Flexible Cold Atmospheric Plasma Jet Sources

Abstract

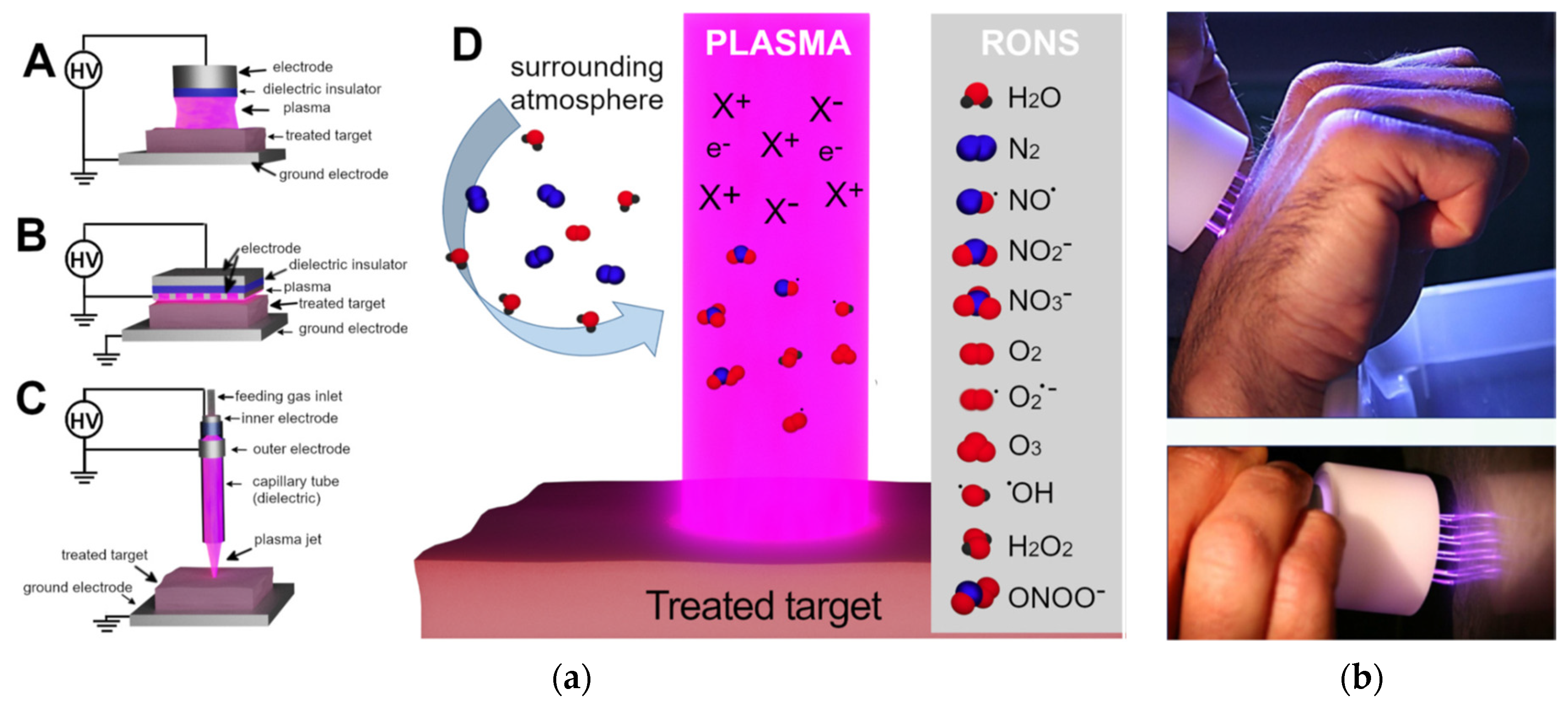

1. Introduction

2. Extended- and Multi-Jet Devices

2.1. Multi-Jet Interactions

2.2. APPJ Nozzle Geometries

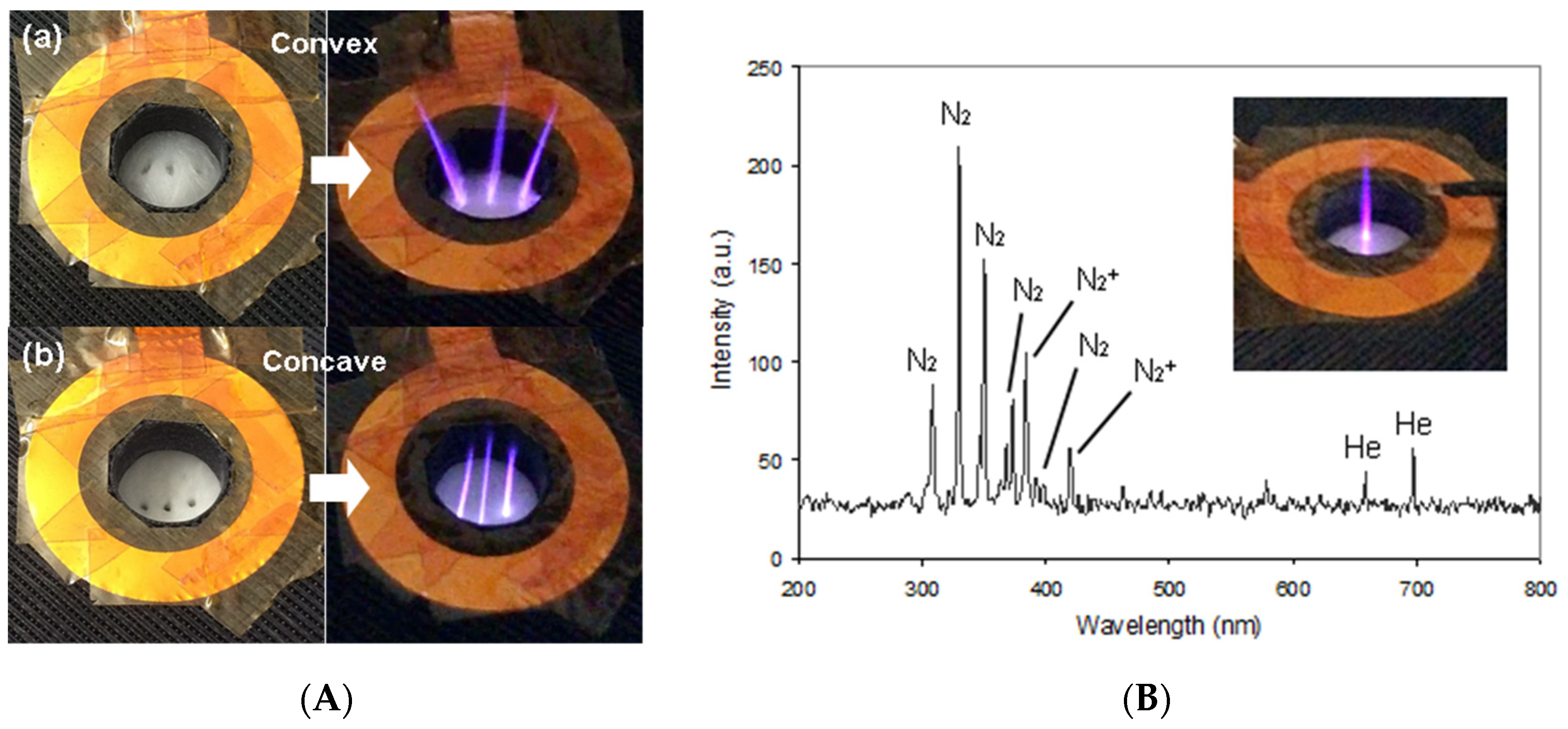

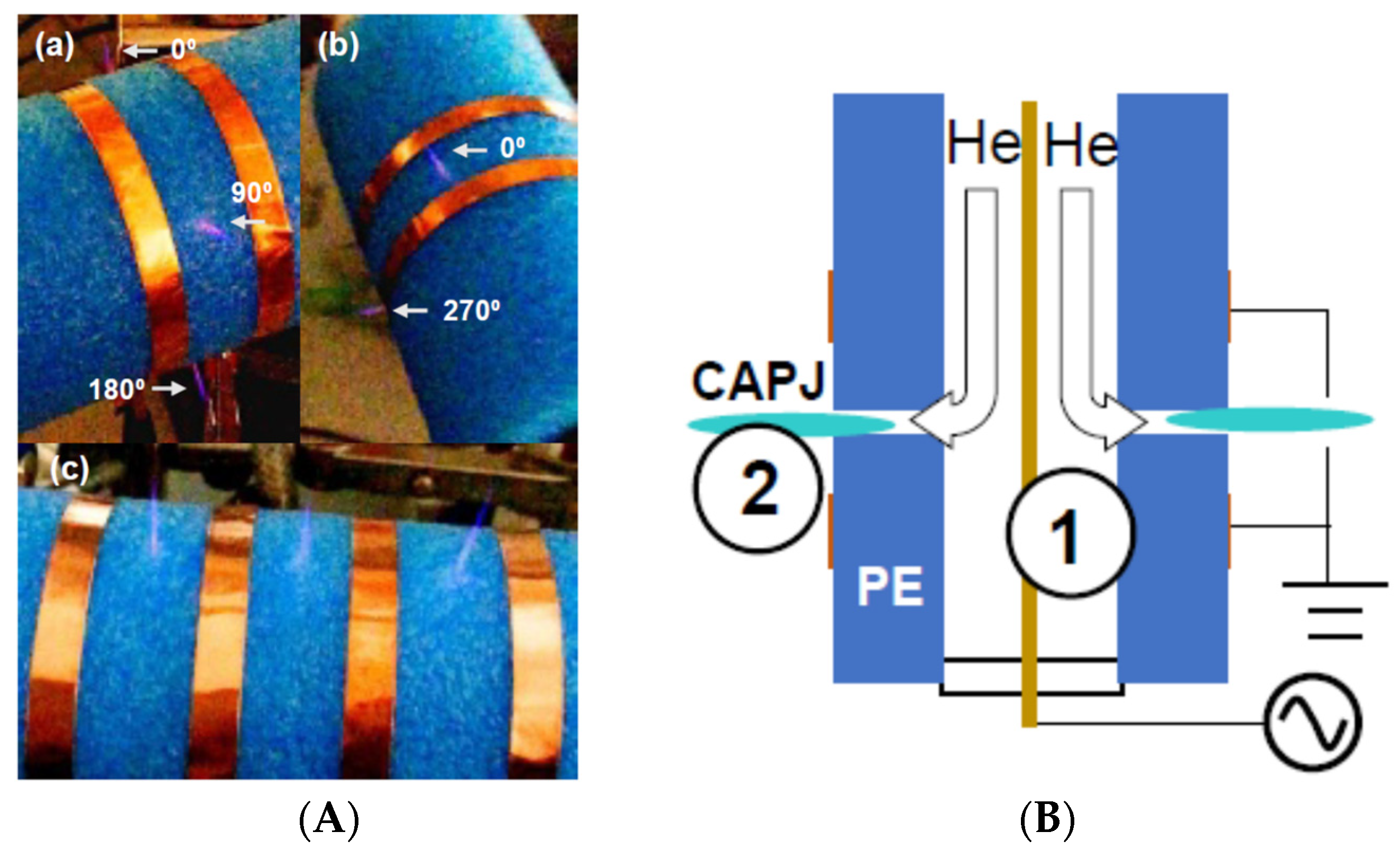

3. Morphing APPJ Arrays

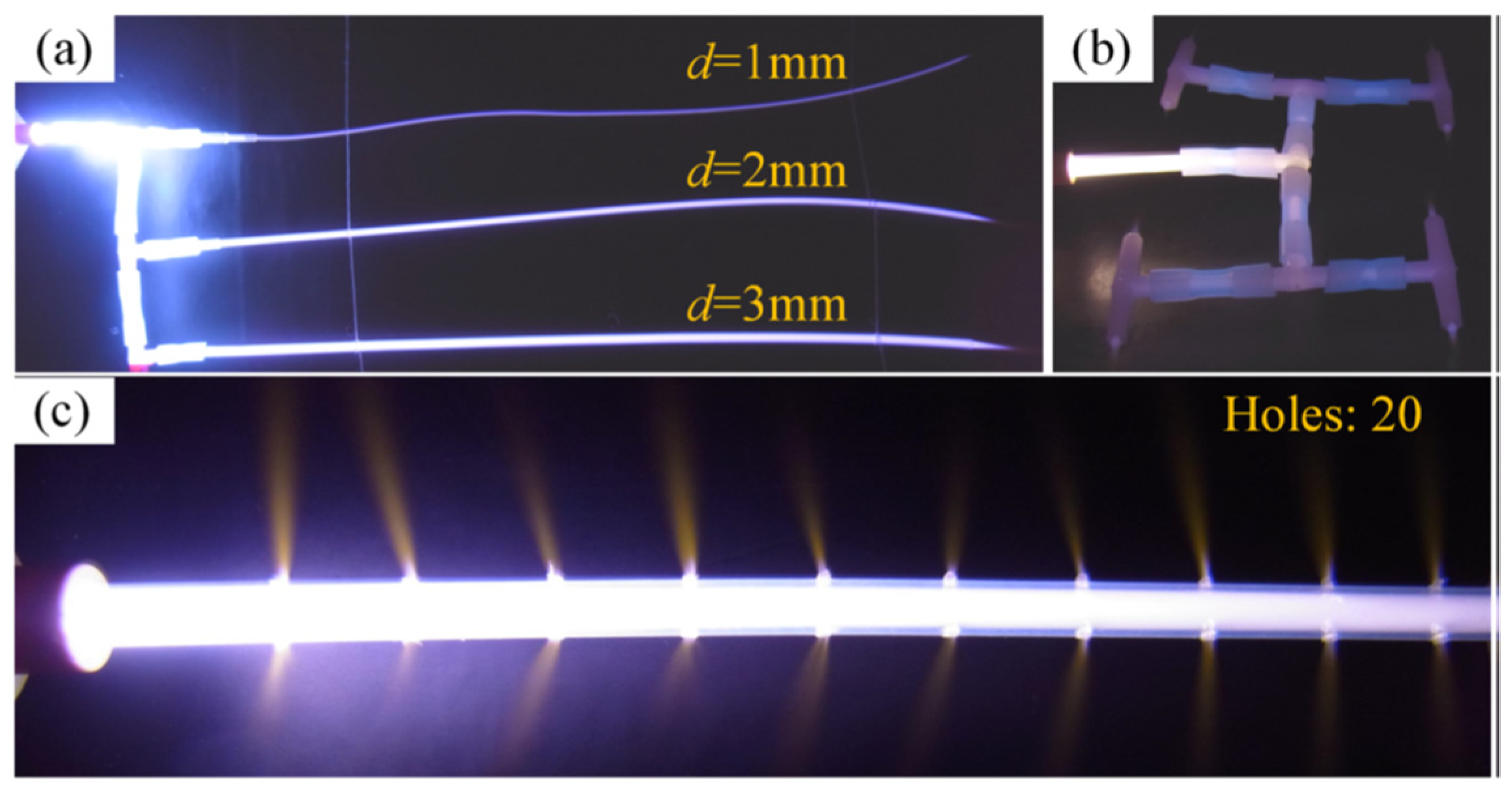

3.1. Close-Packed Microplasma Multijet Arrays

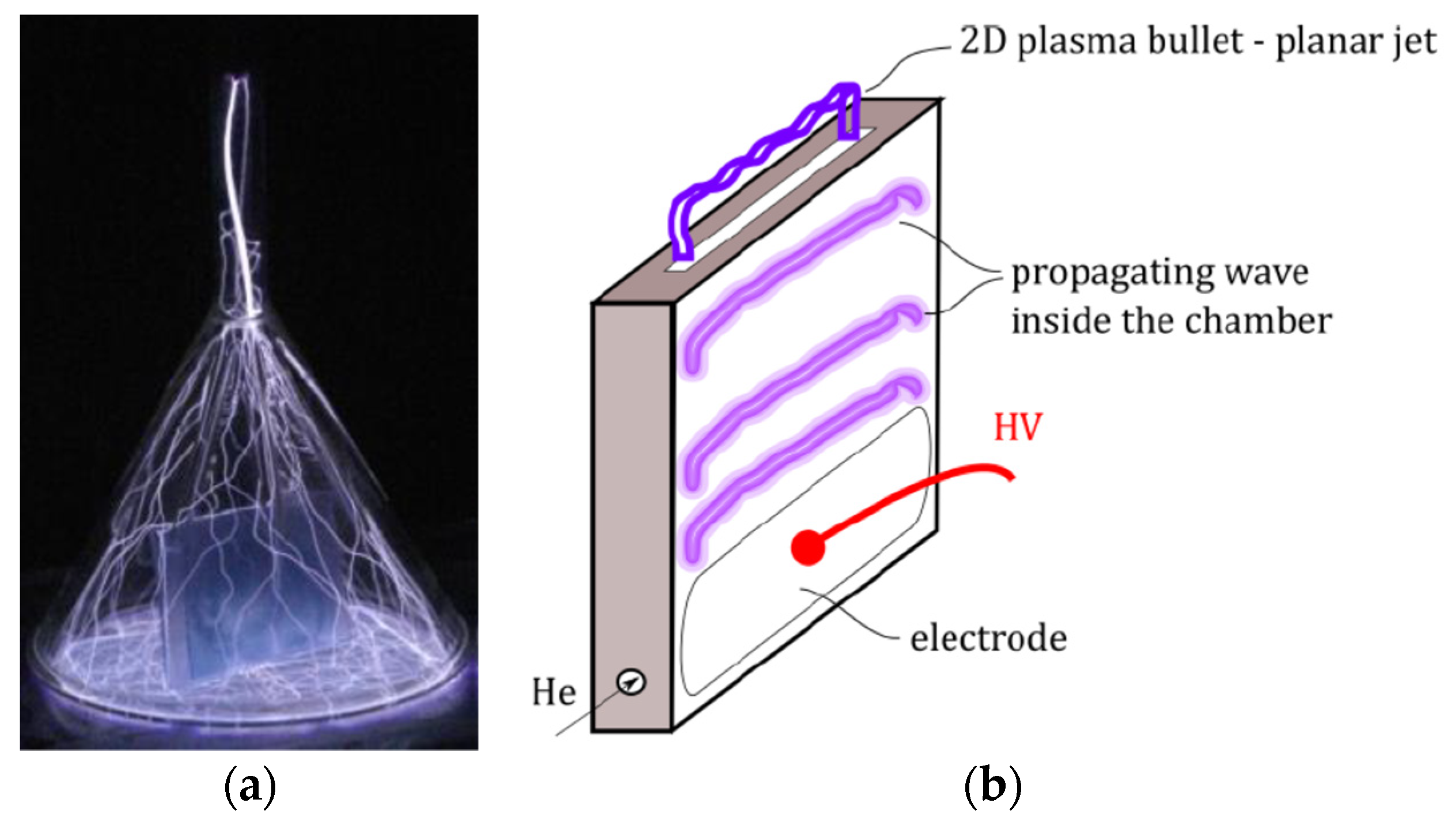

3.2. Low-Power Planar Uniform Jet Arrays

3.3. Deformable APPJ Platforms

4. Flexible APPJ Channels

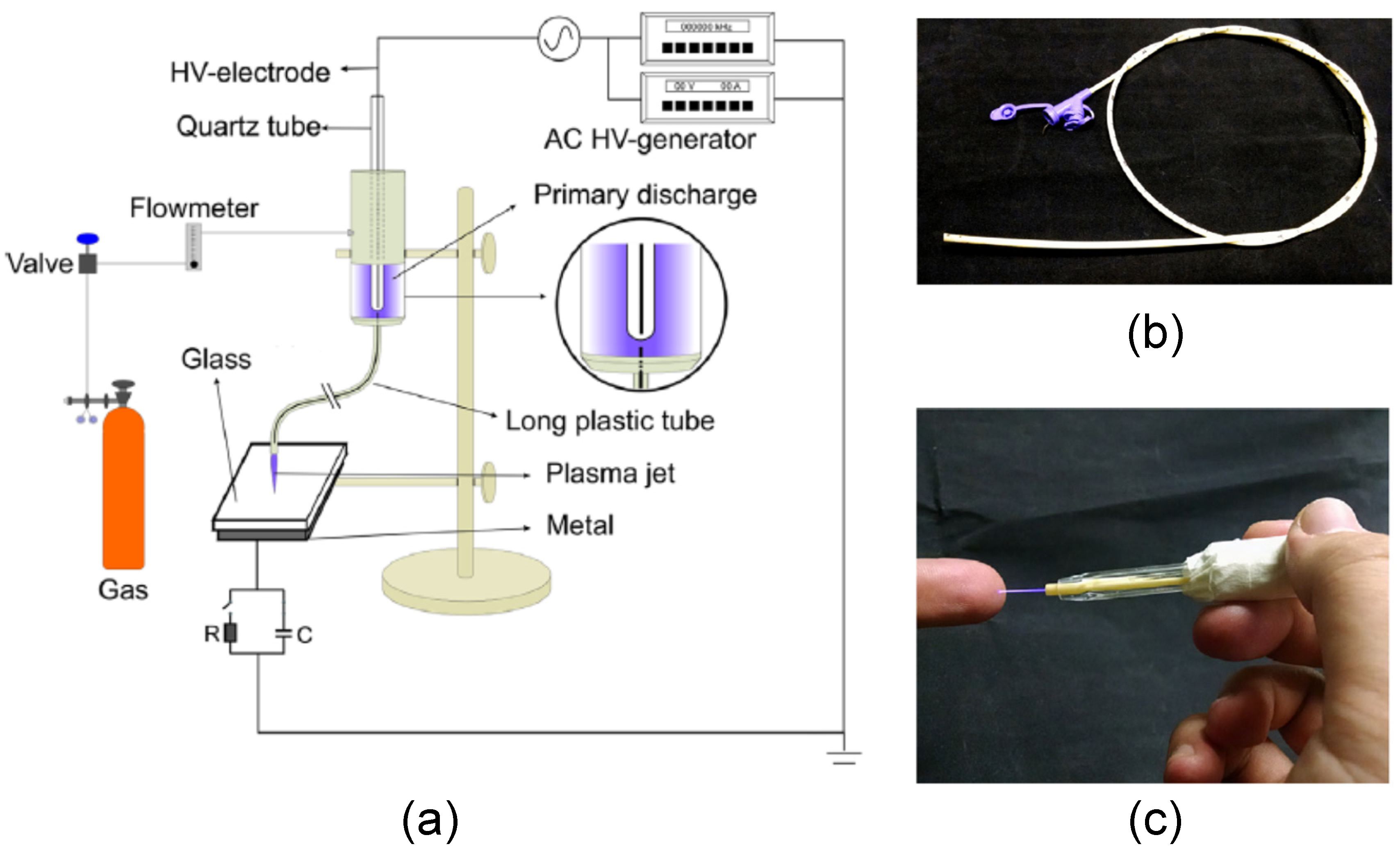

4.1. APPJ at Tube Exit

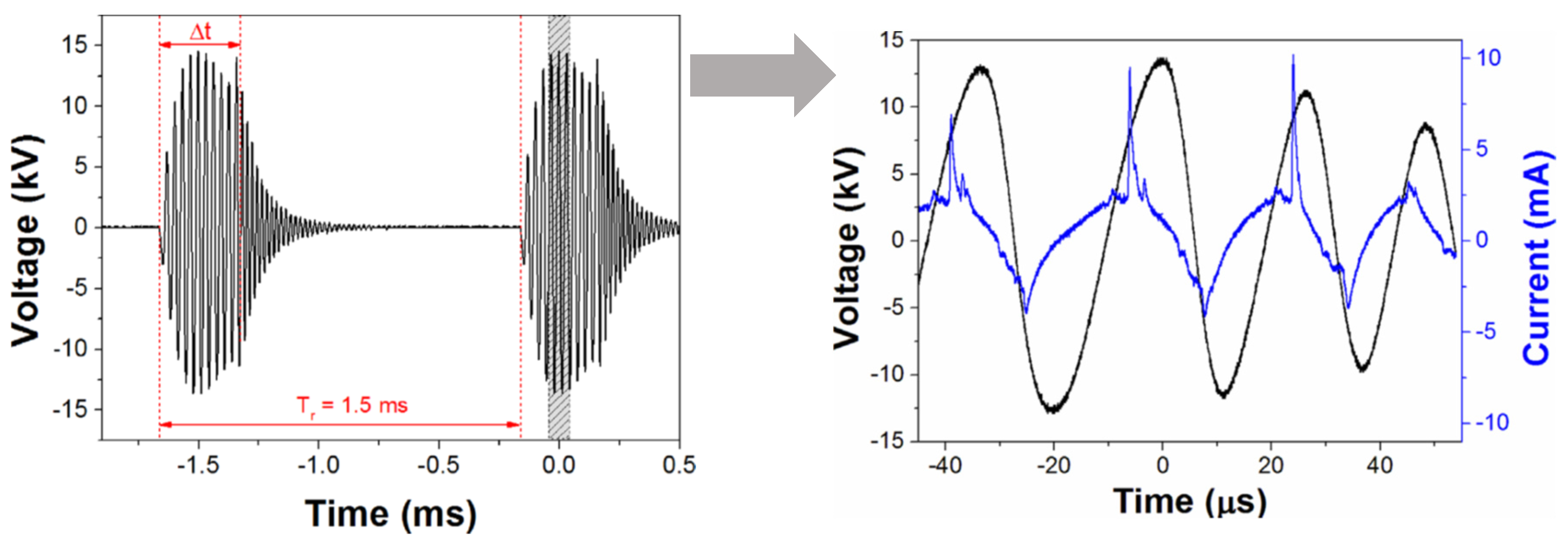

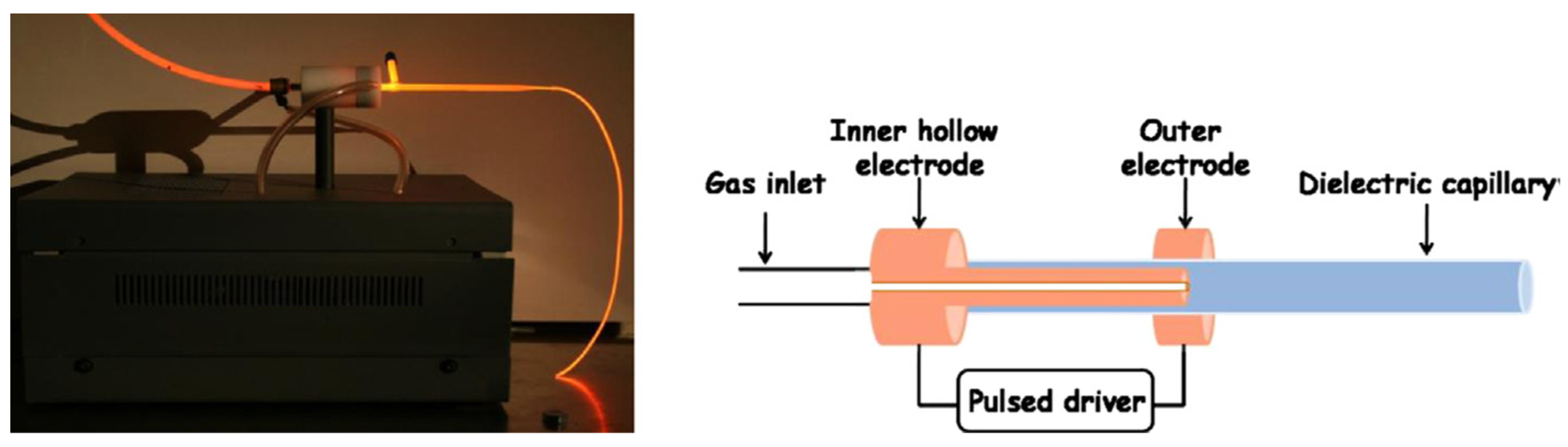

4.2. APPJ along Flexible Tube

5. Final Remarks

5.1. Summary and Discussion

5.2. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schütze, A.; Jeong, J.Y.; Babayan, S.E.; Park, J.Y.; Selwyn, G.S.; Hicks, R.F. The Atmospheric-Pressure Plasma Jet: A Review and Comparison to Other Plasma Sources. IEEE Trans. Plasma Sci. 1998, 26, 1685–1694. [Google Scholar] [CrossRef]

- Viegas, P.; Slikboer, E.; Bonaventura, Z.; Guaitella, O.; Sobota, A.; Bourdon, A. Physics of plasma jets and interaction with surfaces: Review on modelling and experiments. Plasma Sources Sci. Technol. 2022, 31, 053001. [Google Scholar] [CrossRef]

- Li, Q.; Pu, Y.-K.; Lieberman, M.A.; Economou, D.J. Dynamic model of streamer coupling for the homogeneity of glowlike dielectric barrier discharges at near-atmospheric pressure. Phys. Rev. E 2011, 83, 046405. [Google Scholar] [CrossRef] [PubMed]

- Fridman, G.; Peddinghaus, M.; Ayan, H.; Fridman, A.; Balasubramanian, M.; Gutsol, A.; Brooks, A.; Friedman, G. Blood Coagulation and Living Tissue Sterilization by Floating-Electrode Dielectric Barrier Discharge in Air. Plasma Chem. Plasma Process. 2006, 26, 425–442. [Google Scholar] [CrossRef]

- Graves, D.B. Low temperature plasma biomedicine: A tutorial review. Phys. Plasma 2014, 21, 080901. [Google Scholar] [CrossRef]

- Laroussi, M. Plasma Medicine: A Brief Introduction. Plasmas 2018, 1, 47–60. [Google Scholar] [CrossRef]

- Keidar, M.; Yan, D.; Sherman, J.H. Cold Plasma Cancer Therapy; Morgan & Claypool Publishers: San Rafael, CA, USA, 2019. [Google Scholar] [CrossRef]

- Reuter, S.; von Woedtke, T.; Weltmann, K.-D. The kINPen-a review on physics and chemistry of the atmospheric pressure plasma jet and its applications. J. Phys. D Appl. Phys. 2018, 51, 233001. [Google Scholar] [CrossRef]

- Xie, J.; Chen, Q.; Suresh, P.; Roy, S.; White, J.F.; Mazzeo, A.D. Paper-based plasma sanitizers. PNAS 2017, 114, 5119–5124. [Google Scholar] [CrossRef]

- Kim, J.; Choi, K.-H.; Kim, Y.; Park, B.J.; Cho, G. Wearable Plasma Pads for Biomedical Applications. Appl. Sci. 2017, 7, 1308. [Google Scholar] [CrossRef]

- Jung, H.; Seo, J.A.; Choi, S. Wearable Atmospheric Pressure Plasma Fabrics Produced by Knitting Flexible Wire Electrodes for the Decontamination of Chemical Warfare Agents. Sci. Rep. 2017, 7, 40746. [Google Scholar] [CrossRef]

- Gershman, S.; Harreguy, M.B.; Yatom, S.; Raitses, Y.; Efthimion, P.; Haspel, G. A low power flexible dielectric barrier discharge disinfects surfaces and improves the action of hydrogen peroxide. Sci. Rep. 2021, 11, 4626. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Keidar, M. A map of control for cold atmospheric plasma jets: From physical mechanisms to optimizations. Appl. Phys. Rev. 2021, 8, 011306. [Google Scholar] [CrossRef]

- Busco, G.; Robert, E.; Chettouh-Hammas, N.; Pouvesle, J.-M.; Grillon, C. The emerging potential of cold atmospheric plasma in skin biology. Free Radic. Biol. Med. 2020, 161, 290–304. [Google Scholar] [CrossRef] [PubMed]

- Maho, T.; Damany, X.; Dozias, S.; Pouvesle, J.-M.; Robert, E. Atmospheric Pressure Multijet Plasma Sources For Cancer Treatments. Clin. Plasma Med. 2018, 9, 3–4. [Google Scholar] [CrossRef]

- Babaeva, N.Y.; Kushner, M.J. Interaction of multiple atmospheric-pressure micro-plasma jets in small arrays: He/O2 into humid air. Plasma Sources Sci. Technol. 2014, 23, 015007. [Google Scholar] [CrossRef]

- Lietz, A.M.; Damany, X.; Robert, E.; Pouvesle, J.-M.; Kushner, M.J. Ionization wave propagation in an atmospheric pressure plasma multi-jet. Plasma Sources Sci. Technol. 2019, 28, 125009. [Google Scholar] [CrossRef]

- Ghasemi, M.; Olszewski, P.; Bradley, J.W.; Walsh, J.L. Interaction of multiple plasma plumes in an atmospheric pressure plasma jet array. J. Phys. D Appl. Phys. 2013, 46, 052001. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, Y.; Zhang, S.; Zhang, P.; Zheng, S.; Shao, T. The Effect of Accumulated Charges and Fluid Dynamics on the Helium Plasma Jet Array Behavior. IIIE Trans. Plasma Sci. 2019, 47, 4861–4867. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, B.; Fang, Z.; Wan, M.; Wan, H.; Ostrikov, K. Jet-to-jet interactions in atmospheric-pressure plasma jet arrays for surface processing. Plasma Process. Polym. 2018, 15, 1700114. [Google Scholar] [CrossRef]

- Martinez, L.; Dhruv, A.; Lin, L.; Balaras, E.; Keidar, M. Interaction between a helium atmospheric plasma jet and targets and dynamics of the interface. Plasma Sources Sci. Technol. 2019, 28, 115002. [Google Scholar] [CrossRef]

- Viegas, P.; Slikboer, E.; Bonaventura, Z.; Garcia-Caurel, E.; Guaitella, O.; Sobota, A.; Bourdon, A. Quantification of surface charging memory effect in ionization wave dynamics. Sci. Rep. 2022, 12, 1181. [Google Scholar] [CrossRef] [PubMed]

- Wan, M.; Liu, F.; Fang, Z.; Zhang, B.; Wan, H. Influence of gas flow and applied voltage on interaction of jets in a cross-field helium plasma jet array. Phys. Plasma 2017, 24, 093514. [Google Scholar] [CrossRef]

- Xiong, R.; Xiong, Q.; Nikiforov, A.Y.; Vanraes, P.; Leys, C. Influence of helium mole fraction distribution on the properties of cold atmospheric pressure helium plasma jets. J. Appl. Phys. 2012, 112, 033305. [Google Scholar] [CrossRef]

- Mericam-Bourdet, N.; Laroussi, M.; Begum, A.; Karakas, E. Experimental investigations of plasma bullets. J. Phys. D Appl. Phys. 2009, 42, 055207. [Google Scholar] [CrossRef]

- Boeuf, J.-P.; Yang, L.L.; Pitchford, L.C. Dynamics of a guided streamer (‘plasma bullet’) in a helium jet in air at atmospheric pressure. J. Phys. D Appl. Phys. 2013, 46, 015201. [Google Scholar] [CrossRef]

- Cho, G.; Kim, J.; Kang, H.; Kim, Y.; Kwon, G.-C.; Uhm, H.S. Electrical potential measurement in plasma columns of atmospheric plasma jets. J. Appl. Phys. 2012, 112, 103305. [Google Scholar] [CrossRef]

- Fang, Z.; Ruan, C.; Shao, T.; Zhang, C. Two discharge modes in an atmospheric pressure plasma jet array in argon. Plasma Sources Sci. Technol. 2016, 25, 01LT01. [Google Scholar] [CrossRef]

- Gorbanev, Y.; Golda, J.; Schulz-von der Gathen, V.; Bogaerts, A. Applications of the COST Plasma Jet: More than a Reference Standard. Plasma 2019, 2, 316–327. [Google Scholar] [CrossRef]

- Reuter, R.; Rügner, K.; Ellerweg, D.; de los Arcos, T.; von Keudell, A.; Benedikt, J. The Role of Oxygen and Surface Reactions in the Deposition of Silicon Oxide like Films from HMDSO at Atmospheric Pressure. Plasma Process. Polym. 2012, 9, 1116–1124. [Google Scholar] [CrossRef]

- Taghioskoui, M.; Zaghloul, M. U-Shaped Ultrahigh Frequency Atmospheric Pressure Plasma Jet With Magnetic Loop Antenna. IEEE Trans. Plasma Sci. 2017, 45, 43–53. [Google Scholar] [CrossRef]

- Lin, L.; Pho, H.Q.; Zong, L.; Li, S.; Pourali, N.; Rebrov, E.; Tran, N.N.; Ostrikov, K.; Hessel, V. Microfluidic plasmas: Novel technique for chemistry and chemical engineering. Chem. Eng. J. 2021, 417, 129355. [Google Scholar] [CrossRef]

- Castro, A.H.R.; Kostov, K.G.; Prysiazhnyi, V. Influence of Nozzle Shape on the performance of Low-Power Ar Plasma Jet. IEEE Trans. Plasma Sci. 2015, 43, 3228–3233. [Google Scholar] [CrossRef]

- Mui, T.S.M.; Mota, R.P.; Quade, A.; Hein, L.R.O. Uniform surface modification of polyethylene terephthalate (PET) by atmospheric pressure plasma jet with a horn-like nozzle. Surf. Coat. Technol. 2018, 352, 338–347. [Google Scholar] [CrossRef]

- Dobrynin, D.; Fridman, A. Planar He plasma jet: Plasma bullets formation, 2D bullets concept and imaging. arXiv 2018, arXiv:1806.04626. [Google Scholar] [CrossRef]

- Gugin, P.P.; Zakrevsky, D.E.; Milakhina, E.V. Investigation of a cold atmospheric plasma jet generation in single and multichannel planar devices. J. Phys. Conf. Ser. 2021, 2064, 012127. [Google Scholar] [CrossRef]

- Weltmann, K.-D.; Fricke, K.; Stieber, M.; Brandenburg, R.; von Woedtke, T.; Schnabel, U. New Nonthermal Atmospheric-Pressure Plasma Sources for Decontamination of Human Extremities. IEEE Trans. Plasma Sci. 2012, 40, 2963–2969. [Google Scholar] [CrossRef]

- Liu, B.; Qi, F.; Zhou, D.; Nie, L.; Xian, Y.; Lu, X. A novel flexible plasma array for large-area uniform treatment of an irregular surface. Plasma Sci. Technol. 2022, 24, 035403. [Google Scholar] [CrossRef]

- Ma, J.H.; Shih, D.C.; Park, S.-J.; Eden, J.G. Microplasma Jets Generated by Arrays of Microchannels Fabricated in Flexible Molded Plastic. IEEE Trans. Plasma Sci. 2011, 39, 2700–2701. [Google Scholar] [CrossRef]

- Sun, P.P.; Cho, J.H.; Park, C.-H.; Park, S.-J.; Eden, J.G. Close-Packed Arrays of Plasma Jets Emanating From Microchannels in a Transparent Polymer. IEEE Trans. Plasma Sci. 2012, 40, 2946–2950. [Google Scholar] [CrossRef]

- Lee, O.J.; Ju, H.W.; Khang, G.; Sun, P.P.; Rivera, J.; Cho, J.H.; Park, S.-J.; Eden, J.G.; Park, C.H. An experimental burn wound-healing study of non-thermal atmospheric pressure microplasma jet arrays. J. Tissue Eng. Regen. Med. 2016, 10, 348–357. [Google Scholar] [CrossRef]

- Sun, P.P.; Araud, E.M.; Huang, C.; Shen, Y.; Monroy, G.L.; Zhong, S.; Tong, Z.; Boppart, S.A.; Eden, J.G.; Nguyen, T.H. Disintegration of simulated drinking water biofilms with arrays of microchannel plasma jets. NPJ Biofilms Microbiomes 2018, 4, 24. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, J.; Lei, B.; Zhang, T.; Tang, J.; Wang, Y.; Zhao, W.; Duan, Y. A Highly Cost-Efficient Large-Scale Uniform Laminar Plasma Jet Array Enhanced by V-I Characteristic Modulation in a Non-Self-Sustained Atmospheric Discharge. Adv. Sci. 2020, 7, 1902616. [Google Scholar] [CrossRef] [PubMed]

- Corbella, C.; Portal, S.; Lin, L.; Keidar, M. Non-thermal plasma multi-jet platform based on a flexible matrix. Rev. Sci. Instrum. 2021, 92, 083505. [Google Scholar] [CrossRef] [PubMed]

- Corbella, C.; Portal, S.; Lin, L.; Keidar, M. Towards the fabrication of a morphing plasma source for biomedical applications. arXiv 2021, arXiv:2102.02937. [Google Scholar] [CrossRef]

- Thiyagarajan, M.; Sarani, A.; Nicula, C. Optical emission spectroscopic diagnostics of a non-thermal atmospheric pressure helium-oxygen plasma jet for biomedical applications. J. Appl. Phys. 2013, 113, 233302. [Google Scholar] [CrossRef]

- Corbella, C.; Portal, S. Flexible plasma multi-jet source operated in radial discharge configuration. Rev. Sci. Instrum. 2021, 92, 123502. [Google Scholar] [CrossRef]

- Robert, E.; Vandamme, M.; Brulle, L.; Lerondel, S.; Le Pape, A.; Sarron, V.; Ries, D.; Darny, T.; Dozias, S.; Collet, G.; et al. Perspectives of endoscopic plasma applications. Clin. Plasma Med. 2013, 1, 8–16. [Google Scholar] [CrossRef]

- Kostov, K.G.; Machida, M.; Prysiazhnyi, V.; Honda, R.Y. Transfer of a cold atmospheric pressure plasma jet through a long flexible plastic tube. Plasma Sources Sci. Technol. 2015, 24, 025038. [Google Scholar] [CrossRef]

- Kostov, K.G.; Nishime, T.M.C.; Machida, M.; Borges, A.C.; Prysiazhnyi, V.; Koga-Ito, C.Y. Study of Cold Atmospheric Plasma Jet at the End of Flexible Plastic Tube for Microbial Decontamination. Plasma Process. Polym. 2015, 12, 1383–1391. [Google Scholar] [CrossRef]

- Bousba, H.E.; Sahli, S.; Namous, W.S.E.; Benterrouche, L. On the Stability and Turbulences of Atmospheric-Pressure Plasma Jet Extracted From the Exit of a Long Flexible PVC Tube. IEEE Trans. Plasma Sci. 2022, 50, 1218–1226. [Google Scholar] [CrossRef]

- Bastin, O.; Thulliez, M.; Servais, J.; Nonclercq, A.; Delchambre, A.; Hadefi, A.; Deviere, J.; Reniers, F. Optical and Electrical Characteristics of an Endoscopic DBD Plasma Jet. Plasma Med. 2020, 10, 71–90. [Google Scholar] [CrossRef]

- Binenbaum, Y.; Ben-David, G.; Gil, Z.; Slutsker, Y.Z.; Ryzhkov, M.A.; Felsteiner, J.; Krasik, Y.E.; Cohen, J.T. Cold Atmospheric Plasma, Created at the Tip of an Elongated Flexible Capillary Using Low Electric Current, Can Slow the Progression of Melanoma. PLoS ONE 2017, 12, e0169457. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.; Wang, S.; Chen, S.; Wang, X.; Yang, W.; Li, M.; Shi, L. Atmospheric micro-sized cold plasma jet created by a long and ultra-flexible generator with sputtered gold thin film electrode. J. Micromech. Microeng. 2022, 32, 095006. [Google Scholar] [CrossRef]

- Geng, J.; Yin, S.; Huang, S.; Tang, Q.; Luo, H.; Chen, F. Flexible cold plasma jet with controllable length and temperature for hydrophilic modification. Phys. Plasma 2018, 25, 083508. [Google Scholar] [CrossRef]

- Park, S.; Choe, W.; Moon, S.Y.; Yoo, S.J. Electron characterization in weakly ionized collisional plasmas: From principles to techniques. Adv. Phys. X 2019, 4, 1526114. [Google Scholar] [CrossRef]

- Johnson, M.J.; Boris, D.R.; Petrova, T.B.; Walton, S.G. Characterization of a Compact, Low-Cost Atmospheric-Pressure Plasma Jet Driven by a Piezoelectric Transformer. IEEE Trans. Plasma Sci. 2019, 47, 434–444. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Pang, B.; Gao, Y.; Li, Q.; Xu, D.; Liu, D.; Zhou, R. A novel designed 3D multi-microhole plasma jet device driven by nanosecond pulse at atmospheric pressure. Plasma Sources Sci. Technol. 2022, 31, 05LT03. [Google Scholar] [CrossRef]

- Mariotti, D.; Belmonte, T.; Benedikt, J.; Velusamy, T.; Jain, G.; Svrcek, V. Low-Temperature Atmospheric Pressure Plasma Processes for “Green” Third Generation Photovoltaics. Plasma Process. Polym. 2016, 13, 70–90. [Google Scholar] [CrossRef]

- Hong, Y.C.; Yoo, S.R.; Lee, B.J. An atmospheric-pressure nitrogen-plasma jet produced from microdischarges in a porous dielectric. J. Electrostat. 2011, 69, 92–96. [Google Scholar] [CrossRef]

- Ma, S.H.; Kim, K.G.; Lee, S.J.; Moon, S.Y.; Hong, Y.C. Effects of a porous dielectric in atmospheric-pressure plasma jets submerged in water. Phys. Plasma 2018, 25, 083519. [Google Scholar] [CrossRef]

| Source | Array | Gas/Power Supply | Applications | Refs. |

|---|---|---|---|---|

| Close-packed micro-APPJ | Silicone polymer | <5 lpm He | Wound healing | [39,40,41] |

| Integrated rod electrodes | 20 kHz, 1–100 mW | Drinking-water treatment | ||

| 8 × 8 nozzles, 0.35 mm diam. | ||||

| Low-power planar discharge cells | Ceramic cells | <15 lpm Ar | Large and uniform plasmas | [43] |

| Activation by independent switching 6 cells, 0.5 × 15 mm2/cell | 8 kHz, 5–10 W/cell | |||

| Flexible APPJ platforms | Silica aerogel (flat), PE (cylindric) External Cu tape electrodes | <10 lpm He | Wound healing, surgical margins, and surface processing (proposed) | [44,45,47] |

| 1–5 nozzles, 1 mm diam. | 15 kHz, 0.1–5 W | |||

| Flexible micro-APPJ tube | Silicone, Teflon | <1 lpm He, Ne, Ar, N2, +O2 * | Plasma endoscopy Internal surface processing, machining | [48,54,55] |

| Empty or coated tube 0.1–1 mm diam., a few meters long | 1–20 kHz, 1–20 kV | |||

| APPJ at the end of a flexible tube | PVC, PTFE | ≈1 lpm He, Ar | Plasma endoscopy Fungal deactivation | [49,50,51,52,53] |

| Floating Cu wire >1 mm diam., <5 m-long | 5–20 kHz, 1–80 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corbella, C.; Portal, S.; Keidar, M. Flexible Cold Atmospheric Plasma Jet Sources. Plasma 2023, 6, 72-88. https://doi.org/10.3390/plasma6010007

Corbella C, Portal S, Keidar M. Flexible Cold Atmospheric Plasma Jet Sources. Plasma. 2023; 6(1):72-88. https://doi.org/10.3390/plasma6010007

Chicago/Turabian StyleCorbella, Carles, Sabine Portal, and Michael Keidar. 2023. "Flexible Cold Atmospheric Plasma Jet Sources" Plasma 6, no. 1: 72-88. https://doi.org/10.3390/plasma6010007

APA StyleCorbella, C., Portal, S., & Keidar, M. (2023). Flexible Cold Atmospheric Plasma Jet Sources. Plasma, 6(1), 72-88. https://doi.org/10.3390/plasma6010007