Characterization of Chalcolithic Ceramics from the Lisbon Region, Portugal: An Archaeometric Study

Abstract

:1. Introduction

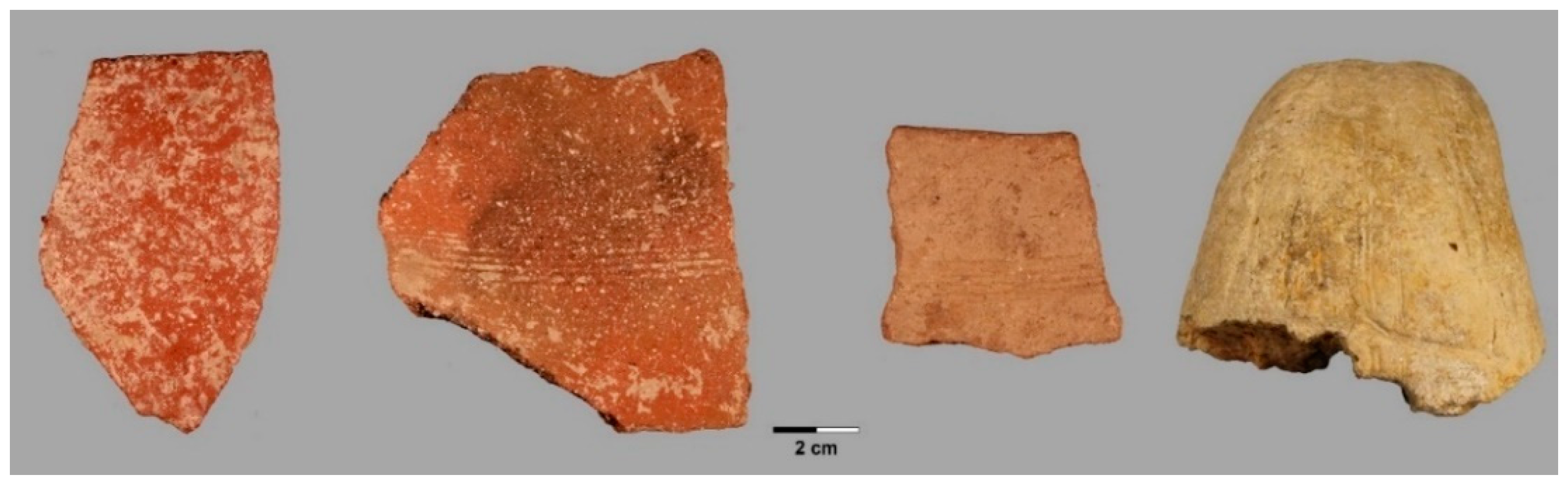

2. Materials and Methods

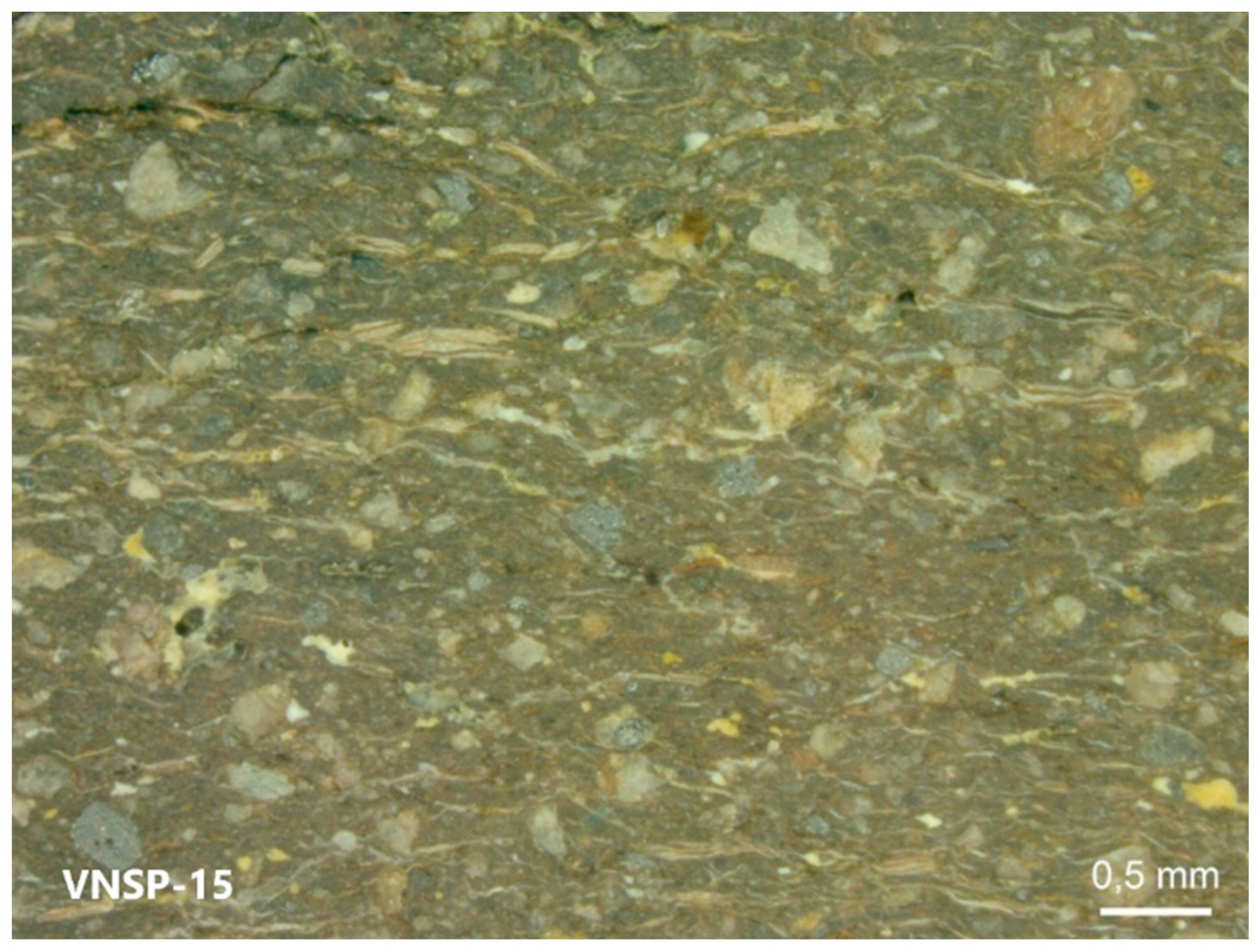

2.1. Textural Analysis

2.2. Chemical Analysis

2.3. Mineralogical Analysis

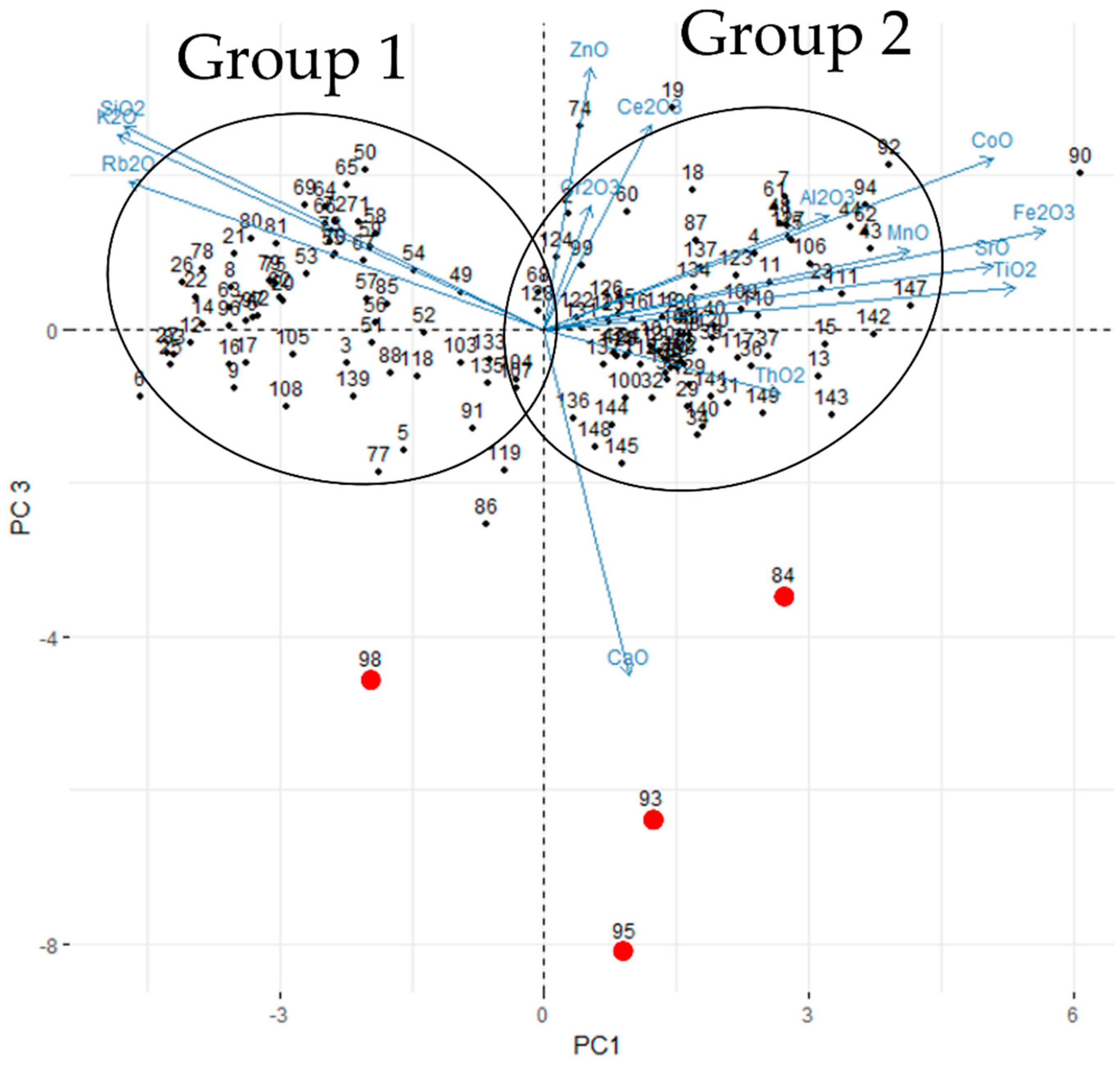

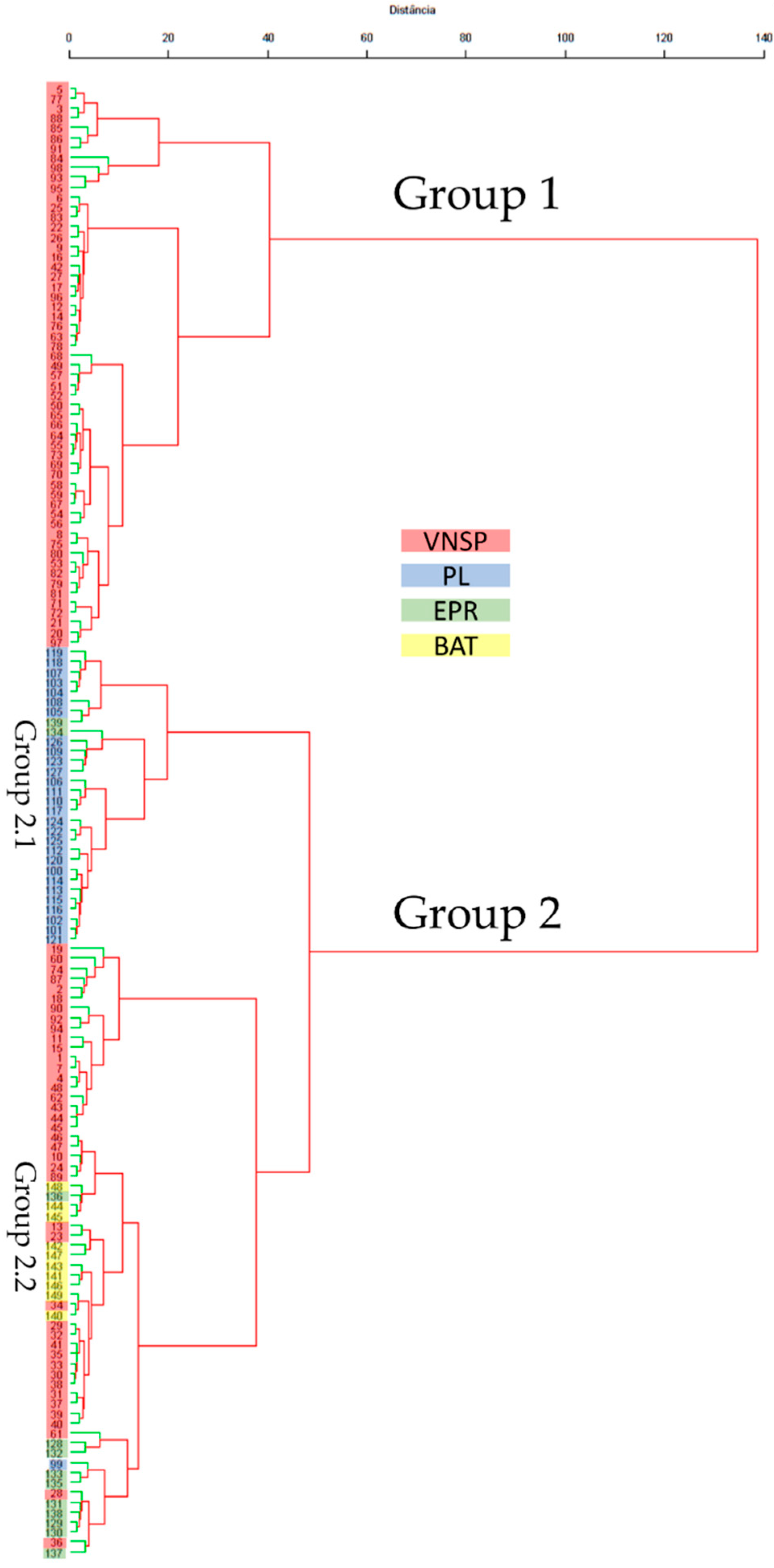

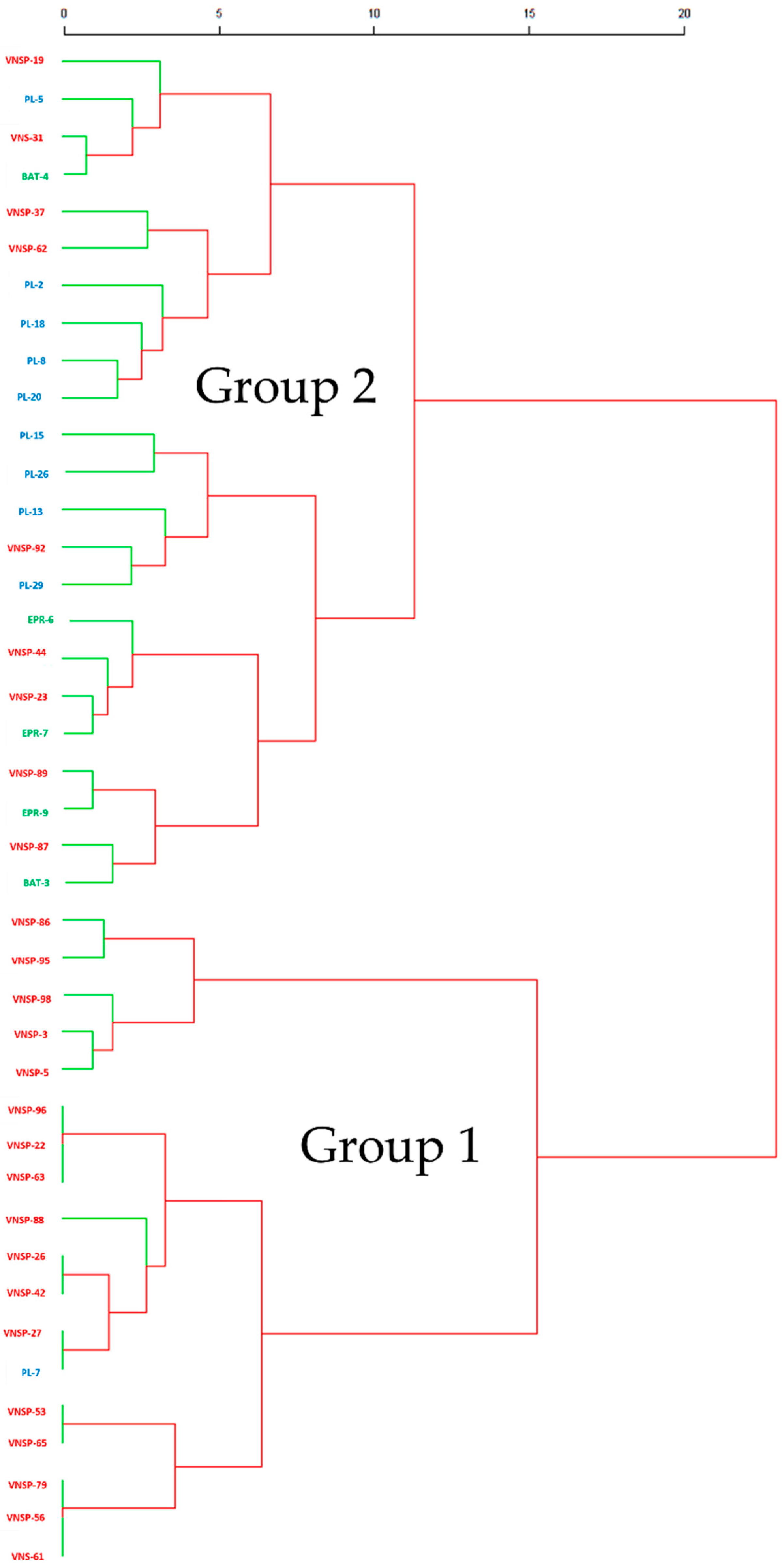

2.4. Statistical Analysis

3. Results

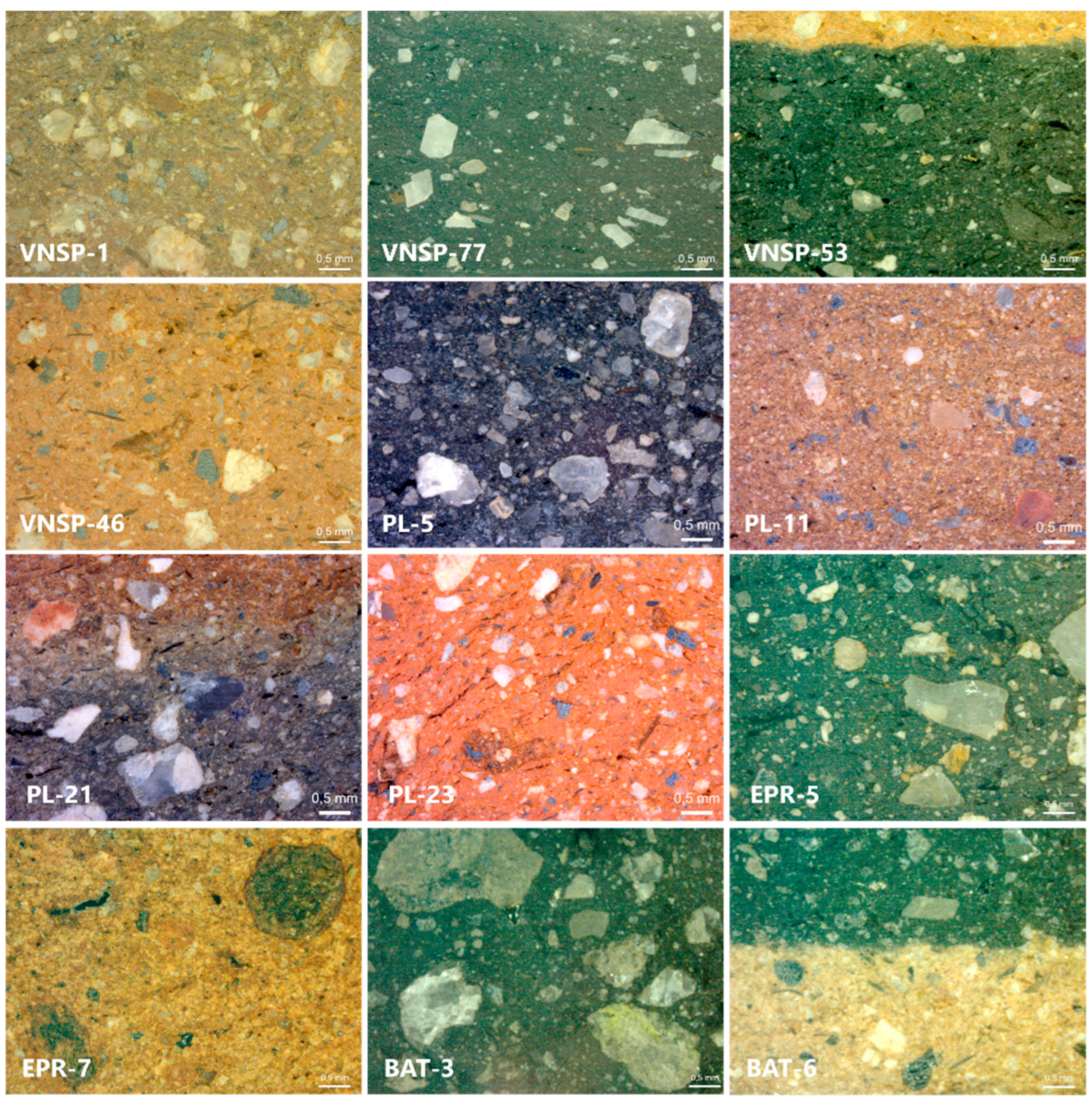

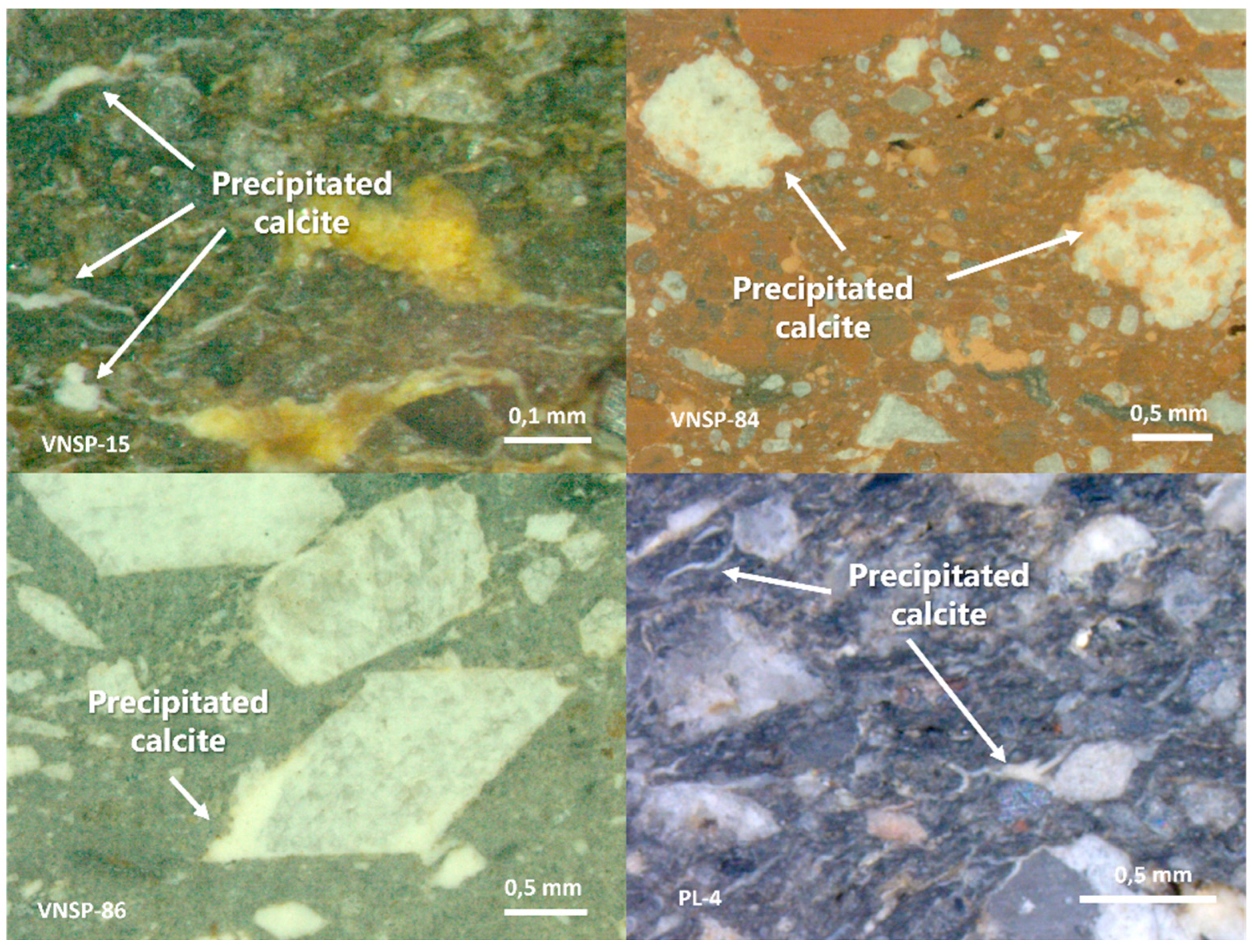

3.1. Textural Analysis

3.2. Chemical Analysis

3.3. Mineralogical Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dias, M.I.; Prudêncio, M.I. Neutron Activation Analysis of Archaeological materials: An overview of the ITN NAA Laborartory, Portugal. Archaeometry 2007, 49, 383–393. [Google Scholar] [CrossRef]

- Amaro, G. La cerâmica com Decoración Acanalada y Bruñida en el Contexto Pre-Campaniforme del Calcolítico de la Extremadura Portuguesa—Nuevos Aportes a la Comparensión del Processo de Procucción de Cerâmicas em la Prehistoria Reciente de Portugal. Ph.D. Thesis, Universidad Autonoma de Madrid, Madrid, Spain, 2010. [Google Scholar]

- Kunst, M. As Cerâmicas decoradas do Zambujal e o faseamento do Calcolítico da Estremadura Portuguesa. Estud. Arqueol. Oeiras 1996, 6, 257–287. [Google Scholar]

- Ferreira, S. Os Copos no Povoado Calcolítico de Vila Nova de S. Pedro. Rev. Port. Arqueol. Arqueol. 2003, 6, 181–228. [Google Scholar]

- Neto, N. A cerâmica decorada Neolítica e Calcolítica do Povoado das Baútas (Amadora). ARQA Patrim. Res. 2004, 1, 36–51. [Google Scholar]

- Sousa, A.C. O Penedo do Lexim e a Sequência do Neolítico Final e Calcolítico da Península de Lisboa. Ph.D. Thesis, Universidade de Lisboa, Lisboa, Portugal, 2010. [Google Scholar]

- Cardoso, J.L. Pré-História de Portugal; Editorial Verbo: Lisboa, Portugal, 2002; pp. 247–324. [Google Scholar]

- Dias, M.I.; Varela, A.; Lago, M.; Prudêncio, M.I. Proveniência e tecnologia de produção de cerâmicas nos Perdigões. Vipasca Arqueol. Hist. 2007, 2, 117–121. [Google Scholar]

- Kunst, M. Zambujal—Glockenbecher und kerbblattverzierte Keramik aus den Grabungen 1964 bis, 1973. In Mainzam Rhein; Ger.: P. von Zabern, Deutschland, 1987. [Google Scholar]

- Cardoso, J.L.; Soares, A.M. Contribution d’une série de datations C14, provenant, du site de Leceia, (Oeiras, Portugal), à la chronologie absolute du néolithique et du calcolithique de l’Estremadura portugaise. In Actes du Colloque de Périgueux (Supplément de la Révue d’Archeométie); Colloque de Périgueux: Périgueux, France, 1996; pp. 45–50. [Google Scholar]

- Serrão, E. Sobre a periodização do Neolítico e Calcolítico do território português. In Actas da 1 Mesa Redonda Sobre o Neolítico e o Calcolítico em Portugal; Abril: Porto, Portugal, 1979; pp. 125–140. [Google Scholar]

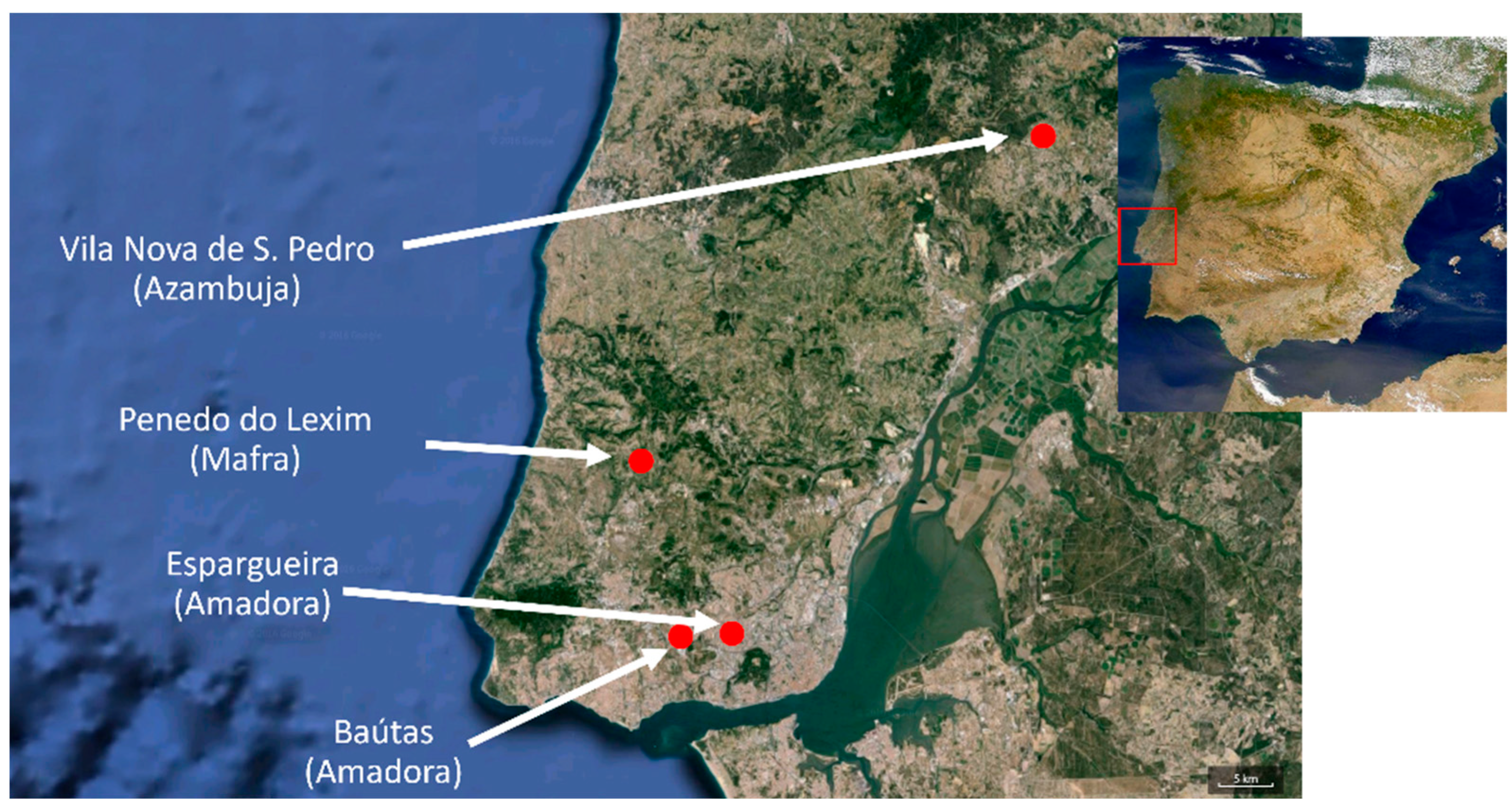

- Zbyszewski, G. Carta Geológica de Portugal—Notícia Explicativa da Folha 31-A; Serviços Geológicos de Portugal: Santarém, Lisboa, Portugal, 1953. [Google Scholar]

- Brilha, J.; Braga, M.; Proust, D.; Dudoignon, P. A disjunção colunar na chaminé vulcânica de Penedo de Lexim (Complexo Vulcânico de Lisboa)—Morfologia e Génese. Comun. Inst. Geol. Min. 1998, 84, 164–167. [Google Scholar]

- Ramalho, M.; Pais, J.; Ray, J.; Berthou, P.; Alves, C.; Palácios, T.; Leal, N.; Kullberg, M. Carta Geológica de Portugal—Notícia Explicativa da folha 34-A; Serviços Geológicos de Portugal: Santarém, Lisboa, Portugal, 1993. [Google Scholar]

- Bronk, H.; Röhrs, S.; Bjeoumikhov, A.; Langhoff, N.; Schmalz, J.; Wedell, R.; Gorny, H.; Herold, A.; Waldschläger, U. ArtTAX—a new mobile spectrometer for energy-dispersive micro X-ray fluorescence spectrometry on art and archaeological objects. Fresenius J. Anal. Chem. 2001, 371, 307–316. [Google Scholar] [CrossRef] [PubMed]

- Vyverberg, K.L.; Jaeger, J.M.; Dutton, A. Quantifying Detection Limits and Uncertainty in X-ray Diffraction Mineralogical Assessments of Biogenic Carbonates. J. Sediment. Res. 2018, 88, 1261–1275. [Google Scholar] [CrossRef]

- Riederer, J. Thin Section Microscopy Applied to the Study of Archaeological Ceramics. Hyperfine Interact. 2004, 154, 143–158. [Google Scholar] [CrossRef]

- Sandu, I.; Joosten, I.; Leal, N. Optical imaging applications for the study of cultural heritage artifacts. In Advances in Laser and Optics Research; Arkin, T., Ed.; Nova Science Publishers: New York, NY, USA, 2015; Volume 2, pp. 65–108. [Google Scholar]

- Lafuente, B.; Downs, R.; Yang, H.; Stone, N. The power of databases: The RRUFF project. In Highlights in Mineralogical Crystallography; Armbruster, T., Danisi, R.M., Eds.; De Gruyter: Berlin, Germany, 2015; pp. 1–30. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2022. Available online: https://www.R-project.org/ (accessed on 4 August 2022).

- Johnson, R.; Wichern, D. Applied Multivariate Statistical Analysis; Prentice Hall: Hoboken, NJ, USA, 1982. [Google Scholar]

- Ward, J. Hierarchical Grouping to Optimize a Objective Function. J. Am. Stat. Assoc. 1963, 58, 236–244. [Google Scholar] [CrossRef]

- Little, G. The Technology of Pottery Production in Northwestern Portugal during the Iron Age; Cadernos de Arqueologia: Braga, Portugal, 1990. [Google Scholar]

- Rice, P. Pottery Analysis—A Sourcebook; The University of Chicago Press: Chicago, IL, USA; London, UK, 1987. [Google Scholar]

- Shepard, A. Ceramics for the Archaeologist, Carnegie Institution of Washington; Braun Brumfield: Washington, DC, USA, 1976. [Google Scholar]

- Amaro, G.; Anunciação, C. Tentativa de Compreensão da Cadeia Operatória de Produção de Cerâmicas Campaniformes Através de Métodos Experimentais: Exemplo baseado no estudo das peças do povoado calcolítico do Zambujal e da necrópole da Cova da Moura (Torres Vedras, Portugal). Al-Madan 2013, 17, 59–68. [Google Scholar]

- Fabbri, B.; Gualtieri, S.; Shoval, S. The presence of calcite in archaeological ceramics. J. Eur. Ceram. Soc. 2014, 34, 1899–1911. [Google Scholar] [CrossRef]

- Ouahabi, M.; Daoudi, L.; Hatert, F.; Fagel, N. Modified Mineral Phases During Clay Firing. Clays Clay Miner. 2015, 63, 404–413. [Google Scholar] [CrossRef]

- Chaves, R.C.; Lima, A.; Coroado, J.; Teixeira, A.; Vilarigues, M.; Leal, N.; Azzeddine, K.; Soares, A.M. Medieval and early modern ceramics from Azemmour (Morocco)—Textural, mineralogical and chemical analysis. J. Archaeol. Rep. 2018, 21, 1152–1162. [Google Scholar] [CrossRef]

- Arnold, D. Ceramics, Theory and Cultural Process, New Studies in Archaeology; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Convertini, F.; Cardoso, J.L. Les poteries campaniformes de la fortification chalcolihique de Leceia (Oeiras, Portugal): Étude pétrographique, analyse des provenances et degraissants. Estud. Arqueol. Oeiras 2022, 30, 11–34. [Google Scholar]

- Buys, S.; Oakley, V. Conservation and Restoration of Ceramics; Butterworth-Heinmann: Oxford, UK, 1993. [Google Scholar]

- Salanova, L.; Sheridan, A. When the Potter Make the Story: What can pottery tell us about the people who made and used it? Eur. Archaeol. 2013, 40, 80–82. [Google Scholar]

| Paste | Inclusions | ||||

|---|---|---|---|---|---|

| Color | Distribution | Size | Geometry | % | |

| Vila Nova de São Pedro—98 Samples | |||||

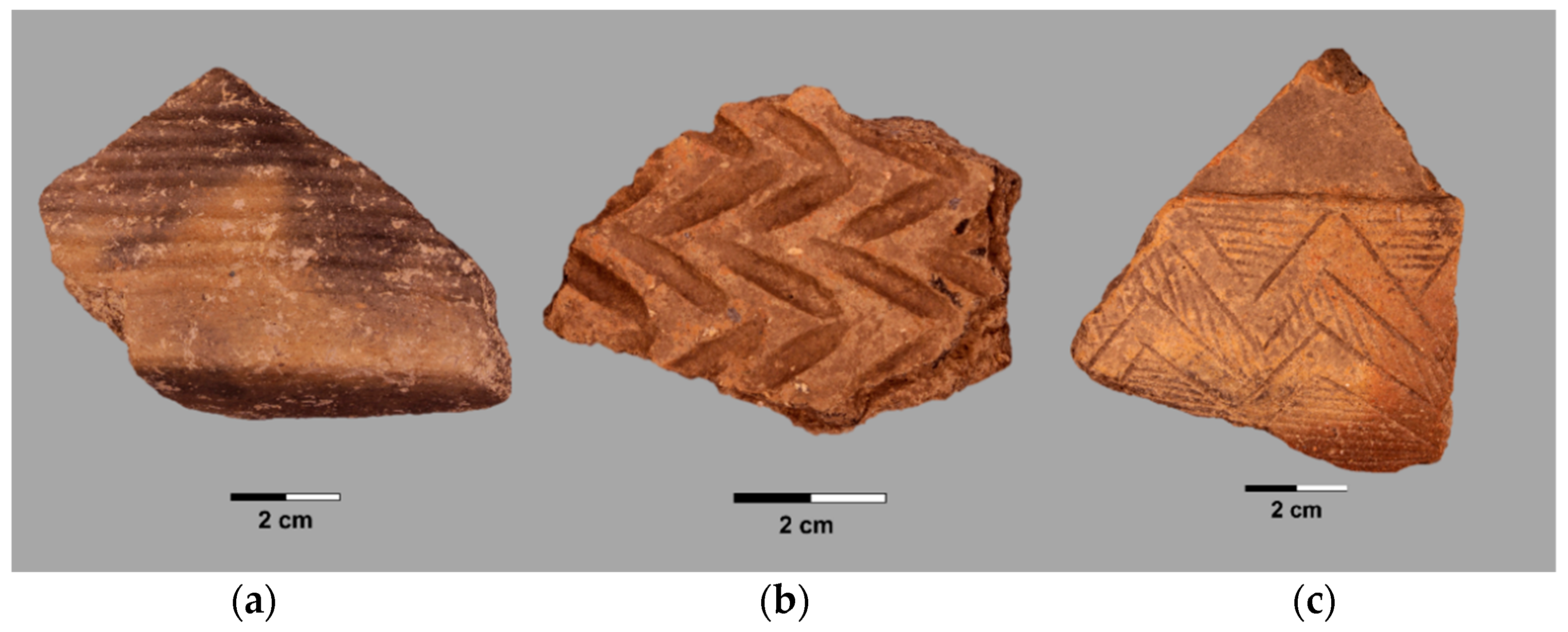

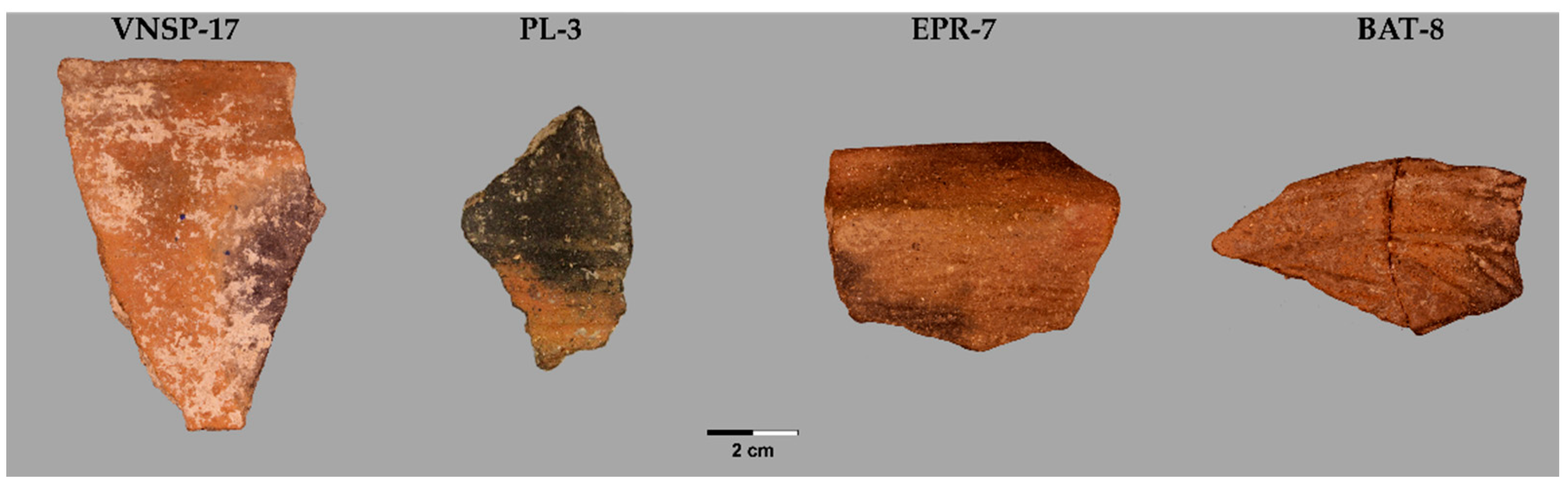

| Early Chalcolithic (Corrugated) | Mostly a range of browns | Non uniform | Mostly fine (89%) | Mostly subrounded (69%) | 29% |

| Full Chalcolithic (Acacia leaf) | Mostly a range of grays | Non uniform | Fine to small (50% fine and 50% small) | Mostly subangular (77%) | 26% |

| Late Chalcolithic (Beaker pottery) | Mostly with black core and orange surfaces | Non uniform | Mostly fine (58%) | Mostly subangular (54%) | 20% |

| Other decoration | Random | Non uniform | Dense to small (46% fine) | Mostly subangular (55%) | 23% |

| No decoration | Random | Non- uniform | Fine to small (46% fine and 39% small) | Mostly subangular (69%) | 24% |

| Penedo do Lexim—29 samples | |||||

| Early Chalcolithic (Corrugated) | Mostly a range of grays | Non uniform | Mostly fine (83%) | Mostly subrounded (67%) | 27% |

| Early Chalcolithic (No decoration) | Mostly a range of browns | Non uniform | Mostly fine (67%) | Subrounded (100%) | 23% |

| Full Chalcolithic (Acacia leaf) | Mostly a range of browns | Non uniform | Mostly small (71%) | Mostly subangular (71%) | 24% |

| Full Chalcolithic (Other decoration) | Mostly with black core and brown surfaces | Non uniform | Mostly small (100%) | Subangular to subrounded (50%) | 25% |

| Full Chalcolithic (No decoration) | Mostly a range of browns | Non uniform | Mostly fine (67%) | Mostly subrounded (83%) | 23% |

| Espargueira—12 samples | |||||

| Late Neolithic/ Early Chalcolithic | Mostly a range of browns | Non uniform | Mostly small (50%) | Subangular to subrounded (50%) | 24% |

| Baútas—10 samples | |||||

| Full Chalcolithic (Acacia leaf) | Mostly a range of browns, sometimes with a black core | Non uniform | Mostly fine (70%) | Subangular to subrounded (50%) | 28% |

| Vila Nova de São Pedro—98 Samples | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % (m/m) | ppm | |||||||||||||

| Al2O3 | SiO2 | K2O | CaO | TiO2 | Fe2O3 | Cr2O3 | MnO | CoO | ZnO | Rb2O | SrO | Ce2O3 | ThO2 | |

| Early Chalc. (Corrugated) | 16.5 | 57.7 | 2.31 | 4.54 | 1.15 | 6.65 | 102 | 791 | 23 | 190 | 124 | 208 | 475 | 10 |

| σ | 2.9 | 11.4 | 0.71 | 3.81 | 0.72 | 2.96 | 24 | 560 | 10 | 66 | 48 | 157 | 155 | 3 |

| Full Chalc. (Acacia leaf) | 19.8 | 48.8 | 1.69 | 4.66 | 1.71 | 9.74 | 92 | 985 | 28 | 182 | 87 | 327 | 388 | 13 |

| σ | 2.4 | 8.4 | 0.38 | 1.17 | 0.49 | 2.00 | 21 | 317 | 7 | 36 | 31 | 93 | 184 | 3 |

| Late Chalc. (Beaker pottery) | 18.4 | 60.6 | 2.53 | 2.55 | 0.97 | 6.86 | 143 | 682 | 25 | 192 | 146 | 103 | 521 | 9 |

| σ | 2.1 | 5.0 | 0.55 | 1.07 | 0.52 | 1.68 | 22 | 768 | 6 | 40 | 40 | 110 | 171 | 2 |

| No decoration | 15.3 | 59.9 | 2.53 | 7.66 | 0.78 | 6.09 | 132 | 586 | 22 | 151 | 157 | 94 | 464 | 9 |

| σ | 1.9 | 14.8 | 0.84 | 8.65 | 0.40 | 2.39 | 38 | 519 | 8 | 29 | 50 | 71 | 114 | 3 |

| Other decoration | 15.2 | 44.3 | 1.78 | 15.89 | 1.33 | 7.68 | 128 | 900 | 27 | 159 | 99 | 189 | 522 | 13 |

| σ | 5,2 | 13.6 | 0.88 | 17.29 | 0.81 | 4.32 | 30 | 628 | 14 | 52 | 56 | 161 | 223 | 5 |

| Mean (n = 98) | 17.5 | 55.3 | 2.20 | 5.73 | 1.20 | 7.44 | 117 | 791 | 25 | 180 | 123 | 190 | 471 | 11 |

| σ | 3.3 | 11.7 | 0.73 | 7.74 | 0.66 | 2.86 | 33 | 589 | 9 | 49 | 50 | 149 | 174 | 3 |

| Maximum | 24.1 | 76.0 | 3.69 | 49.13 | 2.90 | 14.53 | 243 | 3987 | 49 | 437 | 219 | 533 | 1100 | 20 |

| Minimum | 7.7 | 24.8 | 0.27 | 1.07 | 0.33 | 3.00 | 58 | 57 | 8 | 73 | 14 | 43 | 220 | 5 |

| Penedo do Lexim—29 samples | ||||||||||||||

| % (m/m) | ppm | |||||||||||||

| Al2O3 | SiO2 | K2O | CaO | TiO2 | Fe2O3 | Cr2O3 | MnO | CoO | ZnO | Rb2O | SrO | Ce2O3 | ThO2 | |

| Early Chalc. (Corrugated) | 24.9 | 52.8 | 1.95 | 4.60 | 1.71 | 8.70 | 88 | 782 | 24 | 150 | 49 | 231 | 346 | 4 |

| σ | 3.2 | 5.8 | 0.28 | 1.31 | 0.27 | 1.01 | 9 | 253 | 3 | 75 | 9 | 50 | 115 | 1 |

| Early Chalc. (No decoration) | 21.5 | 58.7 | 1.99 | 3.67 | 1.93 | 8.12 | 113 | 1151 | 23 | 153 | 51 | 217 | 271 | 4 |

| σ | 3.6 | 10.4 | 0.58 | 1.56 | 1.02 | 3.74 | 65 | 513 | 10 | 40 | 16 | 110 | 57 | 1 |

| Full Chalc. (Acacia leaf) | 29.3 | 50.3 | 1.73 | 4.19 | 1.94 | 10.18 | 100 | 1003 | 28 | 142 | 44 | 218 | 331 | 4 |

| σ | 2.6 | 5.2 | 0.23 | 0.74 | 0.53 | 1.13 | 12 | 289 | 3 | 16 | 10 | 55 | 138 | 0 |

| Full Chalc. (Other decoration) | 26.5 | 53.8 | 1.85 | 3.93 | 1.60 | 8.38 | 81 | 809 | 23 | 121 | 46 | 204 | 233 | 4 |

| σ | 2.3 | 6.1 | 0.57 | 0.49 | 0.46 | 2.44 | 25 | 109 | 7 | 29 | 14 | 86 | 79 | 0 |

| Full Chalc. (No decoration) | 25.6 | 52.3 | 2.31 | 4.27 | 1.75 | 10.22 | 147 | 1352 | 29 | 150 | 61 | 253 | 329 | 4 |

| σ | 1.0 | 2.7 | 0.49 | 0.74 | 0.29 | 1.77 | 66 | 474 | 6 | 25 | 7 | 34 | 75 | 0 |

| Mean (n = 29) | 25.6 | 53.4 | 1.97 | 4.15 | 1.80 | 9.21 | 107 | 1033 | 26 | 145 | 51 | 226 | 308 | 4 |

| σ | 3.7 | 6.7 | 0.45 | 1.04 | 0.56 | 2.24 | 47 | 404 | 6 | 41 | 12 | 67 | 102 | 1 |

| Maximum | 32.8 | 71.9 | 3.01 | 6.94 | 2.98 | 13.07 | 240 | 2290 | 36 | 303 | 80 | 327 | 563 | 5 |

| Minimum | 16.1 | 40.8 | 1.47 | 1.59 | 0.80 | 3.49 | 47 | 313 | 11 | 91 | 25 | 76 | 129 | 3 |

| Espargueira and Baútas—22 samples | ||||||||||||||

| % (m/m) | ppm | |||||||||||||

| Al2O3 | SiO2 | K2O | CaO | TiO2 | Fe2O3 | Cr2O3 | MnO | CoO | ZnO | Rb2O | SrO | Ce2O3 | ThO2 | |

| Late Neo./Early Chalc. (EPR—No decorated) | 18.9 | 51.8 | 1.99 | 3.91 | 1.66 | 8.75 | 113 | 1142 | 22 | 204 | 52 | 168 | 294 | 11 |

| σ | 2.1 | 5.7 | 0.33 | 1.17 | 0.65 | 1.77 | 78 | 737 | 5 | 45 | 9 | 60 | 94 | 2 |

| Full Chalc. (BAT—acacia leaf) | 21.8 | 44.8 | 1.27 | 5.31 | 2.20 | 10.27 | 83 | 974 | 25 | 164 | 51 | 279 | 327 | 13 |

| σ | 0.6 | 4.4 | 0.30 | 1.14 | 0.89 | 1.92 | 17 | 293 | 5 | 28 | 10 | 77 | 84 | 2 |

| Mean4 (n = 22) | 20.2 | 48.6 | 1.66 | 4.55 | 1.90 | 9.44 | 99 | 1065 | 23 | 186 | 52 | 218 | 309 | 12 |

| σ | 2.2 | 6.2 | 0.48 | 1.33 | 0.80 | 1.95 | 60 | 573 | 5 | 42 | 9 | 88 | 89 | 2 |

| Maximum | 22.9 | 66.7 | 2.78 | 6.89 | 4.09 | 14.30 | 350 | 2800 | 35 | 287 | 71 | 400 | 530 | 18 |

| Minimum | 16.6 | 40.2 | 0.77 | 2.02 | 0.47 | 6.23 | 53 | 233 | 15 | 123 | 37 | 58 | 173 | 8 |

| Semi-Quantification Using XRD | Minerals Identified by XRD, Raman and Petrographic Microscopy | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspars | Phyllosilicates | Calcite | Iron Oxi-Hydroxides | Pyroxene | Amphibole | |||

| Vila Nova de São Pedro—26 Samples | |||||||||

| Early Chalc. (corrugated) | VNSP-3 | xxxx | x | x | xxx | x | - | - | Cal, Ph(Ms, Bt, Chl), Fld(Or), IOH(Hem), Qz |

| VNSP-5 | xxx | x | x | xxx | x | - | - | Cal, Ph, Fld(San, Plg), IOH(Hem), Qz | |

| VNSP-19 | xx | x | x | - | - | - | x | Anf(Tr), Ph(Bt, Chl), Fld(Plg, San), Op, Qz | |

| VNSP-22 | xxxx | xx | x | - | x | - | - | Fld(Plg, San), Ph, IOH(Hem), Qz | |

| VNSP-23 | xx | xx | x | - | x | - | - | Epd, Ph(Ms, Bt, Chl), Fld(Ab, An, K), Op, IOH(Hem, Mag), Qz | |

| VNSP-26 | xxxx | xx | x | - | - | - | - | Ph, Fld(Mc), Qz | |

| Full Chalc. (acacia leaf) | VNSP-27 | xxxx | xx | x | - | v | - | - | Ph(Bt, Chl, Ms), Fld(Mc, Plg) IOH(Hem), Qz |

| VNSP-31 | xxx | xx | x | - | x | - | x | Anf(Act), Ph(Bt), Fld(Ab, K), Op, IOH(Hem, Ilm), Qz | |

| VNSP-37 | x | xx | x | - | x | - | x | Anf, Epd, Ph(Bt, Chl), Fld(Ab, An, K), Op, IOH, Qz | |

| VNSP-42 | xxxx | xx | x | - | - | - | - | Epd, Ph, Fld(Mc), Qz | |

| VNSP-44 | xx | xx | x | - | x | v | - | Ph(Bt), Fld(Ab, Or, San), Op, IOH(Hem), Px(Aug), Qz | |

| Beaker | VNSP-53 | xxxx | x | x | - | - | - | - | Ph(Ms), Fld(Ab, Or), Qz |

| VNSP-56 | xxxx | x | x | - | x | - | - | Ph(Ms), Fld(Ab, An, Or), Op, IOH, Qz | |

| VNSP-61 | xxxx | x | x | - | x | - | - | Ph(Bt, Chl), Fld(Mc, Plg), IOH(Hem), Qz | |

| VNSP-62 | x | xx | v | - | - | x | x | Anf(Act), Ph(Bt), Fld(Ab, K), Op, Px(Aug), Qz | |

| VNSP-63 | xxxx | xx | x | - | x | - | - | Ph, Fld(San), Op, IOH(Hem), Qz | |

| VNSP-65 | xxxx | x | x | - | - | - | - | Ph(Ms), Fld(Ab, An, Or), Qz | |

| No decoration | VNSP-79 | xxxx | x | x | - | x | - | - | Ph, FldK (Or), IOH, Qz |

| VNSP-86 | xx | x | v | xxx | - | - | - | Cal, Ph, Fld(K, Ab), Qz | |

| VNSP-87 | xxx | xxx | v | - | v | x | - | Ph, Fld(Ab, Anl, Or), Op, IOH(Hem), Px(Aug), Qz | |

| Other Decorations | VNSP-88 | xxxx | xx | x | xx | v | - | - | Cal, Ph, Fld(Mc, Plg), IOH, Qz |

| VNSP-89 | xx | xx | x | - | x | x | - | Epd, Ph(Bt), Fld(Ab, And),Op, IOH(Hem, Ilm), Px(Aug), Qz | |

| VNSP-92 | xx | xx | v | - | v | - | - | Epd, Ph(Bt), Fld(Ab, And, Anl, K), Op, IOH(Ilm), Qz | |

| VNSP-95 | xxx | x | v | xxxx | - | - | - | Cal, Ph, Fld(Plg), Qz | |

| VNSP-96 | xxxx | xx | x | - | x | - | - | Ph(Ms), Fld(Mc), IOH, Qz | |

| VNSP-98 | xx | x | x | xxx | x | - | - | Cal, Ph, Fld(Ab), Op, IOH(Hem), Qz | |

| Quartz | Feldspars | Phyllosilicates | Calcite | Iron oxi-hydroxides | Pyroxene | Amphibole | Minerals identified by XRD, Raman and petrographic microscopy | ||

| Penedo do Lexim—10 samples | |||||||||

| Early Chalc. (corrugated) | PL-2 | x | xxx | v | - | xx | x | x | Anf(Act), Epd, Ph(Chl, Ms), Fld(Anl, K, Ort), Op, IOH(Mag), Px(Aug), Qz |

| PL-5 | xxx | xx | x | - | xx | - | x | Anf(Trem), Ph(Bt), Fld(And), IOH, Qz | |

| PL-7 | xxxx | xx | x | - | v | - | - | Fld(Ab, Anl, Or), Op, IOH, Qz | |

| PL-8 | xx | xxx | x | - | x | x | x | Anf(Tr), Ph(Bt), Fld(Ab), Op, IOH(Hem), Px(Aug), Qz | |

| Early Chalc (No) | PL-13 | x | xx | - | - | xxx | - | - | Anf, Ph(Bt), Fld(Ab, Anl), Op, Px, Qz |

| PL-15 | xxx | xx | - | - | x | x | - | Anf, Chl, Epd, Ph(Bt), Fld(Anl), Op, IOH(Hem, Mag), Px(Aug), Qz | |

| PL-18 | xxx | xx | x | - | v | x | x | Anf(Tr), Ph(Bt, Ms), Fld(Anl, Or), IOH(Mag), Px(Aug), Qz | |

| No dec. | PL-20 | xxx | xxx | x | - | xx | x | x | Anf(Tr), Ph(Bt), Fld(Or, Plg), Op, IOH(Hem), Px(Aug), Qz |

| PL-26 | xxx | xx | v | - | xx | - | - | Ph, Fld(Ab, Anl, Or), Op, IOH(Hem, Mag), Qz | |

| PL-29 | xx | xxx | - | - | v | - | - | Ph, Fld(Ab), IOH(Hem), Qz | |

| Quartz | Feldspars | Phyllosilicates | Calcite | Iron oxi-hydroxides | Pyroxene | Amphibole | Minerals identified by XRD, Raman and petrographic microscopy | ||

| Espargueira and Baútas—5 samples | |||||||||

| EPR-6 | xx | x | x | - | x | x | - | Epd, Ph(Bt), Fld(Ab, An), IOH(Mag), Px(Aug), Qz | |

| EPR-7 | x | xx | x | - | x | x | x | Anf, Ph(Bt), Fld(Ab, An, K), Op, IOH(Hem, Mag), Px, Qz | |

| EPR-9 | xxx | xx | x | - | x | x | x | Anf, Ph, Fld(Ab, Or),Op, IOH(Hem), Px(Aug), Qz | |

| BAT-3 | xxx | xxx | x | - | v | v | - | Ph, Fld(Ab, And), Op, IOH(Hem), Px, Qz | |

| BAT-4 | xxx | xx | x | - | v | x | x | Anf, Ph(Chl), Fld(Ab, An, K), IOH(Mag), Px, Qz | |

| Group 1 | Group 2 | |||

|---|---|---|---|---|

| Group 2.1 | Group 2.2 | |||

| VNSP | Early Chalc. (corrugated) | VNSP-3, 5, 6, 8, 9, 12, 14, 16, 17, 20, 21, 22, 25, 26 | VNSP-1, 2, 4, 7, 10, 11, 13, 15, 18, 19, 23, 24 | |

| Full Chalc. (acacia leaf) | VNSP-27, 42 | VNSP-28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 43, 44, 45, 46, 47, 48 | ||

| Late Chalc. (beaker) | VNSP-49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 63, 64, 65, 66, 67, 68, 69, 70, 71, 72, 73 | VNSP-60, 61, 62, 74, | ||

| No decoration | VNSP-75, 76, 77, 78, 79, 80, 81, 82, 83, 84, 85, 86 | VNSP-87 | ||

| Other decoration | VNSP-88, 91, 93, 95, 96, 97, 98 | VNSP-89, 90, 92, 94 | ||

| PL | Early Chalc. (corrugated) | PL-2, 3, 4, 5, 6 | PL-1 | |

| Early Chalc. (no decoration) | PL-7, 8, 9, 10, 11, 12 | |||

| Full Chalc. (acacia leaf) | PL-13, 14, 15, 16, 17, 18, 19 | |||

| Full Chalc. (no decoration) | PL-20, 21, 22, 23 | |||

| Full Chalc. (other decoration) | PL-24, 25, 26, 27, 28, 29 | |||

| EPR | Late Neo./Early Chalc. (carinated bowls) | EPR-7, 12 | EPR-1, 2, 3, 4, 5, 6, 8, 9, 10, 11 | |

| BAT | Full Chalc. (acacia leaf) | BAT-1, 2, 3, 4, 5, 6, 7, 8, 9, 10 | ||

| Total | 57 samples | 30 samples | 62 samples | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaves, R.C.; Veiga, J.P.; Monge Soares, A. Characterization of Chalcolithic Ceramics from the Lisbon Region, Portugal: An Archaeometric Study. Heritage 2022, 5, 2422-2443. https://doi.org/10.3390/heritage5030126

Chaves RC, Veiga JP, Monge Soares A. Characterization of Chalcolithic Ceramics from the Lisbon Region, Portugal: An Archaeometric Study. Heritage. 2022; 5(3):2422-2443. https://doi.org/10.3390/heritage5030126

Chicago/Turabian StyleChaves, Rute Correia, João Pedro Veiga, and António Monge Soares. 2022. "Characterization of Chalcolithic Ceramics from the Lisbon Region, Portugal: An Archaeometric Study" Heritage 5, no. 3: 2422-2443. https://doi.org/10.3390/heritage5030126

APA StyleChaves, R. C., Veiga, J. P., & Monge Soares, A. (2022). Characterization of Chalcolithic Ceramics from the Lisbon Region, Portugal: An Archaeometric Study. Heritage, 5(3), 2422-2443. https://doi.org/10.3390/heritage5030126