Lead-Free BiFeO3 Thin Film: Ferroelectric and Pyroelectric Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Structural Investigations

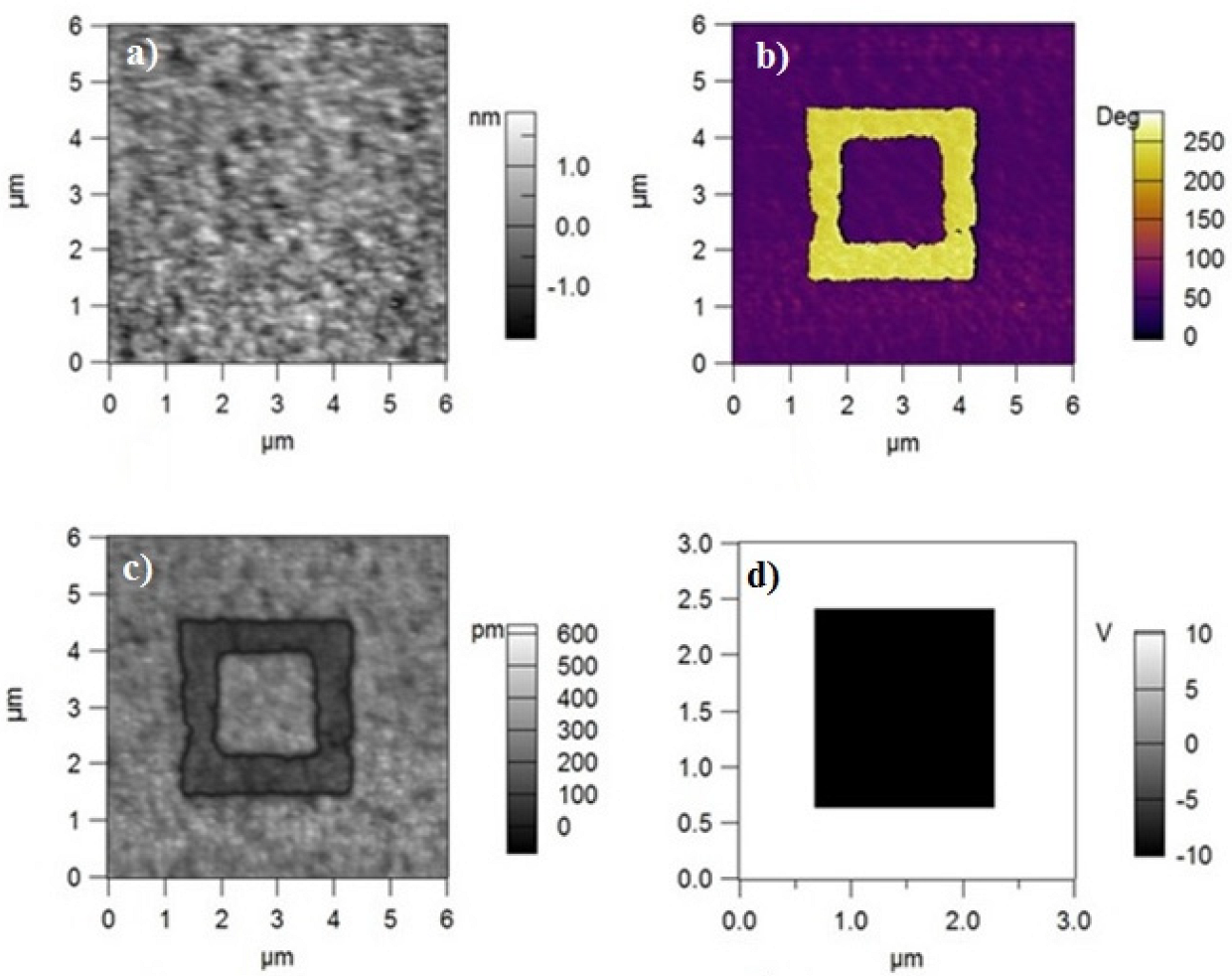

2.3. AFM/PFM Investigations

2.4. Electrical Measurements

2.5. Measurement of the Pyroelectric Signal

3. Results and Discussion

3.1. Structural Characterization

3.2. AFM/PFM Investigations

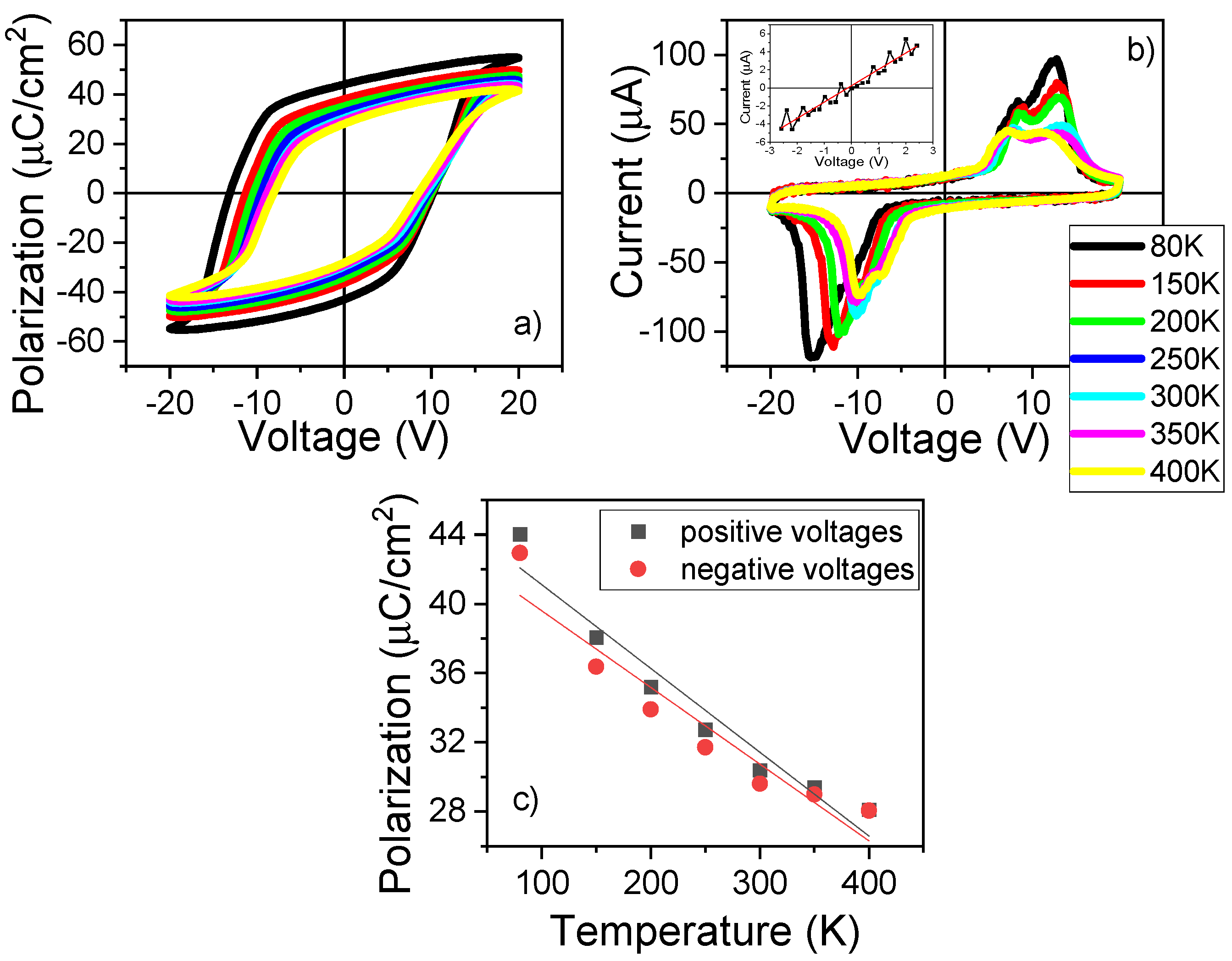

3.3. Ferroelectric Characterization and Extraction of the Pyroelectric Coefficient

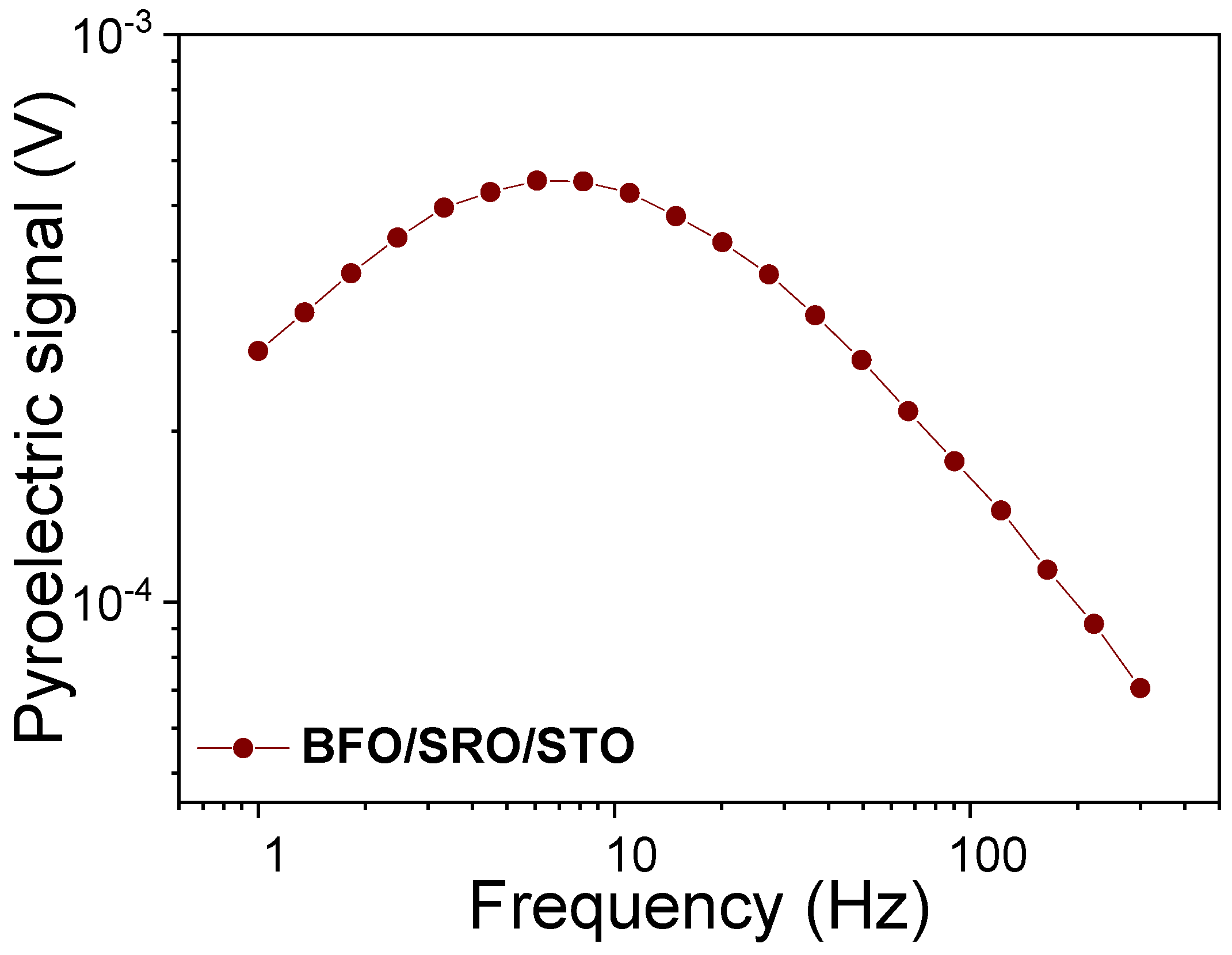

3.4. Analysis of the Frequency Dependence of the Pyroelectric Signal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lines, M.E.; Glass, A.M. Principles and Applications of Ferroelectrics and Related Materials; Oxford University Press: Oxford, UK, 2001; ISBN 978-0-19-850778-9. [Google Scholar]

- Pawade, V.B.; Salame, P.H.; Bhanvase, B.A. Multifunctional Nanostructured Metal Oxides for Energy Harvesting and Storage Devices; CRC Press: Boca Raton, FL, USA, 2020; ISBN 978-1-00-007320-1. [Google Scholar]

- Martin, L.W.; Rappe, A.M. Thin-Film Ferroelectric Materials and Their Applications. Nat. Rev. Mater. 2016, 2, 16087. [Google Scholar] [CrossRef] [Green Version]

- Fan, Z.; Wang, J.; Sullivan, M.B.; Huan, A.; Singh, D.J.; Ong, K.P. Structural Instability of Epitaxial (001) BiFeO3 Thin Films under Tensile Strain. Sci. Rep. 2014, 4, 4631. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jaffe, B.; Cook, W.R.; Jaffe, H. Piezoelectric Ceramics; Cook, B.J.R., Jaffe, H., Eds.; Academic Press: Cambridge, MA, USA, 1971; ISBN 978-0-12-379550-2. [Google Scholar]

- Shrout, T.R.; Zhang, S.J. Lead-Free Piezoelectric Ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Damjanovic, D.; Klein, N.; Li, J.; Porokhonskyy, V. What Can Be Expected from Lead-Free Piezoelectric Materials? Funct. Mater. Lett. 2010, 3, 5–13. [Google Scholar] [CrossRef]

- Wang, J.; Neaton, J.B.; Zheng, H.; Nagarajan, V.; Ogale, S.B.; Liu, B.; Viehland, D.; Vaithyanathan, V.; Schlom, D.G.; Waghmare, U.V.; et al. Epitaxial BiFeO3 Multiferroic Thin Film Heterostructures. Science 2003, 299, 1719–1722. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.; Basu, S.; Manna, P.K.; Yusuf, S.M.; Pal, M. Giant Magnetodielectric and Enhanced Multiferroic Properties of Sm Doped Bismuth Ferrite Nanoparticles. J. Mater. Chem. C 2014, 2, 5885–5891. [Google Scholar] [CrossRef]

- Kuo, C.-Y.; Hu, Z.; Yang, J.C.; Liao, S.-C.; Huang, Y.L.; Vasudevan, R.K.; Okatan, M.B.; Jesse, S.; Kalinin, S.V.; Li, L.; et al. Single-Domain Multiferroic BiFeO3 Films. Nat. Comm. 2016, 7, 12712. [Google Scholar] [CrossRef] [PubMed]

- Lebeugle, D.; Colson, D.; Forget, A.; Viret, M. Very Large Spontaneous Electric Polarization in BiFeO3 Single Crystals at Room Temperature and Its Evolution under Cycling Fields. Appl. Phys. Lett. 2007, 91, 022907. [Google Scholar] [CrossRef] [Green Version]

- Pintilie, L.; Dragoi, C.; Chu, Y.H.; Martin, L.W.; Ramesh, R.; Alexe, M. Orientation-Dependent Potential Barriers in Case of Epitaxial Pt–BiFeO3–SrRuO3 Capacitors. Appl. Phys. Lett. 2009, 94, 232902. [Google Scholar] [CrossRef]

- Oikawa, T.; Aratani, M.; Funakubo, H.; Saito, K.; Mizuhira, M. Composition and Orientation Dependence of Electrical Properties of Epitaxial Pb(ZrxTi1−x)O3 Thin Films Grown Using Metalorganic Chemical Vapor Deposition. J. Appl. Phys. 2004, 95, 3111–3115. [Google Scholar] [CrossRef]

- Yang, N.; Hu, C.-Z.; Ren, Z.-Q.; Bao, S.-Y.; Tian, B.-B.; Yue, F.-Y.; Xiang, P.-H.; Zhong, N.; Duan, C.-G.; Chu, J.-H. Nonvolatile Negative Optoelectronic Memory Based on Ferroelectric Thin Films. ACS Appl. Electron. Mater. 2020, 2, 1035–1040. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Roy Chaudhuri, A.; Heon Kim, Y.; Hesse, D.; Alexe, M. Role of Domain Walls in the Abnormal Photovoltaic Effect in BiFeO3. Nat. Commun. 2013, 4, 2835. [Google Scholar] [CrossRef] [Green Version]

- Gao, W.; Lv, J.; Lou, X. Large Electric-Field-Induced Strain and Enhanced Piezoelectric Constant in CuO-Modified BiFeO3-BaTiO3 Ceramics. J. Am. Ceram. Soc. 2018, 101, 3383–3392. [Google Scholar] [CrossRef]

- Zhang, J.X.; Xiang, B.; He, Q.; Seidel, J.; Zeches, R.J.; Yu, P.; Yang, S.Y.; Wang, C.H.; Chu, Y.-H.; Martin, L.W.; et al. Large Field-Induced Strains in a Lead-Free Piezoelectric Material. Nat. Nanotechnol. 2011, 6, 98–102. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Huang, Y.-L.; Velarde, G.; Ghosh, A.; Pandya, S.; Garcia, D.; Ramesh, R.; Martin, L.W. Enhanced Pyroelectric Properties of Bi1−xLaxFeO3 Thin Films. APL Mater. 2019, 7, 111111. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Ploss, B.; Mak, C.L.; Wong, K.H. Pyroelectric Properties of BiFeO3 Ceramics Prepared by a Modified Solid-State-Reaction Method. Appl. Phys. A 2010, 99, 211–216. [Google Scholar] [CrossRef]

- Yuan, G.L.; Or, S.W. Enhanced Piezoelectric and Pyroelectric Effects in Single-Phase Multiferroic Bi1−xNdxFeO3 (X = 0–0.15) Ceramics. Appl. Phys. Lett. 2006, 88, 062905. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.W.; Sun, J.L.; Chen, J.; Meng, X.J.; Chu, J.H. Preparation and Characterization of BiFeO3 Thin Films Grown on LaNiO3-Coated SrTiO3 Substrate by Chemical Solution Deposition. J. Cryst. Growth 2005, 285, 595–599. [Google Scholar] [CrossRef]

- Yao, Y.; Tao, T.; Liang, B.; Mak, C.L.; Lu, S.G. Pyroelectric Properties and AC Impedance Study of Bismuth Ferrite (BiFeO3) Ceramics. Ceram. Int. 2019, 45, 1308–1313. [Google Scholar] [CrossRef]

- Shaldin, Y.V.; Matyjasik, S.; Bush, A.A. Pyroelectric Properties of Bismuth Ferrite in the Low-Temperature Range. Crystallogr. Rep. 2007, 52, 123–128. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, W.C.; Mak, C.L. Pyroelectric Properties and Electrical Conductivity in Samarium Doped BiFeO3 Ceramics. J. Alloys Comp. 2012, 527, 157–162. [Google Scholar] [CrossRef]

- Ihlefeld, J.F.; Podraza, N.J.; Liu, Z.K.; Rai, R.C.; Xu, X.; Heeg, T.; Chen, Y.B.; Li, J.; Collins, R.W.; Musfeldt, J.L.; et al. Optical Band Gap of BiFeO3 Grown by Molecular-Beam Epitaxy. Appl. Phys. Lett. 2008, 92, 142908. [Google Scholar] [CrossRef] [Green Version]

- Kumari, S.; Ortega, N.; Kumar, A.; Scott, J.F.; Katiyar, R.S. Ferroelectric and Photovoltaic Properties of Transition Metal Doped Pb(Zr0.14Ti0.56Ni0.30)O3−δ Thin Films. AIP Adv. 2014, 4, 037101. [Google Scholar] [CrossRef] [Green Version]

- Eason, R. Pulsed Laser Deposition of Thin Films: Applications-Led Growth of Functional Materials; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Chen, Z.H.; Damodaran, A.R.; Xu, R.; Lee, S.; Martin, L.W. Effect of “Symmetry Mismatch” on the Domain Structure of Rhombohedral BiFeO3 Thin Films. Appl. Phys. Lett. 2014, 104, 182908. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.M.; Eom, C.B.; Nagarajan, V.; Ouyang, J.; Ramesh, R.; Vaithyanathan, V.; Schlom, D.G. Thickness Dependence of Structural and Piezoelectric Properties of Epitaxial Pb(Zr0.52Ti0.48)O3 Films on Si and SrTiO3 Substrates. Appl. Phys. Lett. 2006, 88, 142904. [Google Scholar] [CrossRef]

- Chirila, C.; Boni, G.A.; Filip, L.D.; Husanu, M.; Neatu, S.; Istrate, C.M.; Le Rhun, G.; Vilquin, B.; Trupina, L.; Pasuk, I.; et al. Effect of Strain and Stoichiometry on the Ferroelectric and Pyroelectric Properties of the Epitaxial Pb(Zr0.2Ti0.8)O3 Films Deposited on Si Wafers. Mater. Sci. Eng. B 2021, 266, 115042. [Google Scholar] [CrossRef]

- Chirila, C.; Boni, A.G.; Pasuk, I.; Negrea, R.; Trupina, L.; Rhun, G.L.; Yin, S.; Vilquin, B.; Pintilie, I.; Pintilie, L. Comparison between the Ferroelectric/Electric Properties of the PbZr0.52Ti0.48O3 Films Grown on Si (100) and on STO (100) Substrates. J. Mater. Sci. 2015, 50, 3883–3894. [Google Scholar] [CrossRef]

- Holcomb, M.; Ramesh, R. Controlling magnetism with multiferroics. Mater. Today 2007, 10, 16–223. [Google Scholar] [CrossRef]

- Ohnishi, T.; Shibuya, K.; Lippmaa, M.; Kobayashi, D.; Kumigashira, H.; Oshima, M.; Koinuma, H. Preparation of Thermally Stable TiO2-Terminated SrTiO3(100) Substrate Surfaces. Appl. Phys. Lett. 2004, 85, 272–274. [Google Scholar] [CrossRef]

- Koster, G.; Kropman, B.L.; Rijnders, G.J.H.M.; Blank, D.H.A.; Rogalla, H. Quasi-Ideal Strontium Titanate Crystal Surfaces through Formation of Strontium Hydroxide. Appl. Phys. Lett. 1998, 73, 2920–2922. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.-Z.; Guan, Z.; Yang, N.; Xiang, P.-H.; Qi, R.-J.; Huang, R.; Yang, P.-X.; Zhong, N.; Duan, C.-G. Epitaxial Growth of BiFeO3 Films on SrRuO3/SrTiO3. Mater. Charact. 2017, 131, 217–223. [Google Scholar] [CrossRef]

- You, L.; Chua, N.T.; Yao, K.; Chen, L.; Wang, J. Influence of oxygen pressure on the ferroelectric properties of epitaxial BiFeO3 thin films by pulsed laser deposition. Phys. Rev. B 2009, 80, 024105. [Google Scholar] [CrossRef]

- Pintilie, L.; Iuga, A.; Stancu, V.; Botea, M. Estimation of the Pyroelectric Coefficient for Ceramic Pb(Zr,Ti)O3 Samples: Comparison of the Results Obtained by Two Easy to Implement Methods. Infrared Phys. Techn. 2020, 106, 103269. [Google Scholar] [CrossRef]

- Achenbach, G.D.; James, W.J.; Gerson, R. Preparation of Single-Phase Polycrystalline BiFeO3. J. Amer. Ceram. Soc. 1967, 50, 437. [Google Scholar] [CrossRef]

- Yang, Y.; Schlepütz, C.M.; Adamo, C.; Schlom, D.G.; Clarke, R. Untilting BiFeO3: The Influence of Substrate Boundary Conditions in Ultra-Thin BiFeO3 on SrTiO3. APL Mater. 2013, 1, 052102. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.; Hiraka, H.; Shirane, G.; Li, J.; Wang, J.; Viehland, D. Low Symmetry Phase in (001) BiFeO3 Epitaxial Constrained Thin Films. Appl. Phys. Lett. 2005, 86, 182905. [Google Scholar] [CrossRef] [Green Version]

- Christen, H.M.; Nam, J.H.; Kim, H.S.; Hatt, A.J.; Spaldin, N.A. Stress-Induced R−MA−MC−T Symmetry Changes in BiFeO3. Phys. Rev. B 2011, 83, 144107. [Google Scholar] [CrossRef] [Green Version]

- Sando, D.; Barthélémy, A.; Bibes, M. BiFeO3 Epitaxial Thin Films and Devices: Past, Present and Future. J. Phys. Condens. Matter 2014, 26, 473201. [Google Scholar] [CrossRef]

- Lim, S.H.; Murakami, M.; Sarney, W.L.; Ren, S.Q.; Varatharajan, A.; Nagarajan, V.; Fujino, S.; Wuttig, M.; Takeuchi, I.; Salamanca-Riba, L.G. The Effects of Multiphase Formation on Strain Relaxation and Magnetization in Multiferroic BiFeO3 Thin Films. Adv. Funct. Mater. 2007, 17, 2594–2599. [Google Scholar] [CrossRef]

- Béa, H.; Bibes, M.; Barthélémy, A.; Bouzehouane, K.; Jacquet, E.; Khodan, A.; Contour, J.-P.; Fusil, S.; Wyczisk, F.; Forget, A.; et al. Influence of Parasitic Phases on the Properties of BiFeO3 Epitaxial Thin Films. Appl. Phys. Lett. 2005, 87, 072508. [Google Scholar] [CrossRef] [Green Version]

- Yurtseven, H.; Kiraci, A. Temperature dependence of the polarization and the dielectric constant near the paraelectric-ferroelectric transitions in BaTiO3. J. Mol. Model. 2013, 19, 3925–3930. [Google Scholar] [CrossRef] [PubMed]

- Phillpot, S.R.; Gopalan, V. Coupled displacive and order–disorder dynamics in LiNbO3 by molecular-dynamics simulation. Appl. Phys. Lett. 2004, 84, 1916–1919. [Google Scholar] [CrossRef] [Green Version]

- Chaib, H.; Toumanari, A.; Khatib, D.; Kinase, W. Theoretical study of temperature dependence of spontaneous polarization, optical properties and free and clamped linear electrooptic coefficients of BaTiO3 in the tetragonal phase. Ferroelectrics 1999, 234, 61–80. [Google Scholar] [CrossRef]

- Chen, Z.; Song, L.; Zhao, H.; Zhang, Y.; Cao, W. Temperature- and electric field-dependence of polarization hysteresis for a [001]c poled PMN-PT single crystal. J. Asian Ceram. Soc. 2022, 10, 203–214. [Google Scholar] [CrossRef]

- Glass, A.M. Dielectric, Thermal, and Pyroelectric Properties of Ferroelectric LiTaO3. Phys. Rev. 1968, 172, 564–571. [Google Scholar] [CrossRef]

- Arnold, D.C.; Knight, K.S.; Morrison, F.D.; Lightfoot, P. Ferroelectric-Paraelectric Transition in BiFeO3: Crystal Structure of the Orthorhombic β Phase. Phys. Rev. Lett. 2009, 102, 027602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lubomirsky, I.; Stafsudd, O. Invited Review Article: Practical Guide for Pyroelectric Measurements. Rev. Sci. Instrum. 2012, 83, 051101. [Google Scholar] [CrossRef] [PubMed]

- Whatmore, R.W. Pyroelectric Devices and Materials. Rep. Prog. Phys. 1986, 49, 1335–1386. [Google Scholar] [CrossRef]

- Botea, M.; Iuga, A.; Pintilie, L. Giant Pyroelectric Coefficient Determined from the Frequency Dependence of the Pyroelectric Signal Generated by Epitaxial Pb(Zr0.2Ti0.8)O3 Layers Grown on Single Crystal SrTiO3 Substrates. Appl. Phys. Lett. 2013, 103, 232902. [Google Scholar] [CrossRef]

- Yamanaka, S.; Maekawa, T.; Muta, H.; Matsuda, T.; Kobayashi, S.; Kurosaki, K. Thermophysical properties of SrHfO3 and SrRuO3. J Solid State Chem. 2004, 177, 3484–3489. [Google Scholar] [CrossRef]

- Elements, A. Bismuth Ferrite. Available online: https://www.americanelements.com/bismuth-ferrite-12010-42-3 (accessed on 11 February 2022).

- Klyndyuk, A.I.; Khort, A.A. Thermophysical Properties of BiFeO3, Bi0.91Nd0.09FeO3, and BiFe0.91Mn0.09O3 Multiferroics at High Temperatures. Phys. Solid State 2016, 58, 1285–1288. [Google Scholar] [CrossRef]

- Zhang, C.; Huberman, S.C.; Ning, S.; Pelliciari, J.; Duncan, R.A.; Liao, B.; Ojha, S.; Freeland, J.W.; Nelson, K.A.; Comin, R.; et al. Thermal Conductivity in Self-Assembled CoFe2O4/BiFeO3 Vertical Nanocomposite Films. Appl. Phys. Lett. 2018, 113, 223105. [Google Scholar] [CrossRef]

- Karthik, J.; Agar, J.C.; Damodaran, A.R.; Martin, L.W. Effect of 90 Domain Walls and Thermal Expansion Mismatch on the Pyroelectric Properties of Epitaxial PbZr0.2Ti0.8O3 Thin Films. Phys. Rev. Lett. 2012, 109, 257602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karthik, J.; Martin, L.W. Pyroelectric Properties of Polydomain Epitaxial PbZr1-XTixO3 Thin Films. Phys. Rev. B 2011, 84, 024102. [Google Scholar] [CrossRef] [Green Version]

- De Cicco, G.; Morten, B.; Dalmonego, D.; Prudenziati, M. Pyroelectricity of PZT-Based Thick-Films. Sens. Actuat. A Phys. 1999, 76, 409–415. [Google Scholar] [CrossRef]

- Bowen, C.R.; Taylor, J.; LeBoulbar, E.; Zabek, D.; Chauhan, A.; Vaish, R. Pyroelectric Materials and Devices for Energy Harvesting Applications. Energy Environ. Sci. 2014, 7, 3836–3856. [Google Scholar] [CrossRef] [Green Version]

- He, H.; Lu, X.; Hanc, E.; Chen, C.; Zhang, H.; Lu, L. Advances in Lead-Free Pyroelectric Materials: A Comprehensive Review. J. Mater. Chem. C 2020, 8, 1494–1516. [Google Scholar] [CrossRef]

- Stancu, V.; Amarande, L.; Botea, M.; Iuga, A.; Leonat, L.N.; Tomulescu, A.G.; Cioangher, M.; Balescu, L.M.; Pintilie, L. Comparison between Dielectric and Pyroelectric Properties of PZFNT and BST Type Ceramics. Process. Appl. Ceram. 2019, 13, 269–276. [Google Scholar] [CrossRef]

| Layer | Thickness (w) | Density (kg/m3) | Specific Heat (J/kg⋅K) | Thermal Conductivity (W/m⋅K) |

|---|---|---|---|---|

| BFO | 150 nm | 8220 [55] | 385 [56] | 1.32 [57] |

| STO | 500 µm | 5120 [53] | 544 [53] | 11.2 [53] |

| Sample | Pyroelectric Coefficient (10−4 C/m2 K) | Reference |

|---|---|---|

| Au/SRO/BFO/SRO/STO | 2.8–4.8 | Present Study |

| BFO ceramics | 0.9 | Ref. [19] |

| Bi1−𝑥Nd𝑥FeO3 (𝑥 = 0–0.15) ceramics | 0.3–0.4 | Ref. [20] |

| BiFeO3 thin films on SrTiO3 substrate by chemical solution deposition | 0.14 | Ref. [21] |

| BFO ceramics | 0.71 | Ref. [22] |

| BFO single crystals | 1.2 | Ref. [23] |

| Sm-doped BFO ceramics | 0.93–1.37 | Ref. [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botea, M.; Chirila, C.; Boni, G.A.; Pasuk, I.; Trupina, L.; Pintilie, I.; Hrib, L.M.; Nicu, B.; Pintilie, L. Lead-Free BiFeO3 Thin Film: Ferroelectric and Pyroelectric Properties. Electron. Mater. 2022, 3, 173-184. https://doi.org/10.3390/electronicmat3020015

Botea M, Chirila C, Boni GA, Pasuk I, Trupina L, Pintilie I, Hrib LM, Nicu B, Pintilie L. Lead-Free BiFeO3 Thin Film: Ferroelectric and Pyroelectric Properties. Electronic Materials. 2022; 3(2):173-184. https://doi.org/10.3390/electronicmat3020015

Chicago/Turabian StyleBotea, Mihaela, Cristina Chirila, Georgia Andra Boni, Iuliana Pasuk, Lucian Trupina, Ioana Pintilie, Luminiţa Mirela Hrib, Becherescu Nicu, and Lucian Pintilie. 2022. "Lead-Free BiFeO3 Thin Film: Ferroelectric and Pyroelectric Properties" Electronic Materials 3, no. 2: 173-184. https://doi.org/10.3390/electronicmat3020015

APA StyleBotea, M., Chirila, C., Boni, G. A., Pasuk, I., Trupina, L., Pintilie, I., Hrib, L. M., Nicu, B., & Pintilie, L. (2022). Lead-Free BiFeO3 Thin Film: Ferroelectric and Pyroelectric Properties. Electronic Materials, 3(2), 173-184. https://doi.org/10.3390/electronicmat3020015