Novel Approaches to Enhancing Sustainable Adhesive System Solutions in Contemporary Book Binding: An Overview

Abstract

1. Introduction

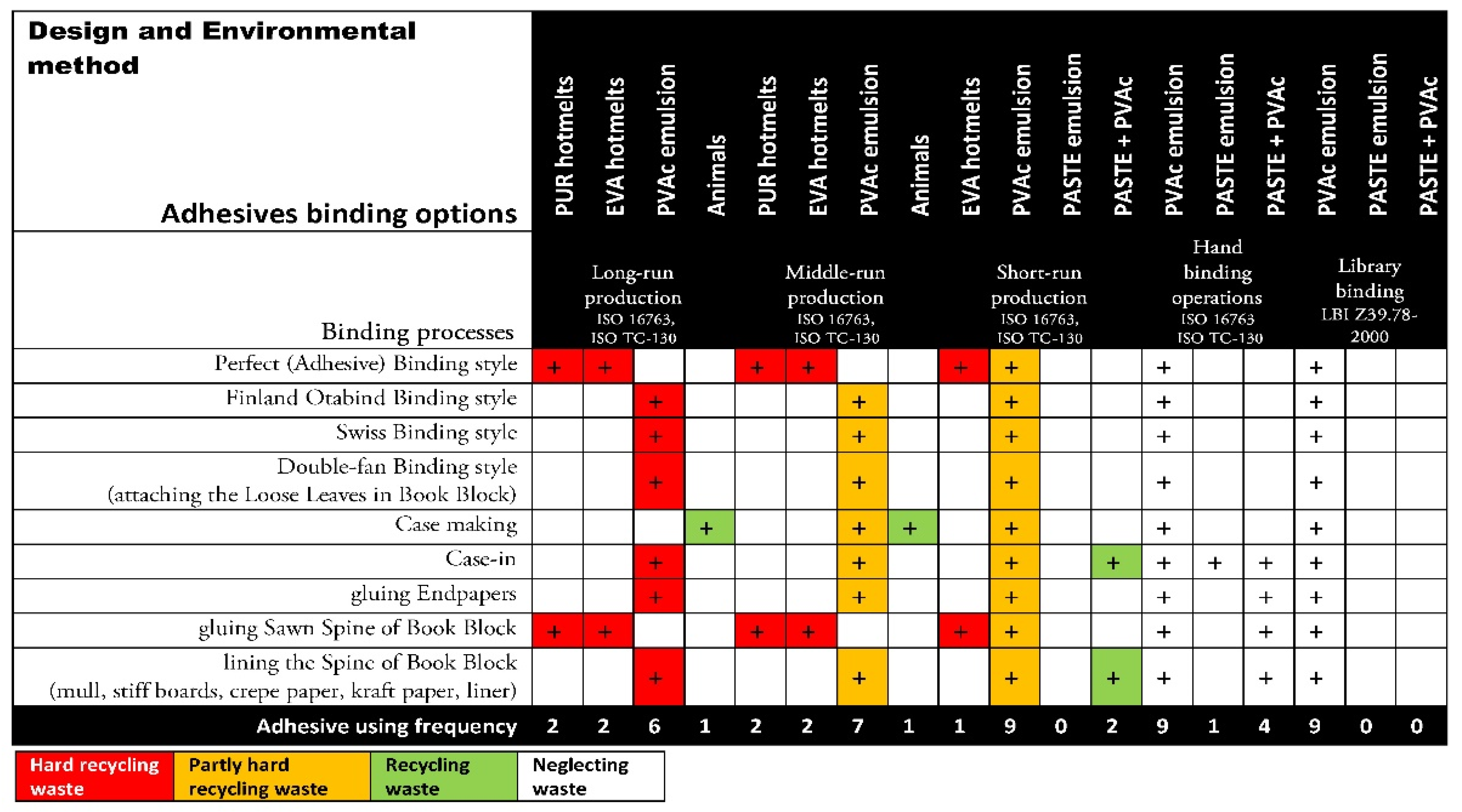

2. Library Binding vs. Publishing Binding

3. The Viewpoints in the Contemporary Binding Processes with Different Adhesive Solutions

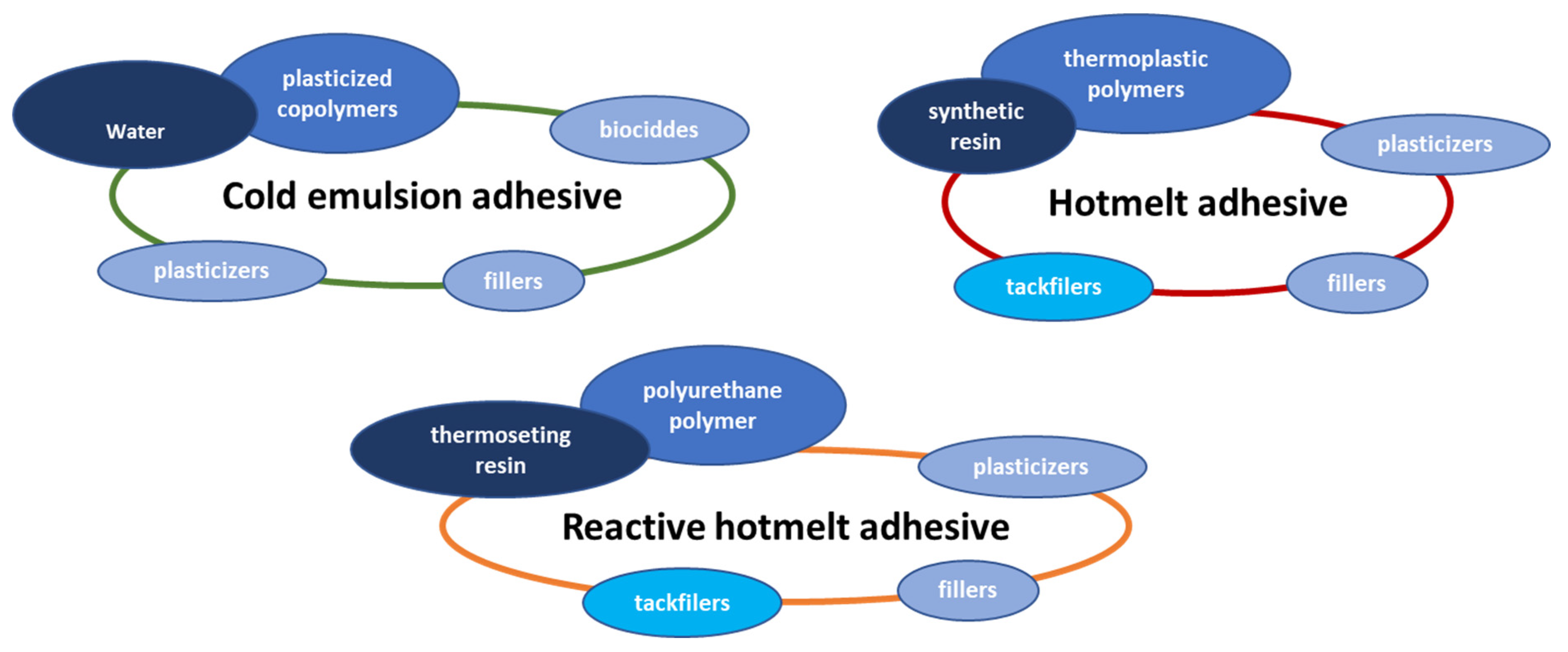

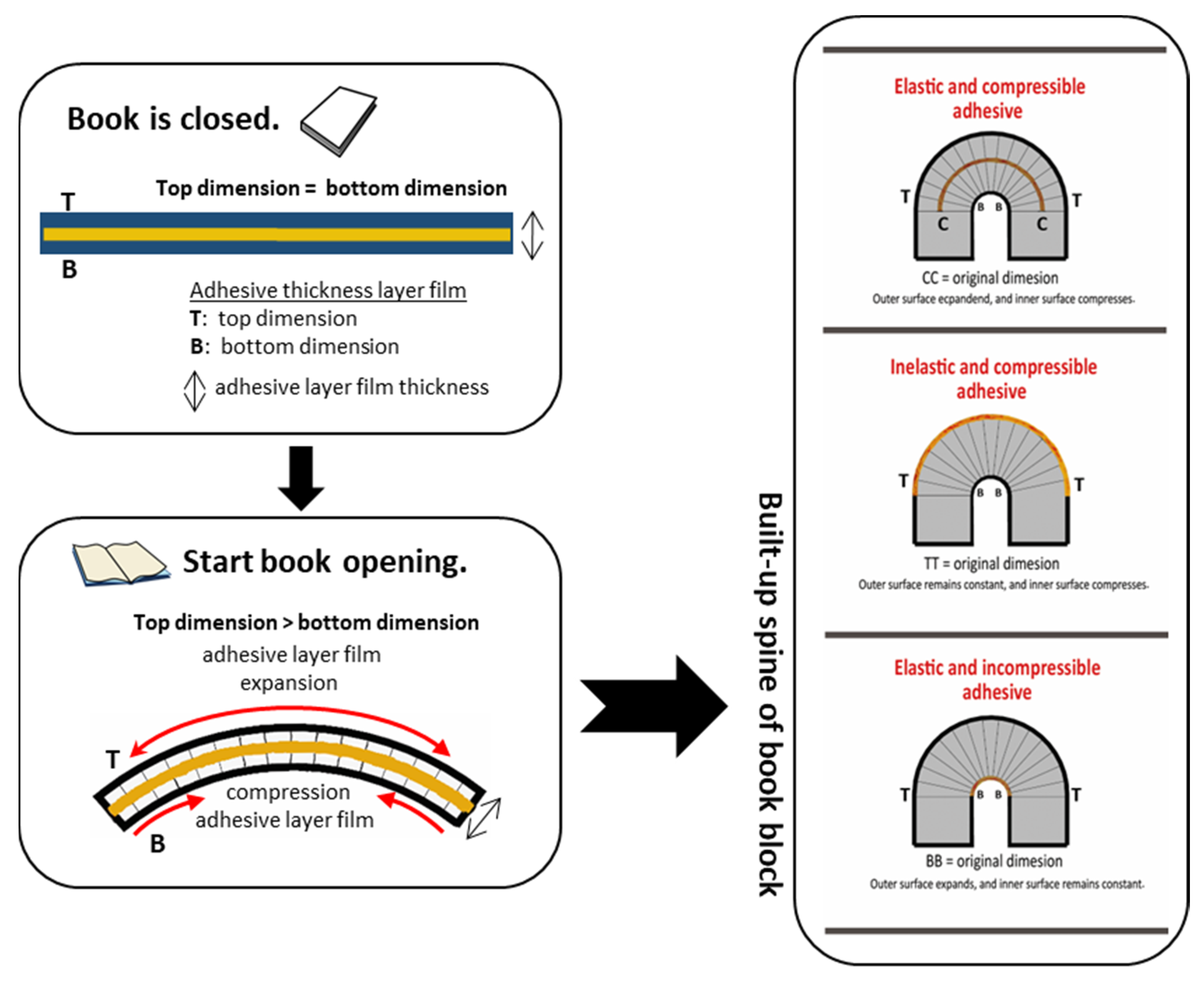

3.1. Comprehensive Guiding Principles of Adhesive Application in Bookbinding

- Drapability: this paper ability expresses the natural falling and draping of a paper sheet into the gutter margin of an opened book (paper stiffness declines perpendicularly to fiber grain direction and paper sheet bends more easily);

- Bindability: this paper ability expresses the successful binding with adhesive solutions and the paper cohesive strength which appears under stress conditions;

- Cohesiveness: this paper ability expresses a possessed paper energy on bond lines.

3.2. The Eco-Efficiency Guidelines for Adhesive Applications in Bookbinding

4. Eco-Efficiency Binding Style Enhancement and Advanced Adhesive System Solutions

Novel Advanced Adhesive System Solutions in Bookbinding (Modified Nano PVAc Adhesives)

5. Sustainability in Library Binding

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The Organization for Economic Cooperation and Development (OECD) Report “Trends Shaping Education 2022”. Available online: https://www.oecd.org/education/ceri/trends-shaping-education-22187049.htm (accessed on 1 September 2022).

- INTERGRAF-European Printing Industry Association. Available online: https://www.intergraf.eu/about-us (accessed on 31 August 2022).

- Joint Statement: No Christmas Without Books. Books are Essential for Europe’s Culture, Education and Economy 2021. Available online: https://www.intergraf.eu/images/pdf/2021-12%20Joint%20Statement%20FEP%20EIBF%20Intergraf.pdf?_t=1639063709 (accessed on 1 September 2022).

- Federation of European Publishers (2022) The Voice of European Publishers: European Book Publishing Statistics 2020. Available online: https://fep-fee.eu/European-Book-Publishing-1400 (accessed on 2 March 2022).

- INTEGRAF–European Federation for Print and Digital Communication (2020) Reynaud, L.: The European Graphic Industry: Regulatory Initiatives and Industry Trends. Available online: https://era-eu.org/wp-content/uploads/Intergraf.pdf (accessed on 8 April 2022).

- Towers, J. Sustainable Graphic Design for the Print Industry. Learning Deficiency. 2008. Available online: https://vdocuments.net/sustainable-graphic-design-for-the-print-sustainable-graphic-design-for-the.html?page=1 (accessed on 25 April 2022).

- INTEGRAF–European Federation for Print and Digital Communication (2021) INTERGRAF Members: INTERGRAF Activity Report 2020-2021. Available online: https://www.intergraf.eu/images/pdf/ActivityReport_2021_Final_Web.pdf (accessed on 12 March 2022).

- Koltun, P. Materials and sustainable development. Prog.-Nat. Sci. Mater. Int. 2010, 20, 16–29. [Google Scholar] [CrossRef]

- Guidelines Design for Environment Guidelines for the Design for Environment (DfE) (gdrc.org). Available online: https://gdrc.org/uem/lca/guidelines.html (accessed on 15 September 2022).

- Library Bindery. Available online: https://bindery.berkeley.edu (accessed on 26 September 2022).

- Dunn, C. Life in a Modern Library Bindery. Serials 1997, 10, 236–240. [Google Scholar] [CrossRef] [PubMed]

- Rebsamen Talking. Available online: https://www.btsb.com/2014/07/30/bound-in-accordance-to-industry-standards/ (accessed on 12 September 2022).

- Rebsamen Technically Speaking. Available online: http://mekatronicsinc.com/wp-content/uploads/2019/08/Adhesive-library-binding-books-Werner_1983.pdf (accessed on 26 September 2022).

- Rebsamen Binding Style. Available online: http://welboundtimes.blogspot.com/2006/11/werner-rebsamen-on-binding-methods.html (accessed on 26 September 2022).

- Library Binding Standards ANSI/NISO/LBI Z39.78-2000 (R2010). Available online: https://groups.niso.org/higherlogic/ws/public/download/18247/Z39.78-2000_%28R2010%29.pdf (accessed on 26 September 2022).

- de Souza Melaré, A.V.; González, S.M.; Faceli, K.; Casadei, V. Technologies and decision support systems to aid solid-waste management: A systematic review. Waste Manag. 2017, 59, 567–584. [Google Scholar] [CrossRef]

- ISO/DTR 19305; Graphic Technology-Framework for TC 130 Standards; International Organization for Standardization within print and publishing. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO16763:2016; Graphic Technology: Post-Press Requirements for Bound Products. International Organization for Standardization within print and publishing; International Organization for Standardization: Geneva, Switzerland, 2016.

- Johnson, A.W. Manual of Book Binding, 2nd ed.; Thames and Hudson: London, UK, 1998; pp. 41–43. [Google Scholar]

- Weston, H. Bookcraft: Techniques for Binding, Folding, and Decorating to Create Books and More, 1st ed.; Quarry Book: Gloucester, MA, USA, 2008; p. 8. [Google Scholar]

- Golden, A. Making Handmade Books: 100+ Bindings Structures & Forms, 1st ed.; Lark Crafts: Asheville, NC, USA, 2000; pp. 20–21. [Google Scholar]

- Clark, T. Book Binding with Adhesive, 1st ed.; McGraw-Hill Book Company Europe: London, UK, 1994; pp. 1–9. [Google Scholar]

- ISO 9706:1994; Information and Documentation-Paper for Documents-Requirements for Permanence. International Organization for Standardization: Geneva, Switzerland, 1994.

- ISO 186:2002; Paper and Board-Sampling to Determine Average Quality. International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 187:1990; Paper, Board and Pulps-Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. International Organization for Standardization: Geneva, Switzerland, 1990.

- ISO 302:2004; Pulps-Determination of Kappa Number. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 536:2019; Paper and Board-Determination of Grammage. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 1974:2012; Paper-Determination of Tearing Resistance-Elmendorf Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 4046-1:2016; Paper, Board, Pulps and Related Terms-Vocabulary-Part 1: Alphabetical Index. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 5127-1:1983; Documentation and Information-Vocabulary-Part 1: Basic Concepts. International Organization for Standardization: Geneva, Switzerland, 1983.

- ISO 6588-1:2020; Paper, Board and Pulps-Determination of pH of Aqueous Extracts-Part 1: Cold Extraction. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 10716:2022; Paper and board-Determination of Alkali Reserve. International Organization for Standardization: Geneva, Switzerland, 2022.

- Vukoje, M.; Rožić, M. Various valorization routes of paper intended for recycling—A review. Cellul. Chem. Technol. 2018, 52, 515–541. Available online: https://www.researchgate.net/publication/327601883_VARIOUS_VALORISATION_ROUTES_OF_PAPER_INTENDED_FOR_RECYCLING-A_REVIEW (accessed on 1 October 2022).

- Jermann, P. Reflections on Book Structures Part 3 (2008). Spine Control. Available online: https://www.pinterest.se/pin/93801604717783850/ (accessed on 26 September 2022).

- Brockman, W.; Geiss, P.L.; Klingen, J.; Schröder, K.B. Adhesive Bonding: Materials, Applications and Technology, 1st ed.; WILEY-VCH Verlag GmbH & Co.: Weinheim, Germany, 2009; p. 278. [Google Scholar]

- Thompson, B. 7th Miscellaneous topic. In A PIRA International Printing Guide-Printing Materials: Science and Technology, 2nd ed.; Pira Reference Series: USA Leatherhead, UK, 2004; pp. 297–320. [Google Scholar]

- Budzik, M.K.; Wolfahrt, M.; Reis, P.; Kozłowski, M.; Sena-Cruz, J.; Papadakis, L.; Nasr Saleh, M.; Machalicka, K.V.; Teixeira de Freitas, S.; Vassilopoulos, A.P. Testing mechanical performance of adhesively bonded composite joints in engineering applications: An overview. J. Adhes. 2022, 98, 2133–2209. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Adhesive Technology Handbook, 2nd ed.; William Andrew: Norwich, NY, USA, 2009; pp. 159–181. [Google Scholar]

- Niskanen, K. Paper Physics Book 16, 2nd ed.; Paperi ja Puu Oy: Uusimaa, Finland, 2008; pp. 159–181. [Google Scholar]

- Packham, D.E. Handbook of Adhesion, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005; pp. 14–32, 266–270. [Google Scholar]

- ISO 14005:2019; Environmental Management Systems-Guidelines for a Flexible Approach to Phased Implementation. International Organization for Standardization: Geneva, Switzerland, 2019.

- Enroth, L. Tools for Eco-Efficiency in the Printing Industry. Licentiate Thesis, Royal Institute of Technology, Stockholm, Sweden, 2001. [Google Scholar]

- World Business Council for Sustainable Development (WBCSD). Available online: https://www.wbcsd.org/Overview/About-us (accessed on 26 September 2022).

- ISO 14040 Life Cycle Assessment Best Practices. Available online: https://www.apec.org/docs/default-source/Publications/2004/2/Life-Cycle-Assessment-Best-Practices-of-International-Organization-for-Standardization-ISO-14040-Ser/04_cti_scsc_lca_rev.pdf (accessed on 26 September 2022).

- Chen, Z.; Huang, L. Application review of LCA (Life Cycle Assessment) in circular economy: From the perspective of PSS (Product Service System). Procedia CIRP 2019, 83, 210–217. [Google Scholar] [CrossRef]

- Muredzi, P. ISO 14040 Life Cycle Assessment (LAS) as a Tool for Effective Environmentally Friendly Waste Management in the Food Industry. Available online: https://www.researchgate.net/publication/264796208_ISO_14040_Life_Cycle_Assessment_LAS_as_a_tool_for_effective_environmentally_friendly_waste_management_in_the_Food_Industry (accessed on 26 September 2022).

- Floriana Perugini, F.; Mastellone, M.L.; Arena, U. A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ. Prog. 2005, 24, 137–154. [Google Scholar] [CrossRef]

- Tools for Eco-Efficiency in the Printing Industry. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.195.1634&rep=rep1&type=pdf (accessed on 2 September 2022).

- ISO 16762:2016; Graphic Technology-Post-Press- General Requirements for Transfer, Handling and Storage. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 16759:2013; Graphic Technology-Quantification and Communication for Calculating the Carbon Footprint of Print Media Products. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 20690:2018; Graphic Technology-Determination of the Operating Power Consumption of Digital Printing Devices. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 21632:2018; Graphic Technology-Determination of the Energy Consumption of Digital Printing Devices Including Transitional and Related Modes. International Organization for Standardization: Geneva, Switzerland, 2018.

- Pasanec Preprotić, S. Book Strength in Relation to the Ageing Process. Ph.D. Thesis, Faculty of Graphic Arts University of Zagreb, Zagreb, Croatia, 2012. [Google Scholar]

- Pasanec Preprotić, S.; Budimir, I.; Lajić, B. The Bulky Paper Properties Influence on the Adhesive Bond Strength. Mater. Test. 2012, 54, 271–279. [Google Scholar] [CrossRef]

- Pasanec Preprotić, S.; Babić, D.; Tuzović, A. Research on Adhesive Joint Strength Dependency on Loose Leaf Position in a Text Block. Tech. Gaz. 2012, 19, 43–49. [Google Scholar]

- Pasanec Preprotić, S.; Babić, D.; Tuzović, A. Bind ability of High Grades Papers by Perfect Binding Technique. Acta Graph. J. 2011, 22, 21–32. [Google Scholar]

- Pasanec Preprotić, S.; Budimir, I.; Tomić, G. Evaluation of binding strength depending on the adhesive binding methods. Acta Graph. J. 2015, 26, 20–27. [Google Scholar]

- Pasanec Preprotić, S.; Lajić, B.; Jurečić, D. Perfect Binding Technique Affects the Paperback Adhesive Binding Strength. In Proceedings of the 15th International Conference on Printing, Design and Graphic Communication, Senj, Croatia, 21–24 September 2011. [Google Scholar]

- Petrović, M.; Pasanec Preprotić, S.; Majnarić, I. Paperback Block Spine Stiffness proposition. In Proceedings of the 16th International Conference on Printing, Design and Graphic Communication, Zagreb, Croatia, 26–29 September 2012. [Google Scholar]

- Pasanec Preprotić, S.; Jurecic, D.; Babic, D.; Lajic, B. Important Factors of Paperback Books Quality of Adhesion Strength in Adhesive Binding. In Proceedings of the 21st International DAAAM Symposium: Intelligent Manufacturing & Automation: Focus on Interdisciplinary Solutions, Vienna, Austria, 20–23 October 2010. [Google Scholar]

- Heinrich, L.A. Future opportunities for bio-based adhesives–advantages beyond renewability. R. Soc. Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef]

- Nugusse, M. Production and Characterization of Bio-Adhesive from Euphorbia Tirucalli Latex. Master Diploma Thesis, Addis Ababa University Institute of Technology, Addis Ababa, Ethiopia, 2019. [Google Scholar]

- Types of Adhesives Used in the Printing Industry. Available online: http://www.cobrpp.com.pl/actapoligraphica/uploads/pdf/AP2015_02_Polkowski.pdf (accessed on 26 September 2022).

- The European Association Representing the Paper Industry (CEPI) is a Non-Profit-Making Organization. Available online: https://www.cepi.org/about-cepi/organisation/ (accessed on 26 September 2022).

- Sustainability is Integral in STORA Enso’s Business Strategy. Available online: https://www.storaenso.com/en/sustainability (accessed on 26 September 2022).

- Abbas, Z. Bio-Based Polyurethane Adhesives: A Review. Master Thesis, Government College University, Faisalabad, Pakistan, 2020. [Google Scholar]

- Magalhães, S.; Alves, L.; Medronho, B.; Fonseca, A.C.; Romano, A.; Coelho, J.F.; Norgren, M. Brief Overview on Bio-Based Adhesives and Sealants. Polymers 2019, 11, 1685. [Google Scholar] [CrossRef] [PubMed]

- Vineeth, S.K. Sustainable Raw Materials in Hot Melt Adhesives: A Review. Open J. Polym. Chem. 2020, 10, 49–65. [Google Scholar]

- Muobom, S.S.; Umar, A.M.S.; Soongseok, Y.; Brolin, A.P. Title: A Review on Plasticizers and Eco-Friendly Bioplasticizers: Biomass Sources and Market. Int. J. Eng. Res. Technol. 2020, 9, 1138–1144. Available online: https://www.ijert.org/research/title-a-review-on-plasticizers-and-eco-friendly-bioplasticizers-biomass-sources-and-market-IJERTV9IS050788.pdf (accessed on 15 October 2022).

- Cardwell, K. A Chemical Investigation of PVA Based Adhesives in Book Binding. AICCM Bull. 2015, 17, 21–29. [Google Scholar] [CrossRef]

- Kim, Y.H.; Om, C.Y.; Hwang, Y.S.; Hong, Y.B. Adhesive Properties of Water-Soluble and Biodegradable Hot-Melt Adhesive Based on Partially Saponified Poly (Vinyl Acetate). Mater. Res. Express 2020, 7, 075301. Available online: https://iopscience.iop.org/article/10.1088/2053-1591/aba148 (accessed on 15 October 2022). [CrossRef]

- Gadhave, R.V.I.; Dhawale, P.V. State of Research and Trends in the Development of Polyvinyl Acetate-Based Wood Adhesive. Open J. Polym. Chem. 2022, 12, 13–42. [Google Scholar] [CrossRef]

- Gadhave, R.V.I.; Mahanwar, P.A.; Gadekar, P.T. Starch Stabilized Polyvinyl Acetate Emulsion: Review. Polym. Renew. Resour. 2018, 9, 75–84. [Google Scholar] [CrossRef]

- Gadhave, R.V.I.; Mahanwar, P.A.; Gadekar, P.T. Starch-Based Adhesives for Wood/Wood Composite Bonding: Review. Open J. Polym. Chem. 2017, 7, 19–32. [Google Scholar] [CrossRef]

- Sandip, K.S.; Ostendorf, K.; Euring, M.; Zhang, K. Environmentally sustainable, high-performance lignin-derived universal adhesive. Green Chem. 2017, 24, 2624–2635. [Google Scholar] [CrossRef]

- Gadhave, R.V.I.; Srivastava, S.; Mahanwar, P.A.; Gadekar, P.T. Lignin: Renewable Raw Material for Adhesive. Open J. Polym. Chem. 2019, 9, 27–38. [Google Scholar] [CrossRef]

- Patel, A.K.; Mathias, J.D. Polysaccharides as Adhesives. Rev. Adhes. Adhes. 2013, 3, 312–345. Available online: https://www.researchgate.net/publication/270791327_Polysaccharides_as_Adhesives (accessed on 20 October 2022). [CrossRef]

- Müller, M.; Valášek, P. Composite adhesive bonds reinforced with microparticle filler based on eggshell waste. In Proceedings of the 6th International Conference on Mechatronics and Control Engineering (ICMCE 2017), St. Petersburg, Russia, 2–4 December 2017. [Google Scholar]

- Martinez, G.; Merinero, M.; Pérez-Aranda, M.; Pérez-Soriano, E.; Ortiz, T.; Villamor, E.; Begines, B.; Alcudia, A. Erratum: Guillermo M., et al. Environmental Impact of Nanoparticles’ Application as an Emerging Technology: A Review. Materials 2021, 14, 1710. [Google Scholar] [CrossRef] [PubMed]

- Dastjerdi, Z.; Cranston, E.D.; Berry, R.; Fraschini, C.; Dubé, M.A. Polymer Nanocomposites for Emulsion-Based Coatings and Adhesives. Macromol. React. Eng. 2018, 13, 1800050. [Google Scholar] [CrossRef]

- Petković, G.; Vukoje, M.; Bota, J.; Preprotić, S.P. Enhancement of Polyvinyl Acetate (PVAc) Adhesion Performance by SiO2 and TiO2 Nanoparticles. Coatings 2019, 9, 707. [Google Scholar] [CrossRef]

- Petković, G.; Rožić, M.; Vukoje, M.; Pasanec Preprotić, S. Interactions in Polyvinyl Acetate-Paper Adhesive Joint and Influence on Its Adhesion Parameters. Ann. Fac. Eng. Hunedoara-Int. J. Eng. 2017, 15, 35–42. [Google Scholar]

- Petković, G.; Preprotic, S.P.; Vukoje, M. The Quality Assessment of Bookbinding Strength for Polyvinyl Acetate Adhesive (PVAc) and Nano-Modified PVAc Adhesives. In Proceedings of the the 9th International Symposium on Graphic Engineering and Design, Novi Sad, Serbia, 8–10 November 2018. [Google Scholar]

- Petković, G.; Mirković, I.B.; Preprotić, S.P. Strength of Nano-Modified Polyvinyl-Acetate Adhesive Joints at Temperature and Humidity Changes. In Proceedings of the 20th International Conference on Materials MATRIB 2019, Vela Luka, Croatia, 27–29 June 2019. [Google Scholar]

- Hudika, T.; Cigula, T.; Žličarić, M.; Strižić Jakovljević, M. PCL-TiO2 Nanocomposite to Improve Ageing of Offset Prints. In Proceedings of the 10th International Symposium on Graphic Engineering and Design, Novi Sad, Serbia, 12–14 November 2020. [Google Scholar]

- Petković, G.; Vukoje, M.; Preprotić, S.P.; Kulčar, R. Changes in Color and Drying Time of Modified Polyvinyl Acetate Adhesive with Nanoparticles. Eur. J. Sustain. Dev. Res. 2021, 5, 48–54. Available online: https://cnrpublishing.com/index.php/ejsdr/2021_articles (accessed on 1 September 2022).

- Rainer, H.; Avtar Singh, M.; Zhanrong, Z. Green Chemistry for Surface Coatings, Inks and Adhesives: Sustainable Applications; RSC Publishers: Cambridge, UK, 2019. [Google Scholar]

- Lippard, K.L. Library Preservation and Sustainability Challenges; UARK Libraries. 2018. Available online: https://librariesblog.uark.edu/library-preservation-and-sustainability-challenges/ (accessed on 5 January 2023).

- Rachman, Y.; Ratnasari, W. Academic Libraries’ Sustainable Preservation and Conservation Practices. Preserv. Digit. Technol. Cult. 2022, 51, 121–129. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasanec Preprotić, S.; Vukoje, M.; Petković, G.; Rožić, M. Novel Approaches to Enhancing Sustainable Adhesive System Solutions in Contemporary Book Binding: An Overview. Heritage 2023, 6, 628-646. https://doi.org/10.3390/heritage6010033

Pasanec Preprotić S, Vukoje M, Petković G, Rožić M. Novel Approaches to Enhancing Sustainable Adhesive System Solutions in Contemporary Book Binding: An Overview. Heritage. 2023; 6(1):628-646. https://doi.org/10.3390/heritage6010033

Chicago/Turabian StylePasanec Preprotić, Suzana, Marina Vukoje, Gorana Petković, and Mirela Rožić. 2023. "Novel Approaches to Enhancing Sustainable Adhesive System Solutions in Contemporary Book Binding: An Overview" Heritage 6, no. 1: 628-646. https://doi.org/10.3390/heritage6010033

APA StylePasanec Preprotić, S., Vukoje, M., Petković, G., & Rožić, M. (2023). Novel Approaches to Enhancing Sustainable Adhesive System Solutions in Contemporary Book Binding: An Overview. Heritage, 6(1), 628-646. https://doi.org/10.3390/heritage6010033