Detection, Characterization and Modeling of Localized Defects and Thermal Breakdown in Photovoltaic Panels from Thermal Images and IV Curves

Abstract

1. Introduction

2. Materials and Methods

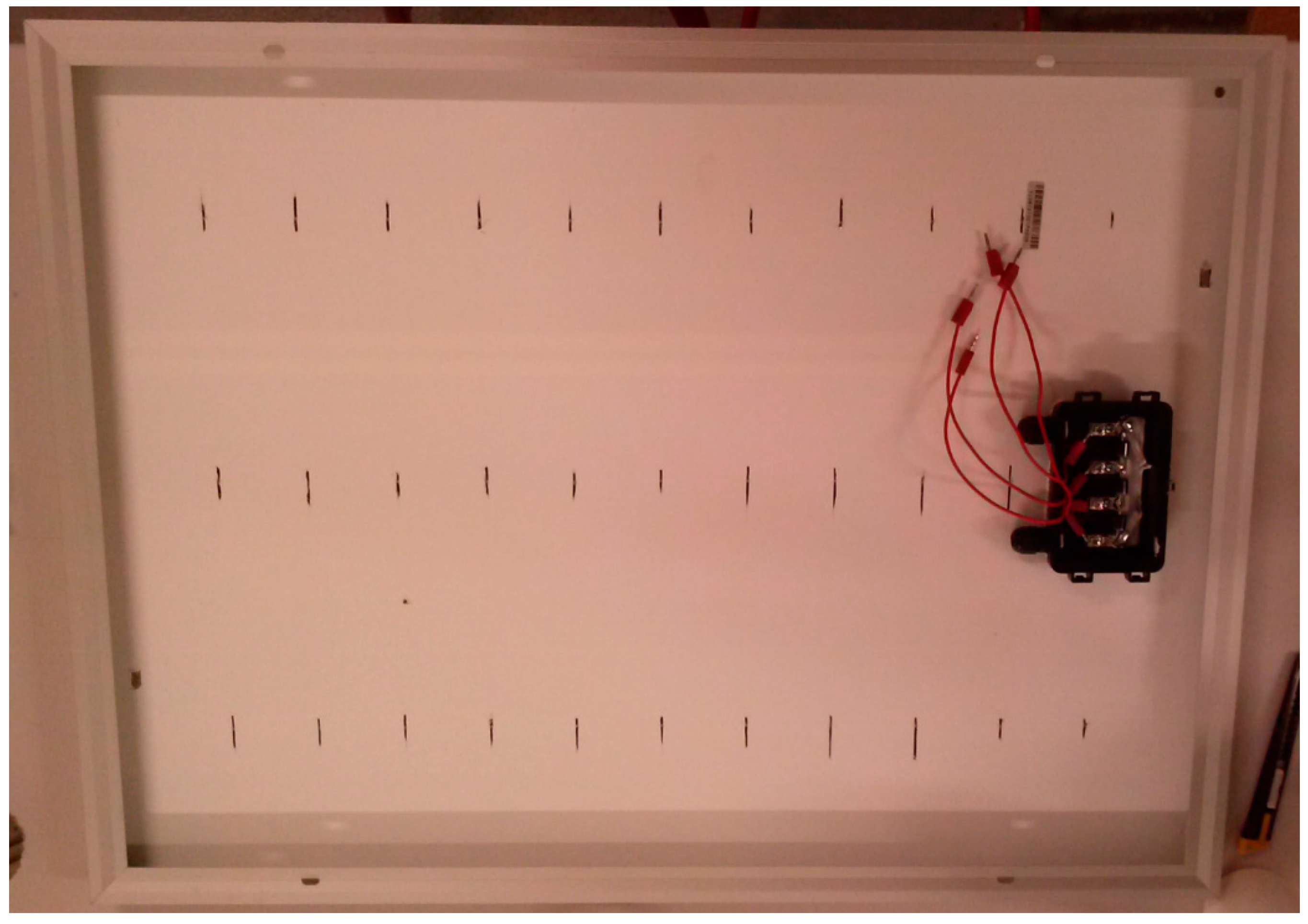

2.1. Thermal Images

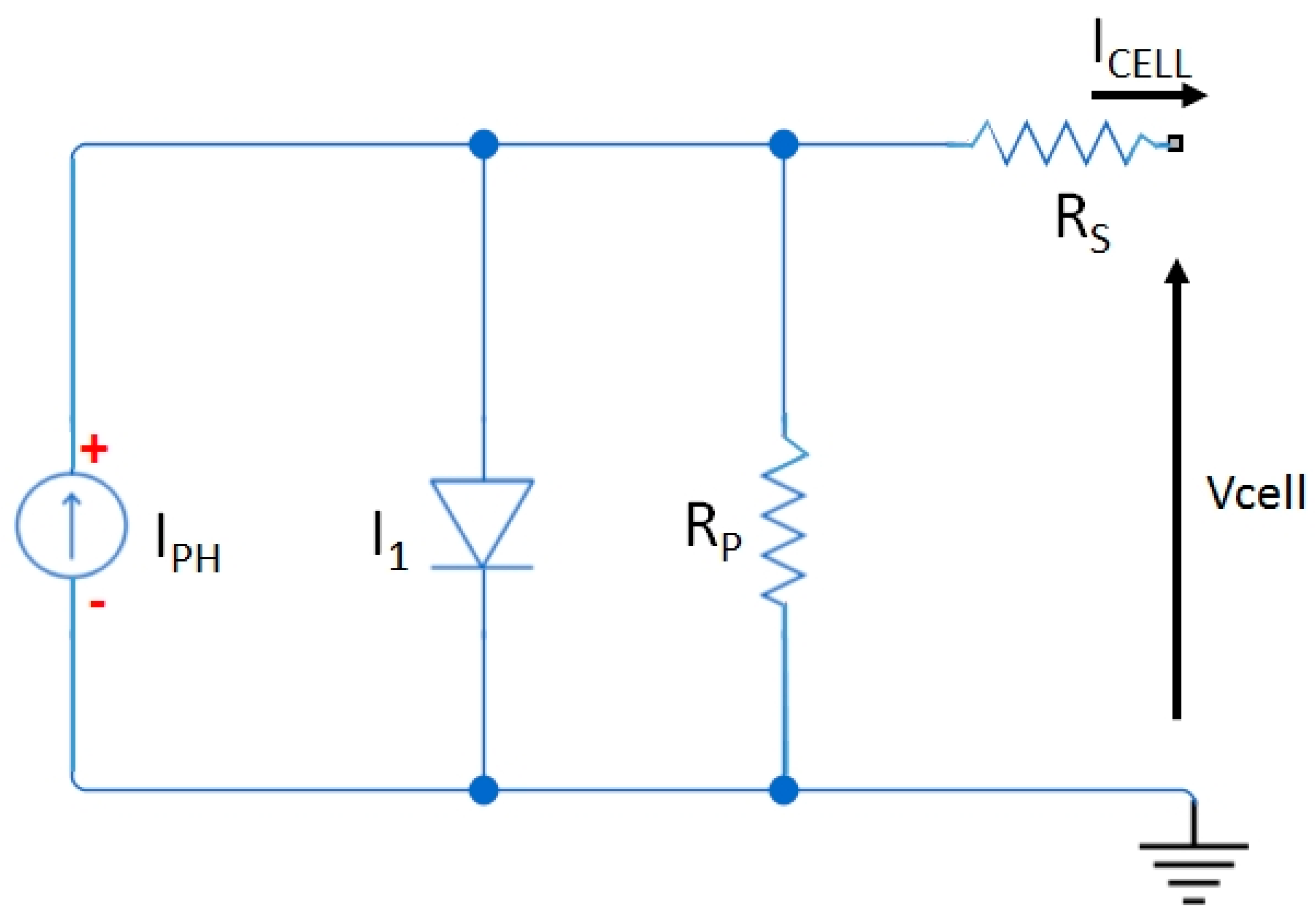

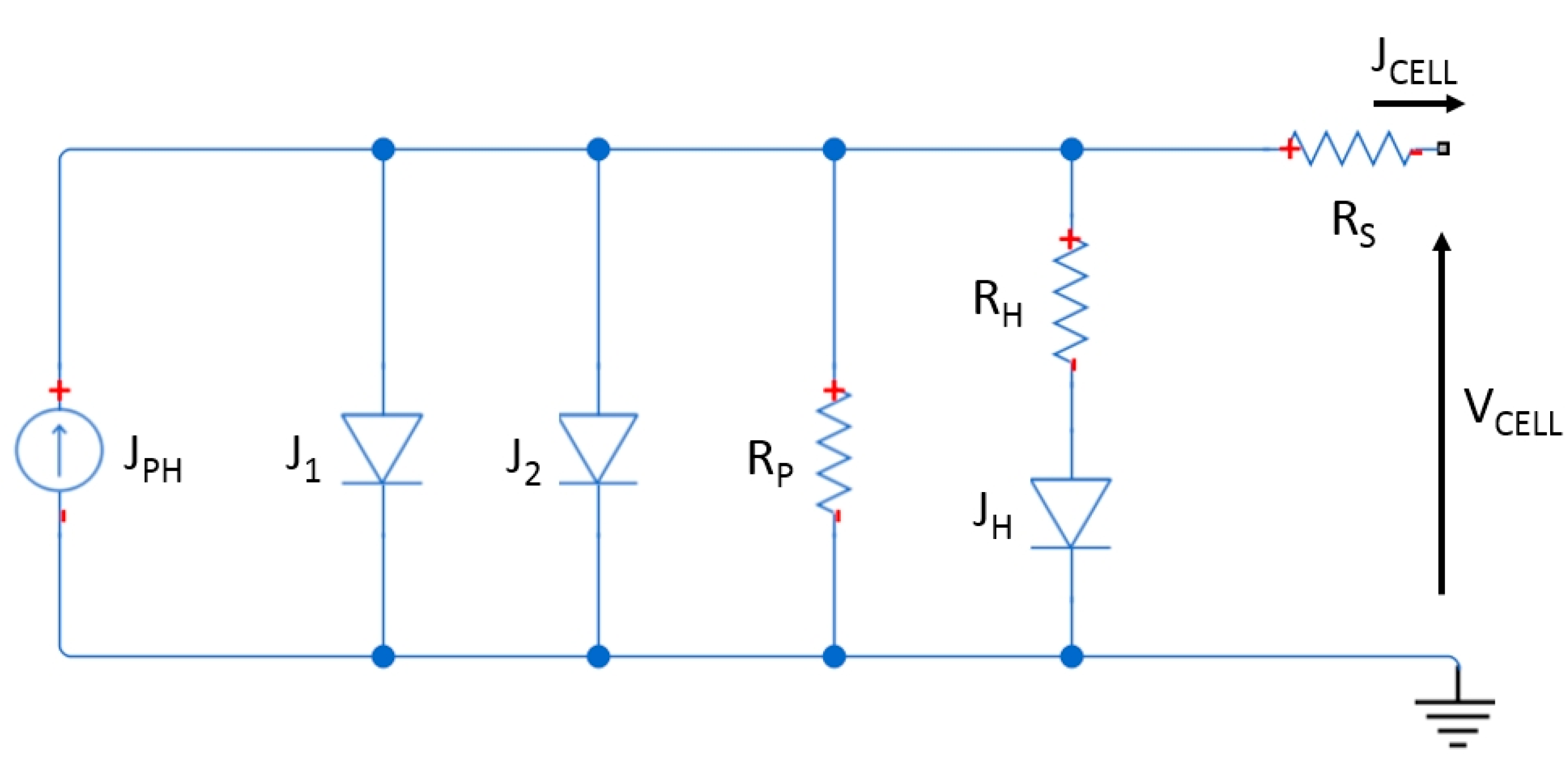

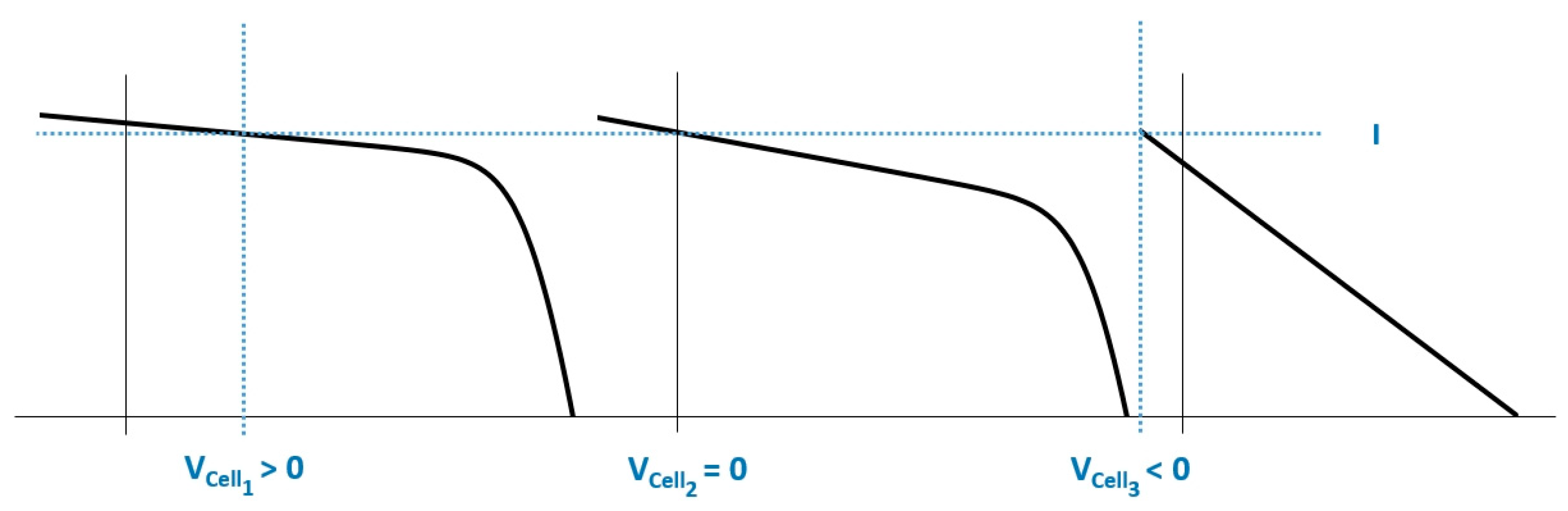

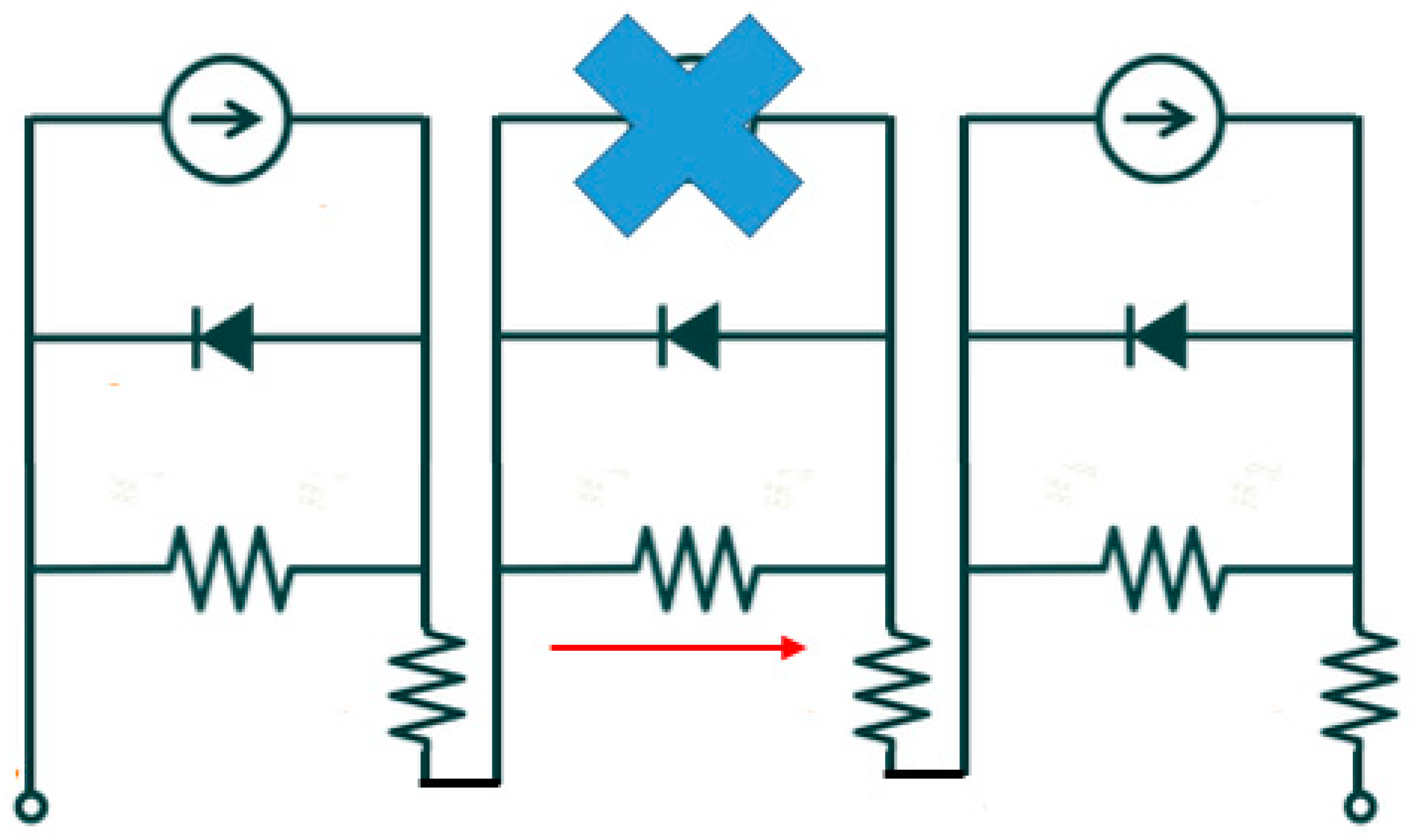

2.2. Module’s IV Curves-Based Method

2.3. Direct IV Curves

3. Theory/Calculation

4. Results and Discussion

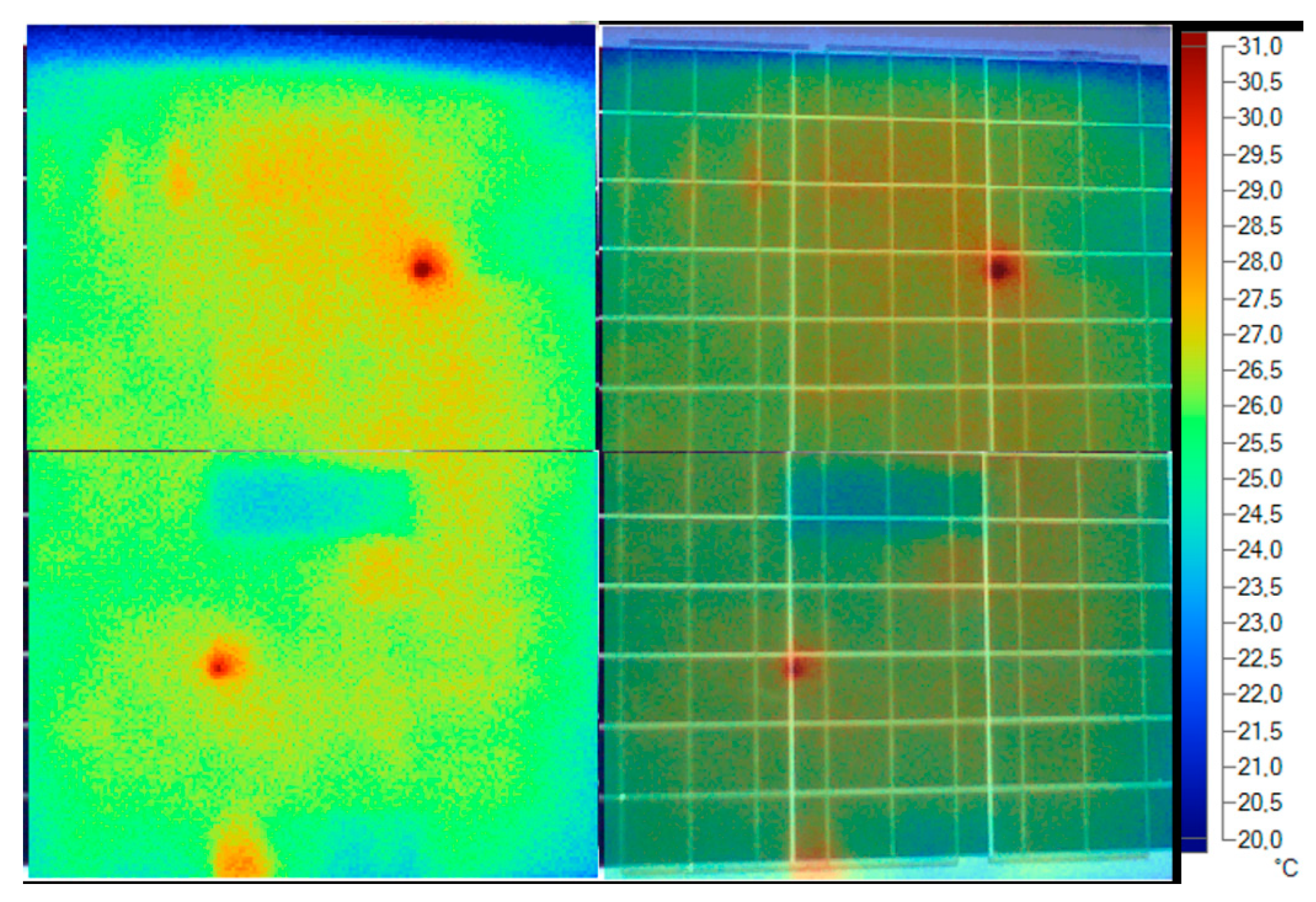

4.1. Module’s Thermal Images

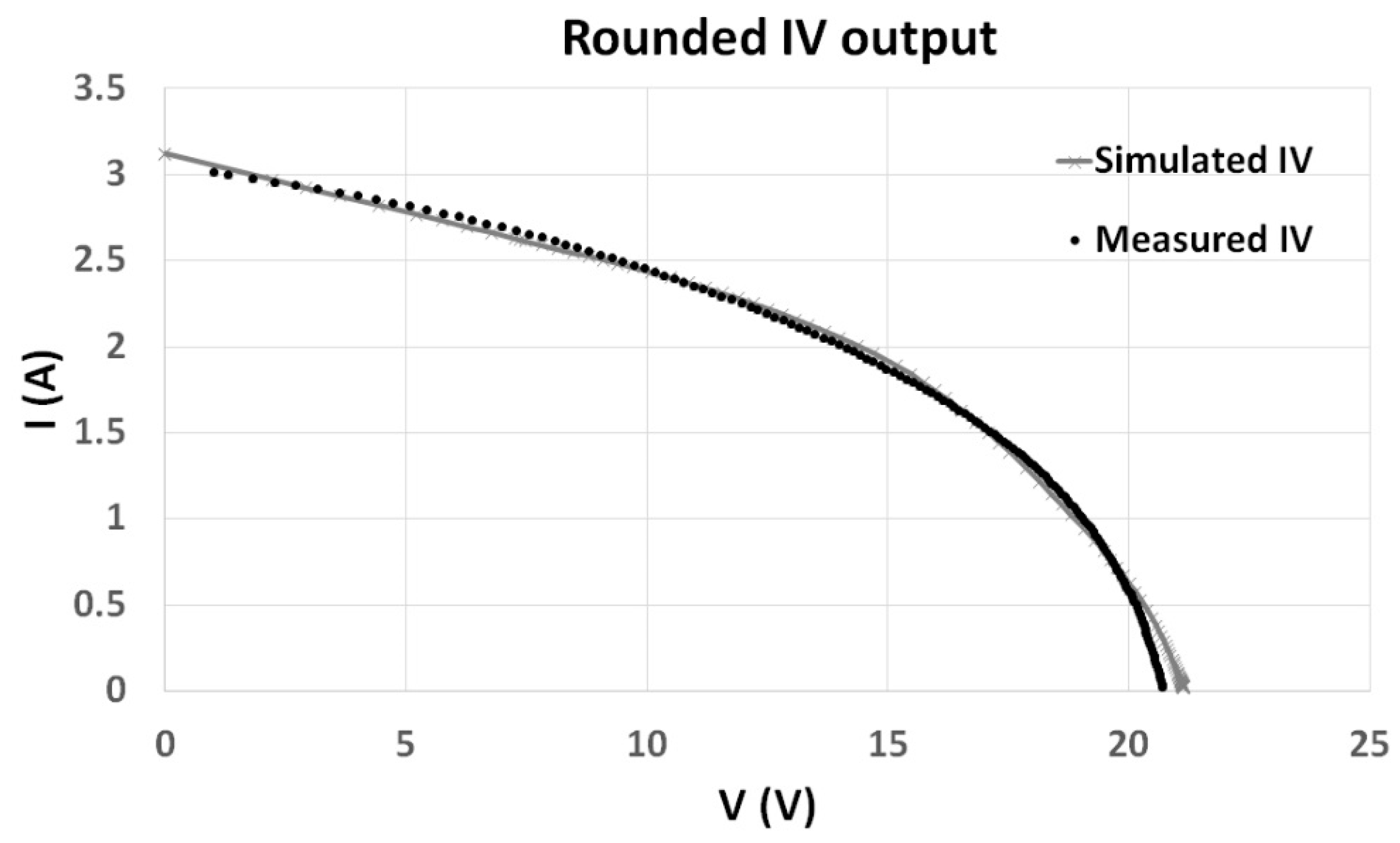

4.2. Module’s IV Curves

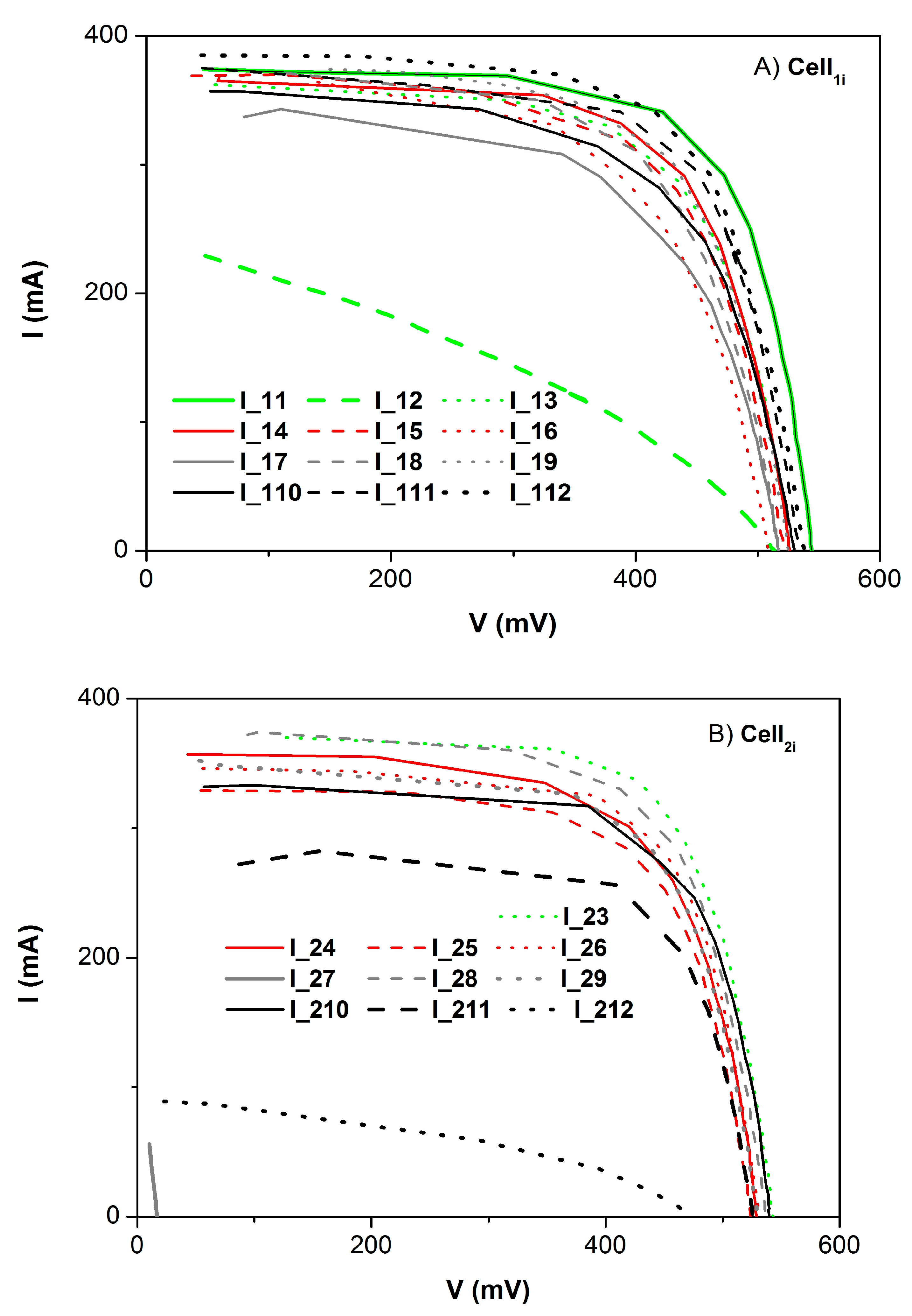

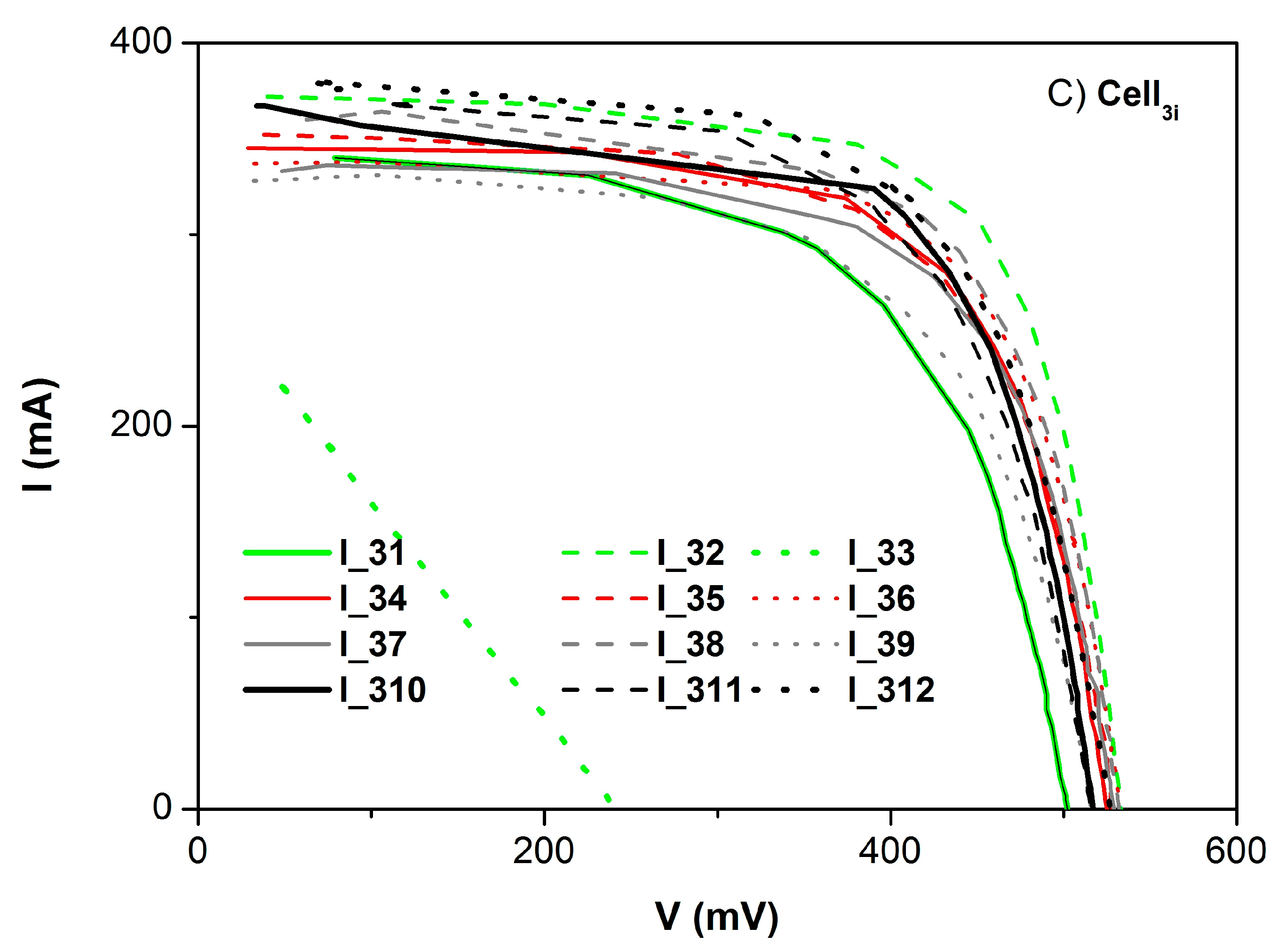

4.3. Individual Cell’s IV Curves

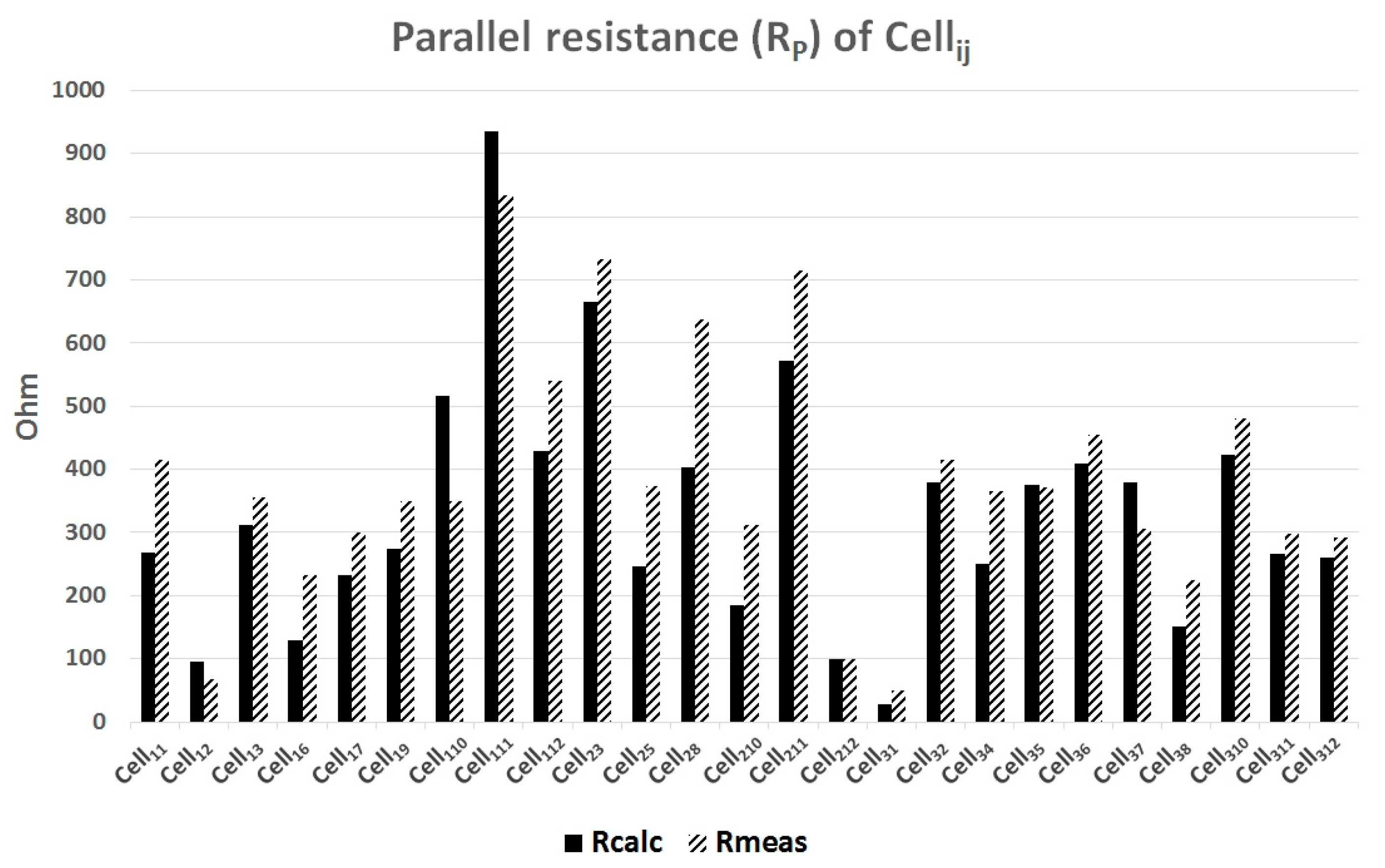

4.4. Individual Cell’s Resistance Measurement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Philipps, S.P. Photovoltaics Report. Fraunhofer Institute for Solar Energy Systems ISE. 2021. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 8 February 2022).

- Philipps, S.P.; Bett, A.W.; Horowitz, K.; Kurtz, S. Current status of concentrator photovoltaic (CPV) technology. Natl. Renew. Energy Lab. (NREL) 2015. [Google Scholar] [CrossRef]

- Sarper, H.; Melnykov, I.; Martínez, L.A. Prediction of daily photovoltaic energy production using weather data and regression. J. Sol. Energy Eng. 2021, 143, 064502. [Google Scholar] [CrossRef]

- Doumane, R.; Balistrou, M.; Logerais, P.O.; Riou, O.; Durastanti, J.F.; Charki, A. A circuit-based approach to simulate the characteristics of a silicon photovoltaic module with aging. J. Sol. Energy Eng. 2015, 137, 021020. [Google Scholar] [CrossRef]

- Fanney, A.H.; Dougherty, B.P.; Davis, M.W. Comparison of predicted to measured module performance. J. Sol. Energy Eng. 2007, 131, 021011. [Google Scholar] [CrossRef]

- Hernández-Callejo, L.; Gallardo-Saavedra, S.; Alonso-Gómez, V. A review of photovoltaic systems: Design, operation and maintenance. Sol. Energy 2019, 188, 426–440. [Google Scholar] [CrossRef]

- Triki-Lahiani, A.; Abdelghani, A.B.-B.; Slama-Belkhodja, I. Fault detection and monitoring systems for photovoltaic installations: A review. Renew. Sustain. Energy Rev. 2018, 82, 2680–2692. [Google Scholar] [CrossRef]

- Pillai, D.S.; Rajasekar, N. A comprehensive review on protection challenges and fault diagnosis in PV systems. Renew. Sustain. Energy Rev. 2018, 91, 18–40. [Google Scholar] [CrossRef]

- Santhakumari, M.; Sagar, N. A review of the environmental factors degrading the performance of silicon wafer-based photovoltaic modules: Failure detection methods and essential mitigation techniques. Renew. Sustain. Energy Rev. 2019, 110, 83–100. [Google Scholar] [CrossRef]

- Du, B.; Yang, R.; He, Y.; Wang, F.; Huang, S. Nondestructive inspection, testing and evaluation for Si-based, thin film and multi-junction solar cells: An overview. Renew. Sustain. Energy Rev. 2017, 78, 1117–1151. [Google Scholar] [CrossRef]

- Fouad, M.M.; Shihata, L.A.; Morgan, E.I. An integrated review of factors influencing the perfomance of photovoltaic panels. Renew. Sustain. Energy Rev. 2017, 80, 1499–1511. [Google Scholar] [CrossRef]

- Hasan, M.A.; Parida, S.K. An overview of solar photovoltaic panel modeling based on analytical and experimental viewpoint. Renew. Sustain. Energy Rev. 2016, 60, 75–83. [Google Scholar] [CrossRef]

- Nacar, M.; Özer, E.; Yılmaz, A.E. A six parameter single diode model for photovoltaic modules. J. Sol. Energy Eng. 2021, 143, 011012. [Google Scholar] [CrossRef]

- Humada, A.M.; Hojabri, M.; Mekhilef, S.; Hamada, H.M. Solar cell parameters extraction based on single and double-diode models: A review. Renew. Sustain. Energy Rev. 2016, 56, 494–509. [Google Scholar] [CrossRef]

- Guo, L.; Meng, Z.; Sun, Y.; Wang, L. Parameter identification and sensitivity analysis of solar cell models with cat swarm optimization algorithm. Energy Convers. Manag. 2016, 108, 520–528. [Google Scholar] [CrossRef]

- Chin, V.J.; Salam, Z.; Ishaque, K. Cell modelling and model parameters estimation techniques for photovoltaic simulator application: A review. Appl. Energy 2015, 154, 500–519. [Google Scholar] [CrossRef]

- Alonso-Garcia, M.C.; Ruiz, J.M.; Chenlo, F. Experimental study of mismatch and shading effects in the I–V characteristic of a photovoltaic module. Sol. Energy Mater. Sol. Cells 2006, 90, 329–340. [Google Scholar] [CrossRef]

- Kaushika, N.D.; Rai, A.K. An investigation of mismatch losses in solar photovoltaic cell networks. Energy 2007, 32, 755–759. [Google Scholar] [CrossRef]

- Daliento, S.; Di Napoli, F.; Guerriero, P.; d’Alessandro, V. A modified bypass circuit for improved hot spot reliability of solar panels subject to partial shading. Sol. Energy 2016, 134, 211–218. [Google Scholar] [CrossRef]

- Kim, K.A.; Krein, P.T. Hot spotting and second breakdown effects on reverse IV characteristics for mono-crystalline Si photovoltaics. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Denver, CO, USA, 15–19 September 2013. [Google Scholar] [CrossRef]

- Giaffreda, D.; Magnone, P.; Meneghini, M.; Barbato, M.; Meneghesso, G.; Zanoni, E.; Sangiorgi, E.; Fiegna, C. Local shunting in multicrystalline silicon solar cells: Distributed electrical simulations and experiments. IEEE J. Photovolt. 2014, 4, 40–47. [Google Scholar] [CrossRef]

- Dhimish, M. Micro cracks distribution and power degradation of polycrystalline solar cells wafer: Observations constructed from the analysis of 4000 samples. Renew. Energy 2020, 145, 466–477. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.E.; Jahn, U.; Berger, K.A.; Kato, K.; Friesen, T.; Liu, H.; Iseghem, M.V. Review of Failures of Photovoltaic Modules. International Energy Agency Photovoltaics Power Systems Programme. 2014. Available online: https://iea-pvps.org/key-topics/review-of-failures-of-photovoltaic-modules-final/ (accessed on 8 February 2022).

- Bouaichi, A.; Merrouni, A.A.; Hajjaj, C.; Messaoudi, C.; Ghennioui, A.; Benlarabi, A.; Ikken, B.; El Amrani, A.; Zitouni, H. In-situ evaluation of the early PV module degradation of various technologies under harsh climatic conditions: The case of Morocco. Renew. Energy 2019, 143, 1500–1518. [Google Scholar] [CrossRef]

- Silva, A.M.; Melo, F.C.; Reis, J.H.; Freitas, L.C.G. The study and application of evaluation methods for photovoltaic modules under real operational conditions, in a region of the Brazilian Southeast. Renew. Energy 2019, 138, 1189–1204. [Google Scholar] [CrossRef]

- Dhimish, M.; Mather, P.; Holmes, V. Evaluating power loss and performance ratio of hot-spotted photovoltaic modules. IEEE Trans. Electron Devices 2018, 65, 5419–5427. [Google Scholar] [CrossRef]

- Sánchez-Friera, P.; Piliougine, M.; Pelaez, J.; Carretero, J.; Sidrach de Cardona, M. Analysis of degradation mechanisms of crystalline silicon PV modules after 12 years of operation in Southern Europe. Prog. Photovolt. Res. Appl. 2011, 19, 658–666. [Google Scholar] [CrossRef]

- Jordan, D.C.; Silverman, T.J.; Wohlgemuth, J.H.; Kurtz, S.R.; VanSant, K.T. Photovoltaic failure and degradation modes. Prog. Photovolt. Res. Appl. 2017, 25, 318–326. [Google Scholar] [CrossRef]

- Bauer, J.; Kwapil, W.; Lausch, D.; Schubert, M.C.; Warta, W.; Bothe, K.; Breitenstein, O. Comments on the paper “Detection and analysis of hot-spot formation in solar cells” published by M. Simon and E.L. Meyer in Sol. Energy Mater. Sol. Cells 2010, 94, 106–113. Sol. Energy Mater. Sol. Cells 2012, 99, 362–364. [Google Scholar] [CrossRef]

- El Iysaouy, L.; Lahbabi, M.; Baskys, A.; Oumnad, A. Performance analysis of partially shaded photovoltaic array using magic square view configuration for shade dispersion. J. Sol. Energy Eng. 2020, 142, 064502. [Google Scholar] [CrossRef]

- Anjum, S.; Mukherjee, V.; Mehta, G. Advanced SuDoKu-based reconfiguration strategies for maximum power extraction from partially shaded solar photovoltaic array. J. Sol. Energy Eng. 2021, 143, 061003. [Google Scholar] [CrossRef]

- Trzmiel, G.; Głuchy, D.; Kurz, D. The impact of shading on the exploitation of photovoltaic installations. Renew. Energy 2020, 153, 480–498. [Google Scholar] [CrossRef]

- Solheim, H.J.; Fjær, H.G.; Sørheim, E.A.; Foss, S.E. Measurement and simulation of hot spots in solar cells. Energy Procedia 2013, 38, 183–189. [Google Scholar] [CrossRef][Green Version]

- Buerhop, C.; Schlegel, D.; Niess, M.; Vodermayer, C.; Weißmann, R.; Brabec, C.J. Reliability of IR-imaging of PV-plants under operating conditions. Sol. Energy Mater. Sol. Cells 2012, 107, 154–164. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mather, P.; Sibley, M. Novel hot spot mitigation technique to enhance photovoltaic solar panels output power performance. Sol. Energy Mater. Sol. Cells 2018, 179, 72–79. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M.; Mather, P. PV output power enhancement using two mitigation techniques for hot spots and partially shaded solar cells. Electr. Power Syst. Res. 2018, 158, 15–25. [Google Scholar] [CrossRef]

- Ghosh, S.; Yadav, V.K.; Mukherjee, V. Improvement of partial shading resilience of PV array though modified bypass arrangement. Renew. Energy 2019, 143, 1079–1093. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Vumbugwa, M.; Crozier McCleland, J.L.; van Dyk, E.E.; Vorster, F.J. Effects of dynamic operational conditions on thermal infrared imaging of monocrystalline silicon photovoltaic modules. J. Sol. Energy Eng. 2021, 143, 024501. [Google Scholar] [CrossRef]

- Bressan, M.; El Basri, Y.; Galeano, A.G.; Alonso, C. A shadow fault detection method based on the standard error analysis of I-V curves. Renew. Energy 2016, 99, 1181–1190. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, J.; Wang, L.; Liu, F.; Jia, P.; Dai, L.; Lu, Y.; Bian, T. The analysis on simulation and invalidation of hot-spot temperature distribution in micro-defective crystalline silicon solar cells. Renew. Energy 2020, 147, 2218–2228. [Google Scholar] [CrossRef]

- Fluke Ti10 Infrared Camera. Available online: http://www.myflukestore.com/pdfs/cache/www.myflukestore.com/fluke/thermal_imager/ti10_9hz/manual/fluke_ti10_9hz_thermal_imager_manual.pdf (accessed on 8 February 2022).

- IEC System of Conformity Assessment Schemes for Electrotechnical Equipment and Components (IECEE). Available online: https://www.iecee.org/dyn/www/f?p=106:48:0 (accessed on 8 February 2022).

- Adamo, F.; Attivissimo, F.; Di Nisio, A.; Lanzolla, A.M.L.; Spadavecchia, M. Parameters Estimation for a Model of Photovoltaic Panels. In Proceedings of the XIX IMEKO World Congress Fundamental and Applied Metrology, Lisbon, Portugal, 6–11 September 2009; Available online: https://www.imeko.org/publications/wc-2009/IMEKO-WC-2009-TC4-622.pdf (accessed on 8 February 2022).

- Adamo, F.; Attivissimo, F.; Di Nisio, A.; Spadavecchia, M. Characterization and testing of a tool for photovoltaic panel modeling. IEEE Trans. Instrum. Meas. 2011, 60, 1613–1622. [Google Scholar] [CrossRef]

- Hernando, F.; Gutierrez, R.; Bueno, G.; Recart, F.; Rodriguez, V. Humps, a surface damage explanation. In Proceedings of the 2nd World Conference and Exhibition on Photovoltaic Solar Energy Conversion, Vienna, Austria, 6–10 July 1998. [Google Scholar]

- Nishioka, K.; Sakitani, N.; Uraoka, Y.; Fuyuki, T. Analysis of multicrystalline silicon solar cells by modified 3-diode equivalent circuit model taking leakage current through periphery into consideration. Sol. Energy Mater. Sol. Cells 2007, 91, 1222–1227. [Google Scholar] [CrossRef]

- Ramspeck, K.; Schenk, S.; Duphorn, D.; Metz, A.; Meixner, M. In-line thermography for reliable hot spot detection and process control. Energy Procedia 2014, 55, 133–140. [Google Scholar] [CrossRef]

- Schafft, H.A. Second breakdown—A comprehensive review. Proc. IEEE 1967, 55, 1272–1288. [Google Scholar] [CrossRef]

- Smith, W.B.; Pontius, D.H.; Budenstein, P.P. Second breakdown and damage in junction devices. IEEE Trans. Electron Devices 1973, 20, 731–744. [Google Scholar] [CrossRef]

- Schafft, H.A.; French, J.C. “Second breakdown” in transistors. IRE Trans. Electron Devices 1962, 9, 129–136. [Google Scholar] [CrossRef]

- Mars, P. Some aspects of the p-n junction second-breakdown mode. PI Electr. Eng. 1969, 116, 1860–1862. [Google Scholar] [CrossRef]

- Ward, A. Studies of second breakdown in silicon diodes. IEEE Trans. Parts Hybrids Packag. 1977, 13, 361–368. [Google Scholar] [CrossRef]

- Scarlett, R.M.; Shockley, W.; Haitz, R.H. Thermal instabilities and hot spots in junction transistors. In Proceedings of the First IEEE Annual Symposium on the Physics of Failure in Electronics, Chicago, IL, USA, 26–27 September 1962. [Google Scholar] [CrossRef]

- Khurana, B.S.; Sugano, T.; Yanai, H. Thermal breakdown in silicon p-n junction devices. IEEE Trans. Electron Devices 1966, 13, 763–770. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Material | Polycrystalline Silicon |

| Number of cells | 36 |

| Maximum Power (W) | 50 |

| VOC (V) | 22.5 |

| ISC (A) | 3.02 |

| VMP (V) | 18.32 |

| IMP (A) | 2.94 |

| Cell size (mm2) | 156 × 52 |

| RP (Ω·cm2) | RS (Ω·cm2) | J01 (A/cm2) | J02 (A/cm2) |

|---|---|---|---|

| 1 × 104 | 1 | 1 × 10−12 | 1 × 10−9 |

| Low parallel conductivity (no shunts) | Low series resistance (good contact) | Low recombination diodes’ saturation currents | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azkona, N.; Llaria, A.; Curea, O.; Recart, F. Detection, Characterization and Modeling of Localized Defects and Thermal Breakdown in Photovoltaic Panels from Thermal Images and IV Curves. Electron. Mater. 2022, 3, 154-172. https://doi.org/10.3390/electronicmat3020014

Azkona N, Llaria A, Curea O, Recart F. Detection, Characterization and Modeling of Localized Defects and Thermal Breakdown in Photovoltaic Panels from Thermal Images and IV Curves. Electronic Materials. 2022; 3(2):154-172. https://doi.org/10.3390/electronicmat3020014

Chicago/Turabian StyleAzkona, Nekane, Alvaro Llaria, Octavian Curea, and Federico Recart. 2022. "Detection, Characterization and Modeling of Localized Defects and Thermal Breakdown in Photovoltaic Panels from Thermal Images and IV Curves" Electronic Materials 3, no. 2: 154-172. https://doi.org/10.3390/electronicmat3020014

APA StyleAzkona, N., Llaria, A., Curea, O., & Recart, F. (2022). Detection, Characterization and Modeling of Localized Defects and Thermal Breakdown in Photovoltaic Panels from Thermal Images and IV Curves. Electronic Materials, 3(2), 154-172. https://doi.org/10.3390/electronicmat3020014