Renewable Biomass Utilization: A Way Forward to Establish Sustainable Chemical and Processing Industries

Abstract

1. Global Biobased Products Scenario: Feedstock Availability and Sustainability

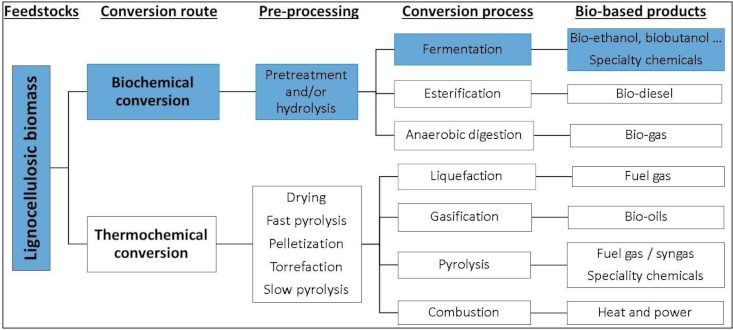

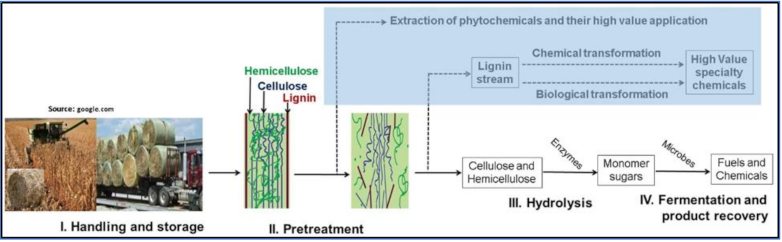

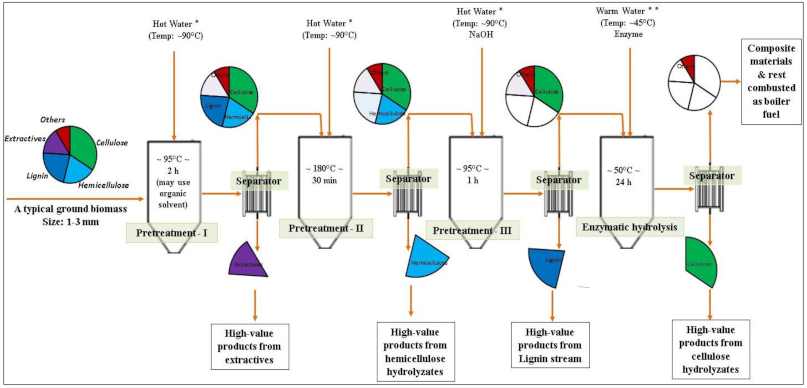

2. Conversion of Lignocellulose Biomass to Fuels and Chemicals

3. Lignocellulosic Biomass Pretreatment

- Physical methods: extrusion, ball milling, wet-disc milling, microwave pretreatment.

- Chemical methods: acid pretreatment, alkali pretreatment, organosolv pretreatment, ozonolysis pretreatment.

- Physico-chemical methods: steam explosion, ammonia fiber explosion, liquid hot water, carbon dioxide explosion, wet oxidation.

- Biological methods: white-rot fungi, brown-rot fungi, soft-rot fungi.

3.1. Extrusion Pretreatment

- Easy process monitoring and control.

- No inhibitory compounds formation due to sugar degradation.

- Adaptability for process modification.

- Continuous and high throughput.

- No need for washing of pretreated biomass if extrusion is performed without chemical addition.

- Can be combined with other methods of pretreatment for better results [40].

- Lack of data for economic analysis.

- Energy intensive process.

- Poor flow during continuous processing leading to burning of material [35].

3.2. Acid Pretreatment

- A method of deconstruction can be designed for biomass processing to generate separate hemicellulose hydrolyzates (after pretreatment) and cellulose hydrolyzates (after enzymatic hydrolysis).

- Cost saving for xylanase enzymes: Hemicellulose is extensively hydrolyzed during pretreatment depending upon the feedstock type and processing conditions; therefore, high-cost xylanase enzymes are not generally required for hydrolysis [27].

- Inhibitors, such as furfural and hydroxymethylfurfural (HMF), produced from sugar degradation requires an additional detoxification step to make the released sugars fermentable [43].

- Need expensive stainless-steel vessels due to the corrosive nature of acid [44].

- Additional cost for alkali to neutralize acid after pretreatment.

- Environmental concern due to excessive use of chemicals.

3.3. Alkali Pretreatment

- Effective delignification [45].

- Lower sugar degradation compared to dilute acid pretreatment due to the lower processing temperature; possible to pretreat at room temperature using longer time.

- Lignin and other extractives can be separated before enzymatic hydrolysis without loss of carbohydrate; high possibility of getting reactive lignin for high value application [46].

3.4. Organosolv Pretreatment

- All three biopolymers—cellulose, hemicellulose and lignin—can be separated into different streams [48].

- It can be combined with other pretreatment processes for effective biomass hydrolysis.

- Formation of inhibitory compounds, such as furfural and HMF, due to sugar degradation when acid catalyst is used [41].

- Residual solvent will be inhibitory for enzymatic hydrolysis and fermentative organisms.

- Environmental and health concerns due to the use of volatile organic liquids at high temperature [41].

3.5. Ionic Liquid Pretreatment

- Ionic liquids, considered as green solvent, are stable up to 300 °C; have extremely low volatility with minimum environmental impact [3].

- Possible to separate each of the biopolymers—cellulose, hemicellulose and lignin.

- Ionic liquid with desirable properties can be synthesized.

- Cost of ionic liquids are still very high.

- Many ionic liquids are toxic to the hydrolytic enzymes and the fermenting organisms [60].

- Cost of solvent recovery is tedious and expensive.

- Difficult to handle the viscous biomass slurry with ionic liquid during pretreatment at temperature beyond 150 °C [52].

3.6. Steam Explosion Pretreatment

- No use of chemicals and hence no recycling and environmental costs.

- Relatively less dilution of released hemicellulose.

- High particle size biomass can be used, leading to significant energy savings. Size reduction accounts to around one third of the entire pretreatment process [61].

- Incomplete de-construction of lignin-carbohydrate complex may lead to condensation and precipitation of soluble lignin; thereby resulting in reduced biomass hydrolysis efficiency [62].

- Weak acids and phenolic compounds, such as acetic, formic and levulinic acids, generated during this process are inhibitory for subsequent enzymatic hydrolysis and fermentation [42].

3.7. Ammonia Fiber Explosion Pretreatment (AFEX)

- High selectivity for delignification.

- Easy for recycling due to volatile nature of ammonia; 99% ammonia recovery is possible.

- Residual ammonia can serve as a nitrogen source for the organisms during fermentation.

- Excess water requirement because the phenolic fragments of lignins must be washed to avoid inhibition during enzymatic hydrolysis and fermentation [64].

- Ammonia recycling is very costly for commercial scale processing [25].

- Inefficient for high lignin content biomass, such as softwood and newspapers waste.

- Environmental concern due to the use of volatile chemicals.

3.8. Liquid Hot Water (LHW) Pretreatment

- No use of additional chemicals.

- No need to use expensive and corrosive-resistant materials for pretreatment reactors.

- Relatively large size particles can be used leading to energy saving, which is required for size reduction of biomass to fine particles.

- Possible to recover separately the cellulose and hemicellulose streams.

- Minimum formation of inhibitory compounds.

- The xylose stream is of very low concentration and hence needs an additional cost-intensive evaporation of water operation to get appropriate sugar concentration for fermentation.

- High cost since high pretreatment temperature is required.

- Not suitable for biomass with high-lignin content.

3.9. Biological Pretreatment

- ❖

- Lignin-manganese peroxidase group—P. chrysosporium and Phlebia radiate.

- ❖

- Manganese peroxidase-laccase group—Dichomitus squalens and Rigidoporus lignosus.

- ❖

- Lignin peroxidase-laccase group—Phlebia ochraceofulva and Junghuhnia separabilima [70].

- No inhibitory compounds are produced.

- The process is environmentally friendly.

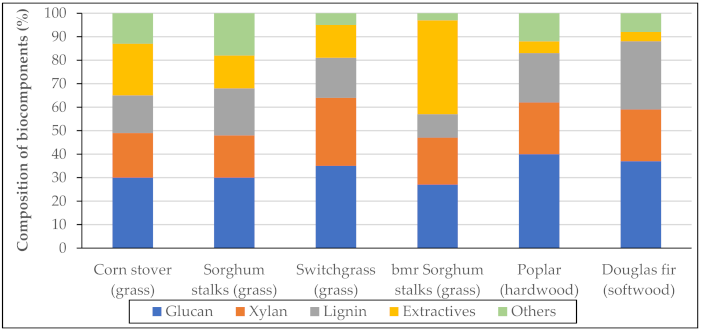

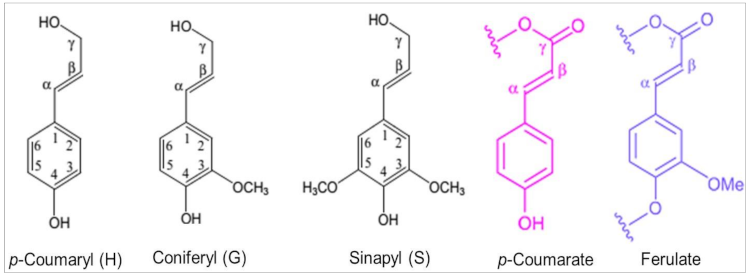

4. Variation of Composition and Structure among Biomass and Their Effect on Pretreatment Process

5. Toward a Sustainable Lignocellulosic-Based Chemical Industry

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Charpentier, J.-C. In the frame of globalization and sustainability, process intensification, a path to the future of chemical and process engineering (molecules into money). Chem. Eng. J. 2007, 134, 84–92. [Google Scholar] [CrossRef]

- Vadlani, P.V. Financing strategies for sustainable bioenergy and the commodity chemicals industry. In Green Energy to Sustainability: Strategies for Global Industries, 1st ed.; Vertès, A.A., Qureshi, N., Blaschek, H.P., Yukawa, H., Eds.; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 569–586. [Google Scholar]

- Mousdale, D.M. Biofuels: Biotechnology, Chemistry, and Sustainable Development; CRC press, Taylor & Francis Group: New York, NY, USA, 2008. [Google Scholar]

- Klein-Marcuschamer, D.; Blanch, H.W. Renewable fuels from biomass: Technical hurdles and economic assessment of biological routes. AIChE J. 2015, 61, 2689–2701. [Google Scholar] [CrossRef]

- Guragain, Y.N.; Probst, K.V.; Vadlani, P.V. Fuel alcohol production. In Encyclopedia of Food Grain; Corke, H., Faubion, J., Seethraman, K., Wrigley, C., Eds.; Elsevier: Oxford, UK, 2016; pp. 405–414. [Google Scholar]

- Guragain, Y.N. Sustainable bioprocessing of various biomass feedstocks: 2,3-butanediol production using novel pretreatment and fermentation. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2015. [Google Scholar]

- Ladanai, S.; Vinterbäck, J. Global Potential of Sustainable Biomass for Energy; SLU Report 013; Department of Energy and Technology: Stockholm, Sweden, 2009. [Google Scholar]

- Bonin, C.; Lal, R. Bioethanol Potentials and Life-Cycle Assessments of Biofuel Feedstocks. Crit. Rev. Plant Sci. 2012, 31, 271–289. [Google Scholar] [CrossRef]

- Nanda, S.; Azargohar, R.; Dalai, A.K.; Kozinski, J.A. An assessment on the sustainability of lignocellulosic biomass for biore-fining. Renew. Sust. Energy Rev. 2015, 50, 925–941. [Google Scholar] [CrossRef]

- Langholtz, M.H.; Stokes, B.J.; Eaton, L.M. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, Volume 1: Economic Availability of Feedstocks; ORNL/TM-2016/160; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016; p. 448. [Google Scholar] [CrossRef]

- U.S. Department of Energy. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, Volume 2: Environmental Sustainability Effects of Select Scenarios from Volume 1; ORNL/TM-2016/727; Efroymson, R.A., Langholtz, M.H., Johnson, K.E., Stokes, B.J., Eds.; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2017; p. 640. [Google Scholar]

- Chew, J.; Doshi, V. Recent advances in biomass pretreatment—Torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Kurian, J.K.; Nair, G.R.; Hussain, A.; Raghavan, G.V. Feedstocks, logistics and pre-treatment processes for sustainable lig-nocellulosic biorefineries: A comprehensive review. Renew. Sustain. Energy Rev. 2013, 25, 205–219. [Google Scholar] [CrossRef]

- Guragain, Y.N.; Wilson, J.; Staggenborg, S.; McKinney, L.; Wang, N.; Vadlani, P.V. Evaluation of pelleting as a pre-processing step for effective biomass deconstruction and fermentation. Biochem. Eng. J. 2013, 77, 198–207. [Google Scholar] [CrossRef]

- Lopes, M.S.G. Engineering biological systems toward a sustainable bioeconomy. J. Ind. Microbiol. Biotechnol. 2015, 42, 813–838. [Google Scholar] [CrossRef] [PubMed]

- Bozell, J.J.; Astner, A.; Baker, D.; Biannic, B.; Cedeno, D.; Elder, T.; Hosseinaei, O.; Delbeck, L.; Kim, J.-W.; O’Lenick, C.J.; et al. Integrating separation and conversion—Conversion of biorefinery process streams to biobased chemicals and fuels. BioEnergy Res. 2014, 7, 856–866. [Google Scholar] [CrossRef]

- Menon, V.; Rao, M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals and biorefinery concept. Prog. Energy Combust. Sci. 2012, 38, 522–550. [Google Scholar] [CrossRef]

- Dale, B.E.; Ong, R.G. Energy, wealth, and human development: Why and how biomass pretreatment research must improve. Biotechnol. Prog. 2012, 28, 893–898. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Kucharska, K.; Hołowacz, I.; Konopacka-Łyskawa, D.; Rybarczyk, P.; Kamiński, M. Key issues in modeling and optimization of lignocellulosic biomass fermentative conversion to gaseous biofuels. Renew. Energy 2018, 129, 384–408. [Google Scholar] [CrossRef]

- Montague, L.; Slayton, A.; Lukas, J. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis for Corn Stover; NREL/TP-510-32438; National Renewable Energy La-boratory: Golden, CO, USA, 2002. [Google Scholar]

- Yang, B.; Wyman, C.E. Pretreatment: The key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod. Biorefining 2008, 2, 26–40. [Google Scholar] [CrossRef]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; Technical Report NREL/TP-5100-47764; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2011. [Google Scholar]

- Guragain, Y.N.; Bastola, K.P.; Madl, R.L.; Vadlani, P.V. Novel biomass pretreatment using alkaline organic solvents: A green approach for biomass fractionation and 2,3-butanediol production. BioEnergy Res. 2016, 9, 643–655. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pre-treatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef]

- Guragain, Y.N.; Wang, D.; Vadlani, P.V. Appropriate biorefining strategies for multiple feedstocks: Critical evaluation for pre-treatment methods, and hydrolysis with high solid loading. Renew. Energy 2016, 96, 832–842. [Google Scholar] [CrossRef]

- Sousa, L.C.; Chundawat, S.P.; Balan, V.; Dale, B.E. Cradle-to-grave’assessment of existing lignocellulose pretreatment technologies. Curr. Opin. Biotech. 2009, 20, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Laskar, D.D.; Yang, B.; Wang, H.; Lee, J. Pathways for biomass-derived lignin to hydrocarbon fuels. Biofuels Bioprod. Biorefining 2013, 7, 602–626. [Google Scholar] [CrossRef]

- Mood, S.H.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. extrusion pretreatment of lignocellulosic biomass: A review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef]

- Zhan, X.; Wang, D.; Bean, S.; Mo, X.; Sun, X.; Boyle, D. Ethanol production from supercritical-fluid-extrusion cooked sorghum. Ind. Crop. Prod. 2006, 23, 304–310. [Google Scholar] [CrossRef]

- Chinnadurai, K.; Muthukumarappan, K.; Julson, J.L. Enzymatic Hydrolysis of Corn Stover Pretreated in High Shear Bioreactor. In Proceedings of the ASABE Annual International Meeting, Providence, RI, USA, 29 June–2 July 2008. [Google Scholar] [CrossRef]

- Lee, S.-H.; Teramoto, Y.; Endo, T. Enhancement of enzymatic accessibility by fibrillation of woody biomass using batch-type kneader with twin-screw elements. Bioresour. Technol. 2010, 101, 769–774. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Influence of extruder temperature and screw speed on pretreatment of corn stover while varying enzymes and their ratios. Appl. Biochem. Biotechnol. 2010, 162, 264–279. [Google Scholar] [CrossRef]

- Yoo, J.; Alavi, S.; Vadlani, P.; Amanor-Boadu, V. Thermo-mechanical extrusion pretreatment for conversion of soybean hulls to fermentable sugars. Bioresour. Technol. 2011, 102, 7583–7590. [Google Scholar] [CrossRef]

- Lamsal, B.; Yoo, J.; Brijwani, K.; Alavi, S. Extrusion as a thermo-mechanical pre-treatment for lignocellulosic ethanol. Biomass-Bioenergy 2010, 34, 1703–1710. [Google Scholar] [CrossRef]

- Lee, S.-H.; Teramoto, Y.; Endo, T. Enzymatic saccharification of woody biomass micro/nanofibrillated by continuous extrusion process I—Effect of additives with cellulose affinity. Bioresour. Technol. 2009, 100, 275–279. [Google Scholar] [CrossRef]

- Kang, K.E.; Han, M.; Moon, S.-K.; Kang, H.-W.; Kim, Y.; Cha, Y.-L.; Choi, G.-W. Optimization of alkali-extrusion pretreatment with twin-screw for bioethanol production from Miscanthus. Fuel 2013, 109, 520–526. [Google Scholar] [CrossRef]

- Liu, C.; Van Der Heide, E.; Wang, H.; Li, B.; Yu, G.; Mu, X. Alkaline twin-screw extrusion pretreatment for fermentable sugar production. Biotechnol. Biofuels 2013, 6, 97. [Google Scholar] [CrossRef] [PubMed]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W. Sequential extrusion-microwave pretreatment of switchgrass and big bluestem. Bioresour. Technol. 2014, 153, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Agbor, V.B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D.B. Biomass pretreatment: Fundamentals toward application. Biotechnol. Adv. 2011, 29, 675–685. [Google Scholar] [CrossRef] [PubMed]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Hu, F.; Ragauskas, A.J. Pretreatment and lignocellulosic chemistry. BioEnergy Res. 2012, 5, 1043–1066. [Google Scholar] [CrossRef]

- Esteghlalian, A.; Hashimoto, A.G.; Fenske, J.J.; Penner, M.H. Modeling and optimization of the dilute-sulfuric-acid pre-treatment of corn stover, poplar and switchgrass. Bioresour. Technol. 1997, 59, 129–136. [Google Scholar] [CrossRef]

- Hu, G.; Heitmann, J.A.; Rojas, O.J. Feedstock pretreatment strategies for producing ethanol from wood, bark, and forest res-idues. BioResources 2008, 3, 270–294. [Google Scholar]

- Ghaffar, S.H.; Fan, M. Lignin in straw and its applications as an adhesive. Int. J. Adhes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, K.; Liu, D. Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl. Microbiol. Biotechnol. 2009, 82, 815–827. [Google Scholar] [CrossRef]

- Duff, S.J.; Murray, W.D. Bioconversion of forest products industry waste cellulosics to fuel ethanol: A review. Bioresour. Technol. 1996, 55, 1–33. [Google Scholar] [CrossRef]

- Ni, Y.; Van Heiningen, A. The swelling of pulp fibers derived from the ethanol-based organosolv process. Tappi J. 1997, 80, 211–213. [Google Scholar]

- Zhu, L.; O’Dwyer, J.P.; Chang, V.S.; Granda, C.B.; Holtzapple, M.T. Structural features affecting biomass enzymatic digestibility. Bioresour. Technol. 2008, 99, 3817–3828. [Google Scholar] [CrossRef]

- Sun, F.; Chen, H. Enhanced enzymatic hydrolysis of wheat straw by aqueous glycerol pretreatment. Bioresour. Technol. 2008, 99, 6156–6161. [Google Scholar] [CrossRef] [PubMed]

- Guragain, Y.N.; De Coninck, J.; Husson, F.; Durand, A.; Rakshit, S.K. Comparison of some new pretreatment methods for second generation bioethanol production from wheat straw and water hyacinth. Bioresour. Technol. 2011, 102, 4416–4424. [Google Scholar] [CrossRef] [PubMed]

- Bournay, L.; Casanave, D.; Delfort, B.; Hillion, G.; Chodorge, J. New heterogeneous process for biodiesel production: A way to improve the quality and the value of the crude glycerin produced by biodiesel plants. Catal. Today 2005, 106, 190–192. [Google Scholar] [CrossRef]

- Hongzhang, C.; Liying, L. Unpolluted fractionation of wheat straw by steam explosion and ethanol extraction. Bioresour. Technol. 2007, 98, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Diner, B.A.; Fan, J. Organic Solvent Pretreatment of Biomass to Enhance Enzymatic Saccharification. U.S. Patent 2012/0270269 A1, 2012. [Google Scholar]

- Li, Q.; He, Y.-C.; Xian, M.; Jun, G.; Xu, X.; Yang, J.-M.; Li, L.-Z. Improving enzymatic hydrolysis of wheat straw using ionic liquid 1-ethyl-3-methyl imidazolium diethyl phosphate pretreatment. Bioresour. Technol. 2009, 100, 3570–3575. [Google Scholar] [CrossRef] [PubMed]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Sankaran, R.; Show, P.L.; Ibrahim, T.N.B.T.; Chew, K.W.; Culaba, A.; Chang, J.-S. Pretreatment methods for lignocellulosic biofuels production: Current advances, challenges and future prospects. Biofuel Res. J. 2020, 25, 1115–1127. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Nakashima, K.; Kamiya, N.; Goto, M. Recent advances of enzymatic reactions in ionic liquids. Biochem. Eng. J. 2010, 48, 295–314. [Google Scholar] [CrossRef]

- Zhao, H.; Jones, C.L.; Baker, G.A.; Xia, S.; Olubajo, O.; Person, V.N. Regenerating cellulose from ionic liquids for an accelerated enzymatic hydrolysis. J. Biotechnol. 2009, 139, 47–54. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Van Hooijdonk, G.; Faaij, A.P. Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 2005, 28, 384–410. [Google Scholar] [CrossRef]

- Li, J.; Gellerstedt, G. Improved lignin properties and reactivity by modifications in the autohydrolysis process of aspen wood. Ind. Crop. Prod. 2008, 27, 175–181. [Google Scholar] [CrossRef]

- Teixeira, R.S.; Silva, A.S.; Moutta, R.O.; Ferreira-Leitão, V.S.; Barros, R.R.; Ferrara, M.A.; Bon, E.P. Biomass pretreatment: A critical choice for biomass utilization via biotechnological routes. BMC Proc. 2014, 8, O34. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed]

- Sendich, E. (Newton); Laser, M.; Kim, S.; Alizadeh, H.; Laureano-Perez, L.; Dale, B.; Lynd, L. Recent process improvements for the ammonia fiber expansion (AFEX) process and resulting reductions in minimum ethanol selling price. Bioresour. Technol. 2008, 99, 8429–8435. [Google Scholar] [CrossRef] [PubMed]

- Bals, B.; Teachworth, L.; Dale, B.; Balan, V. Extraction of proteins from switchgrass using aqueous ammonia within an integrated biorefinery. Appl. Biochem. Biotechnol. 2007, 143, 187–198. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, L.; Liu, D. Biomass recalcitrance. Part II: Fundamentals of different pre-treatments to increase the enzymatic digestibility of lignocellulose. Biofuels Bioprod. Biorefining 2012, 6, 561–579. [Google Scholar] [CrossRef]

- Wang, P.; Hu, X.; Cook, S.; Begonia, M.; Lee, K.S.; Hwang, H.-M. Effect of culture conditions on the production of ligninolytic enzymes by white rot fungi Phanerochaete chrysosporium (ATCC 20696) and separation of its lignin peroxidase. World J. Microbiol. Biotechnol. 2008, 24, 2205–2212. [Google Scholar] [CrossRef]

- Irshad, M.; Asgher, M. Production and optimization of ligninolytic enzymes by white rot fungus Schizophyllum commune IBL-06 in solid state medium banana stalks. Afr. J. Biotechnol. 2013, 10, 18234–18242. [Google Scholar]

- Hatakka, A. Lignin-modifying enzymes fungi: Production and role. FEMS Microbiol. Rev. 1994, 13, 125–135. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Terchnical report NREL/TP-510-42618; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass; Terchnical report NREL/TP-510-42619; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008. [Google Scholar]

- Del Río, J.C.; Rencoret, J.; Prinsen, P.; Martínez Ángel, T.; Ralph, J.; Gutiérrez, A. Structural Characterization of Wheat Straw Lignin as Revealed by Analytical Pyrolysis, 2D-NMR, and Reductive Cleavage Methods. J. Agric. Food Chem. 2012, 60, 5922–5935. [Google Scholar] [CrossRef] [PubMed]

- Martínez Ángel, T.; Rencoret, J.; Marques, G.; Gutiérrez, A.; Ibarra, D.; Jiménez-Barbero, J.; Del Río, J.C. Monolignol acylation and lignin structure in some nonwoody plants: A 2D NMR study. Phytochemistry 2008, 69, 2831–2843. [Google Scholar] [CrossRef] [PubMed]

- Guragain, Y.N.; Herrera, A.I.; Vadlani, P.V.; Prakash, O. Lignins of Bioenergy Crops: A Review. Nat. Prod. Commun. 2015, 10, 201–208. [Google Scholar] [CrossRef] [PubMed]

- NGM. Next Generation Manufacturing Study Overview and Findings; The Manufacturing Performance Institute for the American Small Manufacturers Coalition: Washington, DC, USA, 2009. [Google Scholar]

- Clark, J.H.; Farmer, T.J.; Herrero-Davila, L.; Sherwood, J. Circular economy design considerations for research and process development in the chemical sciences. Green Chem. 2016, 18, 3914–3934. [Google Scholar] [CrossRef]

- Song, C.; Qiu, Y.; Liu, Q.; Ji, N.; Zhao, Y.; Kitamura, Y.; Hou, X. Process intensification of cellulosic ethanol production by waste heat integration. Chem. Eng. Res. Des. 2018, 132, 115–122. [Google Scholar] [CrossRef]

- Nhien, L.C.; Long, N.V.D.; Lee, M. Novel heat–integrated and intensified biorefinery process for cellulosic ethanol production from lignocellulosic biomass. Energy Convers. Manag. 2017, 141, 367–377. [Google Scholar] [CrossRef]

- Huang, R.; Su, R.; Qi, W.; He, Z. Bioconversion of lignocellulose into bioethanol: Process intensification and mechanism re-search. BioEnergy Res. 2011, 4, 225–245. [Google Scholar] [CrossRef]

- Yoon, L.W.; Ngoh, G.C.; Chua, A.S.M.; Patah, M.F.A.; Teoh, W.H. Process intensification of cellulase and bioethanol production from sugarcane bagasse via an integrated saccharification and fermentation process. Chem. Eng. Process. Process. Intensif. 2019, 142, 107528. [Google Scholar] [CrossRef]

- Nagula, K.N.; Pandit, A.B. Process intensification of delignification and enzymatic hydrolysis of delignified cellulosic biomass using various process intensification techniques including cavitation. Bioresour. Technol. 2016, 213, 162–168. [Google Scholar] [CrossRef] [PubMed]

- Gourdon, C.; Elgue, S.; Prat, L. What are the needs for process intensification? Oil Gas Sci. Technol. 2015, 70, 463–473. [Google Scholar] [CrossRef]

- Beckham, G.T.; Johnson, C.W.; Karp, E.M.; Salvachau, D.; Vardon, D.R. Opportunities and challenges in biological lignin valorization. Curr. Opin. Biotech. 2016, 42, 40–53. [Google Scholar] [CrossRef]

- Guragain, Y.N.; Chitta, D.; Karanjikar, M.; Vadlani, P.V. Appropriate lignocellulosic biomass processing strategies for efficient 2,3-butanediol production from biomass-derived sugars using Bacillus licheniformis DSM 8785. Food Bioprod. Process. 2017, 104, 147–158. [Google Scholar] [CrossRef]

- Zhang, Y.; Yoshida, M.; Vadlani, P.V. Biosynthesis of d-lactic acid from lignocellulosic biomass. Biotechnol. Lett. 2018, 40, 1167–1179. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-E.; Vadlani, P.V.; Guragain, Y.N.; San, K.-Y.; Min, D.-H. Production of free fatty acids from switchgrass using recombinant Escherichia coli. Biotechnol. Prog. 2018, 34, 91–98. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guragain, Y.N.; Vadlani, P.V. Renewable Biomass Utilization: A Way Forward to Establish Sustainable Chemical and Processing Industries. Clean Technol. 2021, 3, 243-259. https://doi.org/10.3390/cleantechnol3010014

Guragain YN, Vadlani PV. Renewable Biomass Utilization: A Way Forward to Establish Sustainable Chemical and Processing Industries. Clean Technologies. 2021; 3(1):243-259. https://doi.org/10.3390/cleantechnol3010014

Chicago/Turabian StyleGuragain, Yadhu N., and Praveen V. Vadlani. 2021. "Renewable Biomass Utilization: A Way Forward to Establish Sustainable Chemical and Processing Industries" Clean Technologies 3, no. 1: 243-259. https://doi.org/10.3390/cleantechnol3010014

APA StyleGuragain, Y. N., & Vadlani, P. V. (2021). Renewable Biomass Utilization: A Way Forward to Establish Sustainable Chemical and Processing Industries. Clean Technologies, 3(1), 243-259. https://doi.org/10.3390/cleantechnol3010014