Theoretical and Experimental Comparisons of Total Solar Transmittance for Polycarbonate Sheet with Twin Wall Rectangular Structure

Abstract

:1. Introduction

2. Materials and Methods

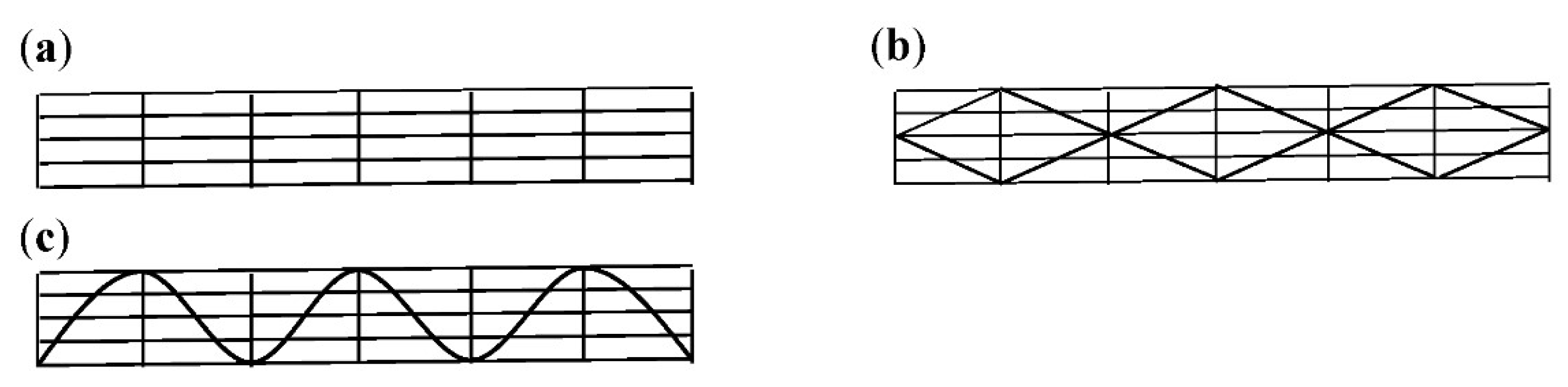

2.1. Object of Research

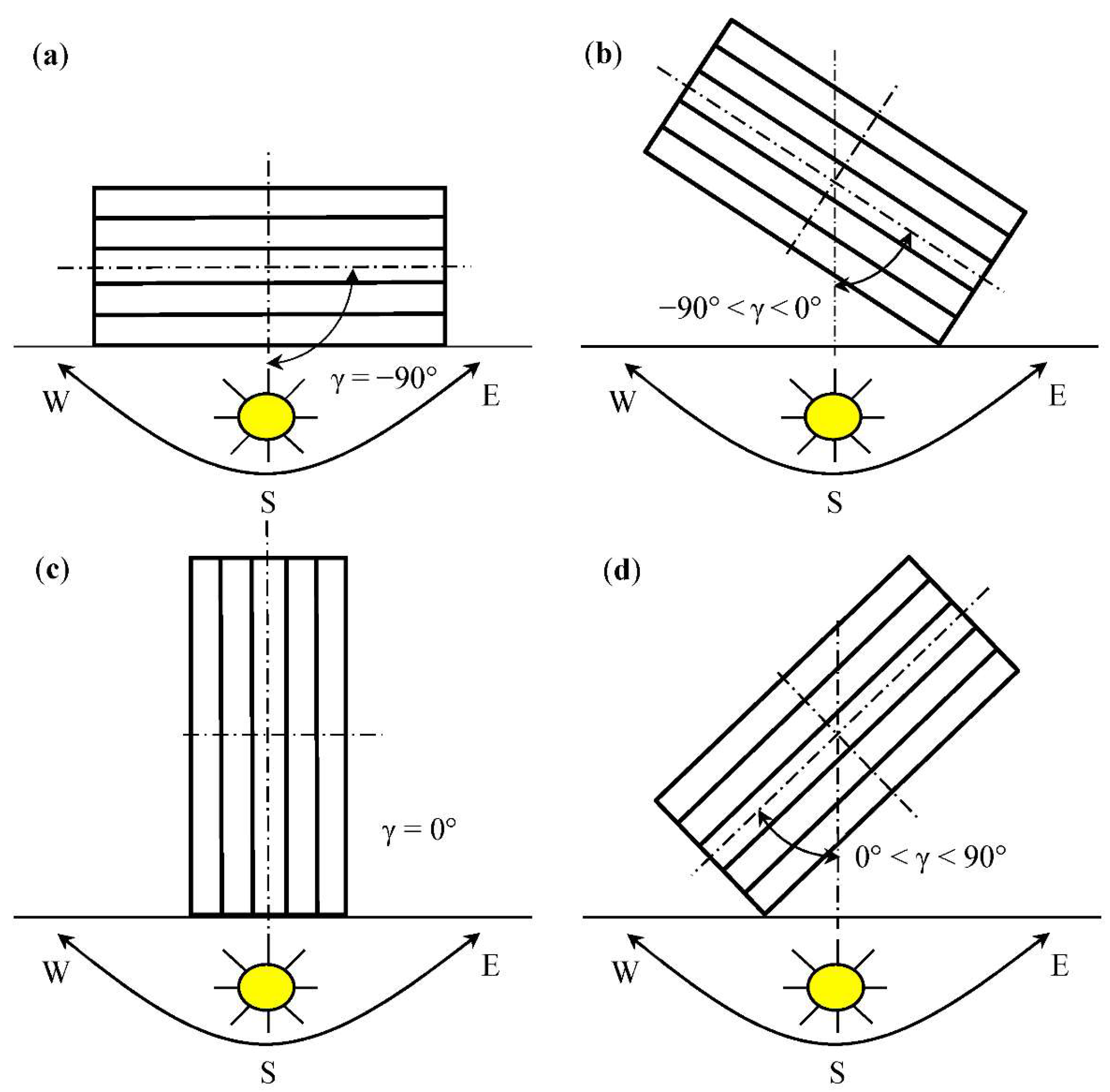

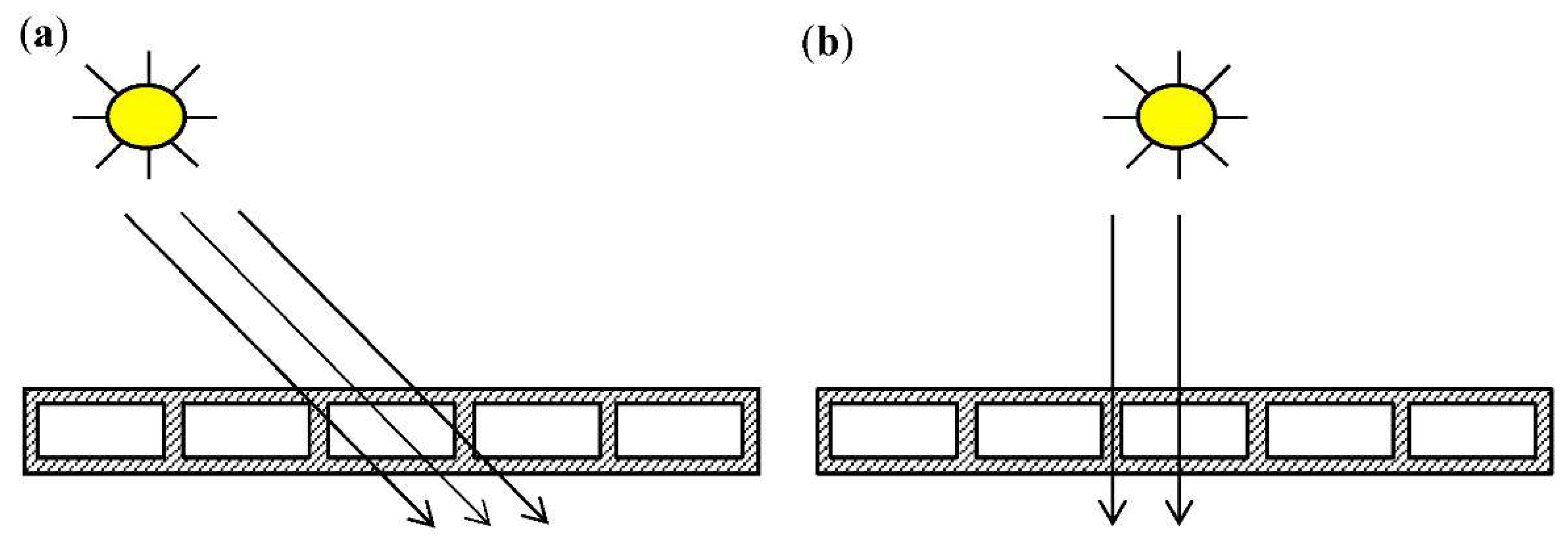

2.2. Methodology of Theoretical Calculation of TST

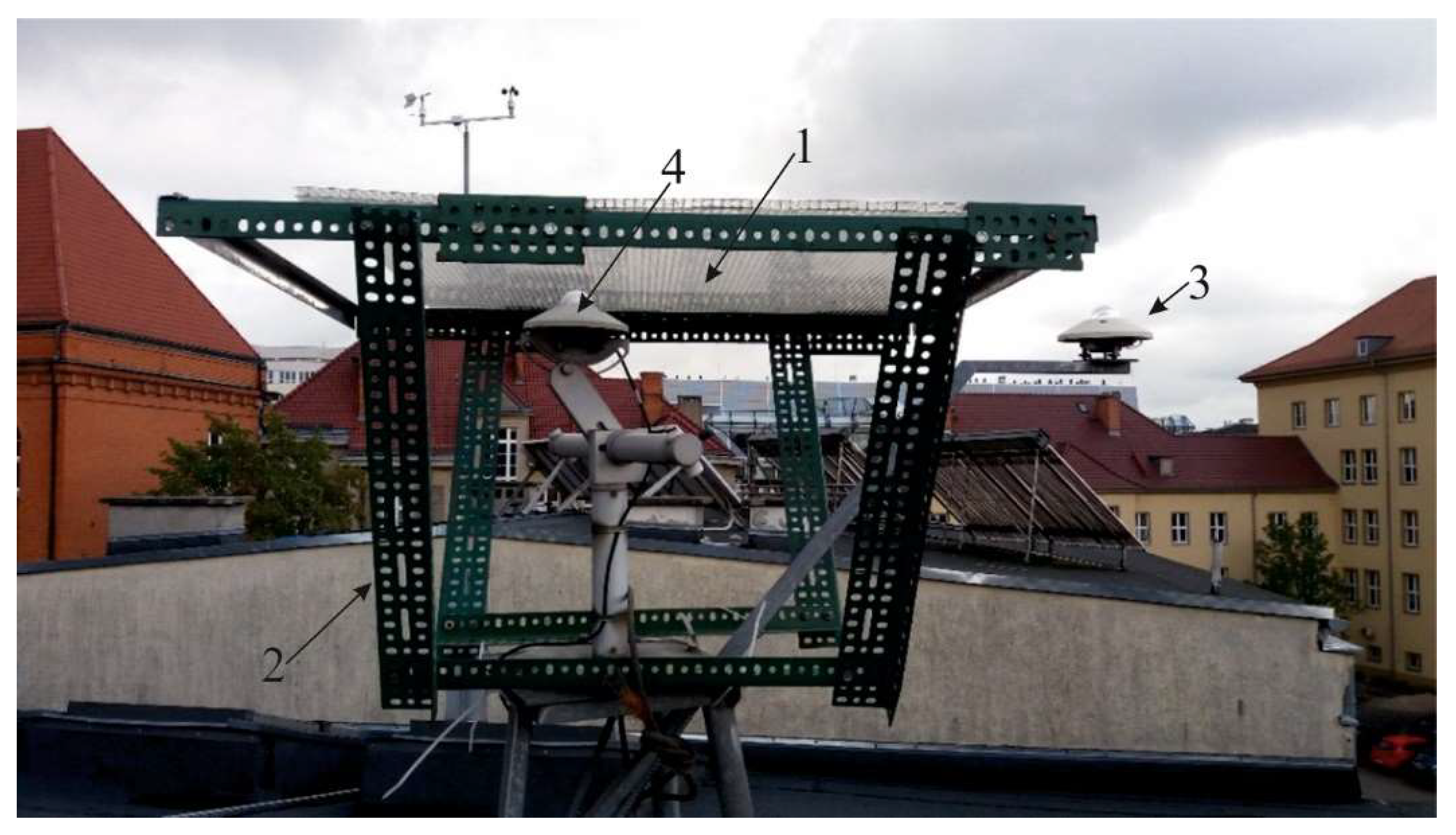

2.3. Methodology of Experimental Determination of TST

3. Results and Discussion

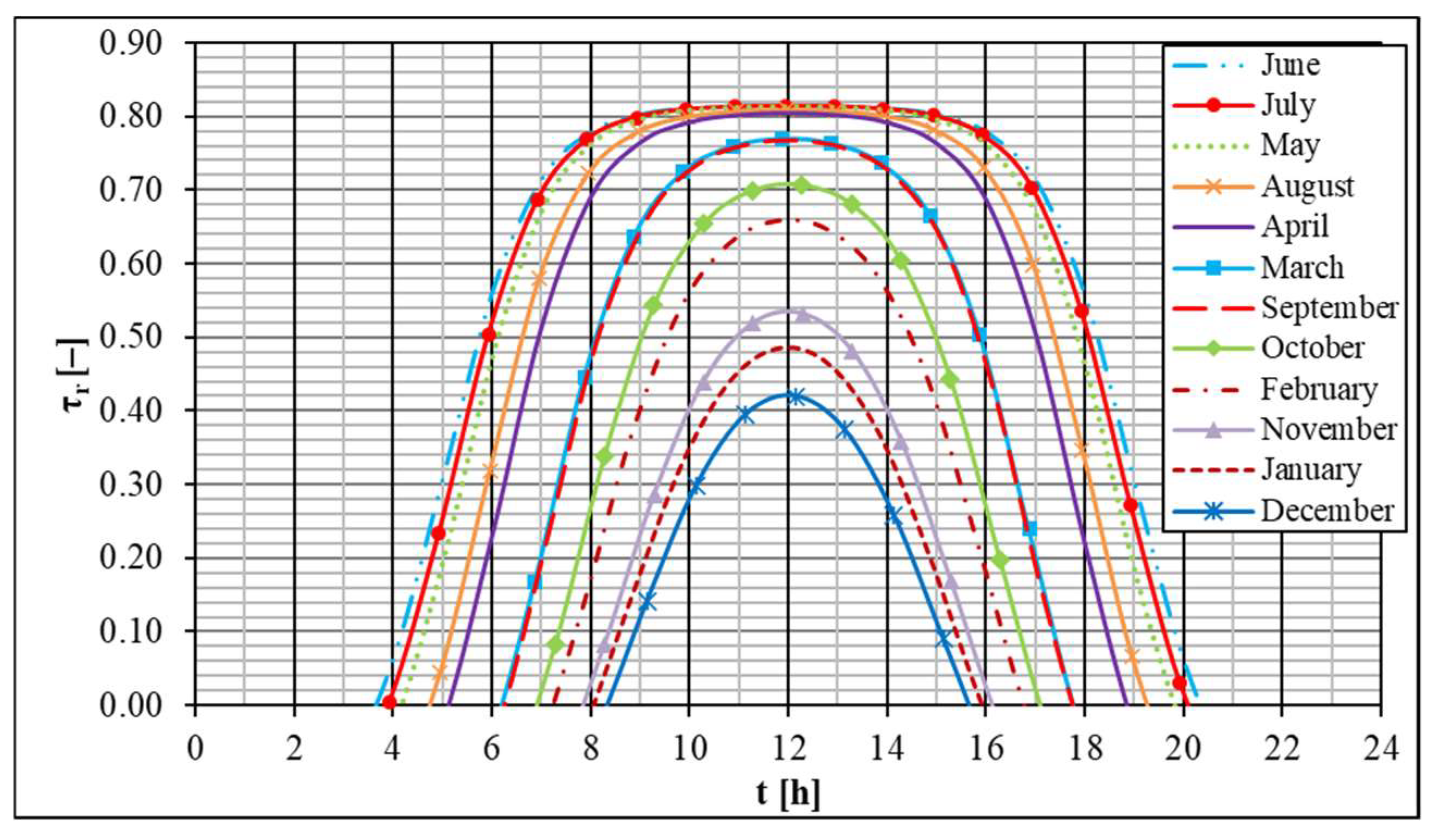

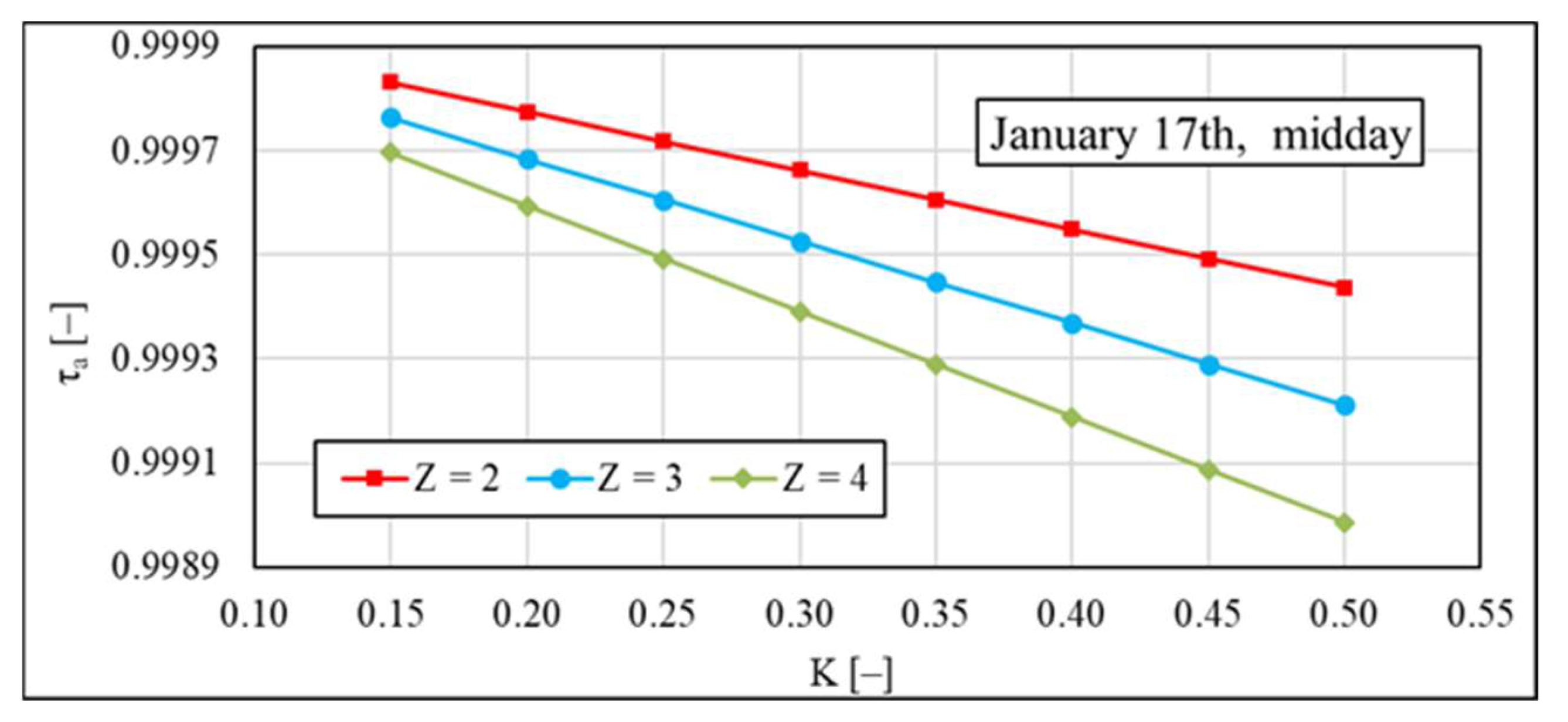

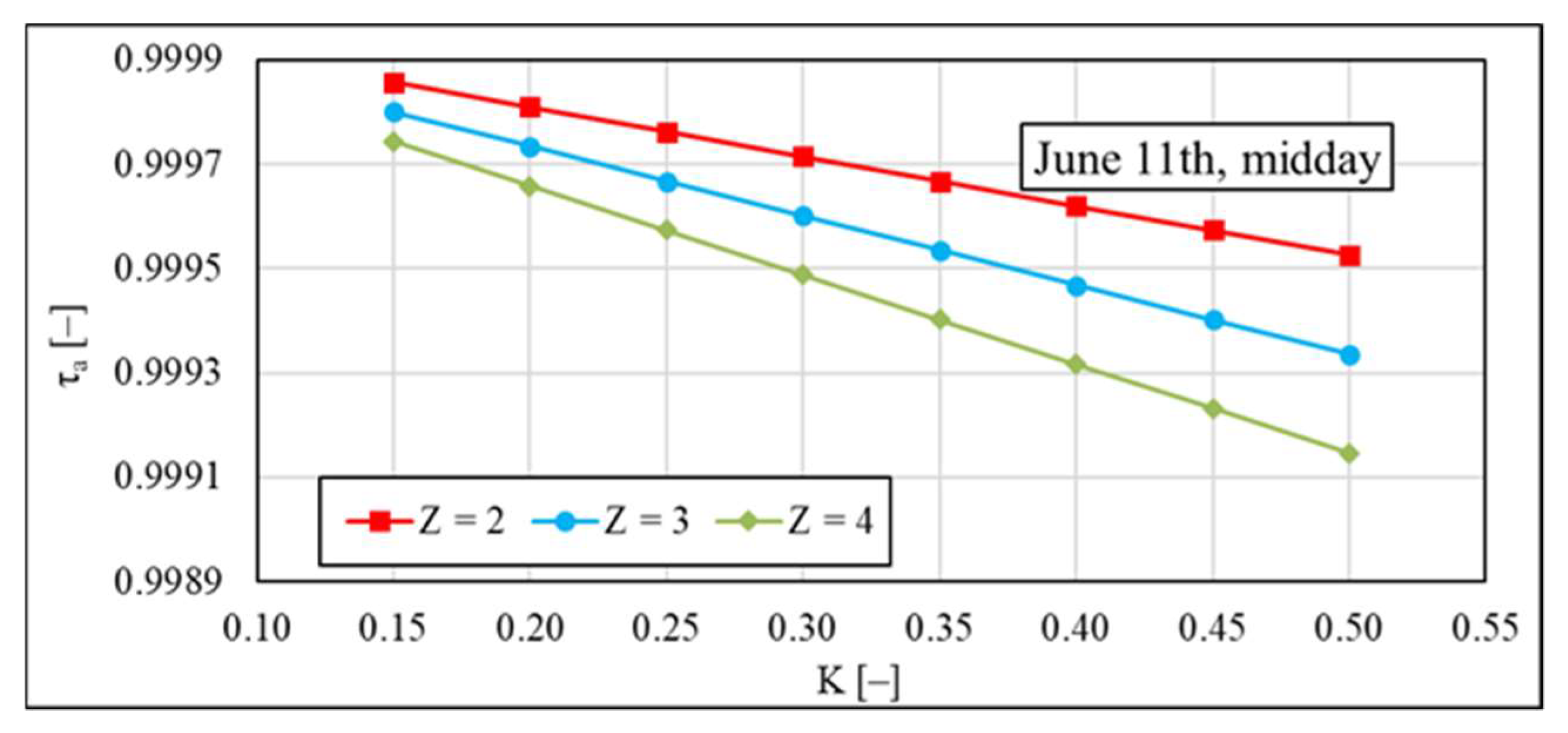

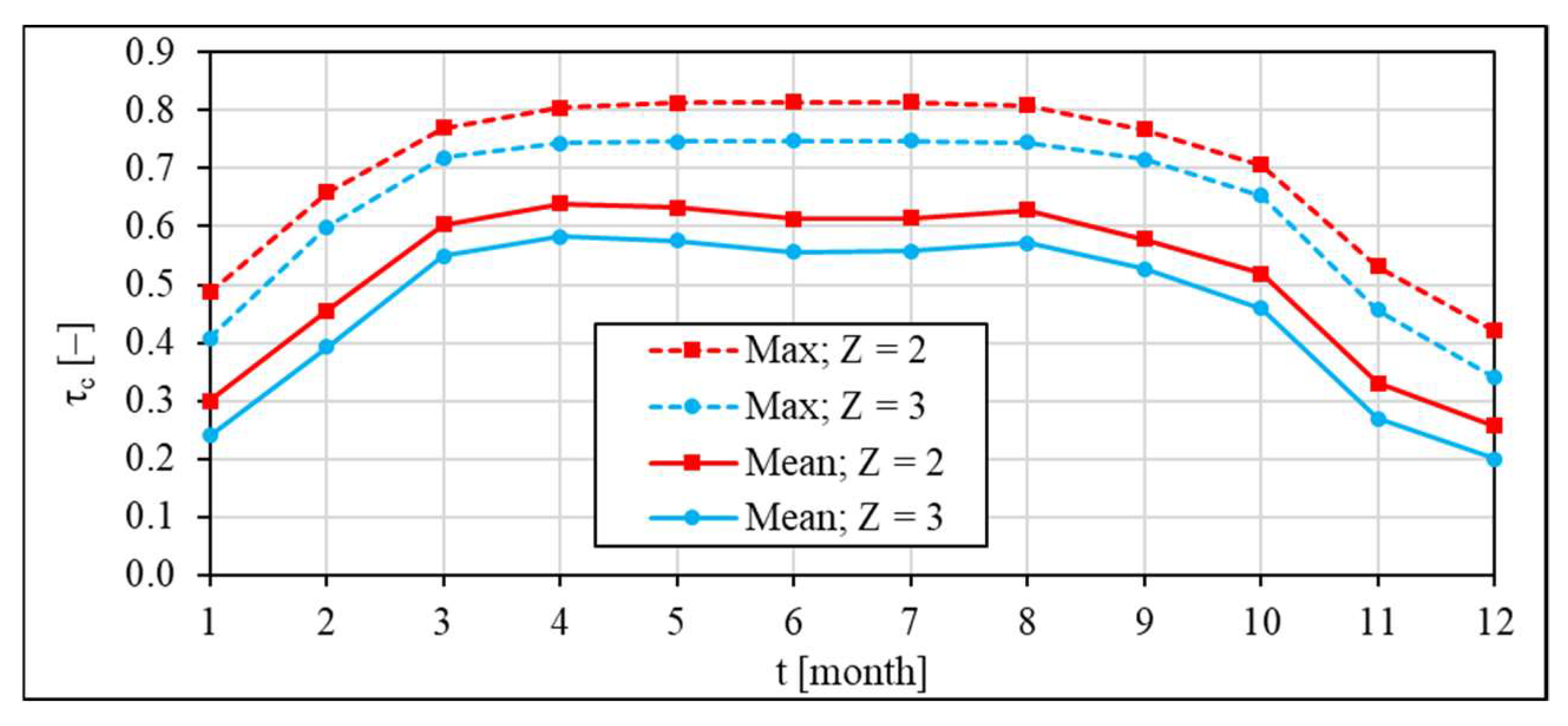

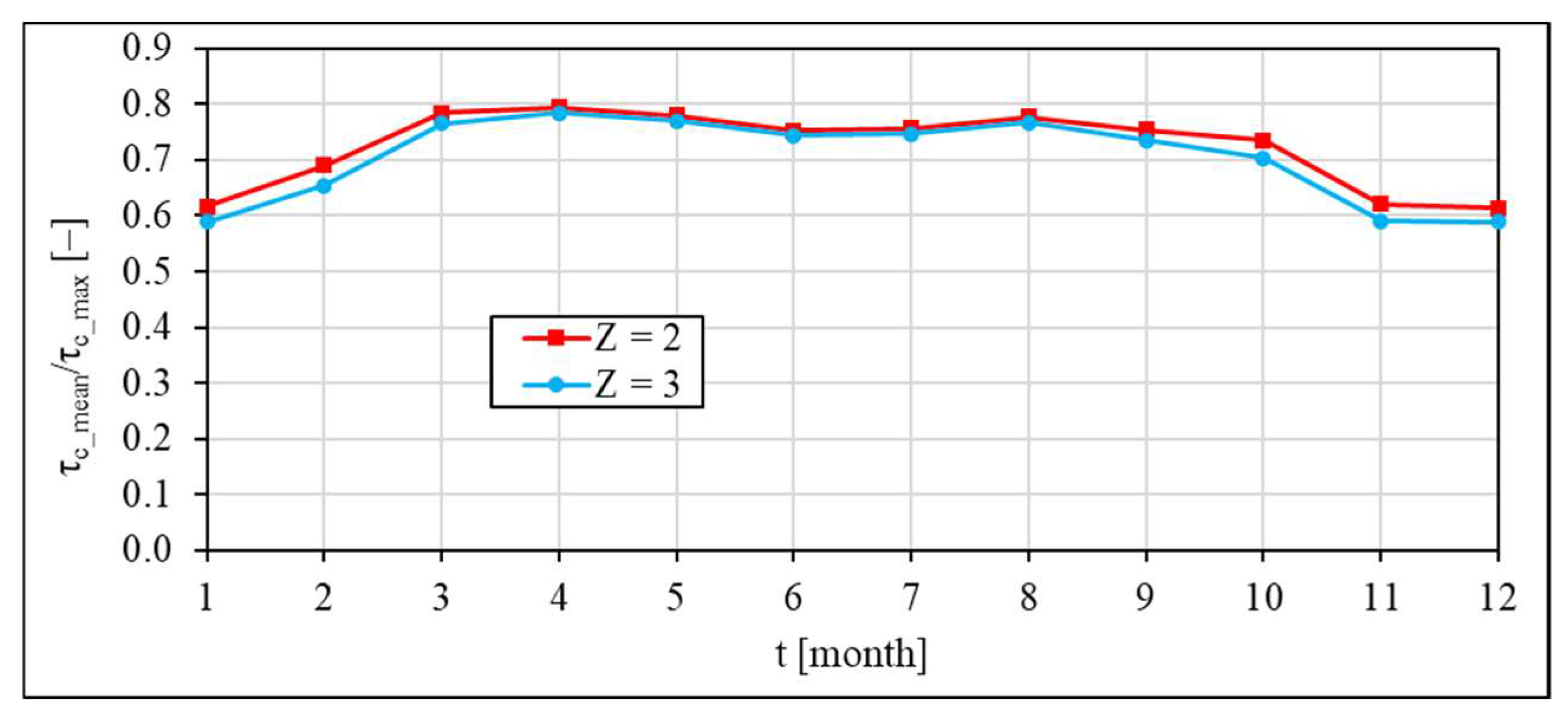

3.1. Results of Theoretical Calculations for TST

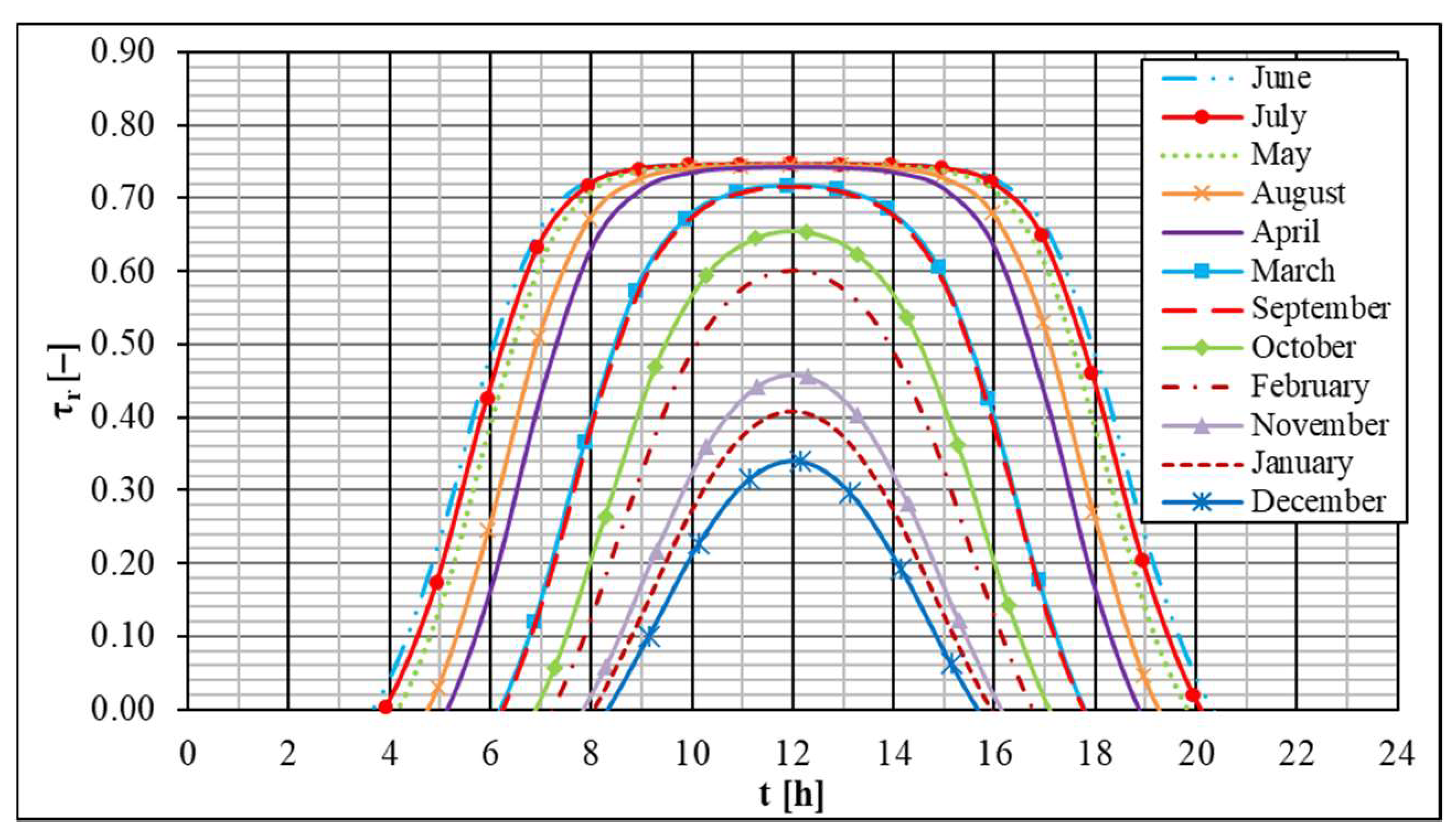

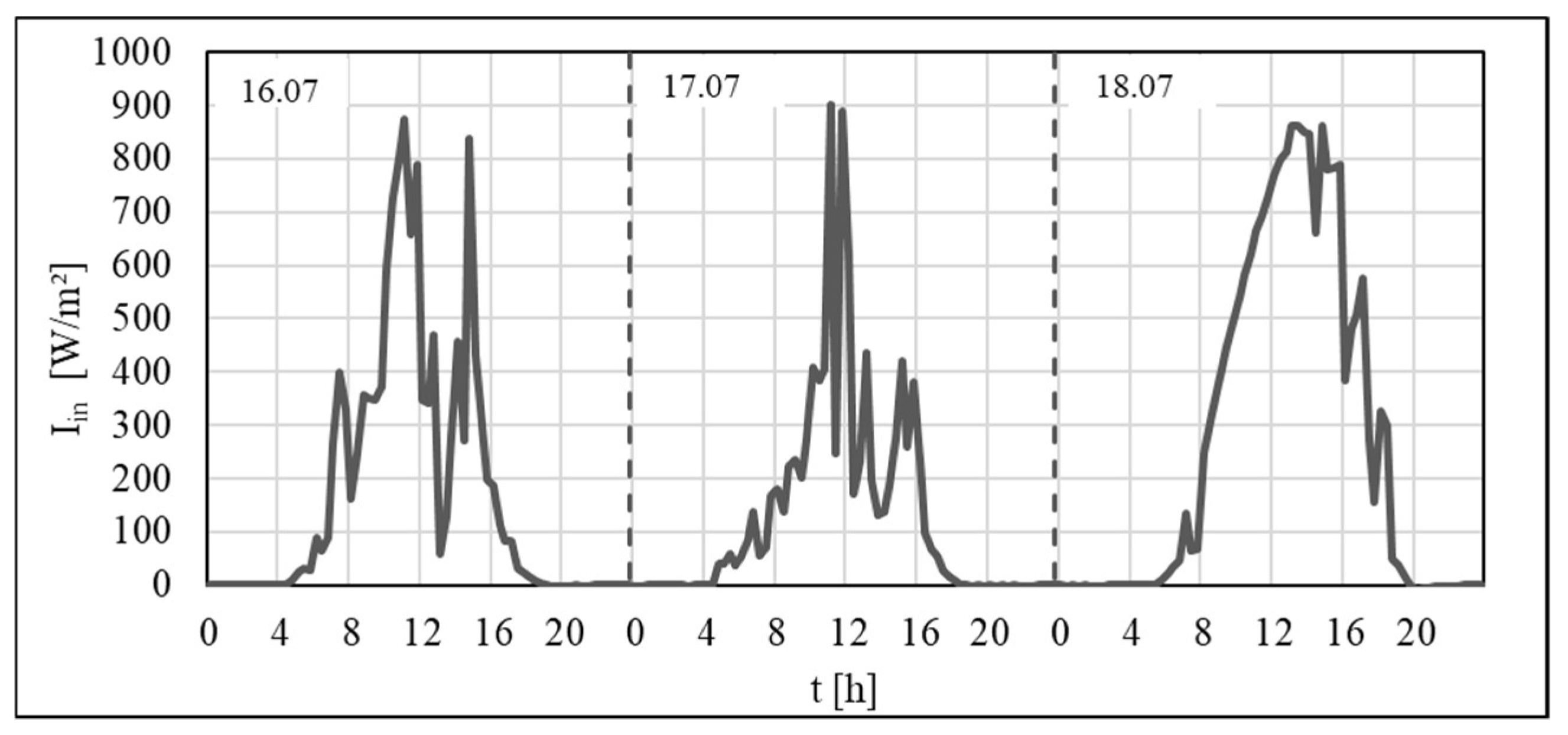

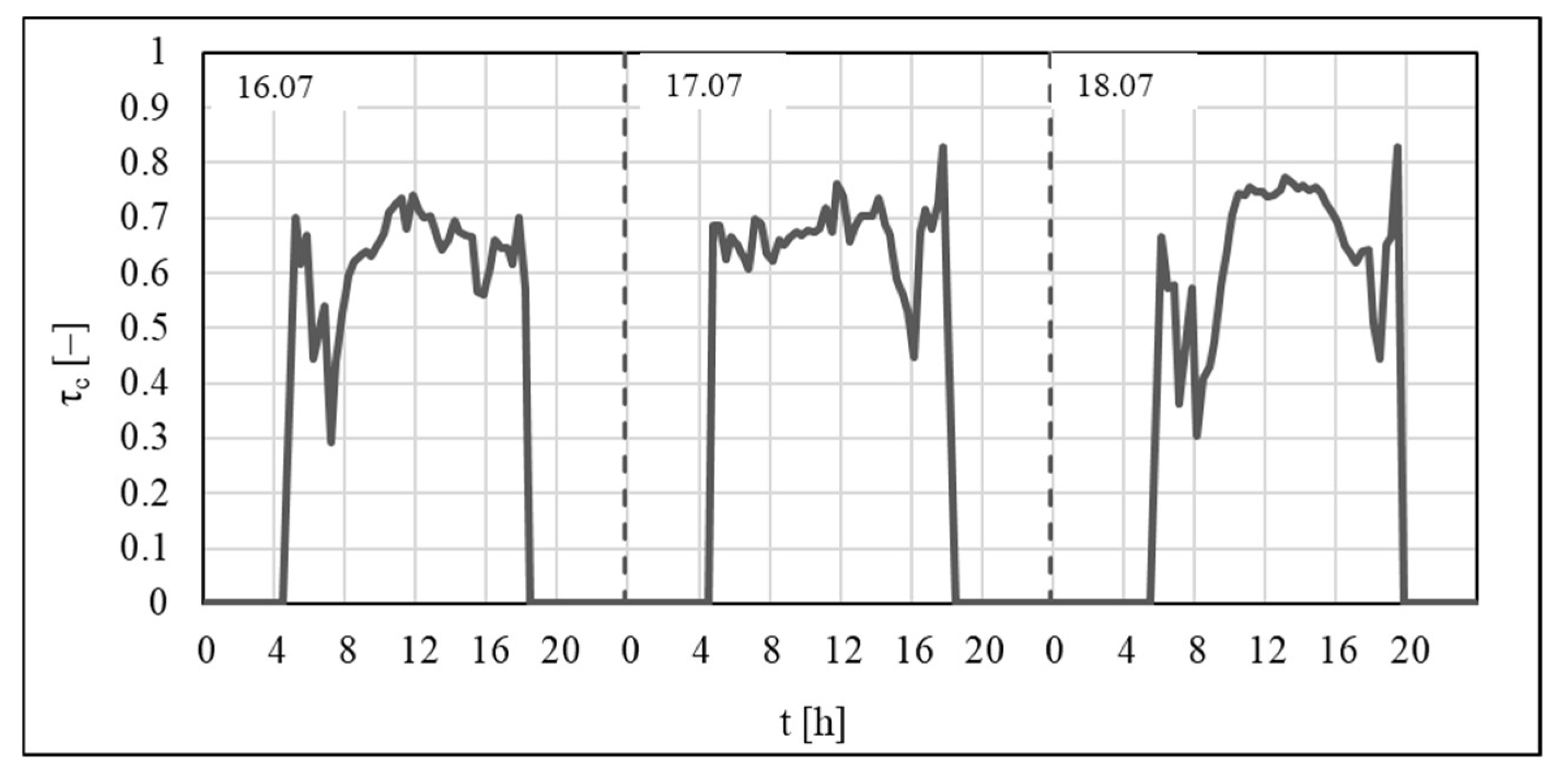

3.2. Calculations Results of Experimentally Determined TST

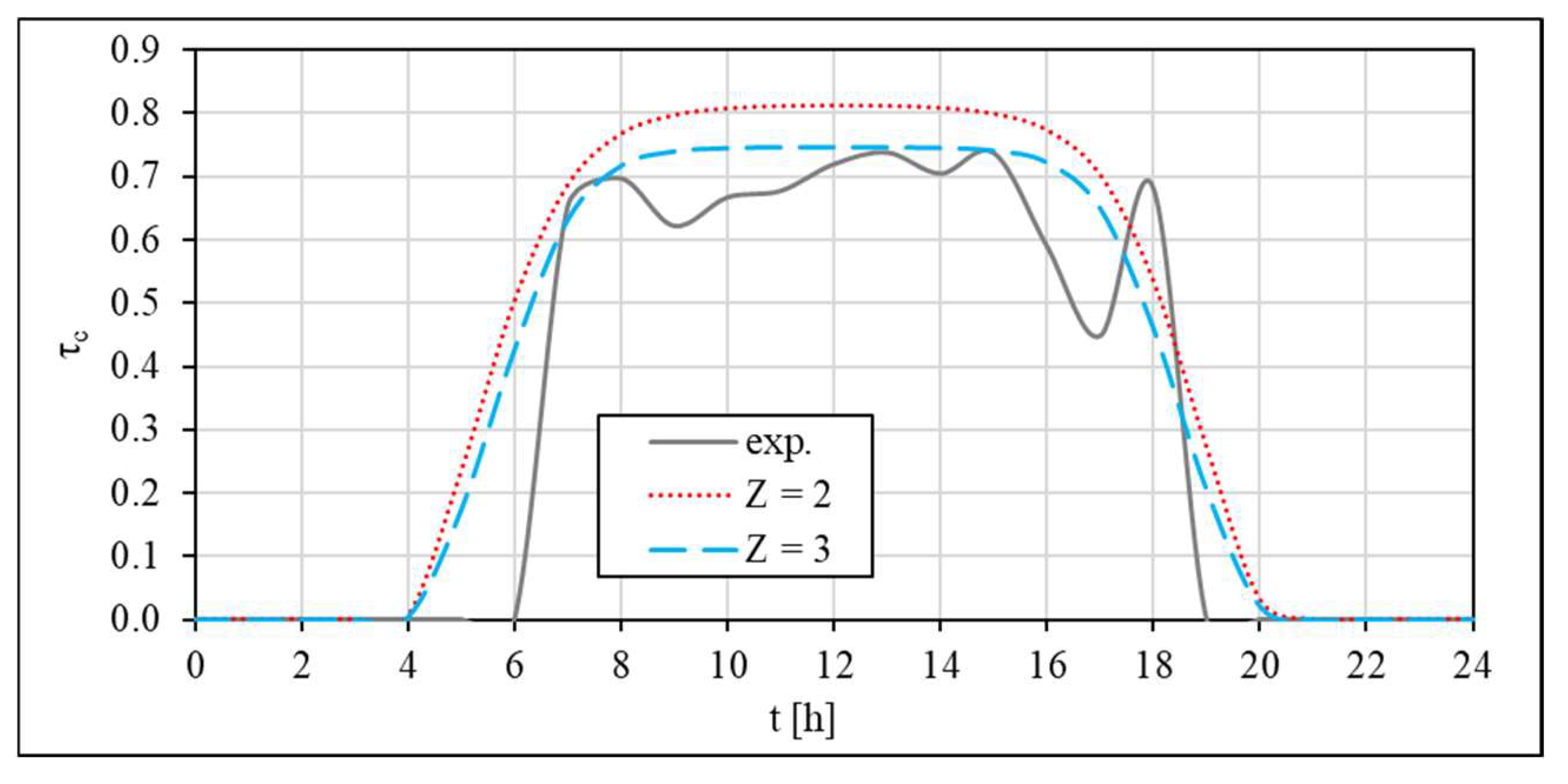

3.3. Comparison of Calculations Results for TST Obtained Theoretically and Experimentally

4. Conclusions

- (a)

- The theoretical value of TST is most of all determined by the value of transmissivity after accounting for multiple reflections of solar rays from the walls of channel; in the case of calculations, it is advisable to assume that solar rays reflect from three surfaces of walls that create the channel; the value of transmissivity after accounting for absorption of solar radiation by polycarbonate is negligible (the approximate value of this last parameter is 0.999).

- (b)

- TST changes with both the season of the year and time of day; TST has an approximately constant value in the time about noon; in the morning and in the evening, respectively, fast rise and drop of TST occurs; maximal values of theoretical TST are 0.34 in December and 0.74 in June if the solar rays reflect from three surfaces of walls of the channel; the maximal value of experimental TST is about 0.75 in June; value of TST presented in technical data is constant and equal to 0.82.

- (c)

- The mean twenty-four-hour theoretical value of TST is about 25% lower than the maximal value obtained for the characteristic day of June; the mean twenty-four-hour theoretical value of TST is about 40% lower than the maximal value obtained for the characteristic day of December; the mean twenty-four-hour theoretical value of TST for the characteristic day of June is about three times higher than the value of this parameter calculated for the characteristic day of December.

- (d)

- Experimentally determined twenty-four-hour values of TST show similar characteristics of changes independently from irradiance changes on particular days of measurements; the value of TST depends on cloudiness; experimentally calculated and determined values of TST are approximately equal in case of cloudless sky—they are, however, lower than the ones given in product data.

- (e)

- The theoretical method of TST calculation should be modified. The correction of incident angle resulting from diffusive radiation could be one of the ways to solve this problem. The new model should involve heat transfer by convection too.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaygusuz, K. Energy for sustainable development: A case of developing countries. Renew. Sustain. Energy Rev. 2012, 16, 1116–1126. [Google Scholar] [CrossRef]

- Sineviciene, L.; Sotnyk, I.; Kubatko, O. Determinants of energy efficiency and energy consumption of Eastern Europe post-communist economies. Energy Environ. 2017, 28, 870–884. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Costa, A.; Keane, M.M.; Torrens, I.; Corry, E. Building operation and energy performance: Monitoring, analysis and optimisation toolkit. Appl. Energy 2013, 101, 310–316. [Google Scholar] [CrossRef]

- Technical Approval (Aprobata Techniczna) ITB AT-15-8917/2012. Płyty komorowe z poliwęglanu Lexan Thermoclear LT2UV: 62RS, 82 RS, 102 RS, 105 RS, 163TS, 166RS, 165X, 169X, 206RS, 205X, 209X, 256RS, 255X, 259X, 253X i 325X; Technical Approval: Warszawa, Poland, 2013; ISBN 978-83-249-6235-8. (In Polish)

- Lexan Sheets Portfolio Brochure, Sabic. 2020. Available online: www.sabic.com/en/products/documents/lexan-sheet-portfolio-brochure/en (accessed on 15 September 2022).

- Technical, Multiwall PC Sheets. Available online: www.epse.org (accessed on 31 August 2020).

- Polycarbonate Panel Systems between Roof Sandwich Panel. Available online: www.polinetlux.com (accessed on 2 September 2020).

- Multi-Wall Polycarbonate Sheets. Available online: https://ugplast-inc.com (accessed on 1 September 2020).

- Lexan Thermoclear Sheet. Available online: https://sfs.sabic.eu (accessed on 28 March 2021).

- Polycarbonate Multiwall. Available online: https://www.arlaplast.com/ (accessed on 28 March 2021).

- Polycarbonaat Op Matt. Available online: www.perquy.be (accessed on 2 September 2020).

- Products, Polycarbonate. Available online: www.edplastics.co.uk (accessed on 31 August 2020).

- Polycarbonate Plastics. Available online: www.quinn-plastics.com (accessed on 3 September 2020).

- Zapałowicz, Z.; Wojnicki, O. Estimation of total solar transmittance for twin-wall polycarbonate sheet with rectangular structure on the basis of experimental research. Energies 2022, 15, 1360. [Google Scholar] [CrossRef]

- Garnysz, A.; Zapałowicz, Z. Thermal calculations for swimming pool with the roofing system. In Proceedings of the 3rd International Conference, Low Temperature and Waste Heat Use in Energy Supply Systems—Theory and Practice, Bremen, Germany, 25–26 October 2012; pp. 72–78. [Google Scholar]

- Garnysz, A.; Zapałowicz, Z. Model of heat and mass transfer in swimming pools with roofing systems. In Developments in Mechanical Engineering; Cieśliński, J.T., Szymczyk, J., Eds.; Gdańsk University of Technology Publishers: Gdańsk, Poland, 2012; Volume 5, pp. 49–58. [Google Scholar]

- Garnysz, A.; Zapałowicz, Z. Comparison of characteristic thermal parameters for a swimming pool with retractable pool enclosures exploited in autumn and spring seasons. In Proceedings of the XVth International Conference on Heat Transfer and Renewable Sources of Energy, Międzyzdroje, Poland, 10–13 September 2014; Stachel, A.A., Mikielewicz, D., Eds.; Wydawnictwo Uczelniane ZUT w Szczecinie: Szczecin, Poland, 2014; pp. 301–306. [Google Scholar]

- Zapałowicz, Z.; Garnysz-Rachtan, A. Estimation of transmission of solar radiation for polycarbonate retractable swimming pool enclosures. Arch. Thermodyn. 2021, 42, 129–146. [Google Scholar] [CrossRef]

- EN 16153:2013 + A1:2015; Light Transmitting Flat Multiwall Polycarbonate (PC) Sheets for Internal and External Use in Roofs, Walls and Ceilings. Requirements and Test Methods. British Standards Institution: London, UK, 2015.

- Manz, H. Total solar energy transmittance of glass double façades with free convection. Energy Build. 2004, 36, 127–136. [Google Scholar] [CrossRef]

- Čekon, M. Optical Performance of Polycarbonate Multi-Wall Panels in the Form of Transparent Insulation Based on Long-Term Outdoor Measurements. Available online: https://www.researchgate.net/publication/328465260 (accessed on 2 September 2020).

- Čekon, M.; Slávik, R. Total solar transmittance quantifying of transparent insulation building materials based on real climate outdoor measurements. Energy Procedia 2017, 132, 243–248. [Google Scholar] [CrossRef]

- Čekon, M.; Struhala, K. Polycarbonate multi-wall panels integrated in multi-layer solar façade concepts. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018; Volume 415, p. 012019. [Google Scholar] [CrossRef]

- Čekon, M.; Slávik, R.; Zach, J. Experimental analysis of transparent insulation based on polycarbonate multi-wall systems: Thermal and optical performance. Energy Procedia 2017, 132, 502–507. [Google Scholar] [CrossRef]

- ASTM E1084-86; International Standard Test Method for Solar Transmittance (Terrestrial) of Sheet Materials Using Sunlight. ASTM International: West Conshohocken, PA, USA, 2015.

- Pluta, Z. Podstawy Teoretyczne Fototermicznej Konwersji Energii Słonecznej (Theoretical Basis of Photothermal Solar Energy Conversion); Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2006; ISBN 83-7207-229-9. (In Polish) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zapałowicz, Z.; Garnysz-Rachtan, A. Theoretical and Experimental Comparisons of Total Solar Transmittance for Polycarbonate Sheet with Twin Wall Rectangular Structure. Appl. Mech. 2022, 3, 1163-1175. https://doi.org/10.3390/applmech3040066

Zapałowicz Z, Garnysz-Rachtan A. Theoretical and Experimental Comparisons of Total Solar Transmittance for Polycarbonate Sheet with Twin Wall Rectangular Structure. Applied Mechanics. 2022; 3(4):1163-1175. https://doi.org/10.3390/applmech3040066

Chicago/Turabian StyleZapałowicz, Zbigniew, and Agnieszka Garnysz-Rachtan. 2022. "Theoretical and Experimental Comparisons of Total Solar Transmittance for Polycarbonate Sheet with Twin Wall Rectangular Structure" Applied Mechanics 3, no. 4: 1163-1175. https://doi.org/10.3390/applmech3040066

APA StyleZapałowicz, Z., & Garnysz-Rachtan, A. (2022). Theoretical and Experimental Comparisons of Total Solar Transmittance for Polycarbonate Sheet with Twin Wall Rectangular Structure. Applied Mechanics, 3(4), 1163-1175. https://doi.org/10.3390/applmech3040066