1. Introduction

Gaochang Ancient City is located on the northern edge of the Turpan Basin in Xinjiang, covering an area of approximately 2.2 million square meters. It was initially constructed during the Western Han Dynasty (around the first century BCE). As a key nodal city along the Silk Road, it long served as the political, economic, and cultural center of the Western Regions [

1]. In 2014, this archaeological site was inscribed on the World Cultural Heritage List as an important component of the “Silk Roads: the Routes Network of Chang’an-Tianshan Corridor” [

2].

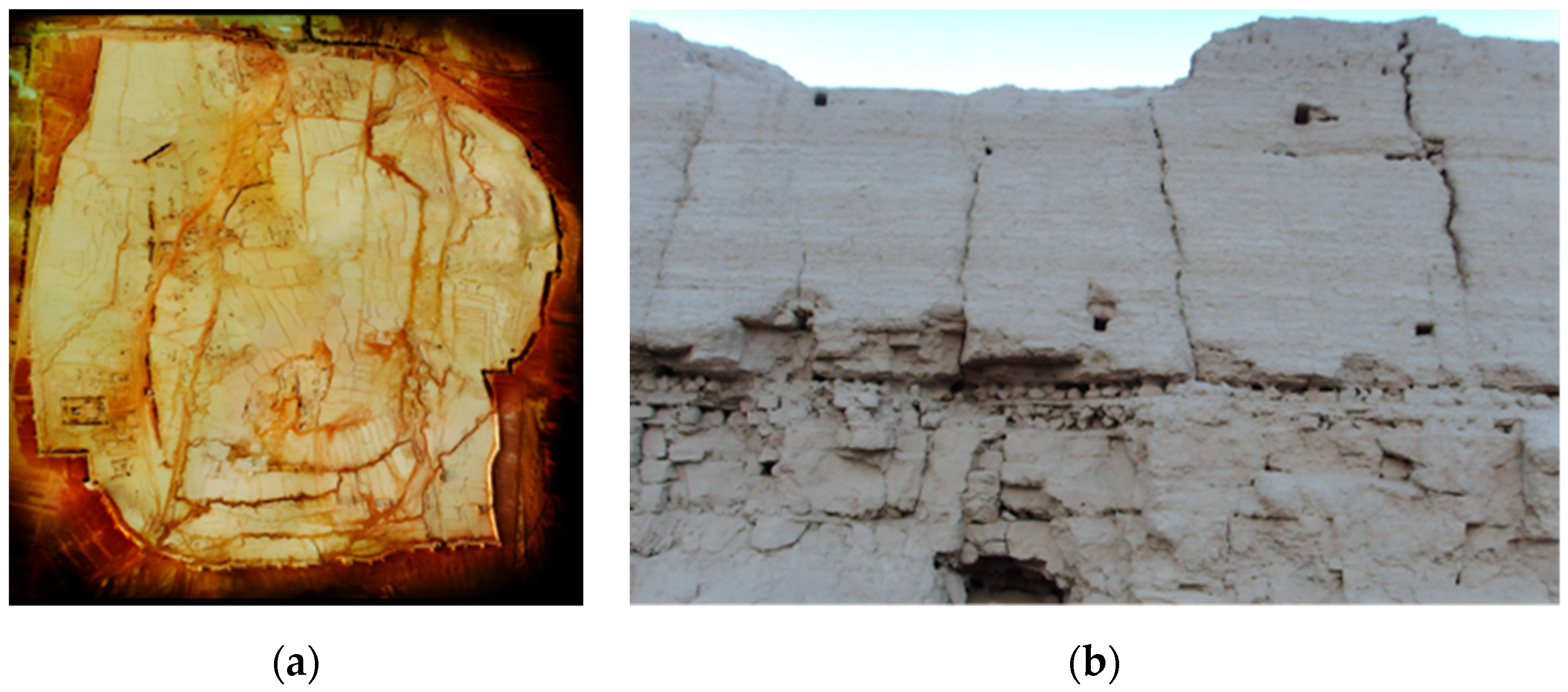

The Gaochang Ancient City ruins preserve a triple concentric city wall structure consisting of outer city, inner city, and palace city, as shown in

Figure 1a. Its construction primarily employed traditional building techniques such as rammed earth and adobe brick masonry, fully embodying the unique characteristics and value of earthen architectural ruins in arid regions [

3]. However, as a typical earthen cultural heritage in an arid region, Gaochang Ancient City faces severe climatic tests and preservation challenges [

4]. The extreme continental arid climate of the Turpan Basin results in significant diurnal temperature variations in this region, with daily temperature differences exceeding 30 °C during summer [

5]. Severe temperature fluctuations have been confirmed as one of the primary driving factors in the structural deterioration of earthen ruins in arid regions [

6]. The mechanism of thermal stress induced by temperature gradients can be summarized in two key stages. During the daytime, the surface soil layer directly receives solar radiation and rapidly heats up and expands, while the inner layer experiences delayed heat conduction due to the low thermal conductivity of soil (0.5~1.0 W/(m·K)), resulting in significant tensile stress at the interface [

7]. At night, the surface layer rapidly cools and contracts, while the inner layer still maintains relatively high temperatures, generating significant shear stress at the interface [

8]. As shown in

Figure 1b, this cyclic stress acting long-term on weak areas of the soil structure, such as rammed earth joints and unloading cracks, eventually leads to the formation of microcracks that gradually expand, ultimately resulting in macroscopic structural damage [

9].

Traditional grouting techniques [

10,

11] have achieved significant results in crack repair, structural reinforcement, and material compatibility protection of earthen ruins, providing reliable technical support for the preservation of earthen archaeological sites. However, in the face of extreme environmental conditions brought about by increasingly intensified climate change, the preservation strategy for earthen ruins urgently needs to shift from passive remedial intervention to proactive preventive conservation approaches [

12,

13]. In recent years, researchers have proposed innovative solutions utilizing microencapsulated phase change material (MPCM) to achieve temperature regulation, which has attracted widespread attention in academic circles [

14,

15]. Sevilla et al. [

16] incorporated MPCM into clay grouting and found that it could reduce peak temperatures by up to 10%. Rady et al. [

17] investigated the application of MPCM in grouting materials, with results indicating that the addition of MPCM does not significantly affect the rheological properties of the material. Research by Srinivasaraonaik et al. [

18] revealed that MPCM can significantly reduce the thermal conductivity of materials, thereby effectively delaying the material deterioration process caused by thermal shock. Katish et al. [

19] conducted 10,000 accelerated thermal cycling experiments on MPCM and discovered that the MPCM maintained stable phase change temperatures and latent heat energy, demonstrating acceptable stability. Based on the aforementioned background, this study developed a dual-functional MPCM grouting material that combines structural repair and temperature regulation capabilities by incorporating MPCM into traditional restoration grouting materials, aiming to establish a proactive preventive system that integrates structural reinforcement with environmental regulation for earthen cultural heritage.

The key innovation of this work lies in breaking through the limitations of traditional repair materials that only focus on mechanical compatibility, enhancing the adaptability of earthen sites to withstand severe temperature fluctuations. This aspect has been notably underrepresented in previous literature. This study systematically evaluated various properties of MPCM grouting materials, providing new technical solutions for earthen cultural heritage to address the impacts of extreme temperature fluctuations.

2. Materials and Methods

2.1. Environmental Characteristics

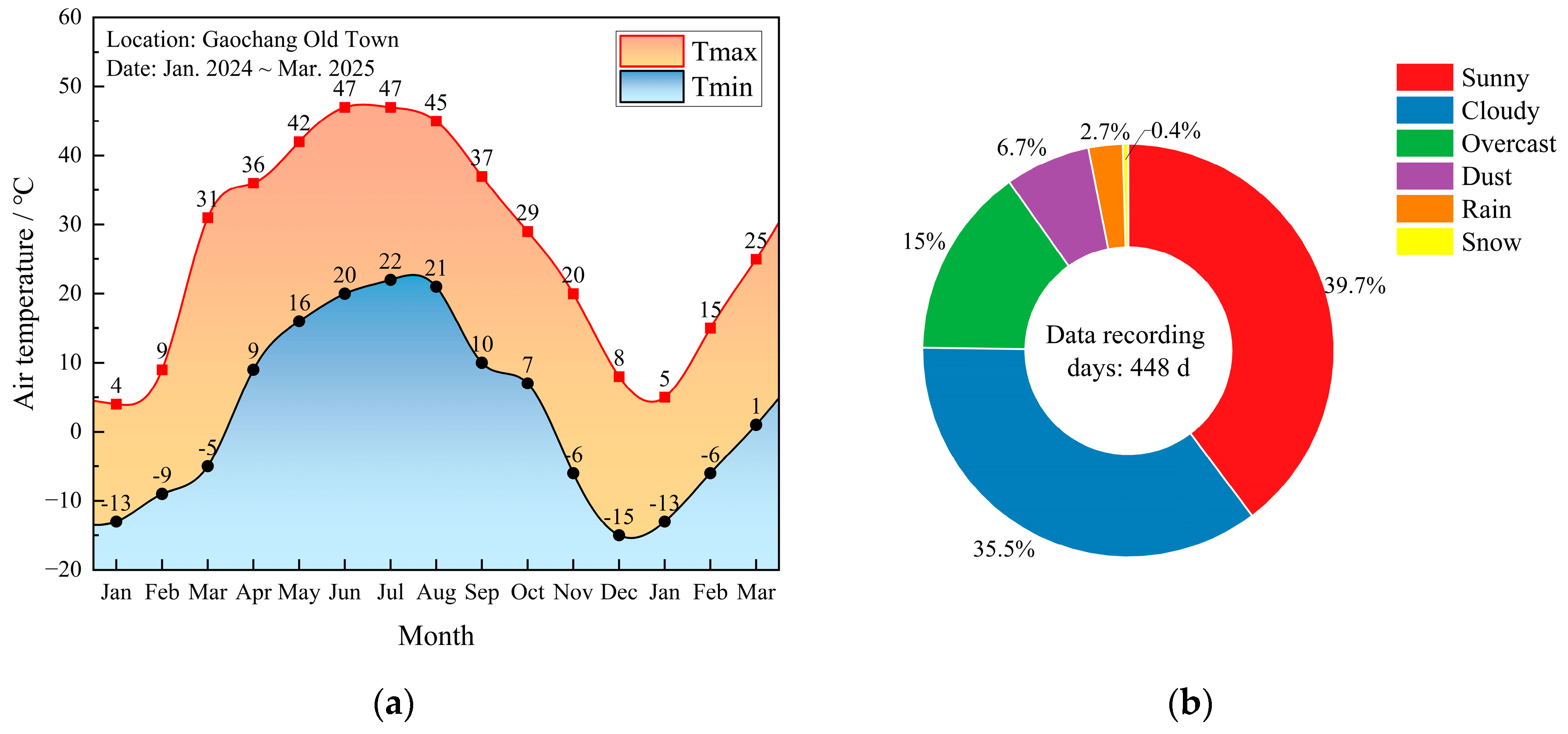

Preliminary research has revealed that Gaochang Ancient City is situated in a typical continental warm temperate desert climate, characterized by extreme aridity and significant temperature variations. The region experiences abundant sunshine (around 3000–3200 h/year), large diurnal and annual temperature swings (annual average 13.9 °C, extreme lows reaching −28.7 °C in winter and extreme highs up to 49.6 °C air temperature in summer; surface temperatures can exceed 80 °C), and severe dryness (annual precipitation 16.4 mm, evaporation greater than 3000 mm), the extreme temperature trend and weather conditions of Gaochang Ancient City are shown in

Figure 2. The main components of the soil are lime, SiO

2, and CaCO

3, with a small amount of salt efflorescence on the surface, primarily migrating through capillary action of moisture [

20]. In arid environments, wind erosion and salt crystallization cycles are typically coupled under the activation of temperature gradient effects, jointly accelerating the structural deterioration of earthen ruins, with the core mechanism being material fatigue induced by thermal stress. Therefore, there is an urgent need to develop effective temperature control strategies and technical systems to mitigate the adverse effects of thermal stress cycles on structural safety and the integrity of historical information.

2.2. Test Materials

The site soil used in this experiment was collected from undisturbed surface soil layers around the Gaochang Ancient City ruins. Various physical parameters of the site soil samples were analyzed according to the “Standard for Soil Test Methods” GB/T 50123-2019, and the measurement results are shown in

Table 1.

The main components of the cementitious materials added to the grouting in the experiment were calcium silicate and calcium oxide, purchased from Jiangxi Kete Fine Powder Co., Ltd., China (Yichun, Shanggao, China). Calcium silicate, as a material modifier, can significantly enhance the stability of soil. Calcium oxide reacts with water to form slaked lime, which subsequently reacts with carbon dioxide in the air to form calcium carbonate. Calcium silicate forms hydrated calcium silicate (C-S-H) gel in water, a chemical process that imparts good adhesion and durability to the material.

MPCM is manufactured by encapsulating phase change materials (PCMs) through microencapsulation technology [

21], which not only possesses excellent thermal stability but also ensures long-term usability. The MPCM used in this experiment was prepared using the emulsion polymerization method [

22] by the Chemistry Laboratory of Xi’an University of Architecture and Technology (Xi’an, China). The specific types of PCM used as core materials in this study include paraffin (C

18H

38, C

20H

42, C

22H

46), and the shell material is acrylic (PMMA). Other parameters of the MPCM are shown in

Table 2.

2.3. Test Method

The experiment followed the requirements specified in “Test Methods for Strength of Cement Grouting (ISO Method)” GB/T 17671-2021. After air-drying and sieving the soil, MPCM, cementitious materials, and soil were thoroughly mixed according to the proportions shown in

Table 3 using a mixer, then poured into molds with dimensions of 40 mm × 40 mm × 40 mm and 40 mm × 40 mm × 160 mm and compacted by vibration. After being set for 24 h, the specimens were demolded and labeled. The specimens were then cured under natural conditions for 7, 14, and 28 d. The flowability was tested according to the “Technical Specification for Application of Cement-based Grouting Materials” GB/T 50448-2015, with the arithmetic mean of the maximum diffusion diameter and the diameter in its perpendicular direction serving as the flowability index of the grouting material.

Synchronous thermal analysis–infrared-gas chromatography-mass spectrometry (TGA/DSC3+-Nicolet iS50-TRACE 1300 ISQ 7000) (Thermo Fisher Scientific, Waltham, MA, USA) was used to analyze the thermal stability, latent heat, and phase composition of MPCM; a field emission scanning electron microscope (GeminiSEM500) (Zeiss, Oberkochen, Germany) was employed to observe the microstructure of MPCM and MPCM grouting; an X-ray diffractometer (Bruker D8) (Billerica, MA, USA) was utilized to analyze the site soil and MPCM grouting; a heating stage (70 °C) was used for MPCM phase change cycling stability tests; a soil density and porosity tester (MAYB302J) (MAYZUM Scientific Instrument, Shenzhen, China) was used to measure the bulk density and porosity of MPCM grouting; a universal testing machine was employed to test the mechanical strength of MPCM grouting samples at a loading rate of 0.5 mm/min; and a laser thermal conductivity meter (LFA1000) (Selb, Germany) was used to measure the thermal conductivity and thermal resistance of MPCM grouting.

To investigate the temperature control performance of MPCM grouting, an insulated test box was constructed based on Illampas’s related research [

23]. The insulated test box measured 100 mm × 100 mm × 100 mm (length × width × height). The box was surrounded by 30 mm thick foam boards on all four sides; the bottom was directly embedded in the heating platform surface, which was covered with a heat-distributing paper. During the experiment, the test sample was placed inside the insulated test box, and the heating platform temperature was set at a constant 70 °C. Heating was stopped when the temperature increase rate at the top surface became less than 2 °C/h, allowing the sample to cool naturally. Throughout the process, an infrared thermometer was used to measure and record data every 10 min. The temperature setting of the heating platform referenced the maximum surface temperature of the Gaochang Ancient City earthen ruins recorded in July 2023.

3. Results

3.1. Thermal Analysis of MPCM

Figure 3a presents the thermogravimetric analysis (TG) curves of three paraffin-based phase change materials (PCMs) in the temperature range of 25–400 °C. The experiment was conducted using equal amounts (10 mg) of samples, under a nitrogen (N

2) protective atmosphere, at a constant heating rate (10 °C/min).

The TG curves indicate that all PCM samples exhibit a single-stage thermal degradation process, but with differences in thermal decomposition onset temperatures and weight loss rates. When reaching 40% mass loss, the corresponding temperatures for n-octadecane (C

18H

38), n-eicosane (C

20H

42), and n-docosane (C

22H

46) are 165 °C, 216 °C, and 228 °C, respectively, and the complete thermal decomposition temperatures of all PCM samples are significantly lower than their theoretical boiling points. This thermal stability issue can be effectively resolved through microencapsulation technology, which involves preparing PCMs into MPCMs using polymethyl methacrylate (PMMA) through physical encapsulation or surface adsorption, thereby significantly inhibiting the thermal volatilization behavior of PCMs [

24].

Figure 3b displays the differential scanning calorimetry (DSC) test results of three MPCMs. The thermal analysis data show that PCM-28 has a melting temperature of 27.0 °C with a corresponding melting enthalpy of 184.8 J/g; PCM-35 has a melting temperature of 33.8 °C with a corresponding melting enthalpy of 166.0 J/g; and PCM-45 has a melting temperature of 43.0 °C with a corresponding melting enthalpy of 134.3 J/g. These thermophysical parameters directly characterize the phase change properties and potential thermal energy storage capacity of each MPCM sample, providing a theoretical foundation for subsequent applications.

To evaluate the long-term thermal stability of the prepared MPCM samples, this study conducted thermal cycling durability tests.

Table 4 records in detail the mass data of three MPCM types after different temperature ranges and different numbers of cycles. The test results indicate that both temperature range and number of thermal cycles have significant effects on MPCM stability. In the high-temperature range of 15~150 °C, PCM-28 exhibited the highest mass loss rate. After 20, 40, 60, and 80 thermal cycles, its mass loss rates reached 1.89%, 5.49%, 12.67%, and 27.39%, respectively, while under the same conditions, PCM-45 demonstrated significantly higher thermal stability, with its mass loss rate remaining below 1.53% throughout the process. In the temperature range of 15–70 °C, which is closer to actual application environments, all MPCM samples exhibited excellent thermal cycling stability. PCM-28 samples experienced mass loss rates of only 0.58%, 0.60%, 0.63%, and 0.65% after 50, 100, 150, and 200 thermal cycles, while PCM-45 demonstrated even better thermal stability, with its mass loss rate never exceeding 0.11% throughout all 200 cycles. Previous research has shown that MPCM structural damage primarily occurs under extreme conditions, such as prolonged high-temperature exposure, rapid temperature fluctuations, or excessive mechanical stress [

25].

3.2. SEM of MPCM

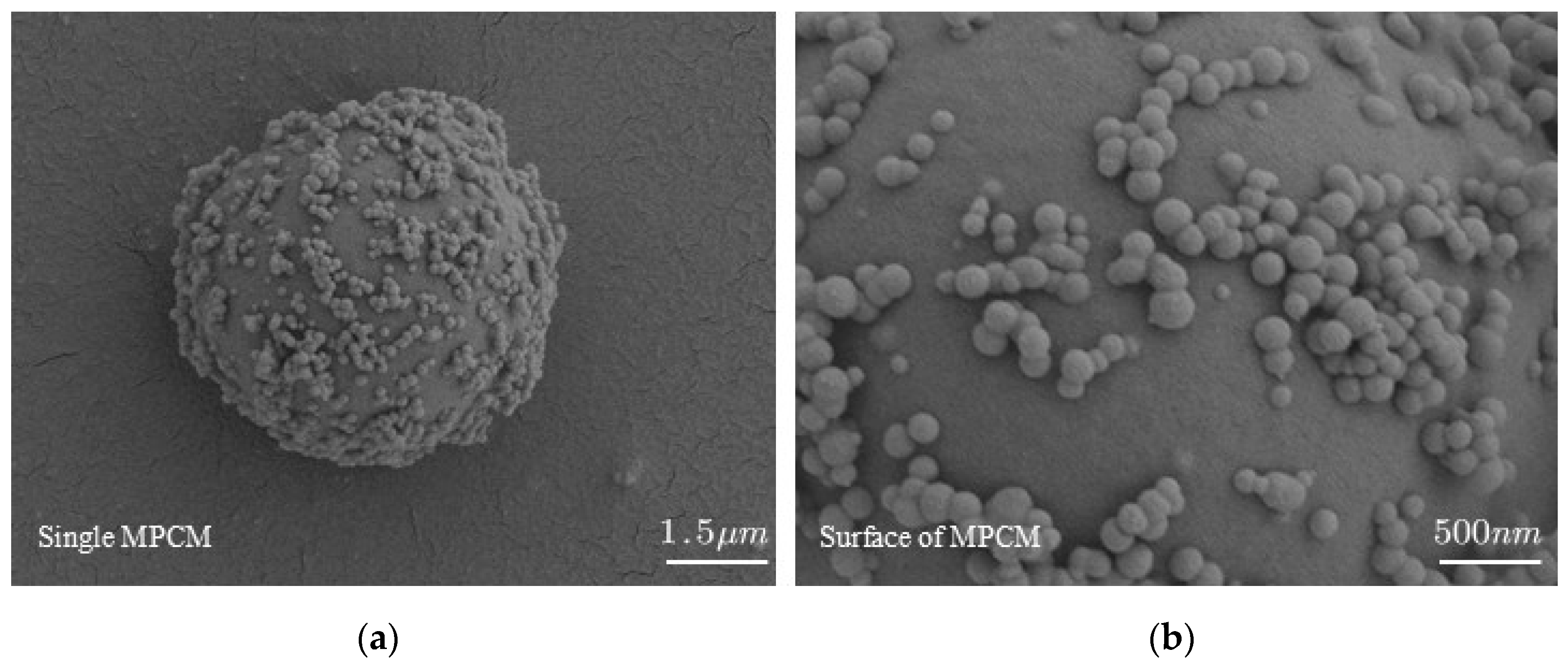

Figure 4 displays the microscopic morphological characteristics of MPCM after preparation.

Figure 4a shows that MPCM presents a regular spherical structure, which is beneficial for its uniform dispersion in grouting materials. The MPCM particle size is mainly distributed in the range of 3~7 μm.

Figure 4b is an SEM image of the MPCM surface. Nano-scale PMMA particles are adsorbed on the MPCM surface; these particles spontaneously aggregate and physically adsorb onto the MPCM surface through van der Waals forces and hydrophobic interactions during the emulsion curing stage [

26]. This surface microstructure increases roughness and specific surface area, while also increasing the water demand of the grouting material.

3.3. Physical Properties of MPCM Grouting

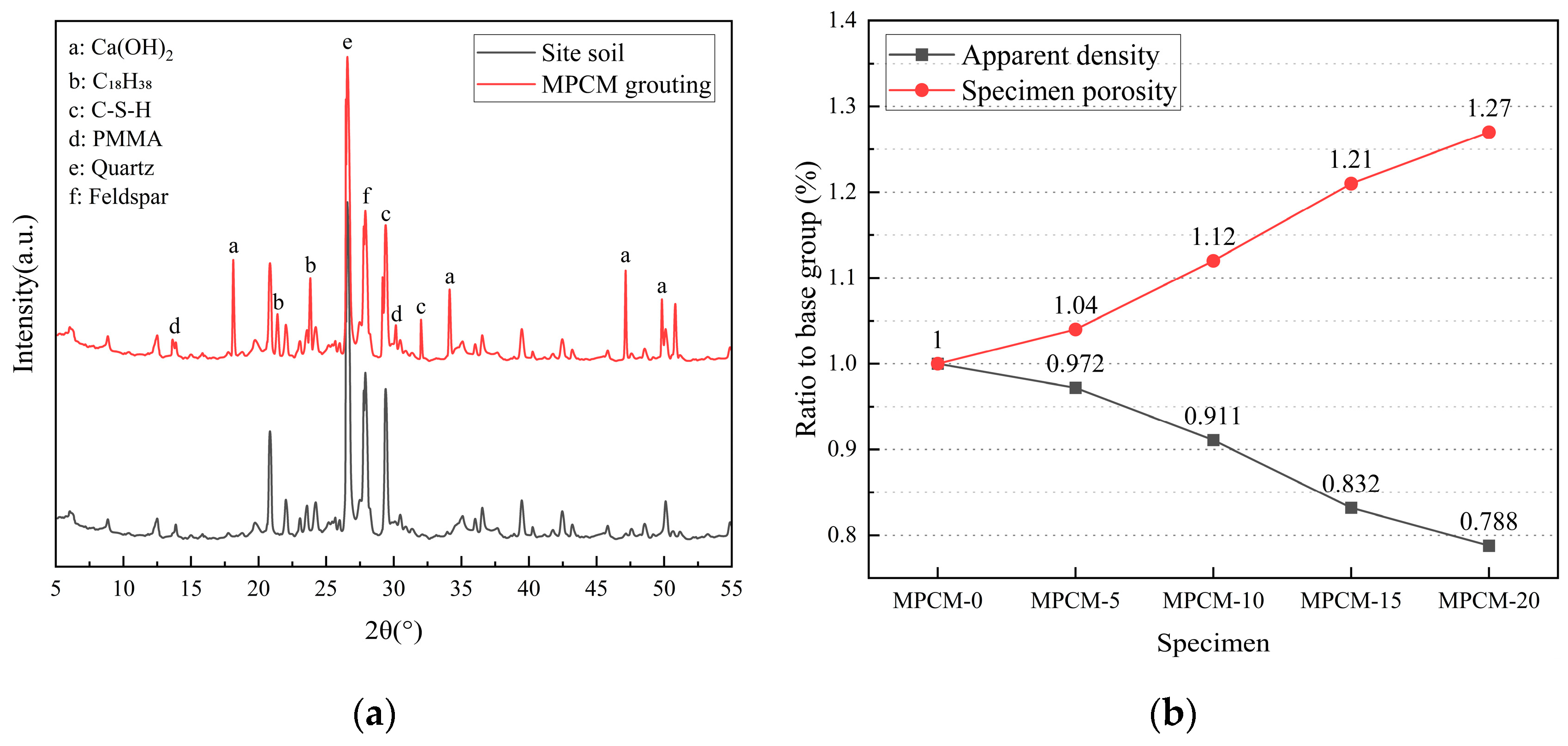

Figure 5a shows the comparison of X-ray diffraction (XRD) patterns between the site soil sample and MPCM grouting material. By analyzing the two curves, significant characteristic diffraction peaks can be observed at 2θ angles of 18.1°, 34.1°, 47.1°, and 50.8°, which precisely correspond to the crystal structure characteristics of Ca(OH)

2. The XRD spectra present sharp diffraction peaks at 2θ = 21.4° and 23.8°, as well as low-intensity characteristic peaks at 2θ = 13.7° and 30.1°, which are attributed to the characteristic structures of the MPCM core material (C

18H

38) and shell material (PMMA), respectively. Meanwhile, relatively broad diffraction peaks detected at 2θ = 29.1° and 32.0° confirm the formation of C-S-H hydration products with strong bonding properties.

Figure 5b shows the change ratio of bulk density and porosity of MPCM grouting relative to the reference grouting. The reference sample MPCM-0 has a bulk density of 1.79 g/cm³ and a porosity of 30.0%. The vacuum saturation test results of samples with different MPCM contents are shown in

Table 5. When 5%, 10%, 15%, and 20% MPCM are added, the bulk density gradually decreases to 1.74, 1.63, 1.49, and 1.41 g/cm³, with an overall reduction of 21.2%; simultaneously, the porosity increases to 31.2%, 33.5%, 36.3%, and 38.0%, respectively, representing an increase of 26.7%.

3.4. SEM of MPCM Grouting

Figure 6 shows SEM images of MPCM grouting samples, clearly presenting the systematic evolution of the grouting material’s microstructure with increasing MPCM content.

Figure 6a shows the control group sample (MPCM-0), displaying a dense microstructure formed by the tight combination of soil particles and calcium silicate hydrate (C-S-H) gel, with continuous interfaces and low porosity. In

Figure 6b, MPCM particles begin to disperse in the cement matrix, exhibiting discrete distribution characteristics, while small micropores form at the interface between the MPCM and the matrix, but the overall structure still maintains relative density. As shown in

Figure 6c, as the MPCM content increases to 10%, the number of MPCM particles significantly increases with more uniform distribution, the distance between MPCM particles decreases, forming local aggregation areas, and the porosity increases.

Figure 6d displays samples under higher content conditions, with further increased MPCM particle numbers, accompanied by an increase in the number and size of pores, and the matrix continuity begins to be affected.

As shown in

Figure 6e, when the MPCM content reaches 20%, the MPCM density reaches a critical value, the particle spacing decreases, the porosity significantly increases, and the overall microstructure transforms into a relatively loose state, with matrix continuity notably damaged. In

Figure 6f, the characteristic dendritic framework structure formed by C-S-H gel can be observed; this three-dimensional network structure can effectively encapsulate MPCM particles and soil particles, making a critical contribution to the overall mechanical properties and structural integrity of the grouting material.

MPCM, dispersed as “microscopic fillers” in the grouting, disrupts the original dense packing state, significantly altering the pore structure and spatial distribution of the grouting. Under high proportion conditions, the porosity of the grouting notably increases, bulk density decreases, and the structure tends to become loose. The strength reduction phenomenon can be attributed to the following two key factors:

(1) Interface bonding effect: Although the PMMA nanoparticles deposited on the MPCM surface enhance interface roughness and strengthen the interlocking effect through mechanical engagement, their spherical geometric configuration makes it difficult to form continuous effective stress transfer paths under high content conditions.

(2) Porosity: The incorporation of MPCM leads to increased porosity in the grouting material and reduced interface bonding area, making it difficult to form a strong bonding transition zone, directly resulting in a decline in the early mechanical performance of the grouting material.

3.5. Flowability of MPCM Grouting

According to the data shown in

Figure 7, as the MPCM content increases, the flowability of the grouting exhibits a gradual declining trend. Without MPCM incorporation, the grouting flowability is 216.5 mm; when the MPCM content reaches 20%, the flowability decreases to 195.3 mm. This change primarily stems from the high specific surface area of MPCM particles, which increases the water demand during the mixing process. This consequently leads to a reduction in freely flowing water within the grouting, resulting in decreased flowability. During the restoration process of earthen ruins, to ensure that the flowability of manually injected grouting reaches the ideal standard, its qualifying index generally should not be less than 200 mm and should be controlled within the range of 200 mm ± 10 mm. Therefore, the MPCM content is controlled within the range of 0~20% to ensure the quality of the restoration effect.

3.6. Mechanical Properties of MPCM Grouting

Figure 8 shows the variation pattern of compressive strength with age for MPCM grouting materials of different proportions. The results indicate that with the extension of curing age (7 d, 14 d, 28 d), the compressive strength of all proportion samples exhibits a significant growth trend, confirming that the strength of MPCM grouting materials continues to increase with time development.

However, it is noteworthy that as the MPCM content increases from 0 to 20%, the compressive strength shows an obvious declining trend. The control group MPCM-0 demonstrates the most excellent strength performance at all ages (7 d: 1.48 MPa, 14 d: 1.92 MPa, 28 d: 2.22 MPa), while MPCM-20 has the lowest strength (only 1.08 MPa at 28 d, a 51% reduction compared to the control group). This trend suggests that although the addition of MPCM may improve the temperature control characteristics of the soil, it significantly weakens its load-bearing capacity.

3.7. Thermal Performance of MPCM Grouting

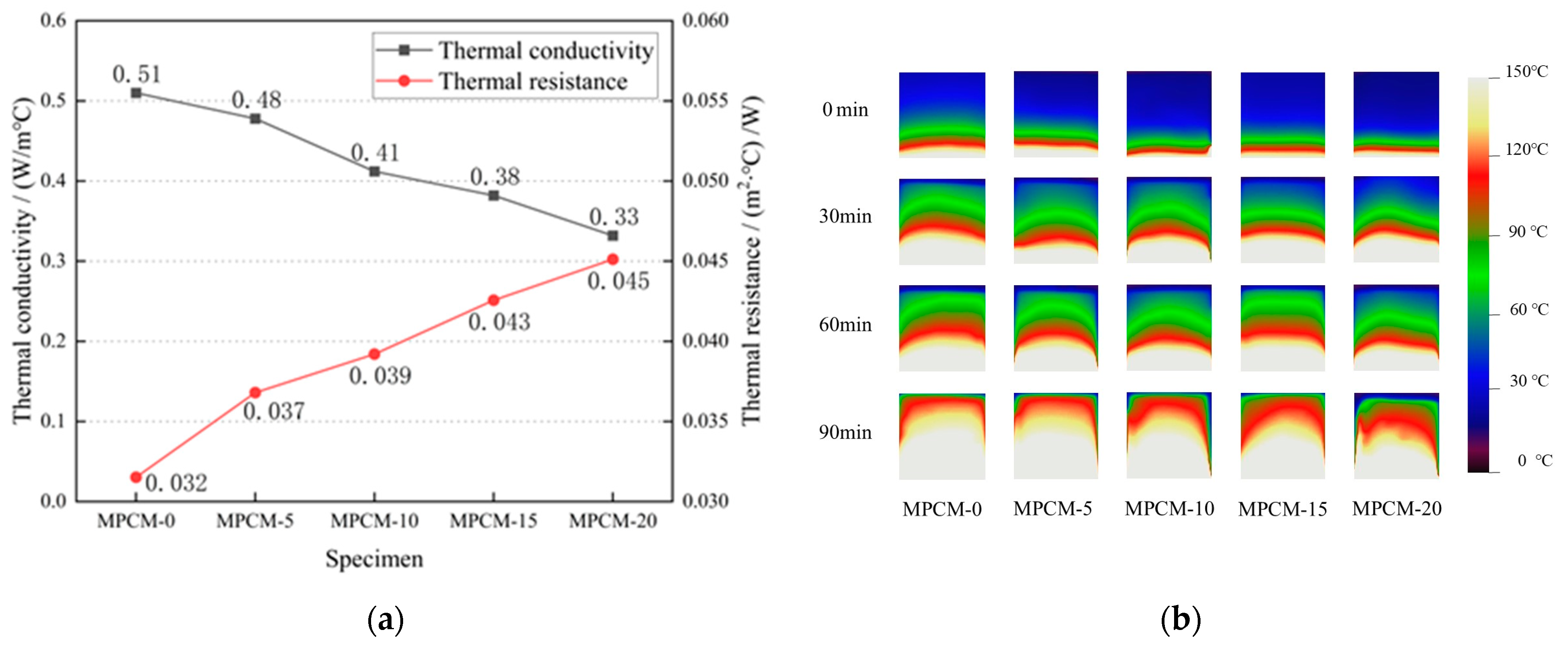

From

Figure 9a, it can be observed that as the MPCM content increases, the thermal conductivity of the grouting shows a significant downward trend, gradually decreasing from 0.51 W/(m·°C) for MPCM-0 to 0.33 W/(m·°C) for MPCM-20, with a total reduction of 35.3%; simultaneously, the thermal resistance increases from 0.032 (m

2·°C)/W to 0.045 (m

2·°C)/W, an increase of approximately 40.6%.

Figure 9b displays the dynamic process of heat conduction in grouting with different MPCM proportions during heating (0 min, 30 min, 60 min, and 90 min) with a 150 °C heat source applied from the bottom. In the initial stage (0 min), the bottom of the sample shows a high-temperature zone (approximately 120 °C, red area), while the top maintains a lower temperature (about 30 °C). As the heating time extends to 30 min and 60 min, heat gradually conducts upward, the temperature gradient gradually changes, manifested as the upward movement of color bands. By 90 min, the temperature distribution of all samples has changed significantly, with the top area temperature notably increased (90–120 °C, green to red area).

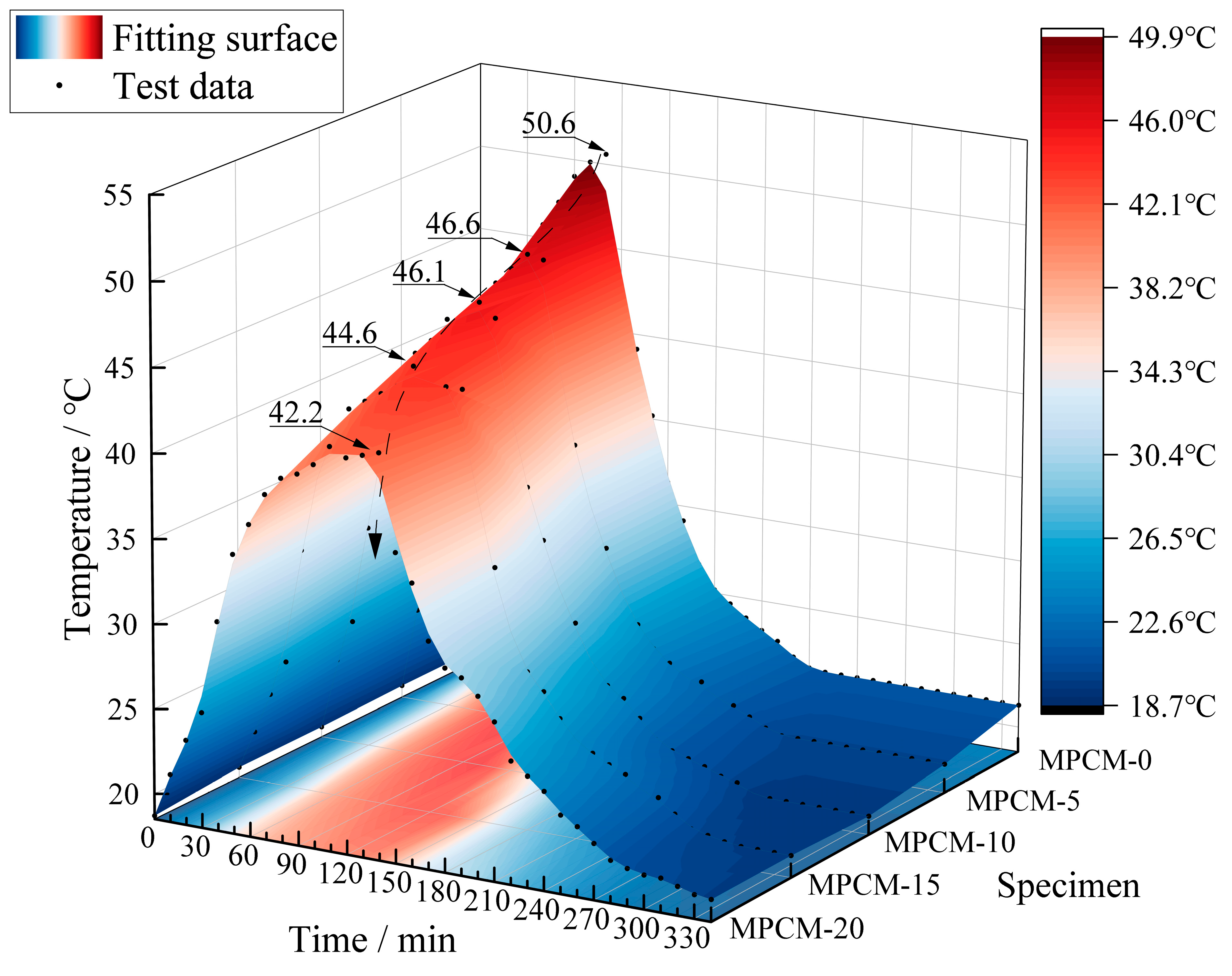

3.8. Temperature Control Performance of MPCM Grouting

Figure 10 shows the temperature variation pattern of the sample’s top surface during temperature control testing. The experimental results demonstrate that MPCM grouting possesses excellent temperature control performance. Comparison of the temperature response characteristics shows that the control group without MPCM addition (MPCM-0) exhibits the fastest heating rate (19.2 °C/h) and the highest peak temperature (50.6 °C). With increasing MPCM content, the thermal response parameters show significant changes. MPCM-5’s heating rate and peak temperature decrease by 3.0 °C/h and 4.0 °C, respectively, compared to the control group; when the content increases to 10%, the reduction expands to 7.2 °C/h and 4.5 °C; at 15% content, the reductions reach 9.7 °C/h and 6.0 °C, respectively. The highest content group (MPCM-20) demonstrates the maximum regulatory effect, with heating rate and peak temperature reduced by 13.6 °C/h and 8.4 °C. Notably, the time of temperature peak occurrence for all modified samples shows a delayed trend.

When MPCM undergoes the phase change process, significant heat absorption or release occurs near the phase change temperature, causing the effective specific heat capacity of the grouting material to increase dramatically in this temperature range. According to thermodynamic principles, materials exhibit a “thermal retention” phenomenon near the phase change temperature, i.e., the temperature change rate slows down (forming a peak), with thermal energy primarily used for the phase change process rather than temperature increase. The “path” of heat transfer progresses along the direction of minimum thermal resistance in the material. Under different proportions, these peaks connect to form a characteristic path similar to a ridge line, as shown by the dashed line in

Figure 10.

3.9. Field Repair Effect of MPCM Grouting

Figure 11 shows field photographs of Gaochang Ancient City after restoration using MPCM grouting. The grouting proportion used was MPCM-15. During the restoration process, technicians precisely injected the MPCM grouting material into cracks through manual injection. After it had completely solidified, infrared thermal imaging technology was applied to conduct non-destructive testing and evaluation of the repaired areas. Thermal imaging technology can intuitively display the distribution and compactness of grouting materials by capturing temperature distribution differences. Due to the unique temperature control characteristics of MPCM grouting, the restored areas show a distinct temperature contrast with unrestored areas in the thermal images, providing a scientific basis for evaluating the restoration effect. This approach ensures that the protection work for this precious cultural heritage is completed with high quality without damaging the original structure.

Through on-site inspection, the MPCM grouting restoration areas exhibit color characteristics highly similar to the native soil, achieving good visual consistency. No secondary cracking has appeared on the restored grouting surface, indicating its excellent structural stability and crack resistance. Quantitative detection through infrared thermal imaging technology confirms that the internal soil of the treated site demonstrates ideal adhesion without internal structural defects. As shown in

Figure 11a,b, the top cracks of the west gate wall appear highly compacted after MPCM grouting treatment, with the surface temperature in the grouting hole area significantly lower than the surrounding untreated areas, indicating that the grouting material has a significant temperature regulation function.

Figure 11c,d display the repair effect of cracks in the barbican of the south city wall, showing high compactness of crack filling after grouting and good interface bonding. Thermal imaging analysis shows a regular decrease in temperature distribution at the crack positions and grouting hole locations, confirming the effective distribution of grouting material within the structure.

Figure 11e,f record the repair status of local cracks in the south gate barbican, with infrared thermal imaging detection results showing that the repaired areas exhibit characteristic red thermal signals with slightly lower temperatures than the surrounding areas. This temperature gradient difference confirms that the phase change temperature regulation function of the MPCM material has been successfully activated.

Comprehensive analysis indicates that MPCM grouting technology not only effectively fills cracks in earthen ruins, restoring structural integrity, but also significantly reduces the temperature gradient within the earthen ruins through its unique temperature control mechanism. Based on the above survey results, it can be determined that this MPCM grouting reinforcement protection technology has a long-lasting restoration effect, can effectively ensure the adhesion stability of the soil, and achieves the dual goals of cultural relic protection and functional restoration.

4. Discussion

This research is dedicated to developing and evaluating MPCM grouting technology based on improvements to traditional grouting, aiming to achieve proactive preventive restoration of earthen ruins. Although traditional grouting technology has achieved significant results in repairing cracks in earthen ruins, its protective effect remains insufficient in the face of long-term complex environmental changes, especially the thermal deterioration of earthen ruins caused by frequent temperature fluctuations. Targeting the characteristic temperature fluctuations of Gaochang Ancient City earthen ruins within the range of −15 °C to 47 °C, this study carefully selected three phase change materials that exist in the solid state at normal temperature: PCM-28, PCM-35, and PCM-45. Research has found that the thermal properties of a PCM are positively correlated with its carbon chain length [

27]. The lower the relative molecular weight, the lower its boiling point, which is manifested as an earlier weight loss process in TG tests. Based on thermal stability analysis results, the microencapsulated MPCM has been confirmed to provide sufficient reliability assurance for its application to the earthen ruins of Gaochang Ancient City.

In the preservation of earthen ruins, the compatibility of material mechanical properties is crucial. Research indicates that the compressive strength of soil in earthen ruins typically ranges between 0.7 and 1.3 MPa, while MPCM-15 reaches a compressive strength of 1.39 MPa after 28 days of curing. This result suggests that although MPCM grouting material may not be suitable for other building materials with high strength requirements, its strength can be precisely matched with that of earthen ruins by controlling the proportion, avoiding secondary damage caused by material strength incompatibility. It is noteworthy that MPCM possesses a certain self-healing capability [

28]. When microcracks appear in the MPCM shell and the temperature reaches the phase change temperature of the PCM, its self-healing mechanism is triggered. The liquid PCM exudes along the shell cracks through capillary action and fills the cracks. When the temperature drops below the phase change temperature, the PCM solidifies, thereby sealing the cracks and completing the repair. The reduction in thermal conductivity of MPCM grouting material is highly consistent with results reported in the literature [

29]. On one hand, the thermal conductivity of MPCM is lower than that of the grouting matrix material, forming “thermal resistance points” when dispersed in the grouting, which extends the heat transfer path; on the other hand, the incorporation of MPCM increases the material’s porosity, not only increasing the length of the heat transfer path but also introducing more air with thermal conductivity far lower than the grouting matrix, jointly reducing the overall thermal conductivity efficiency. These two mechanisms work synergistically, enabling MPCM grouting to exhibit excellent temperature control performance that can effectively reduce local temperature gradients. According to the thermal stress formula, temperature control performance can also reduce the cyclic fluctuation of thermal stress, thereby inhibiting the expansion of thermal deterioration cracks in earthen ruins, which also constitutes the focus of future research for this research team.

Although this study has verified the effectiveness of MPCM grouting technology under normal and high-temperature conditions, there is still room for further exploration to fully address the annual temperature fluctuation range of Gaochang Ancient City, especially in sub-zero low-temperature environments. Subsequent research should focus on finding low-temperature phase change materials suitable for sub-zero environments to address soil freeze/thaw issues. While the methodology and results of this study can be applied by analogy to different temperature ranges, sub-zero environments involve the special deterioration mechanism of soil freeze/thaw cycles. MPCM may have great application potential in this aspect and is expected to provide a more comprehensive technical solution for all-around, all-weather protection of earthen ruins, achieving long-term protection of cultural heritage.

5. Conclusions

Traditional grouting can repair cracks in earthen ruins, but its protective effect remains insufficient against the thermal deterioration of earthen ruins caused by frequent temperature fluctuations. This study first investigated the thermophysical properties and microscopic morphology of MPCM, comprehensively researched the physical properties, microstructure, flowability, mechanical properties, thermal properties, and temperature control performance of MPCM grouting, and conducted field surveys of the restoration effects of MPCM grouting. The main conclusions are as follows.

Microencapsulated phase change material (MPCM), as confirmed by microscopic analysis, demonstrates good encapsulation, with phase change latent heats of 184.8 J/g, 166.0 J/g, and 134.3 J/g, respectively. They exhibit excellent thermal stability, with a maximum mass loss rate of only 0.65% after 200 phase change cycles, confirming that MPCM possesses good long-term stability for use, laying the foundation for its subsequent application in grouting materials.

MPCM altered the pore structure and spatial distribution in the grouting, with porosity increasing by a maximum of 26.7% under high proportion conditions, and bulk density decreasing to 1.41 g/cm³. The flowability showed a gradual declining trend, all meeting the injectability requirements for manual grouting (200 mm ± 10 mm). At a content of 15%, MPCM grouting possesses mechanical properties compatible with earthen ruins, capable of meeting the practical needs for earthen ruins restoration.

MPCM grouting material demonstrates excellent temperature control capability, effectively regulating temperature gradients, reducing peak temperatures, and extending the time lag effect. At a content of 15%, the sample’s heating rate decreased by 9.7 °C/h compared to the reference sample, with the peak temperature reduced by 6.0 °C. This temperature regulation capability stems from the MPCM’s reduction of the grouting material’s thermal conductivity and increase in thermal resistance, providing effective protection and preventive measures to mitigate thermal deterioration of earthen ruins.

Through on-site inspection, the MPCM grouting restoration areas are highly similar to the native soil. No secondary cracking has appeared on the restored grouting surface, and there are no internal structural defects. The MPCM grouting reinforcement protection technology has a long-lasting restoration effect, can effectively ensure the adhesion stability of the soil, and achieves the dual goals of cultural relic protection and functional restoration.