Characterizing and Predicting the Quality of Milled Rice Grains Using Machine Learning Models

Abstract

1. Introduction

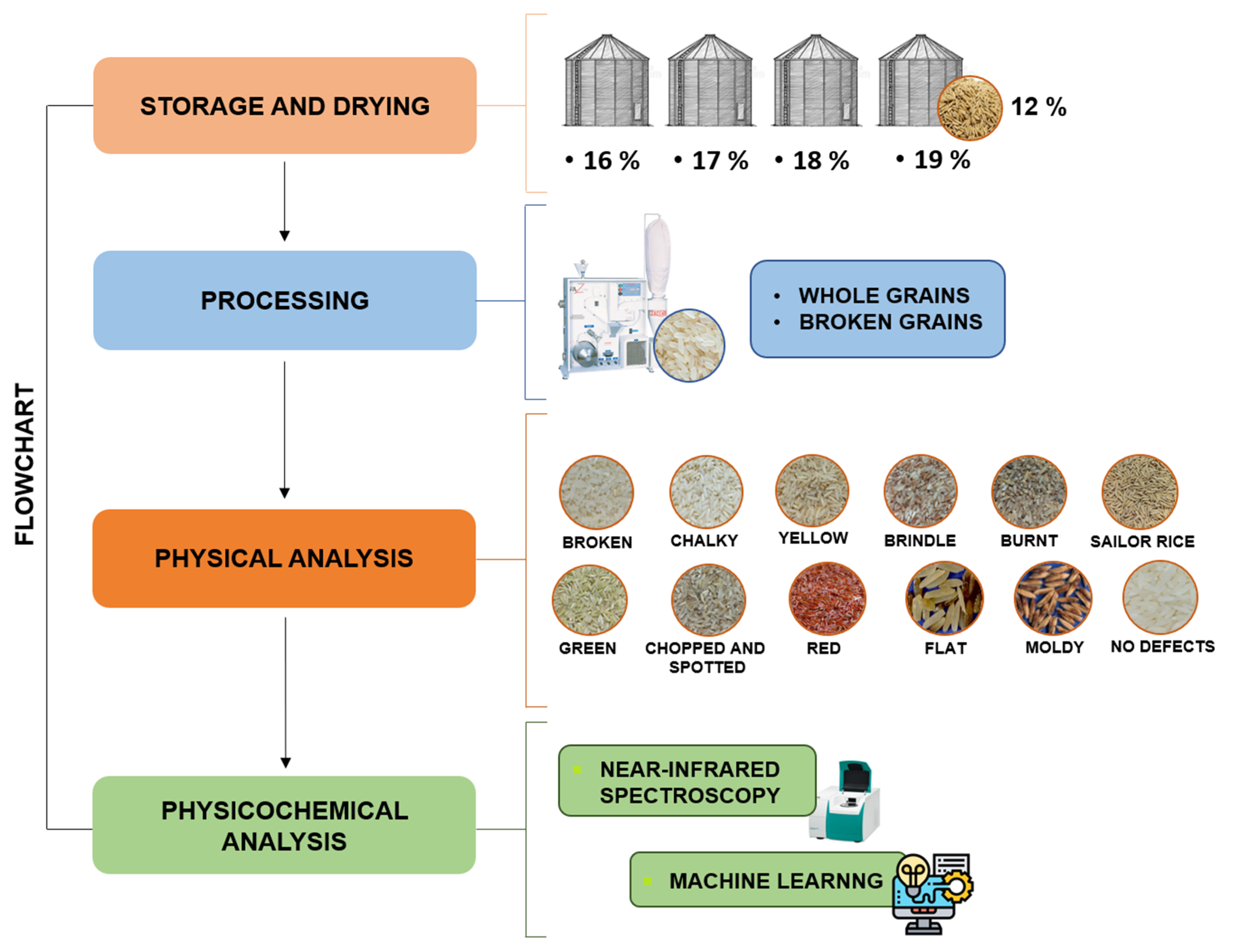

2. Materials and Methods

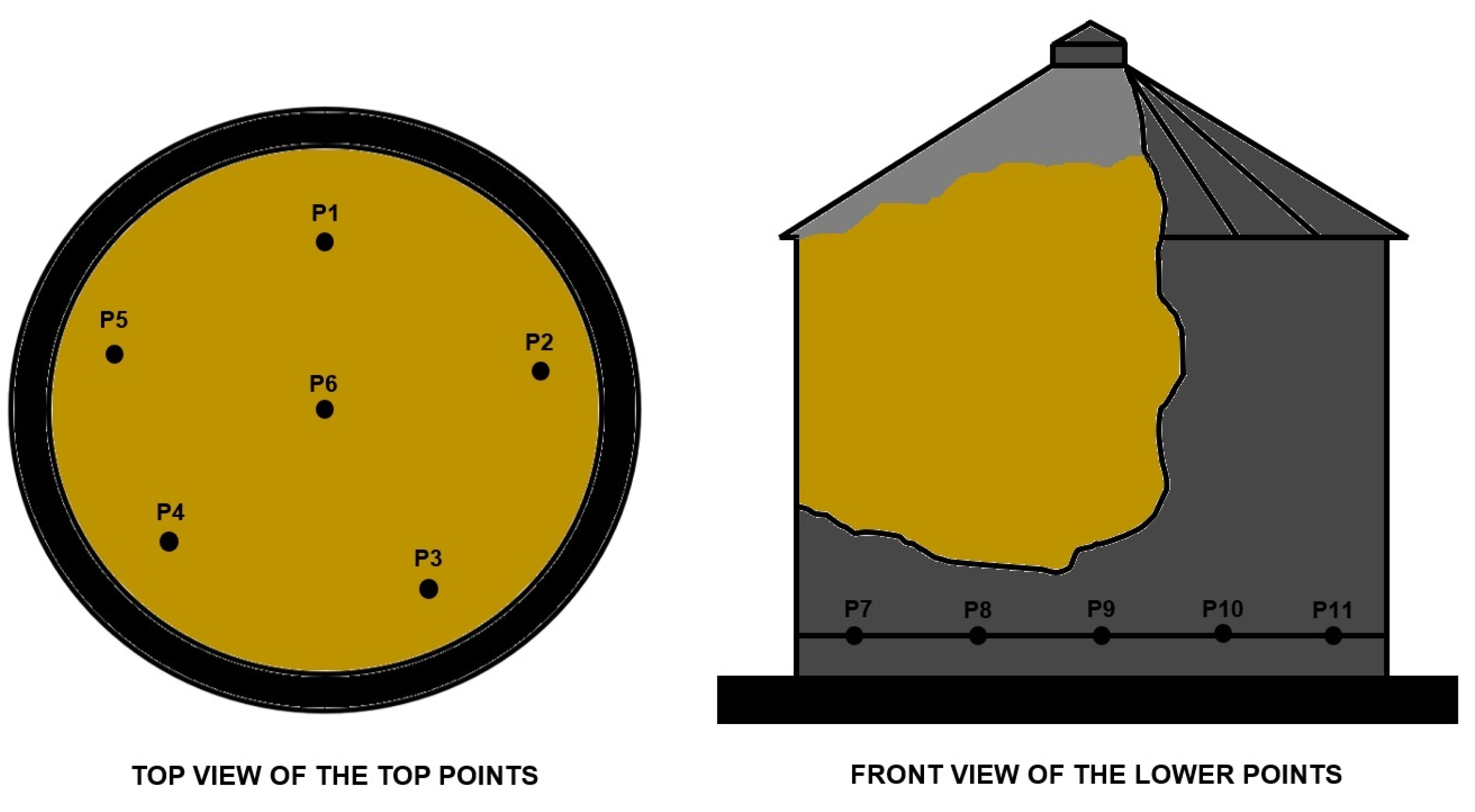

2.1. Description and Experimental Design

2.2. Rice Processing and Physical Classification

2.3. Near-Infrared Spectroscopy (NIRS)

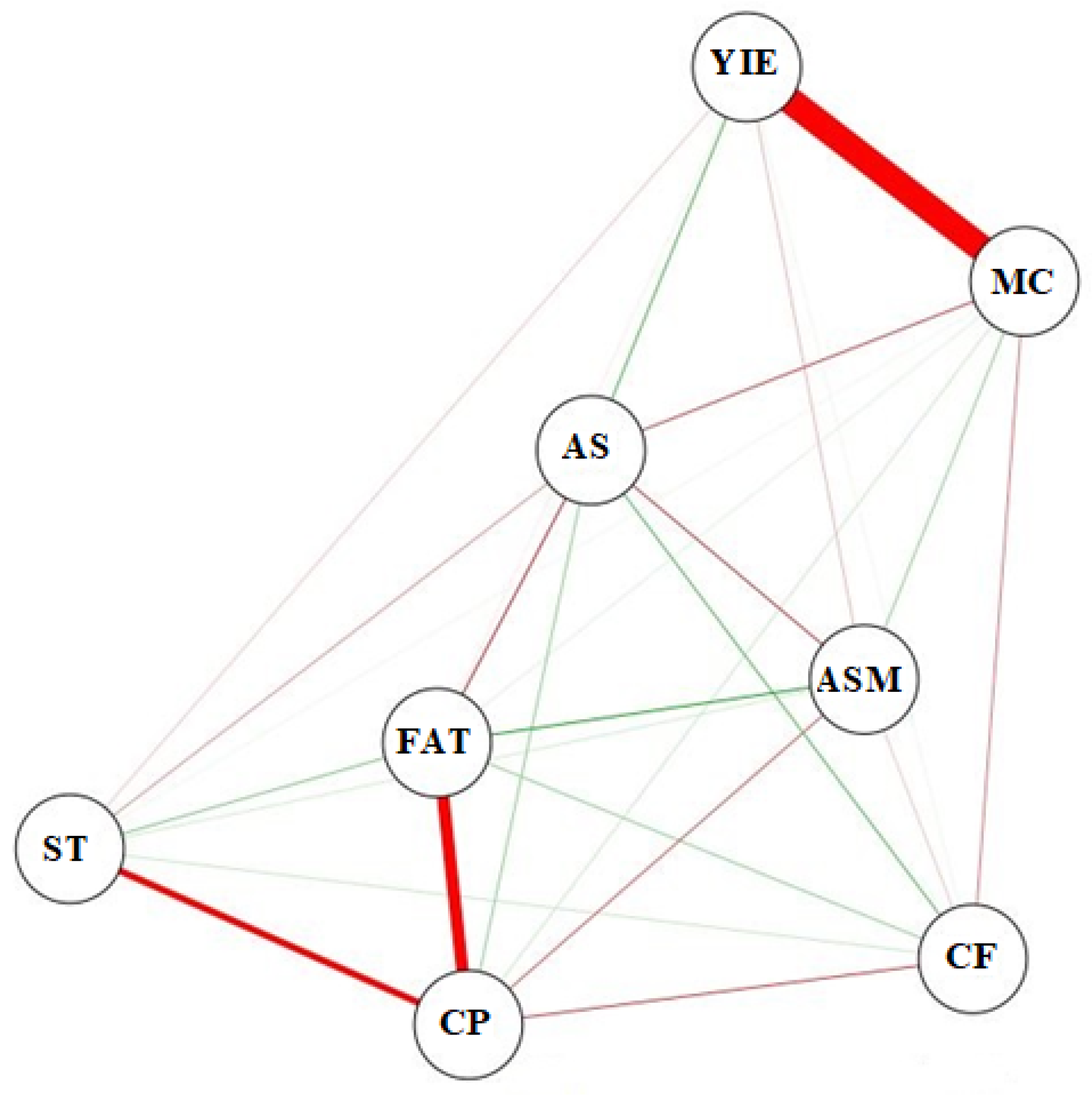

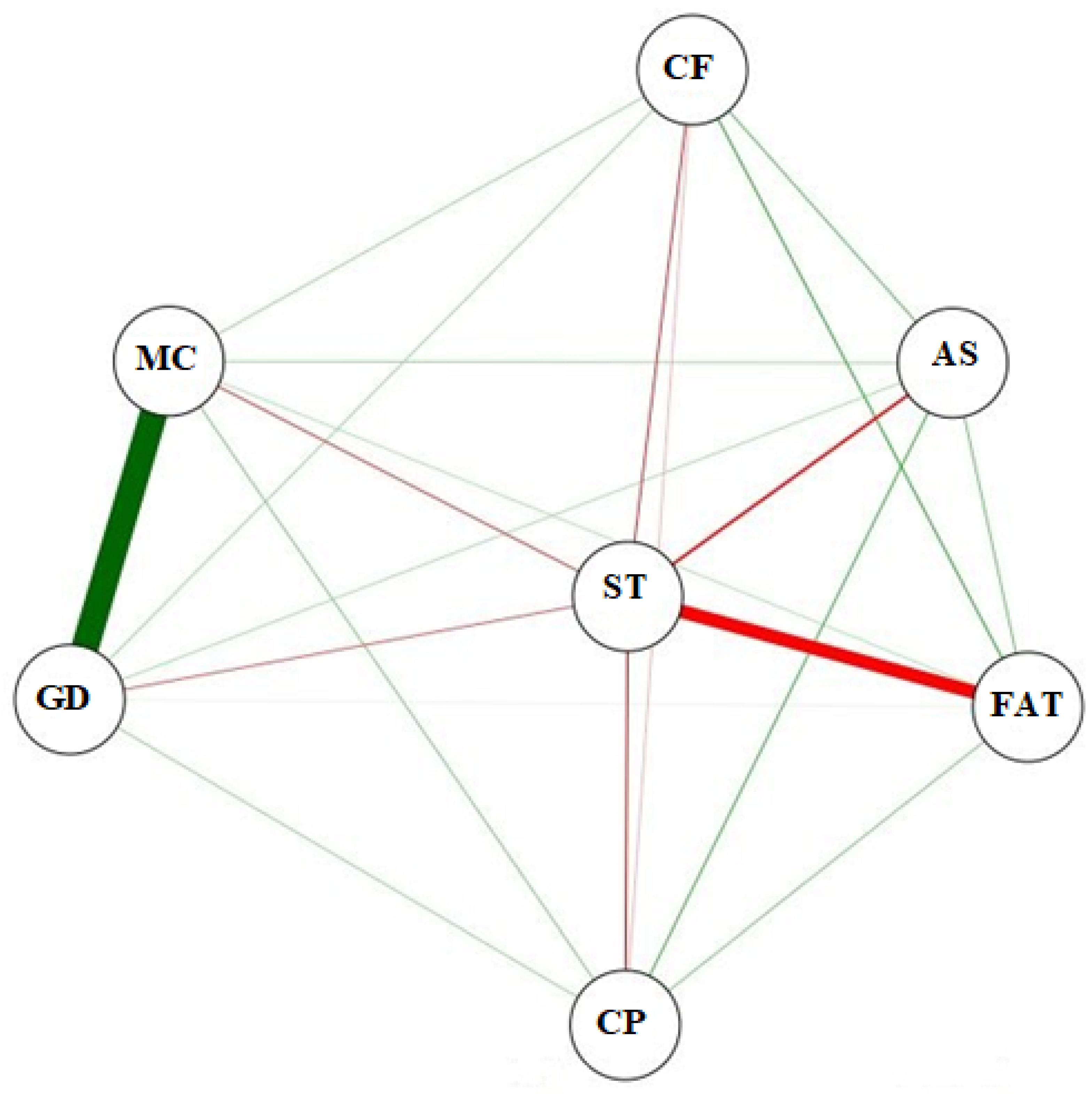

2.4. Pearson Correlation Network

2.5. Machine Learning Algorithms

3. Results and Discussion

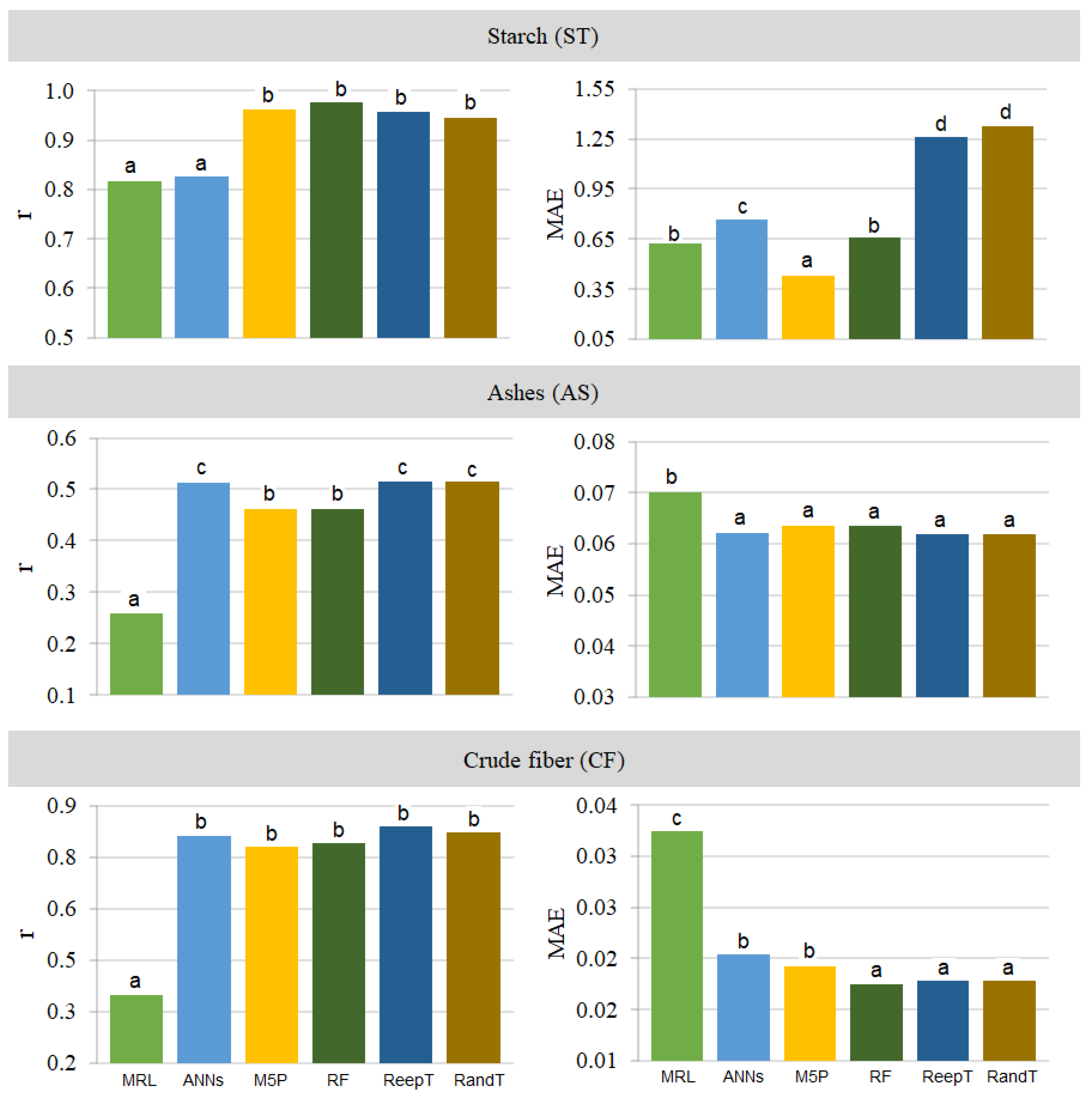

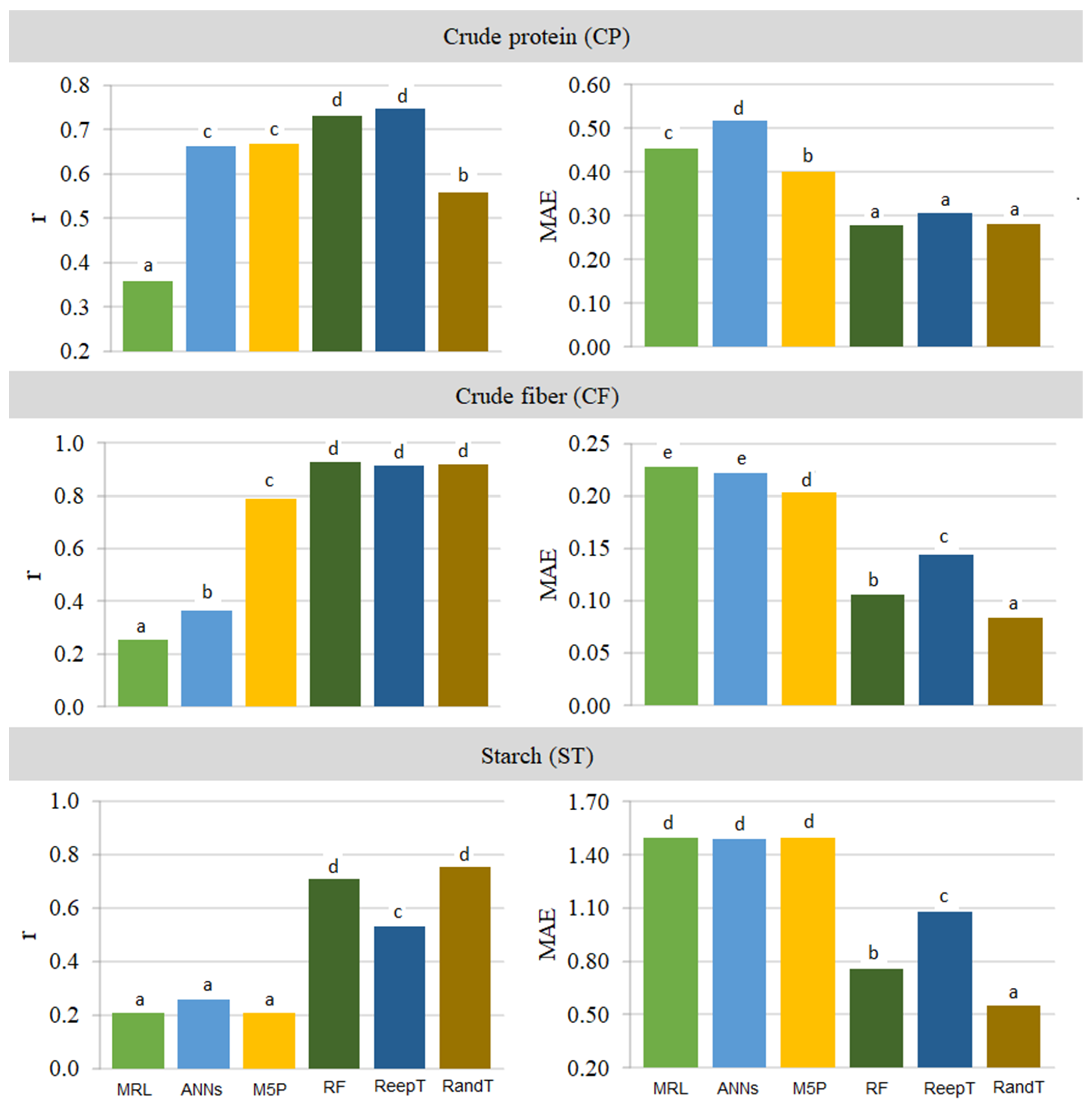

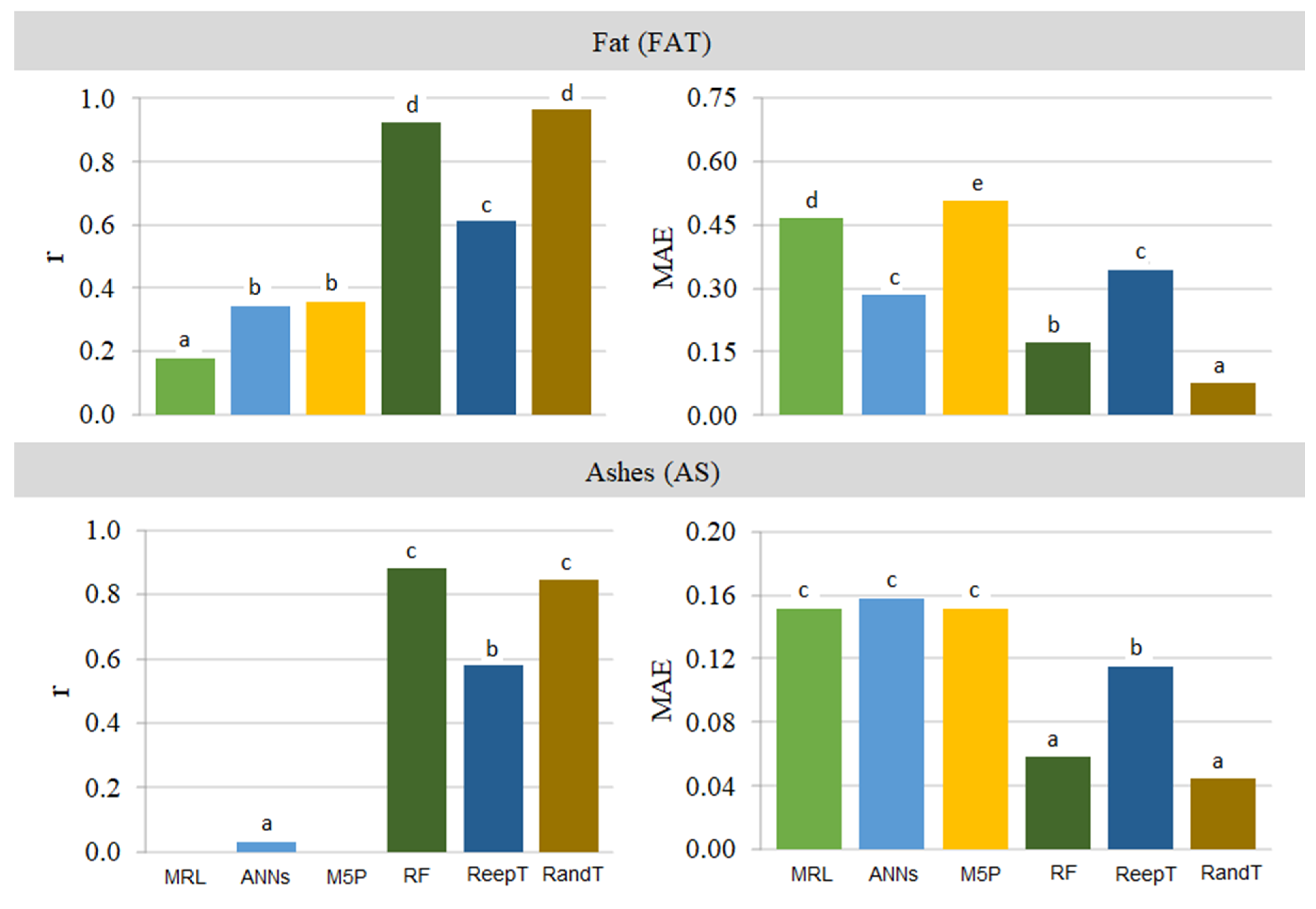

3.1. Whole Rice Grains

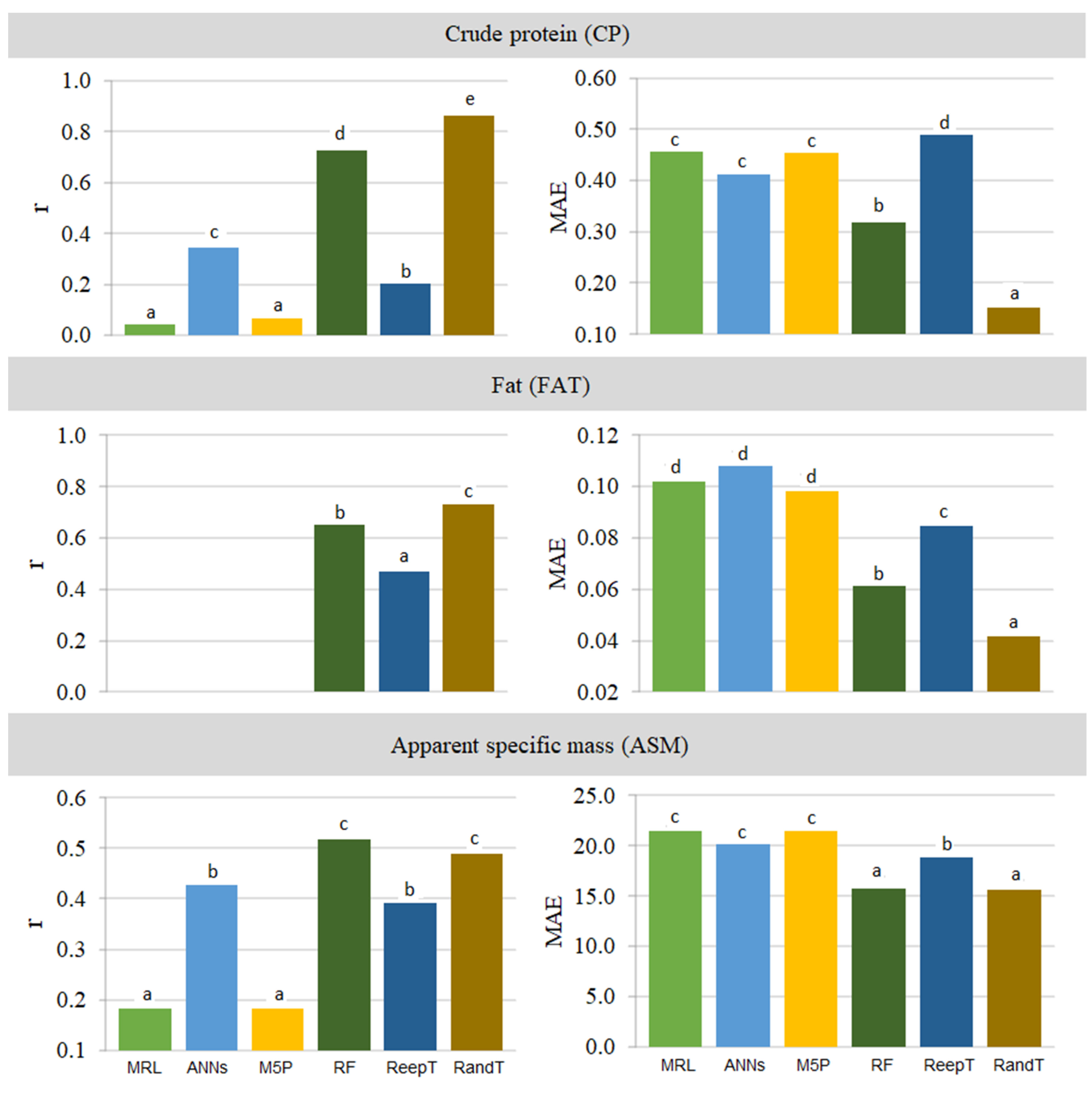

3.2. Defective Rice Grains

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Müller, A.; Coradi, P.C.; Nunes, M.T.; Grohs, M.; Bressiani, J.; Teodoro, P.E.; Anschau, K.F.; Flores, E.M.M. Effects of cultivars and fertilization levels on the quality of rice milling: A diagnosis using near-infrared spectroscopy, x-ray diffraction, and scanning electron microscopy. Food Res. Intern. 2021, 147, 110524. [Google Scholar] [CrossRef] [PubMed]

- Kuo, T.Y.; Chung, C.L.; Chen, S.Y.; Lin, H.A.; Kuo, Y.F. Identifying rice grains using image analysis and sparse-representation-based classification. Comput. Electron. Agric. 2016, 127, 716–725. [Google Scholar] [CrossRef]

- Zareiforoush, H.; Minaei, S.; Alizadeh, M.R.; Banakar, A. Qualitative classification of milled rice grains using computer vision and metaheuristic techniques. J. Food Sci. Technol. 2015, 53, 118–131. [Google Scholar] [CrossRef] [PubMed]

- Mittal, S.; Dutta, M.K.; Issac, A. Non-destructive image processing based system for assessment of rice quality and defects for classification according to inferred commercial value. Measurement 2019, 148, 106969. [Google Scholar] [CrossRef]

- Burestan, N.F.; Sayyah, A.H.A.; Taghinezhad, E. Prediction of some quality properties of rice and its flour by near-infrared spectroscopy (NIRS) analysis. Food Sci. Nutr. 2020, 9, 1099–1105. [Google Scholar] [CrossRef]

- Moreti, M.P.; Oliveira, T.; Sartori, R.; Caetano, W. Artificial intelligence in agribusiness and the challenges for the protection of intellectual property. Prospect. Noteb. 2021, 14. Available online: https://periodicos.ufba.br/index.php/nit/article/view/33098/23546 (accessed on 15 January 2023).

- André, G.S.; Coradi, P.C.; Teodoro, L.P.R.; Teodoro, P.E. Predicting the quality of soybean seeds stored in different environments and packaging using machine learning. Sci. Rep. 2022, 12, 8793. [Google Scholar] [CrossRef]

- Lutz, É.; Coradi, P.C. Applications of new technologies for monitoring and predicting grains quality stored: Sensors, internet of things, and artificial intelligence. Measurement 2022, 188, 110609. [Google Scholar] [CrossRef]

- Ramos, A.P.M.; Osco, L.P.; Furuya, D.E.G.; Gonçalves, W.N.; Cordeiro, D.C.; Pereira, L.R.T.; Junior, C.A.S.; Silva, G.F.C.; Li, J.; Baio, F.H.R.; et al. A Random Forest ranking approach to predict yield in maize with UAV-based vegetation spectral indices. Comput. Electron. Agric. 2020, 178, 105791. [Google Scholar] [CrossRef]

- Pazoki, A.; Pazoki, Z. Classification system for rain fed wheat grain cultivars using artificial neural network. Afr. J. Biotechnol. 2011, 10, 8031–8038. [Google Scholar] [CrossRef]

- Osco, L.P.; Paula, A.; Ramos, M.; Pereira, D.R.; Akemi, E.; Moriya, S.; Matsubara, E.T. Predicting canopy nitrogen content in citrus-trees using Random Forest algorithm associated to spectral vegetation indices from UAV-imagery. Remote Sens. 2019, 11, 2925–2942. [Google Scholar] [CrossRef]

- Hussain, L.; Ajaz, R. Seed Classification using Machine Learning Techniques. J. Multidiscip. Eng. Sci. Technol. 2015, 2, 1098–1102. [Google Scholar]

- Kumar, S.; Deswal, S. Estimation of phosphorus reduction from wastewater by artificial neural network, Random Forest and M5P model tree approaches. India. Pollution 2020, 6, 427–438. [Google Scholar] [CrossRef]

- Radhika, V.; Rao, V. Computational approaches for the classification of seed storage proteins. J. Food Sci. Technol. 2014, 52, 4246–4255. [Google Scholar] [CrossRef]

- Kiratiratanapruk, K.; Temniranrat, P.; Sinthupinyo, W.; Prempree, P.; Chaitavon, K.; Porntheeraphat, S.; Prasertsak, A. Development of Paddy Rice Seed Classification Process using Machine Learning Techniques for Automatic Grading Machine. J. Sens. 2020, 2020, 7041310. [Google Scholar] [CrossRef]

- MAPA. Normative Instruction 2/2012. Available online: https://sistemasweb.agricultura.gov.br/sislegis/action/detalhaAto.do?method=visualizarAtoPortalMapa&chave=918108049 (accessed on 15 January 2023).

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Gordon and Breach Publishers: New York, NY, USA, 1986; 841p. [Google Scholar]

- Naldi, M.C.; Campello, R.J.; Hruschka, E.R.; Carvalho, A.C.P.L.F. Efficiency issues of evolutionary k-means. Appl. Soft Comput. 2011, 11, 1938–1952. [Google Scholar] [CrossRef]

- Bouckaert, R.; Frank, E.; Hall, M.; Kirkby, R.; Reutemrna, P.; Seewald, A. WEKA Manual for Version 3-7-1; University of Waikato: Hamilton, New Zealand, 2016. [Google Scholar]

- Egmont-Petersen, M.; Ridder, D.; Handels, H. Image processing with neural networks a review. Pattern Recognit. 2002, 35, 2279–2301. [Google Scholar] [CrossRef]

- Snousy, M.B.A.; El-Deeb, H.M.; Badran, K.; Khlil, I.A.A. Suite of decision tree-based classification algorithms on cancer gene expression data. Egypt. Inform. J. 2011, 12, 73–82. [Google Scholar] [CrossRef]

- Blaifi, S.; Moulahoum, S.; Benkercha, R.; Taghezouit, B.; Saim, A. M5P model tree based fast fuzzy maximum power point tracker. Sol. Energy 2018, 163, 405–424. [Google Scholar] [CrossRef]

- Belgiu, M.; Dr’aguń, L. Random Forest in remote sensing: A review of applications and future directions. J. Photogram. Remote Sens. 2016, 114, 24–31. [Google Scholar] [CrossRef]

- Nunes, M.T.; Coradi, P.C.; Muller, A.; Carneiro, L.O.; Steinhaus, J.I.; Anschau, K.F.; Souza, G.C.; Müller, E.I.; Teodoro, P.E.; Dutra, A.P. Stationary rice drying: Influence of initial moisture contents and impurities in the mass grains on the physicochemical and morphological rice quality. J. Food Proc. Preserv. 2022, 46, e16558. [Google Scholar] [CrossRef]

- Coradi, P.C.; Nunes, M.T.; Dutra, A.P.; de Souza, G.A.C.; Carneiro, L.d.O.; Steinhaus, J.I. Evaluation of the operating system of a drying silo storage unit and the quality of rice grains. Res. Soc. Dev. 2020, 9, e235997073. [Google Scholar] [CrossRef]

- Denardin, C.C.; Silva, L.P. Estrutura dos grânulos de amido e sua relação com propriedades físico-químicas. Ciência Rural 2009, 39, 945–954. [Google Scholar] [CrossRef]

- Cecchi, H.M. Fundamentos Teóricos e Práticos em Análise de Alimentos, 2nd ed.; Unicamp: Campinas, Brazil, 2003; 207p. [Google Scholar]

- Zeymer, J.S.; Guzzo, F.; Araujo, M.E.V.; Gates, R.S.; Corrêa, P.C.; Vidigal, M.C.T.R.; Neisse, A.C. Machine learning algorithms to predict the dry matter loss of stored soybean grains (Glycine max L.). J. Food Proc. Eng. 2021, 44, e13820. [Google Scholar] [CrossRef]

- Walter, M.; Marchezan, E.; Avila, L.A.D. Rice: Composition and nutritional characteristics. Ciência Rural 2008, 38, 1184–1192. [Google Scholar] [CrossRef]

- Scariot, M.A.; Karlinski, L.; Dionello, R.G.; Radünz, A.L.; Radünz, L.L. Effect of drying air temperature and storage on industrial and chemical quality of rice grains. J. Stored Prod. Res. 2020, 89, 101717. [Google Scholar] [CrossRef]

- Coradi, P.C.; de Oliveira, M.B.; Carneiro, L.O.; de Souza, G.A.C.; Elias, M.C.; Brackmann, A.; Teodoro, P.E. Technological and sustainable strategies for reducing losses and maintaining the quality of soybean grains in real production scale storage units. J. Stored Prod. Res. 2020, 87, 101624. [Google Scholar] [CrossRef]

- Huang, S.J.; Zhao, C.F.; Zhu, Z.; Zhou, L.H.; Zheng, Q.H.; Wang, C.L. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Int. Agric. 2020, 19, 988–998. [Google Scholar] [CrossRef]

- Lima, R.E.; Coradi, P.C.; Nunes, M.T.; Bellochio, S.D.C.; Timm, N.d.S.; Nunes, C.F.; Carneiro, L.d.O.; Teodoro, P.E.; Campabadal, C. Mathematical modeling and multivariate analysis applied earliest soybean harvest associated drying and storage conditions and influences on physicochemical grain quality. Sci. Rep. 2021, 11, 23287. [Google Scholar] [CrossRef]

- Jeong, J.H.; Resop, J.P.; Mueller, N.D.; Fleisher, D.H.; Yun, K.; Butler, E.E.; Timlin, D.J.; Shim, K.M.; Gerber, J.S.; Reddy, V.R. Random Forests for Global and Regional Crop Yield Predictions. PLoS ONE 2016, 11, e0156571. [Google Scholar] [CrossRef]

- Astaoui, G.; Dadaiss, J.E.; Sebari, I.; Benmansour, S.; Mohamed, E. Mapping wheat dry matter and nitrogen content dynamics and estimation of wheat yield using UAV multispectral imagery machine learning and a variety-based approach: Case study of Morocco. AgriEngineering 2021, 3, 29–49. [Google Scholar] [CrossRef]

- Bomoi, M.I.; Nawi, N.M.; Abd Aziz, S.; Mohd Kassim, M.S. Sensing Technologies for Measuring Grain Loss during Harvest in Paddy Field: A Review. AgriEngineering 2022, 4, 292–310. [Google Scholar] [CrossRef]

- Zhang, L.; Hashimoto, N.; Saito, Y.; Obara, K.; Ishibashi, T.; Ito, R.; Homma, K. Validation of Relation between SPAD and Rice Grain Protein Content in Farmer Fields in the Coastal Area of Sendai, Japan. AgriEngineering 2023, 5, 369–379. [Google Scholar] [CrossRef]

- Goyal, S. Artificial Neural Networks in Fruits: A Comprehensive Review. Intern. J. Image Graph. Sign. Proc. 2014, 6, 53–63. [Google Scholar] [CrossRef]

- Martello, M.; Molin, J.P.; Wei, M.C.F.; Canal Filho, R.; Nicoletti, J.V.M. Coffee-Yield Estimation Using High-Resolution Time-Series Satellite Images and Machine Learning. AgriEngineering 2022, 4, 888–902. [Google Scholar] [CrossRef]

- Paidipati, K.K.; Chesneau, C.; Nayana, B.M.; Kumar, K.R.; Polisetty, K.; Kurangi, C. Prediction of rice cultivation in India—Support vector regression approach with various kernels for non-linear patterns. AgriEngineering 2021, 3, 182–198. [Google Scholar] [CrossRef]

| Silos | Total Stored (Sc of 50 kg) | Moisture Content (% d.b.) |

|---|---|---|

| Silo 1 | 42,218.60 | 19 |

| Silo 2 | 36,871.40 | 18 |

| Silo 3 | 28,660.20 | 17 |

| Silo 4 | 46,212.20 | 16 |

| Moisture Content (% d.b.) | Whole Grain Yield (%) | Crude Protein (%) | Fat (%) | Crude Fiber (%) | Ashes (%) | Starch (%) | Specific Apparent Mass (kg m−3) |

|---|---|---|---|---|---|---|---|

| 19 | 49.884 | 8.13 | 1.85 | 2.08 | 0.92 | 70.85 | 585.51 |

| 19 | 50.529 | 9.06 | 1.82 | 2.07 | 0.89 | 71.82 | 538.25 |

| 19 | 51.015 | 8.23 | 1.86 | 2.06 | 0.80 | 70.75 | 562.79 |

| 19 | 52.536 | 8.90 | 1.68 | 2.04 | 0.97 | 71.42 | 517.52 |

| 19 | 52.944 | 7.58 | 2.02 | 2.09 | 0.78 | 70.32 | 585.98 |

| 19 | 53.836 | 9.07 | 1.64 | 2.01 | 0.92 | 73.21 | 493.52 |

| 19 | 53.836 | 7.67 | 1.94 | 2.06 | 0.85 | 72.91 | 588.97 |

| 19 | 54.395 | 8.01 | 1.77 | 2.01 | 0.88 | 71.59 | 555.68 |

| 19 | 54.531 | 8.27 | 1.86 | 2.07 | 0.88 | 72.53 | 541.94 |

| 19 | 54.976 | 8.74 | 1.65 | 2.02 | 0.95 | 71.94 | 524.56 |

| 19 | 54.976 | 7.78 | 1.92 | 2.07 | 0.87 | 72.91 | 584.46 |

| 19 | 55.057 | 7.78 | 1.92 | 2.07 | 0.87 | 72.91 | 584.46 |

| Average | 53.836 d | 8.18 a | 1.855 a | 2.065 a | 0.88 b | 71.88 b | 559.235 a |

| Standard deviation | 1.760 | 0.523 | 0.116 | 0.026 | 0.053 | 0.932 | 30.826 |

| 18 | 58.237 | 8.44 | 1.62 | 2.09 | 1.09 | 71.34 | 548.90 |

| 18 | 58.668 | 10.24 | 1.51 | 2.07 | 1.12 | 70.62 | 469.23 |

| 18 | 58.903 | 7.19 | 1.91 | 2.13 | 1.02 | 72.47 | 571.40 |

| 18 | 59.030 | 8.61 | 1.61 | 2.06 | 1.07 | 72.30 | 493.12 |

| 18 | 59.298 | 8.02 | 1.86 | 2.11 | 1.01 | 71.19 | 524.85 |

| 18 | 59.537 | 10.19 | 1.71 | 2.05 | 0.95 | 68.98 | 499.48 |

| 18 | 59.564 | 7.78 | 1.87 | 2.10 | 1.02 | 71.47 | 561.26 |

| 18 | 60.075 | 10.14 | 1.75 | 2.00 | 0.97 | 71.56 | 523.58 |

| 18 | 60.115 | 7.410 | 1.94 | 2.11 | 1.01 | 72.65 | 560.69 |

| 18 | 60.702 | 10.81 | 1.74 | 2.06 | 1.09 | 67.39 | 521.58 |

| 18 | 61.143 | 7.490 | 1.89 | 2.14 | 1.03 | 72.38 | 516.77 |

| 18 | 61.223 | 7.490 | 1.89 | 2.14 | 1.03 | 72.38 | 516.77 |

| Average | 59.5505 b | 8.23 a | 1.805 a | 2.095 a | 1.025 a | 71.515 b | 522.58 b |

| Standard deviation | 0.923 | 1.270 | 0.134 | 0.040 | 0.048 | 1.519 | 29.205 |

| 17 | 55.089 | 7.45 | 1.77 | 2.15 | 0.94 | 72.46 | 550.98 |

| 17 | 55.752 | 8.1 | 1.74 | 2.11 | 1.02 | 72.90 | 498.30 |

| 17 | 55.848 | 7.74 | 1.96 | 2.13 | 0.97 | 72.60 | 519.91 |

| 17 | 56.002 | 8.25 | 1.88 | 2.14 | 1.07 | 70.06 | 500.51 |

| 17 | 56.398 | 7.73 | 1.86 | 2.10 | 1.06 | 72.76 | 509.76 |

| 17 | 56.431 | 8.83 | 1.72 | 2.15 | 1.04 | 70.89 | 523.38 |

| 17 | 56.586 | 8.02 | 1.78 | 2.11 | 1.08 | 72.18 | 535.72 |

| 17 | 56.586 | 8.30 | 1.76 | 2.15 | 1.00 | 72.68 | 514.19 |

| 17 | 57.058 | 8.11 | 1.78 | 2.12 | 1.01 | 71.93 | 521.70 |

| 17 | 57.122 | 7.71 | 1.77 | 2.12 | 0.94 | 73.12 | 470.51 |

| 17 | 57.352 | 8.24 | 1.76 | 2.14 | 1.10 | 71.32 | 520.98 |

| 17 | 57.657 | 8.24 | 1.76 | 2.14 | 1.10 | 71.32 | 520.98 |

| Average | 56.5085 c | 8.105 a | 1.77 b | 2.135 a | 1.03 a | 72.32 a | 520.445 b |

| Standard deviation | 0.708 | 0.349 | 0.066 | 0.017 | 0.055 | 0.896 | 19.207 |

| 16 | 61.534 | 7.47 | 1.85 | 2.05 | 0.99 | 72.26 | 550.14 |

| 16 | 61.759 | 9.00 | 1.67 | 2.10 | 1.11 | 70.51 | 544.36 |

| 16 | 62.547 | 8.33 | 1.67 | 2.10 | 1.00 | 70.38 | 491.48 |

| 16 | 62.547 | 9.13 | 1.78 | 2.07 | 1.02 | 72.01 | 527.28 |

| 16 | 62.797 | 7.56 | 1.80 | 2.08 | 0.98 | 71.35 | 507.31 |

| 16 | 62.818 | 7.72 | 1.85 | 2.10 | 1.07 | 72.68 | 552.41 |

| 16 | 63.235 | 8.10 | 1.95 | 2.07 | 0.87 | 71.99 | 552.61 |

| 16 | 63.941 | 8.78 | 1.63 | 2.07 | 1.06 | 71.22 | 551.15 |

| 16 | 64.083 | 8.08 | 1.85 | 2.04 | 0.82 | 72.05 | 551.16 |

| 16 | 64.724 | 9.32 | 1.66 | 2.05 | 1.10 | 69.93 | 548.89 |

| 16 | 65.784 | 7.40 | 1.94 | 2.09 | 0.97 | 72.09 | 534.21 |

| 16 | 66.456 | 7.40 | 1.94 | 2.09 | 0.97 | 72.09 | 534.21 |

| Average | 63.0265 a | 8.09 a | 1.825 a | 2.075 a | 0.995 a | 72.00 a | 546.625 a |

| Standard deviation | 1.464 | 0.682 | 0.113 | 0.020 | 0.083 | 0.829 | 18.960 |

| Variables | MC | YIE | CP | FAT | CF | AS | ST | ASM |

|---|---|---|---|---|---|---|---|---|

| MC | 1 | −0.76864 | 0.11273 | 0.06508 | −0.30666 | −0.43654 | 0.03568 | 0.24787 |

| YIE | −0.76864 | 1 | 0.00219 | −0.03730 | 0.03704 | 0.40562 | −0.12241 | −0.16039 |

| CP | 0.11273 | 0.00219 | 1 | −0.66926 | −0.45180 | 0.26111 | −0.63285 | −0.36902 |

| FAT | 0.06508 | −0.03730 | −0.66926 | 1 | 0.25374 | −0.49700 | 0.30056 | 0.54024 |

| CF | −0.30666 | 0.03704 | −0.45180 | 0.25374 | 1 | 0.38640 | 0.12262 | −0.12615 |

| AS | −0.43654 | 0.40562 | 0.26111 | −0.49700 | 0.38640 | 1 | −0.23959 | −0.45760 |

| ST | 0.03568 | −0.12241 | −0.63285 | 0.30056 | 0.12262 | −0.23959 | 1 | 0.10019 |

| ASM | 0.24787 | −0.16039 | −0.36902 | 0.54024 | −0.12615 | −0.45760 | 0.10019 | 1 |

| Models | r | MAE | R2 | r | MAE | R2 |

|---|---|---|---|---|---|---|

| Starch (ST) | Ashes (AS) | |||||

| MLR | 0.8169 | 0.6235 | 0.6674 | 0.2596 | 0.0700 | 0.0673 |

| ANNs | 0.8251 | 0.7657 | 0.6808 | 0.5125 | 0.0621 | 0.2626 |

| M5P | 0.9613 | 0.4299 | 0.9241 | 0.4609 | 0.0636 | 0.2124 |

| RF | 0.9758 | 0.6594 | 0.9522 | 0.4609 | 0.0636 | 0.2124 |

| REPTree | 0.9570 | 12.591 | 0.9160 | 0.5160 | 0.0620 | 0.2663 |

| RandTree | 0.9456 | 13.227 | 0.8942 | 0.5160 | 0.0620 | 0.2663 |

| Crude Fiber (FB) | Crude Protein (CP) | |||||

| MRL | 0.3488 | 0.0324 | 0.1217 | 0.0404 | 0.4557 | 0.0016 |

| RNAs | 0.8118 | 0.0204 | 0.6590 | 0.3461 | 0.4108 | 0.1198 |

| M5P | 0.7805 | 0.0192 | 0.6091 | 0.0651 | 0.4547 | 0.0042 |

| RF | 0.7913 | 0.0175 | 0.6261 | 0.7246 | 0.3185 | 0.5250 |

| REPTree | 0.8391 | 0.0178 | 0.7041 | 0.2029 | 0.4889 | 0.0411 |

| RandTree | 0.8228 | 0.0178 | 0.6770 | 0.8614 | 0.1520 | 0.7421 |

| Fat (Fat) | Apparent Specific Mass (ASM) | |||||

| MRL | 0.2065 | 0.1017 | 0.0426 | 0.1830 | 21.4990 | 0.0335 |

| RNAs | 0.2266 | 0.1081 | 0.0513 | 0.4278 | 20.1854 | 0.1830 |

| M5P | 0.0500 | 0.0981 | 0.0345 | 0.1830 | 21.4990 | 0.0335 |

| RF | 0.6490 | 0.0614 | 0.4212 | 0.5183 | 15.7880 | 0.2687 |

| REPTree | 0.4683 | 0.0846 | 0.2193 | 0.3920 | 18.7946 | 0.1540 |

| RandTree | 0.7325 | 0.0415 | 0.5366 | 0.4886 | 15.5575 | 0.2387 |

| Moisture Content (% d.b.) | Grain Defects (%) | Crude Protein (%) | Fat (%) | Crude Fiber (%) | Aches (%) | Starch (%) |

|---|---|---|---|---|---|---|

| 16 | 0.768 | 10.77 | 2.09 | 2.48 | 1.65 | 65.46 |

| 16 | 0.798 | 11.49 | 3.34 | 2.35 | 1.75 | 62.64 |

| 16 | 0.816 | 11.52 | 3.24 | 2.57 | 2.01 | 61.51 |

| 16 | 0.816 | 11.52 | 3.24 | 2.57 | 2.01 | 61.51 |

| 16 | 0.858 | 11.59 | 3.81 | 3.07 | 2.22 | 60.9 |

| 16 | 0.861 | 10.48 | 2.22 | 2.70 | 1.75 | 63.9 |

| 16 | 0.871 | 11.17 | 3.38 | 2.59 | 1.76 | 64.01 |

| 16 | 0.880 | 11.07 | 3.68 | 2.73 | 1.63 | 63.40 |

| 16 | 0.960 | 11.72 | 3.46 | 3.00 | 2.08 | 62.17 |

| 16 | 0.969 | 11.37 | 2.93 | 2.74 | 1.82 | 62.95 |

| 16 | 1.009 | 11.19 | 1.97 | 2.63 | 1.78 | 63.03 |

| 16 | 1.024 | 11.60 | 2.67 | 2.97 | 2.07 | 64.39 |

| Average | 0.866 d | 11.43 a | 3.24 a | 2.665 c | 1.80 b | 62.99 a |

| Standard deviation | 0.0815 | 0.3562 | 0.5998 | 0.2090 | 0.1832 | 1.2795 |

| 17 | 1.026 | 11.65 | 3.34 | 2.60 | 1.87 | 62.62 |

| 17 | 1.269 | 11.00 | 3.78 | 2.96 | 1.74 | 61.5 |

| 17 | 1.295 | 11.73 | 3.46 | 2.67 | 1.97 | 61.73 |

| 17 | 1.307 | 11.89 | 2.72 | 2.51 | 1.75 | 62.13 |

| 17 | 1.332 | 12.41 | 3.25 | 2.87 | 2.41 | 60.08 |

| 17 | 1.385 | 10.84 | 2.25 | 2.73 | 1.94 | 65.38 |

| 17 | 1.442 | 11.06 | 1.87 | 2.51 | 1.89 | 64.64 |

| 17 | 1.528 | 10.76 | 2.38 | 2.60 | 2.00 | 63.89 |

| 17 | 1.528 | 10.76 | 2.38 | 2.60 | 2.00 | 63.89 |

| 17 | 1.549 | 11.35 | 3.51 | 2.88 | 2.08 | 62.28 |

| 17 | 1.555 | 11.02 | 2.06 | 2.57 | 1.81 | 65.79 |

| 17 | 1.663 | 11.26 | 3.09 | 2.63 | 1.91 | 62.29 |

| Average | 1.4135 c | 11.16 a | 2.905 b | 2.615 c | 1.925 a | 62.455 a |

| Standard deviation | 0.1661 | 0.4925 | 0.6146 | 0.1439 | 0.1706 | 1.6338 |

| 18 | 1.713 | 11.18 | 3.46 | 2.53 | 1.69 | 62.71 |

| 18 | 1.713 | 11.18 | 3.46 | 2.53 | 1.69 | 62.71 |

| 18 | 1.953 | 10.81 | 2.27 | 2.59 | 1.81 | 64.01 |

| 18 | 1.966 | 12.07 | 3.73 | 3.05 | 2.24 | 59.86 |

| 18 | 1.966 | 12.07 | 3.73 | 3.05 | 2.24 | 59.86 |

| 18 | 2.094 | 12.20 | 3.32 | 2.87 | 2.01 | 60.03 |

| 18 | 2.195 | 10.98 | 3.30 | 2.68 | 1.87 | 63.43 |

| 18 | 2.380 | 11.79 | 3.02 | 2.86 | 1.99 | 61.85 |

| 18 | 2.408 | 11.37 | 2.97 | 2.91 | 1.94 | 62.39 |

| 18 | 2.420 | 11.66 | 3.76 | 2.88 | 2.04 | 59.41 |

| 18 | 2.433 | 10.70 | 2.94 | 2.60 | 1.86 | 64.36 |

| 18 | 2.444 | 12.15 | 3.16 | 2.87 | 2.03 | 60.99 |

| Average | 2.1445 b | 11.515 a | 3.31 a | 2.865 a | 1.965 a | 62.12 a |

| Standard deviation | 0.2664 | 0.5227 | 0.4094 | 0.1822 | 0.1726 | 1.6616 |

| 19 | 2.799 | 12.05 | 3.84 | 3.10 | 2.33 | 59.11 |

| 19 | 2.895 | 11.23 | 2.97 | 2.77 | 2.05 | 61.79 |

| 19 | 3.063 | 11.99 | 3.45 | 2.46 | 2.06 | 59.49 |

| 19 | 3.167 | 11.41 | 3.35 | 3.11 | 1.99 | 61.02 |

| 19 | 3.211 | 12.25 | 2.84 | 2.67 | 1.90 | 62.26 |

| 19 | 3.293 | 12.66 | 2.98 | 2.63 | 1.76 | 60.88 |

| 19 | 3.617 | 11.25 | 2.77 | 2.76 | 1.79 | 63.38 |

| 19 | 3.645 | 12.43 | 3.25 | 2.57 | 1.95 | 61.99 |

| 19 | 4.079 | 10.88 | 2.73 | 2.96 | 1.94 | 63.00 |

| 19 | 4.213 | 10.32 | 4.31 | 4.85 | 2.04 | 58.36 |

| 19 | 5.692 | 12.13 | 2.70 | 2.38 | 2.13 | 60.09 |

| 19 | 5.704 | 11.66 | 2.51 | 2.61 | 1.89 | 62.62 |

| Average | 3.455 a | 11.825 a | 2.975 b | 2.715 b | 1.97 a | 61.405 c |

| Standard deviation | 0.9520 | 0.6604 | 0.5042 | 0.6264 | 0.1475 | 1.5496 |

| Variables | MC | GD | CP | FAT | CF | AS | ST |

|---|---|---|---|---|---|---|---|

| MC | 1 | 0.87568 | 0.28664 | 0.16684 | 0.22435 | 0.21161 | −0.43199 |

| GD | 0.87568 | 1 | 0.23186 | 0.03914 | 0.21896 | 0.18746 | −0.36516 |

| CP | 0.28664 | 0.23186 | 1 | 0.29798 | −0.15680 | 0.45045 | −0.57519 |

| FAT | 0.16684 | 0.03914 | 0.29798 | 1 | 0.49972 | 0.35167 | −0.72743 |

| CF | 0.22435 | 0.21896 | −0.15680 | 0.49972 | 1 | 0.36886 | −0.47669 |

| AS | 0.21161 | 0.18746 | 0.45045 | 0.35167 | 0.36886 | 1 | −0.61148 |

| ST | −0.43199 | −0.36516 | −0.57519 | −0.72743 | −0.47669 | −0.61148 | 1 |

| Models | r | MAE | R2 | R | MAE | R2 |

|---|---|---|---|---|---|---|

| Ashes (AS) | Crude Fiber (CF) | |||||

| MLR | 0.0555 | 0.1511 | 0.0030 | 0.2546 | 0.2276 | 0.0648 |

| ANNs | 0.0309 | 0.1575 | 0.0009 | 0.3639 | 0.2218 | 0.1324 |

| M5P | 0.0555 | 0.1511 | 0.0030 | 0.7904 | 0.2033 | 0.6247 |

| RF | 0.8790 | 0.0586 | 0.7726 | 0.9267 | 0.1053 | 0.8588 |

| REPTree | 0.5787 | 0.1153 | 0.3348 | 0.9128 | 0.1437 | 0.8333 |

| RandTree | 0.8449 | 0.0443 | 0.7138 | 0.9184 | 0.0842 | 0.8434 |

| Fat (Fat) | Crude Protein (CP) | |||||

| MLR | 0.1785 | 0.4664 | 0.0318 | 0.3574 | 0.4531 | 0.1278 |

| ANNs | 0.3430 | 0.2847 | 0.1177 | 0.6615 | 0.5165 | 0.4376 |

| M5P | 0.3548 | 0.5056 | 0.1258 | 0.6678 | 0.4007 | 0.4459 |

| RF | 0.9221 | 0.1731 | 0.8504 | 0.7317 | 0.2793 | 0.5355 |

| REPTree | 0.6133 | 0.3434 | 0.3762 | 0.7462 | 0.3060 | 0.5568 |

| RandTree | 0.9640 | 0.0757 | 0.9292 | 0.5577 | 0.2814 | 0.3110 |

| Starch (ST) | ||||||

| MLR | 0.2063 | 1.4960 | 0.0425 | |||

| ANNs | 0.2589 | 1.4880 | 0.0670 | |||

| M5P | 0.2063 | 1.4960 | 0.0425 | |||

| RF | 0.7096 | 0.7586 | 0.5036 | |||

| REPTree | 0.5300 | 1.0770 | 0.2809 | |||

| RandTree | 0.7540 | 0.5515 | 0.5686 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira Carneiro, L.; Coradi, P.C.; Rodrigues, D.M.; Lima, R.E.; Teodoro, L.P.R.; Santos de Moraes, R.; Teodoro, P.E.; Nunes, M.T.; Leal, M.M.; Lopes, L.R.; et al. Characterizing and Predicting the Quality of Milled Rice Grains Using Machine Learning Models. AgriEngineering 2023, 5, 1196-1215. https://doi.org/10.3390/agriengineering5030076

de Oliveira Carneiro L, Coradi PC, Rodrigues DM, Lima RE, Teodoro LPR, Santos de Moraes R, Teodoro PE, Nunes MT, Leal MM, Lopes LR, et al. Characterizing and Predicting the Quality of Milled Rice Grains Using Machine Learning Models. AgriEngineering. 2023; 5(3):1196-1215. https://doi.org/10.3390/agriengineering5030076

Chicago/Turabian Stylede Oliveira Carneiro, Letícia, Paulo Carteri Coradi, Dágila Melo Rodrigues, Roney Eloy Lima, Larissa Pereira Ribeiro Teodoro, Rosana Santos de Moraes, Paulo Eduardo Teodoro, Marcela Trojahn Nunes, Marisa Menezes Leal, Lhais Rodrigues Lopes, and et al. 2023. "Characterizing and Predicting the Quality of Milled Rice Grains Using Machine Learning Models" AgriEngineering 5, no. 3: 1196-1215. https://doi.org/10.3390/agriengineering5030076

APA Stylede Oliveira Carneiro, L., Coradi, P. C., Rodrigues, D. M., Lima, R. E., Teodoro, L. P. R., Santos de Moraes, R., Teodoro, P. E., Nunes, M. T., Leal, M. M., Lopes, L. R., Vendrusculo, T. A., Robattini, J. C., Soares, A. H., & dos Santos Bilhalva, N. (2023). Characterizing and Predicting the Quality of Milled Rice Grains Using Machine Learning Models. AgriEngineering, 5(3), 1196-1215. https://doi.org/10.3390/agriengineering5030076