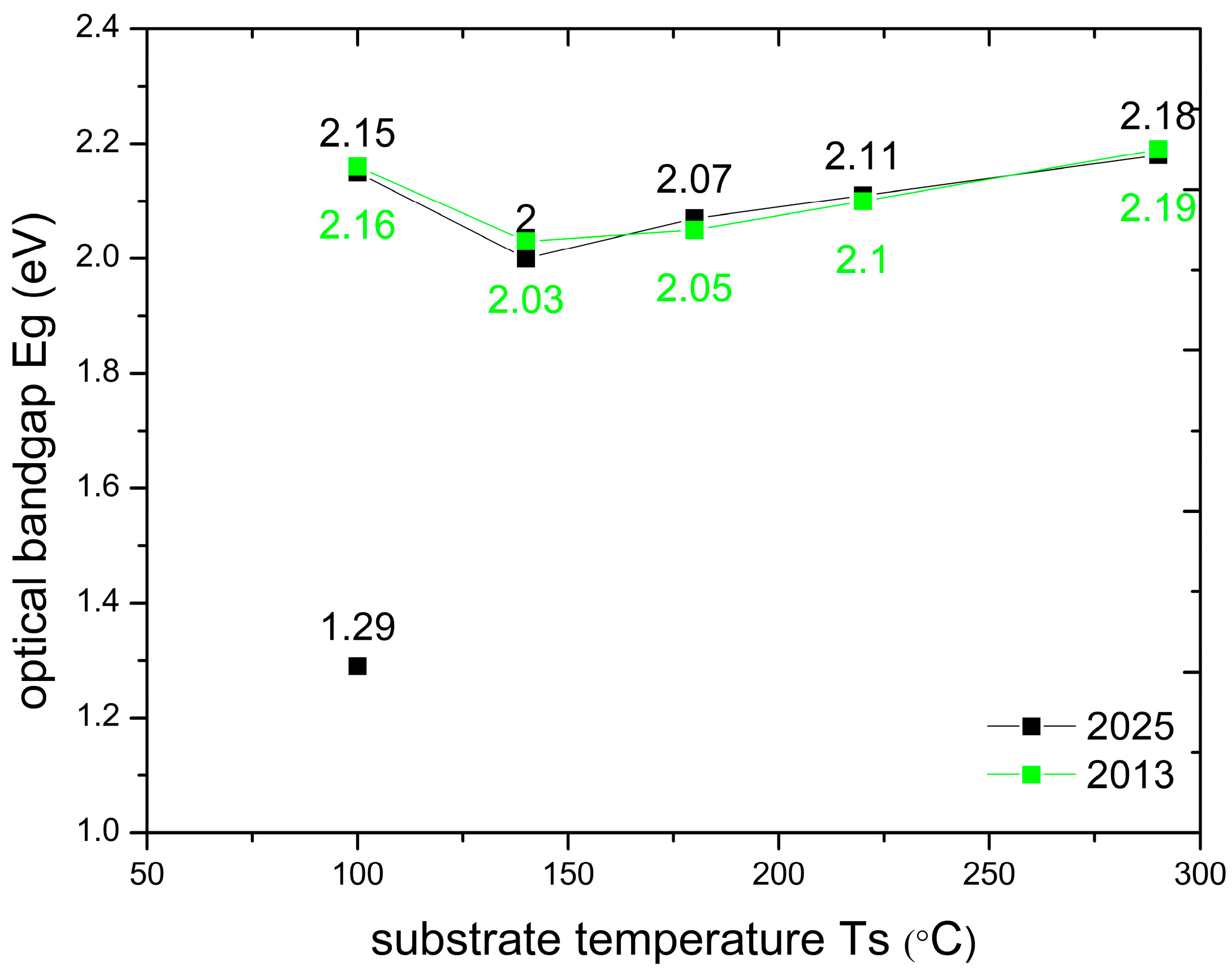

| Sample | Substrate Temperature Ts | Optical Bandgap Eg | Slope B | Refractive Index n | Hydrogen Flow |

|---|---|---|---|---|---|

| A | 1.29 | 224.34 | 3.917 | 0 sccm | |

| B | 2.15 | 450.93 | 2.623 | 20 sccm | |

| C | 2 | 353.63 | 3.142 | 20 sccm | |

| D | 2.07 | 399 | 2.81 | 20 sccm | |

| Ε | 2.11 | 460.32 | 2.493 | 20 sccm | |

| F | 2.18 | 308.38 | 1.887 | 20 sccm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veneti, C.; Magafas, L.; Papadopoulou, P. Optical Properties of a-SiC:H Thin Films Deposited by Magnetron Sputtering. Electron. Mater. 2025, 6, 8. https://doi.org/10.3390/electronicmat6020008

Veneti C, Magafas L, Papadopoulou P. Optical Properties of a-SiC:H Thin Films Deposited by Magnetron Sputtering. Electronic Materials. 2025; 6(2):8. https://doi.org/10.3390/electronicmat6020008

Chicago/Turabian StyleVeneti, Christina, Lykourgos Magafas, and Panagiota Papadopoulou. 2025. "Optical Properties of a-SiC:H Thin Films Deposited by Magnetron Sputtering" Electronic Materials 6, no. 2: 8. https://doi.org/10.3390/electronicmat6020008

APA StyleVeneti, C., Magafas, L., & Papadopoulou, P. (2025). Optical Properties of a-SiC:H Thin Films Deposited by Magnetron Sputtering. Electronic Materials, 6(2), 8. https://doi.org/10.3390/electronicmat6020008