Abstract

Aluminum alloys are very interesting witnesses of industrial and technical development. The first ever developed was Duralumin, a light metal with good mechanical properties. In the 1930s, the rise of nationalism stimulated research and development, generating various aluminum alloys. This work reports the comparison of two versions of aluminum alloys, which were found in collected parts of WWII crashed aircraft from four nations: a Messerschmitt Bf 109 (DE), a Dewoitine D.520 (FR), and a P-51 Mustang (USA) and an Avro Lancaster (United Kingdom). The first version of alloy with magnesium content below or equal to 1 wt.% and the second version with higher magnesium content (1.5 wt.%), were identified as respectively AlCuMg1, AlCuMg2 in Germany; Duralumin, Duralumin F.R. in France; Hiduminium DU Brand, Hiduminium 72 in the UK and 17S, 24S in the USA. This study uses a multiscale approach based on historical research complimented by laboratory analyses of materials directly collected on the crashed aircraft. It allows a comparison and a better knowledge of the alloys used in each nations: their chemical composition, designations, microstructure, and mechanical properties are investigated.

1. Introduction

Improving aircraft performances has always been at the heart of the priority since the beginning of aviation. Performance, amongst other factors such as motorization, are deeply linked to materials. At the very beginning of aircraft construction, aircraft were mostly made of organic materials such as wood and fabric [1]. Although wood was very light, with the Great War and the changes in aircraft duty description, it was no longer the appropriate material. Metal was introduced in aircraft construction for the first time during the First World War. Hugo Junkers tried, on several occasions, to assemble an all-metal airplane [2]: The J I had a skin made out of steel in 1915. Steel was replaced in 1918 by aluminum alloy in the J 7 aircraft. Very quickly after that, a great number of attempts were made to lighten the metallic structures to reach aircraft construction requirements. These requirements pushed industrialists to develop new light alloys based on aluminum. In particular, Duralumin-type alloys contained 3 to 5 wt.% of copper, 1 wt.% of manganese and 0.5 wt.% of magnesium. In these alloys, structural hardening was obtained with a particular sequence of treatments involving heat treatment until solution heat treatment and quenching followed by room temperature aging [3]. Thanks to its good mechanical properties combined with lightness, Duralumin became a material of choice for aircraft construction. The United States of America and European nations quickly appropriated Duralumin and made their own improvements, leading to different variations of series of alloys [4,5,6]. Beginning in the 1930s, the rise of nationalism and the development of military forces greatly stimulated research and development in the field of military aviation worldwide. The industrial processes to obtain the best alloy for the development of high performance aircraft became strategic for nations who wished to develop their own air forces. It thus became of high importance to master the manufacturing processes for aluminum alloys. In this sense, aluminum alloys are very intriguing witnesses to the industrial and technical developments made at this time [7].

This work focuses on wrought aluminum alloys, especially Duralumin that was developed for aeronautics by the nations involved in the WWII conflict in a period from 1930 to 1945. The materials analyses are carried out on archaeological remains that were collected from crashed World War II fighters, bombers, and aircraft used in various missions. The studied remains of the aircraft were all excavated by the members of the Aerocherche association who investigated, identified, and traced the history of every single aircraft. The aim of this work was to identify and compare these alloys. A dual approach which consists of combining archives and physicochemical characterization was used. These artifacts were manufactured almost a century ago; in a wartime when resources were limited, shortages of raw materials were common. As surprising as it may seem, industrial records were not always kept, so the archives are now superficial. Laboratory analyses then allow to complete the missing information on these historic materials. Although collected remains cannot provide a full representative view of the aircraft technology itself, the analyses will reveal some of the aluminum alloys used by industrials in the four studied nations. Their chemical composition, designation, and mechanical properties are technical information that can help answer the historical question around the technological know-how of each country involved in the conflict.

In the first part of the article, alloys of collected remains from 15 aircraft were identified, and a presentation was made of duralumin-type alloys from the 1930s to 1945 of Germany, France, the United Kingdom, and the United States. Their mechanical properties will be compared based on archival research. Their differences and similarities are highlighted and interpreted based on historical facts. It will be shown that nations followed parallel developments in this highly strategic field. However, differences can be highlighted, especially in the case of the United Kingdom. In the second part, hardness measurements are performed on four samples collected from wrecks. A full metallurgical investigation from the millimeter to nanometer scale is performed to reveal the microstructure and nanostructure of these particular alloys. The latter contains crucial information on the manufacturing processes (thermomechanical treatments undergone) as well as on the history of the part itself. In particular, past events experienced by the aircraft (crashes for instance) were shown to have a strong influence on the microstructure of the alloys and hence on the associated mechanical properties.

2. Materials and Methodology

2.1. Materials

All the remains were found after extensive search from archaeological excavations (Under permits delivered by the archaeological department of the French Regional Cultural Affairs Directorates (DRAC)), and identified thanks to testimonies of local people and contemporary reports. The remains have stayed buried in the ground for decades and, once they were excavated, they were stored indoors.

Excavated remains with high archaeological value (a serial number, or a certain historical importance) were looked after by various museums or associations. Other remains with lower importance were studied, their low archaeological value allowed for setting up and improving a methodological protocol and to learn more about these materials using destructive analytical techniques.

In this work, remains from 15 aircraft were studied (see supplementary information for details), and at least one part (plate, rivet, stringer) per remain undergoing an extensive metallurgical study.

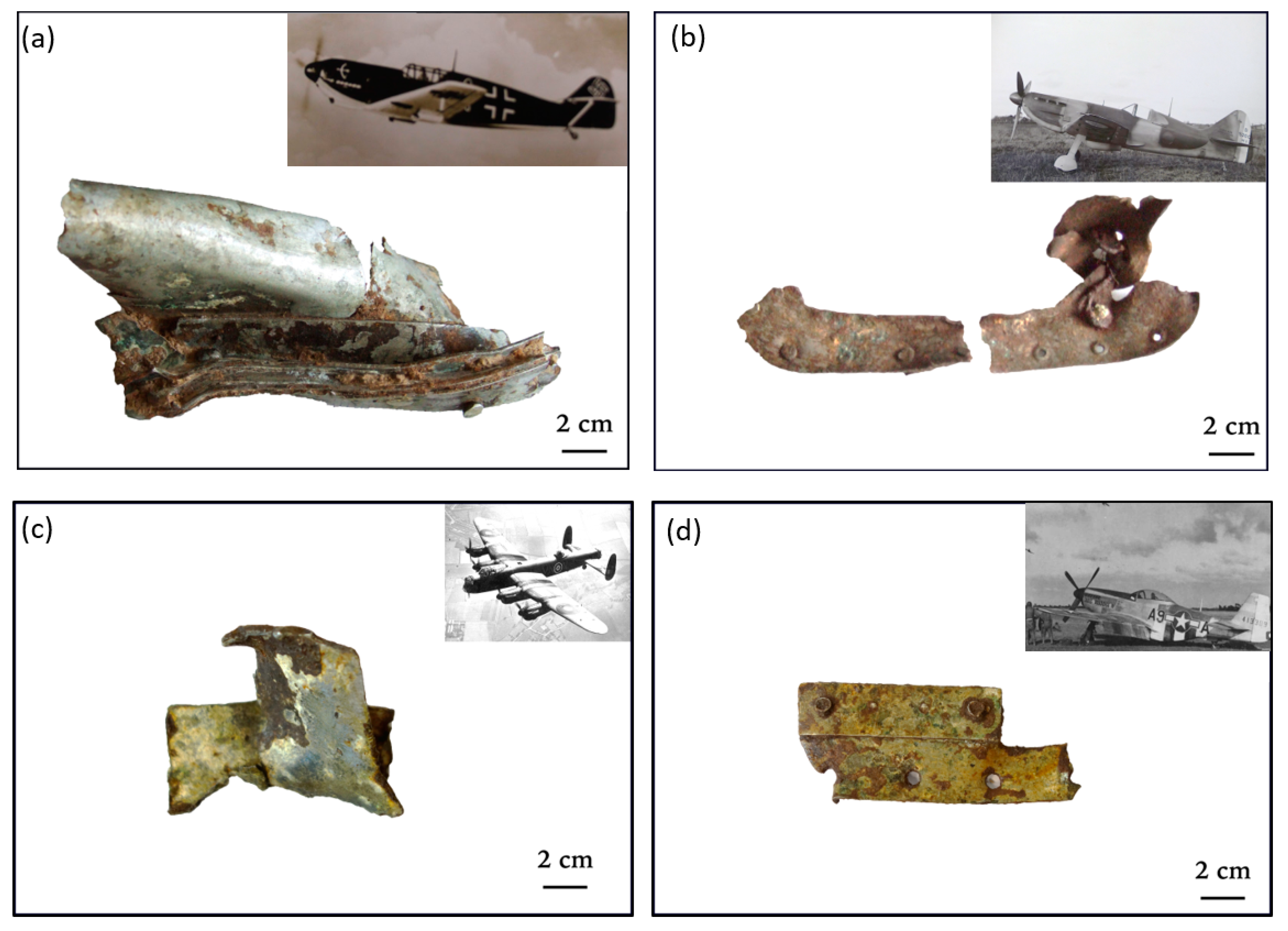

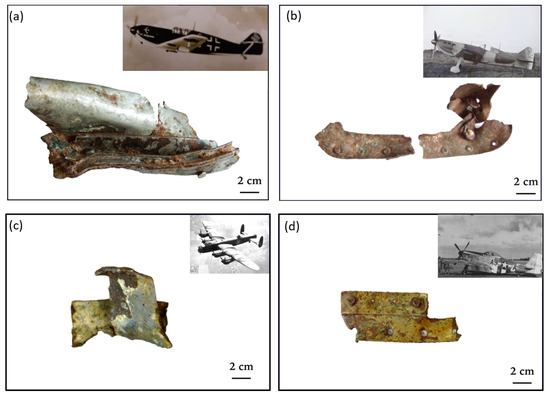

For the sake of this article, only 4 plates will be presented, corresponding to one alloy per nation, selected on aircraft of the same period.

2.2. Methodology

The adopted methodology involved a dual approach: physicochemical characterization and research in archives. The first allows a precise identification, while the latter helps the examination of related historical and technical aspects.

2.2.1. Archives Research and Analyses

For this study, valuable information was found using various primary and secondary sources. Indeed, gathering resources from four nations was necessary in order to have an accurate idea of the preferred alloy used for the construction aeronautical structures. However, finding relevant technical data was not easy as technical documents were often gotten rid of after the start of a new project. Industrial records were not seen indeed as valuable heritage material.

The archival study was made along three axes: airplane manufacturers, alloy manufacturing companies, and material sciences.

Since aircraft manufacturers’ technical data were often either lacunar, not found or unavailable, general data on the aluminum manufacturing companies were sought after. It was possible to link aluminum manufacturing companies to aircraft manufacturers. For example, a Dewoitine purchase order document (from the Departmental Archives of the Haute Garonne box n°56J22.), from La Société du Duralumin, was found. This allowed to link the technical information to the mechanical properties and manufacturing processes of the alloys used by the Emile Dewoitine company (Toulouse, France).

In France, information regarding French alloys and aircraft manufacturers were found in different sites such as the Institute for History of Aluminum (IHA, Paris), the Departmental Archives of the Haute Garonne (giving access to technical documents regarding the construction of the D.520 series of aircraft), and the Institute of Transportation and Technology Communications (ITTC, Toulouse) also held valuable information.

For the German side, tremendous information was found in the National Air & Space Museum archives (Washington DC, USA). In fact, in the final days of WWII, after the defeat of Germany, several technical documents were confiscated by Allies, especially the United States Army Air Force, and scanned by the Air Document Division(from the National Air and Space Museum archives in Technical Information Section (T-2), Air Materiel Command, at Wright Field, Ohio (a.k.a CatD collection). Therefore, numerous microfilms regarding the development of aluminum alloys for aeronautics in Germany were studied. Technical data regarding aircraft manufacturers were also obtained and studied (from the Berlin Brandenburg archives on armament production). Indeed, a Dornier, a Junkers and a Messerschmitt (Bf 109) construction files were investigated.

Other ancient books and reports were found using the website Archive.org—for instance, various NACA (National Advisory Committee for Aeronautics) and B.I.O.S. (British Intelligence Objectives Sub-Committee) reports on the duralumin type alloys were obtained using this website. At the end of WWII, this British organization was in charge of collecting relevant documents and writing reports and technical briefs on various topics. Research were also done in the American National Archives, and information on ALCOA was found amongst the numerous publication made by ALCOA using the online book by Aluminum Company of America.

Other sources were also employed namely databases regarding the material sciences such as: Metallurgical research and technology database (issues from 1904 until nowadays) and La revue de l’Aluminum, l’Aluminum Français.

Aircraft specialized magazines such as Flight magazine archives, Flight Global, l’Aéronautique, or Revue Aéronautique de France, were full of information concerning the aircraft, and, sometimes, the alloys used for their construction. Other general reviews or databases such as Retro News and Gallica gave access to contemporary information. Combining all these sources was a way of linking material data to the construction of aircraft.

Therefore, although information in archives can be scattered and dispersed or is not always available (lost during the war), relevant information can be found by correlating various secondary sources. Research in archives is necessary for it helps to put in context and interpret the results found from analyses.

2.2.2. Experimental Techniques

A multiscale approach was used to examine archaeological materials with various techniques. Selected remains were carefully recorded, numbered, and photographed using Optical Microscopy (OM). Next, more specific analyses on the alloys’ chemistry and structure were conducted after cutting samples from the remains (see supplementary information). The identification of the alloys was done with a Scanning Electron Microscopy (SEM) paired with an Energy Dispersive X Ray spectrometer (EDS). A JEOL JSM 6490 (Peabody, M.A. 01960, USA) along with an IncaPentaFet X3 software (Oxford Instrument, Abingdon, United Kingdom) is used.

For the characterization of the microstructure and chemical composition, OM and SEM were used. Samples were embedded along three directions (L: longitudinal; T: transverse; S: Small transverse) in an epoxy resin. They were then mechanically polished using P600 and P1200 grit SiC (silicon carbide) grinding paper with water as a lubricant. To reach a mirror finish, polishing cloths were used with diamond suspensions containing decreasing particle sizes (3 μm down to 1 μm).

Etching using Keller’s reagent (HF 1 mL, HNO3 2.5 mL, HCl 1.5 mL in demineralized H2O 95 mL) was applied, which brought to light the microstructure. OM is preferred for measuring the size and shape of the grains. An inversed microscope Nikon MA200 (Melville, NY, USA) was used.

For the precipitation investigation, a transmission electron microscope (TEM) was used (JEOL 2010 at 200 kV). Samples preparation for the TEM analysis is as follows: samples were polished to reach a 25 μm thickness. After mechanical polishing, the samples were then electrochemically thinned using a Tenupol-5 Struers apparatus (Ballerup, Denmark) operating at 60 V in a solution of methanol and nitric acid (3:1) at −15 °C.

The nanostructure was observed using a JEOL2010 and nanoprecipitation was identified thanks to a CM20 FEG TEM/STEM microscope paired with Energy Dispersive X-ray Spectrometer (EDS) both operating at 200 kV.

The mechanical properties were investigated, especially the hardness which was measured thanks to a Buehler Omnimet series 2100 (Lake Bluff, IL6044, USA), with a load of 300 g during 10 s on polished surfaces, following the ASTM E 384 standard. Average results on 5 indents were obtained in Hardness Vickers (HV) numbers. Hardness in Brinell (HB) was then calculated using ASTM E 140 standard (specific to aluminum alloys) [8] so that a comparison with archive data was possible.

3. Results—Part A: Aluminum Alloys for WWII Aircraft’s Construction

3.1. Identification of Aluminum Alloys

The chemical composition of the parts studied in this work is reported in Table 1. Identification of these alloys was possible thanks to a research in the archives of each nation. They all belong to the duralumin family, containing aluminum as the base, copper (3.5–4.8 wt.%) magnesium (0.4–1.8 wt.%), and manganese (0.4–1.5 wt.%). Iron and silicon were also systematically found in analyses, although they were not always added on purpose. In fact, they are impurities present in the bauxite ore [9]. Two versions of duralumin can be distinguished, with the major difference being their magnesium content.

Table 1.

Average chemical composition (in wt.%) of alloys of all the samples from all the aircraft composing the corpus, measured with SEM-EDS (5–10 % error), and the thickness of the studied parts.

Archival studies revealed that, amongst other aluminum alloys (from different series, i.e., with addition of elements such as zinc or silicon), two versions of duralumin were used in these countries for aircraft construction.

At that time, no international common designation policy was yet established, and similar alloys were named differently by these nations. Table 2 summarizes the elemental composition of the alloys found in archival data. They can be classified as follows: the first version with magnesium content below or equal to 1 wt.%, was designated as AlCuMg1 in Germany [10], Duralumin in France [4], Hiduminium DU Brand in the United Kingdom [5], and 17S [6] in the United States.

Table 2.

Alloys’ chemical composition (in wt.%) referenced in archive documents.

A second version with higher magnesium content (0.8–1.8 wt.%) was known as AlCuMg2 in Germany [10], Duralumin F.R. [4,11] in France, Hiduminium 72 in the United Kingdom [5], and 24S [6] in the United States.

All aluminum alloys were identified by confronting the measured chemical compositions to the archival data (see last column of Table 1). Apart from the Focke–Wulf part, AlCuMg1 (duralumin with low magnesium content) was the alloy used for plates’ construction in all the German samples that were studied. All French samples were made of Duralumin (low magnesium), and the two British samples were made of a similar alloy: Hiduminium DU Brand. All American samples were made of 24S alloy (high magnesium content).

The correlation between results in Table 1 and the archival study indicates that the alloys presented are indeed representative.

3.2. Associated Mechanical Properties

Table 3 reports the mechanical properties found in archives for both versions of duralumin used by these nations. For this table, in order to facilitate comparisons, values are reported in kg/mm2. However, according to the British specifications (B.S.I 2L391), these values were expressed in tons. per sq. in. In the case of the American values, they were expressed in lbs. per sq. in. Because the aluminum industry was at its beginning, standardization was still being set up amongst each country. However, there was not any normalization between countries, possibly in view of the uprising tensions [12]. Therefore, measurements were performed using different techniques. For instance, hardness measurements were not made with the same equipment; it was measured using 1000 kg load in both Germany and France [4,10], while Americans used a 500 kg load [6]. No information related to the hardness measurement was found in case of the British industry. For measuring the yield strength, British archival data showed that a different strain percentage was used (0.1% instead of 0.2%(σ0.2)).

Table 3.

Mechanical properties reported in the archives of the two versions of Duralumin.

In this table, alloys are divided according to their magnesium content, which corresponds to the mechanical properties. Indeed, the first observation that can be made is that, generally, alloys with high magnesium content have better mechanical properties. For many years, it has been established that the first version of duralumin (with low magnesium content) was an aircraft structural material. It found considerable use in applications where its particular combination of strength and ductility and its natural aging properties were advantageous. From 1903 to the 1930s, the main focus of research and development was weight reduction [12]. However, the mechanical properties were no longer suitable for the aircraft industry requirements, and it soon became more important to focus the research on the performance of the material. Hence, from the 1930s up until the 1960s, increasing the performances of the material became the main focus so there were considerable improvements in the strength/weight ratios of sheet alloys and in the yield and ultimate strengths. Thus, other versions were developed for various usages [13], which allowed the extension of new mechanical properties to new aluminum alloys. Indeed, the alloys with the higher magnesium content showed better tensile and yield strengths, leading to a duralumin era in aircraft construction.

Similarities were observed for the French and German alloys. The first version of duralumin used by Germans and French is close to the original Duralumin set up by Wilm [14], with a hardness ranging from 100 to 110 Brinell. Although this old version was more ductile than the one with higher magnesium content, it presented lower hardness, yield, and tensile strengths.

Similarities were also observed for Germany and France for the high magnesium content alloy. For the German alloy AlCuMg2, it is a high resistant alloy that was strain-hardened. In France, according to archival study, Duralumin F.R. is a light alloy with high resistance and heat treatment that was developed primarily for structural parts that were subject to heavy forces and were not to undergo shaping. In both cases, ductility was not the main focus [15]: as opposed to the low magnesium content alloy, AlCuMg2 and Duralumin F.R. were not meant to be drawn into thin wires [10,15].

Hiduminium 72 was developed in the United Kingdom to meet the demand for an aluminum alloy, which was naturally aged which would attain high tensile properties, after only one heat treatment [5]. Eventually, the mechanical properties of the American 24S are quite similar to the mechanical properties of the German AlCuMg2.

The case of the Hiduminium alloys presents a particularity. Hiduminium DU Brand appears to be harder than the rest of the alloys even though the yield and ultimate strength are not as high as the other three alloys with low magnesium content. Similarly, Hiduminium 72 (129–148 HB) is way harder than the German AlCuMg2 (110 HB), the French Hiduminium F.R. (110 HB), and the American 24S-T (105 HB). However, the yield and ultimate strengths are lower. This point will be investigated hereafter in part B.

3.3. Discussion

Aluminum alloys of different nations were investigated through chemical analysis of collected samples and archival research. Chemical analysis results coincide with information found in archives. In the beginning of the 20th century, the British bought the Duralumin patent from the Germans and used it to produce an airship: The Mayfly, which broke during a trial. The construction of the British airship represented the first use of the Duralumin [15]. German alloys were then discredited for the British. Very quickly after the incident in 1911, they sold the patent to the French and started to develop their own version of Duralumin. This explains the differences in chemical composition between the British and the German alloys. In France, the company “La Société du Duralumin” started to produce Duralumin under the German patent since 1911. This explains the similarities in the French and German alloys. Americans on their side did not have the German patent, but they obtained samples during the First World War (from captured aircraft). The samples were analyzed at the National Bureau of Standards in Washington D.C., which led to Paul Merica’s understanding of the hardening [16], and gave birth to the American version 17S. This version, developed by Earl Blough [17], is close to the German AlCuMg1 in terms of chemical composition. Consequently, from archives and with the confirmation of material analysis, it is clear that two approaches were followed: coming from the same patent. Germany, France, and the US have relatively similar alloys regarding the chemical composition and mechanical properties, while the British have slightly different alloys.

The archival research made on the material used for aircraft construction, especially plates manufacturing, revealed that, although by 1935 all these nations had developed the second version of duralumin, its use in aircraft construction was not immediately established in all nations. Indeed, in Germany, the choice for the alloy used for the plates’ construction was left to aircraft manufacturers. In 1940, Focke–Wulf apparently used the alloy with higher magnesium content (AlCuMg2) as it was found in one of the archaeological remains. A Messerschmitt archive document2 proves that the alloy used for plates’ construction was the AlCuMg1 (low magnesium content). In France, although duralumin F.R. was available since 1935, it was not used in aircraft construction before the end of WWII [18]. This information is corroborated by analyses. When it comes to Great Britain, both alloys were used, but the limited number of parts available in the corpus does not allow to confirm it.

Finally, the alloy found in the P-51 aircraft is the second version with higher mechanical properties. An ALCOA document reveals that 24S alloy (high magnesium content) was first used in aircraft construction in the Douglas DC-3 airplane in 1937, and it was the only alloy used for plate construction after that date in the United States [6]. The results of this study are synthesized in a companion article [18].

In terms of mechanical properties: archives show that alloys with high magnesium content present the best mechanical properties. This finds its explanation in the nanostructure. Wilm’s discovery was mainly based on intuition, as the mechanism of hardening was not scientifically explained at the time. However, he empirically developed an alloy that changed both the metal-making world and the aircraft industry. Following on this discovery, the works of Merica in 1929 [3] and Orowan in 1934 [19] were a major contribution to the comprehension of the structural hardening, and led to tremendous improvements in the mechanical properties of aluminum alloys. Indeed, in the case of heat-treated alloys, nanoscale fine precipitation takes place during aging, and gives extensively thin and scattered crystals. By preventing the movement of the dislocations, nanoprecipitates are the main cause for the hardening of duralumin alloys. It occurs after solution treatments about 450 °C and quenching, followed either by maturation for a few days at room temperature or by a moderate temperature (between 100 °C and 200 °C); this is respectively known as natural aging and artificial aging. Several types of precipitation sequences can take place in the duralumin depending on the composition, the sequences giving rise to θ-Al2Cu, S-Al2CuMg, β-Mg2Si and/or Q-AlCuMgSi equilibrium phases. The predominance of one precipitation sequence over another depends on the Cu/Mg, Cu/Si and Mg/Si ratios [8]. Although these compounds were not detectable using contemporary techniques notably optical microscopes, scientists were aware of their existence and their role in improving mechanical properties [20,21,22]. The addition of Mg and Cu was indeed known for improving the mechanical properties. However, the phases causing the hardening were not yet identified. It is now known that the metastable and coherent nanoprecipitates of the S-Al2CuMg sequence produce a greater hardening than the ones of the θ-Al2Cu sequence [23]. Compared to the alloy with lower magnesium content, this explains the better mechanical properties of the AlCuMg2, Duralumin F.R., Hiduminium 72, and the 24S alloys.

4. Results: Part B: Analysis of Archaeological Remains

4.1. Selection of Four Representative Alloys

Correlating results from chemical analyses and the archival study was crucial in the selection of the samples presented hereafter. Since the aim was to compare alloys that were representative of the ones mostly used for plates’ construction in the aircraft industry of each nation, the selection of the studied alloys was made in this sense. Four out of five German plates were made of the AlCuMg1 alloy. All French parts were made out of the Duralumin. The only alloy found in British aircraft parts was the Hiduminium DU Brand alloy. In addition, all the American parts were made of the 24S alloy. Therefore, it can be confirmed that the alloys collected on the Messerschmitt Bf109, the Dewoitine D.520, the Avro Lancaster, and the Mustang P-51 aircraft are representative. Because of their archaeological nature, the exact localization and the role of the parts were not systematically found. However, an investigation on the background of the aircraft, and on the conditions of the crash was done for each aircraft.

4.2. Historical Background of Aircraft

The Messerschmitt Bf 109 is an iconic German aircraft which took part in the Spanish civil war in 1936. It had operated from then until the end of WWII, with 33,000 manufactured copies. The studied parts come from the Bf 109 n°5145, which was manufactured by the Wiener Neustädter Flugzeugwerke GmbH, as a E-3 model, in August 1940. Like other Bf 109 of this period, it was quickly upgraded to E-4 standards and, sometime later3, it was further upgraded to become an E-7. Each of these upgrades involved rather simple changes to the airframe with the exception of its last modification: the fuel delivery system was modified to allow the aircraft to carry a 300 L drop tank, or, alternatively, an under fuselage bomb load. This fighter flew until 1943 when it crashed in the Pyrénées mountains during a training session.

The Dewoitine D.520 is believed to be the best French fighter of the time, although only 775 copies were made (because of the delays and the annexation of France by Nazi Germany). The samples come from the aircraft n°531 produced in 1942 and crashed in 1944 in Encausse-les-Thermes. The crash caused an explosion and a fire.

The Avro Lancaster is the most famous British bomber with more than 7378 produced copies. The one of interest in this paper, with a serial number ME685, was built at the end of 1943/beginning of 1944 and was delivered to the Royal Air Force in March 1944. The same year, it was shot down by the Germans in Toulouse/Montaudran, where it exploded in the air.

Finally, the North American P-51 Mustang, conceived in only 120 days, is famous for being one of the best fighters of WWII, which explains its 13,300 copies made in the USA. The parts used in this work were collected from the P-51 n°413309 also known as Fool’s Paradise IV, which was manufactured in 1943. It crashed in 1944 after losing its coolant during a very violent impact. Figure 1 shows the studied remains and their corresponding aircraft.

From each remain, a plate was selected (see supplementary information). Analyzed parts, all plates, are made out of wrought alloys and in a thickness range between 1 and 2.2 mm. The Bf 109 plate is 2.0 mm thick, the D.520 plate is 1.1 mm, the Lancaster plate is 1.5 mm, and the P-51 plate is 2.2 mm. The thickness of the metal plate plays a significant role in the mechanical properties as will be demonstrated hereafter.

4.3. Hardness Measurements of Archaeological Samples

On the selected remains, only limited amount of material was available. Because of their archaeological nature, all these aircraft crashed and the parts were contorted, which makes mechanical tests on flat and large surfaces difficult. For these reasons, only hardness was scrutinized in this paper. It constitutes a first step towards the full investigation of the mechanical properties of the parts. Hardness was measured along three directions and is reported in Table 4.

Table 4.

Hardness measurements in Vickers for 4 plates: Bf 109 (2.0 mm), D.520 (1.1 mm), Lancaster (2.0 mm), P-51 (2.2 mm) in L-S, L- T, S-T planes, Hardness in Brinell calculated using ASTM E140 standard: HB = 3.76211 + 0.825368 (HV) for wrought aluminum alloys.

In general, for all studied parts but the Lancaster one, higher hardness was measured for the transverse (L-T) and short transverse (S-T) planes, which finds its explanation in the microstructure of the samples and can be linked to the thermomechanical treatments of the metal sheets. This will be developed hereafter.

Hardness values announced in Table 4 indicate that the D.520 part has a hardness in Brinell of 82–88 depending on the direction, which is strangely soft compared to the other samples and to the value found in archive data for the corresponding alloy (Duralumin 100–110 HB). Apart from the D.520 sample, all the other samples present hardness values much higher than the values disclosed in archive documents, especially the Lancaster and the P-51 samples. Comparisons between archive data and measurements executed on the samples in their current state are to be taken with care. Historically, measurements were done on billets along one single direction (rolling plane) which could explain the difference. Other factors are to be considered since every single aircraft has endured a crash leading to the deformation of parts, which is known for causing work hardening, while some aircraft have had a fire that might lead to the modification of the microstructure of the metal. For these reasons, the study of the microstructure, hereafter developed, is used to determine the effect of various fabrication and thermal treatments on mechanical properties. Additionally, the past events undergone by the aircraft, in particular the condition of the crash will be taken into account for interpretation.

4.4. Structural Characterization

For the structural investigation, a metallographic characterization was done by observing the bulk material from microscale to nanoscale. Grain structure will be examined first, then the secondary phases of the Al-Cu-Mg alloys (constituents, dispersoids and precipitates) will be identified.

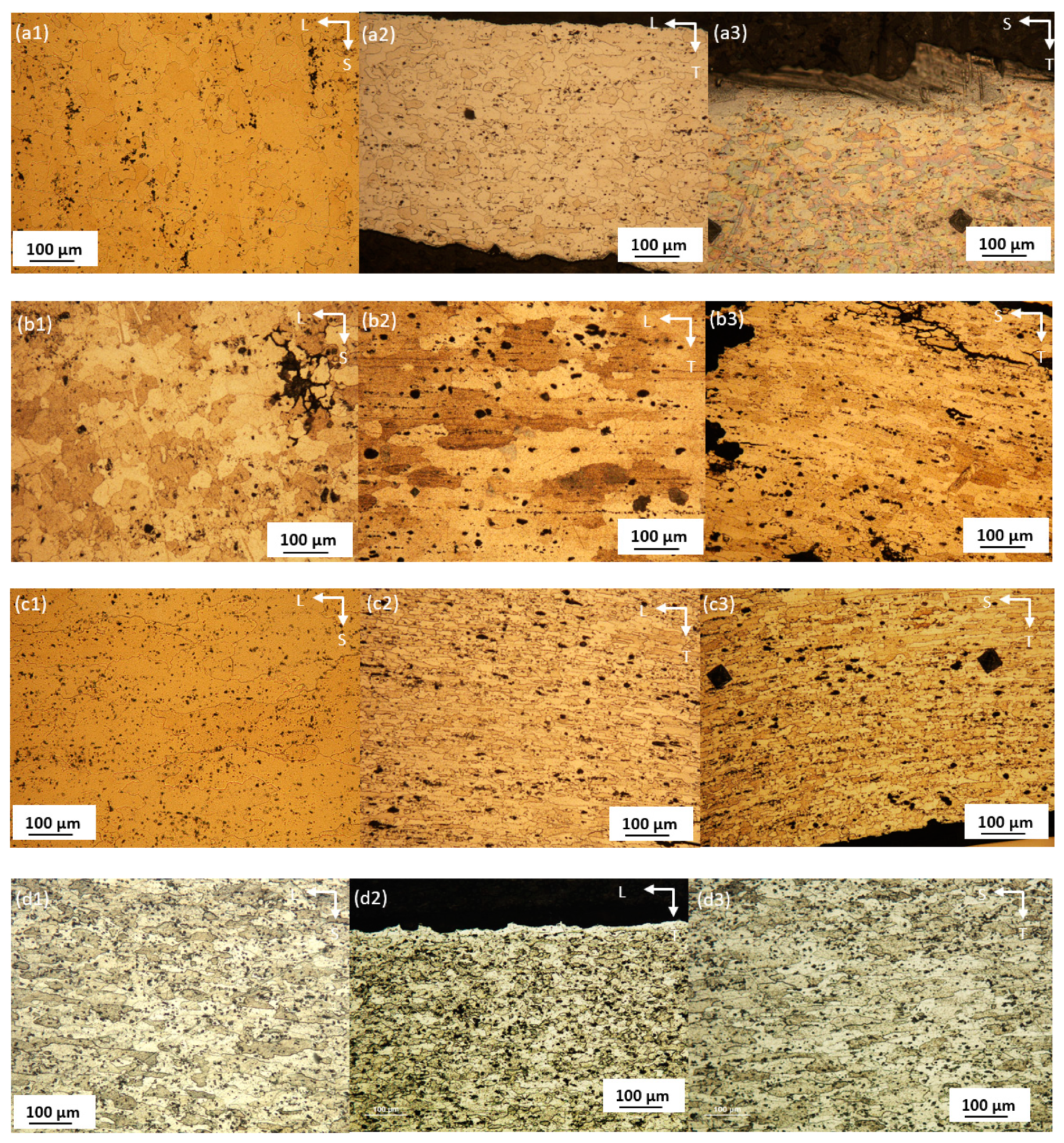

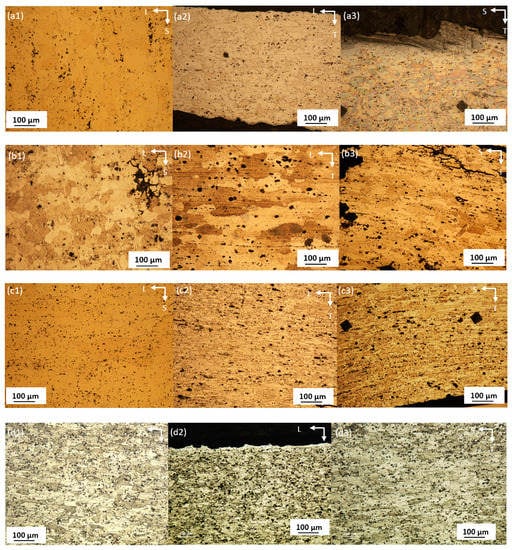

4.4.1. Microstructure: Grain Size

Figure 2 shows the grains revealed after a Keller attack for the four samples in the L-S, L-T and S-T planes. Grain sizes are provided in Table 5. The observations reveal an anisotropy in the grains’ morphology. The grain structure for all four samples is elongated and lamellar, which is typical of rolled plates. From this observation, it is expected that the grain aspect ratio (L/S longitudinal over Small transverse) will be bigger for thinner plates for there is a bigger reduction in thickness [24].

Figure 2.

Optical Micrographs along in the L-S, L-T and S-T planes of Bf 109 (a1–a3), D.520 (b1–b3), Lancaster (c1–c3), and P-51 (d1–d3) samples.

Table 5.

Grain size of Bf 109, D.520, Lancaster and P-51 in the L, T and S directions and the corresponding elongation ratio.

The Keller’s reagent has revealed a completely recrystallized Bf 109 fine-grained sample. It has equiaxed grains (L = 57 µm; T = 47 µm, S = 31 µm) typically obtained after successive rolling passes and heat treatments leading to recrystallization. The relatively low grain elongation ratio is probably linked to a limited amount of cold-working operation, as the thickness of the plate is 2 mm.

The D.520 sample presents coarse grains that are well-defined with a relatively large size. Grains are elongated along the rolling plane (L = 141 µm; T = 72 µm, S = 53 µm). Partial recrystallization occurred. In addition, the grain ratio is relatively high: L/S = 2.7 which is understandable, taking into consideration the thickness of the sample (0.8 mm).

When it comes to the Lancaster sample, its microstructure is typical of a crystallized plate. Its high elongation ratio L/S = 3.5 can partly be explained with the thinness of the sample (1.5 mm).

Eventually, the P-51 sample presents an elongation ratio (L/S) lower than 2, which goes hand in hand with the fact that the American sample is thicker (2.2 mm).

The anisotropy in all four samples clearly explains the difference in hardness along the different planes. Planes (L-T, S-T) with elongated grains (high aspect ratios) exhibit a higher hardness than the planes with equiaxed grains (L-S).

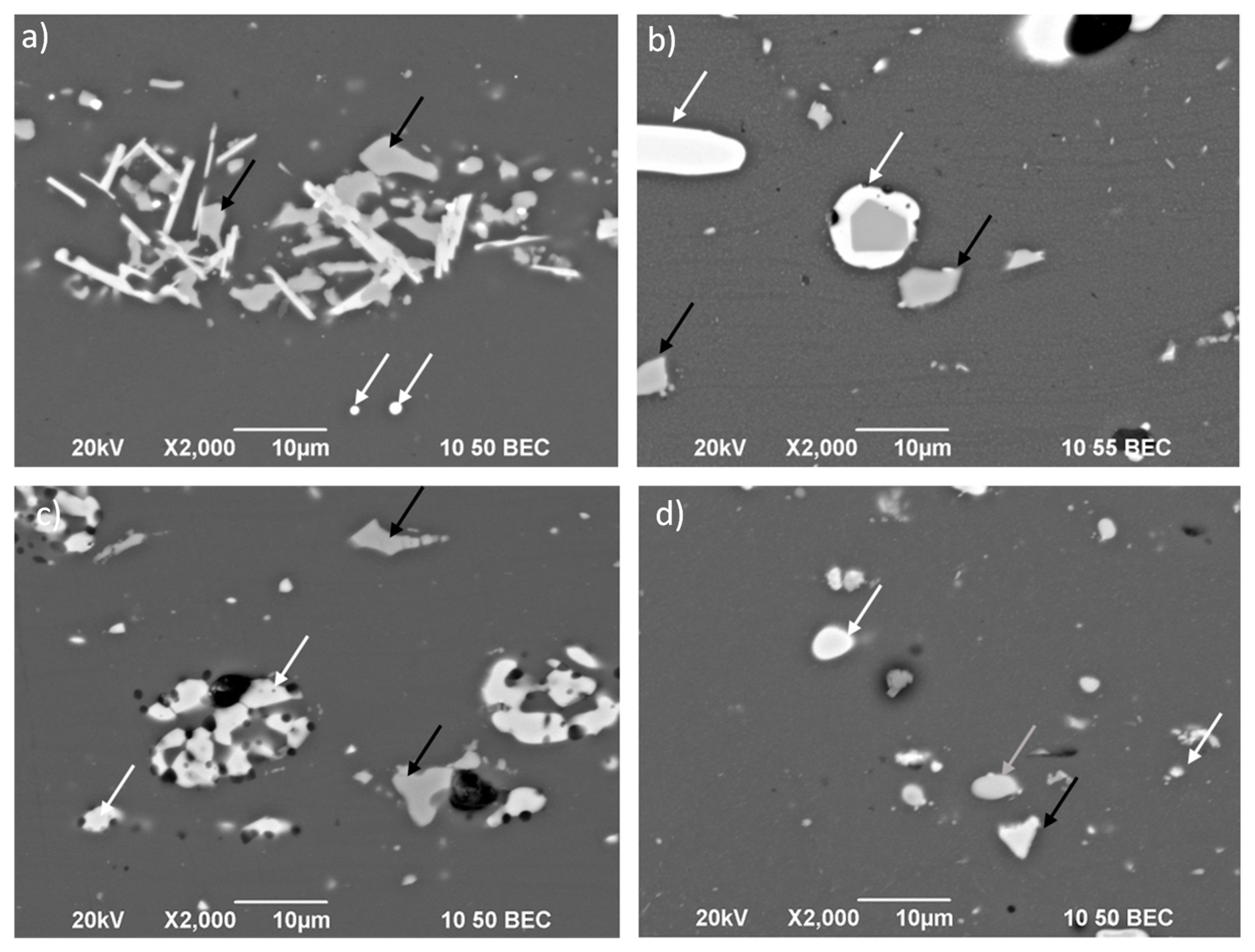

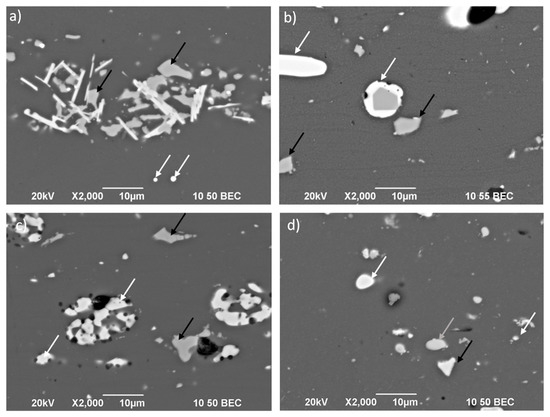

4.4.2. Microstructure: Coarse Intermetallics

In the microstructure, constituents, also known as coarse intermetallic phases, have sizes up to several tens of microns. These particles are formed during the solidification of the ingot and do not participate in the hardening of the alloy. Their size depends mainly on three factors: the content of solidification of the ingot, the rate of iron and silicon, and the deformation that the piece undergoes. The faster the solidification rate and the less silicon and/or iron, the smaller the size of the particles. The shape of the constituents can be influenced by the fabrication stages [13].

Figure 3 shows backscattered SEM images of the various constituents that were observed and identified with EDS on the four samples. Two constituent groups form during the solidification: the soluble ones (from the matrix) and insoluble ones (from the transition elements, generally Fe, Mn). The grey particles with irregular shapes, designated by a black arrow in Figure 3, were identified as the insoluble constituents. They contain Al, Fe, Si, Mn, Cu, with diverse stoichiometry, which corresponds to the phases: α-AlMnSi or α-Al(Fe, Mn)Si in which copper can be incorporated. Constituents rich in Cu and Fe were found in the British (Hiduminium DU Brand) and American alloys (24S). In the case of the American alloy (24S), the presence of the phase Al7Cu2Fe is evidenced. It is known to be present when the Si rate is not high enough to form completely with Fe. Some Fe is left and forms this unwanted phase with Cu [8]. For the 24S, it is coherent with the low Si rate (0.2 wt.%). However, for the Hiduminium DU Brand, which has a relatively high silicon content (0.61 wt.%), the presence of the Al7Cu2Fe phase is surprising.

Figure 3.

SEM images in backscattered electron mode showing coarse intermetallics for (a) Bf 109, (b) D.520, (c) Lancaster, and (d) P-51 samples. Black arrows indicate the presence of insoluble constituents, white arrows, particles precipitates from the matrix: Al2Cu, and grey arrows: Al2CuMg.

Regarding the soluble constituents, they form after the heat treatment and especially during the quench, leading to equilibrium phases [13]. Two types were identified by SEM-EDS: Al2Cu in the shape of round particles, with a high contrast in backscattered-electron mode, and Al2CuMg with the same shape but with a slightly lower contrast. Both types are designated by white or grey arrows respectively in Figure 3.

In conclusion, the AlCuMg1 (Bf 109), the Duralumin (D.520), and the Hiduminium DU Brand (Lancaster) contain only the θ-Al2Cu equilibrium phase, while, for the 24S (P-51), the θ-Al2Cu, and the S-Al2CuMg phase are present. The formation of the latter precipitates is due to the higher magnesium rate in the 24S alloy.

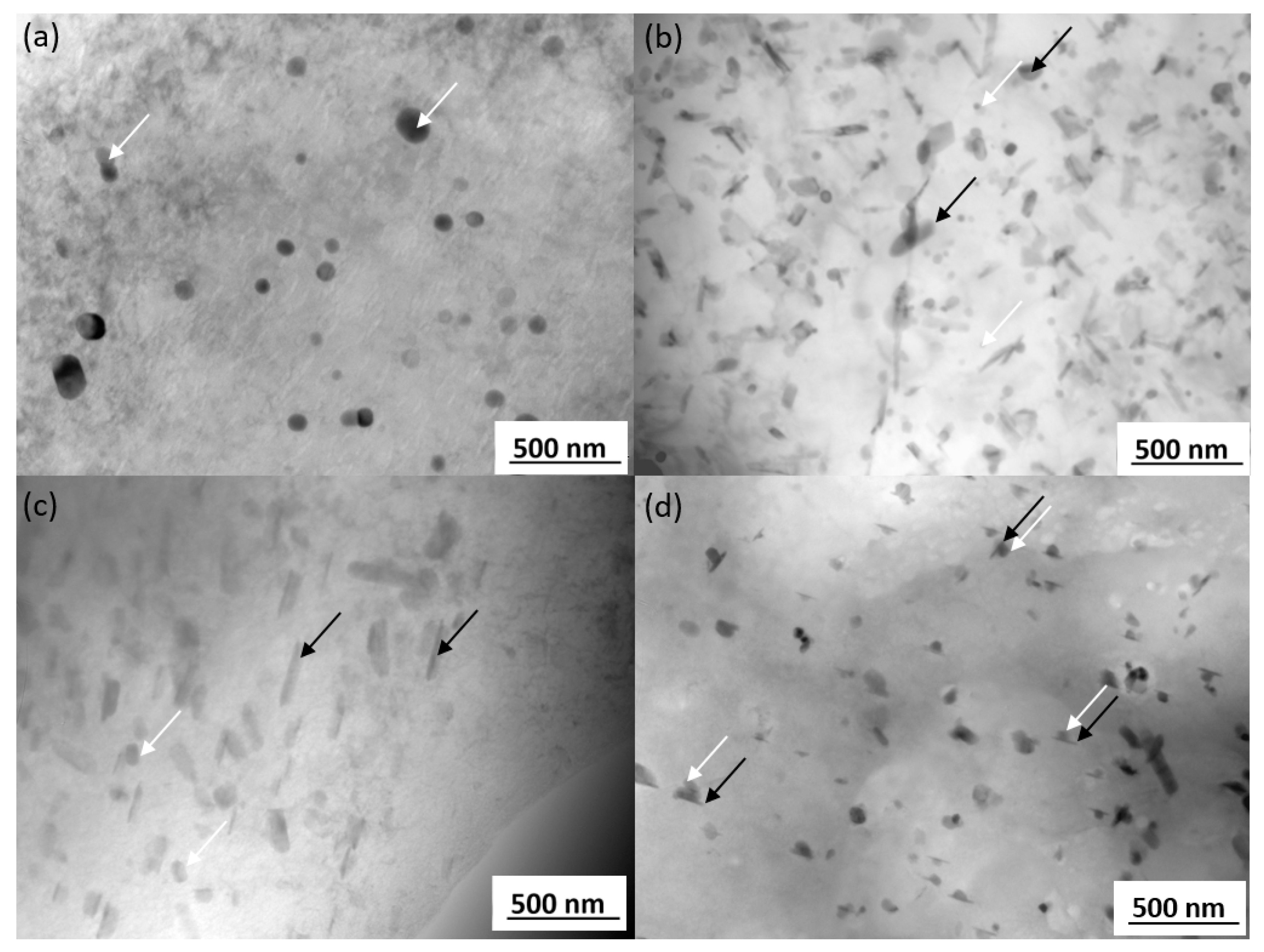

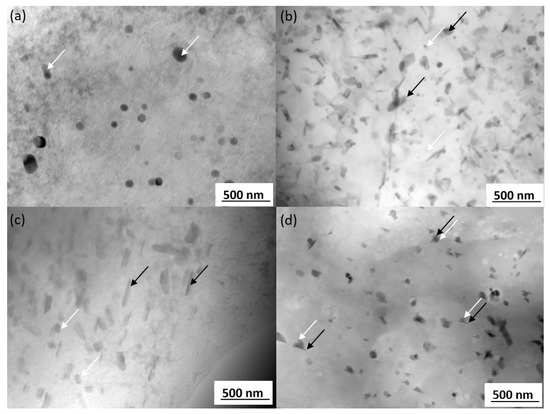

4.4.3. Nanostructure: Precipitation

Figure 4 shows TEM images taken of the samples. Various precipitation at this submicronic scale can be observed. First, dispersoids of sizes up to 0.5 μm, which contain transition elements, here manganese. They are responsible for refining the grain structure during subsequent heat treatments [8]. As the grains are smaller, more grain boundaries are present that prevent dislocation movements, leading to better mechanical properties. The Bf 109 sample (AlCuMg1 alloy) presents dispersoids containing Al, Mn, Si and sometimes Cu. They are ovoid-shape with a mean size of 76 ± 28 nm. Dispersoids containing similar elements with a mean size of 22 ± 11 nm were also found for the Duralumin (D.520 sample). In the Lancaster sample (Hiduminium DU Brand), dispersoids contain Mn and Cu mainly with Si and Fe in little quantities. Their average size is 58 ± 32 nm. As for the P-51 (24S), rod-like dispersoids are smaller, with an average size of 11 ± 6 nm. STEM-EDS analyses revealed their nature: AlCuMn, which correlates with the expected dispersoids Al20Cu2Mn3, also known as T phase [24]. This type of dispersoids is generally found for Al-Cu-Mg alloys.

Figure 4.

Precipitation observed by TEM bright field on the four different samples of two different chemical nature (a) Bf109, (b) D520, (c) Lancaster, (d) P51. Black arrows: hardening precipitates, white arrows: dispersoids.

A second family of precipitation at this scale is the precipitation responsible for hardening. In these structural hardening alloys, precipitation originates indeed from the matrix after solution heat treatment, quenching followed by a room temperature aging or the heat-treatment at moderate temperature. No such precipitation was observed with conventional TEM for the Bf 109 sample (see Figure 4a). On the contrary, in the D.520 sample, additional precipitation besides dispersoids was observed in the matrix (see black arrows in Figure 4b). These precipitates are part of the hardening precipitation sequence. The sample also presents precipitates along the grain boundaries. These two characteristics prove that the sample experienced heat.

In the case of the Lancaster (Hiduminium Du Brand) and the P-51 (24S) samples, various additional precipitation besides dispersoids was also detected (see Figure 4c,d), which leads to the conclusion that they experienced heat as well. STEM-EDS analyses will be conducted in the future to allow the identification of this complex precipitation at nanoscale.

5. Discussion

Hardness on the samples was quite different from that of the archives. Different reasons can be pointed out. The first reason could come from the manufacturing process experienced by the plates (cold-rolling processes). Particular microstructures can indeed be induced through strain-hardening during manufacturing. This was confirmed by the observation of the microstructure. In particular, the high hardness in the Bf 109 sample compared to the archives could be explained by the fine-grain microstructure observed (Figure 2a).

However, the archeological nature of the samples also has an impact on the mechanical properties. All along, it was seen that the French and German samples have close elemental compositions as well as very close microstructures. Indeed, similarities were observed for the AlCuMg1 and Duralumin, especially since they show constituents and dispersoids with similar chemical composition. Differences in the microstructures and hardness of the German and French alloys are mainly observable at nanoscale. The nanostructure of the Bf 109 sample, where only dispersoids are observable at this scale, is typical of a naturally aged alloy. The peculiar nanostructure observed in the D.520 sample is linked to the past of the aircraft. Different features in the micro and nanostructure of the D.520 confirm the long fire the aircraft went through after the crash. This fire altered the structure of the material:

- -

- A large grain structure was observed along with the enlargement of intermetallic compounds.

- -

- Compared with the Bf 109 sample, supplementary precipitation, in the matrix, and along the grain boundaries, was observed on the D.520 sample.

The relatively large size of the nanoprecipitates and the fact that these precipitates are not coherent with the matrix are characteristic of a soft state. As a consequence, and it was verified from the measurements, the hardness of the D.520 sample was lower than the expected value. The sample can be considered in an over-aged state. It is safe to say that, if the D.520 aircraft had not burned for hours, the microstructure of the D.520 sample might have been very similar to the Bf 109.

For the P-51 sample, it is relatively harder than the other samples. It goes along with the fact that it is made out of the alloy with high Mg content (24S), known for inducing better mechanical properties. However, its measured hardness is higher than the data reported in the archives. Although this sample had not gone through major cold working, the amount of roll process it went through can have an impact on the hardness. The observation at nanoscale revealed an additional hardening precipitation (Figure 4d), probably due to the exposure of the sample to heat. This precipitation could also be responsible for the higher hardness measured on the P-51 sample.

Eventually, the Lancaster sample shows a relatively high hardness, although it is made with an alloy with low Mg content, the so-called Hiduminium DU Brand. The British sample is amongst the thinnest samples studied in this paper, which indicates a big reduction in thickness, entailing elongated grains and more grain boundaries, leading probably to higher hardness. In addition, additional hardening precipitation, (probably caused by the heat generated by the explosion) was observed (Figure 4c). These two extrinsic factors can partly explain the observed hardening. However, further investigation is required to identify the intrinsic factors responsible for the superior hardness of the alloy Hiduminium DU Brand reported in the archives.

6. Conclusions

This study looks back at some of the first light alloys used in aircraft construction, their history, their designation, and their physical properties. For this, from parts collected on crashed aircraft, the identification of the alloys was made thanks to chemical analyses and a thorough research in archives. This allowed for discussing the different alloys developed in the four studied nations (France, Germany, UK and USA). Then, the microstructure and nanostructure of the archaeological samples were scrutinized thanks to multiscale analyses, in order to correlate these information with the measured mechanical properties (hardness). Thanks to the cross-checking between archives and material analysis, the following conclusions can be drawn:

- Taking the chemical composition into consideration and the History, two trends were observed: Germany, France, and the USA versus UK. The first three nations followed Alfred Wilm’s patent, while the United Kingdom developed its own slightly different versions of duralumin.

- For the French and British parts, only one type of alloy per aircraft was yet identified: low magnesium content one, respectively Duralumin and Hiduminium DU Brand. For the American aircraft, only a high magnesium content alloy (24S) was found on the remains. Both high and low magnesium content alloys were found on the German parts, although four out of five parts were made out of the low magnesium one. This paper focused on the plates. The study needs to be extended if possible to other parts (stringers, rivets) as many alloys were used for the construction of aircraft.

- Although it seems that England had the alloys with the best mechanical properties according to the archives, we weren’t able to fully confirm it yet as only extrinsic factors were identified as the cause of the increase in hardness: rolling treatments and heat generated during the crash.

Even though aluminum alloys and their fabrication process are widely documented, the study and comparison of the first aluminum alloys can still bring tremendous information whether for materials science or for historical facts. This work is a documentation of artefacts and materials, parts of a past aeronautical heritage. It allows for broadening the knowledge on the materials employed by different nations for the construction of iconic aircraft. It is the first step towards evaluating the impact of the materials and their development on the performance of the aircraft. Evidently, it constitutes important data for curators and restorers working on aeronautical artefacts of the same period. Since it is an ongoing investigation, new measurements are still to be performed on other collected parts from crashed aircraft to broaden the comparisons. Other mechanical properties such as the elongation, and the yield and tensile strengths should be measured, while the investigation on the nanoscale precipitation remains to be completed; a solution heat treatment stage seems unavoidable for a proper comparison of these alloys. Because of the past of the aircraft, it is sometimes difficult to compare these old alloys. Indeed, whether the aircraft has endured a crash or a fire, it results in the change of the microstructure of the metal and thus a change of the hardness. For this reason, a solution heat treatment is necessary in order to get rid of the influence the crash might have on the mechanical properties and microstructure.

Supplementary Materials

The following are available online at https://www.mdpi.com/2571-9408/2/4/172/s1.

Author Contributions

T.O. performed the experiments, the archival study, she also analyzed the data and wrote the paper along with M.B. G.C. performed the archaeological excavations, the identification of the parts and research on the aircraft history. P.S. and J.-M.O. contributed in the analysis of the data and in the writing of the paper.

Acknowledgments

The authors would like to thank the association Aerocherche for providing with the samples and l’Institut pour l’Histoire de l’Aluminium, the NASM-Steven F. Udvar Hazy Center along with the ITTC museum (Institut Technologique des Transports et des Communications) for their help in the Archive section. We would also like to thank the EDAA (École Doctorale Aéronautique et Astronuatique) for their grant. Finally, special thanks go to Christopher F. Bardo and Jean Schreiber.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bally, J. Les avantages de la construction métallique en alliage légers d’aluminium. Revue de l’aluminium et de ses Application 1925, 1, 79–80. [Google Scholar]

- Loftin, L.K., Jr. Quest of Performance: The Evolution of Modern Aircraft; NASA Scientific and Technical Information Branch-National Aeronautics and Space Administration: Washington, DC, USA, 1985. [Google Scholar]

- Waltenberg, R.; Merica, P.D. Heat Treatments of Duralumin; Scientific Papers of the Bureau of Standards: Washington, DC, USA, 1919. [Google Scholar]

- Duralumin. Société du Duralumin, Duralumin, Catalogue général Notice technique; Société du Duralumin in Paris, rue Balzac: Paris, France, 1938. [Google Scholar]

- Slough; High Duty Alloys. HIDUMINIUM High Duty Alloys; Slough; High Duty Alloys: Slough, UK, 1948. [Google Scholar]

- ALCOA. Aluminum Company of America, Aluminum and Its Alloys; ALCOA: Pittsburgh, PA, USA, 1935. [Google Scholar]

- Von Dr-Ing Brenner, P. Aluminium-Knet-Legierungen; Ver Leichtmetallwerke Gmbh: Hannove, Germany, 1939. [Google Scholar]

- Mondolfo, L.F. Metallography of Aluminum Alloys; John Wiley & Sons Inc.: New York, NY, USA, 1943. [Google Scholar]

- Guillet, L. l’Aluminium: Sa fabrication, ses propriétés, ses alliages. Revue de la Métallurgie 1921, 18, 461–526. [Google Scholar] [CrossRef]

- Deutch. Institüt. für. Normung. DIN-1748, Aluminium-Knetlegierungen für Profile; Deutsches Institut für Normung: Berlin, Germany, 1952. [Google Scholar]

- Lebouteux, H. La symbolisation de l’aluminium et de ses alliages en france et dans quelques pays étrangers. Encyclopédie du Travail de l’aluminium Extrait de la Revue de l’aluminium 1956, n°227. [Google Scholar]

- Starke, E.A., Jr.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Unger, E.; SCHMIDT, E. DURALUMIN; National Advisory Committee for Aeronautics (Technical Notes): Washington, DC, USA, 1920. [Google Scholar]

- Wilm, A. DE 244554 Verfahren zum Veredeln von magnesiumhaltigen Aluminiumlegierungen. German Patent Patentschrift N° 244554, 20 March 1909. Klasse 48d, Gruppe 5. [Google Scholar]

- Duparc, O.H. Alfred Wilm et les débuts du Duralumin. Cahier pour l’Histoire de l’Aluminium 2005, 34, 63–77. [Google Scholar]

- Jeffries, Z. National Academy of Sciences-Paul Dyer Merica 1889–1957 A biographical Memoir; National Academy of Sciences: Washington, DC, USA, 1959. [Google Scholar]

- Smith, G.D. From Monopoly to Competition: The transformation of ALCOA from 1888 to 1986; Cambridge university Press: Cambridge, UK, 2003. [Google Scholar]

- Ouissi, T. Evolution of light alloys in aeronautics: The case of duralumin- from its discovery to the end of WWII. Nacelles 2020, n°6. [Google Scholar]

- Orowan, E. Zur kristallplastizität. III. Z. Phys. 1934, 89, 634–659. [Google Scholar] [CrossRef]

- Waltenberg, R.; Merica, P.D. Mechanical Properties and Resistance to Corrosion of Rolled Light Alloys of Aluminum and Magnesium with Copper, with Nickel, and with Manganese; Technologic papers of the Bureau of Standards: Washington, DC, USA, 1919. [Google Scholar]

- Herrmann, E. Notes sur les alliages légers d’aluminium. Bulletin Technique de la Suisse Romande 1933. [Google Scholar] [CrossRef]

- Mondolfo, L. Aluminum Alloys: Structure and Properties; Butterworths: Boston, MA, USA, 1976. [Google Scholar]

- Eskin, D.G. Decomposition of supersaturated solid solutions in Al-Cu-Mg-Si alloys. J. Mater. Sci. 2003, 38, 279–290. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef]

| 1 | British Standard Institution Specifications-Aluminum coated sheet and strip (for high corrosion resistance). |

| 2 | Messerschmitt Technical document: Manual for semi-finished products (1st January 1939). |

| 3 | Probably early 1941. |

| 4 | Bf 109 Emil version picture from National Air and Space Museum Archives box n° 43 reference AM-350536-01. |

| 5 | D.520 picture from Departmental Archives of the Haute Garonne box n°56J22. |

| 6 | Lancaster picture from avionslegnedaires.net website. |

| 7 | Picture of the Mustang P-51 a.k.a Fool’s paradise. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).