Characterization of Ancient Mortars from Minoan City of Kommos in Crete

Abstract

:1. Introduction

2. Sampling and Experimental Procedure

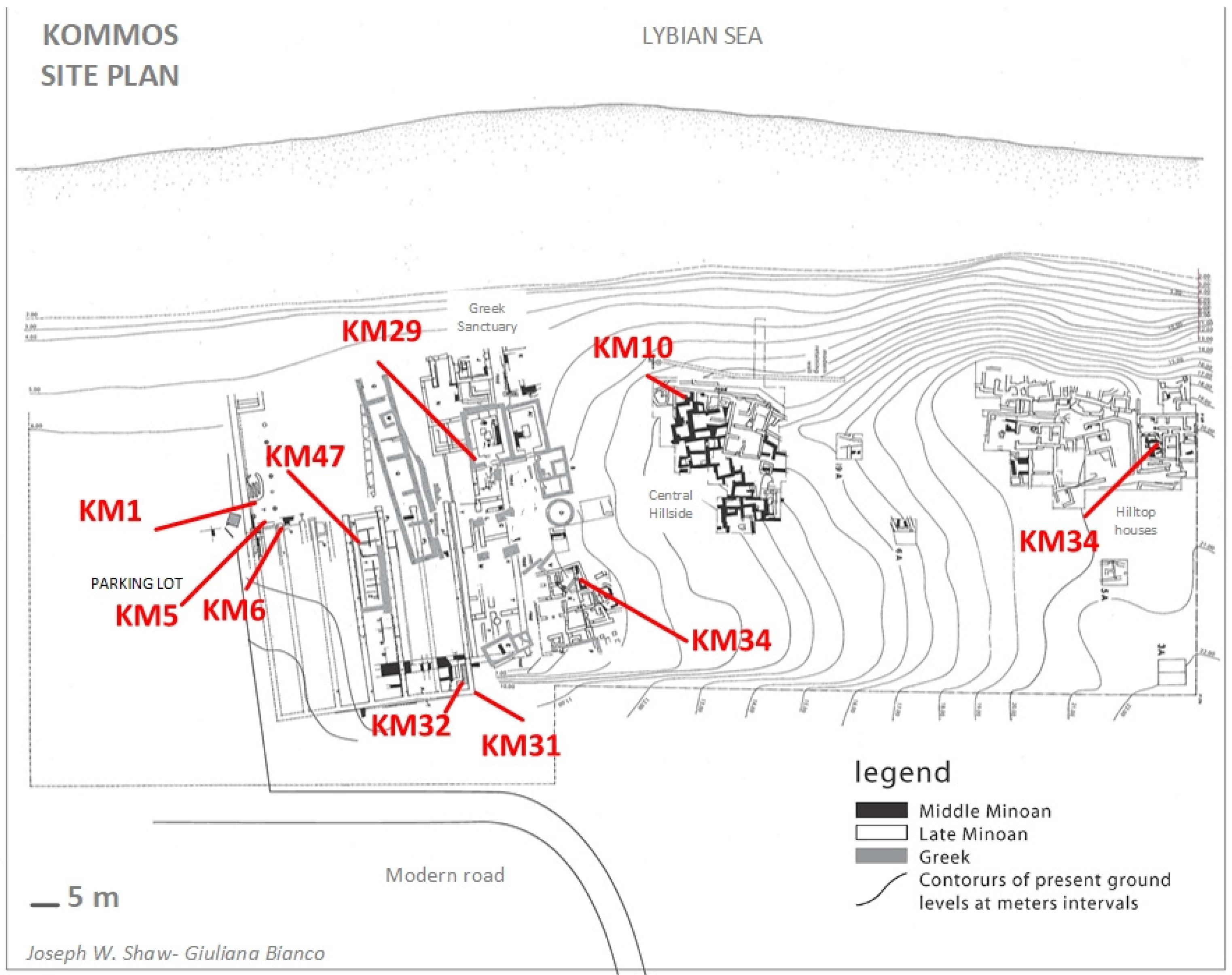

2.1. Sampling

2.2. Experimental

3. Results and Discussion

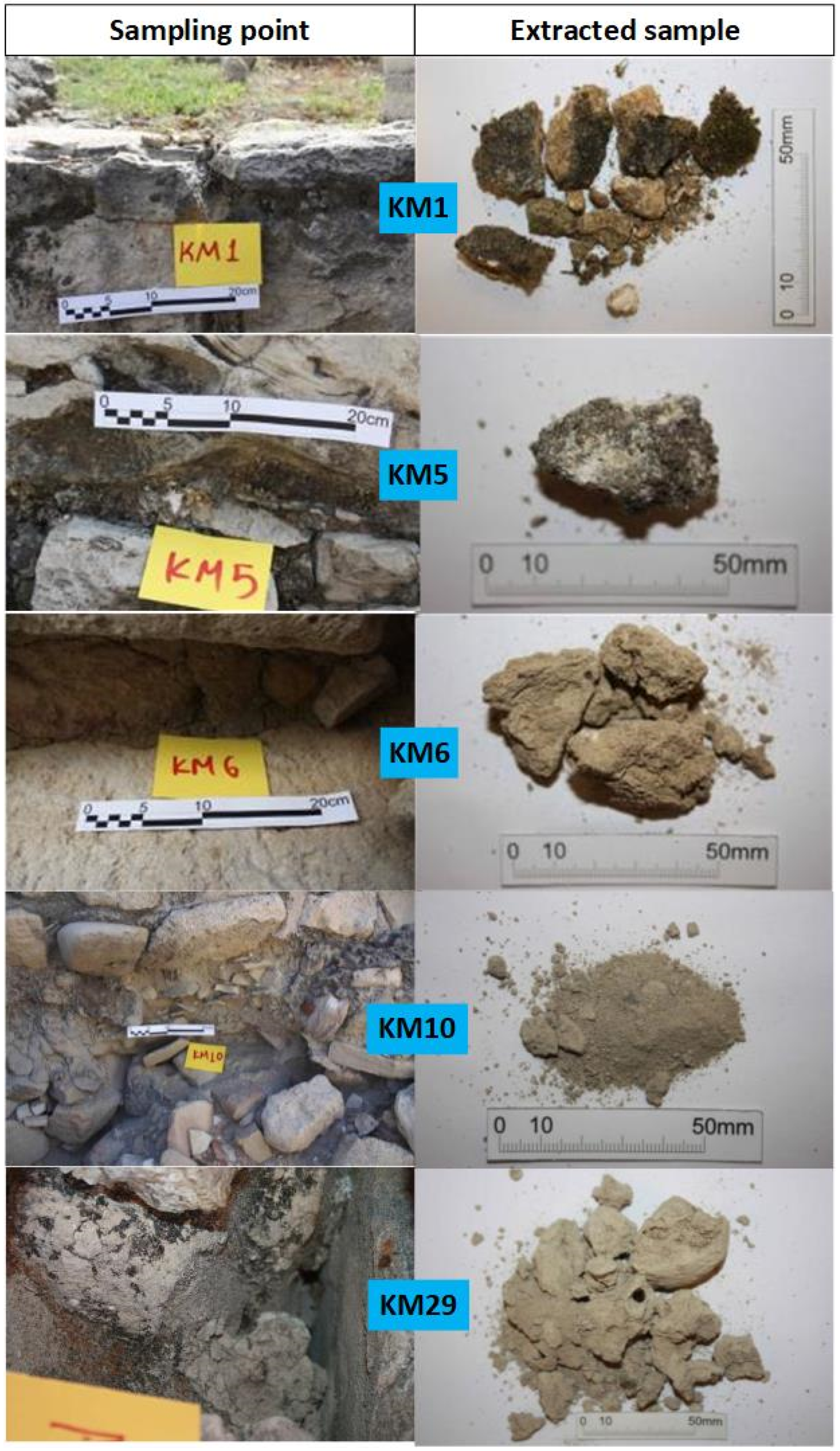

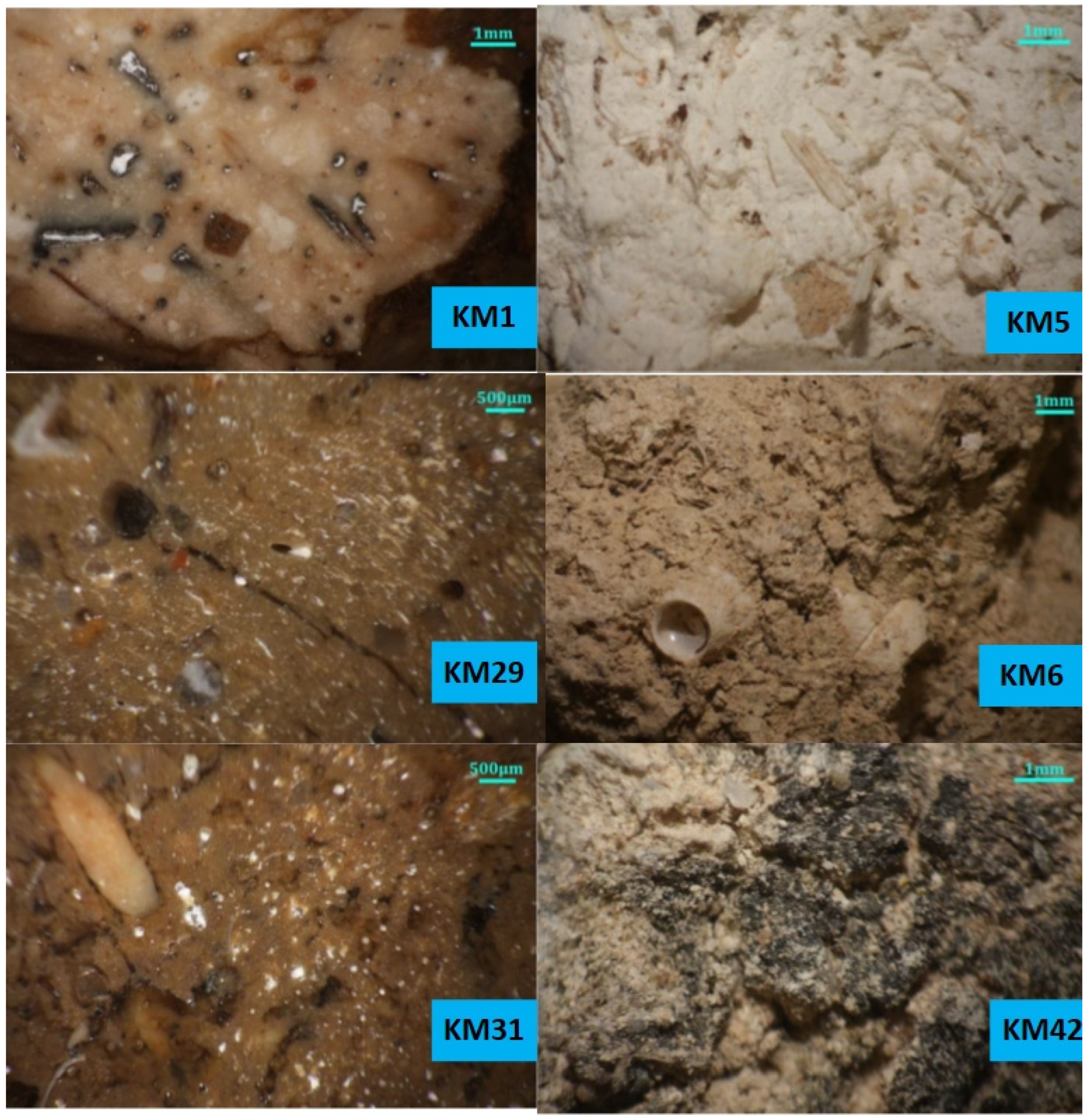

3.1. Macroscopic and Stereomicroscopic Analyses

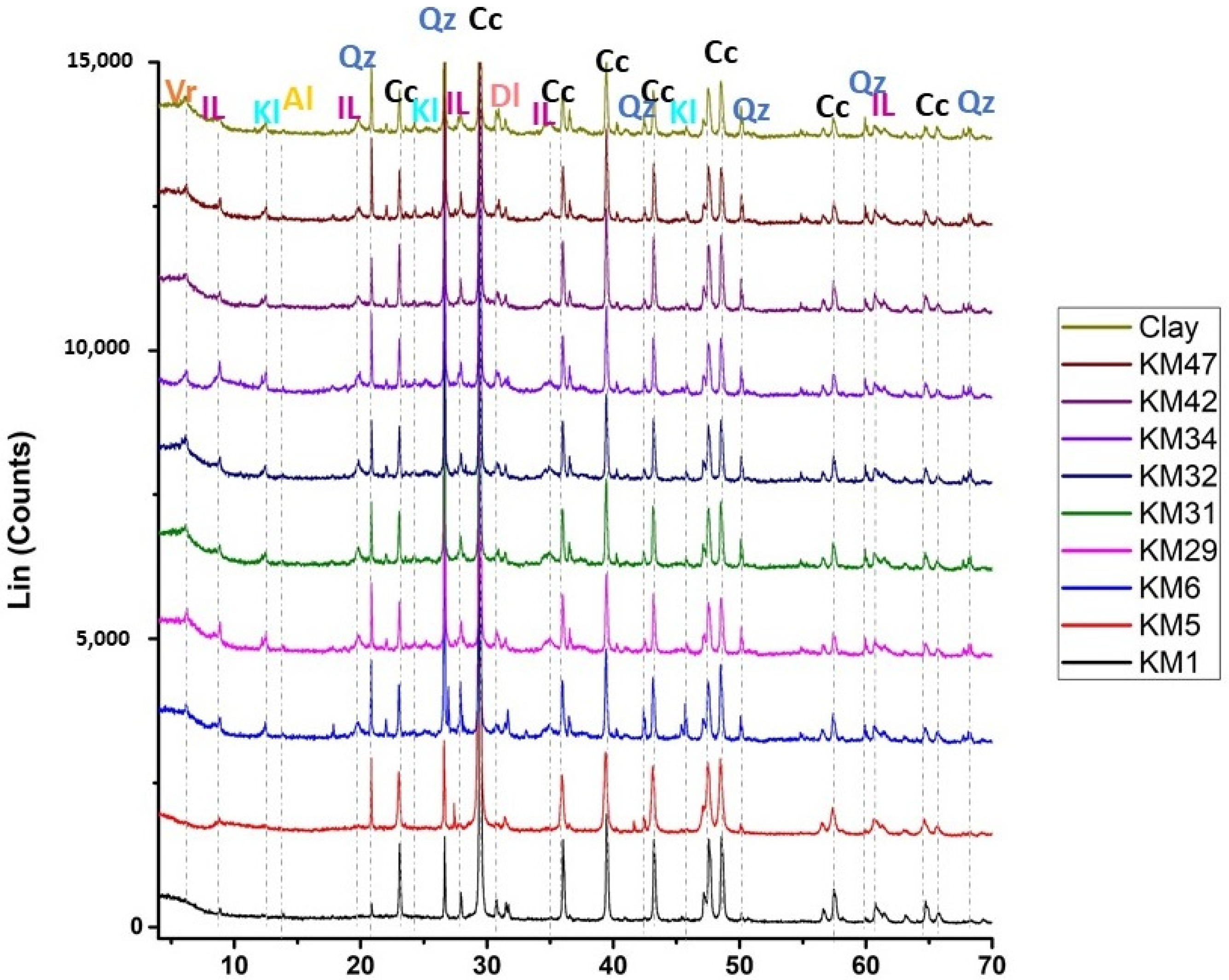

3.2. XRD Analysis

3.3. XRF Analyses

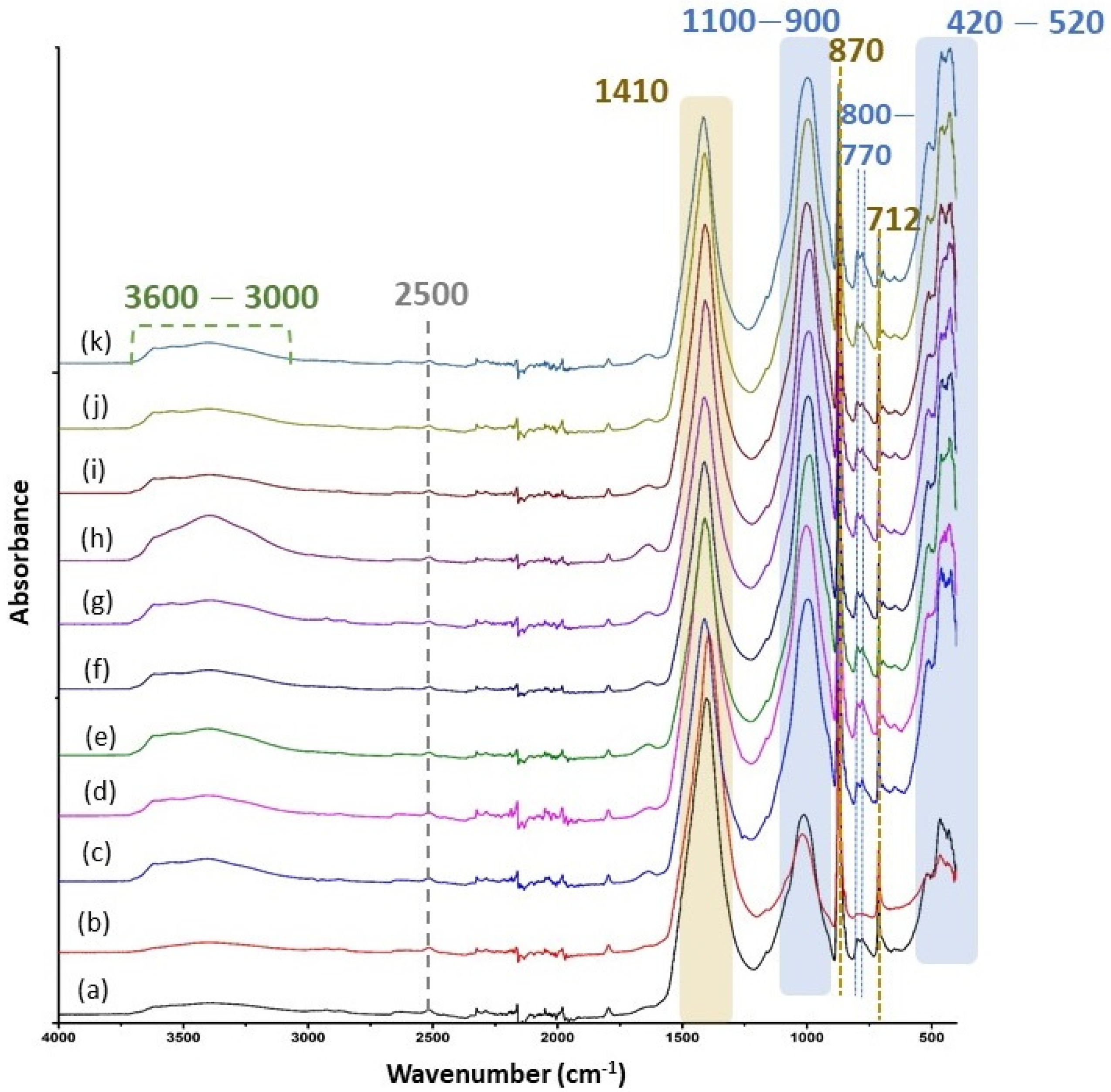

3.4. FTIR Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaw, J.W. Excavations at Kommos (Crete) during 1979. Hesperia 1980, 49, 207–250. [Google Scholar] [CrossRef]

- Shaw, J.W.; Shaw, M.C. Kommos: An excavation on the South Coast of Crete, Volume 1, Part 1: The Kommos Region and Houses of the Minoan Town. Part 2. The Kommos Region, Ecology and Minoan Industries; Princeton University Press: Princeton, NJ, USA, 2014. [Google Scholar]

- Betancourt, P.P. Kommos: An Excavation on the South Coast of Crete, Volume 2: The Final Neolithic through Middle Minoan Pottery; Princeton University Press: Princeton, NJ, USA, 1992. [Google Scholar]

- Shaw, J.W. Kommos: A Minoan Harbour Town and Greek Sanctuary in Southern Crete; American School of Classical Studies at Athens: Souidias, Athina, 2006; ISBN 0876616600/978-0876616604. [Google Scholar]

- Shaw, J.W. Excavations at Kommos (Crete) during 1976. Hesperia 1977, 46, 199–240. [Google Scholar] [CrossRef]

- Shaw, J.W. Excavations at Kommos (Crete) during 1978. Hesperia 1979, 48, 145–173. [Google Scholar] [CrossRef]

- Shaw, J.W. Excavations at Kommos (Crete) during 1980. Hesperia 1981, 50, 211–251. [Google Scholar] [CrossRef]

- Shaw, J.W. Excavations at Kommos (Crete) during 1981. Hesperia 1982, 51, 164–195. [Google Scholar] [CrossRef]

- Shaw, J.W. Excavations at Kommos (Crete) during 1982–1983. Hesperia 1984, 53, 251–287. [Google Scholar] [CrossRef]

- Shaw, J.W. Excavations at Kommos (Crete) during 1984–1985. Hesperia 1986, 55, 219–269. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Optimization of compatible restoration mortars for the earthquake protection of Hagia Sophia. J. Cult. Herit. 2013, 14, e147–e152. [Google Scholar] [CrossRef]

- Van Balen, K.; Papayianni, I.; Van Hees, R.; Binda, L.; Waldum, A. RILEM TC 167-COM: ‘Characterization of Old Mortars with Respect to their Repair’ Introduction to requirements for and functions and properties of repair mortars. Mater. Struct. 2005, 38, 781–785. [Google Scholar] [CrossRef]

- Schueremans, L.; Cizer, Ö.; Janssens, E.; Serré, G.; Van Balen, K. Characterization of repair mortars for the assessment of their compatibility in restoration projects: Research and practice. Constr. Build. Mater. 2011, 25, 4338–4350. [Google Scholar] [CrossRef]

- Loureiro, A.M.S.; da Paz, S.P.A.; Veiga, M.R.; Angélica, R.S. Investigation of historical mortars from Belém do Pará, Northern Brazil. Constr. Build. Mater. 2020, 233, 117284. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Properties of lime-metakolin mortars for the restoration of historic masonries. Appl. Clay Sci. 2011, 53, 15–19. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moudoulas, P.; Aggelakopoulou, E. Reverse Engineering: A proper methodology for compatible restoration of mortars. In Proceedings of the Workshop Repair Mortars for Historic Masonry, Delft, The Netherlands, 26–28 January 2005; RILEM Publications SARL: Delft, The Netherlands, 2009; pp. 278–291. [Google Scholar]

- Pacheco-Torgal, F.; Faria, S.; Jalali, S. Some considerations about the use of lime-cement mortars for building conservation purposes in Portugal: A reprehensible option or a lesser evil? Constr. Build. Mater. 2012, 30, 488–494. [Google Scholar] [CrossRef] [Green Version]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Strength development and lime reaction in mortars for repairing historic masonries. Cem. Concr. Compos. 2005, 27, 289–294. [Google Scholar] [CrossRef]

- Biscontin, G.; Bakolas, A.; Moropoulou, A.; Zendri, E. Microstructural characterization of the historical mortars in Venice. In Proceedings of the 3rd International Symposium on the Conservation of Monuments in the Mediterranean Basin, Venice, Italy, 22–25 June 1994; pp. 405–410. [Google Scholar]

- Biscontin, G.; Bakolas, A.; Maravelaki, P.; Zendri, E. Microstructural and composition characteristics of historic mortars in Venice. In Proceedings of the Conservation of Stone and Other Materials. Conference Proceedings. Volume 1. Rilem-Unesco, Pairs, France, 29 June–1 July 1993; Thiel, M.J., Ed.; Chapman and Hall: Paris, France, 1993; pp. 178–185. [Google Scholar]

- Farmer, V.C. Infrared Spectra of Minerals; Mineralogical Society: London, UK, 1974. [Google Scholar]

- Maravelaki-Kalaitzaki, P.; Galanos, A.; Doganis, I.; Kallithrakas-Kontos, N. Physico-chemical characterization of mortars as a tool in studying specific hydraulic components: Application to the study of ancient Naxos aqueduct. Appl. Phys. A 2011, 104, 335–348. [Google Scholar] [CrossRef]

- Artioli, G.; Secco, M.; Addis, A. The Vitruvian legacy: Mortars and binders before and after the Roman world. EMU Notes Mineral 2019, 20, 151–202. [Google Scholar]

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Investigation of the technology of historic mortars. J. Cult. Herit. 2000, 1, 45–58. [Google Scholar] [CrossRef]

- Regev, L.; Poduska, K.M.; Addadi, L.; Weiner, S.; Boaretto, E. Distinguishing between calcites formed by different mechanisms using infrared spectrometry: Archaeological applications. J. Archaeol. Sci. 2010, 37, 3022–3029. [Google Scholar] [CrossRef] [Green Version]

- Chu, V.; Regev, L.; Weiner, S.; Boaretto, E. Differentiating between anthropogenic calcite in plaster. ash and natural calcite using infrared spectroscopy: Implications in archaeology. J. Archaeol. Sci. 2008, 35, 905–911. [Google Scholar] [CrossRef]

- Weiner, S. Microarchaeology: Beyond the Visible Archaeological Record; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Reeder, R.J. Carbonates: Mineralogy and Chemistry; Mineralogical Soc. of America: Washington, DC, USA, 1990. [Google Scholar]

- Corti, C.; Rampazzi, L.; Bugini, R.; Sansonneti, A.; Biraghi, M.; Castelletti, L.; Nobile, I.; Orsenigo, C. Thermal Analysis and archaeological chronology: The ancient mortars of the site of Baradello (Como. Italy). Thermochim. Acta 2013, 572, 71–84. [Google Scholar] [CrossRef]

- Suzuki, M.D.; Dauphin, Y.; Addadia, L.; Weiner, S. Atomic order of aragonite crystals formed by mollusks. CrystEngComm 2011, 13, 6780–6786. [Google Scholar] [CrossRef]

- Mayer, B.Y. Archaeomalacology: Molluscs in Former Environments of Human Behaviour; Oxbow Books: Oxford, UK, 2005. [Google Scholar]

- Riquelme, F.; Alvarado-Ortega, J.; Cuevas-Garcia, M.; Ruvalcaba-Sil, J.L.; Linares-Lopez, C. Calcareous fossil inclusions and rock-source of Maya lime plaster from the Temple of the Inscriptions. Palenque. Mexico. J. Archaeol. Sci. 2012, 39, 624–639. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Michailidis, P.; Chronopoulos, M.; Spanos, C.H. Traditional technologies in Crete providing mortars with effective mechanical properties. Trans. Built Environ. 1995, 15, 11. [Google Scholar]

- Genestar, C.; Pons, C.; Más, A. Analytical characterisation of ancient mortars from the archaeological Roman city of Pollentia (Balearic Islands, Spain). Anal. Chim. Acta 2006, 557, 373–379. [Google Scholar] [CrossRef]

- Biscontin, G.; Birelli, M.P.; Zendri, E. Characterization of binders employed in the manufacture of Venetian historical mortars. J. Cult. Herit. 2002, 3, 31–37. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, S.V.; Waghmare, S.A.; Sabale, P.D. Aragonite–vaterite–calcite: Polymorphs of CaCO3 in 7th century CE lime plasters of Alampur group of temples India. Constr. Build. Mater. 2016, 112, 386–397. [Google Scholar] [CrossRef]

- Toffolo, M.B.; Regev, L.; Dubernet, S.; Lefrais, Y.; Boaretto, E. FTIR-Based Crystallinity Assessment of Aragonite-Calcite Mixtures in Archaeological Lime Binders Altered by Diagenesis. Minerals 2019, 9, 121. [Google Scholar] [CrossRef] [Green Version]

- Kaufhold, S.; Hein, M.; Dohrmann, R.; Ufer, K. Quantification of the mineralogical composition of clays using FTIR spectroscopy. Vib. Spectrosc. 2012, 59, 29–39. [Google Scholar] [CrossRef]

| Sample Name | Location | Function | Period |

|---|---|---|---|

| KM1 | Civic Center, South Stoa | Pointing Mortar | Bronze Age |

| KM5 | Civic Center, South Stoa | Pointing Mortar | Bronze Age |

| KM6 | Civic Center, South Stoa | Joint Mortar | Bronze Age |

| KM10 | Central Hillside | Joint Mortar | Late Minoan |

| KM29 | Greek Sanctuary | Joint Mortar | Late Minoan |

| KM31 | Greek Sanctuary | Joint Mortar | Late Bronze Age |

| KM32 | House X | Joint Mortar | Late Bronze Age |

| KM34 | House X | Joint Mortar | Late Bronze Age |

| KM42 | Hilltop Houses | Pointing Mortar | Middle Minoan |

| KM47 | Building P | Pointing Mortar | Late Bronze Age |

| Samples | Characteristics |

|---|---|

| KM1 | Intense white color, binder rich in lime, presence of straw fibers |

| KM5 | Intense white color, binder rich in lime, presence of straw fibers |

| KM6 | Earthen binder, coarse microstructure, sea shells, cracks |

| KM10 | Earthen binder, poor performance, many sea shells |

| KM29 | Earthen binder, very fine inert |

| KM31 | Earthen binder, coarse microstructure, sea shells, voids and cracks |

| KM32 | Earthen binder, sea sand, sea shells |

| KM34 | Earthen binder, well performing mortar |

| KM42 | Earthen binder, mortar with poor performance, many sea shells |

| KM47 | Earthen binder, fine sea sand, sporadic sea shells |

| XRD | Mineralogical Composition |

|---|---|

| KM1 | calcite, quartz, illite, kaolinite, dolomite, anorthite, aragonite, orthoclase, halite |

| KM5 | calcite, quartz, illite, dolomite, orthoclase, halite, |

| KM6 | calcite, quartz, illite, kaolinite, dolomite, anorthite, aragonite, halite, corrensite |

| KM10 | calcite, quartz, illite, kaolinite, albite, aragonite, epidote, halite, halite, montmorillonite |

| KM29 | calcite, quartz, illite, kaolinite, dolomite, albite, epidote, lizardite, vermiculite |

| KM31 | calcite, quartz, illite, kaolinite, dolomite, albite, aragonite, lizardite, vermiculite |

| KM32 | calcite, quartz, illite, kaolinite, albite, aragonite, epidote, lizardite, vermiculite |

| KM34 | calcite, quartz, illite, kaolinite, dolomite, albite, aragonite, epidote, lizardite, vermiculite |

| KM42 | calcite, quartz, illite, kaolinite, dolomite, albite, lizardite, vermiculite |

| KM47 | calcite, quartz, illite, kaolinite, dolomite, albite calcian, aragonite, lizardite, vermiculite |

| KM Clay | calcite, quartz, illite, kaolinite, dolomite, albite, vermiculite, montmorillonite |

| XRF | KM1 | KM5 | KM6 | KM10 | KM29 | KM31 | KM32 | KM34 | KM42 | KM47 | KM Clay |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | 41.01 | 47.55 | 32.53 | 34.99 | 29.97 | 30.74 | 30.56 | 30.85 | 37.18 | 32.38 | 29.18 |

| SiO2 | 17.32 | 7.17 | 27.85 | 26.77 | 30.37 | 29.06 | 29.49 | 27.16 | 22.82 | 28.02 | 28.21 |

| Al2O3 | 3.75 | 1.58 | 7.58 | 5.84 | 7.93 | 7.51 | 7.66 | 7.07 | 5.62 | 7.15 | 7.25 |

| MgO | 2.80 | 2.15 | 4.46 | 4.03 | 4.34 | 3.59 | 4.03 | 4.37 | 3.36 | 4.14 | 4.19 |

| Fe2O3 | 2.14 | 1.11 | 4.08 | 3.12 | 4.27 | 4.09 | 4.20 | 4.07 | 3.32 | 4.06 | 3.86 |

| Na2O | 1.01 | 1.51 | 2.50 | 1.63 | 1.56 | 1.13 | 1.06 | 1.79 | 0.93 | 1.10 | 1.81 |

| K2O | 0.59 | 0.26 | 1.24 | 0.98 | 1.43 | 1.28 | 1.27 | 1.26 | 1.01 | 1.26 | 1.24 |

| SO3 | 0.19 | 0.23 | 0.09 | 0.08 | 0.06 | 0.07 | 0.10 | 0.09 | 0.10 | 0.16 | 0.17 |

| Cl | 0.08 | 0.36 | 0.81 | 0.52 | 0.25 | 0.16 | 0.08 | 0.69 | 0.04 | 0.04 | 0.51 |

| P2O5 | 0.12 | 0.08 | 0.11 | 0.18 | 0.10 | 0.13 | 0.21 | 0.33 | 0.15 | 0.22 | 0.10 |

| TiO2 | 0.31 | 0.12 | 0.52 | 0.42 | 0.59 | 0.57 | 0.56 | 0.56 | 0.47 | 0.55 | 0.59 |

| SUM | 69.32 | 62.12 | 81.77 | 78.56 | 80.87 | 78.33 | 79.22 | 78.24 | 75.00 | 79.08 | 77.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maravelaki, P.-N.; Theologitis, A.; Budak Unaler, M.; Kapridaki, C.; Kapetanaki, K.; Wright, J. Characterization of Ancient Mortars from Minoan City of Kommos in Crete. Heritage 2021, 4, 3908-3918. https://doi.org/10.3390/heritage4040214

Maravelaki P-N, Theologitis A, Budak Unaler M, Kapridaki C, Kapetanaki K, Wright J. Characterization of Ancient Mortars from Minoan City of Kommos in Crete. Heritage. 2021; 4(4):3908-3918. https://doi.org/10.3390/heritage4040214

Chicago/Turabian StyleMaravelaki, Pagona-Noni, Antonis Theologitis, Meral Budak Unaler, Chrysi Kapridaki, Kali Kapetanaki, and James Wright. 2021. "Characterization of Ancient Mortars from Minoan City of Kommos in Crete" Heritage 4, no. 4: 3908-3918. https://doi.org/10.3390/heritage4040214

APA StyleMaravelaki, P.-N., Theologitis, A., Budak Unaler, M., Kapridaki, C., Kapetanaki, K., & Wright, J. (2021). Characterization of Ancient Mortars from Minoan City of Kommos in Crete. Heritage, 4(4), 3908-3918. https://doi.org/10.3390/heritage4040214