Abstract

Lacquered brass objects are widely present in scientific and technical heritage collections. Localized atmospheric corrosion occurs on the metal when the coating fails to play its protective role. Although lacquered brass objects are not necessarily endangered by this phenomenon, the presence of dark, unpleasant corrosion spots alters the surface appearance, affecting the readability of the objects. Conservators are therefore frequently asked to clean these surfaces. We hereby present the results of a study conducted in the framework of the CleanLaB (Cleaning of Lacquered Brass) project at the Haute Ecole Arc of Neuchâtel for the cleaning of lacquered brass. This work investigates the effects of several gelled cleaning systems applied on artificially aged, lacquered brass samples to remove the corrosion products without affecting the integrity of the coating. The performance of complexing agents commonly used in conservation was compared on lacquered brass mock-ups coated with shellac resin by means of multiple non-invasive characterization and imaging techniques. The tests included conventional complexing agents like sodium citrate and disodium ethylenediaminetetraacetic acid, as well as a bio-originated system based on deferoxamine, a microbial metal chelator investigated as a green alternative in cleaning formulations.

1. Introduction

1.1. Lacquered Brass Objects

Lacquered brass is typically found in collections of decorative arts as well as in scientific and technical heritage. In the latter instance, the primary goal of these coatings is to offer protection against corrosion, ensuring the object’s function as well as a certain aesthetic appeal. Alloys containing as main components copper and zinc (i.e., brass) were frequently used in the manufacturing process of scientific instruments, especially from the second half of the 19th century onwards [1]. Until the beginning of the 20th century, brass instruments were generally lacquered [2]. Brass was also used to produce decorative so-called “bronzes” and ornaments made of stamped rolled sheets. In this case, these “goldlacquers” served to both protect the metal and imitate the color of gilded objects [3,4,5].

Technical literature of the 19th century suggests that alcohol-based lacquer recipes containing shellac resin were privileged in comparison to essential oil- and fat oil-based systems for the lacquering of brass alloys [6].

The use of shellac as a component of surface finishes on technical heritage and decorative brass objects has been confirmed by non-invasive analysis campaigns conducted by FTIR on scientific instruments, technical objects and gilded bronzes dating from the 18th and 19th centuries [4,6]. FTIR analysis of lacquers dating from the 19th and the very beginning of the 20th century also showed that alcohol-based resin lacquers with shellac as a single component were used [7,8]. Unbleached shellac varnishes, exhibiting a bright to dark orange fluorescence under UV illumination, were frequently observed on various objects, both scientific and decorative, during analysis campaigns [9].

These finishes are an essential step of the manufacturing process and are an integral part of the artifacts. However, aged defective coatings are meant to be renewed during the period of use of the object to ensure its good functionality and aesthetics. Once these artifacts become part of a museum’s collection, their materiality should be considered differently. In fact, these coatings—despite their poor condition in some cases—are part of the object [10], and they are historical evidence of traditional lacquering techniques and of the objects’ life [11,12]. For this reason, they are worth preserving as long as possible.

1.2. Corrosion of Lacquered Brass Objects

In indoor environments, brass alloys are prone to atmospheric corrosion. Mechanically induced coating defects can promote the chemical reaction of the metal substrate and the development of corrosion products, which have an impact on the aesthetics of the object and its readability.

In the specific case of coated metals, water diffusion through the organic layer plays a central role in the corrosion phenomena. The combination of atmospheric pollutants like SO2 and NOx with moisture can lead to a weakened, permeable lacquer by the formation of acidic components (such as H2SO4 and HNO3) [13].

Polished CuZn20 brass alloy exposed to purified humid air (90% R.H. ± 3% and 19.5 °C ± 0.5 °C) tends to develop a superficial ZnO layer followed by a more homogenous Cu2O layer [14]. Dezincification can also occur due to these corrosion phenomena, especially on brass alloys containing more than 15% of zinc. Therefore, zinc can be leached out, leaving a porous copper surface, or both metals may corrode with a redeposition of the more noble copper [15].

However, corrosion phenomena possibly occurring on lacquered brass are not always a threat to the metal’s conservation. Cuprite-rich layers form a dark color over time, which alters the gloss and initial hue of the lacquered brass, but from a conservation point of view, the corrosion product can have passivating properties and slow down corrosion processes [16].

1.3. Cleaning Methods for Lacquered Brass Objects

Until the beginning of the 21st century, only scarce information was available in the literature about corrosion products and corrosion removal methods on lacquered copper alloys. Over the past two decades, practical cleaning recommendations for scientific instruments have been essentially provided for chemical stripping of surfaces and complete relacquering [11,17,18,19,20]. However, in the 1990s, the cleaning of shellac-coated decorative brass with ʺlow pHʺ solutions was reported in conservation literature. Thiourea (8%) combined with sulfuric acid (5%) and formic acid (5%) solutions have been used to complex and dissolve poorly soluble copper oxides without removing the organic coating [5,21].

Although shellac is known to be highly soluble in concentrated formic acid solution (85%) [22], FTIR analyses performed on a shellac coating (likely unbleached because of its orange fluorescence) treated with formic acid did not reveal any modification of the lacquer [5]. However, recent FTIR analyses carried out on shellac-coated brass mock-ups exposed to wet and dry cycles and treated with a 0.1 M (5% w/w) formic acid solution (pH adjusted at 3.5) showed a modification of the chemical structure of the lacquer after a contact of 30 min [23]. Nevertheless, these modifications were not visible at shorter contact times (15 min) and appeared only on bleached, dewaxed shellac-based coatings and not on orange shellac.

1.4. Recent Cleaning Practices for Metallic Heritage

Practice for the removal of copper oxides from lacquered copper alloy surfaces seems to have evolved during the past decades towards the use of complexing agents at concentrations of 2–5% w/w and pH close to neutral (5.5–8.5) to be more compatible with the pH of paintings and varnishes [24]. Several case studies for the conservation of lacquered scientific instruments demonstrate that complexing agents like ethylenediaminetetraacetic acid (EDTA) and citrate salts, especially triammonium citrate, are mostly privileged [16,23,25,26]. In some cases, conservators combine the weak acid EDTA-Na2 salt with EDTA-Na4 (0.1 M) as its conjugate base to create a more stable buffer solution at pH 7 [27].

In addition, the complexing agents are often employed in a gelled form. The gelling agents increase the aqueous solution’s viscosity to limit diffusion and capillarity of the cleaning solution into the lacquer, which might be harmful to the organic coating, causing possible phenomena like ionization and/or dissociation of materials or hydrolysis [28]. Cleaning gels are usually applied with a cotton swab or small brushes to increase contact with the surface and cleaning efficiency: constant movement during application has the advantage of renewing the gel in contact with the corrosion products. In some cases, the gels are also left for several minutes at the surface, working as a poultice. The rinsing method consists of using a cotton swab soaked with deionized water. One drawback of these gelled systems is that residues may subsist despite repeated rinsing [29]. This aspect has been studied recently regarding the cleaning of metals [30].

More recently, a study investigated the cleaning of lacquered scientific instruments with water- and silicone-based methods. The assessment of the cleaning effects was performed with a multi-analytical, non-invasive approach. However, this work focuses on methods for the removal of soil and not on the removal of corrosion products [31].

The use of a bicinchoninic acid (BCA) gel as a complexing cleaning system has been reported for the cleaning of furniture mounts. The buffering of the solution to a pH of 8.5 is recommended to efficiently remove the copper corrosion products [16]. However, the possible negative effect of high pHs on historic natural resin coatings has been pointed out [32]. It has been shown that the risk of dissolution of the shellac film increases with the pH value, especially at about pH 7.2 [33].

New cleaning protocols were also investigated in the past decades for brass, but without considering the possible preservation of an organic coating. Protein- and peptide-based cleaning methods were tested in the field of furniture conservation for brass elements, especially the use of animal glue, naturally containing amino acids that can act as a reducing agent of copper ions [34].

Current treatments for the cleaning of brass marquetry consist of using poultice systems (peel-off gels or a matrix of Japanese paper impregnated with gelled complexing solution). Ancient brass inlays are usually covered with a resin protective coating. In this case, the coating is completely removed to clean the metal surface and is replaced by a new protective coating [35]. For this reason, cleaning criteria and goals differ from the conservation of lacquered brass objects.

Examples of current methods for the cleaning of uncoated brass are systems made with hide glue, citric acid, and triethanolamine (TEA), with the further addition of an oxalate acting as an electron donor [35] or the use of a Pemulen TR2® (Lubrizol, Wickliffe, OH, USA) gel containing citric acid and TEA [36]. The removal of the poultice and rinsing are followed by cleaning with a vinyl eraser, which removes the softened corrosion products. The surface is cleaned down to the limit of the original surface of the metal, which is characterized by superficial zinc loss [34]. Alkaline conditions are recommended during cleaning to avoid corrosion of the base metal [34] and to improve the dissolution of copper oxides as well as copper sulfides [35]. However, a pH higher than 7 is not recommended because of the possible proximity with sensitive organic materials like turtle shells.

The use of innovative bio-based solutions in gelled form has also been explored more recently in the framework of the HELIX project (investigating metal bioremediation for the preservation of historical metal artworks) [30,37,38,39]. N,N′-ethylenediaminedisuccinic acid (EDDS) and siderophores like deferoxamines (DFOs) were investigated for the cleaning of different metal alloys, including brass [40]. The possible removal of aged protective organic coatings on metals was also assessed.

Conservation routines for the cleaning of lacquered brass were developed in recent years with the aim of preserving as much as possible the organic coating. However, no systematic experimental study using assessment methods other than visual observation at a macroscopic and microscopic level was carried out for corrosion cleaning in this field. No in-depth multi-analytical approach has been used to study the effects of this kind of treatment. Newly explored in the conservation field, bio-sourced chelating agents like EDDS or DFO were not investigated in this specific field either. The main goal of this study is to investigate the effect of frequently used cleaning systems in comparison to a bio-based solution for the removal of corrosion products on lacquered brass. This work focuses on preserving the integrity of the coating.

2. Materials and Methods

2.1. Sample Preparation

A pure shellac film was prepared according to a recipe for the lacquering of scientific instruments (“Vernis à chaud pour instruments de précision”) and then applied to a commercial CuZn36 brass rolled sheet (60 × 60 × 1 mm) [41]. Although real objects might have a more complex alloy composition, a binary lead-free CuZn36 brass was selected for the mock-ups to reduce the variables of the coated system.

Before lacquering the brass coupons, the metal was treated with powdered pumice stone by means of a nylon brush, rinsed with tap water, left for a few minutes in a bath of 0.1 M sulfuric acid rinsed again in deionized water and finally degreased in ethanol and dried with a soft paper cloth. This procedure was performed to eliminate possible oxidation products present on the surface and create a satin finish on the metal.

The varnish was prepared by dissolving 112.5 g of orange dewaxed shellac (Kremer Pigmente, Aichstetten, Germany) in 500 g of 96% + 2% MEK ethanol (Kremer Pigmente, Aichstetten, Germany) [40]. The exact procedure for the lacquer preparation has been described in a previous publication [42]. The orange shellac varnish was dewaxed by filtering the solution on 602H filter paper.

Right before the application of the lacquer, the metal was heated around 30 °C, the ideal temperature for lacquer application according to the results of former experiments [4]. The coating was applied to the coupons with a soft, flat synthetic brush. During the lacquering process, the excess varnish was removed 3 times from the brush and was passed twice on the coupon to homogenize the layer. The coated samples were directly transferred into the oven at 40 °C and left for a week to improve the hardening of the coating. Samples were stored in the dark in a dry climate.

A total of 30 lacquered samples (VA N-1–30) were produced. Seventeen coupons were selected for the tests according to their thickness (Table 1). For each tested cleaning system, three samples with an average lacquer thickness of 3 µm were selected. This thickness range refers to lower values that can be measured on ancient technical objects [6]. The standard deviation of the lacquer thickness on a single sample varies from 4 to 8% due to the natural heterogeneities of the brush application. The creation of a thin, potentially more permeable and fragile layer was privileged to promote degradation of the coating during artificial aging. A set of two additional samples presenting a slightly thicker coating were used as control samples for the water gel.

Table 1.

Sample series and average thickness with standard deviation values for each selected coupon and series.

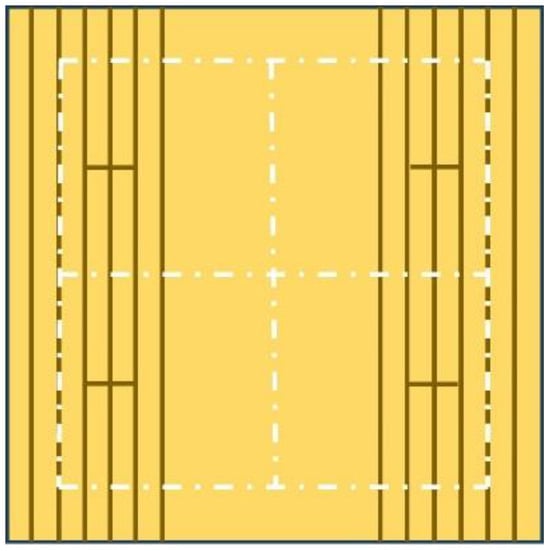

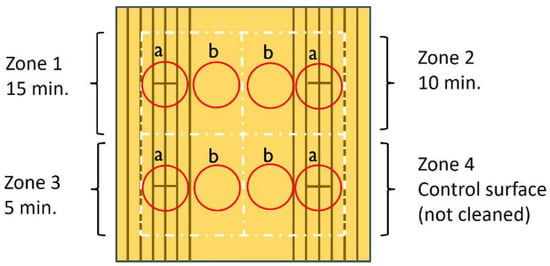

After drying, all coupons were scratched to create defects in the lacquer and trigger corrosion phenomena, according to the guideline NF EN ISO 17872 [43]. Scratching was performed with a crosscutter Labomat (TQC Cross Cut Adhesion Test KIT CC3000—SP1682), allowing for the creation of reproducible scratch marks in terms of blade distance, depth and width. Six parallel scratches at a 3 mm distance were carried out vertically on the left and right sides of the coupons, and one additional scratch was made horizontally with a scalpel to ease the localization of the 4 zones of interest, as can be seen in Figure 1 (white dotted line). Each zone of interest is divided into a scratched area and an unscratched area of lacquer (see also Figure 2). The external area was not assessed because of possible edge phenomena.

Figure 1.

Schema of the crosscut performed on each lacquered coupon. The white dotted line indicates the four zones of interest.

Figure 2.

Localization of the four zones of interest on each coupon. White dotted line: delimitation of the 4 areas of interest; red circles: spot a = scratched, spot b = unscratched; dark lines = scratches in the lacquer.

2.2. Artificial Aging

The lacquered and scratched coupons were aged artificially in a three-step protocol (1—photochemical; 2—wet/dry cycles; 3—sodium sulfate vapor) to induce corrosion phenomena. It was decided to focus on the combination of hygrometric variations and daylight (natural light filtered through a window), two major parameters influencing the aging of coated metals [44]. For this reason, the samples were photochemically aged for two months and then exposed to further wet and dry cycles for two other months. For technical reasons, it was not possible to combine both parameters at the same time. Eventually, the samples were exposed to Na2SO4 atmosphere for two weeks to promote further corrosion. The details of the aging protocol are reported in Table 2.

Table 2.

Artificial aging protocol.

2.3. Cleaning Protocol

Two complexing agents that are widely used were selected according to conservation literature: citrate and EDTA salts. A bio-sourced chelating agent known as deferoxamine (Desferal®, Novartis), which showed promising cleaning efficiency on lacquered brass test objects in the framework of the CleanLaB project, was also selected. Although this chelating agent is privileged for the treatment of iron, it works at a slightly acidic pH, which is compatible with ancient natural resins. The use of sodium citrate was favored over triammonium citrate because, for the latter, past studies pointed out its possible release of ammonium ions by hydrolysis [45]. This could harm both the lacquer and the copper alloy in the case residues of the cleaning agent being left on the surface. All solutions were prepared at 0.13 M, the highest concentration reported in the literature [23,25,26] for the cleaning with EDTA of lacquered brass.

Sodium citrate was prepared with citric acid (Carl Roth, Karlsruhe, Germany) and a 10% sodium hydroxide solution (Carl Roth). The pH of the EDTA-Na2 (Kremer Pigmente, Aichstetten, Germany) solution was adjusted with 10% sodium hydroxide. All solutions were made with deionized water.

The solutions were prepared at pH 5.5, and an additional solution of sodium citrate was also tested at pH 7. This choice was made because citrate might be used in cleaning practice at pH 7 due to its higher efficiency. Citrate is a weaker complexing agent of copper when compared to EDTA, and its use at pH 7 increases its pKF (Table 3).

Table 3.

pKF of citrate and EDTA as a function of pH and concentration [46].

The adequate pH range of the cleaning solutions was determined by pH measurements of the shellac coating. The measured average conductivity is 235 µS/cm, and the average pH value is 6.16. The chosen pH value of 5.5 is slightly more acidic than the surface to clean, which is adequate for the preservation of oxidized organic surfaces [47]. This is coherent with the pH value around 5, which is more generally recommended for the conservation of a natural resin [48]. Furthermore, a slightly lower pH can increase the solubility of copper oxides like cuprite.

All solutions were gelled with xanthan gum (2% w/w, Kremer Pigmente, Aichstetten, Germany). Xanthan gum was chosen as a gelling medium because of its good chemical stability and its less adhesive properties in comparison with derivate cellulose products. Agar-agar or agarose were not selected because of the high temperature required for their application and peel-off properties. Minimum temperatures for brush application of the gels, around 35 °C for agar, provide semi-rigid gels [28], which might not guarantee good contact with corrosion products present in small scratches or pits.

To obtain reproducible tests, it was decided to privilege the application of cleaning gels as poultices: a gel layer of ~3 mm was applied and left on each coupon for 15 min (zone 1), 10 min (zone 2) and 5 min (zone 3) (Figure 2). One area (zone 4) was left uncleaned for control and protected with a silicone mask during gel application. A control water gel (without a chelating agent) was also applied for 15 min on two further samples. Rinsing was conducted in two steps: first, the gel was swiped off with dry rigid paper; second, the surface was rinsed twice with a cotton swab soaked in an ammonium bicarbonate solution.

For rinsing, conditions close to isotonic were chosen to reduce the risks of swelling of the organic coating in contact with an aqueous solution [49].

A rinsing solution with an ionic strength of 1368 µS/cm was prepared with diluted ammonium hydroxide (Carl Roth, Karlsruhe, Germany) and carbonic acid, and its pH was adjusted to 5.5. All cotton swabs had an identical weight (0.16 g), and an identical volume of rinsing solution was injected into the cotton (0.7 mL).

2.4. Characterization Methods

Coupons were characterized before and after cleaning with the methods listed in Table 4.

Table 4.

Characterization methods (× = all coupons/all zones of interest).

Before and after cleaning, images of the coupons were obtained under white light and ultraviolet illumination, and microphotographs were taken under optical microscopy to assess possible visual changes, like color and gloss modification, as well as the porosity of the organic coating.

2.5. White Light Imaging

Macroscopic documentation of the samples under white light was performed with a Canon EOS D600 camera (Tokyo, Japan) and Canon macro lens EF-S 60 mm f/2.8 in a lightbox (Kaiser Fototechnik GmbH & Co. KG, Buchen, Germany). The pictures were taken in manual mode, ISO 100, f/7.1, 1/10 s. Calibration of the pictures was carried out with an X-rite ColorChecker® (X-Rite, Inc., Grand Rapids, MI, USA) target in Adobe Lightroom Classic.

2.6. UV Imaging

Imaging under UV light was performed on all samples with an unfiltered Canon CN 750 camera with an 18–35 mm lens equipped with a Baader UV/IR cut (Baader Planetarium GmbH, Mammendorf, Germany) and an X-Nite CC1 filter (LDP LLC, Carlstadt, NJ, USA). The samples, placed on a black non-UV emitting cardboard background, were illuminated by two Dominique Dutscher (Bernolsheim, France) UV lamps with an emission peak at 365 nm mounted at 45° on a custom-made stand. The pictures were taken in manual mode, ISO 200, and f/11 aperture. Calibration of the pictures was performed according to the procedure which has been described in a previous publication [42]. L* a* b* values of three spots (11 px × 11 px) were then recorded for each coupon in Adobe Photoshop using the color sampling tool to compare the color of the fluorescence of each varnish. UV imaging was also performed on a batch of fresh xanthan gum gel as a reference to detect possible cleaning residues left on the surface of the coupons. Moreover, since it has been shown that the outer varnish layers are more exposed to degradation phenomena [50], UV imaging was selected as a monitoring technique because the possible dissolution of oxidized superficial lacquer might produce a slight decrease in fluorescence after cleaning [51].

2.7. Optical Microscopy

Imaging of all four zones of interest for each series was performed with a Zeiss Axioscope 2 MAT Optical Microscope (Carl Zeiss, Oberkochen, Germany) and Zeiss ZEN core 3.5 software. Additional imaging was carried out with a portable Dino-Lite AM-413 ZT USB microscope. Pictures were recorded at magnifications ×50 and ×230 with the DinoCapture 2.0 software.

2.8. Fourier-Transform Infrared (FTIR) Spectroscopy

All samples were analyzed with a ThermoFischer Scientific Nicolet iN10 MX FTIR microscope (Thermo Fisher Scientific Inc, Waltham, MA, USA). FTIR spectra were collected in reflectance mode using 128 scans at 4 cm−1 resolution, with a spectral range between 4000 and 650 cm−1. Unscratched lacquer areas were analyzed before and after cleaning. FTIR was chosen for assessing possible modifications in surface composition. In fact, experimental studies showed that this technique allows the characterization of thin uppermost layers on brass surfaces [52].

2.9. Gloss Measurements

Gloss measurements on the unscratched spots of each zone of interest were carried out with a two-angle (20° and 60°) glossmeter Zehntner ZGM 1120, aperture 4.7 × 2 mm (Zehntner Gmbh, Reigoldswil, Switzerland, using a paper mask created according to the size of the coupon to precisely locate a specific area. The acquired data in gloss units (GU) at 60° gives comparative information about the samples according to standard ISO 2813 [53]: >70 GU (polished finish); 10–70 GU (satin finish); <10 GU (mat finish). Gloss measurements were carried out to assess possible changes induced by cleaning.

2.10. Color Measurements

Colorimetric measurements on the unscratched spots of each zone of interest were carried out using an X-Rite Ci62 spectrophotometer with a D65 illuminant, a 10° observer and a specular component included (SPIN) to measure color data without the effect of surface appearance using CIELAB 1976 color space. An aperture of 4 mm diameter was used to acquire comparative data. The instrument was positioned on the coupons using a paper mask created according to the size of the coupon. ΔE* was calculated according to the standard color variation formula in CIELab:

This value quantifies the difference in color between two samples but does not provide any qualitative information. ΔE* was calculated for each zone of interest before and after cleaning, including the simple water gel.

2.11. Thickness Measurements

The thickness of the samples was measured before crosscut of the lacquer with an eddy-current Phynix Surfix® Pro S gauge and FN 1.5 probe (PHYNIX Sensortechnik GmbH, Neuss, Germany) with a measurement range of 0–1.5 mm, and an accuracy, with foil calibration, of ± 1.0 µm + 1% of value. The necessary contact zone with the surface to be measured is 12 mm (sensor size 5 mm diameter). Free-hand measurements were taken in the same areas of each sample by means of paper masks created according to the size of the coupon.

2.12. Scanning Electron Microscope (SEM-EDS)

Scanning electron microscopy and energy dispersive X-ray spectroscopy analyses were performed with Jeol JSM-6400 (JEOL Ltd., Tokyo, Japan), secondary vacuum, 10−6–10−5 mbars, 15–20 kV. Secondary electron (SE) and backscattered electron (BSE) images were acquired on a sample of each cleaning system. The surfaces were observed under magnifications ×35, ×50 and ×450. Local sputtering with platinum and palladium was performed before the analysis. The test zone with the longest cleaning time (15 min) was compared to the uncleaned control spot of the same coupon and to a test zone cleaned with a simple water gel. Some EDS analyses were also performed on scratched areas to assess the metal surface composition and a sample of pumice powder was analyzed to identify possible contaminations of the samples.

2.13. Conductivity and pH Measurements

Conductivity measurements were carried out on the unscratched central part of 4 selected coupons after completing artificial aging according to the methodology for water-sensitive coatings [54]. An agarose patch was produced with a 3% (w/w) pure agarose (Sigma Aldrich, St. Louis, MO, USA) in Mili-Q water. The solution was heated over 90 °C twice before pouring a thin layer. A patch of 3 mm diameter was punched out of the agarose layer and left for 2 min on an unscratched lacquered area of the coupon. Conductivity measurements were carried out after calibration with Horiba LACQUAtwin-EC-33. The patch was transferred in a second step into a calibrated Horiba LACQUAtwinpH-22 pH meter, and a drop of pure deionized water was added before measurement.

3. Results

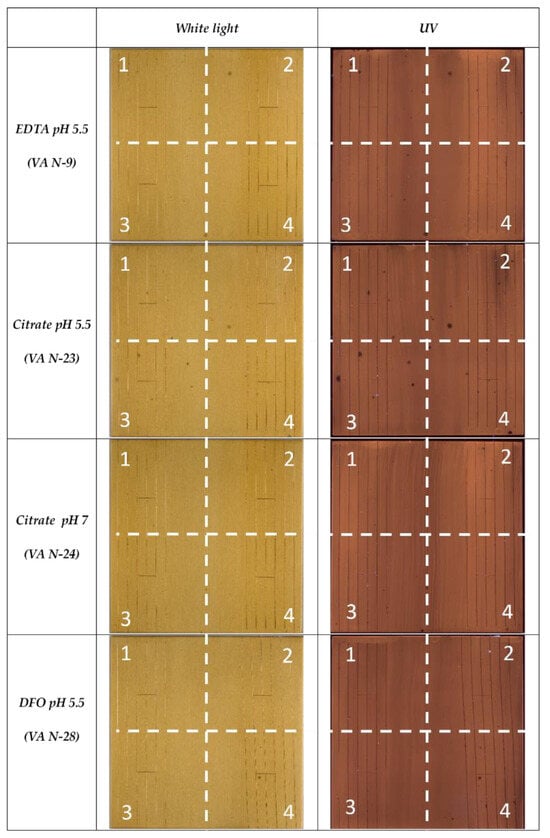

3.1. White Light Imaging

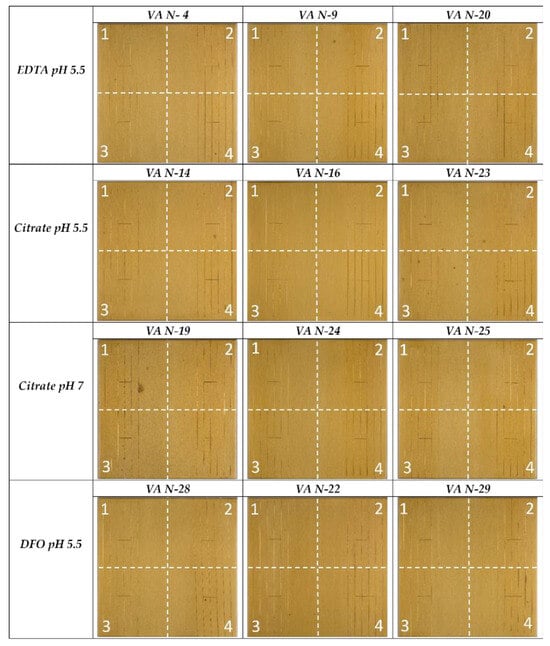

The comparison by visual observation between the cleaned areas of the coupons and the uncleaned control spot on each sample shows two behaviors. Although it was not possible to quantify corrosion removal, it can be noticed that the vertical scratched lines appear brighter after cleaning in all cases in comparison to the control spot, which indicates corrosion removal except for the coupon VA N-19, which is more heavily corroded (Figure 3).

Figure 3.

General views under white light of all coupons and of different series after cleaning (zone 1 = 15 min; zone 2 = 10 min; zone 3 = 5 min; zone 4 = control spot).

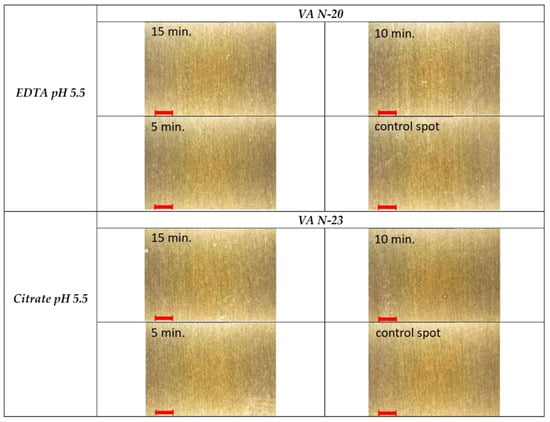

On the other hand, the unscratched lacquer zone does not show a significant change in surface appearance after cleaning (Figure 3 and Figure 4).

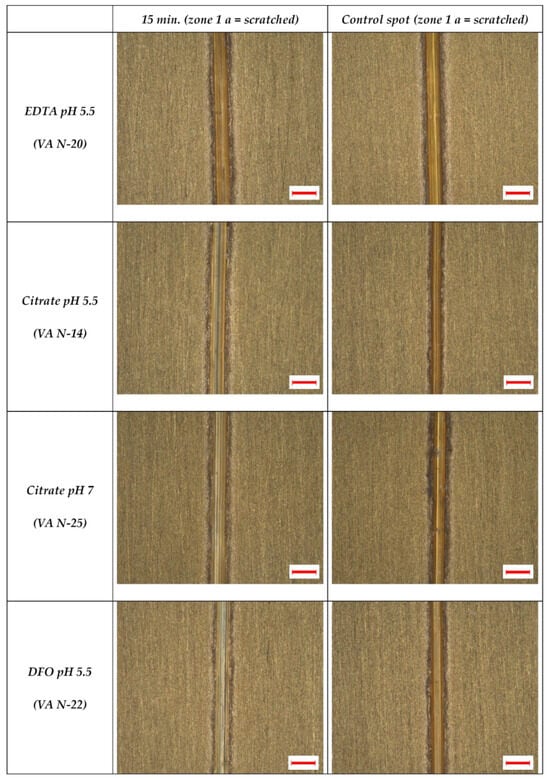

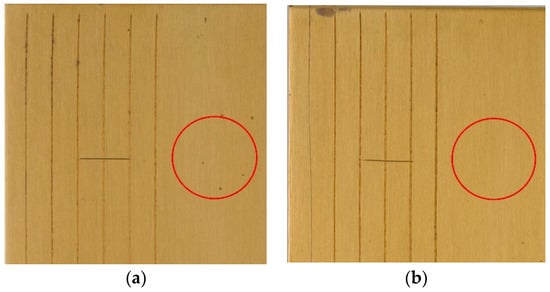

Figure 4.

Microscopic imaging, representative sample of each series, scratched zone 1 cleaned for 15 min compared to the control spot of the same sample (scale = 200 µm).

3.2. Microscopic Imaging

The cleaning efficiency of the four different tested gel systems was confirmed by microscopic observations. Although it is difficult to quantify corrosion removal in the scratches, it can be said that all cleaning systems were able to remove the oxidation layer after at least 15 min, leaving a brighter metal surface. In some cases, the cleaning gel did not completely reach the corroded metal in the scratches, showing that, in practice, the use of a small brush is useful to ensure good contact with the surface to be cleaned. This can be seen in Figure 4: here, it was observed that in some areas of the scratches, the thin oxidation layer is still present.

However, a modification of lacquer topography was not observed (in terms of porosity and other morphological features), as can be observed in Figure 5 and Figure 6.

Figure 5.

Microscopic imaging of a representative sample of the series EDTA pH 5.5 and citrate pH 5.5, all zones of interest (unscratched lacquer zone b), original magnification ×50 (scale = 1 mm).

Figure 6.

Microscopic imaging of a representative sample of the series citrate pH 7 and DFO pH 5.5, all zones of interest (unscratched lacquer zone b), original magnification ×50 (scale = 1 mm).

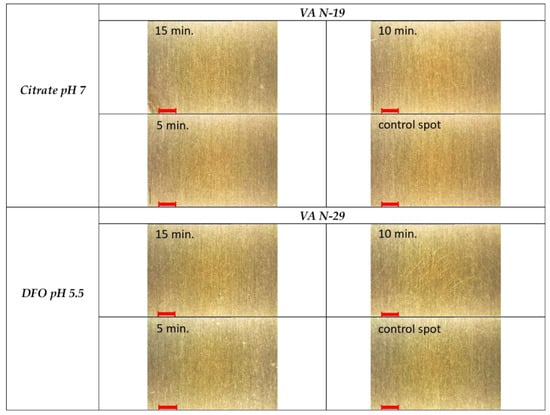

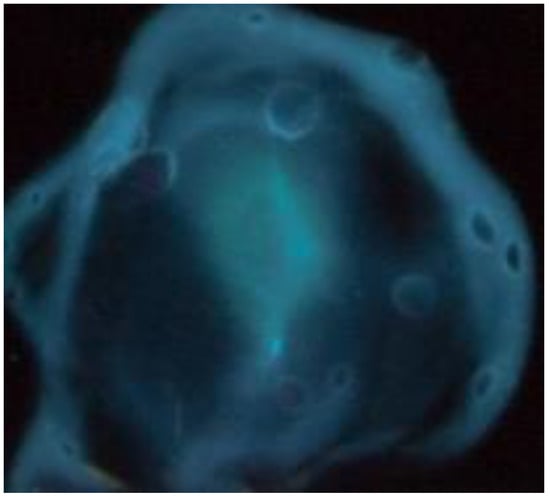

3.3. UV Fluorescence

UV fluorescence intensity did not evolve significantly before and after cleaning (Figure 7). Fluorescent residues of the gel were not detected on the coupons after cleaning. Reference imaging of a xanthan gum gel shows a bluish, easily detectable, fluorescence color (Figure 8).

Figure 7.

General views under white light and UV illumination of representative coupons for each tested system after cleaning (zone 1 = 15 min; zone 2 = 10 min; zone 3 = 5 min; zone 4 = control spot).

Figure 8.

Fluorescence under UV illumination (365 nm) of a drop of xanthan gum gel (1.5% w/w) applied to brass (CuZn36).

The presence of gel residues in the scratches was not revealed, but UV imaging might not be powerful enough for the detection of very small amounts [30].

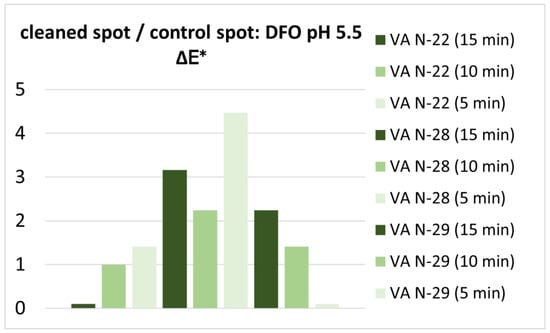

3.4. Color Measurements

Triplicates of color measurements were carried out on the unscratched lacquer surfaces (zone b in Figure 2). The average value for the cleaned areas (zones 1b to 3b) was compared to the average value of the control spot (zone 4b) for each coupon.

Even though the reproducibility of the measurement for each zone of interest is high, it appears that there can be variations between control spots and zones to be cleaned. This is probably due to both different lacquer thicknesses and, in some cases, to local pitting (Figure 9a,b). These phenomena could also explain why the data are not consistent for one cleaning series and why it is not possible to systematically correlate the results with the application time of the gel (Figure 10, Figure 11, Figure 12, Figure 13 and Figure 14).

Figure 9.

(a) pitted lacquer surface on VA N-9 (zone 1 b uncleaned control spot); (b) unpitted lacquer surface on sample VA N-20 (zone 1 b uncleaned control spot).

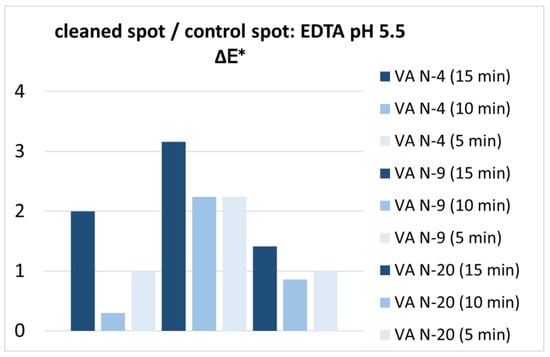

Figure 10.

Color difference expressed in ΔE* between the areas cleaned with EDTA and the uncleaned control spot.

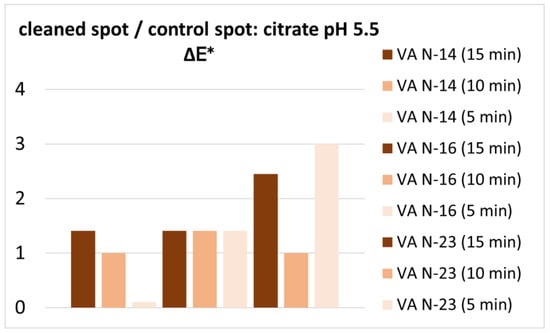

Figure 11.

Color difference expressed in ΔE* between the areas (zone b) cleaned with citrate (pH 5.5) and the uncleaned control spot.

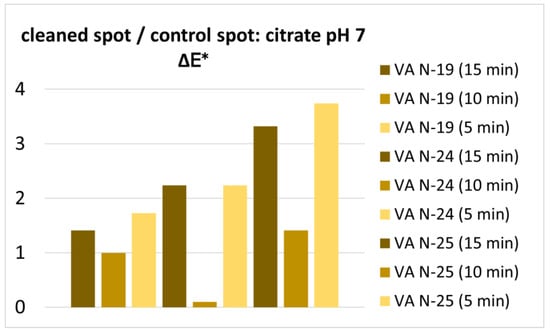

Figure 12.

Color difference expressed in ΔE* between the areas (zone b) cleaned with citrate (pH 7) and the uncleaned control spot.

Figure 13.

Color difference expressed in ΔE* between the areas (zone b) cleaned with DFO and the uncleaned control spot.

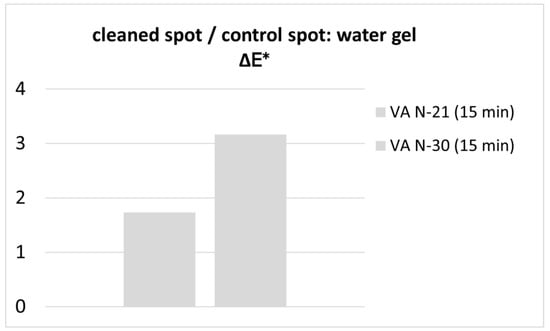

Figure 14.

Color difference expressed in ΔE* between the areas (zone b) cleaned with the water gel and the uncleaned control spot.

Furthermore, it appears that the cleaning systems do not induce a color difference, which is significantly higher than the color difference induced by a water gel that does not contain any active cleaning agent (Figure 14). Here, it can also be observed that the color difference for the water gel differs from one coupon to another which corresponds again to natural heterogeneities between the control spot and surface to be cleaned. It can be concluded that only much higher and more systematic color differences within each series would be significant and would make it possible to assess the different cleaning systems regarding application times.

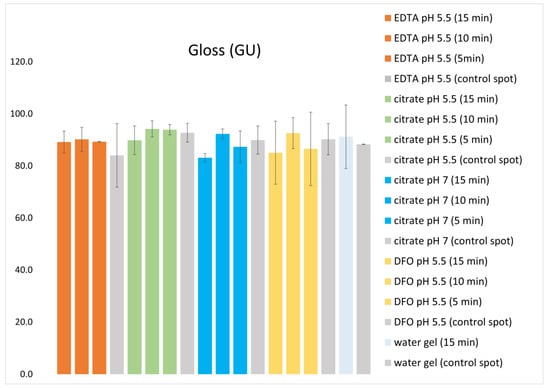

3.5. Gloss Measurements

Gloss measurements do not reveal any significant or conclusive differences between the cleaned zones and the uncleaned control spots (Figure 15). Also, there is no visible trend or correlation between gel application time and the results of gloss measurements. All measured surfaces stay in the range of a glossy finish (>70 GU). The water gel does not induce a lower gloss modification than the gels containing complexing agents. It can be said that they have similar effects on the lacquer.

Figure 15.

Gloss measurements for each cleaning system carried out on an unscratched lacquer area compared to the control spots (average values and standard deviation).

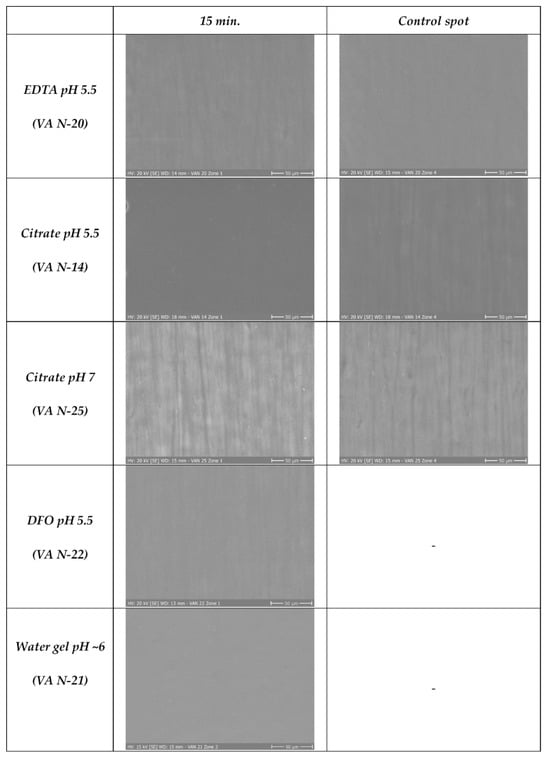

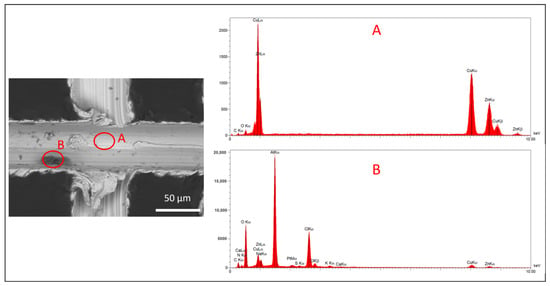

3.6. SEM-EDS

As no modification of the lacquer was observed under white light and UV illumination, additional SEM imaging was performed on representative samples of each series. The examination focused on the possible effects of the selected maximum application time (15 min) SE imaging did not reveal any alteration of the lacquer (microcracks, porosities, or cleaning residues) on the cleaned zones when compared to the uncleaned control spots or the zones cleaned with the water gel (Figure 16). Slight variations in the surface topography—which can be assessed by secondary electron imaging—can be attributed to the application of the lacquer and not to the cleaning treatment. BSE imaging did not provide any additional information.

Figure 16.

Secondary electron image of each cleaning system compared to uncleaned control spots (magnification ×450).

SEM-EDS analysis of scratched brass control spots shows a small peak of oxygen, which might be due to the presence of expected copper oxides (Figure 17, spectrum A). Somehow, no noticeable difference in the intensity of the oxygen peak was detected when comparing cleaned and uncleaned metal areas. This is probably due to the fact that the oxide layer is extremely thin in both cases. Furthermore, local surface contamination—characterized by the presence of chlorine, aluminum, sodium, and potassium—was also observed (Figure 17, spectrum B). This could be due to pollution of the climatic chamber and dust deposits. Contamination during cleaning of the bare metal with pumice powder before lacquering was not clearly identified: no silicon was detected, which appears to be the main component with the highest peak intensity of the analyzed pumice sample.

Figure 17.

Back-scattered image of coupon VA N-14 (zone a of the control area) and EDS analysis of the scratched brass. Spot A: smooth metal surface; spot B: deposit.

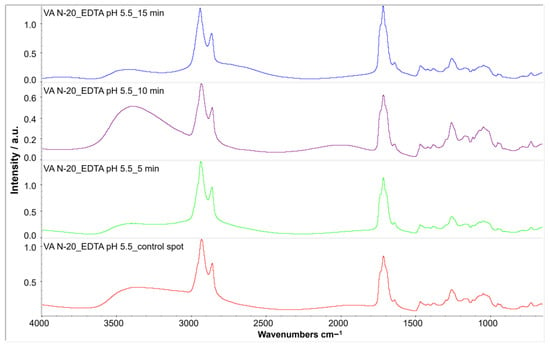

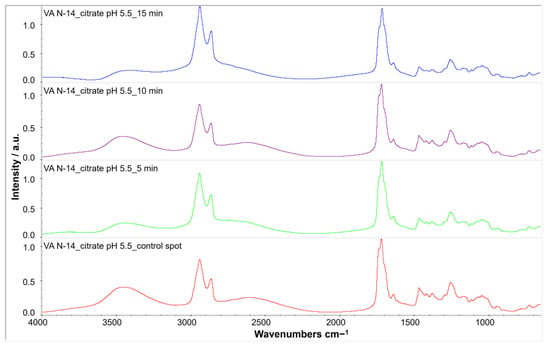

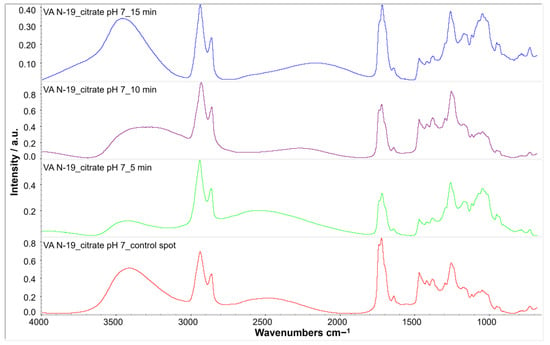

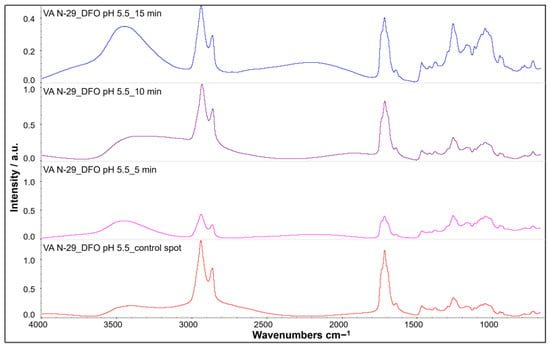

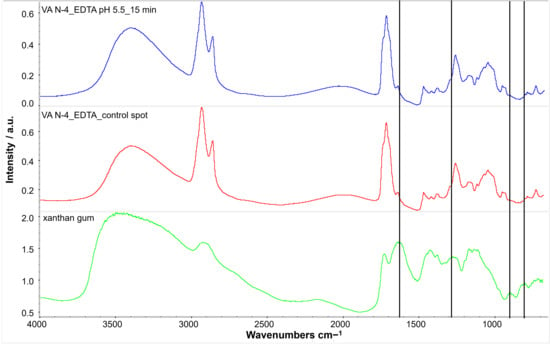

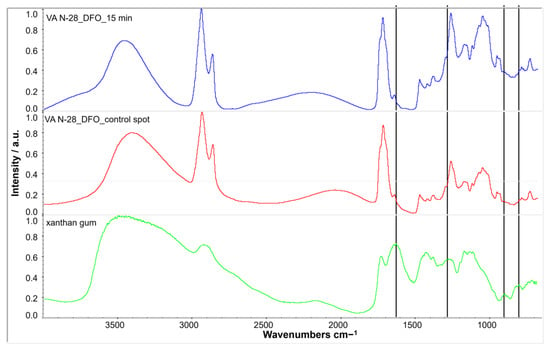

3.7. FTIR

The shellac coating on the brass did not show any significant chemical modifications due to cleaning with the four tested systems. No differences in the main peaks of the FTIR spectra collected before and after cleaning were observed except for a very slight shift of peak at 1714 cm−1.

Changes related to the use of a higher pH—7 instead of 5.5 with sodium citrate—were not detected (Figure 18, Figure 19, Figure 20 and Figure 21).

Figure 18.

FTIR spectra of VA N-20 after cleaning with EDTA pH 5.5: after 15 min (blue spectrum), 10 min (purple spectrum), 5 min (green spectrum) and compared to the uncleaned control spot (red spectrum).

Figure 19.

FTIR spectra of VA N-14 after cleaning with citrate pH 5.5: after 15 min (blue spectrum), 10 min (purple spectrum), 5 min (green spectrum) and compared to the uncleaned control spot (red spectrum).

Figure 20.

FTIR spectra of VA N-19 after cleaning with citrate pH 7: 15 min (blue spectrum), after 10 min (purple spectrum), 5 min (green spectrum) and compared to the uncleaned control spot (red spectrum).

Figure 21.

FTIR spectra of VA N-29 after cleaning with DFO: after 15 min (blue spectrum), 10 min (purple spectrum), 5 min pink spectrum) and compared to the uncleaned control spot (red spectrum).

A comparison of the characteristic peaks of shellac and xanthan gum to identify possible cleaning residues shows that some infrared bands can overlap, especially at 2920, 1724, 1374, and 1165 cm−1 (Table 5). In contrast, bands at 1624, 1275, 895, and 795 cm−1 appear to be characteristic of the gelling medium. It must be noted that the spectrum of the xanthan gum was acquired using the same mode (%R) and parameters as the spectra of the lacquered coupons before and after cleaning to be able to accurately compare the spectra of the different materials studied.

Table 5.

Characteristic peaks of shellac [42] and xanthan gum reference sample.

In fact, characteristic bands of xanthan gum were barely identified in the spectra of the system after cleaning (Figure 22). In isolated cases, a slight broadening of the peak area at 1419 and 1732 cm−1 was observed after treatment, but distinct peaks corresponding to the presence of xanthan gum were not identified (Figure 23). It can be deduced that no cleaning residues due to the use of xanthan gum were detected, which indicates that rinsing was successful. However, this conclusion applies only to the intact, unscratched lacquer surface, as FTIR analysis was not performed on the mechanically damaged areas, which are more difficult to rinse.

Figure 22.

Comparison of FTIR spectra from a reference sample of xanthan gum (green spectrum) and coupon VA N-4: uncleaned control spot 4 (red spectrum) and zone cleaned with an EDTA gel for 15 min (blue spectrum): characteristic peaks of xanthan gum (vertical lines) are not found in the cleaned sample.

Figure 23.

Comparison of FTIR spectra from a reference sample of xanthan gum (green spectrum) and coupon VA N-28: uncleaned control spot 4 (red spectrum) and zone cleaned with a DFO gel for 15 min (blue spectrum): characteristic peaks of xanthan gum (vertical lines) are not found in the cleaned sample.

4. Discussion

No modification of the surface topography and porosity was observed on the lacquer after treatment with the selected cleaning systems at magnifications ×50, ×230 (white light microscopy) and ×35, ×50 and ×450 (SE and BSE imaging) even when the gel was left up to 15 min FTIR analysis did not reveal any difference in the composition of the shellac coating when comparing the control spots with the cleaned areas. Observation under UV illumination did not show any changes in the fluorescence of the lacquer, which might be characteristic of superficial dissolution of a more oxidized coating layer or the presence of xanthan gum residues. FTIR analysis did not reveal possible residues of xanthan gum-based gels either. However, the performance of the gel clearance procedure was investigated by SEM and FTIR only for the smooth, unscratched zones of interest.

Possible limitations of the study must be considered and might explain a better resistance of the shellac coating than expected: artificial aging might not have induced a strong enough degradation. Color modification of orange dewaxed shellac occurred after the first step of the artificial aging protocol and intensified after the two last steps of the artificial aging procedure.

With photochemical aging, the a* and b* values of the surface color evolved towards yellow and red, whereas the a* and b* values evolved to a colder color (green-blue) after exposure to humidity.

However, expected modifications of the IR spectra induced by this aging method were not observed. Modifications caused by photochemical aging include considerable increases in absorbance (especially at ~3200–3400 cm−1), increases and shifts of the bands between ~1700–1725 cm−1, increase in absorbance at ~1370–1380 cm−1 and increases in the fingerprint region between ~400 and 1500 cm−1 [50]. These changes were not clearly identified. It has been shown by a former study on de-waxed unbleached shellac that along polymerization, aleuritic acid formation occurs at the same time scale during photoaging [55]. The formation of aleuritic acid was not observed in our case, and this might be due to a relatively short exposure to light.

The poor degradation of the lacquer—and hence the absence of significative difference between superficial and deeper layers of the coating—could also explain why no changes in UV fluorescence were detected after cleaning.

However, good resistance of shellac-coated brass was also previously observed in the framework of a master thesis [23]. Here, a batch of samples of similar composition (CuZn36 brass coated with orange shellac from Kremer Pigmente, Aichstetten, Germany) was exposed to ultra-violet radiation, and a second batch to wet and dry cycles, and only slight oxidation occurred after one-month exposure [23]. Even if the exposure time chosen for the present study was longer than the one used by Petit [23], the results obtained were comparable, with the difference that, in some cases, more pitting occurred on lacquered, non-scratched zones. From those observations, it can be concluded that harsher conditions are necessary to degrade this type of coating and should be tested in further studies.

In addition, shellac films obtained from dissolution in alcohol show notable hardening due to the continuing polymerization process by esterification [33]. A hypothesis is that the possible diffusion of copper ions into the deeper layer of the film might catalyze polymerization and induce insolubility of the coating.

Also, it needs to be emphasized that these results were obtained for orange shellac, although reduction in solubility over time has also been observed for bleached shellac [56]. Depending on the bleaching process, possible residues of chlorine might decrease the shellac’s chemical stability and influence its sensitivity to cleaning systems. A higher acid value of the coating as well as lower water vapor permeability was observed for shellac films bleached with sodium hypochlorite [57].

5. Conclusions

In the framework of this study, gelled systems, including traditional and innovative chelating agents, were tested for the first time for the cleaning of corroded lacquered brass with the aim of assessing their effect on the organic coating. The aim of these treatments is to remove corrosion products without damaging the ancient lacquer, which is part of the object’s materiality and history. Comparative cleaning with xanthan gum-based gels containing EDTA-Na2, sodium citrate, and deferoxamine solutions was carried out on lacquered brass mock-ups. Equivalent molar concentrations of chelating agents were selected based on the maximum EDTA-Na2 concentration used in practice.

Four different protocols—of which three are frequently used in conservation practice for the removal of corrosion—were tested. The goal of this study was to assess their compatibility with the preservation of orange shellac lacquer, dewaxed by filtering. This type of coating is representative of surface finishes, which can be found on both technical and decorative brass objects. The results of this study show that no modification or degradation due to the cleaning could be identified for a contact time of up to 15 min for all cleaning systems, including the bio-sourced chelating agent, deferoxamine. The use of an adequate pH range for cleaning and rinsing certainly plays an important role. The results of this study show that deferoxamine can be an adequate alternative to currently used chelating agents, although its effectiveness for corrosion removal could not be fully quantified in this case [30]. The rinsing of xanthan-based gels with a cotton swab proved to be satisfying on smooth lacquer surfaces.

A continuous application was selected to improve reproducibility. Application times longer than 15 min were not experimented on as the goal was to validate treatment durations according to conservation practice. A possible limitation of the tested protocol is the fact that this maximum duration could also be achieved by intermediary removal and renewal of the gel, but with less reproducible results. Furthermore, this study did not investigate the possible difference in the cleaning effect and consequence on both the corroded metal and the coating when using another application method like constantly stirring the gel with a brush on the surface. Nevertheless, shorter duration times are expected when using this application technique. An interesting perspective would also be to study the effect of these cleaning systems on other grades of shellac, like bleached coatings, which might be more sensitive to cleaning. The study confirms the possible application of deferoxamine for the cleaning of lacquered brass. In the future, it would be interesting to confirm the results of this study and investigate the cleaning efficiency of this bio-sourced alternative with tests on real cases using non-invasive characterization techniques for monitoring.

Author Contributions

Conceptualization, methodology: J.S., M.T.G., L.B. and E.J.; validation: J.S., M.T.G., L.B. and E.J.; formal analysis and investigation: J.S., M.T.G. and L.B.; writing—original draft preparation: J.S.; writing—review and editing: J.S., M.T.G., L.B., E.J. and L.C.; visualization: J.S.; supervision: J.S.; project administration and funding acquisition: J.S.; resources: E.J. and L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Haute Ecole Spécialisée de Suisse Occidentale, grant number 117969/DAV-RAD22-01, and co-funded by Haute Ecole Arc conservation-restauration.

Data Availability Statement

The datasets presented in this article are not readily available because the data are part of an ongoing study. Requests to access the datasets should be directed to Julie Schröter and Laura Brambilla.

Acknowledgments

The authors would like to thank Catherine Cséfalvay (Haute Ecole Arc, Neuchâtel, Switzerland, surface engineering) for the SEM-EDS analyses. We also would like to thank Stephan Ramseyer (Haute Ecole Arc, Neuchâtel, Switzerland, surface engineering) for his technical advice.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Breton Le, J. La conservation et la restauration des instruments scientifiques des XVIIIème et XIXème siècle: Un terrain de recherches et de valorisation en histoire des sciences. Bull. Sabix 1997, 18, 17–26. [Google Scholar] [CrossRef]

- Brenni, P. From workshop to factory: The evolution of the instrument-making industry, 1850–1930. In The Oxford Handbook of the History of Physics; Buchwald, J.Z., Fox, R., Eds.; Oxford University Press: Oxford, UK, 2013; pp. 584–650. [Google Scholar]

- Schröter, J. Les Vernis or sur les Bronzes d’Ameublement: Acteurs, Pratiques et Marchés à Paris au XIXe Siècle. Ph.D. Thesis, Departement of History of Art, Sorbonne University, Paris, France, 2021. [Google Scholar]

- Schröter, J.; Michel, A.; Mirabaud, S.; Brambilla, L.; Paris, C.; Bellot-Gurlet, L. Transparent varnishes on copper alloys dating from the 19th century: Characterization and identification strategies. In Metal 2019, Proceedings of the Interim Meeting of the ICOM-CC Metals Working Group, Neuchâtel, Switzerland, 2–6 September 2019; Chemello, C., Brambilla, L., Joseph, E., Eds.; ICOM-CC, Pulido & Nunes: Neuchâtel, Switzerland, 2019; pp. 58–66. [Google Scholar]

- Long, D. The treatment of false gilding: A case study. In Gilded Metals: History Technology and Conservation; Drayman-Weisser, T., Ed.; Archetype: London, UK, 2000. [Google Scholar]

- Lanterna, G.; Giatti, A. Caratterizzazione non invasiva delle vernici da ottone degli strumenti scientifici: Ricette storiche, realizzazione di provini verniciati, ricerca analitica e applicazioni “in situ” su strumenti storici. OPD Restauro Riv. Dell’opificio Delle Pietre Dure Lab. Restauro Firenze 2014, 26, 165–180. [Google Scholar]

- Schröter, J.; Foasso, C.; Bellot-Gurlet, L.; Brambilla, L. Investigating five totalizing counters manufactured by the Alphonse Darras company of the CNAM collections in Paris. Conserv. Patrim. 2023, 44, 90–102. [Google Scholar] [CrossRef]

- Molina, M.T.; Cano, E.; Leal, J.; Fort, R.; Álvarez de Buergo, M.; Ramírez-Barat, B. Protective coatings for metals in scientific—technical heritage: The collection of the Spanish National Museum of Science and Technology (MUNCYT). Heritage 2023, 6, 2473–2488. [Google Scholar] [CrossRef]

- Schröter, J. LacCA Project, Scientific Report; unpublished work; Haute Ecole Arc: Neuchâtel, Switzerland, 2020. [Google Scholar]

- Keene, S. Instruments of hhistory: Appearance and evidence. The restoration of scientific instruments. In Proceedings of the Workshop Held in Florence, December 14–15, 1998; Manetti, L., Istituto e Museo di Storia Della Scienza, Opificio Delle Pietre Dure, Eds.; Le Lettere: Florence, Italy, 2000; pp. 57–68. [Google Scholar]

- Brenni, P. Cleaning and relacquering of Brass. Bull. Sci. Instrum. Soc. 1986, 10, 102–103. [Google Scholar]

- Brenni, P. Restoration or repair? The dilemma of ancient scientific instruments. In Reversibility-Does It Exist? Oddy, W.A., Carroll, S., Eds.; British Museum Occasional Paper: London, UK, 1999; pp. 19–24. [Google Scholar]

- Pavlopoulou, L.-C.; Watkinson, D. The degradation of oil painted copper surfaces, Studies in conservation. Stud. Conserv. 2006, 51 (Suppl. S1), 55–65. [Google Scholar] [CrossRef]

- Qiu, P.; Leygraf, C. Initial oxidation of brass induced by humidified air. Appl. Surf. Sci. 2011, 258, 1235–1241. [Google Scholar] [CrossRef] [PubMed]

- Scott, D. Copper and Bronze in Art: Corrosion, Colorants, Conservation; Getty Publications: Los Angeles, CA, USA, 2002; ISBN 0-89236-638-9. [Google Scholar]

- Thackray, A. A methodology for the conservation of furniture mounts. VA Conserv. J. 2014, 62. Available online: http://www.vam.ac.uk/content/journals/conservation-journal/autumn-2014-issue-62/a-methodology-for-the-conservation-of-furniture-mounts/ (accessed on 1 May 2024).

- Birnie, L. Special finishes on non-ferrous metals at the National Maritime Museum. In Metal Plating and Patination; La Niece, S., Craddock, P., Eds.; Butterworth-Heinemann: Oxford, UK, 1993; pp. 148–154. [Google Scholar]

- Cook, C.J. Lacquers for instrument parts. Bull. Sci. Instrum. Soc. 1997, 52, 36. [Google Scholar]

- Steenhorst, P. Schellac varnishing on brass. A practical guide. Bull. Sci. Instrum. Soc. 2008, 96, 34–38. [Google Scholar]

- Granato, M.; Le Guet Tully, F. Les principes de la restauration d’instruments scientifiques: Le cas du cercle méridien Gautier de l’observatoire de Rio de Janeiro. Situ Le Patrim. Sci. 2009, 10. [Google Scholar] [CrossRef][Green Version]

- Thomson, C. Last but not least, examination and interpretation of coatings on brass hardware. In Wooden Artifacts Group Postprints, 3–8 June 1991, Albuquerque, New Mexico; American Institute for Conservation of Historic and Artistic Works: Washington, DC, USA, 1991. [Google Scholar]

- Thombare, N.; Kumar, S.; Kumari, U.; Sakare, P.; Yogi, R.K.; Prasad, N.; Sharma, K.K. Shellac as a multifunctional biopolymer: A review on properties, applications and future potential. Int. J. Biol. Macromol. 2022, 215, 203–223. [Google Scholar] [CrossRef] [PubMed]

- Petit, M. Evaluation de l’impact des traitements de nettoyage de la corrosion du laiton sur le vernis gomme-laque des instruments scientifiques. Master’s Thesis, Haute Ecole Arc, Neuchâtel, Switzerland, 2020. [Google Scholar]

- Wolbers, R. Cleaning Painted Surfaces. Aqueous Methods; Archetype Publications Ltd.: London, UK, 2000. [Google Scholar]

- Geffroy, A.-M. Un Théodolite de la fin du XIXe siècle (Musée des Arts et Métiers). Master’s Thesis, Institut National du Patrimoine, Paris, France, 2004. [Google Scholar]

- Jeanneret, R. Approche pluridisciplinaire pour le traitement de conservation-restauration d’un quart de cercle mural du 18eme siècle, du Musée des Confluences de Lyon. Master’s Thesis, Haute Ecole Arc, Neuchâtel, Switzerland, 2010. [Google Scholar]

- Jourdain-Treluyer, V. L’EDTA et ses sels sodiques, quelques précisions. Conserv.-Restaur. Des Biens Culturels. Cah. Tech. 1991, 3, 57–61. [Google Scholar]

- Cremonesi, P. Rigid Gels and enzyme cleaning. In New Insights into the Cleaning of Paintings, Proceedings of the Cleaning 2010 International Conference, Washington, DC, Universidad Politecnica de Valencia and Museum Conservation Institute; Smithsonian Institution Scholarly Press: Washington, DC, USA, 2012; pp. 179–184. [Google Scholar]

- Cremonesi, P. L’uso dei solventi organici nella pulitura di opere policrome. In I Talenti—Metodologie, tecniche e formazione nel mondo del restauro; Il Prato: Saonara, Italy, 2004; volume 7. [Google Scholar]

- Cuvillier, L. Développement et Evaluation D’Hydrogels Durables Pour Le Nettoyage Microbien D’Objets Historiques en Métal. Ph.D. Thesis, University of Neuchâtel, Neuchâtel, Switzerland, 2024. [Google Scholar]

- Albano, M.; Grassi, S.; Fiocco, G.; Invernizzi, C.; Rovetta, T.; Licchelli, M.; Marotti, R.; Merlo, C.; Comelli, D.; Malagodi, M. A preliminary spectroscopic approach to evaluate the effectiveness of water- and silicone-based cleaning methods on historical varnished brass. Appl. Sci. 2020, 10, 3982. [Google Scholar] [CrossRef]

- Rivers, S.; Umney, N. Conservation of Furniture; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar]

- Farag, Y.; Leopold, C.S. Physicochemical Properties of Various Shellac Types. Dissolution Technol. 2009, 16, 33–39. [Google Scholar] [CrossRef]

- Elie-Lefebvre, D.; Wolbers, R.; Torok, E.; Auffret, S.; Anderson, M. Recent Investigations into a Mechanical–Chemical Method for Removing Brass Corrosion from Furniture Brass; AIC Wooden Artifacts Group Postprints: Albuquerque, NM, USA, 2012; pp. 59–66. [Google Scholar]

- Dorscheid, J.; Considine, B.; Khanjian, H.; Wolfe, J.; Heginbotham, A. The treatment of a longcase clock attributed to Jean-Pierre Latz: Alternative approaches to the removal of copper corrosion products on Boullestyle marquetry. Technè 2020, 49, 28–33. [Google Scholar] [CrossRef]

- Paulin, M.-A.; Leblanc, F. Note sur la restauration du mobilier Boulle du musée du Louvre: Le nettoyage des marqueteries métalliques. Technè 2013, 38, 101–103. [Google Scholar] [CrossRef]

- Passaretti, A. Greener Perspective in Conservation Science. Design, Characterization and Evaluation of Bio-Formulations for the Cleaning of Altered Indoor Historical Metal Heritage. Ph.D. Thesis, University of Neuchâtel, Neuchâtel, Switzerland, 2024. [Google Scholar]

- Cuvillier, L.; Passaretti, A.; Guilminot, E.; Joseph, E. Agar and chitosan hydrogels’ design for metal-uptaking treatments. Gels 2024, 10, 55. [Google Scholar] [CrossRef] [PubMed]

- Passaretti, A.; Cuvillier, L.; Sciutto, G.; Guilminot, E.; Joseph, E. Biologically derived gels for the cleaning of historical and artistic metal heritage. Appl. Sci. 2021, 11, 3405. [Google Scholar] [CrossRef]

- Cuvillier, L.; Passaretti, A.; Guilminot, E.; Joseph, E. Testing of the siderophore deferoxamine amended in hydrogels for the cleaning of iron corrosion. Eur. Phys. J. Plus. 2023, 138, 569. [Google Scholar] [CrossRef]

- Londe, A. Aide-Mémoire Pratique de Photographie; Librairie J.-B. Baillière et Fils: Paris, France, 1893. [Google Scholar]

- Truffa Giachet, M.; Schröter, J.; Brambilla, L. Characterization, and identification of varnishes on copper alloys by means of UV imaging and FTIR. Coatings 2021, 11, 298. [Google Scholar] [CrossRef]

- NF EN ISO 17872; Paints and Varnishes—Guidelines for the Introduction of Scribe Marks through Coatings on Metallic Panels for Corrosion Testing. International Organization for Standardization: Geneva, Switzerland, 2020.

- Tator, K.B. Coating Deterioration, ASM Handbook, Volume 5B, Protective Organic Coatings; ASM International: Almere, Netherlands, 2015. [Google Scholar]

- Carlyle, L.; Townsend, J.H.; Hackney, S. Triammonium citrate: An investigation into its application for surface cleaning. In Dirt and Pictures Separated; Presented at a conference by UKIC and the Tate, Gallery; Townsend, J.H., Hackney, S., Eastaugh, N., Eds.; Institute for Conservation of Historic & Artistic Works: London, UK, 1990; pp. 44–48. [Google Scholar]

- Trémillon, B. Électrochimie Analytique et Réactions en Solution; Masson: Paris, France, 1993. [Google Scholar]

- Stavroudis, C.; Doherty, T.; Wolbers, R. A novel approach to cleaning using mixtures of concentrated stock solutions and a database to arrive at an optimal aqueous cleaning system. WAAC Newsl. 2005, 27, 17–28. [Google Scholar]

- Cremonesi, P. L’ambiente Acquoso per la Pulitura di Opere Policrome; Il Prato: Saonara, Italy, 2011. [Google Scholar]

- Wolbers, R.C.; Stavroudis, C.; Cushman, M. Aqueous methods for cleaning paintings. In Conservation of Easel Paintings, 2nd ed.; Stoner, J.H., Rushfield, R., Eds.; Routledge: London, UK, 2021; pp. 526–548. [Google Scholar]

- Galatis, P.; Boyatzis, S.; Theodorakopoulos, C. Removal of synthetic soiling mixture on mastic, shellac and Laropal® K80 coatings using two hydrogels. e-Preserv. Sci. 2012, 9, 72–83. [Google Scholar]

- Martínez-Weinbaum, M.; Maestro-Guijarroa, L.; Carmona-Quirogaa, P.M.; Siano, S.; Ciofini, D.; Castillejoa, M.; Oujjaa, M. In-depth structural and compositional assessment of aged terpenoid varnish layers by nonlinear optical microscopy. J. Cult. Herit. 2023, 62, 170–180. [Google Scholar] [CrossRef]

- Truffa Giachet, M.; Schröter, J.; Brambilla, L. The lacquering and relacquering of scientific instruments. An interdisciplinary approach to the characterization of layered coatings. In Proceedings of the 42nd Scientific Instrument Symposium, Palermo, Italy, 18–22 September 2023. [Google Scholar]

- ISO 2813:2014; Paints and Varnishes—Determination of Gloss Value at 20°, 60° and 85. International Organization for Standardization: Geneva, Switzerland, 2014.

- Keynan, D.; Hughes, A. Testing the Waters: New Technical Applications for the Cleaning of Acrylic Paint Films and Paper Supports. In The Book and Paper Group Annual, Proceedings of the AIC’s 41st Annual Meeting, Indianapolis, IN, USA, 29 May–1 June 2013; American Institute for Conservation: Whashington, DC, USA, 2013; Volume 32, pp. 43–51. [Google Scholar]

- Coelho, C.; Nanabala, R.; Ménager, M.; Commereuc, S.; Verney, V. Molecular changes during natural biopolymer ageing—The case of shellac. Polym. Degrad. Stab. 2012, 97, 936–940. [Google Scholar] [CrossRef]

- Sutherland, K. Bleached shellac picture varnishes: Characterization and case studies. J. Inst. Conserv. 2010, 33, 129–145. [Google Scholar] [CrossRef]

- Saengsod, S.; Limmatvapirat, S.; Luangtana-Anan, M. A new approach for the preparation of bleached shellac for pharmaceutical application: Solid method. Adv. Mater. Res. 2012, 506, 250–253. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).