Abstract

The leaf extracts of Gymnema sylvestre consist of secondary metabolites which are well known for antioxidant activity. This study aimed to measure the drying characteristics of G. sylvestre leaves under far-infrared radiation (FIR) and to optimize the specific energy consumption for drying and antioxidant activity of ethanol-water extract of dried leaves. Fresh leaves were harvested and exposed to combinations of four different temperatures (125, 150, 175 and 200 °C) and exposure times (5, 10, 15 and 20 min). Drying kinetics, energy consumption, color changes, total phenolic content (TPC) and antioxidant activities were quantified. Both temperature and drying time have significant (p < 0.05) effects on drying characteristics and antioxidant activity. The equilibrium moisture content was achieved at 200 °C and 18 min. The specific energy decreased and total color changes increased with temperature. Under lower temperatures (125 and 150 °C), TPC and antioxidant activity increased with exposure time, whereas higher exposure time (20 min) with high temperatures (175 and 200 °C) significantly decreased TPC and antioxidant activity. The highest TPC of 30.5 mg TAE/g leaf-fresh weight was achieved at 200 °C and 15 min. The optimal drying conditions achieved from the dissimilarity function method were 200 °C and 8.4 min.

1. Introduction

Gymnema sylvestre is a medicinal plant used in ayurvedic and homoeopathic therapy. It is a slow-growing, perennial and woody climber belonging to the family Ascleiapediaceae [1]. This plant possesses several bioactive secondary metabolites, including Gymnemic acid and gymnemasaponins [2]. Moreover, bioactive compounds such as alkaloids, tannins, flavonoids, and phenolic compounds are present in this plant. Therefore, the plant is used for various treatment of illnesses, including diabetes, obesity, liver diseases, asthma, constipation, cardiopathy, arthritis, infections and inflammations [2,3,4].

Free radicals mainly belong to two groups, namely reactive oxygen species and reactive nitrogen species. These vigorously react with other molecules, causing oxidative stresses and damaging multiple-system organs [5]. These free radicals are naturally generated by the biological process in the body and are also accumulated in the body when food with free radicals are consumed [6,7]. Antioxidants are generally used to quench the free radicals and reduce the harm to the vital biological molecules in the body. The interest in finding and using plant-based natural antioxidants has increased due to the adverse effects of synthetic antioxidants [8,9,10].

It is well documented that water and alcoholic extracts of G. sylvestre show antioxidant activity [11,12]. For example, the alcoholic leaf extract of G. sylvestre exhibits a total antioxidant capacity of 17.54 mg/g ascorbic acid [11]. Another study reported that the ethanol extract of G. sylvestre showed high total phenolic and flavonoid contents [13]. The same study reported that the 2,2-diphenyl-1-picrylhydrazyl (DPPH) EC50 value of this extract was 303 μg mL−1. The DPPH EC50 value of ethanolic extract from dried leaves was reported as 76.59 µg mL−1 [12]. Further, this study reported that ethanol extract showed higher antioxidant activity than methanol and water extract.

Dried herbs have been used for medicinal purposes as an alternative to fresh leaves where their availability is lacking. G. sylvestre is also used in traditional medicine in dried powder form [14]. Drying is a cost-effective preservation technique which decreases the moisture content and increases the shelf life of the products [15]. Infrared (IR) has been applied for drying herbs, including curry leaves, tea, peppermint and parsley [16,17,18]. This method rapidly transfers heat to the drying substance and provides uniform heating without heating the air [19,20]. The moisture content, surface roughness and wavelength of IR are a few parameters that influence the penetration depth of IR [21]. Generally, the penetration depth of the IR is low and is therefore only suitable for thin-layer drying [22]. To this end, only a limited number of studies reported the antioxidant properties of dried G. sylvestre leaves [12,14]. Additionally, far-infrared radiation (FIR) has a high potential to be used as a heating source for drying herbs. Nevertheless, it has not been applied to dry the G. sylvestre leaves to the authors’ best knowledge. Therefore, the overall objective of this study was to evaluate the effects of FIR on the color, TPC and antioxidant properties of G. sylvestre. Further, this study used the response surface method (RSM) to optimize the drying conditions to achieve a better-quality product with low specific energy consumption.

2. Materials and Methods

In this study, a batch-type FIR dryer was fabricated and G. sylvestre leaves were exposed under different temperatures and exposure times. The energy consumption for drying was measured and specific energy consumption (SEC) was calculated. The color changes of dried leaves during drying were quantified. Then the dried leaves were ground and made into fine powders. The water-ethanol extracts of dried leaves were obtained and total phenolic compound, DPPH activity and ferric reducing antioxidant power (FRAP) were measured. Finally, the drying parameters were optimized using the RSM to minimize the SEC and to maximize the antioxidant activity.

2.1. Plant Material Preparation

The fresh G. sylvestre leaves were harvested from Jaffna District located in the northern region of Sri Lanka (longitude and latitude are 9.6908° N and 80.0211° E, respectively) during the year 2018. The plant leaves were washed with distilled water and stored at 4 °C (maximum of 2 weeks). Before the experiment, the leaves were taken out and allowed to equilibrate at room temperature (24–25 °C). Initial moisture content was measured using the oven-drying method at 110 °C until the constant moisture content was achieved [23].

2.2. Drying Setup and Treatments

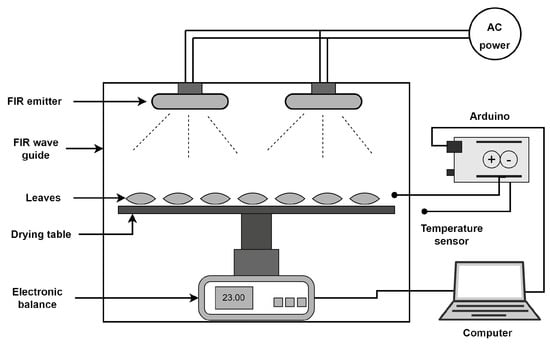

A batch-type FIR dryer was assembled with two FIR panels, each having 650 W (Figure 1). A wave guide made of aluminum was used to direct the FIR toward leaf samples. For each experiment, 25 g of G. sylvestre leaves were spread on the drying table without overlapping each other. For this, leaves of similar sizes were selected to maintain an equal number of leaves dried under each experiment. The leaves were dried under combinations of four different temperatures (125, 150, 175 and 200 °C) and exposure times (5, 10, 15 and 20 min). The corresponding symbols for the temperatures are T1, T2, T3 and T4 and exposure times are X1, X2, X3 and X4, respectively. The drying temperature was adjusted by changing the gap between the FIR emitter and the drying table. A K-type thermocouple (Omega, Norwalk, CT, USA) was used to measure the drying temperature. The continuous weight changes were measured by a top-loading balance. The experiment was repeated five times (serving as replications) for each combination of temperature and exposure time. The dried leaves were stored in a Ziploc polythene bag under ambient conditions.

Figure 1.

The schematic diagram of the batch-type FIR dryer assembled for drying G. sylvestre leaves.

2.3. Drying Kinetics

The drying curves for G. sylvestre leaves were plotted using Equation (1) [24].

where MC0 and MCt are moisture content at the initial stage and at time point t, respectively.

2.4. Specific Energy Consumption

The energy consumption for drying was measured using a portable power analyzer (YOKOGAWA, model CW240). The specific energy consumption (SEC) refers to the energy required to evaporate the unit weight of moisture from the leaves and was calculated using Equation (2) [23].

where SEC is specific energy consumption (MJ kg−1), Eu is energy consumption of FIR (MJ) and Mw is the amount of water removed (kg).

2.5. Color Measurement

The color values L (0 = black, 100 = white), a (−a = greenness, +a = redness) and b (−b = blueness, +b = yellowness) were measured using a colorimeter (Minolta CR 300, Tokyo, Japan). The total color difference (ΔE) was calculated using Equation (3) [20].

where ΔE is total color difference, L, a and b are lightness, greenness to redness and blueness to yellowness of dried leaf samples, respectively. The same symbols with “0” subscript show the color values of fresh leave samples.

2.6. Water-Ethanol Extract of the Leaves

The leaf extract was prepared by a modified method by Khramov, et al. [25]. Fine powder of the dried leaves was obtained by grinding the leaves using a coffee grinder (BLACK + DECKER, CBM4-B5) at 600 rpm and the sample was passed through a 250-micron sieve. An amount of 400 mg of dried powder was treated with 20 mL of water-ethanol (1:1 v/v) mixture in a closed Erlenmeyer flask and this mixture was heated in a water bath at 50 °C for 1 h. Then, the leaf extract was centrifuged (1000× g for 3 min) and the supernatant was filtered through a Whatman No. 45 filter paper. The leaf extract was stored under 4 °C until used for further analysis.

2.7. Total Phenolic Content

The total phenolic content (TPC) of leaf extracts was measured using the Folin–Ciocalteu method [26]. In brief, 0.5 mL of Folin–Ciocalteu reagent (a 10% v/v in distilled water) was added and vortexed well with 50 μL of water-ethanol extract of G. sylvestre. After 5 min, 0.4 mL of 7.5% Na2CO3 was mixed and kept at ambient conditions for 5 min. An amount of 50 μL of distilled water was used in place of plant extract to prepare a blank. The absorbance was quantified at 765 nm using a UV-VIS spectrophotometer (SHIMADZU-UV 1800, Kyoto, Japan). Tannic acid (0.1 g L−1) was used as the stand solution and TPC is expressed in terms of tannic acid equivalent. TPC was calculated using Equation (4).

where TPC is total phenolic content, ABe is absorbance of leaf extract, ABs is absorbance of standard and Sc is concentration of standard.

2.8. DPPH Radical Scavenging Assay

The free radical scavenging activity of the leaf extract was measured using the method by Blois [27] with modifications. A methanolic solution of 0.135 mM 2,2-diphenyl-1-picrylhydrazyl (DPPH) was prepared and used for the analysis. Different volumes of leaf extract (from 0 to 250 μL with an increment of 50 μL) were mixed with distilled water to make the total volume 750 μL and then 300 μL of DPPH solution was added. This mixture was kept in the dark for incubation for 30 min and absorbance was measured at 517 nm using a UV-VIS spectrophotometer (SHIMADZU-UV 1800, Kyoto, Japan). Using Equation (5), the DPPH scavenging activity was calculated. DPPH scavenging activity was plotted against leaf concentration and the concentration that inhibits half of the free radicals (IC50) was estimated.

where ABC and ABS are absorbance of control and sample, respectively.

2.9. FRAP (Ferric Reducing Antioxidant Power) Assay

The ferric-reducing power of the leaf extract was measured using a FRAP assay [28]. A new FRAP solution was prepared by mixing 10 mM of 2, 4, 6-tripyridyl triazine (TPTZ) with a 20 mM ferric chloride and 0.25 M acetate buffer at pH 3.6 in a 1:1:10 volume ratio. Leaf extract of 20 µL was vortexed well with 1 mL FRAP reagent. A 1000 µM FeSO4 solution was used as a standard. The absorbance of standard and leaf extract-reagent mixtures was obtained at 593 nm and ferric-reducing power was calculated using Equation (6). During the FRAP test, colorless Fe3+—TPTZ was reduced to blue color Fe2+—TPTZ and this color change can be measured at 593 nm wavelength [29].

where ABe is absorbance of leaf extract, ABs is absorbance of standard and FRAPc is concentration of FRAP standard.

2.10. Optimization of Drying Conditions

The response surface method (RSM) was used to optimize the drying parameters to obtain better quality products and save energy and time. RSM was performed using Minitab 18. The second-degree polynomial equation was employed in RSM since it is widely used for optimization [22]. The optimization function is expressed in Equation (7).

where Y values are response variables (i.e., specific energy consumption, ΔE, TPC, DPPH and FRAP); β0, βi, βii and βij denote constant regression coefficients of intercept, linear, quadratic and interaction terms, respectively; Xi and Xj are independent variables, namely temperature and exposure time, respectively.

The desirability function was used to develop the desirability value for each response variable and all these individual desirability values were added together to obtain the desirability index (D), which is expressed in Equation (8).

where D is desirability index, di is desirability value of an individual response variable, Vi is relative importance and n is the total number of response variables.

2.11. Data Analysis

The data were presented as mean ± standard deviation (SD) of five replicates. The one-way analysis of variance (ANOVA) was employed to study the effect of treatments at a 5% significance level. Tukey honest significant difference (HSD) test was performed for mean separation at a 5% significance level. Correlation analysis was performed between TPC and antioxidant assays (DPPH and FRAP). All the statistical analyses were done using Minitab 18 (Minitab, Penn State University, State College, PA, USA).

3. Results and Discussion

3.1. Drying Kinetics

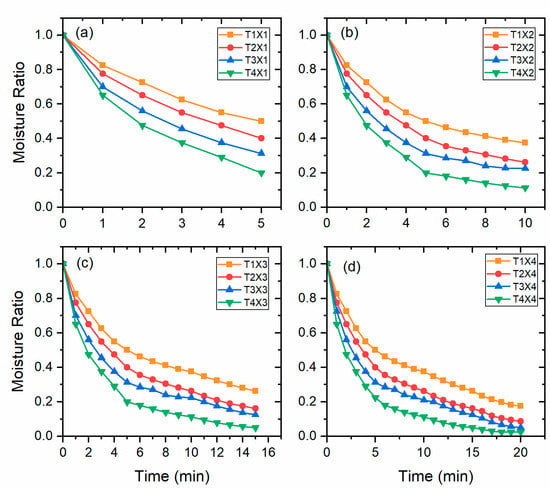

The moisture ratio changes of G. sylvestre dried under FIR are shown in Figure 2. The moisture loss increased with decreasing rate for all exposure times. This could be due to the reason that loosely bound moisture can be rapidly released from the sample; however, tightly bound moisture is harder to evaporate, which decreased the drying rate with time. Increasing the drying temperature increased the drying rate. The samples dried at 200 °C for 18 min only reached the equilibrium moisture content, and other drying combinations did not reach the equilibrium moisture content. Under these drying combinations, treatments T3X4, T4X3 and T4X4 only decreased the moisture content below this recommended level. The total amount of moisture losses for the samples dried for 20 min under 125, 150, 175 and 200 °C were 16.5, 18.25, 19 and 19.5 g, respectively. The lowest and highest drying rates were achieved for T1X1 and T4X4 drying combinations, respectively. The corresponding moisture losses were 10 and 19.5 g, respectively.

Figure 2.

The moisture ratio changes with FIR exposure times: (a) 5 min, (b) 10 min, (c) 15 min and (d) 20 min for different temperatures.

3.2. Specific Energy Consumption (SEC)

Drying is an energy-consuming process and, therefore, it is a very important parameter in engineering design and operation. The SEC for drying of G. sylvestre leaves ranged between 38.8 to 93.9 (Table 1). Temperature and drying time had a significant interaction effect on SEC. The SEC significantly (p < 0.05) increased with drying time for all drying temperatures (Table 1). The highest and lowest SEC were observed for T1X4 and T1X1, respectively. For a fixed exposure time, increasing the temperature significantly (p < 0.05) decreased the SEC. Fast-drying rate under high temperatures decreased the energy consumption for drying, thus the SEC decreased with increasing temperature. Similar observations were reported for the drying of peppermint leaves [30] and blueberries [31].

Table 1.

Specific energy consumption (SEC), total phenolic content (TPC) in terms of tannic acid equivalent (TAE) and antioxidant properties (DPPH and FARP) of dried G. sylvestre.

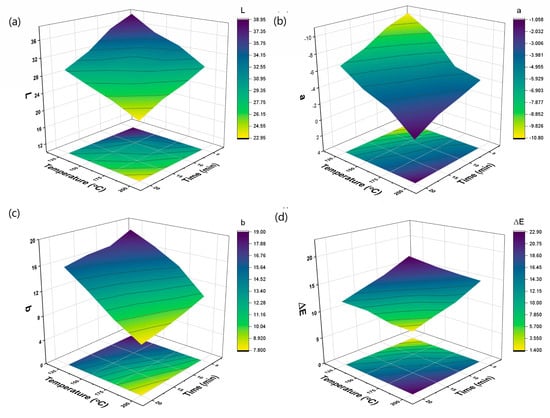

3.3. Color Changes

The color of dried powder is an important sensory quality attribute from the consumers’ perspective. Bright green color of dried leaves is preferred by consumers over dark or off-green colors. The color changes of G. sylvestre leaves during FIR drying are shown in Figure 3. The CIE color scale indicates three values: L (white to black), a (red to green), and b (yellow to blue). The color values of fresh G. sylvestre leaves soon after harvest were 39.9, −11.5 and 19.6, respectively, for L, a and b. The “L” value decreased with increasing temperature and exposure time, which shows that the lightness decreased during drying (Figure 3a). The bright greenness of the dried leaves that decreased with increasing drying conditions can be seen in Figure 3b. The highest and lowest “L” values were 38.94 and 22.98, respectively, while the highest and lowest negative “a” values were −10.76 and −1.058, respectively. Conversely, color value “b” decreased with temperature and time (Figure 3c).

Figure 3.

The color changes of leaves under different drying temperatures and time: (a) L, (b) a, (c) b and (d) total color changes (ΔE).

The total color change (ΔE) of a good drying method should have lower values. All the dried samples exhibited changes in ΔE value, which ranged from 1.4 to 23.1 (Figure 3d). The T1X1 treatment produced the lowest ΔE, whereas the highest ΔE was produced by the T4X4 treatment. Chlorophyll a and chlorophyll b are the pigments that provide the green color for the leaves. Under high thermal treatment, magnesium ion replaces the hydrogen ion in chlorophyll and converts chlorophylls to pheophytins, which decreases the green color [30,32]. A similar observation was reported for drying mint leaves using a microwave vacuum dryer [32]. However, the highest ΔE obtained in this study was lower compared to the highest ΔE of mint leaves dried under FIR as reported by Salarikia et al. [30].

3.4. Total Phenolic Content (TPC)

Polyphenols are chemically and biologically active secondary metabolites which provide several benefits to humans, including antioxidant activity, anticancer effect, anti-inflammatory effect and modulate gene expression [33]. The TPC content of the fresh G. sylvestre leaves was 24.15 ± 0.84 mg tannic acid equivalent per g of fresh leaf weight. The lowest and highest TPC values for dried G. sylvestre leaves were 24.2 and 30.5 mg tannic acid equivalent per g of fresh leaf weight, which was obtained from treatments T1X1 and T4X3, respectively (Table 1).

Under lower temperatures (125 °C—T1 and 150 °C—T2), TPC significantly (p < 0.05) increased with exposure time from 5 to 15 min, but a significant difference was not observed between 15 and 20 min. Several studies showed that TPC increased with temperature and exposure time under FIR drying [34,35,36]. For example, a study reported that TPC increased with the exposure time of FIR emission for a defatted sesame meal [35]. It is well documented that FIR can cleave bounds and release polyphenols from large polymers [36,37], which could be the reason for the observed TPC values. Nevertheless, the relationship for exposure time with TPC was different for high-temperature treatments (175 °C—T3 and 200 °C—T4). At high temperatures, TPC significantly (p < 0.05) increased with exposure time by up to 15 min and then significantly (p < 0.05) declined at 20 min. Although the TPC increased with increasing temperature, it can be denatured for prolonged exposure at high temperatures [38]. A similar observation was reported on onion drying in which the TPC content increased for temperatures from 80 to 120 °C and then declined at 150 °C [39]. However, the effect of temperature and exposure time on TPC varies depending on the drying method, drying conditions and type of plant [36,38].

3.5. Antioxidant Activity

The antioxidant and antiradical activities of the ethanol-water extracts of dried G. sylvestre leaves were measured by DPPH and FRAP assays. The DPPH radicals are stable at ambient conditions and accept an electron from antioxidants to become a stable diamagnetic molecule that can be measured at 517 nm. The IC50 value of fresh G. sylvestre leaves was 9.2 ± 0.7 mg L−1 of leaf extract volume. The IC50 values of dried leaves were between 13.3 and 92 mg L−1 of leaf extract volume. Temperature, drying time and interaction of these two factors have significant (p < 0.05) effects on the IC50 value. The relationship of DPPH with exposure time under low (125 and 150 °C) and high temperatures (175 and 200 °C) were different. For low temperatures, the IC50 value significantly (p < 0.05) increased with exposure time. However, under high temperatures, the IC50 value significantly (p < 0.05) increased for the first three exposure times and significantly (p < 0.05) decreased at 20 min. The highest and lowest DPPH (IC50) values were for T4X3 and TIX1 treatments, respectively (Table 1). However, IC50 values were not statistically significant for treatments T1X1, T1X2 and T2X1. The IC50 values of this study were higher than the values reported for shade-dried G. sylvestre leaves which showed an IC50 value of 76.59 µg mL−1 [12].

The FRAP value of the fresh G. sylvestre leaves was 63.1 ± 2.3 μmol g−1 of fresh leaf weight while the dried leaves ranged between 63.0 and 80.7 μmol g−1 of fresh leaf weight. Treatment T1X1 and T4T3 exhibited the lowest and highest FRAP values, respectively (Table 1). The FRAP values also showed a similar change to DPPH values with temperature and exposure time. Under low temperatures, FRAP values significantly (p < 0.05) increased with time, but under high temperatures, FRAP values significantly (p < 0.05) increased from 5 to 15 min and then significantly (p < 0.05) decreased at 20 min.

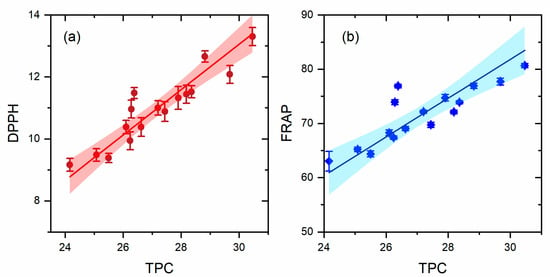

Both DPPH (IC50) and FRAP values of dried G. sylvestre leaves followed a similar trend of TPC and both of these antioxidant assays showed a strong correlation with TPC (Figure 4). The corresponding Pearson’s correlation coefficient values were 0.93 and 0.86. This shows that TPC plays a major role in the antioxidant activity of dried G. sylvestre leaf powder. Another possibility is the formation of Maillard reaction products which have antioxidant activity that can also increase the antioxidant activity of dried G. sylvestre leaves with exposure to FIR [38,40]. This finding is in agreement with the previous studies reported on FIR drying of onion [39] and peanut hulls [36].

Figure 4.

The correlation analysis of TPC with DPPH (IC50) (a) and FRAP (b) values. The error bars show the standard deviation (n = 5). The color shades indicate 95% confidence intervals.

3.6. Optimization of Drying Conditions

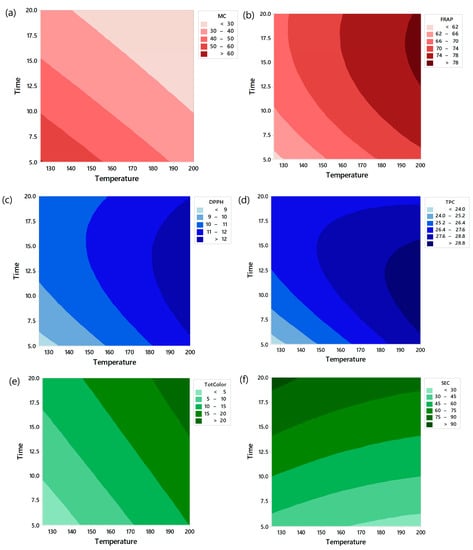

The response surface regression equations were developed for SEC, ΔE, TPC, DPPH, FRAP and moisture content are shown in Table 2. The interaction term and linear terms of temperature and time were more dominant in these regression equations than quadratic and interaction terms. According to the ANOVA, all of the models showed p values <0.001, which indicates that model terms are significant (Table 3). In most of the equations, linear terms of temperature and time were significant (p < 0.05) (Table 3). The temperature-temperature interaction term was significant (p < 0.05) only in the regression equation of SEC.

Table 2.

Regression model for each response variable.

Table 3.

A probability value of response variables extracted from the analysis of variance.

The response surface plots for all the response variables and drying parameters are shown in Figure 5. The optimum level of TPC, FRAP and DPPH were reached at high temperatures (Figure 5b–d). The optimum total color was reached at low temperature (Figure 5e), whereas optimum moisture content and SEC were obtained at high temperature (Figure 5a,f). The optimum drying conditions of G. sylvestre leaves using FIR was determined to obtain minimum SEC and ΔE, maximum values for TPC, DPPH and FRAP, and the target value of final moisture content. Each response variable was given equal weight and importance for calculating the optimum drying conditions. The optimum drying conditions obtained by the desirability function method were 200 °C and 8.4 min of exposure time. These optimum conditions provide 38.6 MJ kg−1 H2O of SEC, 17.0 of ΔE, 29.2 mg TAE/g leaf fresh weight of TPC, 12.3 mg mL−1 of DPPH (IC50), 75.8 μmol g−1 leaf fresh weight of FRAP and 31% of moisture content (w.b) and the composite desirability value for these drying conditions was 0.62.

Figure 5.

Response surface plots for moisture content (a), FRAP (b), DPPH (c), TPC (d), total color (e) and SEC (f) against the process variables.

4. Conclusions

The drying characteristics and antioxidant properties of G. sylvestre dried under far-infrared (FIR) has not been investigated previously. Therefore, this study investigated the potential of far-infrared (FIR) for drying G. sylvestre leaves and its effects on antioxidant properties. The results revealed that drying G. sylvestre leaves under FIR is an effective method in terms of energy consumption and antioxidant property. Both temperature and time influenced the drying and antioxidant properties. Increasing the temperature decreased the specific energy consumption for drying. Drying G. sylvestre leaves under FIR significantly (p < 0.05) enhanced the TPC and antioxidant activity compared to fresh leaves. The changes in TPC and antioxidant activity was temperature-dependent. Lower temperatures (125 and 150 °C) favor the release of TPC and increased antioxidant activity, whereas prolonged exposure (20 min) of leaves under high temperatures (175 and 200 °C) decreased TPC and antioxidant activity. The optimal drying condition achieved from the dissimilarity function was 200 °C for 8.4 min. Therefore, FIR can be used as an effective source of drying to produce the dried powder of G. sylvestre leaves at commercial scales as a rich source of antioxidants. Future studies on applying intermittent FIR drying and hybrid drying could be explored to reduce specific energy consumption.

Author Contributions

G.A.: Conceptualization, methodology, data curation, formal analysis and investigation, resources, software and writing—original draft preparation. A.B.: Data curation, formal analysis and investigation and writing—review and editing. R.E.: Methodology, formal analysis and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

No special funding was received for this study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no known competing interest that could have appeared to influence the work reported in this manuscript.

References

- Saneja, A.; Sharma, C.; Aneja, K.; Pahwa, R. Gymnema sylvestre (Gurmar): A review. Der Pharm. Lett. 2010, 2, 275–284. [Google Scholar]

- Tiwari, P.; Mishra, B.; Sangwan, N.S. Phytochemical and pharmacological properties of Gymnema sylvestre: An important medicinal plant. Biomed Res. Int. 2014, 2014, 830285. [Google Scholar] [CrossRef]

- Chung, I.-M.; Rajakumar, G.; Subramanian, U.; Venkidasamy, B.; Thiruvengadam, M. Impact of copper oxide nanoparticles on enhancement of bioactive compounds using cell suspension cultures of Gymnema sylvestre (Retz.) R. Br. Appl. Sci. 2019, 9, 2165. [Google Scholar] [CrossRef]

- Ghosh, A.R.; Alsayari, A.; Habib, A.H.; Wahab, S.; Nadig, A.P.; Rafeeq, M.M.; Binothman, N.; Aljadani, M.; Al-Dhuayan, I.S.; Alaqeel, N.K. Anti-Tumor Potential of Gymnema sylvestre Saponin Rich Fraction on In Vitro Breast Cancer Cell Lines and In Vivo Tumor-Bearing Mouse Models. Antioxidants 2023, 12, 134. [Google Scholar] [CrossRef]

- Parke, A.; Parke, D. The pathogenesis of inflammatory disease: Surgical shock and multiple system organ failure. Inflammopharmacology 1995, 3, 149–168. [Google Scholar] [CrossRef]

- Pham-Huy, L.A.; He, H.; Pham-Huy, C. Free radicals, antioxidants in disease and health. Int. J. Biomed. Sci. 2008, 4, 89. [Google Scholar] [PubMed]

- Batiha, G.E.-S.; Beshbishy, A.M.; Ikram, M.; Mulla, Z.S.; El-Hack, M.E.A.; Taha, A.E.; Algammal, A.M.; Elewa, Y.H.A. The Pharmacological Activity, Biochemical Properties, and Pharmacokinetics of the Major Natural Polyphenolic Flavonoid: Quercetin. Foods 2020, 9, 374. [Google Scholar] [CrossRef]

- Meghana, K.; Sanjeev, G.; Ramesh, B. Curcumin prevents streptozotocin-induced islet damage by scavenging free radicals: A prophylactic and protective role. Eur. J. Pharmacol. 2007, 577, 183–191. [Google Scholar] [CrossRef]

- Sakar, E.H.; Khtira, A.; Aalam, Z.; Zeroual, A.; Gagour, J.; Gharby, S. Variations in physicochemical characteristics of olive oil (cv ‘Moroccan Picholine’) according to extraction technology as revealed by multivariate analysis. Agric. Eng. 2022, 4, 922–938. [Google Scholar] [CrossRef]

- Čakar, U.; Čolović, M.; Milenković, D.; Medić, B.; Krstić, D.; Petrović, A.; Đorđević, B. Protective Effects of Fruit Wines against Hydrogen Peroxide—Induced Oxidative Stress in Rat Synaptosomes. Agronomy 2021, 11, 1414. [Google Scholar] [CrossRef]

- Rachh, P.; Patel, S.; Hirpara, H.; Rupareliya, M.; Rachh, M.; Bhargava, A.; Patel, N.; Modi, D. In vitro evaluation of antioxidant activity of Gymnema sylvestre r. br. leaf extract. Rom. J. Biol. Plant Biol. 2009, 54, 141–148. [Google Scholar]

- Singh, K.; Deo, B. Phytochemical evaluation and in vitro antioxidant activity of Gymnema sylvestre R. Br. Br. J. Med. Plants Stud. 2014, 2, 19–23. [Google Scholar]

- Rahman, M.M.; Habib, M.R.; Hasan, M.A.; Al Amin, M.; Saha, A.; Mannan, A. Comparative assessment on in vitro antioxidant activities of ethanol extracts of Averrhoa bilimbi, Gymnema sylvestre and Capsicum frutescens. Pharmacogn. Res. 2014, 6, 36. [Google Scholar]

- Spasov, A.; Samokhina, M.; Bulanov, A. Antidiabetic properties of Gymnema sylvestre (a review). Pharm. Chem. J. 2008, 42, 626–629. [Google Scholar] [CrossRef]

- Song, Y.; Tao, Y.; Zhu, X.; Han, Y.; Show, P.L.; Song, C.; Zaid, H.F.M. Ultrasound-enhanced hot air drying of germinated highland barley seeds: Drying characteristics, microstructure, and bioactive profile. Agric. Eng. 2019, 1, 496–510. [Google Scholar] [CrossRef]

- Pääkkönen, K.; Havento, J.; Galambosi, B. Infrared drying of herbs (Research Note). Agric. Food Sci. 1999, 8, 19–27. [Google Scholar] [CrossRef]

- Kumara, H.; Abhiram, G.; Raveendran, K.; Prematilake, K. Pre-Drying of Fermented Black Tea Leaves Using Far-Infrared. In Proceedings of the 4th International Conference of Agricultural Sciences, Belihuloya, Shri Lanka, 26-27 January 2022. [Google Scholar]

- Qiu, L.; Zhang, M.; Mujumdar, A.S.; Liu, Y. Recent developments in key processing techniques for oriental spices/herbs and condiments: A review. Food Rev. Int. 2022, 38, 1791–1811. [Google Scholar] [CrossRef]

- Abhiram, G.; Amaratunga, K.; Galahitiyawa, D.; Karunasinhe, K. Colour development and changes of the gelatinization percentage of rice flour gelatinizes by far-infrared radiation. In Proceedings of the Peradeniya University Research Sessions, Peradeniya, Sri Lanka, 11–12 November 2012; p. 88. [Google Scholar]

- Abhiram, G. The Correlation of Colour and Viscosity Changes of Rice Flour with Gelatinization Percentage under Infrared Heating. Int. J. Res. Rev. 2018, 5, 36–40. [Google Scholar]

- Sakai, N.; Hanzawa, T. Applications and advances in far-infrared heating in Japan. Trends Food Sci. Technol. 1994, 5, 357–362. [Google Scholar] [CrossRef]

- Fernando, A.J.; Gunathunga, C.; Brumm, T.; Amaratunga, S. Drying turmeric (Curcuma longa L.) using far-Infrared radiation: Drying characteristics and process optimization. J. Food Process Eng. 2021, 44, e13780. [Google Scholar] [CrossRef]

- Abhiram, G.; Manathunga, M.; Raveendran, K.; Withanage, N. Performance Analysis of High-Efficiency Motor and Variable Speed Drive in Black Tea Processing Machinery. J. Biosyst. Eng. 2020, 45, 310–317. [Google Scholar] [CrossRef]

- Sledz, M.; Wiktor, A.; Nowacka, M.; Witrowa-Rajchert, D. Drying kinetics, microstructure and antioxidant properties of basil treated by ultrasound. J. Food Process Eng. 2017, 40, e12271. [Google Scholar] [CrossRef]

- Khramov, V.; Spasov, A.; Samokhina, M. Chemical composition of dry extracts of Gymnema sylvestre leaves. Pharm. Chem. J. 2008, 42, 29–31. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Blois, M.S. Antioxidant determinations by the use of a stable free radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Benzie, I.F.; Strain, J. [2] Ferric reducing/antioxidant power assay: Direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. In Methods in Enzymology; Elsevier: Amsterdam, The Netherlands, 1999; Volume 299, pp. 15–27. [Google Scholar]

- Benzie, I.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Salarikia, A.; Miraei Ashtiani, S.H.; Golzarian, M.R. Comparison of drying characteristics and quality of peppermint leaves using different drying methods. J. Food Process. Preserv. 2017, 41, e12930. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, K.; Chen, C. Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries. Foods 2022, 11, 3347. [Google Scholar] [CrossRef]

- Therdthai, N.; Zhou, W. Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J. Food Eng. 2009, 91, 482–489. [Google Scholar] [CrossRef]

- Hervert-Hernández, D.; Goñi, I. Dietary polyphenols and human gut microbiota: A review. Food Rev. Int. 2011, 27, 154–169. [Google Scholar] [CrossRef]

- Lee, S.-C.; Kim, J.-H.; Jeong, S.-M.; Kim, D.-R.; Ha, J.-U.; Nam, K.; Ahn, D. Effect of far-infrared radiation on the antioxidant activity of rice hulls. J. Agric. Food Chem. 2003, 51, 4400–4403. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-C.; Jeong, S.-M.; Kim, S.-Y.; Nam, K.; Ahn, D. Effect of far-infrared irradiation on the antioxidant activity of defatted sesame meal extracts. J. Agric. Food Chem. 2005, 53, 1495–1498. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-C.; Jeong, S.-M.; Kim, S.-Y.; Park, H.-R.; Nam, K.; Ahn, D. Effect of far-infrared radiation and heat treatment on the antioxidant activity of water extracts from peanut hulls. Food Chem. 2006, 94, 489–493. [Google Scholar] [CrossRef]

- Niwa, Y.; Miyachi, Y. Antioxidant action of natural health products and Chinese herbs. Inflammation 1986, 10, 79–91. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Ko, E.Y.; Assefa, A.D.; Ha, S.; Nile, S.H.; Lee, E.T.; Park, S.W. Temperature-dependent studies on the total phenolics, flavonoids, antioxidant activities, and sugar content in six onion varieties. J. Food Drug Anal. 2015, 23, 243–252. [Google Scholar] [CrossRef]

- Manzocco, L.; Calligaris, S.; Mastrocola, D.; Nicoli, M.C.; Lerici, C.R. Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci. Technol. 2000, 11, 340–346. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).